Page 1

FlowMaster™ Single Action Rotary Driven Hydraulic Pump

For 5 Gallon Pail/Container

Model: 85486 Series “A”

U. S. Patent No. 6,102,676

Foreign Patent Pending

This pump conforms to the European Directive for Product Safety

7.5A-18110-J00 Form 403566JUNE 2005

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Section

- A21 - 6H

Page

Page 2

FlowMaster™ Rotary Driven Hydraulic Pump

Table of Contents

Page

Safety ….…………………….....................................................2

Description..................................................................................2

Appropriate Use................................................................2

Pump Performance and Specifications..............................3

Installing the Pump.....................................................................3

Operation.....................................................................................4

Maintenance and Repair...........................................................4

Pump Dimensions.............................................................5

Repair Parts List............................................................................7

Trouble Shooting.........................................................................8

Safety

Read and carefully observe these operating instructions before

unpacking and operating the pump! The pump must be operated, maintained and repaired exclusively by

persons familiar with the operating instructions. Local safety

regulations regarding installation, operation and maintenance

must be followed.

Operate this pump only after safety instructions and this service manual are fully understood.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

Specialized equipment and knowledge is required for repair

of this pump. Contact the factory authorized warranty and

service center nearest you for repair or adjustments other than

maintenance specified in this manual.

Annual inspection by the factory authorized warranty and service center nearest you is recommended.

A list of factory authorized warranty and service centers is

available upon request.

Damaged Pumps

Any pump that appears to be damaged in any way, is badly

worn or operates abnormally, shall be removed from use until

repairs are made. Contact the factory authorized warranty and

service center nearest to you for repairs.

Description

General Description

The Lincoln Industrial FlowMaster Pump Model 85486 is a fully

hydraulically operated grease pump. Grease output is

proportional to the hydraulic input flow. The pump is

primarily designed for use in a 5 gallon pail or small

container.

The pump is driven by the rotary motion of the hydraulic motor.

Rotary motion is converted to reciprocating motion through an

eccentric crank mechanism. The reciprocating action causes

the pump cylinder to move up and down. The pump is a posi

tive displacement single acting pump. Grease output occurs

during the up stroke of the pump.

-

avoided, may result in minor or moderate injury.

Safety Instructions

This equipment generates very high grease pressure. Extreme caution should be used when operating this equipment

as material leaks from loose or ruptured

components can inject fluid through the skin and into the body

causing serious bodily injury. Adequate protection is recom

mended to prevent splashing of material onto the skin or into

the eyes.

If any fluid appears to penetrate the skin, get emergency

medical care immediately. Do not treat as a simple cut. Tell

attending physical exactly what fluid was injected.

-

Inspection

If overpressurizing of the equipment is believed to have occurred, contact the factory authorized warranty and service

center nearest you for inspection of the pump.

During the down stroke, the pump cylinder is extended into

the grease. Through the combination of shovel action and

vacuum generated in the pump cylinder chamber, the grease

is forced into the pump cylinder. During the upstroke, the inlet

check closes, and the grease taken in during the previous

stroke is transferred through the outlet check and discharged

to the outlet port. Typical output of the pump is shown on page

3, under Pump Performance and Specifications.

Appropriate Use

• The pump is exclusively designed to pump and dispense

lubricants using hydraulic power.

• The maximum specification ratings should not be

exceeded.

• Any other use not in accordance with instructions will

result in loss of claims for warranty and liability.

Do not exceed 450 PSIG (32 bar) maximum supply inlet hydraulic pressure. Exceeding the rated pressure may result in

damage to system components and personal injury.

Pump Performance and Specification

Maximum Output Pressure,

Page Number - 2

7.5A-18110-J00 Form 403566

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Page 3

FlowMaster™ Rotary Driven Hydraulic Pump

5

1

3

8

2

7

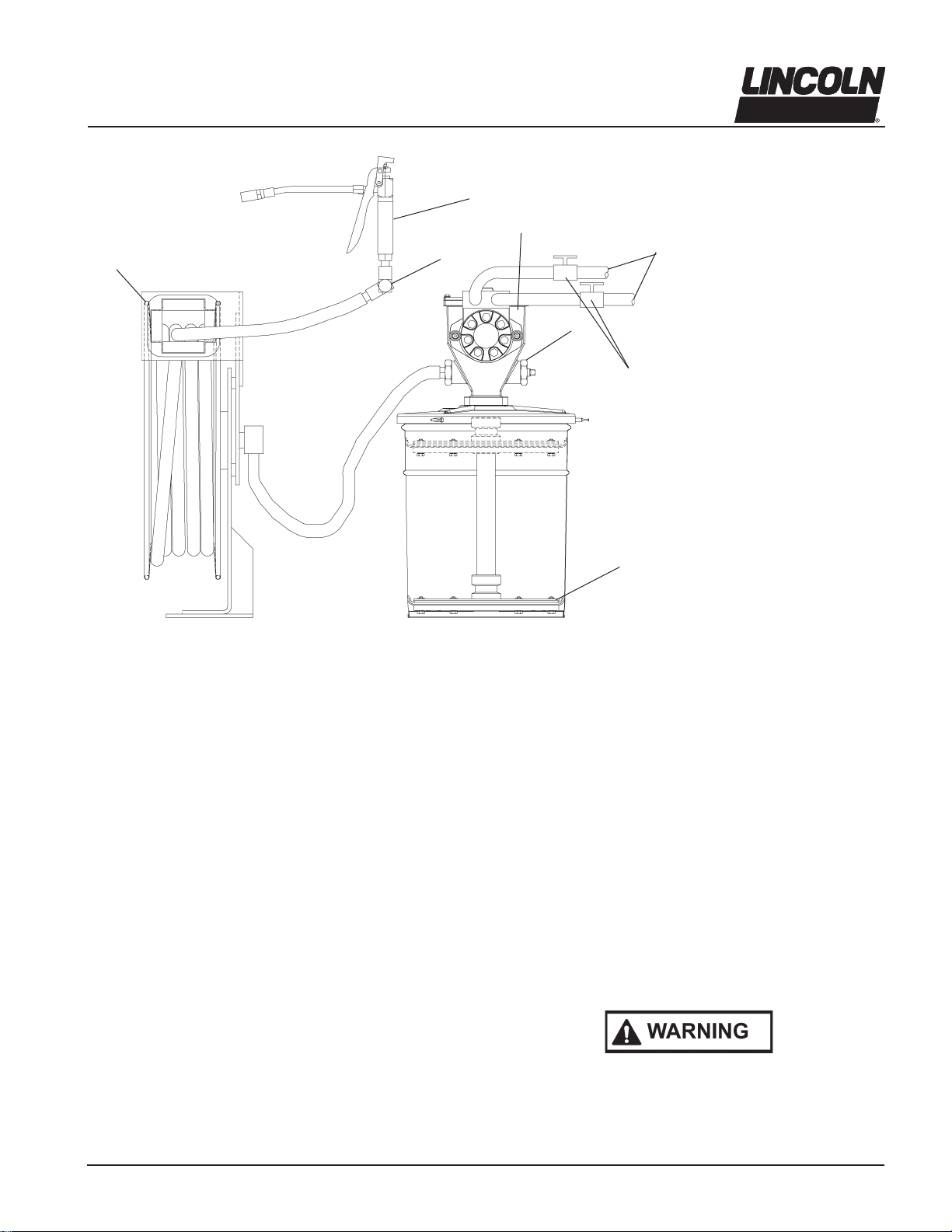

Typical Installation

PSIG (BAR) 4,500 (320)

Supply inlet hydraulic pressure,

maximum,PSIG (bar) -

Hydraulic Inlet Flow,

GPM (l/min) - Up to 7 (28)

Pump Ratio - 10:1

Operating Temperature,ºF (ºC)- -20 to +150 (-10 to 65)

Hydraulic Inlet Port, In - 7/8-14 UNF-2B (SAE-10)

Tank Return Port, In - 7/8-14 UNF-2B (SAE-10)

Pump Outlets, In - 1/4 NPTF

Maximum Pump Output - 22 in³/min. *

(244 grams/min)

Maximum Hydraulic

Fluid Temperature, ºF, (ºC) - 250 (121)

Weight, Lbs (Kg) - 36 (16)

Crankcase oil- 10 oz of API 10W30

motor oilSF-SC

* Tested with NLGI #2 grease and 1,000 PSI (68 bar)

backpressure at 5 gpm (19 l/pm)

450 (32)

6

4

1. Pump Model 85486

2. Plug, unused outlet

3. Hose Reel

4. Follower, Model 252725

5. Control Valve

6. Shut-off Valve

7. Hydraulic Power Supply

and Return

8. Swivel

Installing the Pump

Typical installation is shown only as a guide for selecting and

installing system components. Contact your Lincoln

Industrial representative for assistance in designing a

system to suit your specific needs.

The pump was tested in light weight oil which was left in to pro

tect the pump from corrosion. Flush the pump before

connecting it to the system to prevent contamination of the

grease with residual oil.

Use follower plate 252725 for a 35 lb (5 gallon) pail.

1. Mount the pump securely on the drum cover so that is

cannot move or vibrate during operation.

2. Attach hydraulic supply line and return line to the motor

ports. The pump will work in either direction.

3. Connect hose reel inlet line to the pump outlet. Plug the

unused outlet on the opposite side of the pump.

-

Assembling the Manifold

The pump is shipped without the manifold (33), manifold

mounting screws (32) and O-rings (34) assembled to the

hydraulic motor (36). Assemble these parts to the motor (36)

as shown in Illustration #1 on page 6. Torque screws to 20-25

ft. lbs.

Form 403566

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

7.5A-18110-J00

Mount the pump securely on the drum cover. Failure to do so

could result in personal injury and equipment damage.

Page Number - 3

Page 4

FlowMaster™ Rotary Driven Hydraulic Pump

3. Remove six self-threading Screws (29) and remove the

Housing Cover (30) and the Cover Gasket (31).

Do not exceed 450 PSIG (32 bar) working hydraulic pressure.

Use high pressure components to reduce risk of serious injury

including fluid injection and splashing in the eyes or on the skin.

All accessories connected to the pump outlet must have a work

ing pressure rating of at least 5,000 PSIG (345 bar).

Operation

Connect one port of the pump to a hydraulic power supply and

the other to the tank line. The pump motor will run in either

direction, so it makes no difference which port

connects to the power supply.

1. Slowly turn on the hydraulic flow until the pump begins to

run.

2. Prime the pump by slowly operating the pump until

lubricant begins to flow. Make sure that all air has been

expelled from the pump and even lubricant flow is achieved.

3. Adjust the pump pressure to the desired application

requirements. Do not exceed pump operating pressure of

450 PSIG (32 bar).

4. Always use the lowest pump output pressure to obtain the

desired results. This will reduce the pump wear.

Do not exceed maximum operating temperture of the hydraulic

fluid (200° F (93° C)). Recommended minimum hydraulic fluid

viscosity is 50 SUS. Never allow the pump to run dry of lubri

cant. A dry pump quickly speeds up,creating friction heat, which

can damage the seals. Monitor the supply lubricant level and

refill when necessary.

Maintenance & Repair

Relieve pressure from the pump and supply lines before

serviceing or repairing the pump, to reduce the risk of an

injury from injection, splashing fluid or moving parts.

Always use Lincoln Industrial parts for service and repair.

Disassembly Procedure (See illustration #1)

Tools Required:

- Hex Bit Socket Wrenches (3/8” square drive) with 3/8” hex,

5/32” hex, 1/4” hex.

- 3/8” O.D. Steel Rod, 8” long

- 12” Crescent Wrench

- Spanner Wrench (for 3/8” diameter tube, 1/8” pin)

- 1/2” to 3/8” square drive adapter

- Torque wrench (1/2” square drive, 0 - 50 ft-lb capacity)

- Torque wrench (3/8” square drive, 0 - 120 in-lb capacity)

- 1/4” nut driver

- Screwdriver (flat blade, 1/8” blade width)

1. Remove the four Socket Head Screws (32) and separate

Connection Manifold (33) from the Hydraulic Motor (36).

2. Remove Pipe Plug (39) and drain the crankcase oil from

the Pump Housing (40).

4. Remove Retaining Ring (51) and pull the Shovel Plug

(50) from the Housing Tube (49).

5. Remove two Socket Head Screws (38) and separate the

Hydraulic Motor (36) from the Pump Housing (40).

-

6. Remove two Outlet Pin Nuts (44) from the Pump Housing

(40).

7. Remove the Pump Subassembly (1 through 28) from

the Pump Housing (40). Pushing the subassembly up

with a wooden or plastic rod 3/4 O.D. against the Check

Seat Housing (28) is helpful.

8. Remove the Housing Tube (49) from the Pump Housing

(40) by inserting a 3/8” rod through the inlet holes at the

bottom of the Housing Tube (49) and unscrewing it.

9. Remove the Bronze Bearing (45), the O-Ring (46), and

the Backup Washer (47) from the Housing Tube (49).

10. Remove the Crankrod Assembly (1 through 8) from the

pump by unscrewing the Button Head Screws (12) and

then pulling out the Wrist Pin Bushings (13).

11. Remove the Check Seat Housing (28) from the

Reciprocating Tube (21). There is a 3/8 Allen Head

socket in the throat of the Check Seat Housing (28) to

facilitate removal.

12. Unscrew the Wrist Pin Anchor (14) from the

Reciprocating Tube (21) and pull the Plunger Assembly

(9 through 20) from the tube.

13. Using a 1/2” dia. wooden or plastic rod, push the Cup

Seal (22) and the Pump Cylinder (24) from the

Reciprocating Tube (21).

14. Remove the Pump Plunger (20) from the Plunger Link

Rod (17). A spanner wrench, which uses the holes in

the Pump Plunger, is required.

15. Unscrew the Plunger Link Rod (17) from the Plunger

Tube (11) and slide off the Cup Seal (16), the Backup

Washer (15) and the Wrist Pin Anchor (14).

16. Unscrew the Plunger Tube (11) from the Outlet Pin (9).

17. To dismantle the Crankrod Assembly (1 through 8),

remove Flat Head Screws (1) and the Counter

Weights (2).

18. Remove the Retaining Rings (6) and press the Ball

Bearing Assembly (6, 7, 8) out of the Crank Rod (5). Be

sure to press the Ball Bearing (8) on the outer race.

Pump Assembly Procedure

1. When the pump is dissembled, it is recommended to

replace all seals and gaskets, which are included in the

repair kit.

2. In the process of disassembly, examine the following

components and replace if excessive wear is indicated:

Ball Bearing (8), Crank Eccentric (7), Crankrod (5), Wrist

Pin Bushings (13), Plunger Tube (11), Pump Plunger and

Upper Check Parts (20, 19 and 18), Pump Cylinder (24),

Check Seat Housing and Lower Check Ball and seat (28

and 26), upper Bronze Bushing (45), Housing Tube (49),

Shovel Plug (50), and Reciprocating Tube (21).

3. Assembly Procedure is the reverse of the Disassembly

Procedure except for the following:

Page Number - 4

7.5A-18110-J00 Form 403566

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Page 5

FlowMaster™ Rotary Driven Hydraulic Pump

4. Install parts (22) through (28) into the Reciprocating Tube

(21) after the plunger assembly (9 through 20) is

installed.

5. Install the Pump Subassembly (1 through 28) into the

pump Housing (40) before tightening the Housing Tube

(49) to the Pump Housing (40). Be sure the

Reciprocating Tube (21) is inserted through both

bushings before tightening the Housing Tube (49).

6. Use loctite 242 (or similar product) medium strength

thread lock on all torqued threaded connections. Extreme

care must be exercised to prevent excess compound

from flowing into critical areas such as clearance fits and

ball check. Allow a minimum of 30 minutes cure time

before operating the pump.

7. Fill cranckcase with 10W30 motor oil up to the bottom off

the pipe plug (39).

8. Torque Specifications:

A. Plunger Tube (11) to Outlet Pin (9) - 100 to 110 In.-Lbs.

B. Button Head Screws (12) to Wrist Pin Anchor (14) 100

to 110 In.-Lbs.

5 13/16”

(148.5 mm)

C. Plunger Tube (11) to Plunger Link Rod (17) - 100 to

110 In.-Lbs.

D. Plunger Link Rod (17) to Pump Plunger (20) - 100 to

110 In.-Lbs.

E. Flat Head Screws (1) to Counter Weight (2) - 100 - 110

In.-Lbs.

F. Wrist Pin Anchor (14) to Reciprocating Tube (21) - 20 to

25 Ft.-Lbs.

G. Check Seat Housing (28) to Reciprocating Tube (21) 20 to 25 Ft.-Lbs.

H. Outlet Pin Nut (44) to Pump Housing (40) - 30 to 35 Ft. Lbs.

I. Housing Tube (49) to Pump housing (40) - 20 to 25 Ft. Lbs.

9. Fill crankcase with oil up to pipe plug (39) before

fastening housing cover (30) and housing gasket (31)

8 1/2”

(216 mm)

6 9/16”

(167 mm)

2 13/16

(71.5 mm)

2 1/4”

(57 mm)

1. SAE10© Inlet Port/Tank Port

2. 1/4 NPTF Pump Outlets

2.25”

(57 mm)

1/4-20 THD

2.25”

(57 mm)

5 3/16

(132 mm)

21 3/4”

(552 mm)

13 11/16”

(348 mm)

Form 403566

7.5A-18110-J00

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Page Number - 5

Page 6

FlowMaster™ Rotary Driven Hydraulic Pump

Page Number - 6

Illustration #1

53

52

55

54

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

252725 Follower Plate

Illustration #2

7.5A-18110-J00 Form 403566

56

Page 7

FlowMaster™ Rotary Driven Hydraulic Pump

Repair Parts List

(Common to all Models)

Item Qty Description All Item Qty Description All

No. Models No. Models

1 2 Flat Head Screw 30 1 Housing Cover 270629

(1/4 x 1-3/4) 270635 31 1 Cover Gasket

2 2 Counter Weight 272197 (Nitrile) *

4 2 Retaining Ring 270609 32 4 Socket Head

5 1 Crankrod 270665 Screw (5/16 x 1-1/4) 270680

6 2 Retaining Ring 270608 33 1 Manifold 270700

7 1 Crank Eccentric 270727 34 2 O-Ring (Viton) *

8 1 Ball Bearing 270607 35 1 Motor Gasket *

9 1 Outlet Pin 270670 36 1 Hydraulic Motor

10 1 O-Ring (Nitrile) * (Note #1) 274054©

11

1 Plunger Tube 270729 37 2 Washer 48548

12 2 Button Head Screw 38 2 Socket Head

(1/4 x 1/2) 270634 Screw (1/2 x 1-1/4) 270658

13 2 Wrist Pin Bushing 270668 39 1 Pipe Plug (3/8 NPTF) 67417

14 1 Wrist Pin Anchor 270731 40 1 Pump Housing 270673

15 1 Backup Washer * 41 2 Backup Ring (Polyurethane) *

16 1 Cup Seal 42 2 O-Ring (Polyurethane) *

(Polyurethane) * 43 2 O-Ring (Nitrile) *

17 1 Plunger Link Rod 270728 44 2 Outlet Pin Nut 270619

18 1 Spring 270616 45 1 Bronze Bearing 270674

19 1 Ball 66010 46 1 O-Ring (Polyurethane) *

20 1 Pump Plunger 270671 47 1 Backup Washer *

21 1 Reciprocating Tube 270642 48 1 O-Ring (Nitrile) *

22 1 Cup Seal 49 1 Housing Tube 270662

(Polyurethane) * 50 1 Shovel Plug 270730

23 1 O-Ring 51 1 Retaining Ring 270705

(Polyurethane) * 52 6 Nut 51412

24 1 Pump Cylinder 270672 53 1 O-Ring 249692

25 1 Ball Cage 270675 54 6 Bolts 249693

26 1 Ball 66001 55 1 Seal 249688

27 1 O-Ring (Nitrile) * 56 1 Seal 249687

28 1 Check Seat 270664 57 6 Gasket 252986

29 6 Self-Tapping© Soft parts Kit 249832

Screw (8 x 1/2) 270633

* Included in 249832 Soft Parts Kit.

1. Includes Gasket (Item 35) and O-Rings (Item 34).

© Indicates change

Form 403566

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

7.5A-18110-J00

Page Number - 7

Page 8

FlowMaster™ Rotary Driven Hydraulic Pump

Troubleshooting

Condition Possible Cause Corrective Action

Pump does not run. Closed supply line shut off valve. Open shut-off valve.

Insufficient Hydraulic Fluid supply. Check hydraulic supply for proper

pressure and flow.

Closed fluid outlet line. Check outlet line and clear

obstructions.

Pump is stalled due to grease Relieve grease backpressure.

backpressure.

Pump is seized or damaged. Dismantle the pump and repair

defective or seized component. See

disassembly and assembly

procedure.

Pump speeds up or runs erratically. Low level of grease or reservoir Refill reservoir.

is empty .

Follower plate is stuck and separated Check follower plate and container

from grease. for damage.

Pump piston or checks are worn. Disassemble the pump and repair.

Pump runs, but output is low. Insufficient hydraulic fluid supply. Check hydraulic supply and adjust

flow.

Inlet pressure too low. Increase pressure using valve 38.

Weepage from housing cover 30. Cup seal (16) or O-Ring (48) failure. Check the seals and replace if

necessary.

Pump becomes noisy. No crank case oil. Add crank case oil. Remove Pipe

Plug (39) from Pump Housing (40).

Oil level should be at the bottom of

the Pipe Plug opening. Add 10W30

motor oil until the crankcase is full.

Worn wrist pin bushing 13. Check the bushings and replace if

necessary.

Americas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Page Number - 8

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Europe/Africa:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

Asia/Pacific:

51 Changi Business Park

Central 2

#09-06 The Signature

Singapore 486066

Phone +65.6588.0188

Fax +65.6588.3438

© Copyright 2005 Printed in USA

Web site:

www.lincolnindustrial.com

7.5A-18110-J00 Form 403566

Loading...

Loading...