Page 1

RETURN TO MAIN MENU

OPERATING MANUAL

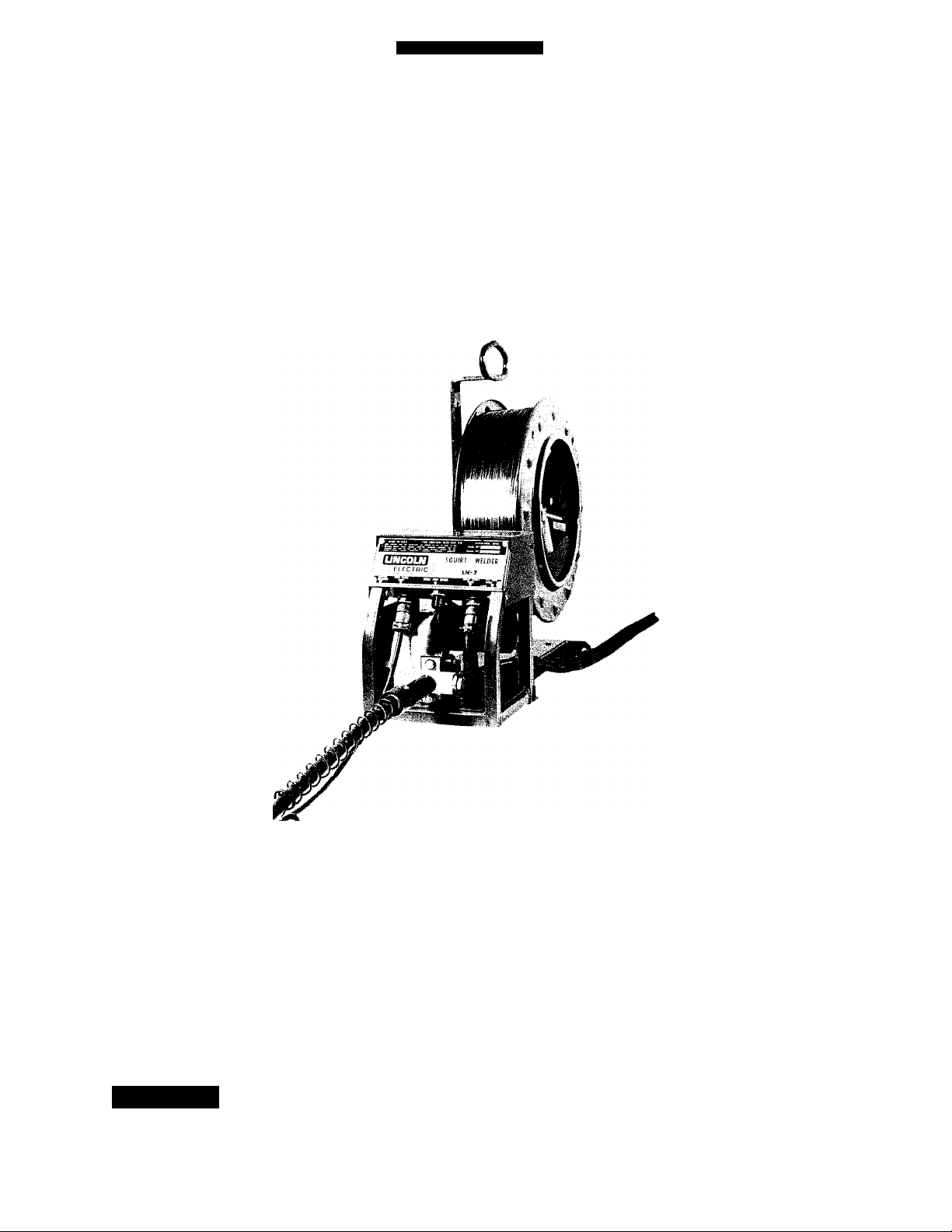

LN-7

SEMIAUTOMATIC WIRE FEEDER

IM-267

January, 1986

Shipping Damage Claims

When this equipment is shipped, title passes to the pur

chaser upon receipt by the carrier. Consequently, claims for

material damaged in shipment must be made by the pur

chaser against the transportation company at the time the

shipment is received.

............

LiWCOLiy

THE LINCOLN ELECTRIC COMPANY

World s Largest Manufacturer of Arc Welding Products • Manufacturer of industrial Motors

Sales and Service Worldwide

This manual covers

equipment which is

obsoiete and no ionger

in production by The

Lincoin Eiectric Co.

Specifications and

avaiiabiiity of optionai

features may have

changed.

Safety Depends On You

Lincoln arc welding equipment is designed and built with

safety in mind. However, your overall safety can be in

creased by proper installation .. . and thoughtful operation

on your part. DO NOT INSTALL, OPERATE OR REPAIR

THIS EQUIPMENT WITHOUT READING THIS OPERAT

ING MANUAL AND THE ARC WELDING SAFETY PRE

CAUTIONS ON THE INSIDE FRONT COVER. And, most

importantly, think before you act and be careful.

Cleveland, Ohio 44117-1199 U.S.A

Page 2

"7>

Arc Welding Safety Precautions

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. READ

AND UNDERSTAND BOTH THE SPECIFIC INFORMATION GIVEN IN THE OPERATING

MANUAL FOR THE WELDER AND/OR OTHER EQUIPMENT TO BE USED AS WELL AS

THE FOLLOWING GENERAL INFORMATION.

1. HAVE ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR WORK performed

only by qualified people.

2. ELECTRIC SHOCK can kill.

Protect yourself from possible dangerous electrical

shock:

a. The electrode and work (or ground) circuits are elec

trically “hot” when the welder is on. Never permit

contact between “hot” parts of the circuits and bare

skin or wet clothing. Wear dry, hole-free gloves to

insulate hands.

b. Always insulate yourself from the work and ground

by using dry insulation. When welding in damp lo

cations, on metal floors, gratings or scaffolds, and

when in positions such as sitting or lying, make cer

tain the insulation is large enough to cover your full

area of physical contact with work and ground.

c. Always be sure the work cable makes a good electri

cal connection with the metal being welded. The

connection should be as close as possible to the area

being welded.

d. Ground the work or metal to he welded to a good

electrical ground.

e. Maintain the electrode holder, work clamp, welding

cable and welding machine in good, safe operating

condition.

f. Never dip the electrode in water for cooling.

g. Never simultaneously touch electrically “hot” parts

of electrode holders connected to two welders be

cause voltage between the two can be the total of

the open circuit voltage of both welders.

h. If using the welder as a power source for mechanized

welding, the above precautions also apply for the

automatic electrode, electrode reel, welding head,

nozzle or semiautomatic welding gun.

i. When working above floor level, protect yourself

from a fall should you get a shock.

Also see Items 6c and 8.

J-

3. FUMES AND GASES can be dangerous to your health.

a. Welding may produce fumes and gases hazardous

to health. Avoid breathing these fumes and gases.

When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to

keep fumes and gases away from the breathing zone.

When welding on galvanized, lead or cadmium

plated steel and other metals which produce toxic

fumes, even greater care must be taken.

b. Do not weld in locations near chlorinated hydrocar

bon vapors coming from degreasing, cleaning or

spraying operations. The heat and rays of the arc

can react with solvent vapors to form phosgene, a

highly toxic gas, and other irritating products.

c. Shielding gases used for arc welding can displace

air and cause injury or death. Always use enough

ventilation, especially in confined areas, to insure

breathing air is safe.

d. Read and understand the manufacturer’s instructions

for this equipment and the consumables to be used,

including the material safety data sheet (MSDS) and

follow your employer’s safety practices.

e. Also see item 9b.

4. ARC RAYS can injure eyes and bum skin.

a. Use a shield with the proper filter and cover plates

to protect your eyes from sparks and the rays of

the arc when welding or observing open arc welding.

Headshield and filter lens should conform to ANSI

Z87.1 standards.

b. Use suitable clothing made from durable, flame-

resistant material to protect your skin and that of

your helpers from the arc rays.

c. Protect other nearby personnel with suitable non

flammable screening and/or warn them not to watch

the arc nor expose themselves to the arc rays or

to hot spatter or metal.

5. FIRE OR EXPLOSION can cause death or property

damage.

a. Remove fire hazards well away from the area. If

this is not possible cover them to prevent the welding

sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily

go through small cracks and openings to adjacent

areas. Have a fire extinguisher readily available.

b. Where compressed gases are to be used at the job

site, special precautions should be used to prevent

hazardous situations. Refer to “Safety in Welding

and Cutting” (ANSI Standard Z49.1) and the operat

ing information for the equipment being used.

c. When not welding, make certain no part of the elec

trode circuit is touching the work or ground. Acci

dental contact can cause overheating and create a

fire hazard.

December 1985

-2-

Page 3

d. Do not heat, cut or weld tanks, drums or containers

until the proper steps have been taken to insure that

such procedures will not cause flammable or toxic

vapors from substances inside. They can cause an

explosion even though they have been “cleaned.”

For information purchase “Recommended Safe Prac

tices for the Preparation for Welding and Cutting

of Containers and Piping That Have Held Hazardous

Substances.”, AWS F4.1-80 from the American

Welding Society (see address below).

e. Vent hollow castings or containers before heating,

cutting or welding. They may explode.

f. Also see items 6c and 9c.

6. For Welding in General.

a. Droplets of molten slag and metal are thrown or

fall from the welding arc. Protect yourself with oil

free protective garments such as leather gloves,

heavy shirt, cuffless trousers, high shoes and a cap

over your hair. Wear ear plugs when welding out

of position or in confined places. Always wear safety

glasses when in a welding area. Use glasses with

side shields when near slag chipping operations.

b. Keep all equipment safety guards, covers and de

vices in position and in good repair. Keep hands,

hair, clothing and tools away from V-belts, gears,

fans and all other moving parts when starting,

operating or repairing equipment.

c. Be sure the work cable is connected to the work

as close to the welding area as practical. Work cables

connected to the building framework or other loca

tions some distance from the welding area increase

the possibility of the welding current passing through

lifting chains, crane cables or other alternate circuits.

This can create fire hazards or overheat lifting chains

or cables until they fail.

7. For Gas-Shielded Arc Welding.

a. Use only compressed gas cylinders containing the

correct shielding gas for the process used and prop

erly operating regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suit

able for the application and maintained in good con

dition.

b. Always keeps cylinders in an upright position sec

urely chained to an undercarriage or fixed support.

c. Cylinders should be located:

• Away from areas where they may be struck or

subjected to physical damage.

• A safe distance from arc welding or cutting oper

ations and any other source of heat, sparks, or flame.

d. Never allow the electrode, electrode holder, or any

other electrically “hot” parts to touch a cylinder.

e. Keep your head and face away from the cylinder

valve outlet when opening the cylinder valve.

f. Valve protection caps should always be in place and

handtight except when the cylinder is in use or con

nected for use.

g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publica

tion P-1 “Precautions for Safe Handling of Compres

sed Gases in Cylinders” available from the Compres

sed Gas Association, 1235 Jefferson Davis High

way, Arlington, VA 22202.

8. For Electrically Powered Equipment.

a. Turn off input power using the disconnect switch

at the fuse box before working on the equipment.

b. Make the electrical installation in accordance with

the National Electrical Code, all local codes and the

manufacturer’s recommendations.

c. Properly ground the equipment in accordance with

the National Electrical Code and the manufacturer’s

recommendations.

9. For Engine Powered Equipment.

a. Turn the engine off before troubleshooting and

maintenance work unless the maintenance work re

quires it to be running.

b. Operate the internal combustion engines in open,

well-ventilated areas or vent the engine exhaust

fumes outdoors.

c. Do not add the fuel near an open flame, welding

arc or when the engine is running. Stop the engine

and, if possible, allow it to cool when refueling to

prevent spilled fuel from vaporizing on contact with

hot engine parts and igniting. Do not spill fuel when

filling tank. If fuel is spilled, wipe it up and do

not start engine until fumes have been eliminated.

d. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when

the maintenance requiring their removal is complete.

Always use the greatest care when working near

moving parts.

e. Do not put your hands near the engine fan. Do not

attempt to override the governor or idler by pushing

on |he throttle control rods while the engine is run

ning.

f. To prevent accidentally starting gasoline engines

while turning the engine or welding generator during

maintenance work, disconnect the spark plug wires,

distributor cap or magneto wire as appropriate.

g. To avoid scalding, do not remove the radiator pres

sure cap when the engine is hot.

For more detailed information it is strongly recommended

that you purchase a copy of “Safety in Welding & Cutting

— ANSI Standard Z49.1” from the American Welding So

ciety, P.O. Box 351040 Miami, Rorida 33135.

December 1985

Page 4

Need Welding Training?

The Lincoln Electric Company operates the oldest and most respected Arc Welding

School in the United States at its corporate headquarters in Cleveland, Ohio. Over

60,000 students have graduated. Tuition is low and the training is “hands on”.

For details write: Lincoln Welding School

22801 St. Clair

Cleveland, Ohio 44117

and ask for bulletin ED-80 or call 216-481-8100 and ask for the Welding School

Registrar.

-4-

Page 5

The Lincoln Electric Company

Cleveland, Ohio 44117

SEC J1 INDEX

Sec. J2 INSTALLATION INSTRUCTIONS

Wire Feed Unit and Wire Reel....................................................................................................................................................... Sec. J2.2.1

Wire Feed Rolls and Guide Tubes..................................................................................................................................................Sec. J2.2.2

Gun & Gun Cable Assemblies . .....................................................................................................................................................Sec. J2.2.3

Input Cable: LN-7 to Power Source...............................................................................................................................................Sec. J2.3.1

Connection Diagrams; LN-7 to Lincoln Power Sources .............................................................................................................Sec. J2.3.2

Connection Diagrams: LN-7 to Other Power Sources.................................................................................................................Sec. J2.3.3

Optional Feature Installation

K-178 Mounting Platform ........................................................................................................................................................Sec. J2.5.3

Auxiliary Equipment Contacts .................................................................................................................................................Sec. J2.5.5

K-162 SpintUe for Mounting 10 thru 30 Pound Spools .........................................................................................................Sec. J2.5.7

K-163 Undercarriage ................................................................................................................................................................ Sec. J2.5.8

Sec. J3 OPERATING INSTRUCTIONS

I } Adjusting Current and Voltage.................................................................................................................................................................. Sec. J3.1.1

Arc Starting......................................................................................................................................................................................Sec. J3.1.2

Circuit Protection............................................................................................................................................................................Sec. J3.1.4

Wire Reel Loading - 50 and 60 Pound Coils ................................................................................................................................Sec. J3.1.5

Wire Reel Loading - 10 to 30 Pound Spools .................................................................................................................................Sec. J3.1.6

Sequence of Welding ...................................................................................................................................................................... Sec. J3.1.7

Wire Reel Changing........................................................................................................................................................................ Sec. J3.1.9

For Iimershield® operating techniques and procedures request

‘Timershield Production Welding Guide”, bulletin N675

Index

k

.

,„.y

Sec. J6 MAINTENANCE

Wire Drive Motor and Gear Box ..................................................................................................................................................Sec. J6.1.1

Drive Rolls and Guide Tubes .........................................................................................................................................................Sec. J6.1.2

Wire Reel Mounting........................................................................................................................................................................Sec. J6.1.3

Control Box..................................................................................................................................................................................... Sec. J6.1.5

Gun Cable ............................................................................................................... »..................................................................Sec. J6.2.1

Gun Disassembly — K-115 and K-126..........................................................................................................................................Sec. J6.2.2

Electrical Sequence of Operation...................................................................................................................................................Sec. J6.4

Troubleshooting ..............................................................................................................................................................................Sec. J6.6

Parts Lists.........................................................................................................................................................................................Sec. J7

Wiring Diagrams ....................................................................................................................................Filed at the back of this manual.

January 1976

-5-

Page 6

-6-

Page 7

f ^

The Lincoln Electric Company

Cleveland, Ohio 44117

SEC.J2.2 MECHANICAL INSTALLATION

Sec. J2.2.1

Wire Feed Unit and Wire Reel

The LN-7 is shipped ready to install in the work

location.

September 1971

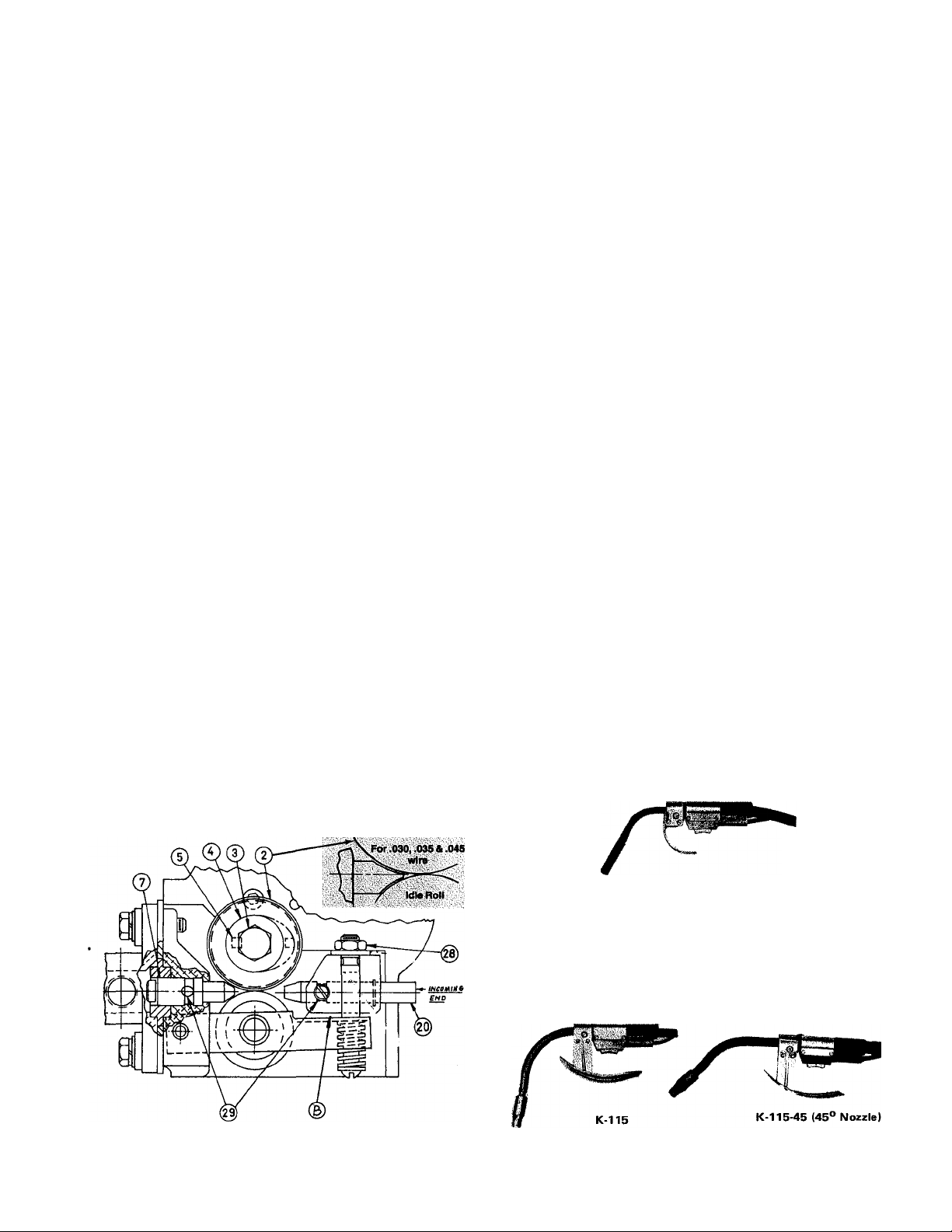

Sec. J2.2.2

Wire Feed Rolls and Guide Tubes

NOTE: The maximum sizes the LN-7 will satisfactorily

feed are 7/64” Innershield® and 3/32” solid electrodes.

The drive roll, idle roll and guide tubes for the electrode

size specified on the order is shipped with the wire feed

unit. The electrode sizes that can be fed with each roll and

guide tube are stenciled on each part. Instructions to install

these parts on new machines or replace them on used

machines, are as follows;

A. Loosen the idle roll tension nut (item 28) approximately

3 full turns or use a screwdriver to pry the idle roll arm

down at point B .

B. Remove hex head screw (item 3) & the drive roll clamp

ing collar (item 4). (On new machines remove the tape &

drive roll key from the collar.) Insert the key (item 5)

into the keyway of the output shaft.

C. Wipe the drive roll & spacer surfaces clean. Install one

drive roll (item 2), then the spacer & the second drive

roll. (For .030, .035 & .045 electrode, the drive roll

is one piece. For '/i6 electrode there is no spacer).

D. Install drive roll clkmping collar & hex head screw pre

viously removed. Tighten hex head screw securely.

E. Back out the two guide tube clamping set screws (item

29).

F. Insert the outgoing guide (item 7) (the one with the plas

tic insert) into the front hole. The guide tube for .030",

.035" and .045" wire has a non-symetrical chisel end.

Be certain the contour with the larger radius and the

exposed oval opening for the wire faces the grooved

Assembly and Installation

drive roll. Push the guide tube back as far as it will

go and tighten the clamping set crew. Insert the incom

ing guide tube (item 20) into the rear hole as far as

it will go and tighten the clamping set screw. These

set screws are dog point. When the two tubes are instal

led properly these dog points will lock into the annular

groves that are in each of the guide tubes,

G. Tighten the idle roll tension nut (item 28) or remove the

screwdriver used as a wedge in step A. The tension nut

should normally be tightened until it bottoms for wire

sizes 1/16” and larger. For smaller wire sizes and alumi

num wire the tension nut should be loosened if the wire

tends to buckle in the guide tube, cable or between the

drive rolls and outgoing guide tube.

H. To change drive rolls and guide tubes for a different size,

reverse the above procedure.

September 1976

Sec. J2.2.3

Gun & Gun Cable Assemblies

General

The LN-7 is used with various guns. In all cases the gun

and cable are shipped assembled ready to weld. Use the gun

and cable assembly for the electrode type (solid or Innershield) and electrode size to be used.

Note; The guns described below were available at the

time this sheet was printed. They may not be today. See

Lincoln Specification literature for up-to-date information.

Innershield® Guns

Squirtgun K-126 is recommended for most welding with

.062 through 3/32" electrodes. Install the insulated nozzle

extension (or thread protector) and the nozzle contact tip

for the stickout and electrode size being used.

K-126

For heavy duty welding with 3/32” electrode use K-1153/32 or K-115-45-3/32. Install a 3/32” contact tip and the

insulated nozzle extension for the stickout being used.

For welding with 7/64” electrode, use K-115-3/32 with

a M-11474-.120 nozzle or a K-11545-3/32 with a

M-11510-.120 nozzle. Also install a 7/64” contact tip and

the insulated nozzle extension for the stickout being used.

-7-

Page 8

Assembly and Installation

Sec. J2.2.3 Continued

Gun Cable: LN-7 to Gun

Lay the cable out straight. Insert the connector on the

welding conductor cable into the brass block on the front

of the LN-7. Make sure it is all the way in and tighten the

locking screw with a 3/16” Allen Wrench. Keep this con

nection clean and bright. Insert the control cable polarized

plug into the receptacle below the nameplate.

Linconditioner'i’M Guns ^

For locations where smoke accumulation is a problem

and conventional exhaust systems are ineffective, the

available smoke removal type Innershield guns and vacuum

units can be used. Instructions are shipped with the

equipment.

April 1974

The Lincoln Electric Company

Cleveland, Ohio 44117

-8-

Page 9

The Lincoln Electric Company

Cleveland, Ohio 44117

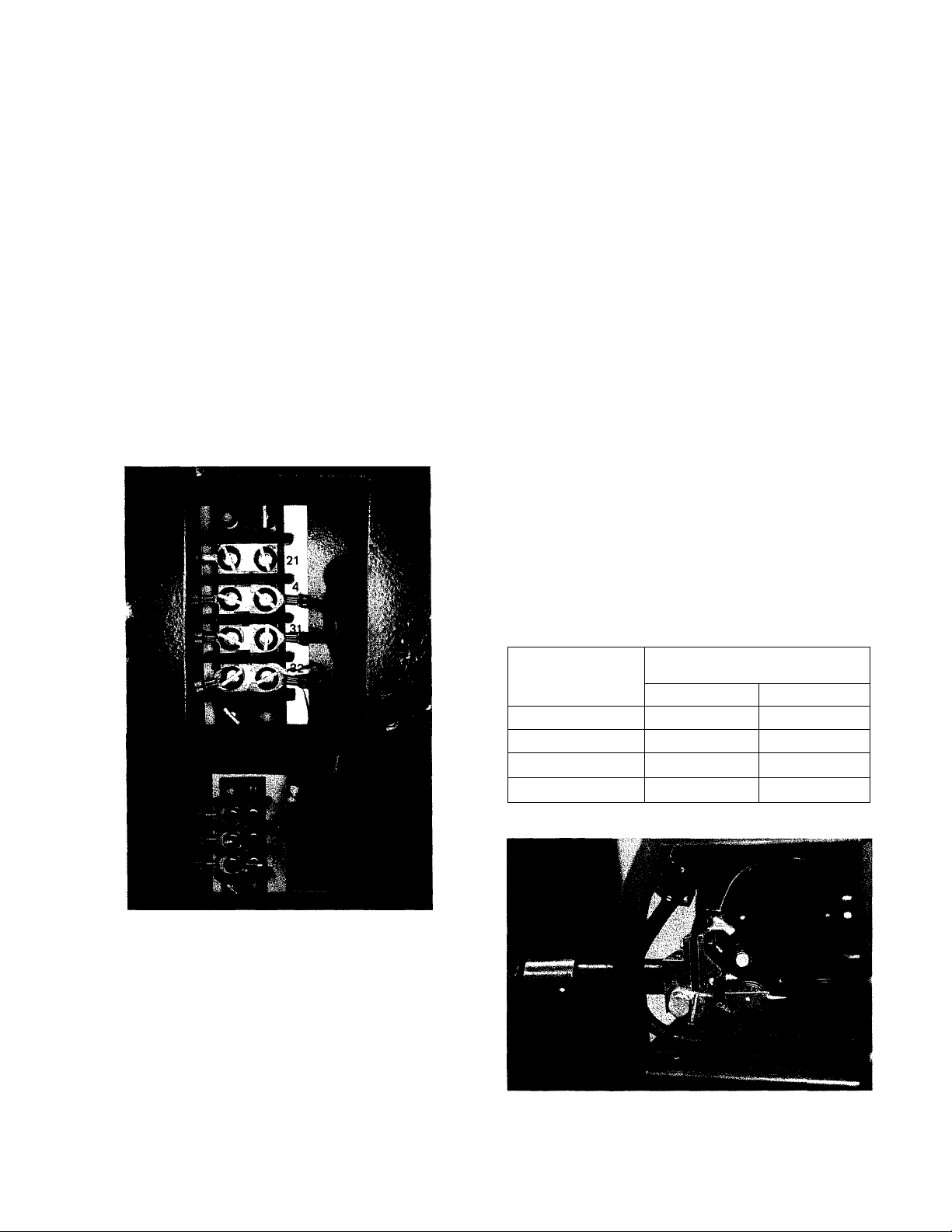

SEC. J2.3 ELEaRICAL INSTALLATION

Sec. J2.3.1

Input Cable: LN-7 to Power Source

The input cable between the wire feeder and the power

source consists of a four-conductor control cable and an

electrode cable. The control cable has lugged leads on the

power source end and a polarized plug on the wire feeder

end. With the power source turned off, install the input

cable per the following instructions: i

I. Connect the end of the control cable with the lugged

‘.-leads to a constant voltage type power source. For

Lincoln power sources follow exactly thé instructions

(including all jumpers on the power source terminai

strips) for the specific power source per the wiring

diagrams in Sec. J2.3.2.

Assembly and Installation

lead length should not exceed 400’. When using the

longer lengths of extension cables, it may be necessary

to add parallel electrode cables to limit the voltage drop

in the cable.

4. Loosen the screws holding the clamp to the rear vertical

support of the wire feeder frame. Put only the electrode

cable under the clamp.

5. Coimect the end of the electrode cable to the end of the

brass block on the wire feeder using the bolt provided.

Be sure the cable is placed to allow easy access to the

drive roll and guide tube screws. (See photo below.)

Tighten the screws on the electrode cable clamp.

6. Run the control cable under the wire feed motor and

insert the plug into the mating receptacle below the

LN-7 nameplate.

2. For constant voltage power sources not included in Sec.

J2.3.2, request a copy of Sec. J2.3.3 for connection

instructions.

7. Connect a ground lead of sufficient size and length (per

the following table) between the To Work’ stud on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal contact.

Current

Amps

60% Duty Cycle

300 0

400 00

500 00 000

600 000 0000

Copper Ground Cable Length

Up to 50' 50' - 100'

00

000

3. If input cables longer than the standard length (available

as 7, 25, 50, 75 and 100’ lengths) must be used, 50’

K-177 extension cables can be installed. These have

polarized plugs on each end of the control cable and a

4/0 electrode cable. Install the extensions between the

standard input cable and the wire feeder. Total input

September 1976

-9-

Page 10

Sec. J2.3.2

Connection Diagrams:

LN-7 to Lincoln Power Sources

The Lincoln Electric Company

Cleveland, Ohio 44117

To an Idealarc R3S-250

pow£g 5oue.ce

SHQSA/S ¿LtC,TfZQoe C0NN£CT€0 PoS/r/^e.TO

v^o^jc. ce/ias at thc Pov^ee. so</€ce.

POLAA/ry^ /e£'^€jese 7HC e.C€CT&00€ ^NO

To a SAN Welder

FW£R SOURCL 5- 14176

5- 14671

6- 25-71

6- 25-71

To an Idealarc R3S-400, 600 or 800 Welder

ABOV£ ^OWS £LECTffQD£ CXitJNECrLD P05l7li^£.

TO (M/9NGC fitPLAmry, R€V£»S£ TN£ £UCr/fOP£ AND WORJ< l£ADS

/ir ^SOaffC£.

To a SAM Motor-Generator or Engine Welder

5- 14179

6- 27-75

S-14177

9-24-76B

To Power Sources Without Output Contactor

Requiring A K-240 Contactor Kit

» i€ttOS mio. rnm OA‘S€A*^'r«4. r

Msv. MMi. fOAn^mccr

Aoe ste AA/ar<. Mr

/AfMAr <WE?

(MOK ■

NA. n» V.AC. wax l|

oi~AUTBWATiC*

R.R. CtAOS »2L*75.*T(*.*‘>7. i OWD. OONOTAPPeAH LM-7 COMTROU CA&Lt

N.C. WttMWe CARLC^ MOST sc Of PKOFIA 4*mCITt fftH THC CUKtW A»B BdTV CVCU Of 1W>M>M>KTt AW PUTUW

APPUCATHWR

¡J R6. TUKMtO OFF WHCM PQWH »OUKC« ta TUfcitCO OFF. COMtACTftg Kff AHOt«*\-WTOWATIC

BlPTMEMT WHX9Tn.L AAVC W3 V. CaWTIOL rftWKE SUmiEP UHTH. POWtl TO TetwiUAL^

<•& 1\m>€0 OFF.

To a SAF-600, SA-800 or SAF-600-B ("-OA") Welder

5- 15416

6- 18-76

cAeie

'•JO seMf-AuroMMue

Se<WBM4J/C SMUAfl

10-

Page 11

The Lincoln Electric Company

Cleveland, Ohio 44117

ELECTRICAL INSTALLATION - CONT’D

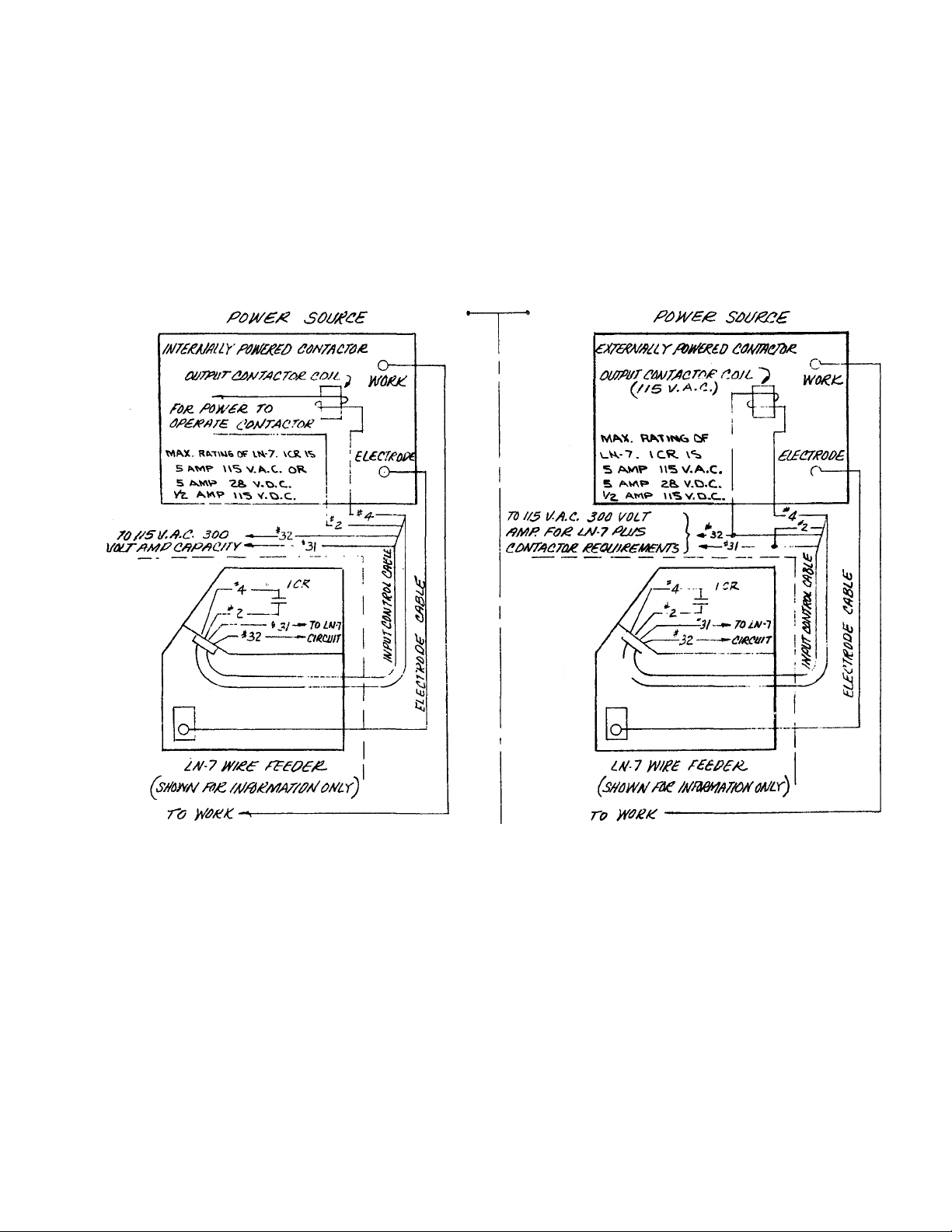

Sec. J2.3.3

Connection of LISI-7 to Other (Not included in Sec. J2.3.2) Power Sources

POW£RSO(/£C£S

TO yT/je/^/'G of POJVFF SOUFCe to

BE useo TO m/o t/te tyae of coArrooroF. o/foo/T

Assembly and Installation

-11

January 1976

Page 12

Assembly and Installation

SEC. J2.5 OPTIONAL FEATURES INSTALLATION

Sec. J2.5.3

K-178 Mounting Platform — LN-7 on Idealarc R3S

This is a turntable type platform for mounting the LN-7

on the top of Idealarc R3S power sources. Bolt the plat

form to the lift bail per instructions supplied with the

platform.

The Lincoln Electric Company

Cleveland, Ohio 44117

Route the leads thru the hole in the bottom of the con

trol box to the terminal strip. Spare quick connect ter

minals are provided on the terminal strip. Remove these

terminals and crimp them to the lead wires. Connect the

leads to numbers 32A and 7 on the terminal strip. Install a

suitable cable clamp on the leads to prevent excess tension

on the terminals and protect the lead insulation at the edge

of the hole.

March 1973

Sec. J2.5.7

K-162 Spindle For Mounting 10 thru 30 Pound

Spools

To mount the spindle kit for 10 thru 30 pound spools,

remove the shaft for the standard 50-60 pound wire coils

from the mounting framework. Install the spindle per the

instructions shipped with the kit.

Adjust the brake tension screw (see Sec. J3.1.6) on the

spindle as needed.

September 1971

September 1971

Sec. J2.5.5

Auxiliary Equipment Contacts

The Power for 115 volt AC auxiliary equipment can be

obtained from the terminal strip inside the control box.

The contacts are “hot” only when the gun trigger is oper

ated. The current draw of this circuit must not exceed 1/4

ampere.

Sec. J2.5.8

K-163 Undercarriage

The undercarriage includes the wheels, handle and hard

ware. Mount the casters at the front and the wheels to the

rear of the platform. Be sure the round, rear axle is to the

rear of the mounting bolts that hold the U-shaped axle

member to the frame. Bolt the handle to the front of the

platform so the LN-7 can be tilted back and wheeled like a

two-wheel truck. Holes for installing the wire reel support

are provided in the platform.

September 1971

12-

Page 13

The Lincoln Electric Company

Cleveland, Ohio 44117

Operating Instructions

SEC J3 OPERATING INSTRUCTIONS

Sec. J3.1.1

Adjusting Current and the Voltage

Use only constant voltage type power sources. If using a

multiple process power source, be sure it is set for constant

voltage output per instructions in the manual for the power

source.

Set the voltage using the controls on the power source.

For the most accurate arc volt^e readings, connect the

meter leads between the work and the brass gun cable con

nection block of the LN-7 and read the voltmeter while

welding. Approximate welding voltages can be obtained by

reading the power source voltmeter while welding.

On constant wire feed speed type wire feeders like the

LN-7, welding current is controlled by the wire feed speed.

With the ‘Wire Feed Speed’ control set on Min. the wire

feeds at a little under 50” per minute and the welding

current is low. When set on Max., the electrode feeds at

more than 500” per minute and the welding current is high.

If the power source is equipped with meters, the welding

current can be read directly on the anuneter while welding.

If the power source has no meters and the relationship

between current and wire feed speed is known, current can

be accurately set by measuring the wire feed speed. To

measure wire feed speed disconnect the electrode cable at

the power source:

1. Press the gun trigger and feed electrode for 15 seconds.

2. Measure the wire feed in inches and multiply by 4. This

gives the wire feed speed in inches/minute.

3. Adjust the ‘Wire Feed Speed’ control until the desired

speed is obtained.

January 1976

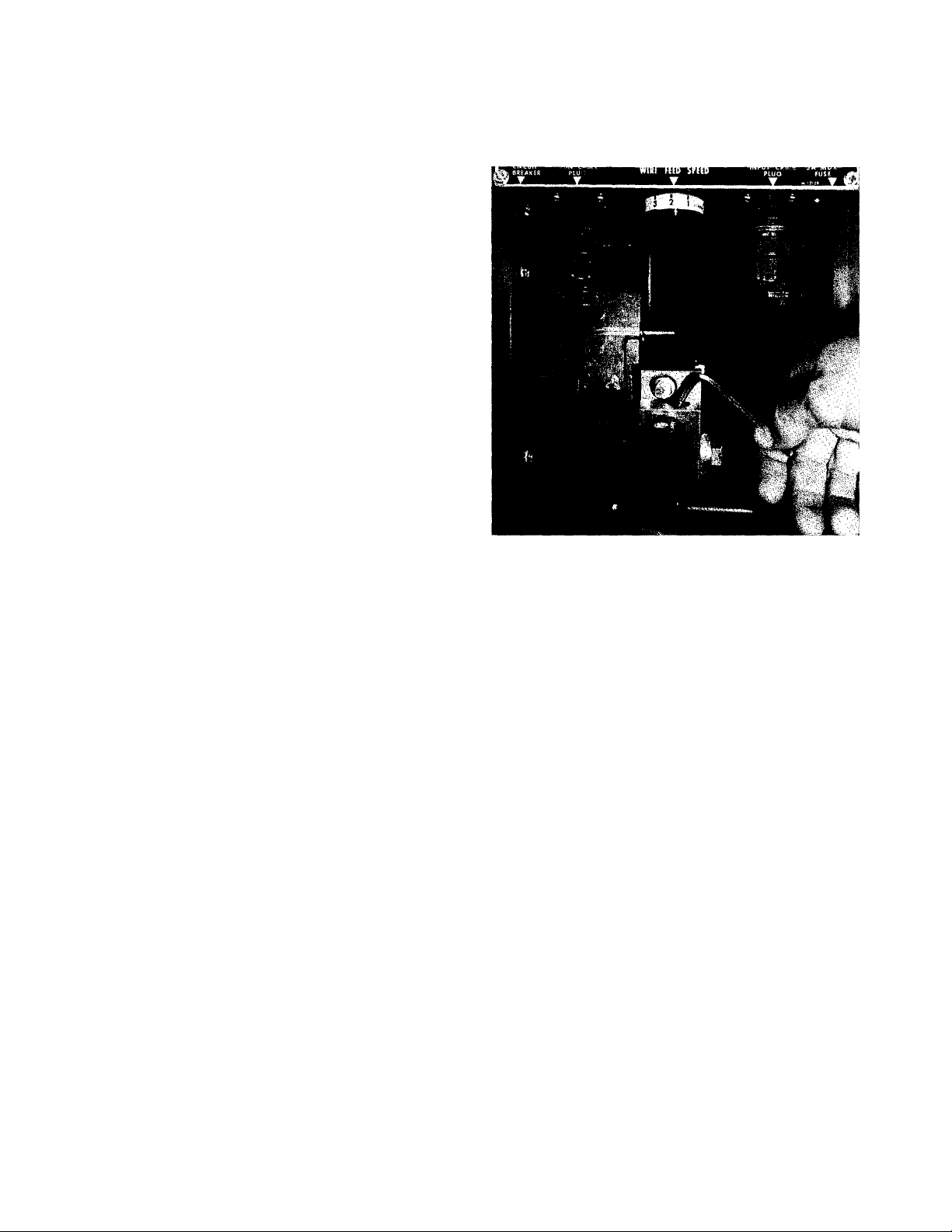

Sec. J3.1.3

Circuit Protection

The AC input line is protected by both a circuit breaker

and a fuse.

The circuit breaker protects the LN-7 from moderate

overloads, usually caused by excessive wire drag or other

wire feeding problems. To reset the circuit breaker, push

the red button on the underside of the control box. If it

opens again, determine the cause of the overload.

The fuse protects the LN-7 from sudden high current

overloads such as a shorted motor or other short circuit

conditions. Determine and correct the cause of overloading.

Replace the fuse with one of the same size and type.

November 1972

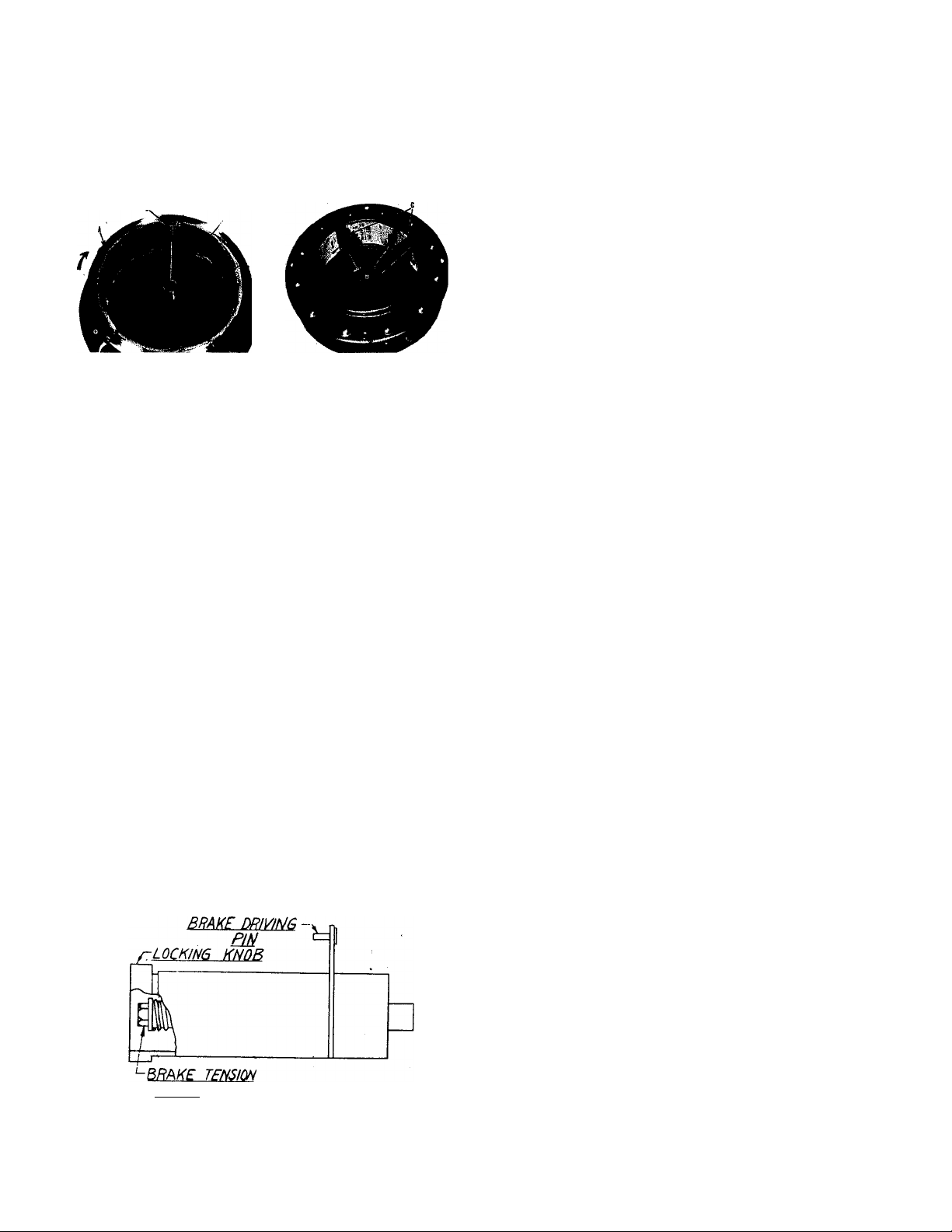

Sec. J3.1.4

Adjustable Wire Reel Brake

The mount for standard 50 and 60 pound electrode coils

includes a two position brake assembly. Generally the

brake should be at the inner position (nearest to the wire

reel shaft) for wire feed speeds below 400”/min. It should

be at the outer position for the faster wire speeds often

used when feeding small diameter electrode.

To adjust the brake position, remove the wire reel. Pull

the cotter pin that holds the brake shoe to the arm, move

the shoe and replace the cotter pin. Do not bend the cotter

pin — it is held in place by a friction fit.

Machines built before November 1972 do not have an

adjustable brake.

See Sec. J3.1.6 for adjustment instmetions for the brake

on the spindle for 10-25 pound spools.

November 1972

Sec. J3.1.2

Arc Starting

The LN-7 starts at a slow wire feed speed and low cur

rent and automatically accelerates quickly to the welding

speed set by the ‘Wire Feed Speed’ control. The electrode

should be lightly touching the work when the gun trigger is

pressed. This low starting current improves the starting

characteristics and minimizes skipping, stubbing, and spat

ter when striking the arc with both normal and Line-Fill

long stickout welding procedures. This standard feature

requires no adjustment.

September 1976

Sec. J3.1.5

Wire Reel Loading — 50 and 60 Pound Coils

1. To remove the wire reel from its shaft, grasp the spring

loaded knob and pull it out. This straightens the knob so

it seats into the shaft when released. Remove the reel.

2. Lay the reel flat on the floor, loosen the spinner nut and

remove the cover plate.

3. Before cutting the tie wires place the coil of electrode on

the reel so it unwinds as the reel rotates clockwise.

A. Be sure the coil is placed so the spring loaded arms

will not interfere with the later removal of the coil tie

wires. (See photo.)

B. When loading .035 and .045” electrode, be certain

the coil is placed on the reel so the spring loaded arms

-13-

Page 14

Operating Instructions

The Lincoln Electric Company

Cleveland, Ohio 44117

are at the center of the slots in the carboard coil liner.

This provides the positive compression of the coil

needed for trouble free wire feeding. (See photo).

C. Put the cover plate on the reel so the four arms of the

cover straddle and are in line with the spring loaded

arm of the reel proper.

4. Tighten the cover as much as possible by hand. DO NOT

hammer on the spinner nut arms.

5. Cut and remove only the tie wire holding the free end of

the coil. Insert the free end into one of the holes in the

cover and secure it by bending it back. Cut and remove

the remaining tie wires.

NOTE; Always be sure the free end of the coil is

securely held while the tie wires are being cut and until

the wire is feeding through the drive rolls. Failure to do

this will result in “back lashing” of the coil, which may

tangle the wire. A tangled coil will not feed so it must

either be untangled or discarded.

6. Replace the reel on the wire feeder. Grasp the shaft

knob, pull it out and swing it across the reel hub.

7. Turn the reel until the free end of the electrode is acces

sible. While tightly holding the electrode, cut off the

bent end. Straighten the first six inches and insert it

through the wire guide to the drive roEs. Press the gun

trigger untE the rolls pick up the wire and feed it

through the gun cable.

WARNING: When inching, the electrode is always “hot” to

ground.

September 1971

Sec. J3.1.6

Wire Reel Loading — 10 to 30 Pound Spools

Remove the locking knob from the shaft. Place the 25

lb. spool on the shaft making certain the brake driving

pin enters one of the holes in the back side of the spool.

Replace and tighten the locking knob. Be certain the wire

comes off the reel in a clockwise direction. The spool

should turn freely without any overrun. Adjust the brake

tension with the hex head screw on the shaft hub, until

the reel turns freely but with little or no overrun.

Sec. J3.1.7

Sequence of Welding

See page 2 for general arc welding safety precautions.

1. Install the LN-7 per Sec. J2.

2. Load the wire reel per Sec. J3.1.5 or J3.1.6.

3. Ground the work.

4. Set the power source polarity switch or properly con

nect the electrode and ground lead for the correct elec

trode polarity.

5. Set the voltage using the power source controls per Sec.

J3.1.1.

6. Set the current per Sec. J3.1.1.

7. Press the gun trigger to inch the wire untE it sticks about

3/4” beyond the end of the gun. Position the gun so the

electrode is l^tly touching the work. Avoid pushing the

electrode against the work before starting to weld. Press

the gun trigger to start welding. Current can be adjusted

whEe welding using the ‘Wire Feed Speed’ control on the

LN-7.

8. To stop welding, release the gun trigger and lift the gun

from the work. The wire feed motor stops and the weld

ing circuit is de-energized the moment the trigger is

released. If an auxEiary device is connected to #7 and

#32 in the LN-7 control box, (See Sec. J2.5.5), this

device is de-energized when the trigger is released.

Sec. J3.1.9

May 1975

Wire Reel Changing

At the end of a coE remove the last of the old electrode

coil from the conductor cable with the foUowing

procedures:

1. Cut the end of the electrode off at the gun end. Do not

break it off by hand because this puts a slight bend in

the wire making it difficult to pull it back through the

nozzle.

2. Uncouple the gun conductor cable from the connection

block on the LN-7 drive unit.

3. Lay the gun and cable out straight.

4. Using pliers to grip the wire, puU it out of the cable from

the connector end. Do not puU it from the gun end.

5. After the electrode has been removed, connect the gun

conductor cable back to the LN-7.

SCRPW

Load a new reel of electrode per the instructions in Sec.

J3.1.5 or J3.1.6.

September 1971

-14-

Page 15

The Lincoln Electric Company

Cleveland, Ohio 44117

WARNING: Have a qualified electrician do the maintenance and trouble shooting work.

Turn the input power off at the power source before working inside the wire feeder.

Maintenance Instructions

SEC. J6.1 WIRE FEEDER MAINTENANCE

Sec. J6.1.1

Wire Drive Motor and Gear Box

Every year inspect the gear box and paint the gear teeth

with graphite grease.

Every six months check the motor bmshes. Replace

them if they are less than 1 /4” long.

September 1971

Sec. J6.I.2

Drive Rolls and Guide Tubes

Periodically inspect the drive roll section. Clean it as

necessary. Do not use solvents for cleaning the idle roll

because it may wash the lubricant out of the bearing. The

drive roll, idle roll and guide tubes are stamped with the

wire sizes they will feed. If a wire size other than that

stamped on the rolls is to be used, the rolls and guide tubes

should be changed.

The drive roll for 1/16, .068, 5/64, 3/32 and 7/64” elec

trode have a double set of teeth so they can be reversed for

additional life. Between the two knurled rolls (except

1/16” rolls) is a shim washer which limits the damage to the

electrode if wire feeding problems occur. See Sec. J2.2.2

for roll changing instructions.

Drive rolls for .045 and .035 electrodes have no teeth.

They are not reversible.

September 1971

Sec. J6.1.3

Wire Reel Mounting — 50 and 60 Pound Coils

To prolong the life of the reel shaft, periodically coat it

with a thin layer of grease.

No maintenance of the two position adjustable brake

installed on machines built after November 1972 is needed

except to replace the shoe assembly if it wears through.

November 1972

Sec. J6.1.5

Control Box

The control box requires no routine maintenance.

September 1971

SEC J6.2 GUN AND CABLE MAINTENANCE

Sec. J6.2.1

Gun Cable

A dirty gun cable can cause rough and erratic wire feed

ing. Therefore, the cable liner must be cleaned periodically.

Remove the cable from the wire feeder. Lay it out

straight on the floor. Remove the contact nozzle tip from

the gun. Using an air hose and only partial pressure, gently

blow out the cable. Work the full length of the cable by

bending it back and forth then blow it out again. Continue

this procedure until cable is clean.

October 1981

Sec. J6.2.2

Gun Disassembly: K-115 and K-126 Innershield

Squirtguns

To remove the nozzle from the gun, loosen the 3/16”

Allen head screw in the gun handle and pull the nozzle

straight out. To reinstall, insert the nozzle into the gun

handle. Push it in as far as possible and tighten the Allen

head screw.

To disassemble Innershield Squirtguns K-115 and K-126,

first loosen the screws which hold the heat shield in place.

Remove the heat shield.

To disassemble the switch housing from all these guns,

remove the four screws holding the saddle around the gun

handle. Then hold the housing with the cable toward the

floor and look into the switch cavity. The tight side of the

larger roll pins is to the right. Drive these pins to the left.

They can be easily removed when they clear the right side

of the casting. Do not remove the smaller roll pins unless

the trigger is being replaced. The height of the Z spring

controls the operating point of the switch with respect to

the trigger movement. Set the spring so the switch operates

at about the mid-point of the trigger travel.

To remove the handle from the cable, slip the spatter

shield out of the front of the handle. Remove the 1/4-20

socket head screw through the hole in the side of the

handle. Then pull the handle back on the cable. Remove

the snap ring and connector clamp and the handle can then

be shpped off the cable.

September 1971

-15-

Page 16

Operation

The Lincoln Electric Company

Cleveland, Ohio 44117

SEC J6.4 LN-7 SEQUENCE OF OPERATION

Start Generator

I

Press Gun Trigger

Closes 524-525

I

Energizes 1 CR

Closes 2-4

pilot relay

and/or I

Energizes welder

Contactor

Electrode now

“hot” to ground

Closes 627-539

I ^

Connects wire feed

motor to

power board

1

Energizes

control board

at low speed and increases

Opens 539-514

2CR and dynamic

brake resistor

Wire feed motor starts

speed to welding speed

I

Arc starts

i

Welding

Release Gun Trigger

I

Opens 524-525

De-energizes 1 CR

I

Disconnects

motor from

Closes 7-31A

Energizes 7-3 2A

auxiliary equipment

I

(for optional

user supplied)

Opens 2-4

De-energizes

welder pilot

relay

and/or I

De-energizes

welder

contactor

Electrode is

cold to work

Closes 539-514

Opens 539-627

... I

Disconnects wire

feed motor from

power board

De-energizes

control board

I

----------------1--------------Wire feed motor stops

^ •

Connects wire

feed motor to

2CR and dynamic

brake resistor

Motor braking current

__________

I

pulls in 2CR

Shorts out relay

1 CR to prevent

it pulling in

while motor

brake current is

flowing

I

Opens 7-31A

De-energizes

auxiliary equipment

I

2 CR drops out

Unit ready for next weld

I

-16-

January 1972

Page 17

The Lincoln Electric Company

Cleveland, Ohio 44117

WARNING: Have a qualified electrician do the maintenance and trouble shooting work.

Turn the input power off using the disconnect switch at the fuse box before woricing

inside the machine.

Maintenance Instructions

SEC J6.6 TROUBLESHOOTING

Trouble Cause

1. Rough wire feeding or wire not

feeding but drive rolls turning.

2. Variable or “hunting” arc. a. Worn and/or melted contact tip.

3. Weld Porosity, narrow and ropey

bead, or electrode stubbing into

plate when welding.

4. LN-7 circuit breaker trips while

welding.

LN-7 or power source electrical

problems such as:

LN-7 fuse blows.

Power Source Fuse blows.

LN-7 circuit breaker trips.

No control of wire feed motor.

Wire feed motor won’t run.

Auxilliary equipment connected

to 32A and 7 won’t work.

Power source contactor won’t

work, but LN-7 feeds wire.

a. Gun cable kinked and/or twisted.

b. Wire jammed in gun and cable.

c. Incorrect drive rolls and guide

tubes.

d. Drive rolls loose.

e. Gun cable dirty.

f. Worn drive rolls.

g. Electrode rusty and/or dirty.

h. Worn nozzle liner,

j. Partially flashed or melted

contact tip.

b. Worn or undersize work cable

or poor work connection.

c. Loose electrode connections.

a. Dirty plate or improper

procedures.

a. See Trouble 1 above.

b. High ambient temperature

(causing circuit breaker to trip.)

c. Electrical problems in power

source or LN-7.

a. Loose connection or broken lead.

b. Electrical component has failed.

What to Do

a. Inspect gun cable and replace if necessary.

b. Remove wire from gun and cable — feed in new

wire. Note any obstructions in gun and cable.

Replace gun and cable if necessary.

c. Check wire diameters stamped on drive rolls,

wire guides, and drive roll spacers for correct

combination for wire being used.

d. Remove, clean, install and tighten.

e. Clean per Sec. J6.2.1.

f. Replace and/or reverse split drive roll type.

g. Replace.

h. Replace.

j. Replace contact tip.

a. Replace tip - remove any spatter on end of tip.

b. Inspect - repair or replace as necessary.

c. Be sure electrode lead is tight. Gun cable tight

in wire feeder contact block. Gun nozzle and

gun tip tight.

See trouble shooting information in Bulletin

N676, “Innershield Semiautomatic Welding

Guide.”

a. Correct problems.

b. Provide better ventilation for LN-7.

c. See Trouble 5.

a. Turn power source and LN-7 off and check

leads and connections.

b. Replace blown fuses or reset circuit breaker

and try to weld. If trouble recurs, call Lincoln

semiautomatic distributor, local representa

tive or authorized Field Service Shop.

-17-

October 1971

Page 18

Sec. J7.2

Page 109-C

The Lincoln Electric Company

Cleveland, Ohio 44117

LN-7 WIRE FEEDER

ITEM

1

<5

12

Parts List P-109-C

PART NAME AND DESCRIPTION

Gun a nd Ca bl e As se m bl y Se e Se c .

2

Con tr ol Bo x Se e

Sel f Ta p pi ng S cr ew (C on tr ol B o x 6 Co ve r to F r am

4

Wir e Dr i ve M ec ha ni s m Se e

inp ut C a bl e an d Ex t en si on C ab l e As se mb ly See

6

Wir e Ree l Sup po rt (50# and 60# ) See

Wir e Ree l Sha ft See

7

Dri ve U n it F ra me A s se mb ly

3

Nam ep la t e

Sel f Ta p pi ng S cr ew to M ou nt N a me pl at e

18-

NO.

REQ’D.

J7. 3

109 -D

0 6

109 -F

loq -H

107 -0

107 -P

1

1

4

Page 19

The Lincoln Electric Company

Cleveland, Ohio 44117

Sec. J7.2

Page 109-D

CONTROL BOX

ITEM

Complete Control Box, Includes:

I

Case

2

P.C. Board Insulation

Control Circuit P.C. Board 1

3

Plastic Expansion Nut 2

4

Round Head Screw 2

Lockwasher 2

Grommet 1V,

5

6

Fuse Holder 1

Lead Clamp 1

7

Sems Screw 1

Hex Nut

8

Potentiometer 1

Relay Socket 1

9

C p I n Q

Round Head Screw 2

Lockwasher 2

II

12

Hex Nut

Circuit Breaker

T ransformer

Round Head Sr.rew

10 А.Г.. Relfly

PART NAME AND DESCRIPTION

___________________________________________________

Parts List P-109-D

NO.

REQ'D.

I

1

7

1

1

2

1

1

1

1

1

2

2 27

1

1

_____

2—

Item

l3

15

16

17

18 P.C. Board Receptacle

20 Round Head Screw

21 Insulating Washer 3

22 Resistor

23 Flat Washer

2k Lockwasher

25

26 Terminal Strip

Parts Not Illustrated

PART NAME AND DESCRIPTION

Lockwasher

Hex Nut

Reed Switch Assembly

Terminal Strip (Small)

Resistor (1/2 Watt)

Resistor (2 Watts)

Reed Switch Coil

Reed Switch

Route Head Screw

Lockwasher

Hex Nut

Power Circuit P.C. Board

Seif Tapping Screw

Plastic Expansion Nut

Input Polarized Plug

Self Tapping Screw

OutDUt Polarized Plua

Self Tapping Screw

P.C. Board Receptacle

Hex Nut

Res istor

Control Box Cover

Mftnnt-ari ta TriWAr

-------------------------------------------------------------------------

-

May 1972

NO.

REQ’D.

2

2

1

1

1

Ì

1

1

2

2

2

I

2

2

1

A

1

4

1

1

1

1

1

1

1

1

1

1

19-

Page 20

Sec. J7.2

Page 109-F

WIRE DRIVE MECHANISM

NOTE A; When ordering these parts, always specify wire size.

Some of these parts can be used for more than one wire size. All

suitable sizes are stenciled on each part.

Complete kits containing items 2, 7, 20, 22 and €5 are available

for wire sizes .035, .045, .052,1/16, .068, 5/64,3/32 and 7/64"

wire diameters. Order "LN-7 Wire Size Conversion Kit For

(specify wire size) Wire."

The Lincoln Electric Company

Cleveland, Ohio 44117

Parts List P-109-F

ITEM

1 Drive Motor and Gear Box, includes:

Drive Motor 1

Drive Motor, Includes

Gear Box

2* Drive Roll - Specify Wire Size 19

------

Ordli 2 foils for 1/16 -y/siy------------------------------------------

Hex Head Screw

3

Collar AssemblV

4

Key 1

5

6 Socket Set Screw 1

7*

Outqolnq Guide Tube - Specify Wire Size 1

Conductor Block Assembly 1

Insulating Bushing

9

10 2

11

Slotted Headless Set Screw 2

Hex Head Screw

l.Qckwashe.r-------------------------------------------------------------

_L2_

PART NAME AND DESCRIPTION

Pinion Gear 1

Rol1 Pin 1

NO.

REQ’D.

1

1

1

1

1

2

2

__2

______

-20-

ITEM

Conductor Block Insulation

13

11)

Socket Set Screw

Pivot pin

15

16 Idle Roll Assembly

Round Head Screw

17

Spring

18

Retaining Ring

20*

Incoming Guide Tube - Soecifv Wire Sire

21

Idle Roli Pull Arm

22*

Spacer - Specify Wire Size - For .068 - 7/6V'

Wi re

Locator Bushing

23

2l|

Hex Head Screw

25 *

Outgoing Guide Tube Insert - Soecifv Wire Size I

26

Flatwasher

Flatwasher 1

27

78

*

See MOTE A Above

PART NAME AND DESCRIPTION

NO.

REQ'D.

1

1

1

1

_J

_______

1

1

1

1

1

-1

November 1972

Page 21

The Lincoln Electric Company

Cleveland, Ohio 44117

U

Sec. J7.3

Page 103-F

K-115 SQUIRTGUN AND CABLE

WHEN ORDERING GIVE: Item No.,

Part Name, Parts List No., and Gun

*Specify wire size.

tSpecify 15’ or 10’ cable as appropriate.

Nozzle

Nozzle ^

linner ^

Nozzle ^

insert

Insert

retainer

Locking

screw ^

! I' I L*_ contact

Li-Li tip

ITEM

t *

1 +

1 r

2

3

Gun and Cable Assembly

Conductor Cable. Includes:

lA

IB

Snap Ring 1

Seat*^Shield Assembly

PART NAME AND DESCRIPTION

Handle and Stiffener, Wire Feeder End

Connector, Wire Feeder End 1

rnnnArtnr Run FnH

Pan Head Screw

6

Spatter Shield

7 Socket Head Screw

“8“

9*

q ^

Handle

Nozzle (82°) Includes:

Nozzle (4So) Includes:

Nozzle Liner, Tight Wound Steel Spring

9BV

9C

9D

lot

Nozzle Insert

NoZ2:le Insert Retainer

Liner Locking Screw

Trigger and Control Cable Assembly

Assembly Parts

11

11

11

12*

12*

17*

15

17

Insulated Guide, 2-3/4" Electrical

Insulated Guide, 3"3/4" Electrical

Insulated Guide, 1-1/4" Flertriral

Contact Tip, .120 Electrode

Contact Tip, 7/64 Electrode

r<-.r,<-=<-t Tin ■J/PO FlertrrwHe

5WItcfi Houirng^CTamp

Shield Mounting Block

Round Head Screw

Parts List P-103-F

NO.

REQ’D.

_J

_L

_]

_J

Ins-K

See P-

St 1ckout 1

St i ckout 1

St i rl/nnt

__________As

As

As

_1

Req' d.

Req' d.

}<an ' rl

_4

August 1974

1

______

1

1

4

1

______

1

1

____

1

1

1

1

1

_____

1

_______

-21-

Page 22

Sec. J7.3

Page 103-J&K

The Lincoln Electric Company

Cleveland, Ohio 44117

K-126 SQUIRTGUN AND CABLE

K-126 - Parts List P-103-J

ITEM

Gun and Cable Assembly

t

1 Handle

2 t

2A

2B

2C

2D

•i

A

5

6

1

8 Contact Tip, 5/6^“ Electrode As Req' d

8

“8

10

lOA Nozzle Liner, Tight Wound Steel Spring 1

IOS

IOC

10D Liner Locking Screw

11 t

12 Clamp

rr~

13

1Í*

18

PART NAME AND DESCRIPTION

Conductor Cable, Includes: 1

Handle and Stiffener, Wire Feeder End 1

Connector, Wire Feeder End

Connector, Gun End

Clamping Tube, Both Ends 2

Snao Rina

Clamp

Spatter Shield

Pan Head Screw A

Socket Head Cap Screw 1

Contact Tip, 3/3 2 “ Electrode Ai Reg' d

Contact Tip, .06 8 “ Electrode As Req' d

Nozzle Assembly, Includes 1

Nozzle Insert 1

Nozzle Insert Retainer 1

Trigger and Control Cable Assembly

Assembly Parts See -103-K

Insulated Guide, 2-3/^" Electrical Stlckout 1

Thread Protector, 3/1* to 1-1/2" Stlckout 1

Round Head Screw

August 1974

NO.

REQ'D.

1

1

I

1

1

I

1

1

1

...-4

TRIGGER AND

1

CONTROL CABLE ASSEMBLY

Cable Assembly - Parts List P-103-K

ITEM

t Trigger and Control Cable Assembly, Includes:

1 Micro-Switch

2

3

A

5

6 Roll Pin

7

8 Insulating Sleeving

9

10

12

12A

PART NAME AND DESCRIPTION

Switch Pad

Trigger Assembly

Cord Clamo

Coil Spring

Roll Pin

Set Screw

Cord Clamp

Polarized Plug, Wire Feeder End, Not lllus.

Clamp at Polarized Plug

August 1974

_

NO.

REQ'D.

1

1

1

1

1

2

2

2

1

1

1

1

1

Page 23

The Lincoln Electric Company

Qeveland, Ohio 44117

Sec. J7.3

Page 107-0

50 AND 60 # WIRE REEL SUPPORT

/

ITEM

Wire Reel Support Assembly, includes; 1

1 W i re Ree1

3

10

2

if

5

6

7

8

9

13

Reel Support

Reel Mounting Shaft Assembly 1

Optional Wire Reel Cover Parts Kit, includes;

\iire Reel Housing

Flatwasher

Lockwasher

Hex Nut

Hex Head Screw

Insulating Washer 12

Insulating Tube

Insulatina Tube

Optional Door Parts Kit, includes;

(Wire Reel Cover Must Be Installed.)

Door and Hinge Welded Assembly 1

Catch 1

Sems Screw (Catch Mounting)

Sealing Panel

\

Parts List P-107-0

PART NAME AND DESCRIPTION

NO.

REQ’D.

1

1

'-107-F

1

1

6

3

3

3

1

2

1

2

1

■23-

January 1973

Page 24

Sec. J7.3

Page 107-P

WIRE REEL SHAFT

APf>ty LINCOLN BEARING <M£ASt PER £-IU7 TO ALL MAT/N6

SURPACE.S AND TO tdt Q.Q. Of THE SPPIN^ AtPOPS.

A^sd^QCY WTO Tuj SUAPT ihiJL.

The Lincoln Electric Company

Cleveland, Ohio 44117

SOPPOfeT

PPPME -

Parts List P-107-P

ITEM

Reel Mounting Shaft Assembly, Includes: 1

2

Flat Spring Steel Washer 2

Reel Mounting Shaft

3*

ii

Sprl ng

Flat Sorinq Steel Washer

5

6 Rivet

Rol1 Pin

7

8 Pu11 Knob

Snap Ring

9

10

12

13

lit Insulating Vilasber

15

16

18 Brake Assembly

*

Bronze Washer

Flatwasher

Hex Head Screw

17

LN"7 welders built before November 1972 did not

have the adjustable brake (Item 18). If a shaft

or fixed brake assembly is needed, order the

complete shaft assembly.

PART NAME AND DESCRIPTION

Insulatina Washer

insulating Tube

Lockwasher

INPUT CABLE AND EXTENSION

CABLE ASSEMBLIES

Parts List P-109-H

ITEM

Power input Cable Assembly, includes:

* When ordering, always specify length required

Extension Cable Assembly, includes:

PART NAME AND DESCRIPTION

Control Cable Assembly, includes:

Polarized Connector (Female)

Clamp

Electrode Cable Assembly

Control Cable Assembly

Polarized Connector fFemale)

Polarized Connector (Hale)

Clamp

Electrode Cable Assemblv

NO.

REQ'D.

1

1

1

1

1

1

1

1

I

1

1

1

1

)

1

January 1973

NO.

REQ'D.

1

1

1

1

I

1

I

1

1

2

1

-24-

August 1971

Page 25

The Lincoln Electric Company

Cleveland, Ohio 44117

M-12380

Wiring Diagram

OPERATING SCHEMATIC

81

iPi*

I

S:

-25-

5

¡5

$s!si 3;5

«Ml

V«» -U 5.11.73c

>

Sli

tfii O

fio «;

iiu

Page 26

M-12381

Wiring Diagram

The Lincoln Electric Company

Cleveland, Ohio 44117

LN-7 CONNECTION SCHEMATIC

For older machines built to Code 7024 only, request diagram M-12354.

(Use M-12381 for Code 7024 A.)

® BE. y<\TH 5 \2.5V

OT< ZSO V SL.O Bt_0 Fuse

-26-

BRKKe cow.

10-8-71

Page 27

The Lincoln Electric Company

Cleveland, Ohio 44117

M-12382

Wiring Diagram

LN-7 WIRING DIAGRAM

For older machines built to Code 7024 only, request diagram M-12355.

Page 28

HOW TO ORDER REPLACEMENT PARTS

Order parts only from Lincoln offices or from the Authorized

Field Service Shops iisted in the "Service Directory”. Give the

foilowing information:

(a) From the namep

numbers.

(b) From this manu

The Lincoin Eiectri(

equipment except (

defects in workman:

from date of shipnr

properiy cared for,

Engines and engin

defects for a period

If the Buyer gives t

equipment or elect)

and the Seller’s ins

defects, then the S<

its option, either by

tory or other piace

provided Buyer her

exclusive.

No expense, iiabiiit

Seiier for repairs m

tion, item number, quantity required and the number of

the iist used to get this information.

Anu ¡tame inHantari in the "Parts Name” coiumn are inciuded

are listed. The indented

entire assembly is

s.

^uential damages

of any warranty,

the supplying of said

the Buyer, whether on

any case exceed the cost

mt or replacing defective

ove guarantee. Upon the

ty, all such liability shall

ledies are exclusive and

e no guarantees or waraccessories, equipment,

>r arising by operation of

iplied, including without

tability, all such warran-

)

LIIMCOLIM

ELECTRIC I

Eff. Jan. ’86

THE LINCOLN ELECTRIC COMPANY

World's Largest Manufacturer of Arc Welding Products * Manufacturer of Industrial Motors

Sales and Service Worldwide Cleveland, Ohio 44117-1199 U.S.A.

Toronto M4G2B9-Canada • Sydney 2211 - Australia • RoUen 76120 - France

5-84

LItho in U.S.A.

Loading...

Loading...