Page 1

40

VDC

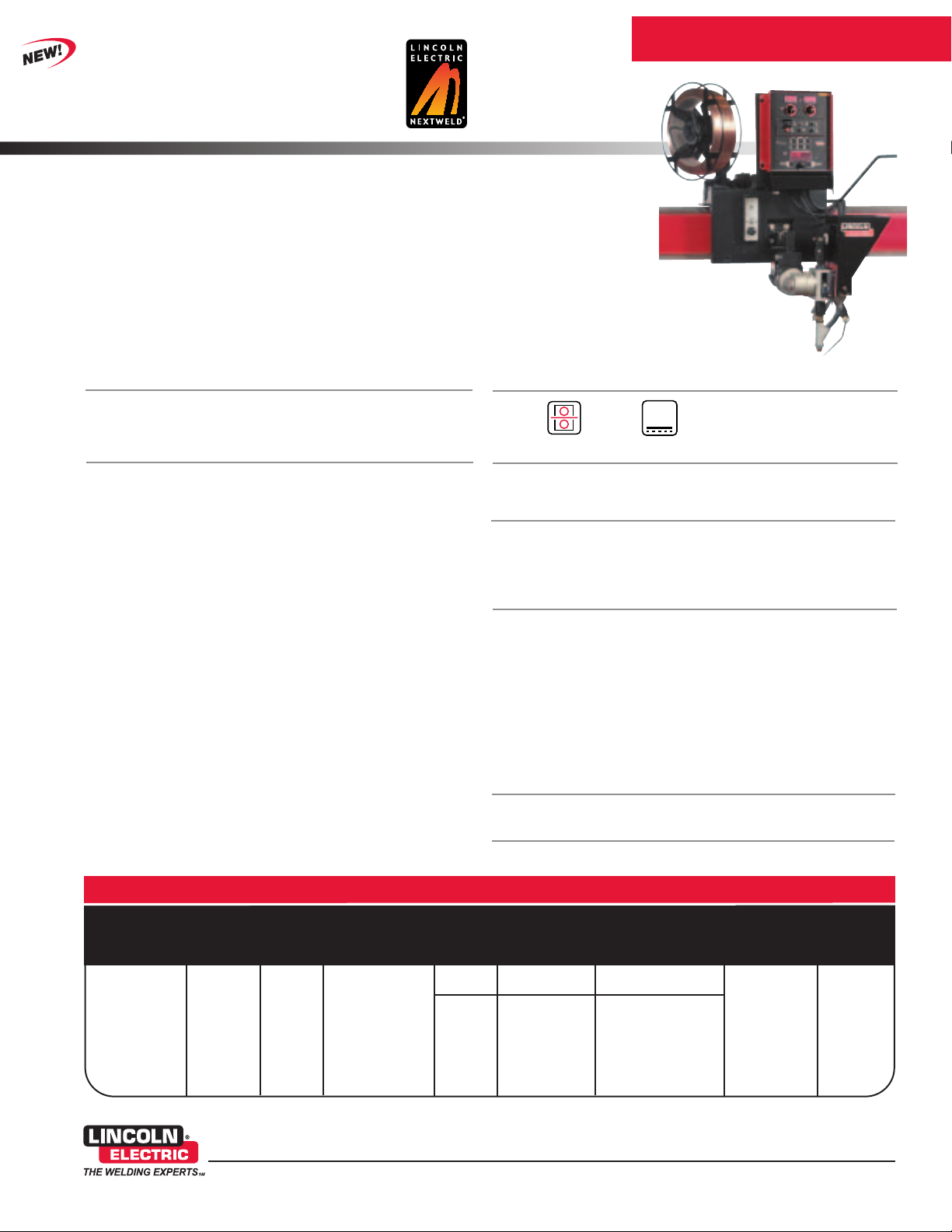

Power Feed™

10A Controller

ArcLink Controller for Power Wave AC/DC Systems.

Built on the enduring and trusted foundation of the NA-5 controller and the innovations of the

new Power Feed 10M wire feeder, the Power Feed 10A Controller is the next generation in

automatic submerged arc feeding. Designed for use with the Power Wave AC/DC 1000 power

source, the Power Feed 10A eliminates the need for a separate AC and DC controller, making this

powerful hard automation system controllable, adaptable and easy to use. The user-friendly

control panel offers a single-point of control over the entire welding cell, including the Power

Wave's Waveform Control Technology™, delivering an unprecedented level of control over wave

balance, amplitude and frequency.

AUTOMATIC WIRE FEEDERS

Processes

Submerged Arc

Advantage Lincoln

• Versatile system set-up options for stand-alone or PLC

configurations help you customize the weld cell to make your

operations as efficient as possible.

• Lincoln’s Waveform Control Technology™ gives you the ability

to select the right waveform for each application.

• The Power Feed 10A Controller provides clear dual digital display

of set-up and weld modes, six memories, AC controls,

strike/start/end options, travel stop/start, and timers.

• Controls can be adjusted on-the-fly to change penetration and/or

deposition rates with Variable Frequency, Variable Amplitude and

Variable Balance.

• Easy-to-use switch panel can be removed and used as a Remote

Control Pendant to create a versatile work station set-up.

• The Power Feed 10SF and Power Feed 10S wire drive systems

are reliable and durable.

• The motor conversion kit allows the use of existing NA-3, NA-4,

and NA-5 feed head mounting hardware.

• Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

• Three-year warranty on parts and labor.

Description

Output Input

Unit Includes:

Power Feed 10A Control Box, Remote Pendant, 10-ft. Remote Pendant

Cable

Unit Requires:

Power Wave AC/DC 1000 power source, and either the K2312-1 Power

Feed 10SF Wire Feed Head for fixed hard automation, or the K2370-1

Power Feed 10S Head for mounting to a Lincoln TC-3 Travel Carriage.

(other options may apply.)

Recommended General Options

Power Feed 10SM Motor Conversion Kit (converts Lincoln NA-style wire

drives), ArcLink Cable, Flux Hopper, Feeder Control Cable (14-pin to 14pin and 5-pin to 5-pin), Contact Nozzle Assembly, Contact Jaw

Assembly, Positive Contact Assembly, Linc-Fill Attachments, Narrow

Gap Deep Groove Nozzle, Concentric Flux Cone Assembly, Tandem Arc

Framework, Tandem Reels, Twinarc Contact Assemblies, Tiny Twinarc

Assemblies, Tiny Twinarc Solid Wire Straightener, TC-3 Travel Carriage,

Vertical Lift Adjuster, Horizontal Adjuster, Wire Reel Assembly for 50-60

lb. Coils, Spindle Kit – 2 in. hub, SpreadArc Oscillator, Flux Screen,

Magnetic Flux Screen Separator

Recommended Power Source Option

Power Wave AC/DC 1000

Order

K2362-1 Power Feed 10A Controller

TECHNICAL SPECIFICATIONS

Product Product Input Rated Output Gear Speed Range

Name Number Power

Power Feed 10A K2362-1 40 VDC 1000A/100% 142:1

Controller with (381 x 259 x 102)

Wire Drive 95:1

(1) 142:1 gear box is standard. Conversion Kit supplied for conversion to 95:1 with Wire Drive (K2370-1, K2312-1, or K2311-1)

(1)

Current / Duty Cycle Box ipm (m/min) Solid Inches (mm) lbs (kg)

(1)

(1)

Wire Feed Wire Size Range

10-200 (.25-5.08) 5/32 - 7/32 (4.0 - 5.6) 15 x 13 x 4 25 (11.3)

10-300 (.25-7.62) 1/8 - 5/32 (3.2 - 4.0)

(1)

Inches (mm) H x W x D Net Weight

(1)

Dimensions

Publication E9.165 1/05

www.lincolnelectric.com

Page 2

A CLOSER LOOK

FEATURES

A Closer Look

Power Feed 10A Control Panel

The Power Feed 10A control panel controls and monitors the advanced

capabilities of the Power Wave AC/DC 1000 in a single, simple, easyto-understand user interface display panel. The Power Feed 10A communicates using ArcLink, and can easily integrate with custom controls

and PLCs, in multiple configurations.

3.

Dual Display Dual Encoder Panel

1. Wire feed speed (WFS) or amps.

1.

2.

2. Voltage

3. Arc Established Indicator - illuminates when a true arc has been established.

4. Status LED - indicates system component ArcLink communication

4.

1.

5.

4.

status. Normal operation is a steady green light.

Switch Panel

®

1. START – Starts the weld sequence, using strike controls.

2.

3.

2. STOP – Stops the weld sequence, using crater/burnback controls.

3. INCH – Up/Down. Inches wire up or down without welding current

4. FLUX FILL– Activates flux hopper.

5. TRAVEL– Controls motion in either manual or automatic modes.

Remote Pendant - The switch panel can be removed and used as a

handheld pendant for remote control.

1. 14-PIN Remote Control Connector

2. 4-PIN TC-3 Carriage Connector

3. 3-PIN Flux Hopper Receptacle

4. 5-PIN ArcLink Connector

5. Auxiliary Circuit Access Holes

2.

1.

3.

4.

5.

Power Feed 10A Controller

[2]

www.lincolnelectric.com

Page 3

A CLOSER LOOK

PERFORMANCE

WHAT IS NEXTWELD®?

Nextweld integrates Lincoln’s technologies, processes and products to create a comprehensive, flexible, user-friendly

welding system that can increase efficiency and reduce fabrication costs.

MSP4 and Memory Panel

Memory panel

Up to six user settings and two procedure settings can be saved and

retrieved using the Memory Panel. Allows the operator to save weld

parameters and set-up options, such as Timers, Start Options, End

Options, AC Controls, etc., before welding begins.

Weld Procedure Limit Controls

The MSP4 panel can be configured to limit the operator’s range of control of weld procedure settings (Wire Feed Speed, Crater Time,

Burnback Time, etc.)

Lockout/Security Controls

Configurations that prevent the operator from changing authorized weld settings can be set at four different lockout levels to provide a

custom level of control.

Mode Select Lockout

Locks START/END Options, AC Controls, Weld Modes and Wave

Options – or various combinations of each.

Memory Panel Lockout

Locks any or all of six memories saved.

Encoder Panel Lockout

Locks either right, left or both control knobs.

Full Lockout

Locks all functions listed above.

Infrared IR Port

Weld Manager™, the Lincoln Electric Palm® OS-based software product, builds upon the usability and efficiency of the Power Feed 10M

user interface design. It offers remote access and availability to system information, set-up, and configuration, allowing you to manage your

Power Wave system from the palm of your hand. The versatile design allows for wireless communication with the Infrared Port on the

Power Feed 10A Controller or through a serial connection and your cradle - the decision is yours.

• Quick and easy user interface set-up that can be transferred

across Power Feed/Power Wave systems.

• Ensure parameters are maintained by locking out numerous

options on the user interface panel.

• Easily set-up the system and ensure repeatability between

multiple cells by transferring memory through a

'back-up'/'restore' or a memory 'clone'.

• Verify current system information right on the production floor.

• Ensure security of the loaded settings through password

protection.

• Any Palm Operating System version 3.5 or higher.

[3]

Power Feed 10A Controller

www.lincolnelectric.com

Page 4

A CLOSER LOOK

PERFORMANCE

Waveform Control Technology®

Driving Superior Welding

Performance

Lincoln’s Waveform Control

Technology controls and shapes the

output waveforms (or weld modes)

to adapt to virtually any application,

material or weld position.

SET-UP OPTIONS (User Preferences)

SETUP

Set-up Mode can store basic user preferences like those listed below, or it can be used to display configurations or

access diagnostic tools.

START ARC FORCE/CRATER ARC FORCE – The Arc Force setting allows the customer to set a specific level of

current during three stages of the welding process.

START: In the start state the arc force sets the starting current for the first 250 mS of the weld. The operator can

control the starting characteristics by adjusting arc force to get a hotter or colder start.

WELD/CRATER: Arc Force is used in these two states to set a specific amount of current if the arc goes into a short.

This setting can be adjusted to create more stable operation during the welding process.

UPSLOPE/DOWNSLOPE TIME – Adjustable time for smooth transition from start to weld and from weld to crater.

RESTRIKE TIME – The time between an electrode short and automatic shutdown – can prevent serious flaws in the

weld. Also shuts off output if the wire stops feeding.

TRAVEL START/END – Start Travel with arc or Start Button strike and End Travel with arc out or Stop Button.

STRIKE

WFS

VOLTS

RESTRIKE

TIME

START

WFS/AMPS

VOLTS

START TIME

ARC FORCE

START OPTIONS

UPSLOPE TIMER

CV/CC

WELD

WFS AMPS

VOLTS

ARC FORCE

WELD MODE

AC

CRATER

WFS/AMPS

VOLTS/

TIME

ARC FORCE

FREQUENCY

BALANCE

DC OFFSET

PHASE

RELATIONSHIP

AC CONTROL END OPTIONS

DOWNSLOPE TIMER

BURNBACK

TIME

START OPTIONS

STRIKE – Adjustable run-in speed that is used for optimizing arc starting. Set independently of weld wire feed speed.

START – Provides separate welding procedure for an adjustable time at the start of the weld. A Hot Start procedure is

used when penetration is required at the arc start location and when run-on tabs are being used.

WIRE FEED SPEED/AMPS/VOLTS/TIME – Set weld parameters to begin at arc start.

WELD MODE

Choose weld procedure-AC, DC, wire size, consumable type.

AC CONTROL

VARIABLE FREQUENCY – The Power Wave AC/DC 1000 and Power Feed 10A Controller system has the widest

range of wave frequency adjustment (0 – 100 Hz) in the industry. Increase Frequency for a more stable arc and less

penetration; dcrease frequency for more penetration.

VARIABLE BALANCE – By setting the correct wave balance (the ratio between positive and negative waveforms), the

operator has greater control of the welding process. Increase Balance to get more penetration and less deposition;

decrease balance to get more deposition and less penetration.

DC OFFSET (VARIABLE AMPLITUDE) – By setting the correct DC Offset, the operator can define the appropriate

penetration and deposition rate, depending on the application.

PHASE RELATIONSHIP – The Power Wave AC/DC 1000 balances the "push" and "pull" of the arc interactions in a

multi-arc environment by using phase shifting to prevent arc blow and optimize the arc stability of virtually any waveform combination.

END OPTIONS

CRATER – Provides a separate welding procedure for an adjustable time at the end of the weld. A crater fill procedure

is used to regulate the bead width and/or fill the crater at the end of the weld.

BURNBACK – Adjustable control over the time delay between the time that the wire feeding stops and the arc is

extinguished to prevent the wire from sticking in the crater.

[4]

Power Feed 10A Controller

www.lincolnelectric.com

Page 5

A CLOSER LOOK

SYSTEM CONFIGURATION

Mounting and Motion Controls

The Power Feed 10S series of Automatic Wire Drives are specially designed for hard automation, submerged arc welding. The heavy-duty

gear box and feed plate are well-known in the industry for years of reliable performance. Now featuring a new high-torque, permanent

magnet motor with more power and even more reliable performance under high heat conditions, The Power Feed 10S series wire drives are

the most rugged in the industry.

Single or Tandem Arc

Power Feed 10S (K2370-1)

(3/32 to 7/32 in. solid wire)

The Power Feed 10S is required to mount to a TC-3 undercarriage for

moving parts. It has many axes of rotation for ease of fixturing and locating.

Sturdy feed plate houses knurled drive rolls for positive accurate wire

feeding of large diameter welding wire (includes flux hopper, wire

straightener cross seam adjuster, head mounting hardware, and 2-5ft 4/0

weld cables).

(95:1 Gear Ratio Conversion Kit included.)

Power Feed 10SF (K2312-1)

(3/32 to 7/32 in. solid wire) Use the Power Feed 10SF for fixed hard

automation applications. Fixture mount wire drive assembly includes motor,

gearbox, drive rolls, guidelines and straightener (fixture builder's head with

wire straightener - insulators not included).

(95:1 Gear Ratio Conversion Kit included.)

Power Feed 10S

(K2370-1)

Power Feed

10SF (K2312-1)

TC-3 Travel Carriage (K325S, F, HCS or HCF)

The self-propelled travel carriage carries the wire feed head and Power Feed

10A in either direction on a beam. It can operate manually or automatically with

the weld controls. The TC-3 comes in two speed ranges (S and F) in

standard or high capacity (HC) models. The standard carriage is equipped for

one wire feed head, and the high capacity carriage is for multi-head systems.

• Standard Carriage – K3255S: 5-75 ipm (0.1-1.9 m/min.)

– K3255F: 15-270 ipm (0.4-6.9 m/min.)

• High Capacity Carriage – K325 HCS: 5-75 ipm (0.1-1.9 m/min.)

– K325 HCF: 15-270 ipm (0.4-6.9 m/min.)

Conversion Kit Power Feed 10SM (K2311-1)

For use with NA Series Gear Head. The ArcLink™ motor retrofit is used to

replace existing motor on NA-3/4 OR NA-5 wire feed head.

(95:1 Gear Ratio Conversion Kit included.)

Multiple Arc

Systems Interface (K2282-1)

This external controller is required for multi-arc applications. The arc-to-arc

interaction is controlled by offsetting the phase relationship in 90° increments,

as each arc is added.

Programmable Logic Controller (PLC)

The Power Wave AC/DC 1000 and Power Feed 10A can easily integrate

into a customer-supplied PLC system. Motion of the TC-3 travel carriage

can be controlled from the PLC, while individual weld controls such as

mode selection, amperage, and voltage are still controlled from the

Power Feed 10A.

TC-3 Travel

Carriage

(K325S, F, HCS

or HCF)

Power Feed 10SM

Motor (K2311-1)

Multi-Arc System

Interface (K2282-1)

[5]

Power Feed 10A Controller

www.lincolnelectric.com

Page 6

A CLOSER LOOK

Set-up Options

1. The Power Feed 10A is shipped configured for easy connection to

the Lincoln TC-3 Travel Carriage and the Automatic Flux Hopper.

(115V AC required to power this configuration.)

2. The switch panel can be easily removed and used as a Remote

Control Pendant for versatile work station set-up.

3. Terminal strip access inside the Power Feed 10A to interface your

custom controls and/or PLCs, or to connect auxiliary circuits.

• Shutdown inputs can be used for limit switches, PLC inputs, etc

in order to shut down the welding operation for any reason.

• Safe and easy to use with numbered and color-coded connectors

for clear identification of inputs.

QUALITY & RELIABILITY

• Powerful permanent magnet DC motor – 32 volt motor on a 40-volt

bus. Rugged aluminum die cast plate is durable and resilient in

high heat.

• Lincoln’s design philosophy adds an extra factor of safety in all

components and construction to maximize reliability and service.

• 100% software controlled — Software based controls can be

upgraded as new features become available.

• Easy access for serviceability.

• Modular construction allows for easy service/maintenance.

• Three-year warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

1.

2.

3.

Printed circuit boards are environmentally-shielded using Lincoln's

engineered potting and protective

frame trays.

For system configuration details, see publication E10.96 on the Power Wave AC/DC 1000™ power source.

RECOMMENDED OPTIONS

ARCLINK®/LINC-NET CONTROL EXTENSION CABLES

Description Order Number

8 ft. (2.5m) Without weld cable K1543-8

16 ft. (4.8m) Without weld cable K1543-16

25 ft. (7.6m) Without weld cable K1543-25

50 ft. (15.2m) Without weld cable K1543-50

100 ft. (30.4m) Without weld cable K1543-100

WELD POWER CABLES

Description Order Number

Lug to Lug, 4/0, 600A, 60% duty cycle, 35 ft. K2163-35

Lug to Lug, 4/0, 600A, 60% duty cycle, 60 ft. K2163-60

Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. K1842-110

0-250 ft. @ 80% Duty Cycle, Qty. 2

5

Description Order Number

12 ft. (3.6m) K1785-12

16 ft. (4.8m) K1785-16

25 ft. (7.6m) K1785-25

50 ft. (15.2m) K1785-50

100 ft. (30.4m) K1785-100

WELD POWER CABLES

Description Order Number

Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. K1842-10

Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. K1842-35

Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. K1842-60

CONTROL CABLE (14 PIN TO 14 PIN)

0-250 ft. @ 100% Duty Cycle, Qty. 3

Power Feed 10A Controller

[6]

www.lincolnelectric.com

Page 7

RECOMMENDED OPTIONS

GENERAL OPTIONS

Power Feed 10SFM Motor

Conversion Kit

Used to convert NA-series wire drives

into PF-10S wire drives. Includes an

ArcLink™ motor retrofit kit used to

replace existing motor on NA-3, 4 or 5

wire feed head. For use with NA-series

gear head.

Order K2311-1

ArcLink Cable (5-pin)

Includes two leads plus two mating

terminals. Connects Power Feed 10A

controller to Power Wave AC/DC 1000.

Order K1543-XX

Flux Hopper for Tandem Arc

Flux Hopper for K387 mountings.

Order K389

Feeder Control Cable (14-pin)

Connects Power Wave AC/DC 1000 to

wire feeder.

Order K1785-xx

Contact Nozzle Assembly

Single arc contact nozzle assembly for

1/8" (3.2 mm) diameter wire. Operates

at currents generally below 600 amps.

Outer flux cone gives full flux coverage

with minimum consumption.

Order K231-x

Contact Jaw Assembly

Single arc contact jaw assembly for

1/8-7/32" (3.2-5.6 mm) diameter wire.

Rugged contact jaws for maximum life

at currents over 600 amps.

Order K226R

Positive Contact Assembly

For single arc welding at high currents

(optional T12928 water cooling attachment recommended when Innershield®

welding over 600 amps).

Order K148x

Linc-Fill® Long Stickout Extension

Linc-Fill long stickout extension for

K148A Single Arc Positive Contact

Nozzle Assembly. Required for long

stickout technique.

Order K149-x

Narrow Gap Deep Groove Nozzle

For single arc 3/32" (2.4 mm) diameter

wire welding on thick walled steel plate

with nearly parallel-sided, narrow gap

joint preparations.

Order K386

Concentric Flux Cone Assembly

For use with K148B, Positive Contact

Nozzle Assembly. Gives concentric flux

coverage around the electrode.

Order K285

Tandem Arc Framework

Provides mountings with desired positioning adjustments for two standard

Automatic Wire Feed Heads. Includes

insulation and hardware to permit direct

mounting to a high capacity TC-3

Carriage, or to the user's gantry or

fixture for either direction of travel.

Order K387

Tandem Reels

Two Wire Reel Mounting for TC-3.

Order K390

Large Wire Twinarc® Contact

Assemblies

Feeds two 5/64" (2.0 mm), 3/32" (2.4

mm) or 1/8" (3.2 mm) wires for submerged arc welding on "Fast-Fill" joints

or hardfacing beads.

Order K225

Tiny Twinarc® Contact Assemblies

Feeds two electrodes for high speed

submerged arc welds. Includes contact

nozzle, wire guides, drive rolls and

guides, and a second wire reel and

mounting bracket.

Order K129-x

Tiny Twinarc Solid Wire Straightener

Straightens wire diameters .045 thru

3/32" (1.2 thru 2.4 mm). Particularly

valuable on longer electrical stickout

procedures.

Order K281

TC-3 Self-Propelled Travel Carriage

Carries head and controls in either direction on a beam. Operates manually or

automatically with the weld controls.

Requires 115V AC 50 or 60 hertz input

power.

Order K325S, F, HCS, HCF

Vertical Lift Adjuster

Provides 4" (102 mm) hand crank

adjustment of vertical head position. It

also includes up to 3-3/4" (95.2 mm) inand-out horizontal adjustment with

stops that can be preset for simple repetition of the same adjustment.

Order K29

Horizontal Adjuster

Provides crank adjustment of head position. Has 2" (51 mm) horizontal travel.

Order K96

Wire Reel Assembly for 50-60 lb. Coils

Accommodates 50 lb. (22.7 kg) or 60 lb.

(27.2 kg) coils of wire on automatic wire

feeders. The unit includes a wire reel

mounting spindle and braking system.

Order K299

[7]

Power Feed 10A Controller

www.lincolnelectric.com

Page 8

RECOMMENDED OPTIONS

GENERAL OPTIONS CONT.

Flux Screen

Spindle Kit - 2 in. hub

For fixture and other custom installations. Features 2" (51mm) O.D. spindle

for mounting Readi- Reels and 2"

For submerged arc welding. Removes

large particles from reused flux.

Includes air-driven vibrator.

Order K310

(51mm) I.D. spools up to 60 lb. (27.2 kg)

capacity.

Order K162-1

Magnetic Flux Screen Separator

For submerged arc welding. Removes

foreign magnetic particles from reused

SpreadArc Oscillator

Oscillates head across the line of travel.

flux.

Order K58

Calibrated dwell time and oscillation

speed controls permit the Spreadarc to

cover large areas quickly with smooth

beads of minimum admixture.

Order K278

POWER FEED 10A CONTROLLER ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

POWER FEED 10A CONTROLLER K2362-1

RECOMMENDED GENERAL OPTIONS

Power Feed 10SM Motor Conversion Kit K2311-1

ArcLink Cable K1543-xx

Flux Hopper for Tandem Arc K389

Feeder Control Cable (14-pin to 14-pin) K1785-xx

Contact Nozzle Assembly K231-x

Contact Jaw Assembly K226R

Positive Contact Assembly K148x

Linc-Fill Long Stickout Extension K149-x

Narrow Gap Deep Groove Nozzle K386

Concentric Flux Cone Assembly K285

Tandem Arc Framework K387

Tandem Reels K390

Large Wire Twinarc Contact Assemblies K225

Tiny Twinarc Contact Assemblies K129-xx

Tiny Twinarc Solid Wire Straightener K281

TC-3 Self-Propelled Travel Carriage – Standard K325S, K325F

TC-3 Self-Propelled Travel Carriage – High Capacity K325HCS, K325HCF

Vertical Lift Adjuster K29

Horizontal Adjuster K96

Wire Reel Assembly for 50-60 lb. Coils K299

Spindle Kit - 2 in. hub K162-1

SpreadArc Oscillator K278

Flux Screen K310

Magnetic Flux Screen Separator K58

RECOMMENDED POWER SOURCE OPTIONS

Power Wave AC/DC 1000 see publication E10.96

TOTAL:

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...