Page 1

Operating Instructions

Pump ZPU 08 ATEX

ZPU 08

810-53711-1 Page 1 / 57

Rev.: 003

31/07/2017

Page 2

EU Declaration of conformity

(following ATEX directive 2014/34/EU, annex X)

The manufacturer

SKF Lubrication Systems Germany GmbH, Heinrich-Hertz-Str. 2-8, D - 69190 Walldorf

hereby declares at its sole responsibility that machinery

Designation:

Pump to supply lubricant within a centralized lubrication system

Type:

ZPU 08

Part number:

605-40759-6 | 605-40759-7 | 605-41759-8

Year of construction

See type identification plate

complies with the following basic safety and health requirements of ATEX directive 2014/34/EU and the basic safety

and health requirements of machinery directive 2006/42/EC at the time when first being launched in the market.

1.1.2, 1.1.3, 1.3.2, 1.3.4, 1.5.1, 1.5.2, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.6.1, 1.7.1, 1.7.3, 1.7.4

Furthermore, the following directives and harmonized standards were applied in the respective applicable areas:

The special technical documents were prepared following:

- ATEX directive 2014/34/EU annex VIII (3) and stored at the named institute (CE 0123).

- Machinery directive 2006/42/EC, annex VII, part B was prepared. We undertake to send this in electronic

form to the respective authorities upon justifiable request.

Harmonized and other standards:

EN ISO 12100:2011

EN 809:2012

EN 1127-1: 2011

EN 60204-1:2007

EN 13463-1: 2009

EN 13463-5:2011

Authorized representative of the technical documentation is the head of standardization. See manufacturer's address.

The machinery must not be put into service until the final machinery into which it is to be incorporated has been

declared in conformity with the previsions of machinery directive 2006/42/EC and any other applicable directives.

Walldorf

31/07/2017

Jürgen Kreutzkämper

Manager R&D Germany

SKF Lubrication Business Unit

Operating Instructions

Pump ZPU 08 ATEX

810-53711-1 Page 2 / 57

Rev.: 003

31/07/2017

Page 3

Operating Instructions

Pump ZPU 08 ATEX

Declaration of conformity

Table of contents

1. Guidelines .......................................................................................................... 6

1.1 Warnings ....................................................................................................... 6

1.2 Illustrations .................................................................................................... 6

1.3 Abbreviations ................................................................................................. 7

1.4 Manufacturer and Service addresses ............................................................ 7

1.5 Warranty ........................................................................................................ 7

1.6 Disclaimer ...................................................................................................... 7

1.7 Copyright ....................................................................................................... 7

2. Safety information ............................................................................................. 8

2.1. Emergency stopping of the pump .................................................................. 8

2.2. Intended use .................................................................................................. 8

2.3. Explosion protection class / Explosion protection marking ............................ 8

2.4. Expiry of the ATEX certification ..................................................................... 8

2.5. Pump operation ............................................................................................. 8

2.6. Foreseeable misuse ...................................................................................... 9

2.7. Prohibition of certain activities ....................................................................... 9

2.8. Conversions or modifications ........................................................................ 9

2.9. Inspections .................................................................................................... 9

2.10. Labels on the pump .................................................................................. 10

2.11. Other applicable documents ..................................................................... 11

2.12. Sources of hazard .................................................................................... 12

2.13. Moving, rotating parts ............................................................................... 12

2.14. Energies ................................................................ ................................ ... 12

2.15. Lubricants ................................................................................................. 12

2.16. Explosive substances at the location of use ............................................. 12

2.17. Existing residual risks ............................................................................... 13

2.18. Persons authorized to operate the pump ................................................. 16

2.19. Operator ................................................................ ................................ ... 16

2.20. Specialist for maintenance and repairs

in potentially explosive atmospheres ........................................................ 16

2.21. Protection of special groups of persons ................................................... 16

2.22. Safety recommendations to be complied with .......................................... 17

2.23. General behaviour when handling the pump ............................................ 17

2.24. Explosion protection ................................................................................. 18

2.25. Transport / installation / maintenance / repairs / servicing ........................ 20

2.26. Initial commissioning / daily start-up ......................................................... 22

2.27. Cleaning ................................................................ ................................ ... 22

810-53711-1 Page 3 / 57

Rev.: 003

31/07/2017

Page 4

Operating Instructions

Pump ZPU 08 ATEX

2.28. Operator obligations ................................................................................. 22

2.29. Determination of hazards ......................................................................... 22

2.30. Explosion protection measures following ATEX ....................................... 23

2.31. Provision of necessary information .......................................................... 23

2.32. Instructions / qualification obligations ....................................................... 24

2.33. Briefing of external technicians ................................................................ 24

2.34. Inspection for correct use ................................................................ ......... 24

2.35. Provision of personal protective equipment .............................................. 24

2.36. Training courses ....................................................................................... 25

2.37. Inspection of the delivery .......................................................................... 25

2.38. Returns ..................................................................................................... 25

2.39. Disposal ................................................................................................... 25

3. Lubricant .......................................................................................................... 26

3.1. Selection of lubricants ................................................................................. 26

3.2. Ageing of lubricants ..................................................................................... 26

3.3. Specification ................................................................................................ 27

4. Technical data ................................................................................................. 28

4.1. Ambient temperatures ................................................................................. 28

4.2. Explosion protection marking ...................................................................... 28

4.3. Operating pressure ...................................................................................... 28

4.4. Installation position ...................................................................................... 28

4.5. Sound pressure level ................................................................................... 28

4.6. Maximum set-up height ............................................................................... 28

4.7. Maximum dust thickness ............................................................................. 28

4.8. Weight ......................................................................................................... 28

4.9. Gear ratio .................................................................................................... 28

4.10. Reservoir .................................................................................................. 29

4.11. Space requirements ................................................................................. 30

4.12. Electrical connection ................................................................................ 31

4.13. IP Types of protection .............................................................................. 31

4.14. Tightening torques.................................................................................... 32

4.15. Connections / outlets ................................................................................ 33

4.16. Filling possibilities..................................................................................... 33

4.17. Rotational direction of the pump ............................................................... 33

4.18. Admissible speed of the eccentric shaft ................................................... 33

4.19. Output ...................................................................................................... 33

4.20. Lubricant filter ........................................................................................... 33

4.21. Type identification plate ............................................................................ 34

4.22. Storage until the first use .......................................................................... 35

810-53711-1 Page 4 / 57

Rev.: 003

31/07/2017

Page 5

Operating Instructions

Pump ZPU 08 ATEX

5. Technical data of the capacitive sensor ........................................................ 36

6. Technical data of the motor ............................................................................ 37

7. Brief description of the pump ........................................................................ 38

8. Installation and commissioning ..................................................................... 40

8.1. Filling of the reservoir .................................................................................. 40

8.2. Inadvertent filling with incorrect lubricant ..................................................... 41

8.3. Inspections prior to initial start-up ................................................................ 41

8.4. Activation of the pump ................................................................................. 42

9. Standard operation .......................................................................................... 43

9.1. Daily start-up ............................................................................................... 43

9.2. Inspections .................................................................................................. 43

9.3. Filling of the reservoir during operation ....................................................... 43

9.4. Cleaning ...................................................................................................... 43

10. Maintenance ..................................................................................................... 44

10.1. Maintenance of pump ............................................................................... 44

10.2. Maintenance of lubricant filter .................................................................. 45

10.3. Maintenance of gear unit .......................................................................... 45

10.4. SEW motor maintenance ......................................................................... 46

10.5. Measurement of the insulation resistance ................................................ 46

10.6. Maintenance of gear unit .......................................................................... 46

11. Troubleshooting .............................................................................................. 47

12. Declarations of conformity of the purchase parts ........................................ 51

810-53711-1 Page 5 / 57

Rev.: 003

31/07/2017

Page 6

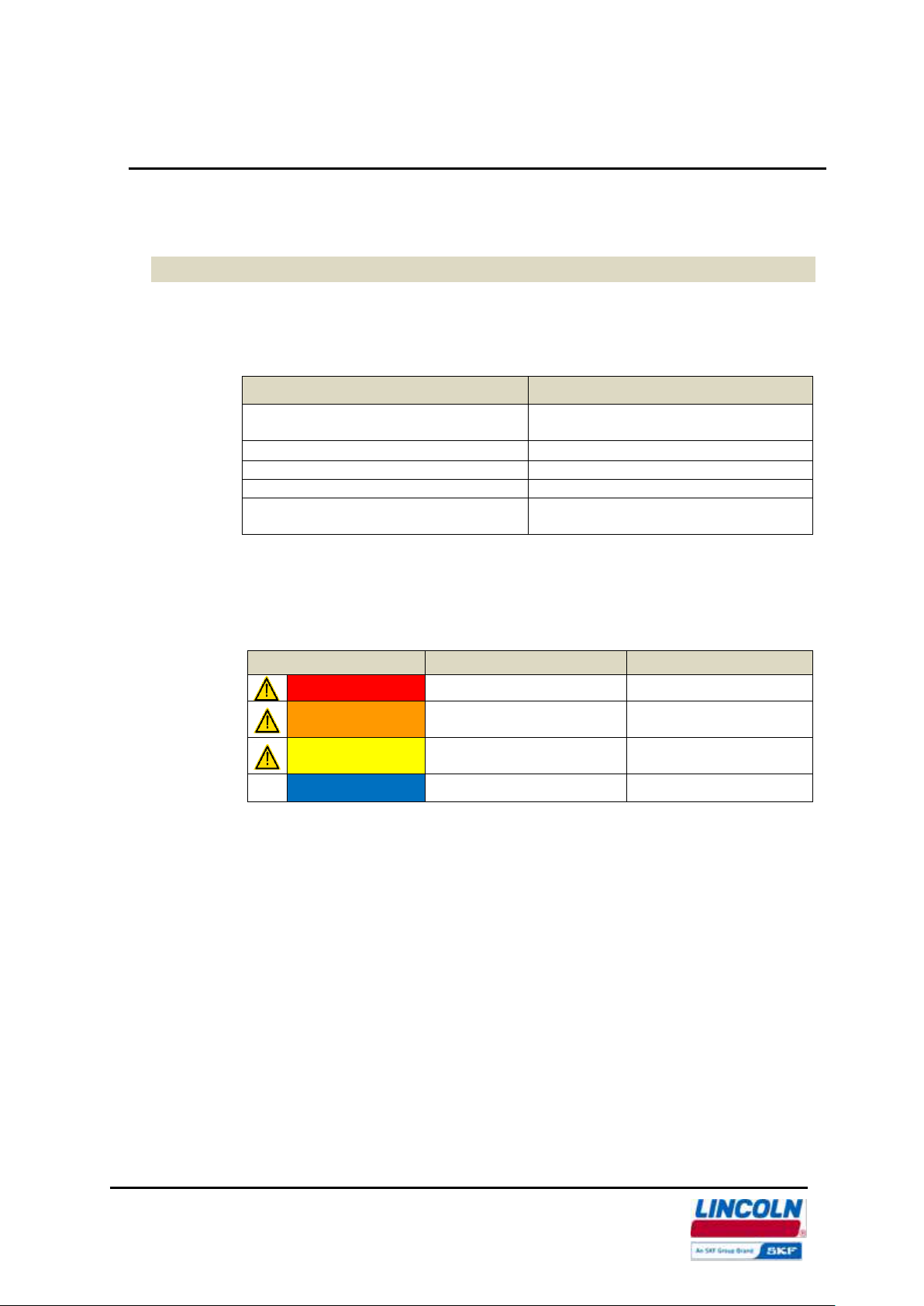

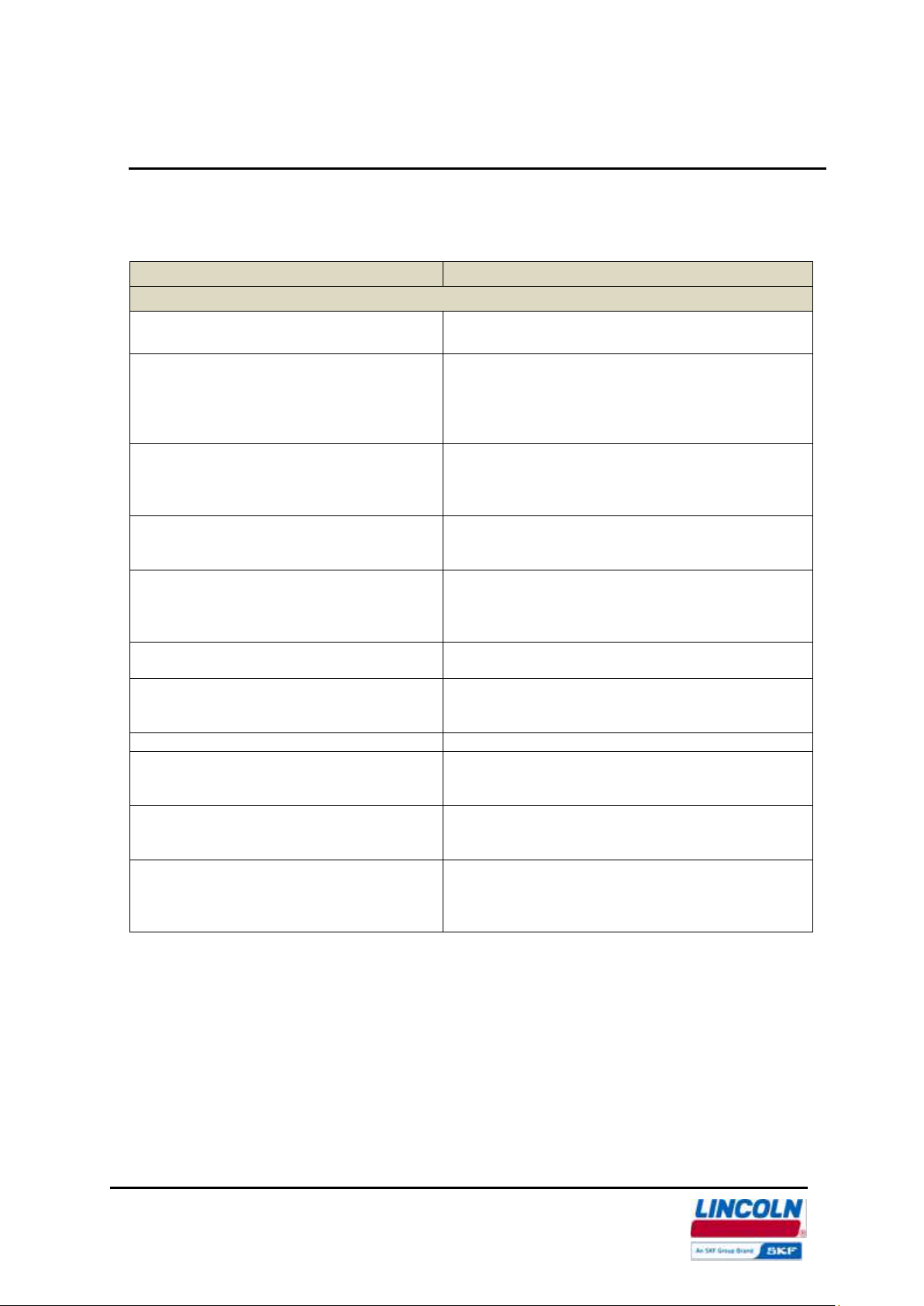

Text representations

Meaning

Bold print

Highlighting of particularly important

words or passages

List 1

Marks lists

o List 2

Marks lists

(parenthesis)

Item numbers

Instructions

Instructions to personnel. These

always appear in chronological order.

Warning level

Consequence

Probability

DANGER

Death/ serious injury

imminent

WARNING

Death/ serious injury

possible

CAUTION

Minor injury

possible

NOTICE

Property damage

possible

Operating Instructions

Pump ZPU 08 ATEX

1. Guidelines

As you read these instructions, you will notice a number of depictions and symbols

which are to facilitate the navigation and understanding of these instructions. For

reasons of better legibility, in these instructions we mainly use the male form for

general references. Of course, the female form is also always intended.

1.1 Warnings

Activities which generate actual hazards (to life and limb or possible damage to the

material) are marked by warnings. Definitely observe the instructions given in the

warnings. The following warnings are possible.

1.2 Illustrations

The illustrations used refer to a specific product. In the case of other products or

product versions they may have a schematic character only. The basic functions,

however, do not change.

810-53711-1 Page 6 / 57

Rev.: 003

31/07/2017

Page 7

max. maximum

min. minimum

min minutes

s seconds

etc. and so on

poss. possibly

e.g. for example

ml millilitre

ccm cubic cm

mm millimetre

°C degrees Celsius

°F degrees Fahrenheit

K Kelvin

inch inch

etc. et cetera

kg kilogram

l litre

mbar millibar

no. number

rpm revolutions per min

Nm Newtonmeter

incl. including

i.e. this means

rh relative humidity

approx. approximately

Ø diameter

® registered trademark

© Copyright

TM Trademark

% per cent

dB (A) sound pressure level

> greater than

< less than

± plus minus

SW width across flats

ESD electrostatic

discharge

N/A not applicable

MTTF mean time to failure

Manufacturer

Customer Service

SKF Lubrication Systems Germany GmbH

Heinrich-Hertz-Str. 2-8

DE - 69190 Walldorf

Central Customer Service Dept.

P.O. Box 1263

DE - 69183 Walldorf

Operating Instructions

Pump ZPU 08 ATEX

1.3 Abbreviations

The following abbreviations may be used within these instructions.

1.4 Manufacturer and Service addresses

1.5 Warranty

The instructions do not contain any information on the warranty. This can be found

1.6 Disclaimer

1.7 Copyright

810-53711-1 Page 7 / 57

Rev.: 003

31/07/2017

in our general terms and conditions.

Observation of these instructions is the prerequisite for safe operation and the

achievement of product characteristics and performance levels. The manufacturer

shall bear no liability for damages - of any kind - resulting from the non-observance

of these instructions.

© SKF. All rights reserved.

Page 8

Operating Instructions

Pump ZPU 08 ATEX

2. Safety information

Safety information is to be read and observed by any persons entrusted with works

on the machine or by those persons who supervise or instruct the beforementioned group of persons. It is prohibited to commission or operate the machine

prior to reading the Instructions. These Instructions must be kept at an accessible

location for further use.

2.1. Emergency stopping of the pump

In case of an emergency stop the pump by:

Switching off the machine or system in which the pump has been

integrated.

2.2. Intended use

Supply of lubricants within a centralized lubrication system following the

specifications made in these Instructions and the stated explosion protection class:

The pump may be used within commercial machines or systems exclusively.

2.3. Explosion protection class / Explosion protection marking

See declaration of conformity or type identification plate of the pump.

2.4. Expiry of the ATEX certification

The ATEX certificate for this product expires through:

Use not in accordance with the intended purpose

Unauthorized modifications.

Use of non-original spare parts.

Non-observance of these instructions and other applicable documents.

Use of non-specified lubricants.

Non-observance of the specified maintenance and repair intervals.

Wrong, lacking or damaged ATEX painting.

2.5. Pump operation

Operation is permitted only, if in compliance with:

All information given in these instructions or stated in the referenced

documents.

All laws and regulations to be complied with by the user.

Information on explosion protection according to directive 1999/92/EC

(ATEX 137).

ATEX approval.

810-53711-1 Page 8 / 57

Rev.: 003

31/07/2017

Page 9

Operating Instructions

Pump ZPU 08 ATEX

2.6. Foreseeable misuse

Any other use and purpose of the pump than the ones described before are strictly

prohibited. It is expressly forbidden to be used:

In a different, more critical potentially explosive atmosphere than stated in

these Instructions.

Outside the indicated temperature range.

In areas with aggressive or corrosive materials (e.g. high ozone pollution).

These may affect seals and painting.

In areas with harmful radiation (e.g. ionising radiation).

to use the CLS to feed, forward, or store hazardous substances and

mixtures in accordance with annex I part 2-5 of the CLP regulation (EC

1272/2008).

to supply, transport, or store hazardous substances and mixtures in

accordance with annex I part 2-5 of the CLP regulation (EC 1272/2008)

and marked with GHS01 - GHS06 and GHS08 hazard pictograms.

For the supply, transport, stockpiling of gases, liquefied gases, dissolved

gases, vapours, and fluids whose vapour pressure exceeds normal

atmospheric pressure (1013 mbar) by more than 0.5 bar at the maximum

admissible operating temperature.

2.7. Prohibition of certain activities

The following activities may be carried out by manufacturer specialists or

authorized persons only due to potential sources of faults that may not be visible

for the user, or due to legal regulations:

Repairs/ changes to the motor/ gear

2.8. Conversions or modifications

Unauthorized conversions or modifications may result in unforeseeable impacts on

safety. Therefore, any unauthorized reconstructions or changes are expressly

prohibited.

2.9. Inspections

The following inspections were carried out prior to delivery:

Inspections following ATEX.

Electrical inspections following DIN EN 60204-1:2007 /

VDE 0113-1:2007.

Safety and functional tests

810-53711-1 Page 9 / 57

Rev.: 003

31/07/2017

Page 10

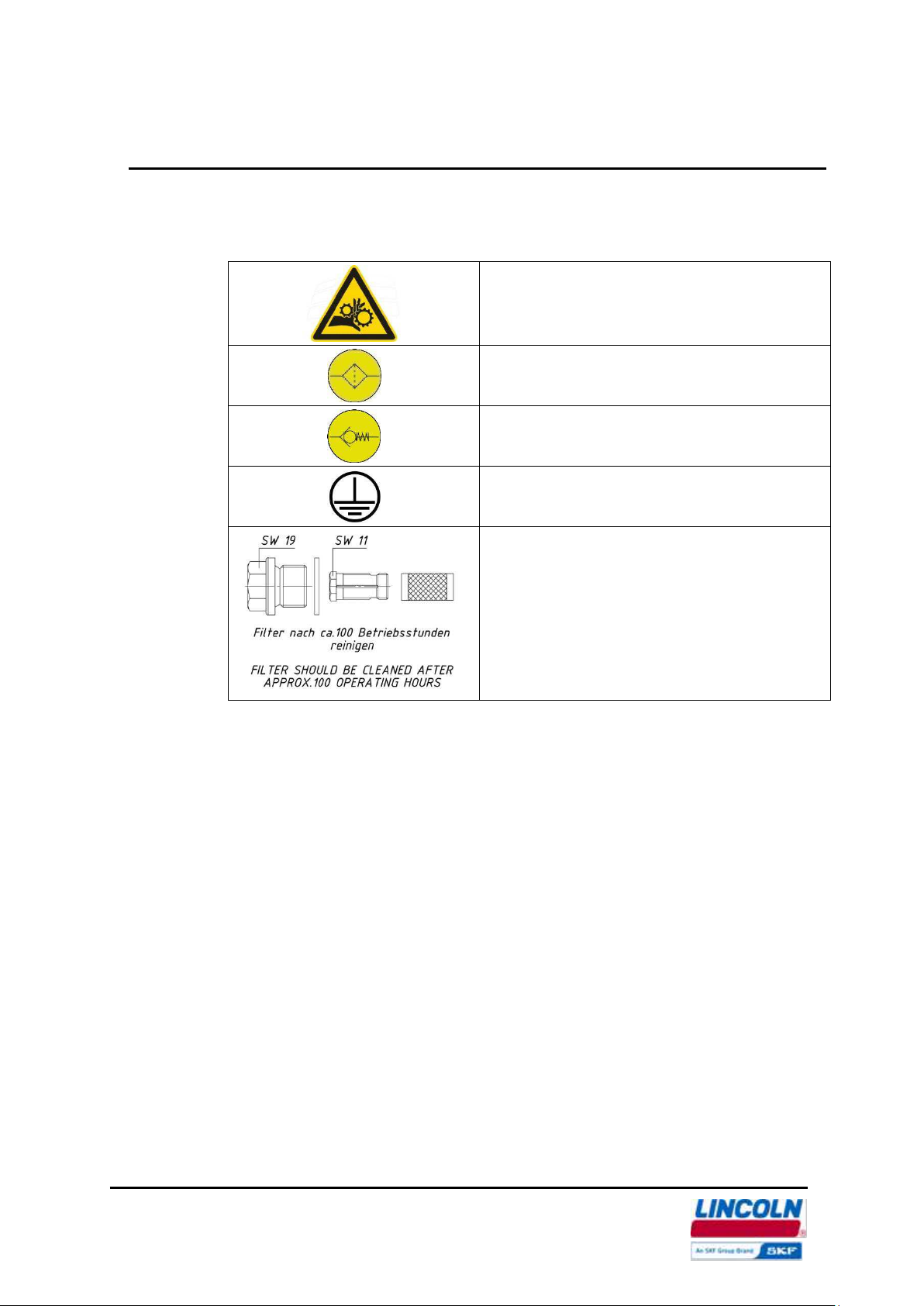

Hand injury warning

During operation of the pump, never remove the

lid and reach into the reservoir. Risk of trapping

or shearing off hands and fingers!

Behind the protective fitting marked with this

symbol there is the lubricant filter.

Behind the protective fitting marked with this

symbol there is the check valve.

Marks the equipotential bonding connection of

the pump.

Provides instructions on how to clean the

lubricant filter.

Operating Instructions

Pump ZPU 08 ATEX

2.10. Labels on the pump

810-53711-1 Page 10 / 57

Rev.: 003

31/07/2017

Page 11

Operating Instructions

Pump ZPU 08 ATEX

2.11. Other applicable documents

In addition to these instructions, the following documents must be observed by the

respective target group:

Operator's explosion protection document.

Operational instructions and release provisions by the operator.

Safety data sheet (MSDS) of the lubricant used.

Gear

Rehfuss

Instructions for the SM type series

Motor

SEW

Explosion-protected three-phase motors EDR.71-225 documentation no.:

19402007

Where appropriate:

Any documents of other components required to set up the centralized

lubrication system.

Project planning documents.

Other relevant documents for the integration of the pump into the machine

or system.

The owner must supplement these documents by the respective valid national

or regional regulations laid down by the country in which the product is to be

used. If the product is sold or transferred, any associated documents must be

passed on to the subsequent operator as well.

810-53711-1 Page 11 / 57

Rev.: 003

31/07/2017

Page 12

Operating Instructions

Pump ZPU 08 ATEX

2.12. Sources of hazard

The pump has been designed, built and tested using state-of-the-art technology. It

will have left our company only after having passed stringent safety and reliability

tests. Like for all complex machines, also for this pump there may still be involved

potential sources of hazard, For example:

2.13. Moving, rotating parts

Drive, stirring paddles

2.14. Energies

Electricity

Temperature (hot/ cold surfaces)

Position energy (raised components)

Parts subject to (operating) pressure

Parts subject to spring tension

2.15. Lubricants

Greases

2.16. Explosive substances at the location of use

Gases, dusts

810-53711-1 Page 12 / 57

Rev.: 003

31/07/2017

Page 13

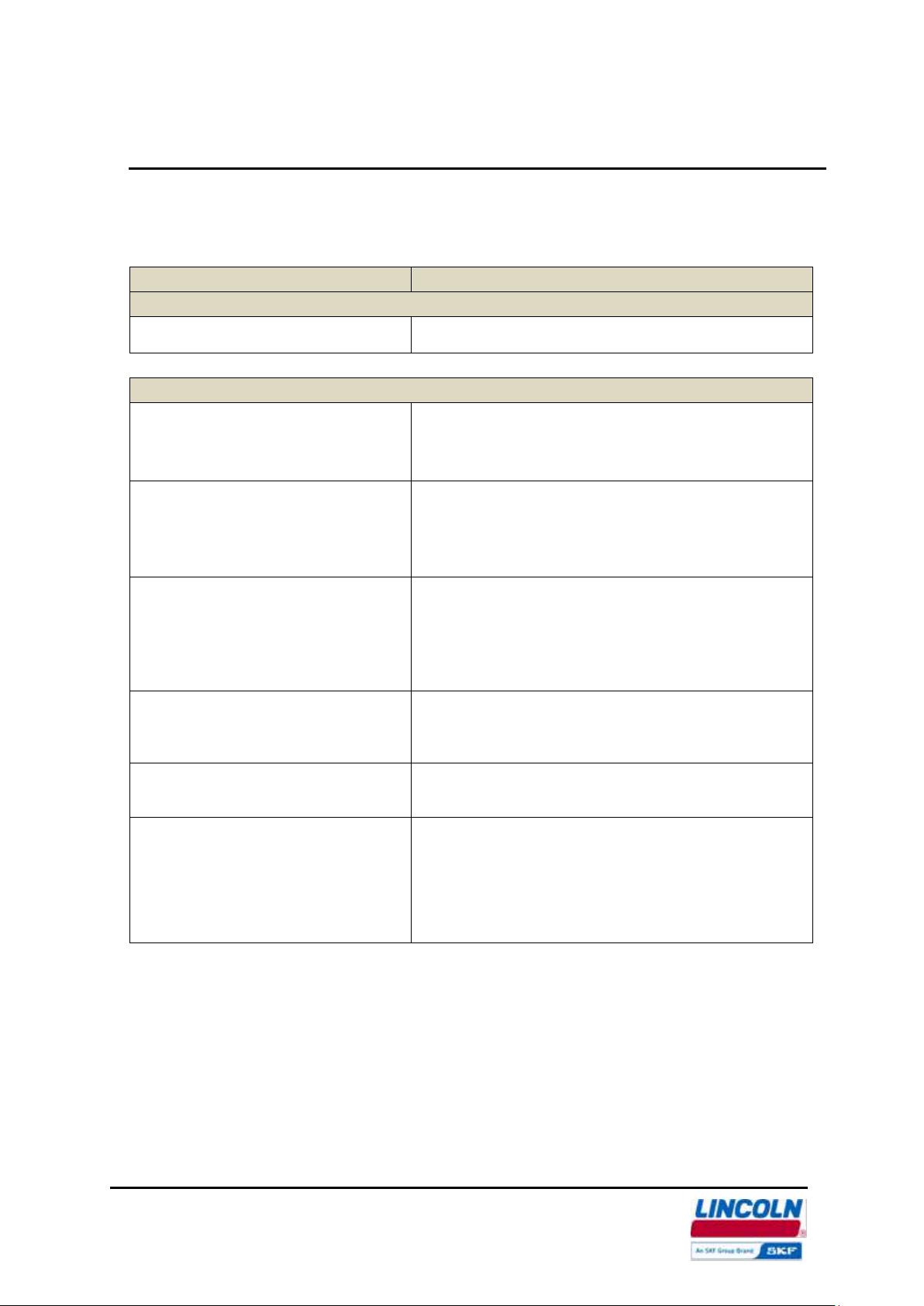

Residual risks

Remedy

Operation in potentially explosive areas

Deviating installation position.

Loss of correct low-level signal function.

Maintain installation position (± 5°). Correct

installation position, if necessary.

Heat-up of non-lubricated lubrication points

in the area of ignition temperature through

undetected faults within the centralized

lubrication system.

The operator must check thoroughly whether an

operation without low-level signal leads to a new

hazard potential (e.g. through heat-up of bearing

points on the machine in the area of ignition

temperature). If uncertain, provide low-level signal.

Heat-up of components in the area of

ignition temperature or formation of a

potentially explosive atmosphere through

whirling up of dust.

Avoid dust accumulation and remove dust

regularly. Select a location of installation with as

little dust as possible.

Strong heating up of the motor in case of

high load or failure of the motor circuit

breaker.

Switch the pump off. Let parts cool down, eliminate

cause. Replace the motor circuit breaker or adjust

it correctly.

Loosening of plug-in connections under

voltage.

Secure plug-in connections against inadvertent

loosening by means of safety clips. Prior to

loosening the plug-in connections: de-energise the

pump.

Generation of electrostatic charges or

sparks through unsuitable clothing or tools.

Within potentially explosive areas use ESD clothing

and tools only.

Generation of sparks through dropping

parts.

Secure parts against falling. Where appropriate,

cover parts in order to avoid the formation of

sparks.

Missing or insufficient grounding

Check the grounding on the pump.

Bringing catalytic, unstable or pyrophoric

substances into a potentially explosive

area.

Ensure that none of these substances gets into the

potentially explosive area. Have all substances

approved by the operator.

Use of isolating amplifiers to operate the

capacitive sensor in potentially explosive

areas.

Mount isolating amplifiers outside potentially

explosive areas only.

Operation with damaged or lacking ATEX

painting or ATEX painting done wrongly

later on and not complying with the

standards applicable for ATEX

Before the first start-up and later at regular

intervals check the painting and let it be renewed

by authorized personnel, where appropriate.

Operating Instructions

Pump ZPU 08 ATEX

2.17. Existing residual risks

810-53711-1 Page 13 / 57

Rev.: 003

31/07/2017

Page 14

Residual risks

Remedy

Transport lifecycle

Tilting or falling of parts during

transport, e.g. over inclines.

Secure parts against tilting or falling during transport

(e.g. using tapes, belts, ropes, etc.).

Installation life cycle

Dropping of lifted parts or tools.

No people may remain under suspended loads. Keep

unauthorized persons away. Secure suspended loads

using suitable hoisting equipment (e.g. tapes, belts,

ropes, etc.).

Falling of parts due to insufficient

fixing to the machine.

Fix parts only to machine parts with sufficient load

capacity. Observe the weight. Observe the stated

tightening torques. If no tightening torques are stated,

the tightening torques are to be applied according to the

screw size for 8.8 screws.

Electric shock when connecting the

pump.

Prior to connection of the pump, de-energize all

affected electrical components. If necessary, please

observe discharge times. The electrical connection may

be carried out by commissioned and qualified

electricians only and in accordance with the connection

diagram.

People falling due to

contamination of floors with spilled

lubricant.

Take care when filling. Bind and remove leaked or

spilled lubricant immediately with a suitable agent.

Observe the legal or company regulations on dealing

with oils and greases and contaminated parts.

Ripping out or damage to lines when

assembling movable machine parts

(e.g. pivot arm).

If possible, do not mount onto movable parts. Should

this not be possible, use flexible hose lines of sufficient

length.

Deviating installation position.

Foreign objects falling into the motor

air intake.

Borehole for drainage of condensation

water is no longer at the lowest point

of the motor.

Installation of a suitable protective roof over the air

intake.

Deviating installation position only, if the formation of

condensation water has been completed.

Operating Instructions

Pump ZPU 08 ATEX

810-53711-1 Page 14 / 57

Rev.: 003

31/07/2017

Page 15

Residual risks

Remedy

Lifecycle Commissioning/ operation/ maintenance

Lubricant spraying out due to incorrect

screw connection of components or

lines.

Tighten all parts with appropriate tightening torques.

Use suitable hydraulic screw connections and lines

for the stated pressures. Check these prior to

commissioning for correct connection and damage.

Contact with the stirring paddle when

filling from the top during operation of

the pump.

Fill preferably via the filling connection. Fill only from

the top when the pump is not moving. When filling,

do not reach into the reservoir.

Electric shock through reduced

insulation resistance.

Check the formation of condensation water in the

motor regularly. If applicable, drain off condensation

water at the drain plug.

Check the insulation resistance regularly.

Electric shock when connecting the

pump.

Prior to connection of the pump, de-energize all

affected electrical components. If necessary, please

observe discharge times. The electrical connection

may be carried out by commissioned and qualified

electricians only and in accordance with the

connection diagram.

Residual risks

Remedy

Fault lifecycle

Severe heat-up or defect of motor

through blockage.

Switch the pump off. Let parts cool down, eliminate

cause.

Residual risks

Remedy

Disposal lifecycle

Contamination of the environment with

lubricant and wetted

parts.

Dispose of the parts following the valid legal and

company regulations.

Operating Instructions

Pump ZPU 08 ATEX

810-53711-1 Page 15 / 57

Rev.: 003

31/07/2017

Page 16

Operating Instructions

Pump ZPU 08 ATEX

2.18. Persons authorized to operate the pump

2.19. Operator

A person who is qualified by training and experience to carry out the functions and

activities related to normal operation. This includes avoiding possible hazards that

may arise during machine operation.

2.20. Specialist for maintenance and repairs in potentially explosive

atmospheres

A person who is qualified by training and experience to identify and assess

possible risks and hazards during work on the machine or partial components in

potentially explosive areas and to initiate suitable measures to prevent such risks.

The specialist has knowledge of the different ignition protection types, installation

procedures and zone divisions. He is familiar with the rules and regulations

relevant for his activities and explosion protection, in particular with ATEX directive

94/9 EG.

2.21. Protection of special groups of persons

The respective legal employment restrictions do apply.

Persons with cardiac pacemakers and/or

metal implants

Magnetic fields existing in the environment of live conductors and motors may

present a hazard to above-mentioned persons. Should it be necessary for them to

access such areas, a doctor should be consulted beforehand, as health

impairments cannot be excluded generally.

810-53711-1 Page 16 / 57

Rev.: 003

31/07/2017

Page 17

Operating Instructions

Pump ZPU 08 ATEX

2.22. Safety recommendations to be complied with

2.23. General behaviour when handling the pump

The pump may be used only in awareness of the potential dangers, in

proper technical condition, and according to the information in these

instructions.

Familiarize yourself with the functions and operation of the product. The

specified assembly and operating steps and their sequences must be

observed.

Any unclear points regarding proper condition or correct assembly/

operation must be clarified. Operation is prohibited until issues have been

clarified.

Keep unauthorized persons away from the machine.

Precautionary operational measures and instructions for the respective

work must be observed.

Responsibilities for different activities must be clearly defined and

observed. Uncertainty seriously endangers safety.

Safety-related protective and emergency devices must not be removed,

modified or affected otherwise in their function and are to be checked at

regular intervals for completeness and function.

Remedy occurring faults in the frame of responsibilities. Immediately

inform your superior in the case of faults beyond your competence.

Do not open the reservoir lid during operation. Do not reach into the

reservoir.

Wear personal protective equipment always.

When handling lubricants, adhere to the respective safety data sheets.

Never use parts of the centralized lubrication system or of the machine as

standing or climbing aids.

810-53711-1 Page 17 / 57

Rev.: 003

31/07/2017

Page 18

Operating Instructions

Pump ZPU 08 ATEX

2.24. Explosion protection

Always behave so that fire and explosion hazards are avoided.

A written work approval from the operator is required prior to working in

potentially explosive areas.

There must be no indications that parts of the explosion protection are

missing or are not working. Should such indications become apparent,

switch off the machine and inform a superior without delay. Keep

unauthorized persons away.

Measures for explosion protection must never be deactivated, modified or

bypassed.

It is forbidden to bring in ignition sources such as sparks, open flames and

hot surfaces in potentially explosive areas.

Check the machine at regular intervals for damage which may represent

an ignition risk.

The ignition temperature of the lubricant must lie at least 50 K over the

maximum admissible surface temperature of the components.

Only use tools and clothing which are permitted for use in potentially

explosive areas (ESD).

Transport, installation, repairs and work on electrical components may only

be carried out, if it has been ensured that the atmosphere is not potentially

explosive.

Repairs or modifications to machines which are protected against

explosions may be carried out only by the manufacturer or by a workshop

recognized by a named institution and confirmed in writing. If the work is

not carried out by the manufacturer, the repairs must be approved by a

named expert and confirmed in writing. The repairs are to be marked by a

repair sign on the machine, stating the following:

o Date

o Company responsible for the work

o Type of repair

o If applicable, expert's code

Transport damages can result in the loss of the explosion protection. If

transport damages can be seen, do not assemble the machine or put it into

operation

810-53711-1 Page 18 / 57

Rev.: 003

31/07/2017

Page 19

Operating Instructions

Pump ZPU 08 ATEX

All parts of the grounding concept must be correctly available and

connected with the superordinate machine.

If transport lugs are dismantled after set-up, the threaded bores must be

permanently sealed in accordance with the protection class.

Handle the materials so that no sparks generated by tilting, falling, sliding,

rubbing, impacting, etc. If needed, cover materials with suitable means.

Never disconnect plug-in connections when energized. Secure plug-in

connections against inadvertent manual disconnection with the safety clips

included in the delivery.

The operator must check thoroughly whether an operation without low-

level signal leads to a new hazard potential (e.g. through heat-up of

bearing points on the machine in the area of ignition temperature). If this

cannot be ascertained, provide a low-level signal or suitable organisational

measures for monitoring of the bearing point temperature.

Avoid dust accumulation and remove dust immediately. Dust

accumulations have a thermally insulating effect and, if whirled up,

generate the formation of a potentially explosive atmosphere.

The pump should be integrated into the operator's lightning protection

concept.

All parts are to be checked regularly for corrosion. Replace the affected

parts.

Terminal boxes must be firmly closed and the cable breakthroughs

correctly sealed.

Additional electrical monitoring devices must be firmly connected and

correctly adjusted.

Protect the motor with a motor circuit breaker against inadmissible heating

up.

When reaching their nominal life, the motor bearings have to be replaced

or inspected to ensure their suitability for further utilisation.

810-53711-1 Page 19 / 57

Rev.: 003

31/07/2017

Page 20

Operating Instructions

Pump ZPU 08 ATEX

2.25. Transport / installation / maintenance / repairs / servicing

All relevant persons (e.g., operating personnel, supervisors) must be

informed of the respective activity prior to starting any work. Observe the

precautionary operational measures and work instructions.

If protective and safety equipment has to be dismantled, it must be

reassembled immediately after finishing the work, and then checked for

correct function.

Ensure through suitable measures that movable or detached parts are

immobilized during the work and that no limbs can be caught in between

by inadvertent movements.

Carry out transport using only suitable hoisting equipment.

All the parts to be mounted onto the shaft end of the motor have to be

dynamically balanced according to the balancing system of the motor. With

a direct coupling, ensure that the parts align precisely (observe the

manufacturer's guidelines).

Assemble the product only outside of the operating range of moving parts,

at an adequate distance from sources of heat or cold.

Dry wet, slippery surfaces.

Cover hot or cold surfaces accordingly.

Prior to performing work, de-energize and depressurize the pump and

secure it against unauthorized switch-on. Work on electrical components

must be carried out by electrical specialists only. Observe any waiting

periods for discharging, if necessary.

Carry out electrical connections only according to the information in the

valid wiring diagram and taking the relevant regulations and the local

connection conditions into account.

Do not touch cables or electrical components with wet or damp hands.

Maintenance and repair work can be subject to restrictions in low or high

temperatures (e.g. changed flow properties of the lubricant). Therefore,

where possible, try to carry out maintenance and repair work at room

temperature.

810-53711-1 Page 20 / 57

Rev.: 003

31/07/2017

Page 21

Operating Instructions

Pump ZPU 08 ATEX

Carry out all works on electrical components using voltage insulated tools

only.

Fuses must not be bypassed. Always replace fuses by such of the same

type.

Ensure correct grounding of the electrical system.

Undertake drilling at non-critical, non-load bearing parts only. Use any

available boreholes. Do not damage lines and cables when drilling.

Observe possible abrasion points. Protect the parts accordingly.

Other units of the machine or vehicle must not be damaged or impaired in

their function by the installation of the centralized lubrication system.

All components used must be designed for:

o maximum operating pressure

o maximum/ minimum ambient temperature

o lubricant to be supplied

o required ATEX zone

o operating/ ambient conditions at the location of use

Parts of the centralized lubrication system must never be subjected to

torsion, shearing or bending.

Check all parts prior to use for contamination and clean, if necessary.

Lubricant lines should be primed with lubricant prior to installation. This

makes the subsequent ventilation of the system easier.

Observe the specified tightening torques. When tightening, use a

calibrated torque wrench.

When working with heavy parts use suitable lifting tools.

Avoid mixing up or wrong assembly of dismantled parts. Mark these parts

accordingly.

810-53711-1 Page 21 / 57

Rev.: 003

31/07/2017

Page 22

Operating Instructions

Pump ZPU 08 ATEX

2.26. Initial commissioning / daily start-up

Ensure that:

All safety devices are completely available and functional.

All connections are correctly connected.

All parts are correctly installed.

All warning labels on the machine are completely available, highly visible

and undamaged.

Illegible or missing warning labels are to be replaced without delay.

The machine is correctly earthed.

2.27. Cleaning

Risk of fire and explosion when using inflammable cleaning agents. Only

use non-flammable cleaning agents suitable for the purpose.

Do not use any aggressive cleaning agents.

Do not use sharp-edged or spark-generating tools for cleaning (e.g. cooling

fins of the motor).

Do not use steam jet or high pressure cleaners. Electrical components may

be damaged. Observe the IP protection class.

Cleaning work on energized components may be carried out by electrical

specialists only.

Do not touch cables or electrical components with wet or damp hands.

Mark damp areas accordingly.

Remove dust accumulations regularly. Do not whirl up dust whilst doing so.

2.28. Operator obligations

2.29. Determination of hazards

The operator must determine all hazards resulting from the integration of the pump

into the superordinate machine and the hazards at the location of operation of the

machine, and carry out the measures necessary to ensure safety and health

protection.

810-53711-1 Page 22 / 57

Rev.: 003

31/07/2017

Page 23

Operating Instructions

Pump ZPU 08 ATEX

2.30. Explosion protection - measures following ATEX

Due to a holistic assessment of the workplace, the operator ensures that the

working equipment and all installation materials are suitable for operation in

potentially explosive areas, and that they are assembled, installed and operated so

that they do not give rise to explosions.

If changes, extension and/or redesigns are undertaken in potentially explosive

areas, the operator must carry out the required measures so that these changes,

extensions or redesigns fulfil the minimum regulations for explosion protection.

The operator

documents the measures for explosion protection.

marks the potentially explosive areas.

prepares written operating instructions.

selects suitable employees.

Provides these employees with sufficient and appropriate instructions

with reference to explosion protection.

applies an approval system for hazardous activities and for those which

may become hazardous in interaction with other work.

carries out the necessary inspections and monitoring.

ensures that only original spare parts are used.

2.31. Provision of necessary information

The operator must make the instructions required for the respective activity

accessible to all people commissioned with operation, maintenance and repairs.

He must ensure that these people have read the necessary instructions and have

understood them.

The same applies for all relevant safety data sheets, company instructions,

accident prevention regulations, instructions from suppliers of purchase parts and

utilities.

Depending on the business organization, the relevant instructions may have to be

made accessible to other people and departments.

810-53711-1 Page 23 / 57

Rev.: 003

31/07/2017

Page 24

Operating Instructions

Pump ZPU 08 ATEX

2.32. Instruction / qualification obligations

The operator clearly determines the responsibility of personnel for operation,

installation and repairs. The operator is obliged to instruct all people authorized for

use in the correct handling of the machine prior to initial use, in accordance with

the respective activity and area of responsibility, based on practical exercises.

The instructions must contain at least:

zone divisions

scope and limits of the activity and area of responsibility of the respective

group of people.

safe behaviour and behaviour in case of emergency.

avoidance of hazards when dealing with the machine.

meaning of warning guidelines and warning labels

dealing with lubricants and cleaning agents.

use and inspection of personal protective equipment, where appropriate.

These instructions are to be documented and repeated at regular intervals. New

personnel may operate the machine under supervision and instruction by

experienced personnel only. Maintenance and repair work may be carried out by

qualified personnel only.

2.33. Briefing of external technicians

Prior to commencing the activities, external technicians must be informed by the

operator of the company safety provisions, the applicable accident prevention

regulations to be maintained, and the functions of the superordinate machine and

its protective devices.

2.34. Inspection for correct use

The operator must check at regular intervals through suitable measures that the

machine is being used according to its intended purpose, that no conversions or

manipulations have been made to the machine and that all parts are fully

functional.

2.35. Provision of personal protective equipment

The operator must provide suitable personal protective equipment for the

respective location of operation and the purpose of operation. This includes ESD

clothing and ESD tools for work in potentially explosive atmospheres.

810-53711-1 Page 24 / 57

Rev.: 003

31/07/2017

Page 25

Do not burden / this side up!

Protect against moisture

Handle with care!

Fragile, do not throw!

Operating Instructions

Pump ZPU 08 ATEX

2.36. Training courses

In order to provide a maximum of safety and economic viability, SKF carries out

detailed training courses. It is recommended that the training courses are attended.

Please contact SKF Customer Service for information.

2.37. Inspection of the delivery

The delivery must be inspected for completeness based on the delivery papers.

Transport damages must be reported to the forwarder immediately. Keep the

packaging material until any discrepancies are resolved.

2.38. Returns

Clean all parts and pack them properly before returning them. Mark returns on the

packaging as follows.

2.39. Disposal

At the end of its service life, the pump must be dismantled correctly and disposed

of according to the respective valid provisions.

It is forbidden to use parts of a pump that is to be disposed of or to assemble these

parts to make a new pump.

Electrical components:

Dispose of or recycle electrical components following WEEE directive 2012/19/EU.

Plastic or metal parts

can be disposed of with commercial waste.

810-53711-1 Page 25 / 57

Rev.: 003

31/07/2017

Page 26

Operating Instructions

Pump ZPU 08 ATEX

3. Lubricant

Lubricants are used specifically for certain application purposes. In order to fulfil

their tasks, lubricants must fulfil various requirements to varying extents. The most

important requirements for lubricants are:

Reduction of abrasion and wear

Corrosion protection

Noise minimisation

protection against contamination or penetration of foreign objects

Cooling (primarily with oils)

longevity (physical/ chemical stability)

Compatibility with as large a number of materials as possible

economic and ecological aspects.

3.1. Selection of lubricants

A suitable lubricant is selected already when designing the machine and forms the

basis for the planning of a centralized lubrication system.

The selection is made by the manufacturer/ operator of the machine, preferably

together with the lubricant supplier based on the requirement profile defined by the

specific application.

Should you have little or no experience with the selection of lubricants for

centralized lubrication systems, please contact SKF. You will avoid possible costly

downtimes through damage to your machine/ system or damage to the centralized

lubrication system.

3.2. Ageing of lubricants

After a prolonged downtime, the lubricant must be inspected prior to

recommissioning as to whether it is still suitable for use due to chemical or physical

ageing. We recommend that you undertake this inspection already after a machine

downtime of 1 week. If doubts arise as to the suitability of the lubricant, please

replace it prior to re-commissioning and, if necessary, undertake initial lubrication

manually.

810-53711-1 Page 26 / 57

Rev.: 003

31/07/2017

Page 27

NOTICE

Risk of damage to the machine or system

Do not mix lubricants. This may have unforeseeable effects on the usability and

therefore on the function of the centralized lubrication system.

Due to the multitude of possible additives, it is possible that individual lubricants,

which - according to the manufacturer's data sheets - fulfil the necessary

specification, are not in fact suitable for use in centralized lubrication systems (e.g.

incompatibility between synthetic lubricants and materials). In order to avoid this,

always use lubricants tested by SKF.

Please contact the SKF Service Department for an overview of lubricants tested

by SKF.

DANGER

Risk of explosion

The ignition temperature of the lubricant must lie at least 50 K over

the maximum admissible surface temperature of the components.

Operating Instructions

Pump ZPU 08 ATEX

3.3. Specification

Lubricants of the following consistencies can in principle be conveyed using SKF

centralized lubrication systems.

Lubricating greases up to NLGI 2

solids content up to 5 % maximum

mineral oils with a viscosity of minimum 40 mm²/s at +40 °C

Lubricants must be compatible with the following materials:

steel / grey iron / brass / copper / aluminium

NBR / FPM / ABS / PA / PU

810-53711-1 Page 27 / 57

Rev.: 003

31/07/2017

Page 28

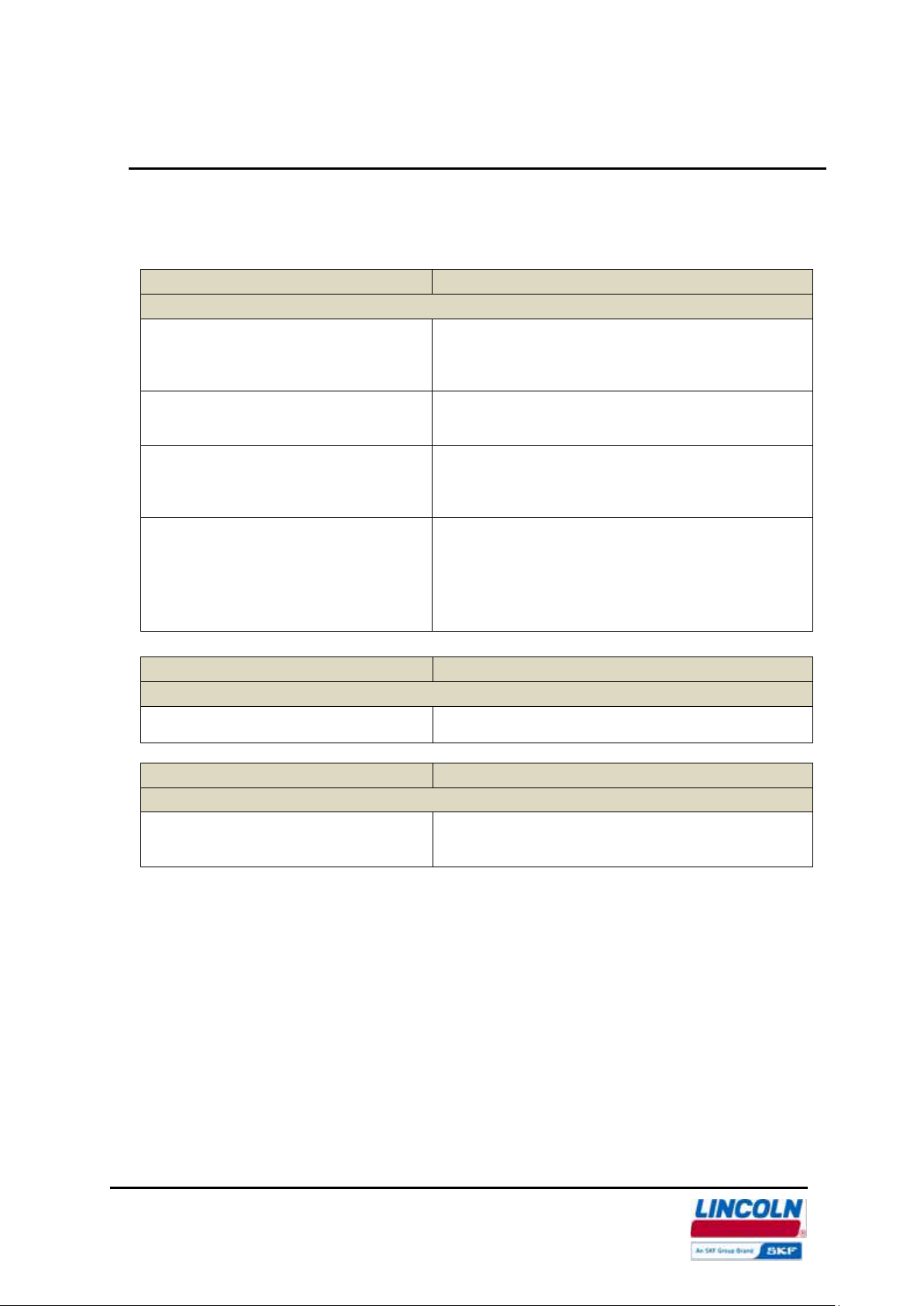

min.

max.

Part no.: 605-40759-6

-20 °C

+50 °C

Part no.: 605-40759-7

-20 °C

+40 °C

Part no.: 605-41759-8

-20 °C

+40 °C

Part no.: 605-40759-6

II 2G c IIB T3 Gb

Part no.: 605-40759-7

II 2G c IIC T4 Gb

II 2D c IIIC T120 °C Db

Part no.: 605-41759-8

II 2G c IIC T4 Gb

II 2D c IIIC T120 °C Db

Operating pressure is limited to max. 410 bar ± 10 % by a pressure control

valve.

All system parts must be designed for the maximum operating pressure.

Operating Instructions

Pump ZPU 08 ATEX

4. Technical data

4.1. Ambient temperatures

4.2. Explosion protection marking

4.3. Operating pressure

4.4. Installation position

Vertical, i.e. reservoir at top. Maximum deviation ± 5°

4.5. Sound pressure level

< 70 dB (A)

4.6. Maximum set-up height

1000 m above sea level.

4.7. Maximum dust thickness

< 5 mm

4.8. Weight

The weight of the empty pump is approx. 62 kg.

4.9. Gear ratio

i = 20:1

810-53711-1 Page 28 / 57

Rev.: 003

31/07/2017

Page 29

40 XB

40 XL

Used with pump

605-41759-8

605-40759-6

Used with pump

605-46554-7

Operating Instructions

Pump ZPU 08 ATEX

4.10. Reservoir

810-53711-1 Page 29 / 57

Rev.: 003

31/07/2017

Page 30

Width

A

Depth

B

Height

C*

approx. 530 mm

approx. 580 mm

approx. 820 mm

It is recommended that an additional free space of 100 mm is provided in each

direction for maintenance and inspections works.

The distance between the motor air intake and any obstacle must total to at least

40 mm. Ensure that the air can flow into the motor without hindrance. Outflowing

air must not be sucked in again directly.

* When planning consider an additional free space of 350 mm above the reservoir

to remove the reservoir lid.

C*

A

B

Operating Instructions

Pump ZPU 08 ATEX

4.11. Space requirements

810-53711-1 Page 30 / 57

Rev.: 003

31/07/2017

Page 31

Nominal voltage

Distance to motors

Ex category 2

For motors up to 500 V

5 mm

gear

Motor

Capacitive sensor

Terminal box

IP 65

IP 55

IP 67

IP 65

Operating Instructions

Pump ZPU 08 ATEX

4.12. Electrical connection

Connection must be done in such way that a permanent, safe electrical connection

can be maintained (use safe protective conductor connection and dedicated cable

ends; avoid protruding wire ends). Make sure that there are no foreign particles,

dirt or humidity in the terminal box. Close the terminal box dust- and watertight.

In addition to the general valid installation prescriptions for electrical systems, the

electrical connection is carried out in accordance with the applicable national ATEX

regulations, for example:

ElexV

DIN EN 60079-14:2014, VDE 0165-1:2014

Electrical systems in explosive areas

DIN EN 60079-17:2014

Electrical equipment for use in areas with combustible dust

DIN VDE 0100

Tolerance voltage ± 5 %

Tolerance frequency ± 2 %

The waveform and mains symmetry must be maintained so that the motor heat-up

remains within the permitted limits.

The distance to any voltage-carrying or conductive parts has to correspond to the

minimum values following DIN EN 60079-7:2007 / VDE 0170-6:2007.

4.13. IP Types of protection

810-53711-1 Page 31 / 57

Rev.: 003

31/07/2017

Page 32

Component

Tightening torques

T1

Pressure control valve

AF 24

80 ± 8 Nm

T2

Lubricant filter:

Protective fitting

AF 19

80 ± 8 Nm

Filter element

AF 11

20 ± 2 Nm

T3

Check valve

Protective fitting

AF 19

80 ± 8 Nm

Check valve (flat-bladed screwdriver)

20 ± 2 Nm

T4

Pressure gauge

AF 22

45 ± 4.5 Nm

T6

Grounding connection lid / reservoir

AF 6

8 ± 1 Nm

T7

Pump to foundation

18 ± 2 Nm

If no tightening torques are stated, the tightening torques are to be applied to the

screw size for 8.8 screws.

T1

T2

T4

T3

T5

T6

Operating Instructions

Pump ZPU 08 ATEX

4.14. Tightening torques

810-53711-1 Page 32 / 57

Rev.: 003

31/07/2017

The rotational direction is always clockwise (CW). Observe the

arrow on the reservoir. The rotational direction of the motor is as

needed.

Page 33

Minimum speed

Maximum speed

10 rpm

85 rpm

Operating Instructions

Pump ZPU 08 ATEX

4.15. Connections / outlets

Pressure line G ¾“

Relief line G ¾“

Filling adapter G ¾“

4.16. Filling possibilities

via filling adapter

via reservoir lid

4.17. Rotational direction of the pump

4.18. Admissible speed of the eccentric shaft

When supplying the pump without motor and gear, speeds must be maintained by

selecting a suitable motor and gear.

4.19. Output

approx. 11.2 dm3/h

This information applies for grease of NLGI class 2 at +20 °C and 100 bar

counterpressure. Deviating conditions such as different NLGI class, temperature or

counterpressure may lead to a deviation in the flow rate. This should be taken into

account when designing the lubrication points.

4.20. Lubricant filter

Filter area: 5.1 cm2

Grade of filtration: 280 μm

810-53711-1 Page 33 / 57

Rev.: 003

31/07/2017

Page 34

The following information is stated on the type identification plate:

Product and manufacturer identification

Model:

Type designation of the pump

MADE IN

GERMANY

Country of origin

Part no.:

Order number / Part number

Manufacturer

CE / EX marking

Electrical information

≤ Ta ≤

Min. / max. ambient temperature

Voltage

Voltage

V AC

Series:

Year of construction/ Order no./ batch

4 figures/ 6 figures/ 3 figures

Frequency

Hz

Observe associated instructions

Control

voltage

Control

Voltage

V DC

WW/YY

Calendar week/ year of construction

Power

Output

watt

Operating Instructions

Pump ZPU 08 ATEX

4.21. Type identification plate

810-53711-1 Page 34 / 57

Rev.: 003

31/07/2017

Page 35

NOTICE

Risk of damage to the machine or system

Prior to initial use or after the storage time ends, prefilled components must

be inspected and replaced, if necessary, in case the lubricant quality has

changed, or filled with lubricant suitable for the application purpose.

Operating Instructions

Pump ZPU 08 ATEX

4.22. Storage until the first use

in the original packaging

in dry rooms with little dust

without direct sun or UV radiation

without aggressive, corrosive substances at the place of storage

without vibrations

protected against pests (insects, rodents, etc.)

Temperature range: - 20 °C minimum

+ 40 °C maximum

Air humidity (relative): 90 % maximum

Storage time: 24 months max.

Special storage conditions of the motor

Do not store the motor on the fan cover.

After a longer period of storage, make sure to check the insulation

resistance.

In case of storage > 1 year:

Make sure to observe the grease service life of the ball bearings which is reduced

by 10 % per year.

810-53711-1 Page 35 / 57

Rev.: 003

31/07/2017

Page 36

Type designation

Capacitive sensor (Namur)

Part number

664-34621-3

Rated operating distance

Sn

5 mm in case of flush installation

7.5 mm in case of non-flush

installation

Secured switching distance

≤ (0.72 x Sn) mm

Hysteresis

1….. 20 %

Temperature drift

≤ ± 20 %

Repeatability

≤ 2 %

Ambient temperature

-25 °C - +70 °C

Voltage

nominal 8.2 VDC

Connection diagram

Current consumption, not

activated

≤ 1.2 mA

Current consumption,

activated

≥ 2.1 mA

Switching frequency

0.1 kHz

Output function

2-wire NAMUR

Internal capacity (Ci)

150 nF

Inductivity (Li)

150 µH

Design

Threaded tube M 18 x 1

Dimensions

74 mm

Housing material

Plastic PA12-GF30

Material of active surface

Plastic PA12-GF30, yellow

Admissible pressure onto

front closing cap

≤ 6 bar

Max. tightening torque

Housing nut

2 Nm

Connection

Cable

Cable quality

Ø 5.2 LiYY, PVC, 10 m

Cable cross section

2 x 0.34 mm2

Vibration resistance

55 Hz (1mm)

Shock resistance

30 g (11ms)

Type of protection

IP 67

MTTF

448 years following SN 29500

40 °C

Switching status display

LED, yellow

Fine adjustment

Potentiometer

Approvals

KEMA 02 ATEX 1090X

Marking

II 2G EX ia IIC T6 Gb

II 1D EX ia IIIC T 115 °C Da

max. Ui = 20 V, Ii = 20mA, Pi = 200 mW

Operating Instructions

Pump ZPU 08 ATEX

5. Technical data of the capacitive sensor

810-53711-1 Page 36 / 57

Rev.: 003

31/07/2017

Page 37

Part no.

Type of motor

ATEX no.

Manufacturer

245-13984-6

EDRS80S4

PTB 10 ATEX 3026/01

SEW

Rated power

0.55

kW

Code

---------

Operating mode

S 1 Flange

Ø 120

Rated frequency

60

Hz

IP

55

Rated speed

1715

rpm

Design

B14

Rated voltage

254 / 440

V DC

Size

80

Circuit

D /

Y

Shaft

19x40

Nominal current

2.15

1.24

A

Performance factor

0.81

cos φ

Insulation class

F

Part no.

Type of motor

ATEX no.

Manufacturer

245-13984-7

EDRS80S4

PTB 10 ATEX 3026/01

SEW

Rated power

0.55

kW

Code

---------

Operating mode

S 1 Flange

Ø 120

Rated frequency

50

Hz

IP

55

Rated speed

1415

rpm

Design

B14

Rated voltage

219 – 241 / 380- 440

V DC

Size

80

Circuit

D

Y

Shaft

19x40

Nominal current

2.35

1.36

A

Performance factor

0.81

cos φ

Insulation class

F

Operating Instructions

Pump ZPU 08 ATEX

6. Technical data of the motor

810-53711-1 Page 37 / 57

Rev.: 003

31/07/2017

Page 38

The ZPU 08 pump consists of the

following main components:

(1) Reservoir with stirring paddle,

capacitive sensors for fillinglevel monitoring and

grounding

(2) Pressure gauge

(3) Motor

(4) Gear

(5) Pressure control valve

(6) Pump housing

(7) Lubricant filter

(8) Check valve

Connections:

(A) Pressure line

(B) Relief line

(C) Filling line

DANGER

Risk of explosion

Carry out work on electrical parts only if the atmosphere is not potentially explosive.

Electric shock

Disconnect the pump from the mains prior to all work on electrical parts.

2

7

1

3

4

5

6

A

B

C

8

Operating Instructions

Pump ZPU 08 ATEX

7. Brief description of the pump

810-53711-1 Page 38 / 57

Rev.: 003

31/07/2017

Page 39

Operating principle:

The gear reduces the motor speed to

the necessary speed of the pump.

The eccentric shaft drives the highpressure pump elements and the

stirring paddle. The stirring paddle

homogenizes and vents the lubricant.

The high-pressure pump element

works as a piston pump with two

counter-actively acting pistons that

alternately take in lubricant and

dispense it via the outlet bore to the

pressure line. The outlet channels of

the high-pressure pistons are

controlled by a floating valve piston.

The pump element is driven via a

hollow shaft with eccentric pin and

switch roll, whereby the rotational

movement is transformed into an

oscillating linear movement of the

pump pistons.

This type of drive allows to select or

change the rotational direction of the

pump shaft as needed.

The lubricant supplied by the pump

element is dispensed to the

pressure-line connection via a check

valve and a lubricant filter.

One respectively two sensors

determine the reservoir filling level

(low-level respectively high- and lowlevel indication).

Upper end position

Start of the piston movement

downwards

Downward working stroke

Supply piston 1 displaces the

floating piston upwards together

with the lubricant in front of it.

Lubricant is supplied into the

pressure line via the open outlet

bore. Supply piston 2 generates

a negative pressure that sucks

in lubricant after opening bore II.

Lower end position

Start of the piston movement

upwards

Upward working stroke

By means of the lubricant of the

previous suction stroke, supply

piston 2 displaces the floating

piston downwards.

Lubricant is supplied into the

pressure line.

Supply piston 1 sucks in

lubricant.

Pump ZPU 08 ATEX

810-53711-1 Page 39 / 57

Rev.: 003

31/07/2017

Operating Instructions

Page 40

NOTICE

Risk of centralized lubrication system faults

When filling ensure that no dirt enters the reservoir.

Filling via filling adapter

Automatic Filling:

The filler pump is started by the low-level

indication and stopped by the high-level

indication.

Manual filling:

Filling procedure must be supervised by a

second person.

Switch the filling pump on.

Fill the reservoir

Switch off the filler pump.

Filling port (C)

Filling via the reservoir lid

Switch the pump off.

Open the reservoir lid (1.1).

Ensure that no dirt enters the reservoir

or the inner side of the reservoir lid. In

case of reservoirs equipped with a

sensor, the sensor must not be

damaged or contaminated.

Fill in lubricant up to a maximum of

1 cm below the reservoir rim.

Reposition and close the reservoir lid

(1.1). Make sure not to crush the

grounding cable.

Switch the pump on.

C

1.1

Operating Instructions

Pump ZPU 08 ATEX

8. Installation and commissioning

8.1. Filling of the reservoir

810-53711-1 Page 40 / 57

Rev.: 003

31/07/2017

Page 41

NOTICE

Risk of damage to the machine

Fill the feed lines with lubricant and fill the lubrication points manually. Otherwise

the bearing points may become damaged due to a lack of lubricant.

Check the entire system for accordance with the intended purpose and the

planning documentation.

Ensure that all parameters, characteristic values and means of operation have

been correctly adjusted or are present.

If deviations are detected, they must be remedied without delay.

Operating Instructions

Pump ZPU 08 ATEX

8.2. Inadvertent filling with incorrect lubricant

Should incorrect lubricant have been filled, please proceed as follows:

Switch off the pump and secure it against being switched on.

Remove lubricant.

Clean the reservoir, pump housing and, if applicable, the tubing system.

Fill in lubricant of correct specification.

Switch the pump on.

Inform your superior to ensure that the error won't occur again.

8.3. Inspections prior to initial start-up

In order to warrant safety and function, a person assigned by the operator must

inspect certain areas of the central lubrication system prior to initial commissioning.

Report any detected deficiencies immediately to your superior and remedy them.

Deficiencies may be remedied by an authorized and qualified specialist only.

Check the following points prior to initial commissioning.

810-53711-1 Page 41 / 57

Rev.: 003

31/07/2017

Page 42

Operating Instructions

Pump ZPU 08 ATEX

Electrics

Electrical connections carried out correctly.

Cable entries sealed correctly.

The voltage and frequency of the power network correspond to the

information on the type identification plate of the motor.

Monitoring devices and additional equipment (e.g. motor circuit breaker)

are correctly connected and adjusted.

Grounding is complete.

All parts such as lines, cables, metering devices, etc. have been correctly

installed and are undamaged.

Mechanics:

No dust accumulations present, in particular on the air intake of the motor.

Loose or missing parts remaining (e.g. pressure relief valves, feed lines).

Damages, deformations, or cracks.

Smoke or smouldering spots.

Discolorations, contaminations and/or corrosion.

Unusual humidity.

Unusual odours, vibrations, or sounds.

Leakages of lubricant at connections and from lines.

8.4. Activation of the pump

The pump is activated on:

Installation into a machine

o By switching on the machine contact.

o By a control provided by the customer.

810-53711-1 Page 42 / 57

Rev.: 003

31/07/2017

Page 43

DANGER

Danger to life

Risk of fire and explosion when using inflammable cleaning

agents. Do not use steam jet or high pressure cleaners.

Electrical components may be damaged.

Do not touch cables or electrical components with wet or damp

hands. Cleaning work on energized components may be carried

out by electrical specialists only.

Wear personal protective equipment always.

Operating Instructions

Pump ZPU 08 ATEX

9. Standard operation

9.1. Daily start-up

Below find the activities to be carried out in case of standard operation.

9.2. Inspections

With regard to the actions listed below "Inspections prior to commissioning" the

operator has to determine adequate control intervals depending on the respective

operating situation of the pump.

9.3. Filling of the reservoir during operation

Fill the reservoir as described in the chapter "Installation and commissioning".

9.4. Cleaning

Exterior cleaning

Thorough cleaning of all surfaces with a damp cloth.

Mark and secure wet areas.

Interior cleaning

Normally, interior cleaning is not required.

810-53711-1 Page 43 / 57

Rev.: 003

31/07/2017

Page 44

DANGER

Risk of explosion

When carrying out maintenance, repair or modification works on

explosion-protected machines, observe the legal and operational

prescriptions. If the works are not carried out by the

manufacturer, authorized and qualified personnel only is allowed

to carry out such works. Works then have to be reviewed by a

qualified and officially recognised person.

Carry out work on electrical parts only, if the atmosphere is not

potentially explosive.

Electric shock

Make sure to disconnect the pump from the power supply before

carrying out works on electrical parts.

Operating Instructions

Pump ZPU 08 ATEX

10. Maintenance

Regular and appropriate maintenance is a prerequisite to detect and clear faults in

time. As individual operating conditions cannot be defined for all applications, the

listed terms represent a general advice for undisturbed operation. The terms have

to be adapted to the local conditions always.

10.1. Maintenance of pump

Any maintenance works may be carried out only while the pump is idle and when

there is no potentially explosive atmosphere.

The pump is mainly maintenance-free.

However, the following parts should be inspected and, if necessary, replaced by

new parts at regular intervals:

Pressure relief valves

Check valves

Lubricant filter

Tolerance frequency of the pressure control valve ± 10 %

If this tolerance is exceeded, the pressure control valve must be replaced.

810-53711-1 Page 44 / 57

Rev.: 003

31/07/2017

Page 45

For further relevant information on maintenance, see original Instructions by the

gear manufacturer.

Activity

Interval

Visual check for:

Leakages

Damages to the surface protection/

corrosion protection

Every 3,000 hours, but at least

once a year

Depending on the type of

application and ambient conditions

Switch the pump off.

Unscrew protective fitting (9.1) from

lubricant filter

(AF 19).

Unscrew lubricant fitting (9)

(SW 11).

Clean lubricant filter with non-

flammable cleaning agents.

Blow lubricant filter with compressed

air from inside two outside - as shown

in the accompanying figure - to avoid

contaminations in the strainer.

Reinstall lubricant filter and protective

fitting.

Tightening torques

Lubricant filter 20 ± 2 Nm

Protective fitting 80 ± 8 Nm

9.1

9

Operating Instructions

Pump ZPU 08 ATEX

10.2. Maintenance of lubricant filter

The lubricant filter should be checked and, if necessary, be cleaned every 100

operating hours. To do so proceed as follows:

10.3. Maintenance of gear unit

810-53711-1 Page 45 / 57

Rev.: 003

31/07/2017

Page 46

For further relevant information on maintenance, see original Instructions by the

motor manufacturer.

Activity

Interval

Check the airways and

surfaces

Depending on the local degree of contamination, at

the latest, however, every 4 weeks

Initial inspection

After about 500 operating hours, at the latest,

however, after 1/2 a year.

Ball bearing/ radial sealing

ring

Check and, if necessary, replace every 10,000

operating hours

Re-lubrication / oil change

Re-lubrication interval, grease volume and grease

quality see type identification respectively

lubrication plate of the motor

Main inspection

After about 10,000 operating hours, at the latest,

however, after 1 year.

DANGER

Electric shock

Do not touch the terminals when measuring the

insulation resistance. If necessary, wear insulating

gloves. Observe the manual of the insulation

measurement device.

NOTICE

Risk of damage to the motor

The voltage applied for the insulation test must not exceed 500

V.

Operating Instructions

Pump ZPU 08 ATEX

10.4. SEW motor maintenance

10.5. Measurement of the insulation resistance

Before the first start-up and after longer downtimes measure the insulation

resistance following the standards (e. g. VDE 0100 / DIN EN 61557-1:2007) valid in

the country of use.

If the insulation resistance falls below the required minimum value, determine and

eliminate the cause (e.g. appropriate drying of the coil, etc.).

10.6. Maintenance of gear unit

Capacitive sensor:

The capacitive sensor is maintenance-free. Repairs are not possible.

810-53711-1 Page 46 / 57

Rev.: 003

31/07/2017

Page 47

Motor of pump does not run

Possible cause

Visible

Remedy

Fault in the superior machine/

external control unit.

Motor circuit breaker has tripped.

no pump noise

Check power supply lines/

external control/ motor circuit

breaker.

Motor runs, but pump does not supply lubricant

Possible cause

Visible

Remedy

Reservoir empty

by visual check

Refill

Air pockets in the lubricant

Air bubbles in the lubricant

Vent

Contaminated filter

Short deflections on the

pressure gauge (fluttering)

Check and clean filter and

replace, if necessary.

Suction bore of pump element is

clogged.

After disassembling the

pump element

Disassemble and clean the pump

element.

Defective or dirty check valve

After disassembling the

pump element

Replace check valve.

Eccentric shaft or driving parts of

the swivelling lever and the

stirring device defective.

Visual check

Replace the affected parts.

Faults on the change-over device

See instructions of

change-over device.

See instructions of change-over

device.

Blockade in the downstream

lubrication system

Lubricant leaking from the

pressure relief valve

Determine cause and eliminate it.

If the fault cannot be determined/ remedied, contact our Customer Service.

Operating Instructions

Pump ZPU 08 ATEX

11. Troubleshooting

810-53711-1 Page 47 / 57

Rev.: 003

31/07/2017

Page 48

Rehfuss gear

Fault