Page 1

Operator’s Manual

APEX ® 3 SERIES MIG PENDANT

ORIGINAL INSTRUCTIONS

For use with machines having Code Numbers:

12879

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM6122 | Issue D ate 02/19

© Lincoln Global, Inc. All Rights Reserved.

Need Help? In the USA and Canada, call

1.800.770.0063 to talk to a Service Representative.

Hours of Operation:

7:00 AM to 5:00 PM (PT) Mon. thru Fri.

After hours?

Use “Ask the Experts” at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA and Canada, please call

1.619.628.1022 or e-mail us at:

orbitalsupport@lincolnelectric.com

c/o Balmes, 89 - 80 2

08008 Barcelona

a

SPAIN

Page 2

APEX® 3 SERIES MIG PENDANT MANUAL

SAFETY

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

1WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use corrective lenses if necessary to

stay a reasonable distance away from

the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers of

welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your

breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet properly fitted and

with proper grade of filter plate (See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area AT ALL

TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials

which previously had been in contact with hazardous

substances unless they are properly cleaned. This is extremely

dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR IMMEDIATE

USE AND KNOW HOW TO USE IT.

2

Page 3

APEX® 3 SERIES MIG PENDANT MANUAL

SECTION A:

WARNINGS

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing equipment.

SAFETY

SAFETY

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel Engines

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

Gasoline Engines

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS SHOULD CONSULT WITH

THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135

or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

1.e. In some cases it may be necessary to remove safety guards

to perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is hot.

ELECTRIC AND MAGNETIC FIELDS

MAY BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields

(EMF). Welding current creates EMF fields

around welding cables and welding machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting and

maintenance work unless the maintenance

work requires it to be running.

1.b. Operate engines in open, well-ventilated areas

or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame welding arc or when the

engine is running. Stop the engine and allow it to cool before

refueling to prevent spilled fuel from vaporizing

on contact with hot engine parts and igniting.

Do not spill fuel when filling tank. If fuel is

spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

3

Page 4

APEX® 3 SERIES MIG PENDANT MANUAL

SAFETY

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do not

touch these “hot” parts with your bare skin or wet

clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such

as floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

the two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see It ems 6.c. and 8.

between

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect

your eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES CAN

BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the

fume. Use enough ventilation and/or exhaust at the arc to

keep fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure

as low as possible and within applicable OSHA

PEL and ACGIH TLV limits using local exhaust

or mechanical ventilation. In confined spaces or

in some circumstances, outdoors, a respirator

may be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

cause

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

4

Page 5

APEX® 3 SERIES MIG PENDANT MANUAL

SAFETY

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area.

If this is not possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks and hot

materials from welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near hydraulic lines.

Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations. Refer

to “Safety in Welding and Cutting” (ANSI Standard Z49.1) and the

operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit

is touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside. They

can cause an explosion even though they have been “cleaned”.

For information, purchase “Recommended Safe Practices for the

Preparation for Welding and Cutting of Containers and Piping That

Have Held Hazardous Substances”, AWS F4.1 from the American

Welding Society (see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

Cylinders,” available

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework

or other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to http://www.lincolnelectric.com/

safety for additional safety information.

5

Page 6

APEX® 3 SERIES MIG PENDANT MANUAL

ELECTROMAGNETIC

COMPATIBILITY (EMC)

CONFORMANCE

Products displaying the CE mark are in conformity with European Community

Council Directive of 3 May 1989 on the approximation of the laws of the

Member States relating to electromagnetic compatibility (89/336/EEC). It

was manufactured in conformity with a national standard that implements a

harmonized standard: EN 60974-10

Electromagnetic Compatibility (EMC) Product Standard for Arc Welding

Equipment. It is for use with other Lincoln Electric equipment. It is designed

for industrial and professional use.

INTRODUCTION

All electrical equipment generates small amounts of electromagnetic

emission. Electrical emission may be transmitted through power lines or

radiated through space, similar to a radio transmitter. When emissions are

received by other equipment, electrical interference may result. Electrical

emissions may affect many kinds of electrical equipment; other nearby

welding equipment, radio and TV reception, numerical controlled machines,

telephone systems, computers, etc. Be aware that interference may result

and extra precautions may be required when a welding power source is used

in a domestic establishment.

INSTALLATION AND USE

The user is responsible for installing and using the welding equipment

according to the manufacturer’s instructions. If electromagnetic disturbances

are detected then it shall be the responsibility of the user of the welding

equipment to resolve the situation with the technical assistance of the

manufacturer. In some cases this remedial action may be as simple as

earthing (grounding) the welding circuit, see Note. In other cases it could

involve construction of an electromagnetic screen enclosing the power

source and the work complete with associated input filters. In all cases

electromagnetic disturbances must be reduced to the point where they are

no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons according to national codes.

Changing the earthing arrangements should only be authorized by a person who is competent

to access whether the changes will increase the risk of injury, e.g., by allowing parallel welding

current return paths which may damage the earth circuits of other equipment.

ASSESSMENT OF AREA

Before installing welding equipment the user shall make an assessment of

potential electromagnetic problems in the surrounding area. The following

shall be taken into account:

a. other supply cables, control cables, signaling and telephone cables; above, below

and adjacent to the welding equipment;

b. radio and television transmitters and receivers;

c. computer and other control equipment;

d. safety critical equipment, e.g., guarding of industrial equipment;

e. the health of the people around, e.g., the use of pacemakers and hearing aids;

f. equipment used for calibration or measurement

g. the immunity of other equipment in the environment. The user shall ensure that

other equipment being used in the environment is compatible. This may require

additional protection measures;

h. the time of day that welding or other activities are to be carried out.

SAFETY

The size of the surrounding area to be considered will depend on the

structure of the building and other activities that are taking place. The

surrounding area may extend beyond the boundaries of the premises.

METHODS OF REDUCING EMISSIONS

Mains Supply

Welding equipment should be connected to the mains supply according

to the manufacturer’s recommendations. If interference occurs, it may be

necessary to take additional precautions such as filtering of the mains supply.

Consideration should be given to shielding the supply cable of permanently

installed welding equipment, in metallic conduit or equivalent. Shielding

should be electrically continuous throughout its length. The shielding should

be connected to the welding power source so that good electrical contact is

maintained between the conduit and the welding power source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according to the

manufacturer’s recommendations. All access and service doors and covers

should be closed and properly fastened when the welding equipment is

in operation. The welding equipment should not be modified in any way

except for those changes and adjustments covered in the manufacturers

instructions. In particular, the spark gaps of arc striking and stabilizing

devices should be adjusted and maintained according to the manufacturer’s

recommendations.

Welding Cables

The welding cables should be kept as short as possible and should be

positioned close together, running at or close to floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and adjacent

to it should be considered. However, metallic components bonded to the

work piece will increase the risk that the operator could receive a shock by

touching these metallic components and the electrode at the same time. The

operator should be insulated from all such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, not

connected to earth because of its size and position, e.g., ships hull or

building steelwork, a connection bonding the workpiece to earth may reduce

emissions in some, but not all instances. Care should be taken to prevent the

earthing of the work piece increasing the risk of injury to users, or damage

to other electrical equipment. Where necessary, the connection of the

workpiece to earth should be made by a direct connection to the work piece,

but in some countries where direct connection is not permitted, the bonding

should be achieved by suitable capacitance, selected according to national

regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in the

surrounding area may alleviate problems of interference. Screening of the

entire welding installation may be considered for special applications.

1 Portions of the preceding text are contained in EN 60974-10: “Electromagnetic

Compatibility (EMC) product standard for arc welding equipment.”

6

Page 7

APEX® 3 SERIES MIG PENDANT MANUAL

SAFETY

7

Page 8

APEX® 3 SERIES MIG PENDANT MANUAL

TABLE OF CONTENTS

Safety ....................................................................................................................................................... 2

Symbols & Icons ................................................................................................................................... 10

Safety Precautions ............................................................................................................................... 11

Proper handling .................................................................................................................................11

Operation ............................................................................................................................................... 11

Explanation of Welding Terms ........................................................................................................... 11

System Start Up .............................................................................................................................. B-1

Startup Screen ......................................................................................................................... B-1

Pendant Operation ................................................................................................................... B-2

Button Actions .......................................................................................................................... B-2

Selection Buttons ..................................................................................................................... B-2

Navigation Controls .................................................................................................................. B-2

Menu Buttons ........................................................................................................................... B-3

Control Buttons ........................................................................................................................ B-3

Color Coding ............................................................................................................................ B-3

Fast Movement ......................................................................................................................... B-3

System Log In ................................................................................................................................. B-4

Fast Movement ......................................................................................................................... B-4

Log In Screen ........................................................................................................................... B-5

Idle Screen ...................................................................................................................................... B-6

Menu Option Variables ............................................................................................................. B-6

Idle Screen Buttons .................................................................................................................. B-7

Idle Screen Test/Weld Modes .........................................................................................................B-8

Weld Screen ............................................................................................................................. B-9

Weld Screen Buttons ................................................................................................................ B-9

Test Screen ............................................................................................................................... B-9

Test Screen Buttons ................................................................................................................. B-9

Jog Screen .................................................................................................................................... B-10

Jog Buttons ............................................................................................................................ B-11

Oscillation Screen ......................................................................................................................... B-12

Oscillation Buttons ................................................................................................................. B-13

Setup Menu .................................................................................................................................. B-14

Setup Screen Options ............................................................................................................ B-15

Track Setup ............................................................................................................................ B-15

Track Type .............................................................................................................................. B-15

Track Ring Size ....................................................................................................................... B-15

Pipe Size ................................................................................................................................. B-15

Heavy Wall Pipes .................................................................................................................... B-15

Positioner Setup ..................................................................................................................... B-15

Travel Setup Screen ............................................................................................................... B-16

Travel Pattern ........................................................................................................................ B-16

Process Setup Screen .................................................................................................................. B-17

Standard Process Options ..................................................................................................... B-17

Weave Process Options ......................................................................................................... B-17

Mode Select .................................................................................................................................. B-18

List Mode Select ..................................................................................................................... B-19

Advanced Process Setup ............................................................................................................ B-19

Advanced Options .................................................................................................................. B-19

Wave Controls ........................................................................................................................ B-19

Height/Sensitivity Recommendations .................................................................................... B-19

Start Settings ................................................................................................................................ B-20

End Settings .................................................................................................................................. B-20

8

Page 9

APEX® 3 SERIES MIG PENDANT MANUAL

TABLE OF CONTENTS

GMAW/FCAW Timing Diagram ..................................................................................................... B-21

Service Menu ............................................................................................................................... B-22

Version .................................................................................................................................... B-22

Motion .................................................................................................................................... B-22

Faults ...................................................................................................................................... B-23

Settings .................................................................................................................................. B-23

Input Test ................................................................................................................................ B-23

How to Take a Snapshot ........................................................................................................ B-24

Users ............................................................................................................................................. B-25

Fast Movement ....................................................................................................................... B-25

Adding Users .......................................................................................................................... B-25

Deleting Users ........................................................................................................................ B-26

Changing User Access ........................................................................................................... B-27

Log Out ................................................................................................................................... B-27

Operator Log In ...................................................................................................................... B-27

Increments Settings ...................................................................................................................... B-28

Increment Options .................................................................................................................. B-28

Increment Reference .............................................................................................................. B-29

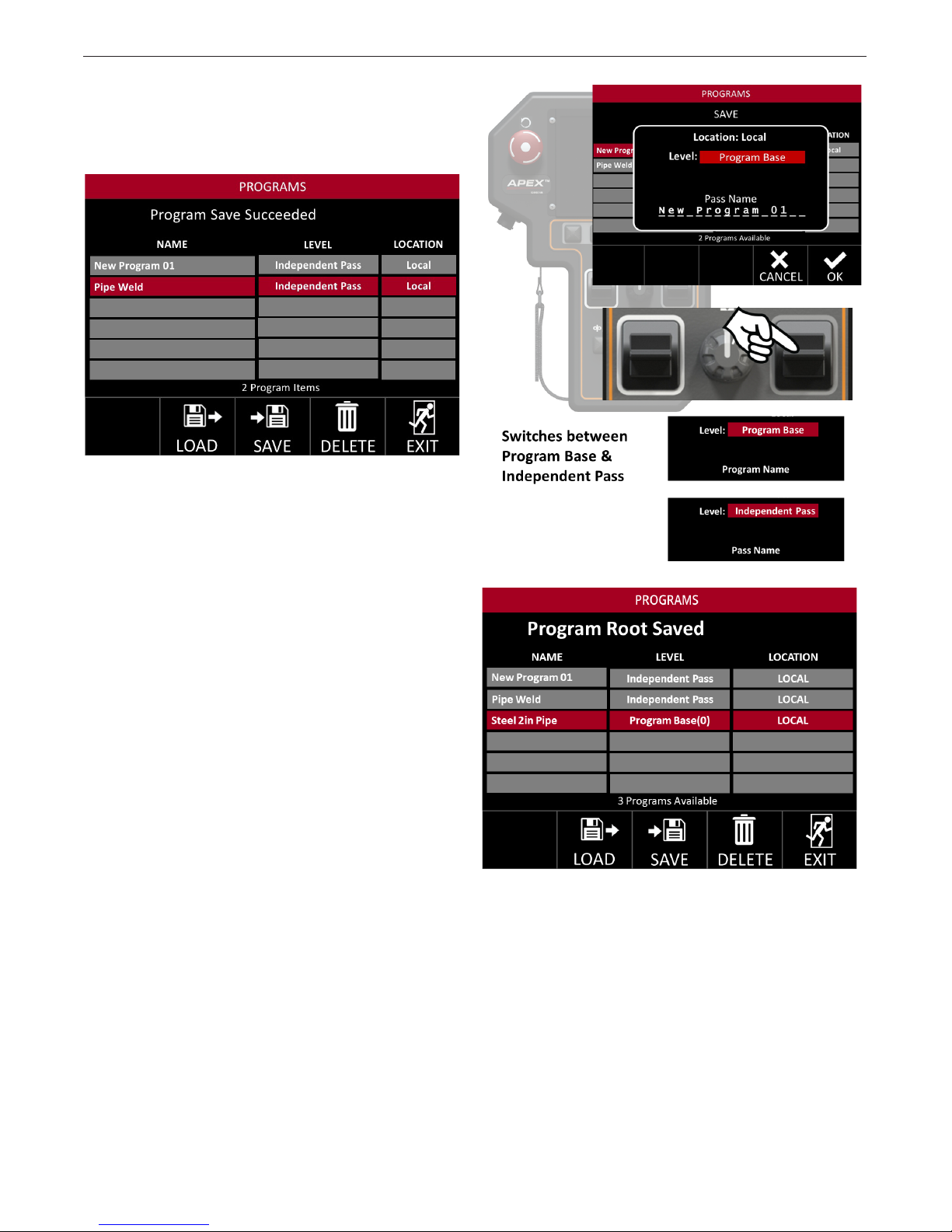

Programs ..................................................................................................................................... B-30

Fast Movement ....................................................................................................................... B-30

Saving an Independent Pass .................................................................................................. B-30

Saving a Program Base .......................................................................................................... B-31

Saving a Program Pass .......................................................................................................... B-31

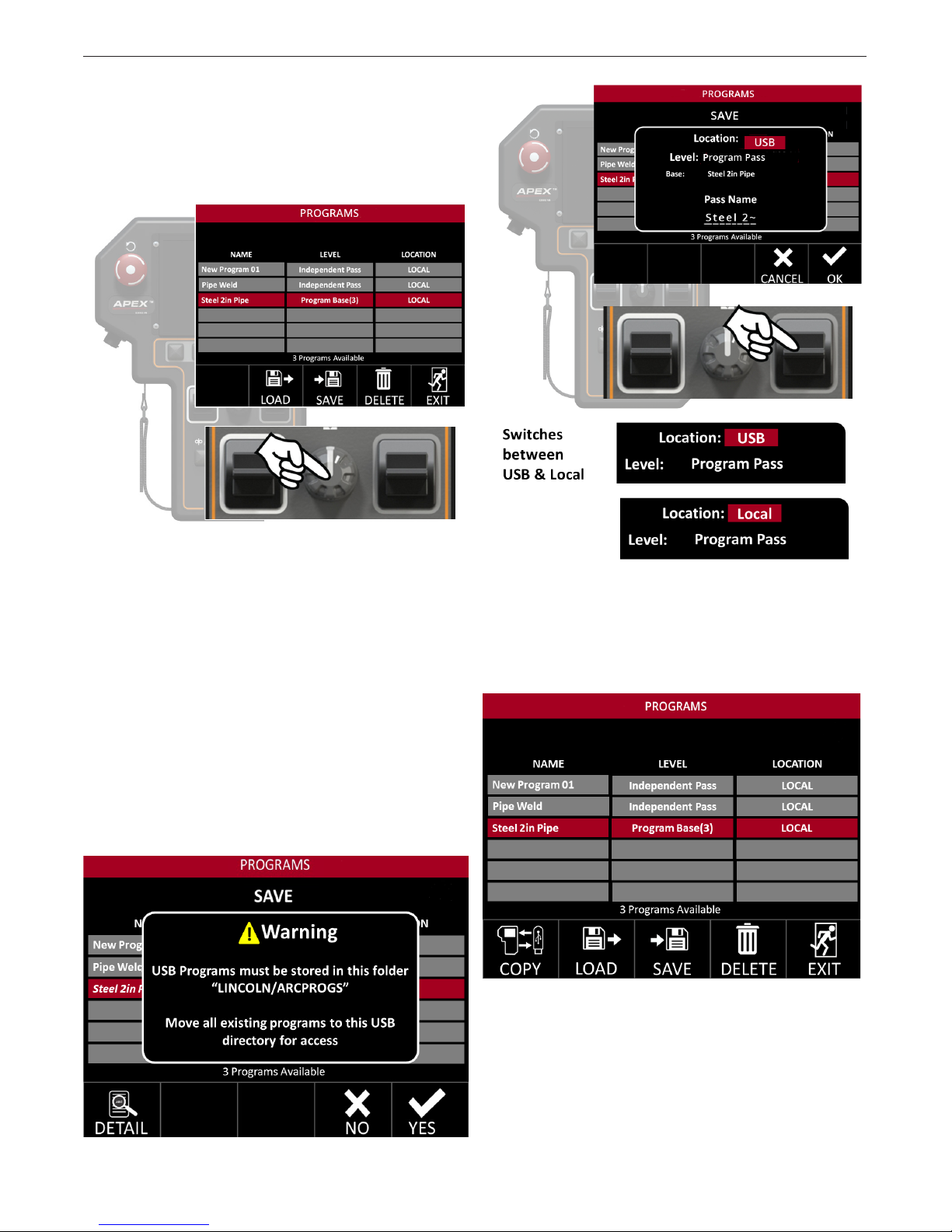

Saving Program Updates ....................................................................................................... B-32

Hide Program Passes ............................................................................................................. B-33

Saving to a USB ..................................................................................................................... B-33

Copy to/from USB .................................................................................................................. B-33

Deleting a Program ................................................................................................................. B-34

Deleting a Program Base ........................................................................................................ B-34

Loading a Program ................................................................................................................. B-34

Overwriting a Program ........................................................................................................... B-35

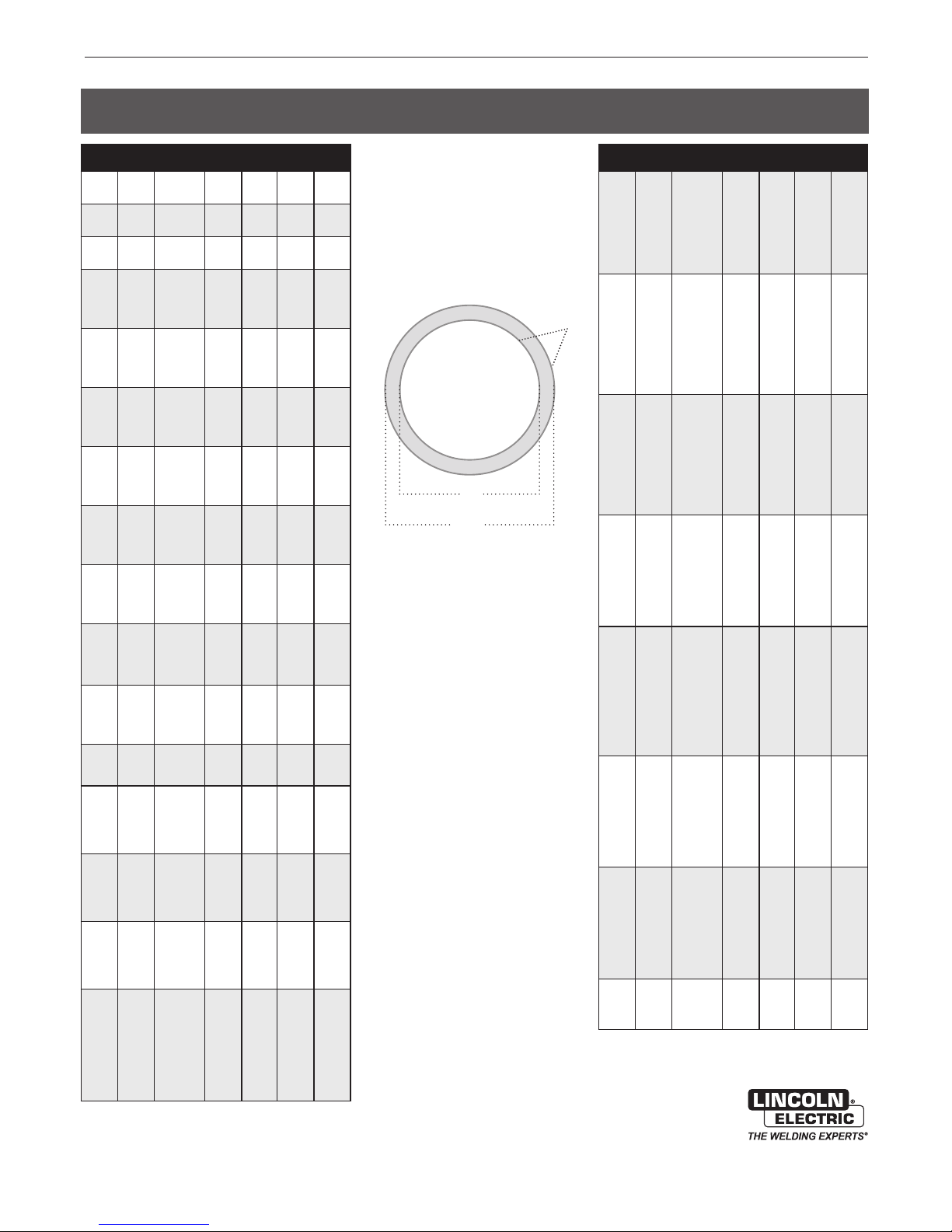

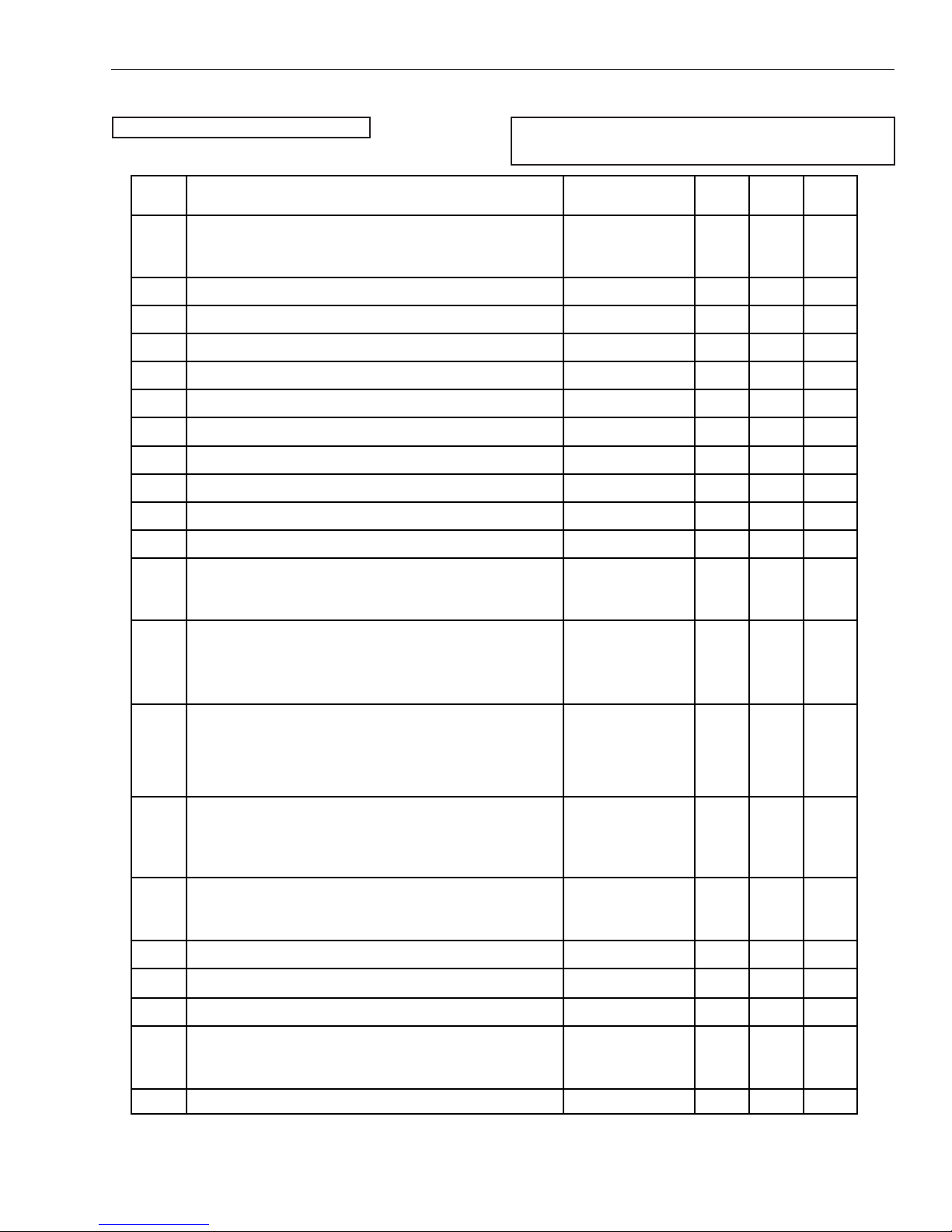

Standard Piping Schedule Chart .......................................................................................................... 36

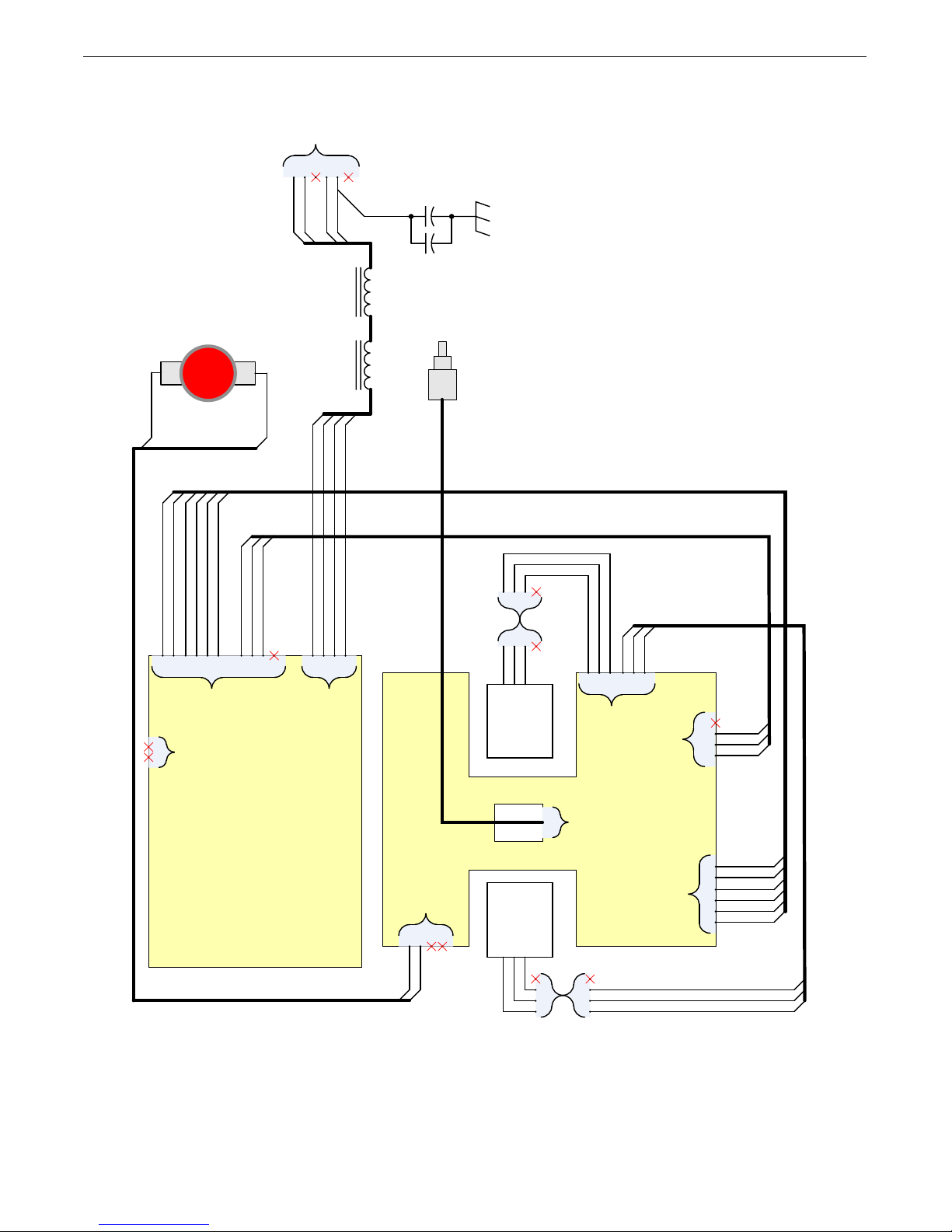

Wiring Diagram ...................................................................................................................................... 37

Parts ....................................................................................................................................................... 38

9

Page 10

APEX® 3 SERIES MIG PENDANT MANUAL

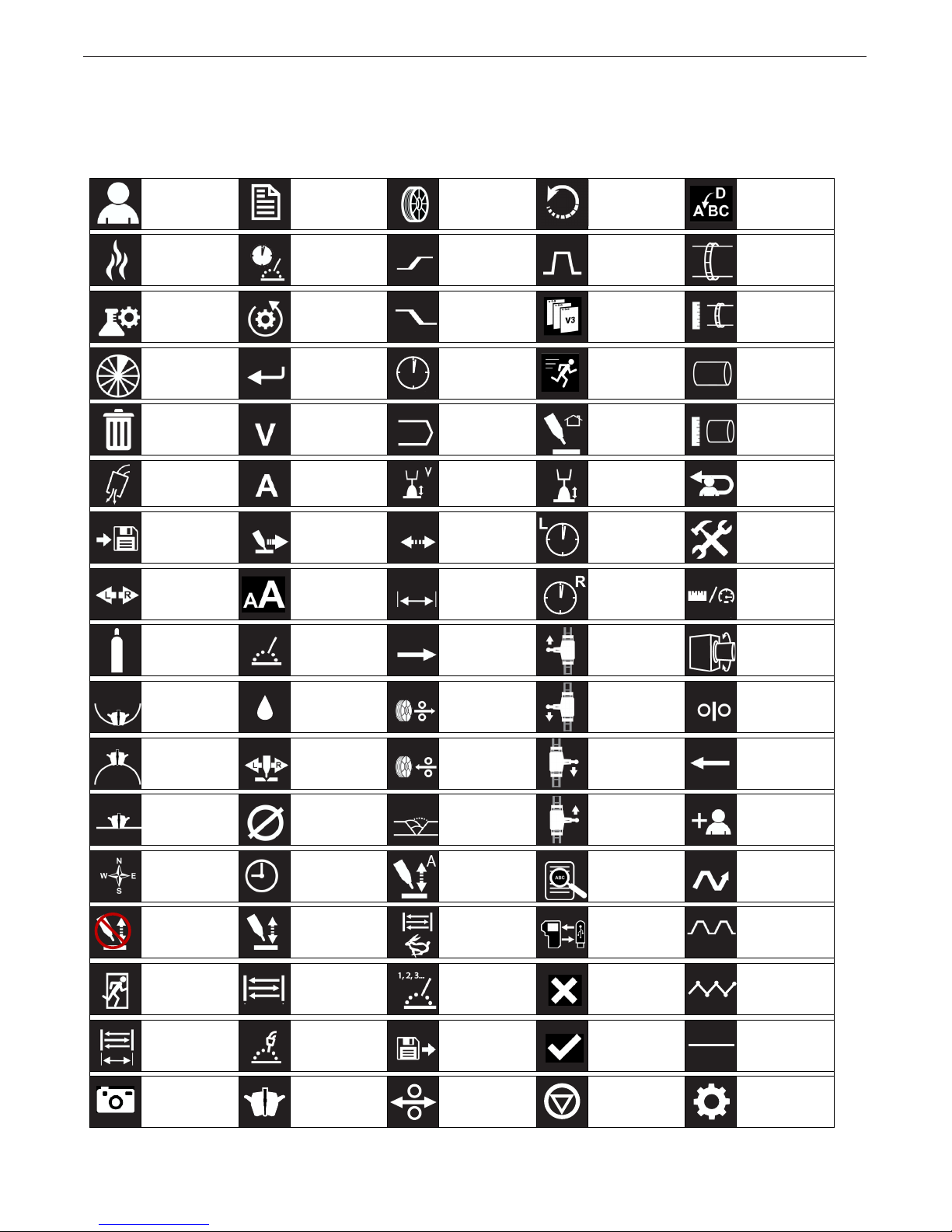

Symbols & Icons

This list is a quick reference for all icons from the

pendant and on the control unit.

OPERATION

Users Set Up/

Modes

Weld Weld Time Upslope /

Test Mode Reset

Settings

Segment Enter Time Motion Pipe

Trash Voltage Program Return Home Pipe

Gas Purge

Pre/Post Flow

Save Travel /

Swap Shift Case Osc Width Right Dwell Increment

Gas Advanced

Amperage Trim Volts Trim Log Out

Travel Setup

Settings

Wire Reboot Insert

Process Track Ring

Start Settings

Downslope /

End Settings

Osc Speed Left Dwell Settings /

Next /

Index

Version Track Ring

Diameter

Diameter

Service Page

Unit Settings

Travel

Direction

Positioner

ID Track

OD Track Steering /

Flat Track Wire Diam-

Direction Delay Amps Details Weave

Manual

Height

Exit Oscillation Mode

Oscillation

Width

Snapshot

Kilowatts Wire Feed Travel

Water

K

Wire

Oscillator

eter

Torch/Auto

Height

Weld Mode Load Okay No Weave

Weld Head Wire On Faults

Retract

Pass Travel

Oscillation

Speed

Select

Direction

Travel

Direction

Direction

Copy To Constant

Cancel Step

Wire / Wire

Feed Speed

Previous /

Index

Add User

Type

Travel

Travel

Travel

Settings

10

Page 11

APEX® 3 SERIES MIG PENDANT MANUAL

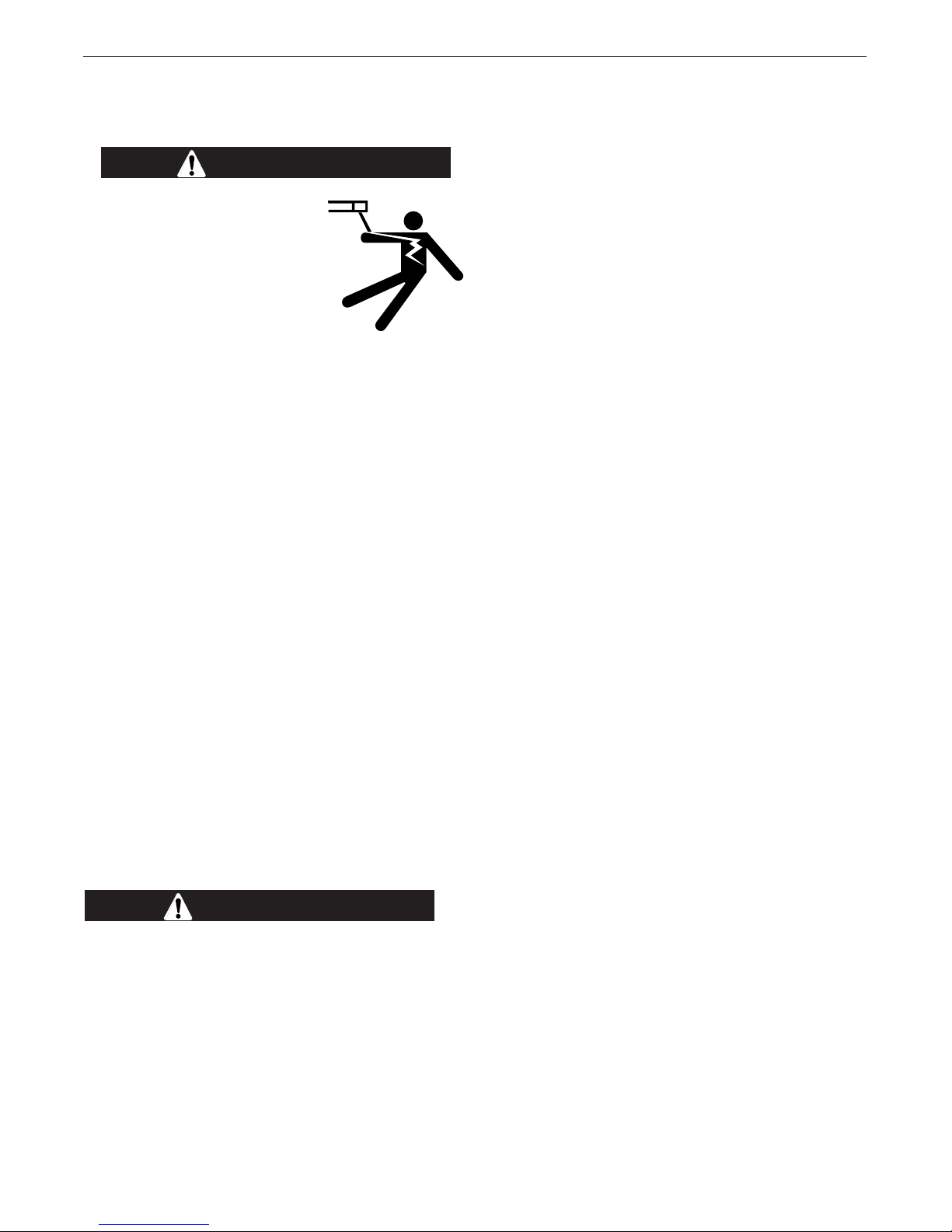

OPERATION

Safety Precautions

Read entire manual before installation or operation.

WARNING

ELECTRIC SHOCK CAN KILL

• Only qualied personnel

should perform this

installation.

• Turn the input power OFF at

the disconnect switch or fuse

box before working on this

equipment turn off the input

power to any other equipment

connected to the welding system at the disconnect switch or fuse box before working on the

equipment.

• Do not touch electrically hot parts.

• Always connect the power supply grounding lug

to a proper safety (Earth) ground.

Proper handling

The APEX® 3 Series Pendant is designed to be turned

on and off through the welding power supply. The

pendant should be kept dry and sheltered from rain

and snow. Do not place or drop the pendant on wet

ground or in puddles. Always place the pendant on a

sturdy, at level surface when not in use and be sure to

unplug it.

Keep hands away from weld head, wire feeder and

other moving parts while in operation. Read this entire

process and operations manual before using the

equipment.

OPERATION

Explanation of Welding Terms

GMAW: Gas Metal Arc Welding

FCAW: Flux Cored Arc Welding

STT: Surface Tension Transfer

WFS: Wire Feed Speed

OSC: Oscillation

ACC: Automatic Current Control

AHC: Automatic Height Control

ID: Inside Diameter

OD: Outside Diameter

WFS: Wire Feed Speed

IPM: Inches per minute

CM/MIN: Centimeters per minute

Volts: Voltage

Amps: Amperage

Only operate the system while on a rm level surface.

Always verify that the system cart is secured in place

before operating the system.

Keep hands away from weld head, wire feeder and

other moving parts while in operation.

CAUTION

Never unplug or plug in control cables to the weld

head while the system is powered on.

Verify that the system is properly grounded before

beginning to weld.

Refer to the individual components manuals for additional instructions.

11

Page 12

APEX® 3 SERIES MIG PENDANT MANUAL

System Start Up

Ensure all components are connected. Refer to the

individual component manuals for full connection

instructions.

Prior to beginning the weld, turn on the welding

power supply. The system is designed to be turned

on and off through the welding power supply.Ensure

all components are connected. Refer to the individual

component manuals for full connection instructions.

Note: With power applied to the system, check the

reset button. If the reset button is engaged

the system will not initialize. To disengage the

reset button, rotate the knob clockwise. See

FIGURE 1 - APEX Pendant Reset Button.

This reset button can be used to restart the system

for troubleshooting purposes and to halt welding and

system movement.

OPERATION

FIGURE 2 - Startup Screen

Startup Screen

When the system is reset at the Power Wave®, the

screen will display “Checking Network Connection...

Calibrating System – FIGURE 2 - Startup Screen.

This is a normal part of the initialization process.

Note: During the start up interval, the weld head goes

through a self-calibration cycle. The system will

not allow the user to log in until the calibration

cycle has been completed.

When the system is fully calibrated, the user is presented with a log in screen – see FIGURE 3 - Log In

Screen. Log in to begin use. See the next sections for

pendant operation.

FIGURE 1 - Pendant Reset Button

FIGURE 3 - Log In Screen

B-1

Page 13

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Pendant Operation

The APEX 3 Series Pendant is designed around full

functionality and easy operator experience. The pendant’s buttons serve multiple purposes, depending on

the screen display. See FIGURE 4 - Pendant Items on

page B-3 – to review each button, knob and switch on

the pendant.

Button Actions

Each of the buttons and toggles may perform

differently depending on how the buttons are pressed.

Listed below are the four types of button presses.

1. SHORT PRESS

A short press is a standard press that engages the

button and is not held in place. Most operations are

performed as a short press.

Example: Quickly pressing down button 7 will center the

oscillator.

2. LONG PRESS

For some screens, holding a button down for a

length of time exceeding two seconds signals the

system to perform an alternate function.

Example: A long press of more than two seconds on button 7 will start the oscillation test mode on some screens.

3. HOLD

By pressing and holding down a button or toggle,

the effects exhibited will continue or speed up.

Example: When pressing button 1 in the jog screen,

gas will purge for three seconds. Holding down button 1

will cause the gas to continuously purge.

4. HOLD AND ROTATE

The steering knob also acts as a button. It can be

pressed or rotated for different actions for some

screens. It can also be held down and rotated

for faster navigation.

6. LEFT TOGGLE (WHITE BORDER)

• Short Press – Navigates or changes the selected

value (in this example, it will change the value in

the left dwell box)

• Hold – Increases or decreases value / change

speed on some screens

7. STEERING KNOB

• Rotate – Steers oscillation in and out or changes

the selected variable

• Short Press – Centers the oscillation or moves to

the next variable

• Long Press – Starts / Stops oscillation test

(in idle mode only)

• Hold & Rotate – Fast navigation between

selected variables

8. RIGHT TOGGLE (GRAY BORDER)

• Short Press – Navigates or changes the selected

value (in this example, it will change the value in

the right dwell box)

• Hold – Increases or decreases value / changes

speed on some screens

Selection Buttons

Buttons 1 through 5 are selection buttons. Their

functions change depending on the screen. In each

screen there will be an icon just above the button to

indicate its function. A short press enables, disables or

selects the shown variable.

Navigation Controls

Items 6 through 8 control navigation. They function

primarily for navigating through the menus and

changing values while setting up the system.

Note: When welding, steering knob 7 functions

only for steering or oscillation steering

if oscillation is enabled.

B-2

Page 14

APEX® 3 SERIES MIG PENDANT MANUAL

Menu Buttons

Buttons 9 through 12 are the menu buttons. Pressing

one of these buttons will bring up a menu while in the

idle, test or welding screens.

9. WIRE FEED/AMPS

• Short Press – Wire Feed/Amps options

• Long Press – Navigates to the Jog Screen from

the Idle Weld screen

10. DWELL

• Short Press – Dwell options

• Long Press – Navigates to the Oscillation Screen

from the Idle Weld screen

11. OSCILLATION

• Short Press – Oscillation options

• Long Press – Navigates to the Oscillation Screen

from the Idle Weld screen

12. TRAVEL/VOLTS

OPERATION

• Short Press - Travel/voltage options

• Long Press - Navigates to the jog screen

from the idle weld screen

Control Buttons

Buttons 13 through 15 are the pendant control

buttons. These buttons have specic purposes that

typically do not change.

Note: The control buttons may be disabled in

menu screens.

13. START/STOP

• Short Press – Start if idle, stop if welding, stop/

start test weld when in test mode

14. SECTOR

• Short Press – Switches between sectors and

changes passes (if available) on the Increments

screen.

15. RESET –

• Short Press – stops the welding sequence

and all motion

• Twist Release

IMPORTANT! The reset button is not an emergency

stop button. Power is still being applied to the system.

FIGURE 4 - Pendant Items

Color Coding

The menu buttons and toggles are color-coded. For

example, the icons above button 9 are Wire Feed

(white icon) and Amps (gray icon). When the operator

presses the 9 button in the weld (idle) screen, the value

for the Wire Feed (white icon) will be presented and

can be changed by the left toggle (white border) and

the value for Amps (gray icon) will be presented and

can be changed by the right toggle (gray border).

Fast Movement

Certain screens allow for fast movement using the

steering knob. Movement and selection can still be

accomplished with the left and right toggle. In addition

the steering knob will allow the user to change the

selection by turning the knob and moving to the next

section by pressing the knob.

For fast movement between selections hold the steering knob down while turning to rapidly move from one

selection to the other.

B-3

Page 15

APEX® 3 SERIES MIG PENDANT MANUAL

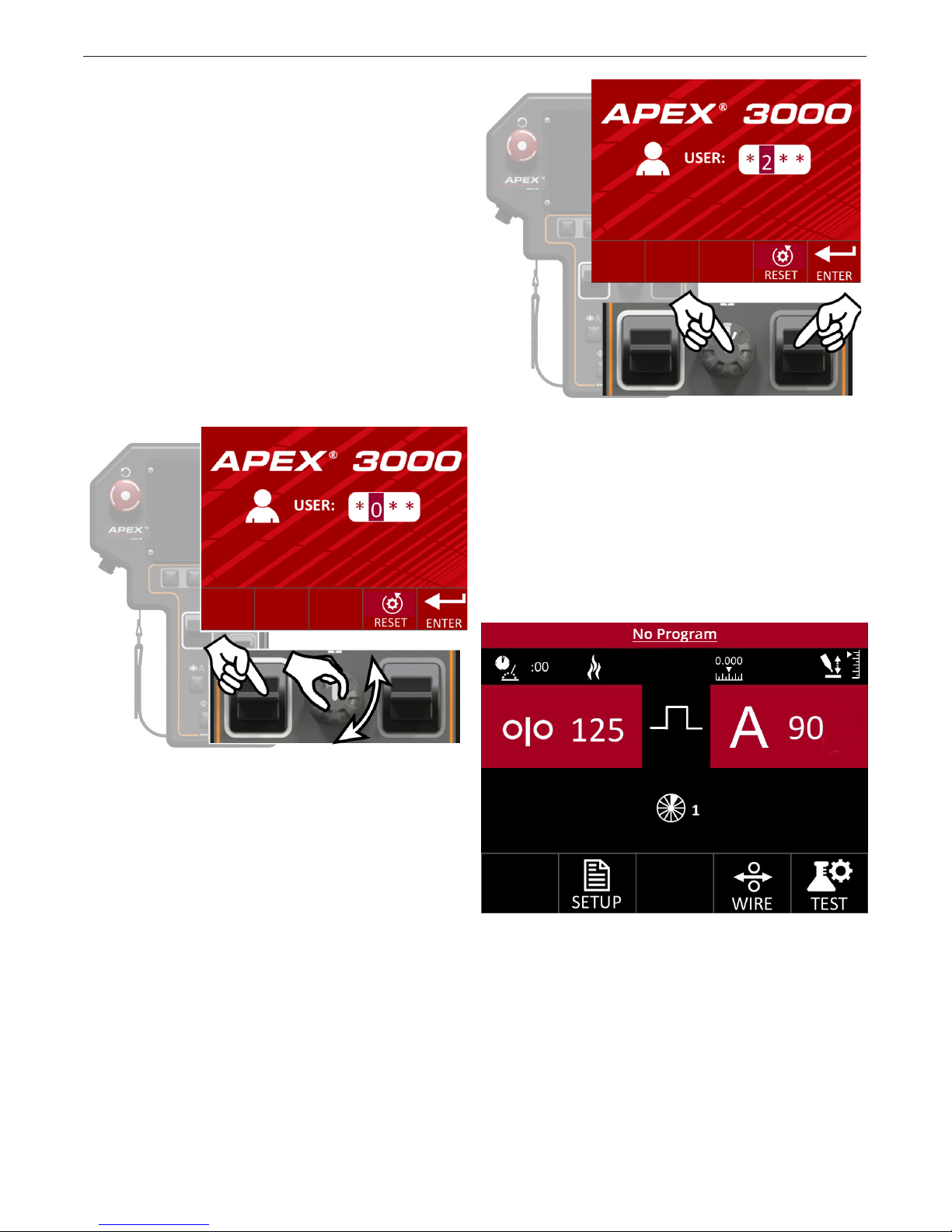

System Log In

When powered on, the system will go through a

self-calibration routine. Make sure the torch is free to

move before starting the system.

When the calibration routine is complete, the user

will be presented with a Log In Screen – see FIGURE

3 - Log In Screen on page B-1 and FIGURE 6 Change User. The system requires a four-digit user

code to log in.

Fast Movement

Fast movement using the steering knob is enabled on

this screen – see FIGURE 5 - Fast Movement. Use

the steering knob or left and right toggles for navigation and selection.

OPERATION

FIGURE 6 - Change User

Press the Enter Selection button when the complete

four digit user code has been entered. Once a four digit code is accepted, the system automatically moves

into the default Idle screen – see FIGURE 7- Idle

Screen Default. This screen is shown when a supervisor logs into the system. Logging in as an operator will

default to the Program Load Screen.

FIGURE 5 - Fast Movement

Use the left toggle or press the steering knob to

change from one variable to the next. Use the right

toggle or turn the steering knob to change the selected

variable.

FIGURE 7 - Idle Screen Default

B-4

Page 16

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Log In Screen

The following buttons and options are available from

the log in screen – see FIGURE 8 - Log in Buttons.

7. STEERING KNOB

• Short Press – Moves cursor to the next space

• Rotation – Quickly cycles through available

character options

• Hold & Rotate – Quickly moves the cursor from

one selection to the next

8. RIGHT TOGGLE (Gray Border)

• Short Press – Pressing up or down changes

value of the selection

9. WIRE FEED/AMPS

• No Effect

10. DWELL

• No Effect

11. OSCILLATION

• No Effect

12. TRAVEL/VOLTs

• No Effect

13. START/STOP

• No Effect

FIGURE 8 - Log in Buttons

1. N/A

• No Effect

2. N/A

• No Effect

3. N/A

• No Effect

4. RESET

• Short Press – Will change password entry back

to “0000”

5. ENTER

• Short Press – Attempts to log in to the system

with the currently entered user code

6. LEFT TOGGLE (White Border)

• Short Press – Pressing up or down moves cursor

between spaces

14. SECTOR

• No Effect

15. Short Press – stops the welding sequence

and all motion

• Twist Release

B-5

Page 17

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Idle Screen

The Idle Screen is the rst screen presented to a

supervisor when logging in – see FIGURE 7 - Idle

Screen Default on page B-4. This screen allows the

supervisor to set up all parameters for welding, test the

parameters if necessary and to start welding.

Menu Option Variables

The Idle Screen will show the user eight variables (two

variables on four separate screens), depending on

which Menu button has been pressed. Pressing the

different Menu buttons will change the values shown.

The different variables shown correspond to the icons

on the Menu buttons.

Similar variables are paired together. The variables

shown on the screen can be changed using the left

and right toggles. It is possible to change between

these menu options while idle or welding.

Press the Menu button to open the

Oscillation Menu options

Press the Menu button to open

the Wire Feed/Amps Menu options

Press the Menu button to open

the Dwell Menu options

Press the Menu button to open

the Travel/Voltage Menu options

B-6

Page 18

APEX® 3 SERIES MIG PENDANT MANUAL

Idle Screen Buttons

The Idle Screen – see FIGURE 9 – will change depending on which menu button has been selected. Some

items in the Selection button windows will change

depending on system congurations.

1. AUTO HEIGHT

• Short Press – Turns Auto Height on and off in

weld mode

2. SETUP

• Short Press – Navigates to the Setup Screen

3. PASS

• Short Press – Switches to the next pass in the

weld program (if available)

4. N/A

• No Effect

5. TEST/WELD

• Short Press – Switches between weld and test

modes (Image shows system in Weld Mode)

OPERATION

6. LEFT TOGGLE (White Border)

• Changes the value displayed in the top left box

(in this example it will change the value in the left

dwell box)

7. STEERING KNOB

• Rotate – Moves the oscillation in and out

• Short Press – Centers the oscillation

• Long Press – Starts/stops oscillation test

8. RIGHT TOGGLE (Gray Border)

• Changes the value displayed in the top right box

(in this example it will change the value in the right

dwell box)

9. WIRE FEED/AMPS

• Short Press – Wire Feed/Amps options

• Long Press – Navigates to the Jog Screen

10. DWELL

• Short Press – Dwell options

• Long Press – Navigates to the Jog Screen Dwell

11. OSCILLATION

• Short Press – Oscillation options

• Long Press – Navigates to the Jog Screen

Oscillation

12. TRAVEL/VOLTS

• Short Press – Travel/Voltage options

• Long Press – Navigates to the Jog Screen

Figure 9 - Idle Screen

13. START/STOP

• Short Press – Starts or stops welding or testing

14. SECTOR

• Short Press – Switches to the next sector if

multiple sectors are enabled

Current sector is displayed here at the center of the screen

near the sector icon.

15. Short Press – stops the welding sequence

and all motion

• Twist Release

* Important! This is not an emergency stop button.

Power is still being applied to the system. The system

will ask you to wait as it resets.

B-7

Page 19

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Idle Screen Test/Weld Modes

After preparing a program, it is recommended that

the user test the parameters before striking an arc.

The system allows for a test mode of all non-weld

functions such as travel, gas purge/ow, oscillation

and others.

Press the Weld/Test Selection button.

Static Screen Items

There are many icons common through the Idle, Weld

and Test screens. These items give helpful information

to the user throughout the setup and welding process.

1. Arc Time – Indicates the amount of time spent

welding

2. Heat Input – Displays the amount of heat input

for the current weld in kilojoules/in or

kilojoules/cm.

3. Sector – Displays the current sector in the weld

program, if applicable

4. Program Name – Displays the currently loaded

weld program and program pass.

Note:

Program Name changes to Italics when

program parameters have changed.

5. Oscillation Location – Displays the relative location

of the oscillation axis.

This example shows how to change the system from

the Test Mode to the Weld mode. The icon in the

Selection Button window indicates what mode the

system is in.

Note:

Auto Height is not an option while in Test Mode.

Pressing the Start/Stop Control Button will switch the

pendant from the Idle Screen to the Test Screen or

Weld Screen depending on which mode the user is in.

6. Torch Height – Displays the relative location of the

height axis.

FIGURE 10 - Static Items

The screen shot above – FIGURE 10 - Static Items

– illustrates the icons that appear on the weld screen.

These icons are for information only and are not

selectable variables.

B-8

Page 20

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Weld Screen

During the weld, the screen will show voltage and

amperage feedback on the Weld Screen – see FIGURE

11 - Weld Screen Options. Pressing the menu buttons

will move the user through the Menu Option Variables

similar to FIGURE 13- All Test Screens.

The Setup Selection is replaced with the Adv Selection. Autoheight can also be engaged or disengaged.

See FIGURE 10 - Weld Screen Options.

Weld Screen Buttons

The Weld Screen buttons work similar to the Idle

screen buttons – see Idle Screen section on page

B-7.

Pressing the Start/Stop button during the weld halts

the weld and moves into the Jog Menu. See FIGURE

16 on page B-11.

Test Screen

Similar to the Weld Screen, the Test Screen will show

voltage and amperage feedback but the feedback

values will be zero – FIGURE 12 - Test Screen

Options. Pressing the menu buttons will move the user

through the Menu Option Variables as shown in the

Idle Screen section.

FIGURE 11 - Weld Screen Options

FIGURE 12 - Test Screen Options

Test Screen Buttons

The Test Screen buttons work similar to the Weld

screen buttons – see FIGURE 13 - All Test Screens.

FIGURE 13 - All Test Screens

B-9

Page 21

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Jog Screen

The Jog Screen – FIGURE 15 - Jog Menu Screen –

is used to test movement of the system before welding. The Jog Screen can be entered from the Idle or

Oscillation screens.

From the Idle Screen, press and hold the Wire Feed/

Amps or the Travel/Voltage menu buttons to enter the

Jog Menu.

Press the Exit selection button to return Idle screen as

shown below.

FIGURE 14 - Engaging Jog Mode

The screen above – FIGURE 14 - Engaging Jog Mode

– provides for moving the weld head along the track,

adjusting torch height, purging gas and shows the

icons for both cold feed forward and cold feed reverse.

B-10

Page 22

APEX® 3 SERIES MIG PENDANT MANUAL

Jog Buttons

The following buttons and options are available from

the Jog Menu.

1. GAS PURGE

• Short Press – Purge welding gas for 3 seconds

• Hold – Continually purges welding gas while held

2. COLD FEED FORWARD

• Short Press – Feeds wire slightly

• Hold – Feeds wire continuously and accelerates

the WFS

3. COLD FEED REVERSE

• Short Press – Retracts wire slightly

• Hold – Retracts wire continuously and accelerates the WFS. Be sure to keep the spool tight as

wire is retracted

4. HOME

• Short Press – Returns the weld head to starting

position on the track. Starting position is determined by previous weld or test start.

OPERATION

5. EXIT

• Short Press – Returns to Idle Screen

6. LEFT TOGGLE (White Border)

• Short Press – Travels forward or backward

slightly

• Hold – Travels forward or reverse and ramps

travel speed

7. STEERING KNOB

• Rotate – Moves the oscillation in and out

• Short Press – Centers the oscillation

• Long Press – Starts/stops oscillation test

8. RIGHT TOGGLE (Gray Border)

• Short Press – Adjusts the torch up and down

• Hold – Adjusts the torch up and down and ramps

adjustment speed

9. WIRE FEED/AMPS

• No Effect

10. DWELL

• Short Press – Navigates to Jog Menu for

oscillation and dwell (short press does the same)

•

11. OSCILLATION

• Short Press – Navigates to Oscillation screen

FIGURE 15 - Jog Menu Screen

13. START/STOP

• If in TEST, it will run the TEST MODE; if in

WELD, the machine will start the weld

14. SECTOR

• No Effect

15. Short Press – stops the welding sequence

and all motion

• Twist Release

* Important! This is not an emergency stop button.

Power is still being applied to the system. The system

will ask you to wait as it resets.

12. TRAVEL/VOLTS

• No Effect

B-11

Page 23

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Oscillation Screen

The Oscillation Screen is used to test and adjust system oscillation before welding. To enter, press and hold

the Dwell or Oscillation menu buttons while in the Jog,

Idle or Weld screens.

From the Idle screen, pressing and holding the Oscillator Menu Button will present the user with the option to

change the oscillation width and the oscillation speed.

Press the Swap Selection Button to be taken to the

Travel Setup Screen.

Travel Setup is discussed in the Travel Setup Screen

section on page B-16. This screen allows the user to

quickly change weld head orientation or change the

weave pattern.

From the Idle screen, holding down the Dwell Menu

Button will present the user with the option to change

the left and right dwells.

In either screen, use a short press to switch between

Oscillation and Dwell. The items highlighted in red are

the variables that can be changed.

Press the “Exit” selection button to return to the Jog

Screens. Once all parameters have been input and

checked, exit out of the Jog Screen to return to the

Weld (also called the “Idle”) Screen.

B-12

Page 24

APEX® 3 SERIES MIG PENDANT MANUAL

Oscillation Buttons

The following buttons and options are available from

the from the Oscillation menu:

1. PURGE

• Short Press – Purge welding gas for 3 seconds

• Hold – Continually purges welding gas while held

2. L/R SWAP

• Short Press – Navigates to the Travel Direction

Setup Screen

3. N/A

• No Effect

4. TEST/WELD

• Short Press – Starts/Stops oscillation test

5. Exit

• Short Press – Returns to Idle Screen

OPERATION

6. LEFT TOGGLE (White Border)

• Short Press – Increases or decreases Left Dwell

time or Oscillation Width

• Hold – Increases increment speed

7. STEERING KNOB

• Rotate – Moves the oscillation in and out

• Short Press – Centers the oscillation

• Long Press – Starts/stops oscillation test

8. RIGHT TOGGLE (Gray Border)

• Short Press – Increases or decreases Right Dwell

time or Oscillation Speed

• Hold - Increases or decreases value continuously

9. WIRE FEED/AMPS

• Short Press – Navigates to Jog Menu

10. DWELL

• Short Press – Switches to Dwell option (when in

Oscillation option, otherwise no effect)

11. OSCILLATION

• Short Press – Switches to Oscillation option

(when in Dwell option, otherwise no effect)

FIGURE 16 - Oscillation Screen

14. SECTOR

• Short Press – If multiple sectors are available,

a short press will move to the next available

sector and display the values associated with

that sector.

15. Short Press – stops the welding sequence

and all motion

• Twist Release

* Important! This is not an emergency stop button.

Power is still being applied to the system. The system

will ask you to wait as it resets.

12. TRAVEL/VOLTS

• Short Press – Navigates to Jog Menu

13. START/STOP

• Starts and stops TEST or WELD MODE

B-13

Page 25

APEX® 3 SERIES MIG PENDANT MANUAL

Setup Menu

The setup screen allows the user to access all

parameters for welding. Please note that this screen

can only be accessed by authorized supervisors set

up in the User’s Menu. This is explained further in the

User’s Setup Screen section.

The Setup Menu – see FIGURE 17 - Setup Menu –

can be accessed from the Weld Menu. This menu is

accessible in either test or weld mode, but it is not

accessible while welding. Press the Setup Selection

button to enter into the setup screen. Once in the

SetUp Menu, the user has access to multiple system

screens.

OPERATION

Setup Screen Options

Track Setup – employs internal or external track, at

track and the size of the pipe (where applicable).

Travel Setup – change the steering controls based on

where the operator is standing in relation to the track,

and set up the weave pattern.

Process Setup – sets up the weld process.

Start Settings – adjustment specic to the programs

affecting how the system will react when the weld

starts.

End Settings – adjustment specic to programs,

affecting how the system will react when the weld ends.

Service – access to current software information and

can change certain motion settings, as well as monitor

production, faults and tests.

Users – assigns operator and supervisor codes for the

system.

Increments – allows limits and the increment value

of each welding variable to be set. This screen also

enables the user to choose between imperial and

metric units.

Programs – The Programs screen is where all

programs are saved, loaded, deleted or copied.

FIGURE 17 - Setup Menu

To select the individual screens, the user moves the

red cursor to the desired eld using the Left Toggle

(White Border), and presses the Enter Selection button.

Pressing Exit will return the user back to the Idle screen.

B-14

Page 26

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

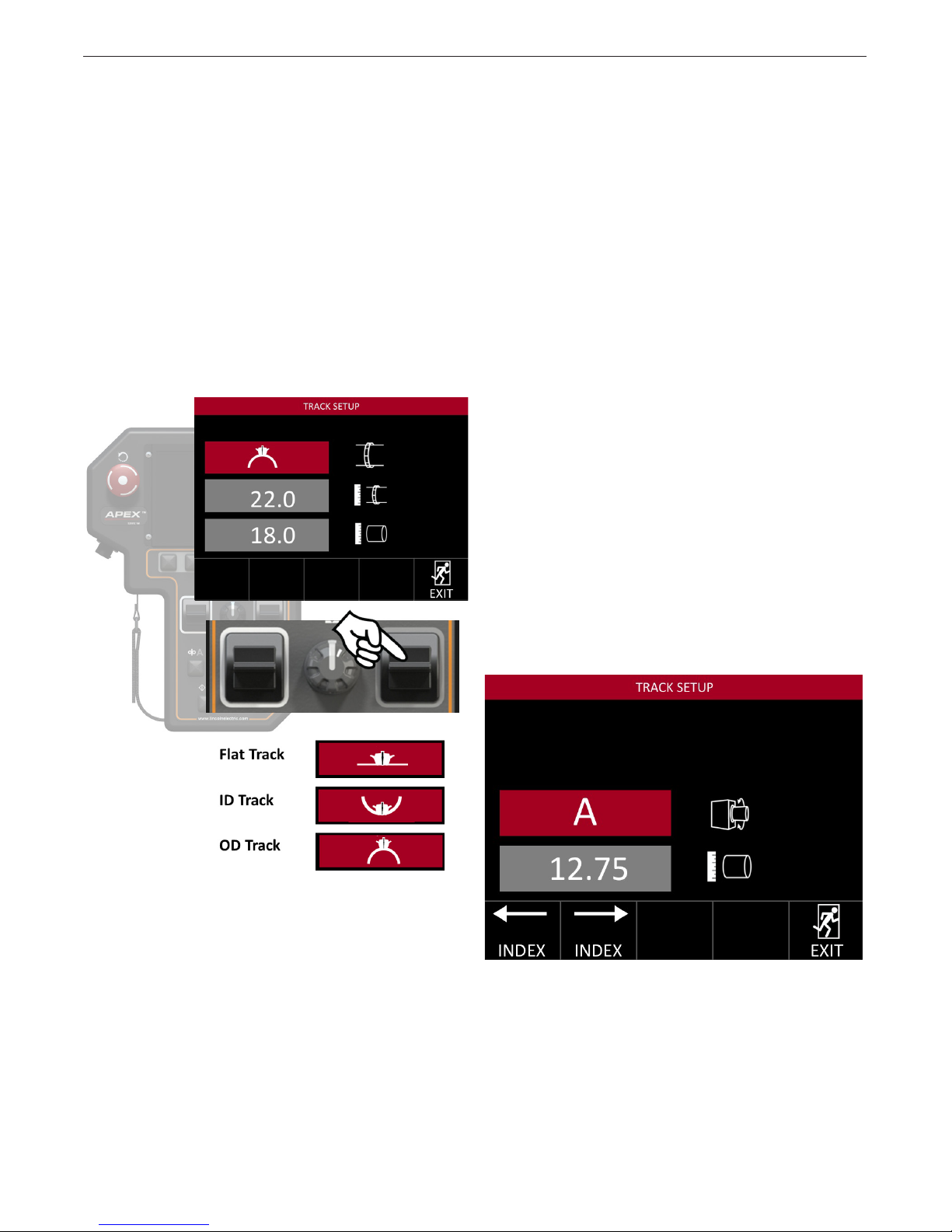

Track Setup

The Track Setup Screen presents the user with several options. From this screen the operator can change

the type of track, the size of the track and the size of

the pipe.

Track Type

The rst selectable option is track type. With the track

type eld highlighted in red the user is able to switch

between the different types of tracks. These tracks

consist of:

• Outside Diameter (OD) Track

• Inside Diameter (ID) Track

• Flat Track

The value can be adjusted in increments of 0.01 inches. Holding the right toggle for longer than 2 seconds

will amplify the speed at which the values increase.

Entering the correct value for track and pipe size

ensures accurate travel speed.

Heavy Wall Pipes

Heavy wall pipes may require the user to change the

pipe size in later passes.

Example: A 20 inch Schedule 120 pipe has an OD of

20 inches and an ID of 17 inches. The pipe diameter

for the root pass should be entered as 17.00 inches,

then increased as the weld progresses outward. This

will help to maintain an accurate welding travel speed

throughout the weld.

Note: For additional OD and ID pipe and tube size in-

formation, please refer to the “Standard Schedule Pipe

and Tube Chart” on page 36.

Positioner Setup

This system can be used as a part of a 1G system with

certain positioners. When the system detects positioners as part of the setup, the Travel Setup screen will

change. See FIGURE 18 - Track Setup Screen.

When the system is set to control multiple positioners

the right toggle will switch between positioner A and B.

Use the Index Selection buttons to index the weld

head on its mount.

Track Ring Size

Track sizes range from 4 to 100 inches in increments of

2 inches. Pressing and holding the right toggle will increase the speed at which the values change. Use the

nominal sizes for the track rings. THESE NOMINAL

SIZES ARE STAMPED INTO THE TRACK.

Pipe Size

The third eld that can be changed is the pipe size.

Currently this can range from 4 inches to 100 inches.

FIGURE 18 - Track Setup Screen

When the system is used to control positioners, the

weld screens will show the current positioner as a

selection. Pressing the Positioner Selection button will

switch from positioner A to positioner B.

B-15

Page 27

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Travel Setup Screen

The travel setup allows the supervisor to set how the

travel controls will work while welding and change the

weave pattern.

Travel

The operator has the option of choosing how the weld

head is oriented on the track. Setting the orientation

and travel direction allows for intuitive operation.

Travel Pattern

The second eld the operator can choose is the

weave pattern. There are three options to choose from:

With the travel eld highlighted, the weld head orientation and the travel direction can be selected. There

are four different options available. All directions refer

to the weld head and are in relation to the user’s view

facing the weld head.

1. Facing Right, Traveling Down

2. Facing Left, Traveling Down

3. Facing Right, Traveling Up

4. Facing Left, Traveling Up

No Weave

When no weave is selected, the oscillator does not

move during the welding process. The user can still

manually steer the oscillator.

Step Travel

During step travel, the travel speed stops during

the dwells. This allows the energy to be directed to

the side walls.

Continuous Travel

Continuous travel will continue travelling throughout the

weld process, during oscillation, excursion and dwells.

B-16

Page 28

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

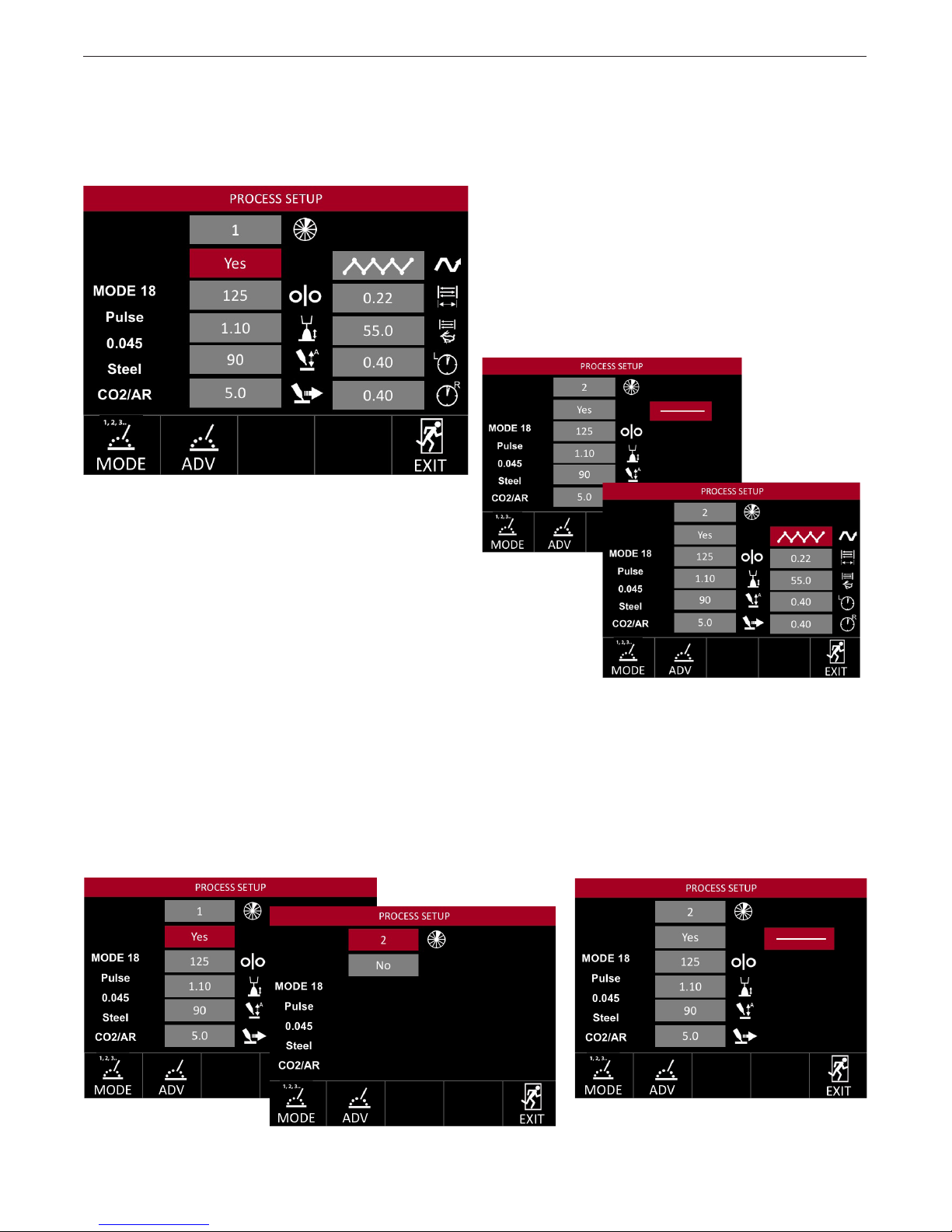

Process Setup Screen

The Process Setup Screen – see FIGURE 19 -

Process Setup – allows the user to select from several

options to determine the variables in the weld.

FIGURE 19 - Process Setup

Standard Process Options

Certain process options should be set up for every

weld and every sector. These options are:

• Sector – Determines which sector the options are

being set for out of eight possible sectors.

• Wire Speed – Sets wire feed speed

• Trim/Voltage – Controls the welding arc length.

• Torch Height (Amperage) – Controls the welding

amperage by raising or lowering the torch when

the Auto Height is turned on.

• Travel Speed – Sets the electrode travel speed

Enabling a sector presents the process variables for

that sector. With only one sector selected, the Idle,

Weld and Test screens will not show the sector icon.

Weave Process Options

• Weave – Refer to the Travel Pattern section on

page page B-16 for the different weave options.

• Oscillation Width – Determines the width of the

oscillation weave (limited by the weld head)

• Oscillation Speed – The speed at which the torch

moves during oscillation

• Left Dwell – How long the torch remains on the

left side of oscillation

• Right Dwell – How long the torch remains on the

right side of oscillation

The purpose of this screen is to set up base settings

before the weld begins. Without a weave selected,

oscillation settings will not appear on the screen.

B-17

Page 29

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

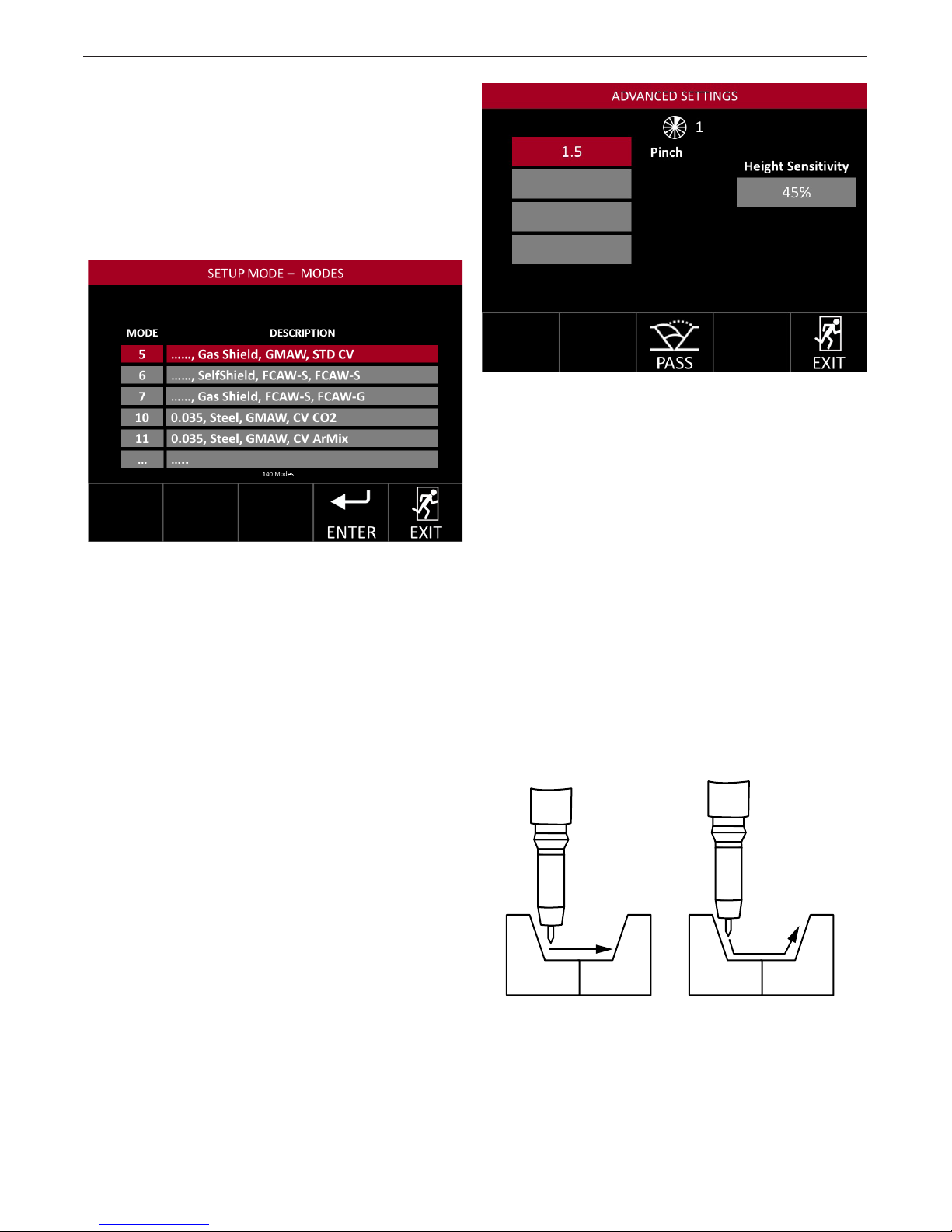

Mode Select

The weld mode is determined by the wire size, type,

process and type of gas being used. Refer to the Power Wave® operator’s manual for additional information

about weld modes. The system can be a guide when

the user is not sure which mode is appropriate for their

application.

Pressing the Mode selection button will take the user

to the Manual Mode Select Screen.

The user is prompted to select the wire size, type,

process and then gas type. Mode Select guides the

user through the settings. Selecting a wire diameter

moves to wire type. See FIGURE 20 - Manual Mode

Select.

Selecting wire type leads to a specic process and

then to gas selection.

Each selection lters the list of available weld modes

to match your application. A cored wire would not

allow the user to select an STT® process.

The selected mode is displayed on the left side of the

screen – see FIGURE 21 - List Mode Screen. These

processes are accessed from the Power Wave, and

are updated with the standard Power Wave updates.

FIGURE 20 - Manual Mode Select

B-18

Page 30

APEX® 3 SERIES MIG PENDANT MANUAL

List Mode Select

Lincoln Electric power supplies come with pre-set

welding modes for particular welding applications and

wire types. Press the Modes selection button on the

Manual Mode Selection Screen to see a list of weld

modes loaded into the power supply.

Press the Modes selection button – see FIGURE 21 -

List Mode Screen – below.

FIGURE 21 - List Mode Screen

The available weld modes are displayed in sequential

order. The available modes depend on the present

equipment.

Use the left toggle or turn the steering knob to choose

an available weld mode then press the Enter Selection

button.

Advanced Process Setup

Certain weld modes have advanced settings specic

to that mode or process. Pressing the ADV Selection

button on the Process Setup screen will present the

user with the advanced options associated with the

selected weld mode – see FIGURE 22 - Advanced

Settings.

OPERATION

FIGURE 22 - Advanced Settings

Height Sensitivity

Height sensitivity is a global setting available regardless of the weld mode selected. The operator can

program the system to react to changes following the

prole of the joint.

Higher sensitivity will result in faster adjustment which

could cause hesitation in torch height and abrupt

changes in the weld as shown in FIGURES A and B.

Maintaining a low height sensitivity allows for higher

quality and more consistent welds. This includes ad-

justing for out-of-round pipes, maintaining heat input

and helping with puddle control on the joint prole. It

is recommended that the operator start the weld at a

lower sensitivity setting for the best performance. This

will also assist in avoiding an over reaction to changes

in the structure of the materials being welded.

Advanced Options

Available options are based on the selected weld

mode.See the Power Wave settings for a full breakdown and explanation of advanced options.

Wave Controls

Some typical wave controls are:

• Pinch

• Hot Start

• UltimArc

®

FIGURE A - JOINT

Low Sensitivity < 50

B-19

FIGURE B - JOINT

High Sensitivity > 50

Page 31

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Start Settings

The Start Settings should be set up after the process

setup has been completed. The start settings screen –

see FIGURE 24 - Start Settings Screen – allows the

user to adjust the start settings specic to the program which affect how the system acts when the weld

starts. The start settings take effect as soon as the

Start/Stop button is pressed to initiate the weld. Refer

to page B-21 to see a full timing diagram.

FIGURE 23- Setup Menu

RunIn WFS

Determines the WFS prior to establishing an arc will

ramp up to welding WFS during upslope.

RunIn Volts

The voltage or trim setting at which the system begins

to weld. Once established, it will ramp to welding voltage during upslope.

Motion Delay

This determines how long the system will wait before

beginning to travel and oscillate.

End Settings

The end settings screen – see FIGURE 25 - End

Settings Screen – allows the user to adjust the end

settings specic to the program, which affect how the

system will behave at the end of the weld. End settings take effect as soon as the Start / Stop button is

pressed to stop the weld. (Refer to page B-21 to see

a full GMAW/FCAW timing diagram.) The settings that

can be changed in this screen are:

Crater WFS - The wire feed speed during crater

Crater Volts/Trim - The amount of voltage/trim during

crater

Crater Time - The duration of crater

Burnback - The time the arc is maintained after the

wire stops at the end of a crater.

Downslope - The time to ramp from welding parameters to crater parameters

Postow - How long the gas continues to ow after

the weld to provide shielding

Both the Start and End Settings screens provide access to the Advanced screen to allow advanced values

to be set for start and end of weld.

FIGURE 24 - Start Settings Screen

The settings that can be changed in this screen are:

Preow

The amount of time (sec) that gas ows before welding

begins to ensure adequate gas coverage for the weld

preventing starting porosity.

Upslope

This is the amount of time (sec) it takes for the system

to ramp up from start settings to welding parameters.

FIGURE 25 - End Settings Screen

B-20

Page 32

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

B-21

Left

Right

Center

Page 33

APEX® 3 SERIES MIG PENDANT MANUAL

OPERATION

Service Menu

The Service Screen allows for advanced welding options.