Page 1

SERVICE MANUAL

(DOMESTIC)

IMPINGER CONVEYOR OVENS

IMPINGER II - ADVANTAGE SERIES

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Phone : (800) 374-3004

U.S. Fax: (888) 790-8193 • Int’l Fax: (260) 436-0735

Technical Service Hot Line

(800) 678-9511

www.lincolnfp.com

1100AdvSvc REV 11/4/08

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS 2

SEQUENCE OF OPERATIONS 4

SEQUENCE OF OPERATIONS 5

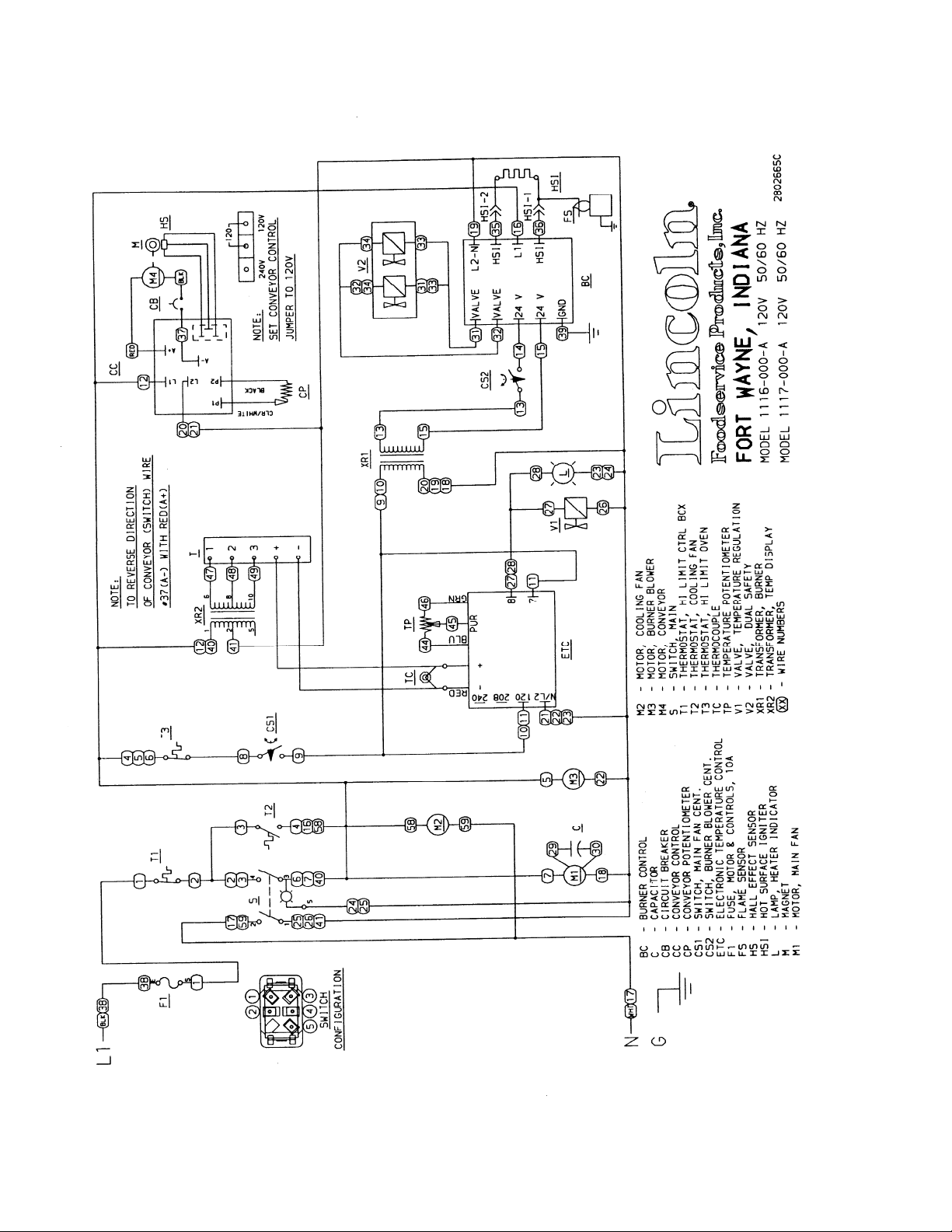

SCHEMATIC 1116-000-A, 1117-000-A 6

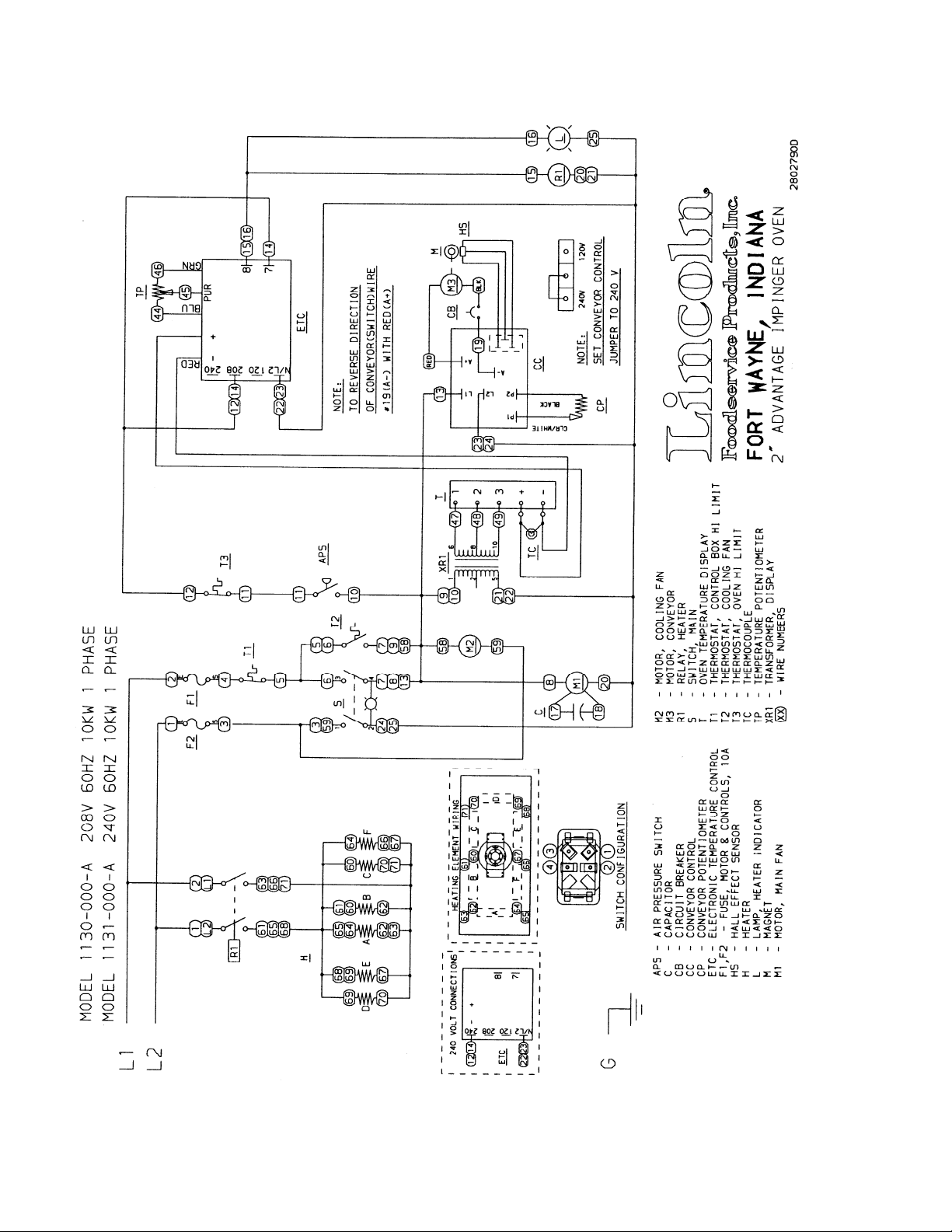

SCHEMATIC 1130-000-A / 1131-000-A 7

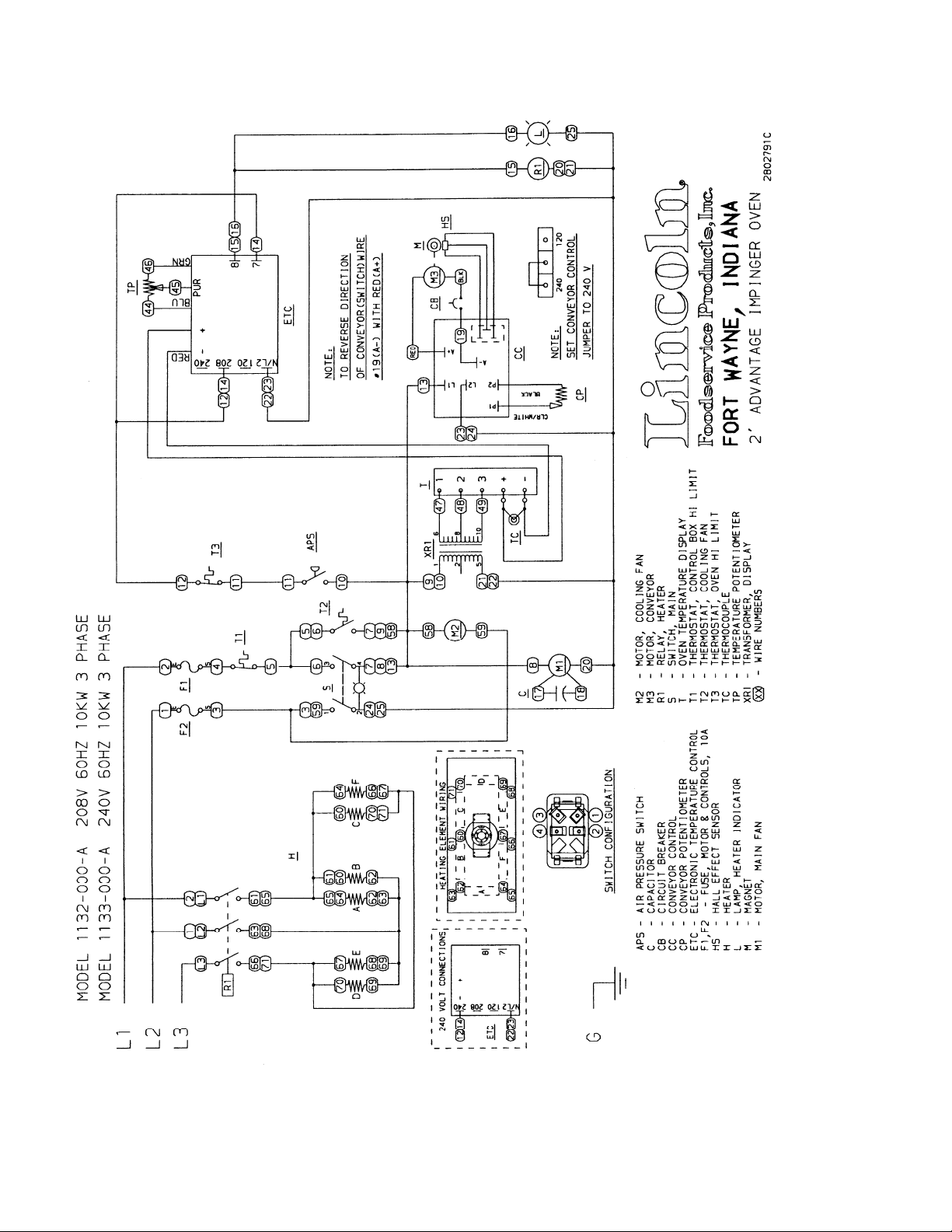

SCHEMATIC 1132-000-A / 1133-000-A 8

TROUBLESHOOTING GUIDE / GAS OVENS 9

TROUBLESHOOTING GUIDE / ELECTRIC OVENS 14

REMOVAL, INSTALLATION, AND ADJUSTMENT 18

PARTS / GENERAL 26

BLOW UP / GENERAL 27

PARTS / CONTROL BOX 1116-000-A, 1117-000-A 28

BLOW UP / CONTROL BOX – 1116-000-A, 1117-000-A 29

PARTS / CONTROL BOX – 1130-000-A THRU 1133-000-A 30

BLOW UP / CONTROL BOX – 1130-000-A THRU 1133-000-A 31

PARTS / CONVEYOR & DOOR 32

BLOW UP / CONVEYOR & DOOR 33

PARTS / OVEN BACK ASSEMBLY 34

BLOW UP / OVEN BACK ASSEMBLY 35

2

Impinger II – Advantage Service Manual - Domestic

Page 3

SEQUENCE OF OPERATIONS

IMPINGER II ADVANTAGE

MODEL 1116-000-A / NATURAL GAS / 120 VAC / 60 HZ / 1 PHASE

MODEL 1117-000-A / L.P. GAS / 120 VAC / 60 HZ / 1 PHASE

POWER SUPPLY Electrical power is supplied to the oven by a three conductor cordset. Voltage

from the black conductor to the white conductor is 120 VAC. The white

conductor is neutral. The green conductor is ground.

CONTROL BOX AUTO When the temperature in the control box reaches 120°F ± 3° (48.9°C ± 1.7°C),

the

COOL DOWN interrupt power to the fans when the control box temperature falls to 100°F ± 3°

(37.8°C ± 1.7°C).

MAIN FAN CIRCUIT Power is permanently supplied, through a 10A fuse, and through a normally

closed control box hi-limit thermostat, to the normally open main fan switch.

Power is also supplied to the normally open cooling fan thermostat. Closing the

main fan switch supplies 120 VAC to the main fan motor, the cooling fan motor,

the primary of the temperature display transformer, the heat and conveyor

circuits.

BURNER CIRCUIT Closing the main fan switch supplies 120 VAC to the burner blower motor. 120

VAC is also supplied, through the normally closed oven cavity hi-limit thermostat,

the main fan centrifugal switch (this switch closes when main fan reaches

approximately 1600 RPM) to the electronic temperature control and to the

primary of the burner transformer.

IGNITION CONTROL The ignition control operates on both 24 VAC and 120 VAC. When the control is

energized by 24 VAC from the transformer, 120 VAC is switched by the ignition

control to the hot surface ignitor for 45 seconds for the hot surface ignitor warm

up. The ignitor glows red, 24 VAC is switched to the gas valve which opens and

ignition should now occur.

TEMPERATURE CONTROL When the centrifugal switch of the main fan motor closes, power is applied to the

temperature control. The 1K ohm temperature pot is adjusted to desired

temperature. The thermocouple will provide varying millivolts to the temperature

controller. The temperature controller supplies 120 VAC to the solenoid valve at

intermittent intervals to maintain desired temperature. The heat lamp is

energized with the solenoid valve.

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC to the motor control board. AC volts

are converted to DC volts and are supplied to the conveyor motor at terminals A+

and A-.

Adjustment of the speed control potentiometer will change resistance at terminals

P1 and P2 varying the DC voltage to the motor. The speed of the conveyor

motor will increase or decrease as the DC voltage from the board increases or

decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor

motor that senses the motor speed. Any change in motor load (±RPM) is

detected by the sensor and the voltage to the motor is adjusted accordingly.

Temperature Display Closing the switch supplies 120 VAC to the primary of the temperature display

transformer. The secondary of this transformer supplies 12 VAC to the temperature

display. The thermocouple supplies D.C. millivolts to the temperature display. The

display converts this millivolt reading to a temperature reading.

Impinger II –Advantage Service Manual - Domestic

3

Page 4

SEQUENCE OF OPERATIONS

1130-000-A / 208V / SINGLE PHASE

1131-000-A / 240V / SINGLE PHASE

1132-000-A / 208V / THREE PHASE

1133-000-A / 240V / THREE PHASE

POWER SUPPLY Electrical power to be supplied to the oven by a three-conductor service on single

phase and a four-conductor service on three phase.

Black conductor is Hot

Red conductor is Hot

Orange conductor is Hot (Used on 3 phase only)

Green conductor is ground.

CONTROL BOX AUTO COOL DOWN When the temperature in the control box reaches 120°F ± 3°F (48.9°F ± 1.7°C),

the cooling fan thermostat will switch power to the cooling fans. The thermostat

will interrupt power to the fans when the temperature falls to 100°F ± 3°F (37°C ±

1.7°C).

MAIN FAN CIRCUIT Power is permanently supplied through the 10A fuses, through the normally

closed control box high limit thermostat, to the normally open main fan switch.

Power is also supplied to the normally open cooling fan thermostat. Closing the

main fan switch supplies 208/240 VAC to the main fan motor, the cooling fan

motor, to the primary of the temperature display transformer and to the heat and

conveyor circuits.

HEATER CIRCUIT Closing the fan switch supplies 208/240 VAC, through the normally open air

pressure switch (closed by air pressure from the main fan) through the normally

closed oven cavity hi-limit thermostat, to the electronic temperature control. The

1K ohm temperature pot is adjusted to desired temperature. The thermocouple

will provide varying millivolts to the temperature controller. The temperature

control then supplies 208/240 VAC to the coil of the contactor at intermittent

intervals to maintain the desired temperature. The heat lamp is energized with

the contactor.

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC to the motor control board. AC volts

are converted to DC volts and are supplied to the conveyor motor at terminals A+

and A-.

Adjustment of the speed control potentiometer will change resistance at terminals

P1 and P2 varying the DC voltage to the motor. The speed of the conveyor

motor will increase or decrease as the DC voltage from the board increases or

decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor

motor that senses the motor speed. Any change in motor load (±RPM) is

detected by the sensor and the voltage to the motor is adjusted accordingly.

Temperature Display Closing the switch supplies 120 VAC to the primary of the temperature display

transformer. The secondary of this transformer supplies 12 VAC to the

temperature display. The thermocouple supplies D.C. millivolts to the

temperature display. The display converts this millivolt reading to a temperature

reading.

4

Impinger II – Advantage Service Manual - Domestic

Page 5

SCHEMATIC 1116-000-A, 1117-000-A

Impinger II –Advantage Service Manual - Domestic

5

Page 6

SCHEMATIC 1130-000-A / 1131-000-A

6

Impinger II – Advantage Service Manual - Domestic

Page 7

SCHEMATIC 1132-000-A / 1133-000-A

Impinger II –Advantage Service Manual - Domestic

7

Page 8

TROUBLESHOOTING GUIDE / GAS OVENS

MODEL 1116-000-A NATURAL GAS 120 VAC 60 HZ 1 PHASE

MODEL 1117-000-A LP GAS 120 VAC 60 HZ 1 PHASE

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run Incoming Power Supply Check breakers, reset it required. Check power plug

to be sure it is firmly in receptacle. Measure

incoming power/call power company if needed.

Fuse, 10 Amp Check, replace if necessary.

Fuse Holder Check, replace if necessary.

Hi Limit Thermostat-Control

Box

Main Fan Motor Check for opens, shorts, or grounds. WITH POWER

Capacitor Check for shorts or grounds.

No control box cooling Incoming Power Check main circuit breakers, reset if required, call

Main Fan Switch Check continuity between switch terminals

Cooling Fan 120 VAC should now be at the fan motor. If voltage

No automatic control Incoming Power Supply Check circuit breakers,

box cooling reset if required. Call the power company if needed.

Cooling Fan Thermostat Check the cooling fan thermostat. (Thermostat

Cooling Fan 120 VAC should be at the motor. If voltage is

Oven will not heat Gas Supply Check for adequate gas supply and closed manual

Main Fan If not operating, refer to "Oven fan will not run".

High Limit Oven Cavity Terminals are normally closed. If

Thermostat open, push in reset button and retest. If thermostat

Centrifugal Switch Check for 120 VAC at lead #9

of Main Fan Motor (located at 6 pin connector in raceway n ear the main

Main Fan Switch Check continuity between switch terminals.

Check for voltage on both sides of the switch.

Terminals are normally closed. If open, reset and

test oven for proper operation. If thermostat will not

hold and control box temperature is not exceeding

140°F (60°), replace thermostat.

OFF turn fan blade to check for locked rotor.

WARNING: Capacitor has a stored charge,

discharge before testing.

power company if needed.

is present, check motors for shorts or opens. WITH

POWER OFF: Check for locked rotor.

closes at 120°F and opens at 100°F). With the

cooling fan thermostat preheated, check for

continuity. If switch is open, replace.

present, check motor for shorts, opens, or grounds.

WITH POWER OFF: check for locked rotor.

gas shut offs. Also, check flexible gas line

connection.

will not hold for maximum oven temperature, and

oven is not exceeding temperature dial setting,

check for proper location of capillary bulb in its

spring holder. If above checks okay, replace hi-limit

thermostat.

fan motor) to neutral. If no voltage is present, and

motor is running, replace motor.

8

Impinger II – Advantage Service Manual - Domestic

Page 9

Burner Blower Motor Visually check to see if motor is running. If not,

check for 120 VAC to motor at motor connector (wire

#5 and #22). If voltage is not present, trace wiring

back to fan switch. If voltage is present and motor is

not running, check for opens, shorts, or grounds.

Also, WITH POWER OFF: check for locked rotor.

Transformer, Burner Primary is 120 VAC with 24 VAC secondary. If 120

VAC is not present, trace wiring back to Main Fan

Centrifugal Switch. If 120 VAC is present, check for

24 VAC at secondary of transformer. If no voltage is

present, replace transformer.

Centrifugal Switch of Burner

Blower Motor

Check of 120 VAC at motor connector, on wire #13

to neutral. If voltage is not present, trace wiring back

to transformer. If voltage is not present and motor is

running, replace the burner blower motor.

Ignition Control 24 volts should be present at 24 volt terminals. If not

present, trace wiring back to centrifugal switch.

When 24 VAC is supplied, the control switches 120

VAC from L1 and L2 to the hot surface ignitor. if 120

VAC is not present at L1 and L2, trace wiring

back to fan switch. If 24 VAC and 120 VAC are

present and 120 VAC is not across the hot surface

ignitor terminals, replace the ignition control.

Hot Surface Ignitor If 120 VAC is present at hot surface ignitor terminals,

visually check to see that the ignitor is heating.

(Ignitor may be viewed through the port glass in end

of burner tube.) The ignitor should glow bright red.

If the ignitor does not heat, replace the ignitor.

Ignition Control After 45 seconds of hot surface ignitor pre-heat, the

ignition control will switch 24 VAC to the gas control

valves. Check for 24 VAC output from ignition

control, across terminals marked "valve" and "valve

ground". If no voltage is present, replace ignition

control.

Gas Control Valves When 24 VAC is supplied to the gas control valve,

the valve should open. Check for gas pressure at

the manifold tap located just before the burner. If

there is no pressure, check the incoming gas supply

to be sure all manual valves are open and flexible

gas hose is properly connected. If gas is present

and coils of gas valve are energized, the gas valve is

probably defective.

Flame will not stay lit Hot Surface Ignitor Six seconds after the gas valve opens, ignition must

occur. if flame is not detected, the ignition control

will shut off and lock out. To reset the ignition

control, turn off the burner switch for 45 seconds,

then turn on the burner switch to retry ignition. The

ignition control requires a minimum of 0.8 D.C.

microamps. To check flame sensing operation,

connect a digital multimeter (capable of measuring

D.C. micro-amps) between the "ground" terminal on

ignition control and the ground lead.

NOTE: This is a current measurement and the

meter must be connected in series. If these

readings are not achieved, replace the hot surface

ignitor.

NOTE: The D.C. micro amp test must be conducted

with the oven in low flame (bypass) operation. Turn

the temperature control to the lowest setting.

Impinger II –Advantage Service Manual - Domestic

9

Page 10

Power Supply If there is sufficient micro-amp current, but the flame

will not stay lit, check for proper polarity of the 120

VAC power supply.

Ignition Control If there is sufficient micro-amp current, and the 120

VAC polarity is correct, but the flame will not stay lit,

replace ignition control.

NOTE: Check for proper ground connection on

ignition control.

NOTE: Flame should be lit at

this time.

Low flame is on,

but no main flame

Temperature Control Check for 120 VAC at terminal #7

to neutral on temperature control. If no voltage,

trace voltage back through centrifugal switch and hilimit. Turn the temperature adjustment knob to

maximum temperature position and check for 120

VAC at the load terminal #8 and neutral. If 120 VAC

is present and unit is not heating, refer to

"Temperature Solenoid Valve" for next check. If 120

VAC is not present, proceed.

Thermocouple Probe WITH POWER ON AND THERMOCOUPLE LEADS

ATTACHED TO THE TEMPERATURE CONTROL

BOARD: Measure the D.C. millivolt output of these

leads. Refer to thermocouple chart in Section D for

proper readings. If these readings are not achieved,

replace the thermocouple.

Temperature Set Disconnect the potentiometer leads

Potentiometer from the board. Place ohm meter test leads on the

blue and green pot leads. Reading should be 1 K

ohms. Place meter leads across the blue and purple

pot leads and rotate knob from high to low. Repeat

on green and purple leads. Check for even rise and

fall of ohms reading to insure that there are no open

or dead spots in the potentiometer. Check each

lead to ground for shorts. Replace pot if it does not

meet the above test.

Temperature Solenoid If 120 VAC is present on the

Valve temperature control board at load terminal #8 to

neutral, check for voltage at temperature regulation

valve. If voltage is present, listen for valve to open

and close. Also check for opens or shorts in the coil.

Replace as necessary.

Intermittent Heating Therm al/Overload of Main Fan

and Burner Blower Motors

The main fan motor and the burner blower motor are

equipped with internal thermal protection and will

cease to operate if over heating occurs. As the

motors overheat and then cool, this will cause the

units to cycle on and off intermittently. This may be

caused by improper ventilation or preventive

maintenance. Also, most of the problems listed

under "Oven will not heat" can cause intermittent

failure.

Conveyor will not run Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 120 VAC. If

not present, check breakers.

10 Amp Fuse Check and/or replace.

Fuseholder Check and/or replace.

Fan Switch See procedure for checking on Page 10.

10

Impinger II – Advantage Service Manual - Domestic

Page 11

Speed Adjustment

Potentiometer

This is a 0 to 10 K ohm, 1 turn potentiometer. With

power off, remove the black and white pot leads

from the motor control board at terminals P1, P2.

Place the meter leads on the black lead (P2) and on

the white lead (P1). Rotating the pot., slowly, from

low to high, the meter readings should show an even

transition from 0 to 10 K ohms ± 5%. There should

be no dead or open spots through out the 1 turn of

the pot. Check both leads to ground. There should

be no continuity to ground. If any of the above

checks fail, replace the pot.

DC Motor Control Board Check for 120 VAC input to the control board at

terminals L1 and L2. If not present, check wiring

back to the oven fan switch. If 120 VAC is present

at L1 and L2, check both fuses on control board (8A

line and 1A armature), check the VDC output at

terminals A+ and A-. If 120 VAC is present at

terminals L1 and L2 and DC voltage is present at

A+ and A-, but the motor does not run, check gear

motor as follows:

Conveyor Gear Motor If DC voltage is present at A+ and A- and the motor

does not run, first check the mini breaker and then

the conveyor. Refer to the next possible cause.

Check the leads to the motor for evidence of any

shorts or opens, and each lead to ground. Check

motor brushes. From the top of the motor, rotate

motor shaft to determine if there is a locked rotor or

a locked gear box (use care so magnet and H.S.

board are not damaged). Replace motor as needed.

Conveyor Check for any mechanical misalignment. Also,

check for worn bearings. A conveyor belt that is

over tightened will cause excessive bearing wear

and sometimes, irregular speed.

Conveyor speed varying or

intermittent

Power Supply Check power supply at the DC control board for the

120 VAC at board terminals L1 and L2.

Motor Control Board Place the test meter probes on terminals A+ and A-.

(With speed potentiometer set to maximum speed

(Approximately 2 min.) The meter reading should be

approximately 100 VDC (±3%), if voltage is not

steady within limits, then the board is probably bad.

Always check the speed pot., be sure it is okay

before changing a board. This test is not always

100% accurate as this test is not performed at

operating speeds. However, this test is the best

method currently available.

DC Gearmotor If the DC control board is steady then the problem

may be the motor or gearbox. Check the brushes in

the motor for excessive arching and/or unusual

wear. Check the motor and gearbox from instruction

located on Page 11 under "possible cause" listing

"conveyor gear motor."

Magnet Check to insure that the magnet (cemented to shaft

of conveyor drive motor) has not been damaged, or

come loose from motor shaft. Replace as needed.

Hall Effect Sensor Check for any physical damage to hall effect sensor

(mounted on conveyor drive motor.) Check all wiring

and connections for damage. Check all connections

for tightness or proper location and check all wiring

for visible damage. Replace as needed. Connect

new hall effect to system and check for steady

operation.

Impinger II –Advantage Service Manual - Domestic

11

Page 12

Temp. display inoperative Display Transformer Measure the transformer primary for a nominal 120

VAC input, if voltage is not present, trace wiring back

to the oven power source. Measure the secondary

output, which will normally be 12-15 VAC. Voltage

across terminals 1 and 3 on the time/temp. display

should read 12-15 VAC. Terminals 1-2 and 2-3

should be 1/2 the voltage reading to 1-3. If the

above secondary readings are not achieved, replace

transformer.

Temp. Display If proper voltage is present at terminals 1, 2, and 3

on temperature display, but the display is not lighted,

recheck all connections for tightness. If temperature

display is still not operating, replace the temperature

display.

Temp. Display inaccurate,

erratic or inoperative

Thermocouple Place the thermocouple of a pyrometer into the

center of the top finger. Be sure the tip of the

thermocouple is not touching metal, it must sense air

temperature only. The pyrometer will indicate oven

temperature. Measure DC millivolts of thermocouple

at the temperature display. See thermocouple chart

on page 19 for proper readings. Replace

thermocouple if proper readings are not achieved. If

readings are correct on the thermocouple, replace

temperature display.

12

Impinger II – Advantage Service Manual - Domestic

Page 13

TROUBLESHOOTING GUIDE / ELECTRIC OVENS

MODEL 1130-000-A 208 VAC SINGLE PHASE 60 HZ

MODEL 1131-000-A 240 VAC SINGLE PHASE 60 HZ

MODEL 1132-000-A 208 VAC THREE PHASE 60 HZ

MODEL 1133-000-A 240 VAC THREE PHASE 60 HZ

REFER TO PROPER SCHEMATIC FOR IDENTIFIED COMPONENTS

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run Incoming Power Supply Check circuit breakers. Rest if required. Call

power company in needed.

Fuses, 10 Amp, Fan and

Controls

Fuseholder Check, replace if necessary.

Control Box High Limit

Thermostat

Switch, Main Fan Check for continuity between switch terminals.

Main Fan Motor Check for opens, shorts, or grounds. WITH

Capacitor Check for opens, shorts, or grounds.

No control box cooling Check for main fan operation. If not operating, refer

Cooling Fan Motor 208/240 VAC should be present at the fan motor. If

No automatic control

box cooling

Thermostat, Cooling Fan This normally open thermostat should close when

Cooling Fan Motor 208/240 VAC should be present at the fan motor. If

Control box cooling fan

continues to run

Oven will not heat Main Fan Motor Check for main fan operation. If it is not operating,

Air Pressure Switch This normally open switch should close when the

Hi-Limit Thermostat Oven

Incoming Power Supply Check circuit breakers. Reset if required. Call

Thermostat, Cooling Fan This normally open thermostat should close at

Cavity

Check, replace if necessary.

Terminals are normally closed, but open at 140°F ±

5°F (60°C ± 2.8°C). Check for over heating and

reset thermostat. Test for proper operation. If it will

not reset and hold, then replace.

POWER OFF: Turn fan blade to check for locked

rotor.

to "Oven Fan Will Not Run".

voltage is present, check for opens or shorts.

WITH POWER OFF: Check for locked rotor of the

fan motor.

power company if needed.

the temperature in the control box reaches 120°F

(48.9°C). If thermostat does to close, replace.

voltage is present, check for opens or short. WITH

POWER OFF: Check for locked rotor of the fan

motor.

120°F (48.9°C) and reopen at 100°F (37.8°C).

refer to "Oven fan will not run".

main fan is activated. Adjust if necessary (Refer to

page 23). Replace if defective.

Terminals are normally closed. If open, reset and

test oven for proper operation. If thermostat will not

hold for maximum oven temperature, and oven is

not exceeding temperature dial setting, check for

proper location of capillary bulb in its spring holder.

If above checks okay, replace hi-limit thermostat.

Impinger II –Advantage Service Manual - Domestic

13

Page 14

Temperature Control Check for supply voltage at temperature control. If

no voltage is present, trace wiring back to hi-limit

thermostat. Turn the temperature adjustment knob

to maximum temperature position and check for

208/240 VAC at the load terminals 7 and 8. If

208/240 VAC is present and unit is not heating,

refer to "Mercury Contactor" for next check. If

208/240 VAC is not present, proceed.

Thermocouple Probe WITH POWER ON AND THERMOCOUPLE

LEADS ATTACHED TO THE TEMPERATURE

CONTROL BOARD: measure D.C. millivolt output

of these leads. Refer to thermocouple chart in

Section D for proper readings. If these readings

are not achieved, replace thermocouple.

Temperature Control

Potentiometer

Disconnect the potentiometer leads from the board.

Place ohm meter test leads on the blue and green

pot. leads. Reading should be 1 K ohms.

Place meter leads across the blue and purple pot.

leads and rotate knob from high to low. Repeat on

green and purple leads. Check for even rise and

fall of ohms reading to insure that there are no open

or dead spots in the potentiometer. Check each

lead to ground for shorts. Replace pot if it does not

meet the above test.

Mercury Contactor Check for supply voltage to the contactor coil. If

voltage is present and the contactor will not

activate, replace the contactor. Also, check each

contactor for proper high voltage input and output.

Heater Elements Check the a m p draw on each hot leg for proper

load. Check the specifications plate for rating

information. If the amp draw is low or high, check

the individual elements for opens, shorts, and

proper resistance. WITH POWER OFF: To check

resistance of the elements, remove all leads from

the elements and use an accurate digital VOM.

The element resistance should be as follows:

208V - 27 ohms approximately

240V - 36 ohms approximately

Oven heats with switch off Mercury Contactor The mercury contactor has probably malfunctioned

in the closed position. If there is no voltage to the

operating coil, but there is high voltage at the

contactor out put, replace the mercury contactor.

Intermittent Heating Thermal/Overload of motor The main fan motor is equipped with internal

thermal protection and will cease to operate if

overheating occurs. As the motor overheats and

then cools, this will cause the oven to cycle on and

off intermittently. This may be caused by improper

ventilation or preventive maintenance. Also, most

of the problems listed under "Oven will not heat"

can cause intermittent failure.

Conveyor will not run Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 208/240 VAC.

If not present, check breakers.

10 Amp Fuse Check and/or replace.

Fuseholder Check and/or replace.

Fan Switch See procedure for checking on page 8.

14

Impinger II – Advantage Service Manual - Domestic

Page 15

Speed Adjustment

Potentiometer

This is a 0 to 10 K ohm, 1 turn potentiometer. With

power off, remove the black and white pot leads

from the motor control board at terminals P1, P2.

Place the meter leads on the black lead (P2) and

on the white lead (P1). Rotating the pot., slowly,

from low to high, the meter reading should show an

even transition from 0 to 10 K ohms ± 5%. There

should be no dead or open spots through out the 1

turn of the pot. Check both leads to ground. There

should be no continuity to ground. If any of the

above checks fail, replace the pot.

DC Motor Control Board Check for 208/240 VAC input to the control board at

terminals L1 and L2. If not present, check wiring

back to the oven fan switch. If voltage is present at

L1 and L2, check both fuses on control board (8A

line and 1A armature), check the VDC output at

terminals A+ and A-. If voltage is present at

terminals L1 and L2, and DC voltage is present at

A+ and A-, but motor does not run, check gear

motor as follows.

Conveyor Gear Motor If DC voltage is present at A+ and A- and the motor

does not run, first check the mini breaker and then

the conveyor. Refer to the next possible cause.

Check the leads to the motor for evidence of any

shorts or opens, and each lead to ground. Check

motor brushes. From the top of the motor, rotate

motor shaft to determine if there is a locked rotor or

a locked gear box (use care so magnet and H.S.

board are not damaged). Replace motor as

needed.

Conveyor Check for any mechanical misalignment. Also

check for worn bearings. A conveyor belt that is

over tightened will cause excessive bearing wear

and sometimes, irregular speed.

Conveyor speed varying or

intermittent

Power Supply Check power supply at the DC control board for the

208/240 VAC at board terminals L1 and L2.

Motor Control Board Place the test meter probes on terminals A+ and A-.

(With speed potentiometer set to maximum speed

(Approximately 2 minutes), the meter reading

should be approximately 100 VDC (± 3%), if voltage

is not steady within limits, then the board is

probably bad. Always check the speed pot. Be

sure it is okay before changing a board. This test is

not always 100% accurate as this test is not

performed at operating speeds. However, this test

is the best method currently available.

DC Gearmotor If the DC control board is steady, then the problem

may be the motor or gearbox. Check the brushes

in the motor for excessive arching and/or unusual

wear. Check the motor and gearbox from

instruction located on page 14 under "possible

cause" listing "conveyor gear motor."

Magnet Check to insure that the magnet (cemented to shaft

of conveyor drive motor) has not been damaged, or

come loose from motor shaft. Replace as needed.

Impinger II –Advantage Service Manual - Domestic

15

Page 16

Hall Effect Sensor Check for any physical damage to hall effect sensor

(mounted on conveyor drive motor.) Check all

wiring and connections for damage. check all

connections for damage. Check all connections for

tightness or proper location and check all wiring for

visible damage. Replace as needed . Connect

new hall effect to system and check for steady

operation.

Temp. Display inoperative

Display Transformer Measure the transformer primary for input, if

voltage is not present, trace wiring back to the oven

power source. Measure the secondary output,

which will normally by 12-15 VAC. Voltage across

terminals 1 and 3 on the time/temp. display should

read 12-15 VAC. Terminals 1-2 and 2-3 should be

1/2 the voltage reading from 1-3. if the above

secondary readings are not achieved, replace

transformer

Temperature Display If proper voltage is present at terminals 1, 2, and 3

on temperature display, but the display is not

lighted, recheck all connections for tightness.

Temperature display is still not operating, replace

the temperature display.

Temp. Display inaccurate,

erratic or inoperative

Thermocouple Place the thermocouple of a pyrometer into the

center of the top finger. Be sure the tip of the

thermocouple is not touching metal, it must sense

air temperature only. The pyrometer will indicate

oven temperature.

Measure DC millivolts of thermocouple at the

temperature display. See thermocouple chart on

page 19 for proper readings. Replace

thermocouple if proper readings are not achieved.

If readings are correct on the thermocouple, replace

temperature display.

16

Impinger II – Advantage Service Manual - Domestic

Page 17

REMOV AL, INST ALLATION, AND ADJUSTMENT

IMPINGER II ADVANTAGE

CAUTION!

BEFORE REMOVING OR INSTALLING ANY COMPONENT IN THE IMPINGER OVEN, BE SURE TO DISCONNECT

ELECTRICAL POWER AND GAS SUPPLY.

MOTOR, MAIN FAN

1. Shut off power at main breaker.

2. Remove motor cover from back of oven.

3. Remove wires for motor and mark for reassembly.

4. Remove hex head bolts from the oven back and slide back straight out of the oven.

5. Loosen bolt from fan hub and remove fan from motor shaft.

NOTE: Measure distance from fan blade to rear wall assembly before removal to aid in reassembly.

6. Remove the bolts from the motor mount and remove motor clamp. Slide the motor assembly out of the

oven back.

7. Remove motor by removing the four (4) mounting nuts and washers.

8. Reassemble in reverse order. When motor mount assembly is set on the oven back, align motor shaft in

the center of the hole. Set fan assembly on the motor shaft.

NOTE: It is recommended that an anti-seize compound be brushed on to the bolts around the back and

motor mount bracket before assembly.

FAN, MAIN

1. Shut off power at main breaker.

2. Remove back assembly. (See motor, main fan)

3. Reinstall and locate fan so that the bottom of the fan spider is 1 1/2" from the top of the oven back cone.

(See drawing)

FAN SPIDER

NOTE: MEASUREMENT MUST BE

MADE FROM CONE TO FAN SPIDER

FAN HUB

CONE

CAPACITOR, MOTOR

1. Shut off power at main breaker.

2. Remove control box cover and front panel.

3. Discharge capacitor.

4. Remove and replace.

ON/OFF SWITCH - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box cover.

3. Remove front panel.

4. Depress spring clips on side of switch and push out.

5. Remove wires from back of switch, note wire number and location.

6. Reassemble in reverse order and check system operation.

NOTE: Make sure switch housing is fully seated in control box housing.

Impinger II –Advantage Service Manual - Domestic

1 1/2 INCH

17

Page 18

FUSE HOLDER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box cover and front panel.

3. Remove wires from fuse holder and mark for reassembly.

4. Remove mounting screws or mounting nut on fuse holder. Push fuse holder out.

5. Reassemble in reverse order.

THERMOSTAT, CONTROL BOX HI-LIMIT - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box cover and front panel.

3. Remove wires from thermostat and mark for reassembly.

4. Remove mounting screws and nuts and remove thermostat.

5. Reassemble in reverse order.

NOTE: Push reset button on new thermostat.

COOLING FAN, CONTROL BOX

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove four (4) screws from the fan frame.

4. Disconnect cord and plug and remove fan.

5. Reassemble in reverse order.

THERMOSTAT, COOLING FAN

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove lead wires and mark for reassembly.

4. Remove two (2) screws and remove thermostat.

5. Reassemble in reverse order.

BURNER BLOWER MOTOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Unplug motor connector.

4. Remove three (3) screws from blower tube at burner housing.

5. Remove air shutter assembly from old motor for installation on new motor assembly.

6. Reassemble in reverse order and check system operation.

NOTE: Check air shutter at approximately 1/2 open and adjust to get a blue flame with an occasional tip of yellow

under high flame. A view port in the burner assembly should be used to observe flame.

HIGH LIMIT THERMOSTAT - REPLACEMENT

1. Remove control panel top and front cover.

2. Remove conveyor and bottom finger assembly.

3. Remove capillary bulb from bracket in oven chamber and pull through tube into control box.

4. Remove two (2) wires from thermostat, note wire numbers and location for reinstallation.

5. Remove mounting nut and remove thermostat.

6. Reassemble in reverse order making sure capillary tube is placed securely in the bracket.

NOTE: Depress reset button to insure thermostat is set for operation.

18

Impinger II – Advantage Service Manual - Domestic

Page 19

BURNER TRANSFORMER - REPLACEMENT

1. Shut power off at main breaker.

2. Remove control panel top and front cover.

3. Remove two (2) wires on primary side, note color and location.

4. Remove two (2) wires on secondary side, note color and location.

5. Remove two (2) screws from transformer base and replace assembly.

6. Reinstall in reverse order and check system operation.

THERMOCOUPLE - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Slide thermocouple out of oven chamber.

NOTE: Remove conveyor and bottom finger assembly to aid in removal and installation of thermocouple.

4. Remove two (2) wires from temperature control. Make note of wire numbers or color and location for

reinstallation.

5. Reassemble in reverse order making sure the metal end on the thermocouple is securely held in the wire

form in the oven chamber.

THERMOCOUPLE MEASUREMENT CHART:

INFORMATION:

When two wires composed of dissimilar metals are joined together and one of the ends is heated, a continuous current

flow is generated. We use an iron constant (Type J) thermocouple. The iron wire increases the number of dissimilar

junctions in the circuit.

It is possible to check a thermocouple with a properly calibrated D.C. millivolt meter. At 32°F, the millivolt reading should

be 0.00. This can be checked by inserting the thermocouple into an ice bath.

The millivolt reading at 72°F should be 1.134.

When using the following chart, the temperature at the terminal connections must be noted. This temperature is called

the Junction Temperature.

The following chart lists the thermocouple millivolt readings from 200°F to 600°F.

EXPLANATION: The junction temperature is the ambient air temperature where the thermocouple fastens to the

electronic temperature control.

200°F 250°F 300°F 325°F 350°F 400°F 425°F 450°F 500°F 550°F 600°F

90°F 3.26 4.77 6.30 7.06 7.83 9.37 10.14 10.91 12.46 14.00 15.53

J

88°F 3.32 4.83 6.36 7.12 7.89 9.43 10.20 10.97 12.51 14.05 15.59

U

86°F 3.37 4.88 6.41 7.17 7.94 9.49 10.26 11.03 12.57 14.11 15.65

N

84°F 3.43 4.94 6.47 7.23 8.00 9.54 10.31 11.09 12.63 14.19 15.71

C

82°F 3.49 5.00 6.53 7.29 8.06 9.60 10.37 11.14 12.69 14.23 15.76

T

80°F 3.55 5.06 6.59 7.35 8.12 9.66 10.43 11.20 12.74 14.28 15.82

I

78°F 3.60 5.11 6.64 7.40 8.17 9.72 10.49 11.26 12.80 14.34 15.86

O

76°F 3.66 5.17 6.70 7.46 8.23 9.77 10.55 11.32 12.86 14.40 15.94

N

75°F 3.69 5.20 6.73 7.49 5.26 9.80 10.57 11.35 12.89 14.43 15.97

74°F 3.72 5.23 6.76 7.52 8.29 9.83 10.60 11.37 12.92 14.46 15.99

72°F 3.78 5.29 6.82 7.58 8.35 9.89 10.66 11.43 12.97 14.51 16.05

70°F 3.83 5.34 6.87 7.63 8.40 9.95 10.72 11.49 13.03 14.57 16.11

T

68°F 3.89 5.40 6.93 7.69 8.46 10.00 10.78 11.55 13.09 14.63 16.17

E

66°F 3.95 5.46 6.99 7.75 8.52 10.06 10.83 11.61 13.15 14.69 16.23

M

64°F 4.01 5.52 7.05 7.81 8.58 10.12 10.89 11.66 13.20 14.74 16.28

P

62°F 4.06 5.57 7.10 7.86 8.63 10.18 10.95 11.72 13.26 14.80 16.34

60°F 4.12 5.63 7.16 7.92 8.69 10.24 11.01 11.78 13.32 14.86 16.40

O V E N T E M P

Impinger II –Advantage Service Manual - Domestic

19

Page 20

ELECTRONIC TEMPERATURE CONTROL BOARD - REPLACE M ENT

1. Remove control box cover.

2. Disconnect wires and molded connector and mark for reinstallation.

3. Depress nylon clips and remove circuit board from mounting bracket.

4. Reassemble in reverse order and check operation.

ELECTRONIC TEMPERATURE CONTROL BOARD - CALIBRATION

1. Place the thermocouple of your test meter through a finger hole in the top center of the oven.

2. With temperature dial fully counter clockwise, align dial red line over "CAL" mark on temperature scale

and tighten dial knob.

3. Turn temperature dial fully clockwise, adjust pot on temperature control to achieve 575°F on temperature

meter.

4. Set dial to 500°F. Adjust dial to match actual temperature.

5. Seal adjustment pot with glyptol or nail polish.

TEMPERATURE CONTROL POTENTIOMETER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Loosen two (2) allen screws and remove knob by sliding off shaft.

4. Remove mounting nut from potentiometer shaft and push out.

5. Unplug wire connector from control board.

6. Reassemble in reverse order and check system operation.

HEAT LIGHT - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front panel.

3. Remove two wires from burner light, note number and location.

4. Grasp body of light assembly and slide sideways to remove.

5. Reassemble in reverse order and check.

BURNER CONTROL - HONEYWELL - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove wires from control, note wire numbers and location for reassembly.

4. Remove screws from control and replace.

5. Reassemble in reverse order and check system operation.

GAS VALVE - REPLACEMENT

1. Shut off power at main breaker.

2. Shut off the gas supply in the main line to the oven.

3. Disconnect the flexible gas hose.

4. Remove the control panel top and front panel.

5. Remove the manual gas shut off valve from piping.

6. Remove screws from the bulkhead plate located on rear of oven at the gas pipe.

7. Remove the section of gas pipe to gas valve.

8. Disconnect the electrical leads from the solenoid valve. Disconnect bypass tube.

9. Loosen the gas line union located near the burner and remove the gas valve and piping assembly.

10. Finish removal of the gas piping from gas valve.

11. Reassemble in reverse order.

12. Check all gas fittings for leaks.

13. Adjust the gas manifold pressure on the gas valve. "Refer to the specification plate on the oven for

proper rating."

20

Impinger II – Advantage Service Manual - Domestic

Page 21

BYPASS ORIFICE

1. Shut off power at main breaker.

2. Shut off gas supply to oven.

3. Remove control panel top and front cover.

4. Remove pilot tube from bypass orifice and remove orifice.

5. Reassemble in reverse order.

TEMPERATURE REGULATION VALVE - REPLACEMENT

1. Shut off power at main breaker.

2. Shut off gas supply.

3. Remove control panel top and front cover.

4. Remove bypass tube from burner manifold.

5. Disconnect wires from valve and mark wires for reassembly.

6. Remove (4) nuts from burner manifold and loosen pipe union.

7. Remove temperature control valve and piping.

8. Remove piping from valve and reassemble in reverse order.

9. Check all pipe fittings for leaks.

HOT SURFACE IGNITOR - REPLACEMENT

1. Shut off the power at main breaker.

2. Shut off the gas supply in the main line to the oven.

3. Remove control panel top and front cover.

4. Remove Gearmotor, DC, Conveyor.

5. Remove electrical plug from the burner cap.

6. Remove "Temperature Regulation Valve."

7. Remove 3 screws holding burner cap to burner tube.

8. Pull out on burner cap removing cap and burner venturi.

9. The hot surface ignitor is held in place on the burner venturi by one nut, loosen nut and remove ignitor.

10. Replace in reverse order.

NOTE: Care must be used when handling the hot surface ignitor as they are quite fragile and may be easily

broken if dropped or bumped.

MAIN BURNER ORIFICE - REPLACEMENT

1. Shut off power at main breaker.

2. Shut off gas supply.

3. Remove control panel top and front cover.

4. Remove burner manifold, see "Temperature Regulation Valve."

5. Remove main burner orifice from burner manifold.

6. Reassemble in reverse order.

7. Check all pipe fittings for gas leaks.

CONVEYOR CONTROL POTENTIOMETER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Loosen two (2) allen screws and remove knob by sliding off shaft.

4. Remove mounting nut from potentiometer shaft and push out.

5. Unplug wire connector from conveyor control board.

6. Reassemble in reverse order and check system operation.

Impinger II –Advantage Service Manual - Domestic

21

Page 22

CONVEYOR CONTROL BOARD - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Disconnect wiring (push on connectors) from control board, note proper location of connectors for

reinstallation and exchange boards on the mounting bracket before reinstallation.

4. Remove mounting screws from control assembly.

5. Reassemble in reverse order and check system operation.

NOTE: Be sure that jumper (on conveyor control) is set to the proper (120/240) position.

CONVEYOR CONTROL BOARD - CALIBRATION

1. Connect digital volt meter to the hall effect sensor. Black meter lead connected to black hall effect sensor

lead, red meter lead to white hall effect sensor lead.

2. Turn conveyor control knob fully counter clockwise. Loosen knob and align with calibration line and

tighten knob.

3. Set knob to one minute setting. Adjust "max" pot on conveyor control to 327.5 Hz.

4. Set control knob to 30 minute setting, and adjust "min" pot on conveyor control to 10.9 Hz. Recheck at

one minute and 30 minutes until proper readings are achieved. Seal pots with glyptol or nail polish.

CIRCUIT BREAKER

1. Shut off power at main breaker.

2. Remove control panel top and front panel.

3. Disconnect two (2) wires from circuit breaker.

4. Remove knurled mounting nut and push out.

5. Reassemble in reverse order.

NOTE: Be sure to reset breaker before operating.

CONVEYOR DRIVE MOTOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove control panel top and front cover.

4. Disconnect wiring from motor and mark for reassembly.

5. Remove coupling from motor drive shaft.

6. Remove 4 screws and remove conveyor motor and mounting bracket.

7. Remove mounting bracket from conveyor motor assembly.

8. Reassemble in reverse order.

REVERSING CONVEYOR DIRECTION

1. Shut off power at main breaker.

2. Remove control panel top.

3. Remove cover from relay box.

4. Reverse wires fastened to terminals A+ and A- on conveyor control board. (See schematic diagram for

wire numbers.)

5. Reassemble in reverse order.

22

Impinger II – Advantage Service Manual - Domestic

Page 23

HALL EFFECT SENSOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove conveyor motor assembly.

4. Remove wire connector from hall effect sensor board.

5. Remove two (2) screws from conveyor drive motor.

6. Remove sensor board from mounting bracket.

7. Reassemble in reverse order.

8. Reinstall plug on hall effect sensor board and check conveyor system operation.

9. Replace control box covers and check system operation.

TEMPERATURE DISPLAY TRANSFORMER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove two (2) wires on primary side, note color and location.

4. Remove three (3) wires on secondary side, note color and location.

5. Remove two (2) screws from transformer base and replace assembly.

6. Reinstall in reverse order and check system operation.

TEMPERATURE DISPLAY - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove all wires from temperature display and mark wires for reassembly.

4. Pry temperature display to remove from mounting tabs (this is a pressure fit).

5. Reassemble in reverse order.

CALIBRATION OF TEMPERATURE DISPLAY

1. Place the thermocouple of your test meter through a finger hole in the top center of the oven. Pre-heat

the oven to 500°F for 30 minutes.

2. Set switch on back of temperature display to read desired temperature (°F or °C).

3. Adjust "Temp. Adj." pot on back of temperature display until display matches actual oven temperature.

MERCURY CONTACTOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Disconnect all wires and mark for reassembly.

4. Remove screws from mounting bracket and remove contactor.

5. Reassemble in reverse order.

AIR PRESSURE SWITCH - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front conveyor.

3. Disconnect wiring and mark for reassembly.

4. Disconnect air tube.

5. Remove mounting screws.

6. Reassemble in reverse order.

7. Turn on power and calibrate air switch as follows:

• Turn adjusting screw counter-clockwise to full out position.

• Turn oven on.

• Turn adjusting screw clockwise until heat shuts off.

• Turn adjusting screw counter-clockwise 1/4 turn and unit should heat.

Impinger II –Advantage Service Manual - Domestic

23

Page 24

HEATING ELEMENT - REPLACEMENT

1. Shut off power at main breaker.

2. Remove back cover.

3. Disconnect heater element wires and mark for reassembly.

4. Disconnect motor wiring and mark for reassembly.

5. Remove oven back from oven.

6. Remove fan shroud.

7. Heater element may now be unbolted and removed.

8. Check heater elements to be sure they ar the proper replacement.

9. Reassemble in reverse order. Apply anti-seize compound to back bolt threads before reassembly.

NOTE: Be sure the lead terminals are tight. If the leads are not tight, a loose connection will result, causing

arcing and lead wire burn off.

BEARING, CONVEYOR

1. Remove conveyor from oven and place on a flat work surface.

2. Remove connecting links from conveyor belting.

3. Move drive shaft or idle shaft toward end of conveyor, and shaft with bearing will now slip out of holding

bracket.

4. Replace bearing and reassemble.

24

Impinger II – Advantage Service Manual - Domestic

Page 25

This page intentionally left blank.

Impinger II –Advantage Service Manual - Domestic

25

Page 26

PARTS / GENERAL

LETTER PART NUMBER DESCRIPTION

A 369390 Caster 4” w/ Mounting Plate

B 369502 Bottom Finger Cover

C Columnating Panel, see Installation & Operations Manual

D 370010 Bottom Finger Housing

E 369504 Top Finger Housing

F Columnating Panel, see Installation & Operations Manual

G 369503 Top Finger Cover

H 369511 Oven Top

I 369659 Conveyo r Hole Cover

J 371066 Baffle

K 369211 Thumb Screw

L 370118 Cross Support

M 369231 Caster 4” w/ Threaded Stem

N 369232 Adjustable Leg

O 369919 Stand Side

P 370066 Plug

26

Impinger II – Advantage Service Manual - Domestic

Page 27

BLOW UP / GENERAL

Impinger II –Advantage Service Manual - Domestic

27

Page 28

PARTS / CONTROL BOX 1116-000-A, 1117-000-A

LETTER PART NUMBER DESCRIPTION

A 370108 Control Box Top

B 369128 Pilot Light

C 370073 Temperature Display

D 370107 Side Panel

E 370131 Operations Label

F 369845 Knob

G 350224 Lens, Yellow

H 369805 On/Off Switch

I 369809 Conveyor Potentiometer

J 369449 Temperature Potentiometer

K 369124 Cooling Fan

L 369537 Power Cord

M 369131 Thermocouple

N 370061 Conveyor Motor Assembly (Includes “O’ & “P”

O 369823 Hall Effect Sensor

P 370065 Magnet 16 Pole

Q 369901 Manifold Burner

R 369568 Venturi, Natural Gas

369938 Venturi, LP Gas

S 369552 Hot Surface Ignitor

T 369398 Solenoid Valve

U 369366 Burner Blower Motor

V 369401 Air Shutter Assembly

W 370072 Transformer, Temperature Display

X 369263 Gas Valve Nat/LP

Y 369556 Bypass Orifice, Nat.

369557 Bypass Orifice LP

Z 369531 Transformer 24 VAC, Burner

AA 370064 Circuit Breaker .4 Amp

BB 357067 Thermostat, Hi-Limit, Oven Cavity

CC 369192 Capacitor

DD 369532 Ignition Control

EE 369507 Thermostat, Cooling Fan

FF 369431 Thermostat, Control Box Hi Limit

GG 369465 Electronic Temperature Control

HH 370074 Conveyor Control

II 369856 Stand-Off Support

JJ 369166 Fuse, 10 Amp

KK 369129 Fuseholder

LL 369331 Finger Guard

MM 369566 Main Burner Orifice Nat.

369524 Main Burner Orifice LP

28

Impinger II – Advantage Service Manual - Domestic

Page 29

BLOW UP / CONTROL BOX – 1116-000-A, 1117-000-A

Impinger II –Advantage Service Manual - Domestic

29

Page 30

PARTS / CONTROL BOX – 1130-000-A THRU 1133-000-A

LETTER PART NUM B ER DESCRIPTION

A 370108 Control Box Top

B 369467 Pilot Light

C 370073 Temperature Display

D 370107 Side Panel

E 370132 Operations Label

F 369845 Knob

G 350224 Lens, Yellow

H 369432 On/Off Switch

I 369809 Conveyor Potentiometer

J 369449 Temperature Potentiometer

K 370065 Magnet 16 Pole

L 369823 Hall Effect Sensor

M 370061 Conveyor Motor Assembly (Includes “K” &”L”)

N 369131 Thermocouple

O 369378 Cooling Fan

P 370067 Mercury Contactor 1 Phase

369479 Mercury Contactor 3 Phase

Q 370072 Transformer, Temperature Display

R 369025 Air Pressure Switch

S 369431 Thermostat, Control Box Hi Limit

T 369507 Thermostat, Cooling Fan

U 369465 Electronic Temperature Control

V 369856 Support, Stand Off

W 370074 Conveyor Control

X 369192 Capacitor

Y 357067 Thermostat, Oven Cavity Hi Limit

Z 370064 Circuit Breaker

AA 370134 Electric Box Cover

BB 370133 Electric Box

CC 353082 Ground Lug

DD 369129 Fuseholder

EE 369166 Fuse 10 Amp

FF 369331 Finger Guard

30

Impinger II – Advantage Service Manual - Domestic

Page 31

BLOW UP / CONTROL BOX – 1130-000-A THRU 1133-000-A

Impinger II –Advantage Service Manual - Domestic

31

Page 32

PARTS / CONVEYOR & DOOR

LETTER PART NUMBER DESCRIPTION

A 369611 Coupler

B 369664 Coupling Center

C 369269 Ball Plunger

D 370116 Set Screw

E 369223 Crumb Pan, Right

F 369224 Crumb Pan, Left

G 369666 Conveyor Frame Assembly

H 369226 Pan Stop

J 369516 Conveyor Bearing

K 369514 Idler Shaft

L

369978 Set Screw

M 369238 Drive Shaft

N 369513 Hinge

O 369510 Door Assembly (Includes N, P, and Q)

P 370016 Impinger Nameplate

Q 369501 Door Latch & Catch

R 1123D Door With Window (Includes N, P, and Q)

S 369927 Window Frame, op

T 369925 Glass, Access Window

U 369926 Window Frame, Bottom

W 369929 Retainer, Window

X 369165 Splice Clip, Conveyor Belt

Y

369515 Sprocket, Regular Conveyor

370509 Sprocket, Heavy-Duty Conveyor

369194 Conveyor Belt (Complete), Regular Conveyor

363394 Conveyor Belt (1-Foot Section), Regular Conveyor

370155 Conveyor Belt (Complete), Heavy-Duty Conveyor

370157 Conveyor Belt (1-Foot Section), Heavy-Duty Conveyor

32

Impinger II – Advantage Service Manual - Domestic

Page 33

BLOW UP / CONVEYOR & DOOR

Impinger II –Advantage Service Manual - Domestic

33

Page 34

PARTS / OVEN BACK ASSEMBLY

LETTER PART NUMBER DESCRIPTION

A 369182 Fan

B 369899 Fan Shroud

C 369655 Stand Off

D 369183 Heating Element 208V

369184 Heating Element 240V

E 369976 Rear Wall, Gas Ovens

369549 Rear Wall, Electric Ovens

F 369581 Motor Mount

G 369539 Motor, Gas Ovens, 120V

369181 Motor, Electric Ovens, 208/240V

H 369695 Motor Bracket

I 369033 Motor Clamps

J 369681 Cover, Back

K 369979 Bracket, Hi-Limit Thermostat

L 369227 Spring

M 369541 Bracket, Thermocouple

34

Impinger II – Advantage Service Manual - Domestic

Page 35

BLOW UP / OVEN BACK ASSEMBLY

Impinger II –Advantage Service Manual - Domestic

35

Page 36

36

Impinger II – Advantage Service Manual - Domestic

Loading...

Loading...