Page 1

SERVICE MANUAL

DUAL TECHNOLOGY FINISHER

MODEL 1920 SERIES

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Phone : (800) 374-3004

U.S. Fax: (888) 790-8193 • Int’l Fax: (260) 436-0735

Technical Service Hot Line

(800) 678-9511

www.lincolnfp.com

DTFsvcman REV 1/5/07

Page 2

SEQUENCE OF OPERATION

DUAL TECHNOLOGY FINISHER

1921 208VAC 60 HZ. 3 PHASE

1922 240VAC 60 HZ. 3 PHASE

POWER SUPPLY Electrical power to be supplied to the oven by a four conductor service for three phase.

Black conductor is hot.

Red conductor is hot.

Orange conductor is hot

Green conductor is ground.

MAIN FAN CIRCUIT Power is permanently supplied through the 10 amp fuses, through the normally closed

oven cavity hi-limit thermostat, to the normally open main power switch and to terminal

number 1 of the 30 minute cool down timer. Closing the main power switch enables the

30 minute cool down timer. The 30 minute cool down timer supplies line voltage to the

coil of the main fan relay, its contacts now close, supplying 208/240VAC to the main fan

motor. Voltage is also supplied to the primary of the control transformer, the conveyor

motor, the oven control and the infrared heater switch.

NOTE: Model 1922 ovens use a 240VAC to 208VAC step down transformer for the

main fan motor

TEMPERATURE CONTROL Closing the main power switch supplies 208/240VAC to the primary of the control

transformer. Secondary voltage, 24VAC, is supplied to the oven control. The oven

control is set to desired temperature. The thermocouple will provide varying millivolts to

the oven control. The oven control supplies 208/240VAC to the coil of the heater relay at

intermittent intervals to maintain the desired temperature. The display on the oven

control will indicate when the main heater relay is energized.

NOTE: The display also indicates oven temperature.

INFRARED HEAT Closing the infrared heater switch supplies line voltage to the coil of the infrared heater

relay, its contacts now close, supplying 208/240VAC to the infrared heaters.

CONVEYOR DRIVE Closing the main power switch supplies 208/240VAC to the primary of the control

transformer and, through the air pressure switch, the Infrared heater switch, to the

conveyor motor. Secondary voltage, 24VAC, is supplied to the oven control. Setting the

oven control to the desired time outputs voltage, through a reversing switch and

capacitor, to the conveyor motor.

NOTE: The conveyor system uses a hall effect sensor and magnet to prove operation of

the conveyor motor. If the conveyor motor is not running, “BELT JAM” is indicated on

the display.

AUTOMATIC COOL DOWN When the machine is started, the time delay relay timing circuit is enabled, permitting

the main fan to operate for approximately 30 minutes after the machine is shut off, to

cool the machine. The 30-minute time delay relay will keep the coil of the main fan relay

energized, maintaining operation of the main fan motor for 30 minutes.

2

DTF – 1920 Series Service Manual

Page 3

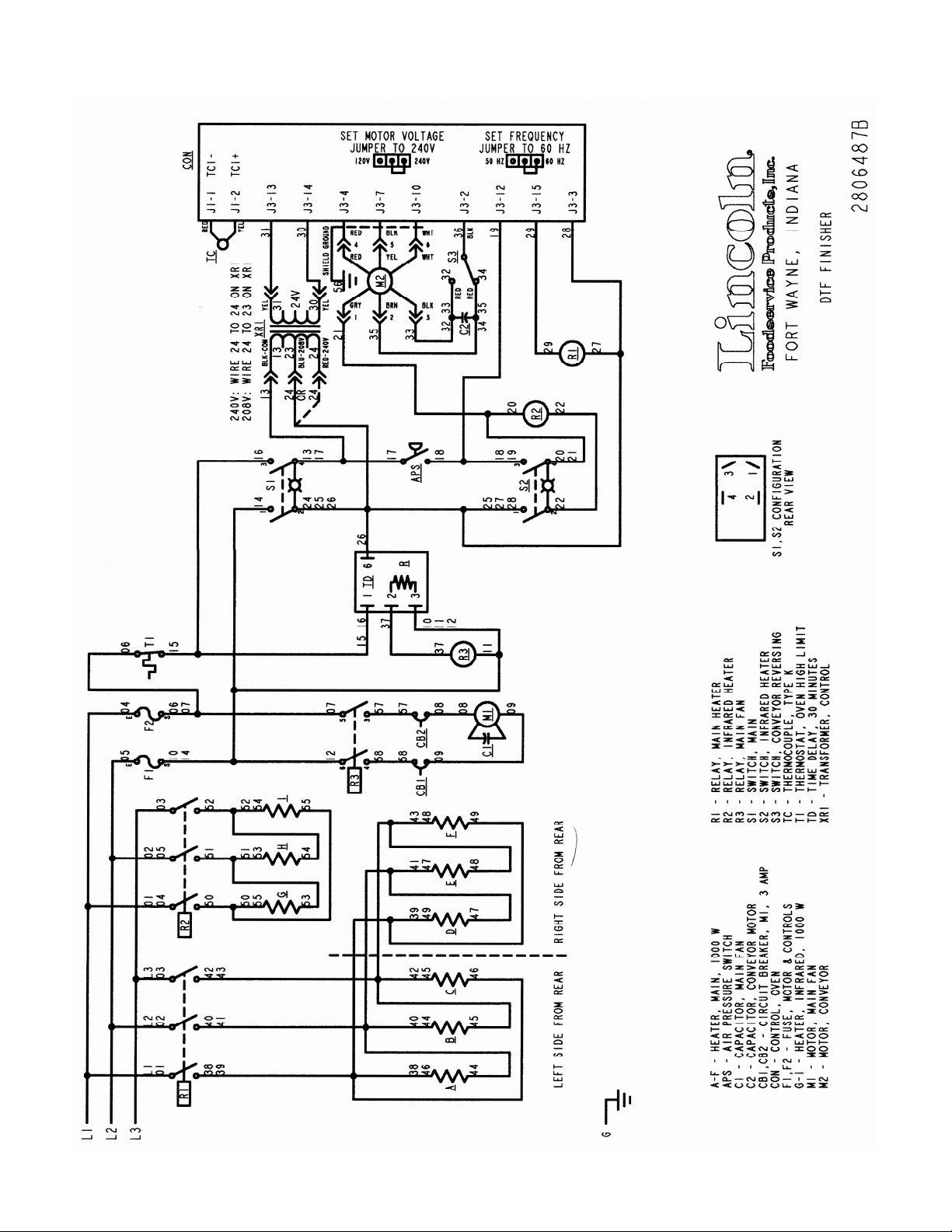

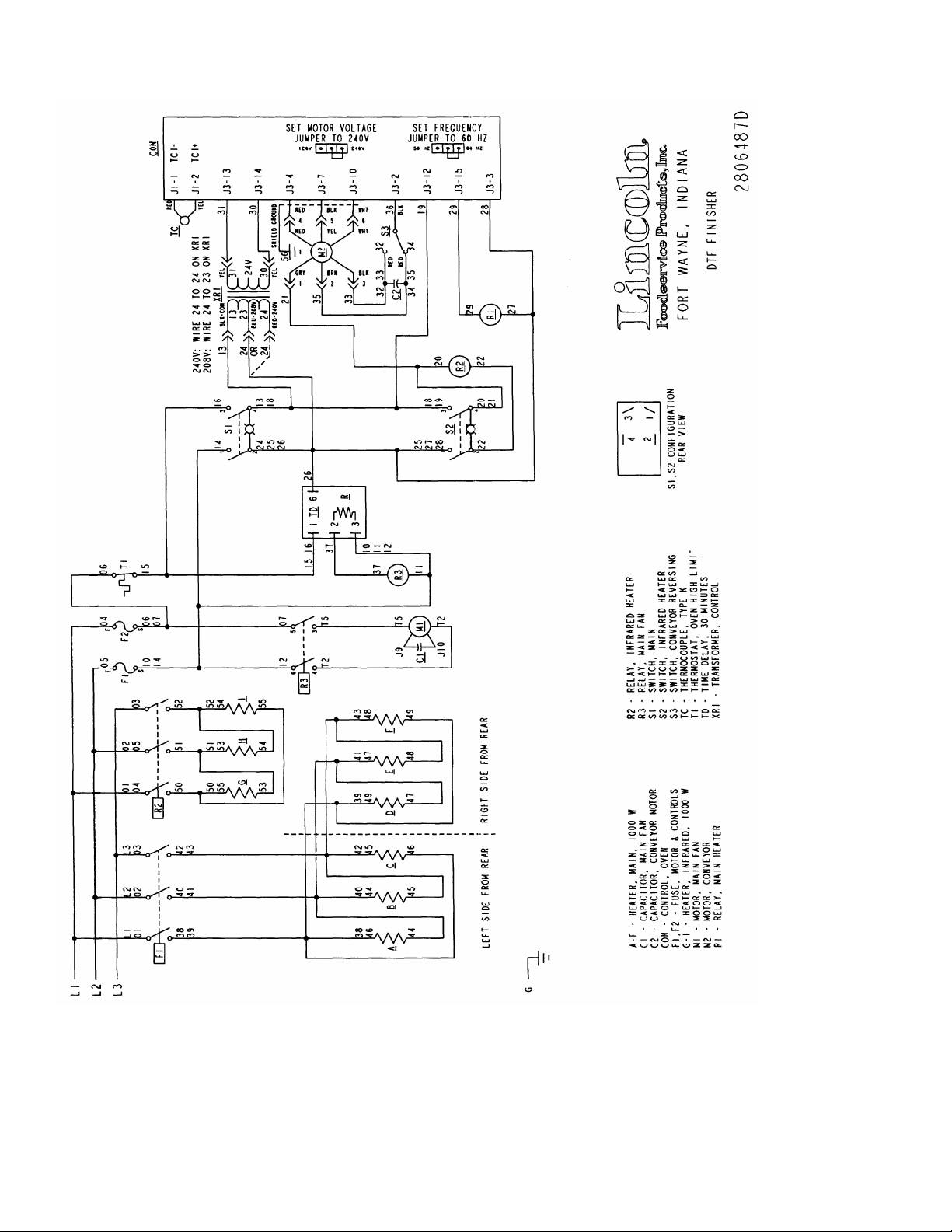

SCHEMATIC DIAGRAM

MODEL 1921 S/N 8001207 and Below

DTF – 1920 Series Service Manual

3

Page 4

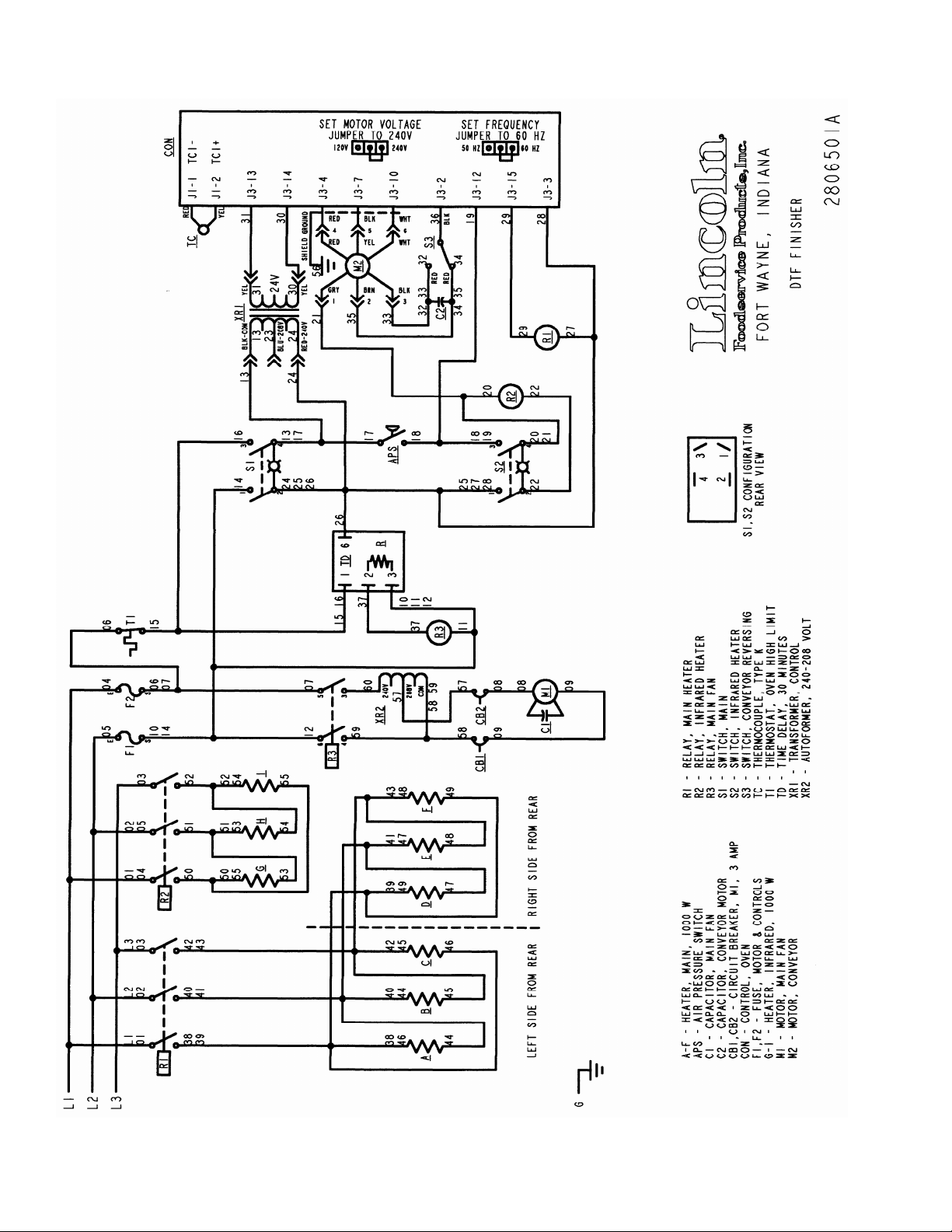

SCHEMATIC DIAGRAM

MODEL 1922 S/N 8001207 and Below

4

DTF – 1920 Series Service Manual

Page 5

SCHEMATIC DIAGRAM

MODEL 1921 / 1922 S/N 8001208 and Above

DTF – 1920 Series Service Manual

5

Page 6

TROUBLESHOOTING GUIDE

1921 208 VAC 60 HZ. 3 PHASE

1922 240 VAC 60 HZ. 3 PHASE

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run Incoming power supply Check circuit breakers. Reset if required. Call power

co. if needed.

Fuses, 10 Amp, motor and

controls

Fuse holder Check, replace if necessary.

Hi-limit thermostat,

Oven cavity

Switch, main power Check continuity between switch terminals. Replace

30 minute time delay relay Check for supply voltage to 30 minute time delay relay

Relay, main fan Check for supply voltage to relay contacts, if no voltage

Transformer, Motor

(MODEL 1922 ONLY)

Circuit breaker(s), 3A. Push and reset circuit breakers. Check for voltage to

Main fan motor Check for supply voltage at motor. If no voltage is

Capacitor Check for shorts or grounds.

Oven will not heat Main fan motor Check for main fan operation. If it is not operating, refer

Air pressure switch This normally open switch should close when the main

Check, replace if necessary.

Terminals are normally closed. If open, reset

thermostat and retest. If thermostat will not hold for

maximum oven temperature, and oven is not exceeding

temperature setting, check for proper location of

capillary bulb in its spring holder. If the capillary checks

okay, replace the hi-limit thermostat.

switch as needed.

at terminals #1 and #6. If no voltage is present, trace

wiring back to main power switch. If there is supply

voltage at terminals #1 and #6, check for output voltage

at terminals #2 and #3. If there is incoming voltage but

no output voltage, and the main power switch is on,

replace the 30 minute time delay relay.

is present, trace wiring back to power supply. Check for

supply voltage to the coil of the main fan relay. If no

voltage is present, trace wiring back to the 30 minute

time delay relay. If voltage is present, check to insure

contacts are closing. Replace as needed.

Check for 240 VAC supply to the transformer primary. If

no voltage is present, trace wiring back to relay. If

240VAC is present at transformer primary, check for

208VAC at the transformer secondary. If there is

primary voltage, but no secondary voltage, replace

transformer.

the circuit breaker. If no voltage is present, trace wiring

back to the main fan relay. If there is voltage present,

proceed. Check for continuity through the circuit

breaker, if the circuit breaker has been reset and there

is no continuity through the circuit breaker, replace the

circuit breaker.

present, trace wiring back to circuit breakers.

WITH POWER OFF: Check for opens, shorts or

grounds. Turn fan blade to check for locked rotor.

WARNING: Capacitor has a stored charge, discharge

before testing.

to “Oven fan will not run”.

fan is activated. Refer to the “Removal and installation”

section for proper adjustment. Replace as needed.

6

DTF – 1920 Series Service Manual

Page 7

Control transformer Check for 208/240VAC supply to the primary of the

control transformer. If no voltage is present, trace

wiring back to the main power switch. If voltage is

present, check for 24VAC at the transformer

secondary. If there is primary voltage, but no secondary

voltage, replace the control transformer.

Oven control Check for 24VAC supply to control. If no voltage is

present, trace wiring back to control transformer. If

24VAC is present, check for a read-out on the display.

If there is 24VAC supplied, but there is no read-out on

the control display, replace the oven control.

If there is a read-out on the control, set the control to

maximum temperature (see installation operations

manual for temperature adjustment). With the control

set at maximum temperature, check for supply voltage

to the oven control at terminals J3-12 and J3-3. If there

is no voltage present, trace wiring back to the air

pressure switch. If there is voltage present, check for

output voltage at the Main heater relay (R1). If there is

voltage at the Main heater relay, proceed to “Main

heater relay” for next check. If there is no voltage at the

Main heater relay, trace wiring back to the oven control.

If there is no voltage output at the oven control, check

the read-out on the control. If the control reads

“PROBE FAIL”, this indicates that the thermocouple

has failed or become disconnected from the oven

control.

Thermocouple Check to be sure that the thermocouple is securely

connected to the oven control. If the thermocouple is

connected to the oven control, and the control indicates

“PROBE FAIL”, disconnect the thermocouple from the

oven control and measure the resistance of the

thermocouple. The thermocouple should read approx.

11Ω. If these readings are not achieved, replace the

thermocouple. If these readings are correct, proceed.

Oven control If the thermocouple checks good, but the oven control

display indicates that there is a thermocouple failure,

replace the oven control. If the oven control indicates a

temperature reading but the oven will not heat,

proceed.

Thermocouple WITH POWER ON AND THERMOCOUPLE

ATTACHED TO THE OVEN CONTROL: Measure the

DC millivolt output of the thermocouple. Refer to the

thermocouple chart (located in the “Removal” section of

the manual) for proper millivolt readings. If these

readings are not achieved, replace thermocouple.

Oven control If the thermocouple checks good, but there is no

voltage output to the Main heater relay, replace the

oven control. If there is voltage output to the Main

heater relay, proceed.

Main heater relay Check for supply voltage to the relay coil. If voltage is

present and the relay will not activate, replace the Main

heater relay. Also check each relay contact for high

voltage input and output.

Heating element(s) Check the Amp draw on each power leg for proper

load. Check the specification plate for rating

information. If the amp draw is high or low, check the

individual elements for opens, shorts and proper

resistance.

WITH POWER OFF: To check resistance of the

elements, remove all leads from the elements and use

DTF – 1920 Series Service Manual

7

Page 8

a digital multimeter.

The element resistance should be as follows:

208V – 43 ohms approx.

240V – 57 ohms approx.

Replace heating elements as needed.

No Infrared Heating Main fan motor Check for main fan operation. If it is not operating, refer

to “Oven fan will not run”.

Air pressure switch Check for 208/240VAC to the air pressure switch. If no

voltage is present, trace wiring back to main power

switch. This normally open switch should close when

the main fan is activated. Refer to the “Removal and

installation” section for proper adjustment. Replace as

needed.

Switch, Infrared heater Check for 208/240VAC to the Infrared heater switch. If

no voltage is present, trace wiring back to the air

pressure switch. WITH POWER OFF: Check continuity

between switch terminals. Replace switch as needed.

Infrared heater relay Check for supply voltage to the relay coil. If no voltage

is present, trace wiring back to Infrared heater switch. If

voltage is present and the relay will not activate,

replace the Infrared heater relay. Also check each relay

contact for high voltage input and output.

Infrared Heating element(s) Check the Amp draw on each power leg for proper

load. Check the specification plate for rating

information. If the amp draw is high or low, check the

individual elements for opens, shorts and proper

resistance.

WITH POWER OFF: To check resistance of the

elements, remove all leads from the elements and use

a digital multimeter.

The element resistance should be as follows:

208V – 45 ohms approx.

240V – 58 ohms approx.

Replace heating elements as needed.

Oven heats with switch off Main heater relay or

Infrared heater relay

The Main heater relay or Infrared heater relay has

probably failed in the closed position. If there is no

voltage to the operating coil, but there is high voltage at

the relay output, replace the heater relay.

Intermittent heating Thermal/overload of motor The main fan motor is equipped with internal thermal

protection and will cease to operate if overheating

occurs. As the motor overheats and then cools, this will

cause the oven to cycle on and off intermittently.

Improper ventilation or lack of preventive maintenance

may cause this. Also, most of the problems listed under

“Oven will not heat” can cause intermittent failure.

Conveyor will not run NOTE: Display will indicate

“Belt Jam”

Power supply Check circuit breakers, reset if required. Check power

plug to be sure it is firmly in receptacle. Measure

incoming power, call power co. if needed.

Fuse, 10 Amp Check, replace if necessary.

Fuse holder Check, replace if necessary.

Hi-limit thermostat, oven cavity Terminals are normally closed. If open, reset

thermostat and retest. If thermostat will not hold for

maximum oven temperature, and oven is not exceeding

temperature setting, check for proper location of

capillary bulb in its spring holder. If the capillary checks

okay, replace the hi-limit thermostat.

8

DTF – 1920 Series Service Manual

Page 9

Switch, Main Power WITH POWER OFF: Check continuity between switch

terminals. Replace switch as needed.

Control transformer Check for supply voltage to the primary of the control

transformer. If no voltage is present, trace wiring back

to the oven power relay. If voltage is present, check for

24 VAC at the transformer secondary. If there is

primary voltage but no secondary voltage, replace

control transformer.

Air pressure switch Check for 208/240VAC to the air pressure switch. If no

voltage is present, trace wiring back to main power

switch. This normally open switch should close when

the main fan is activated. Refer to the “Removal and

installation” section for proper adjustment. Replace as

needed.

Switch, Infrared heater Check for 208/240VAC to the Infrared heater switch. If

no voltage is present, trace wiring back to the air

pressure switch. WITH POWER OFF: Check continuity

between switch terminals. Replace switch as needed.

Conveyor motor Check for supply voltage to the conveyor motor. If no

voltage is present, trace wiring back to the primary of

the control transformer. If voltage is present and the

motor will not run, check the motor windings for opens

or shorts.

WITH POWER OFF: Check the motor windings as

follows:

Grey to black - 236 ohms approx.

Grey to brown - 236 ohms approx.

Brown to black - 472 ohms approx.

If any of the above fails, replace conveyor motor.

Capacitor, conveyor motor Check for shorts or grounds. Replace capacitor as

needed.

WARNING: Capacitor has a stored charge, discharge

before testing.

Switch, conveyor reversing Check continuity between switch terminals. Replace

switch as needed.

Oven control If there is supply voltage to the motor, and the motor,

motor capacitor, and reversing switch check good,

replace the oven control.

Conveyor motor runs, but there

is no speed display

Conveyor motor If there is voltage supplied to the hall effect sensor,

Oven control If the hall effect sensor readings are correct, but there

Oven control Check for output voltage from oven control to hall effect

sensor (sensor is located in conveyor motor). Measure

voltage at the motor connector, red wire and yellow

wire. Voltage should be approx. 10VDC. If no voltage is

present, trace wiring back to oven control. If there is no

voltage present at the oven control, replace the oven

control.

check for a frequency output from the hall effect

sensor. Measure frequency across the yellow and white

wires at the motor connector. Frequency reading

should be approx. 25 – 100 Hz. If these readings are

not achieved, replace conveyor motor. If the readings

are achieved, proceed.

is no speed indicated on the display, replace the oven

control.

DTF – 1920 Series Service Manual

9

Page 10

REMOVAL, INSTALLATION AND ADJUSTMENT

DUAL TECHNOLOGY FINISHER

CAUTION!

BEFORE REMOVING OR INSTALLING ANY COMPONENT IN THE DUAL TECHNOLOGY

FINISHER, BE SURE TO DISCONNECT THE ELECTRICAL POWER SUPPLY.

MOTOR, MAIN FAN - REPLACEMENT

1. Shut off power at main breaker.

2. Remove conveyor and finger assemblies from oven (see installation operations

manual).

3. Remove front plenum assembly. Measure location of main fan on motor shaft for

reassembly. Loosen two set screws and remove main fan from motor shaft.

4. Remove oven top and rear cover. Disconnect wiring from motor. Remove motor and

motor mount assembly from back of oven.

5. Measure proper location of cooling fan on motor shaft for reassembly. Remove cooling

fan. Remove motor from motor mount.

6. Reassemble in reverse order and test for proper operation.

MAIN FAN - REPLACEMENT

See “MOTOR, MAIN FAN” above.

SWITCH, ON/OFF – SWITCH, STANDBY - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box top.

3. Depress clips on sides of switch and remove switch from front panel.

4. Disconnect all wires from switch. Mark all wires for reinstallation.

5. Reassemble in reverse order and check system operation.

RELAY, TIME DELAY - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from time delay relay and mark wires for reinstallation.

4. Remove mounting screw and remove time delay relay.

5. Reassemble in reverse order and check system operation.

RELAY, MAIN FAN - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from main fan relay and mark wires for reassembly.

4. Remove mounting screws and remove main fan relay.

5. Reassemble in reverse order and check system operation.

10

DTF – 1920 Series Service Manual

Page 11

CIRCUIT BREAKER, MAIN MOTOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from appropriate circuit breaker and mark wires for reassembly.

4. Remove mounting nut from circuit breaker and remove circuit breaker.

5. Reassemble in reverse order and check system operation. Be sure to reset circuit

breaker before operation.

FUSE HOLDER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from appropriate fuse holder and mark wires for reassembly.

4. Remove mounting screws from fuse holder and remove fuse holder.

5. Reassemble in reverse order and check system operation.

RELAY, MAIN HEATER – RELAY, INFRARED HEATER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from appropriate heater relay and mark wires for reassembly.

4. Remove mounting screws from heater relay and remove heater relay.

5. Reassemble in reverse order and check system operation. Be sure to mount the heater

relay in the upright position, mounting the relay upside down will cause the relay to be in

the constant “on” position.

REVERSING SWITCH, CONVEYOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from reversing switch and mark wires for reassembly.

4. Remove mounting nut from reversing switch and remove reversing switch.

5. Reassemble in reverse order and check system operation.

TRANSFORMER, CONTROL - REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover.

3. Remove wires from control transformer and mark wires for reassembly.

4. Remove mounting screws and remove control transformer.

5. Reassemble in reverse order and check system operation.

DTF – 1920 Series Service Manual

11

Page 12

CAPACITOR, CONVEYOR MOTOR – REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box top. Remove tube from air pressure switch.

3. Remove wiring from air pressure switch and conveyor motor capacitor and mark all

wires for reassembly.

4. Remove two screws and remove air pressure switch/capacitor mounting bracket.

5. Remove capacitor from mounting bracket.

6. Reassemble in reverse order and check system operation.

CONVEYOR MOTOR – REPLACEMENT

1. Shut off power at main breaker.

2. Remove coupling from conveyor shaft (one screw at end of motor shaft).

3. Remove control box top and rear control box cover.

4. Remove three screws and remove main control board and mounting bracket.

5. Disconnect wiring for motor and remove motor mounting screws. Remove conveyor

motor and mounting bracket.

6. Remove conveyor motor from mounting bracket.

7. Reassemble in reverse order and check system operation.

AIR PRESSURE SWITCH – REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box top. Remove tube from air pressure switch.

3. Remove wiring from air pressure switch and conveyor motor capacitor and mark all

wiring for reassembly.

4. Remove two screws and remove air pressure switch/capacitor mounting bracket.

5. Remove air pressure switch from mounting bracket.

6. Reassemble in reverse order and check system operation.

AIR PRESSURE SWITCH – ADJUSTMENT

1. Apply power to machine, set temperature control to maximum temperature.

2. Allow 30 minute preheat. Adjust air pressure switch so that switch will stay closed at

maximum temperature.

3. Remove air tube from air pressure switch and verify that switch opens.

4. Reconnect air tube and check system operation.

THERMOCOUPLE – REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box top. Remove rear cover. Remove right side heating element cover.

3. Remove mounting screws and remove thermocouple from oven cavity.

4. Disconnect thermocouple from main control, remove thermocouple.

5. Remove connector plug from new thermocouple and mark wires for reassembly. Install

thermocouple and reassemble plug connector.

6. Reassemble in reverse order and check system operation.

12

DTF – 1920 Series Service Manual

Page 13

THERMOCOUPLE MEASUREMENT

TEMPERATURE (°F) D.C. MILLIVOLTS

200° 2.8

250° 4.0

300° 5.1

350° 6.0

400° 7.1

450° 8.2

500° 9.3

550° 10.4

600° 11.5

THERMOSTAT, HI-LIMIT – REPLACEMENT

1. Shut off power at main breaker.

2. Remove rear cover, remove right side heating element cover.

3. Remove hi-limit thermostat from the mounting bracket. Remove mounting nut from hilimit thermostat. Remove hi-limit thermostat.

4. Form 90° bend in hi-limit thermostat.

5. Reassemble in reverse order and check system operation. Be sure to reset thermostat

before testing.

HEATING ELEMENT, MAIN – REPLACEMENT

1. Shut off power at main breaker.

2. Remove conveyor, finger assemblies and plenum front. Remove rear cover and

appropriate heating element cover.

3. Remove wires from heating element and mark wiring for reassembly.

4. Remove mounting screws and remove heating element.

5. Reassemble in reverse order and check system operation.

HEATING ELEMENT, INFRARED – REPLACEMENT

1. Shut off power at main breaker.

2. Remove conveyor and lower finger assemblies. Remove front conveyor support from

oven cavity.

3. Remove front cover and heating element cover. Disconnect wiring from heating element

and mark wires for reassembly.

4. Reassemble in reverse order and check system operation.

MAIN CONTROL – REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box top, front panel and rear control box cover.

3. Remove display board from front panel by pulling board off of it’s mounting pins.

4. Remove three screws from main control mounting bracket and remove main control board

and its mounting bracket. Remove main control from it’s mounting bracket by pulling the

control from the mounting bracket.

5. When installing new control, be sure to use ground strap so that there is no static

electricity. When installing new control, be sure to set the jumpers on the control for proper

DTF – 1920 Series Service Manual

13

Page 14

voltage (120/240) and frequency (50Hz./60Hz.). After the new control is installed, the

control will need to be initialized. To initialize the new control, press and hold the two center

buttons on the front control panel. After the oven starts, release the buttons, the control is

now initialized. Reassemble in reverse order and check system operation.

14

DTF – 1920 Series Service Manual

Page 15

This page intentionally left blank.

DTF – 1920 Series Service Manual

15

Page 16

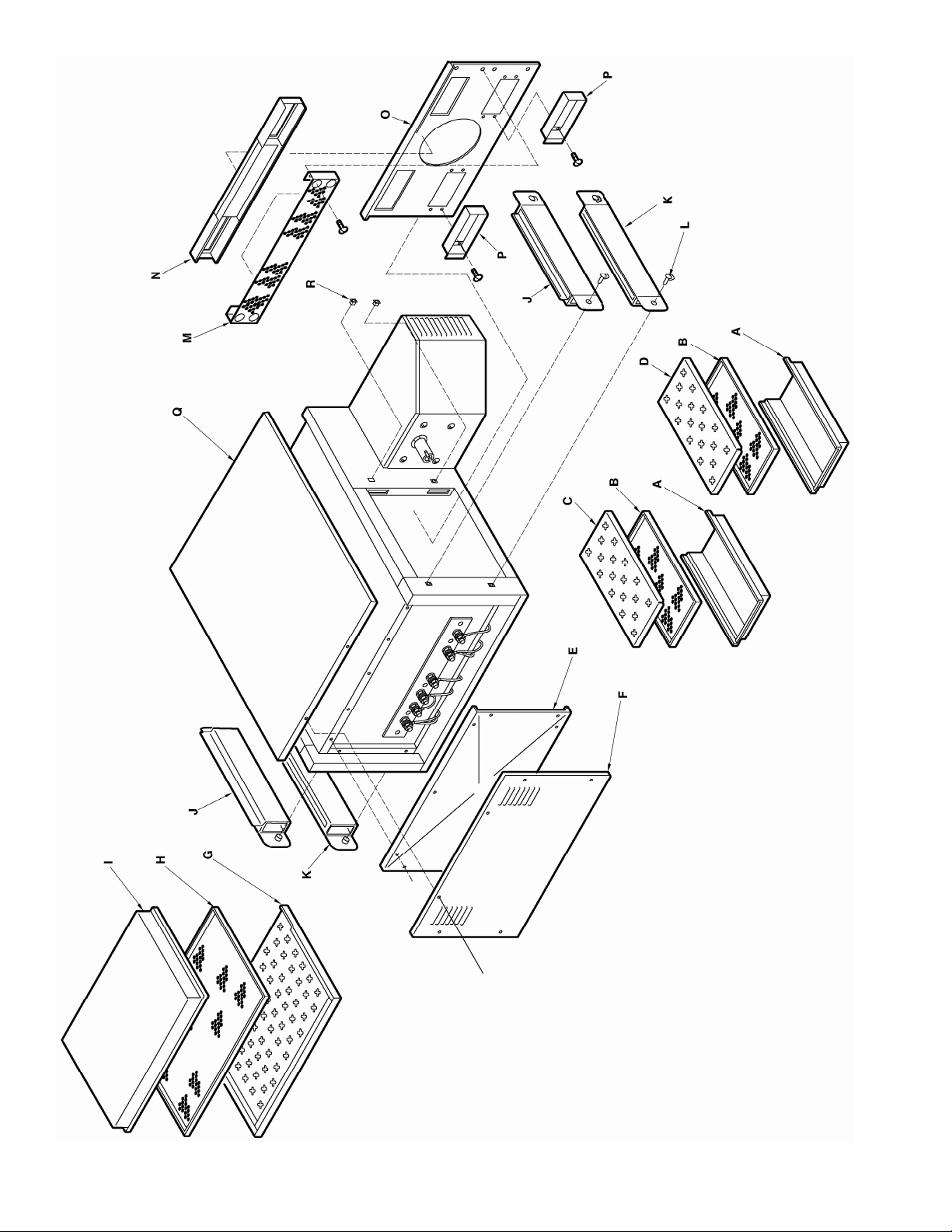

GENERAL VIEW

MODEL 1921, 1922

A 370438 Finger housing, lower

B 370441 Columnating plate, lower

C 370443 Finger cover, lower left. Marked ‘LS’

D 370444 Finger cover, lower right. Marked ’RS’

E 370445 Front element cover

F 370446 Front cover

G 370447 Finger cover, upper

H 370442 Columnating plate, upper

I 370439 Finger housing, upper

J 370448 Air wash panel, upper

K 370449 Air wash panel, lower

L 370450 ¼ turn fastener

M 370451 Air return assy.

N 370452 Finger support, upper

O 370454 Plenum front

P 370453 Finger support, lower

Q 370455 Top

R 369373 Receptacle, ¼ turn fastener

16

DTF – 1920 Series Service Manual

Page 17

DTF – 1920 Series Service Manual

17

Page 18

18

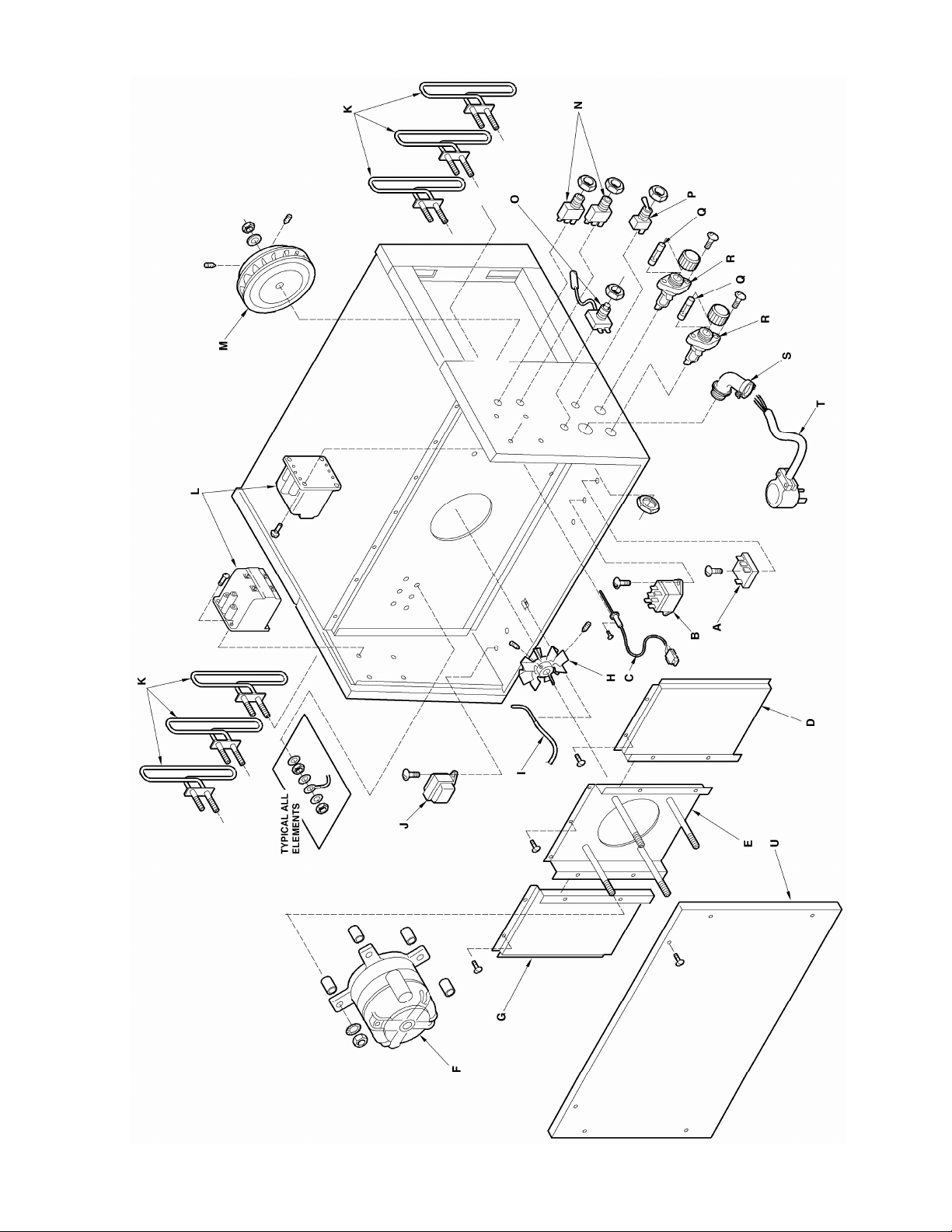

CONTROL BOX VIEW

MODEL 1921, 1922

A 369432 Switch, on/off

B 370456 Label, control panel

C 370457 Front panel

D 369460 Spring, compression

E 369413 Drive key

F 369410 Coupling sleeve

G 370106 Washer

H 350259 Screw

I 370458 Heating element, Infrared – 208VAC

370460 Heating element, Infrared – 240VAC

J 370462 Motor, conveyor

K 370383 Capacitor, conveyor motor

L 369430 Air pressure switch

M 370463 Top, control box

N 370464 Control, main and display

O 370465 Cover, rear control box

DTF – 1920 Series Service Manual

Page 19

DTF – 1920 Series Service Manual

19

Page 20

20

REAR VIEW

MODEL 1921, 1922

A 370466 Timer, cool down, 30 minute

B 369422 Relay, main fan

C 370467 Thermocouple

D 370468 Cover, heating element

E 370469 Motor mount

F 370470 Motor, main fan S/N 8001207 and Below

4060485 Motor, main fan S/N 8001208 and Above

G 370468 Cover, heating element

H 370471 Cooling fan

I 370472 Air switch tube assy.

J 369427 Transformer, control

K 370459 Heating element, 208VAC

370461 Heating element, 240VAC

L 369479 Relay, Heating element

M 369409 Main fan

N 370473 Circuit breaker, 3A

O 357067 Thermostat, hi-limit

P 370359 Reversing switch, conveyor

Q 369166 Fuse, 10A

R 369129 Fuse holder

S 12682 Adapter, cable

T 370474 Power cord

U 370475 Cover, rear

Not shown 370476 Transformer, motor (Model 1922 only)

DTF – 1920 Series Service Manual

Page 21

DTF – 1920 Series Service Manual

21

Page 22

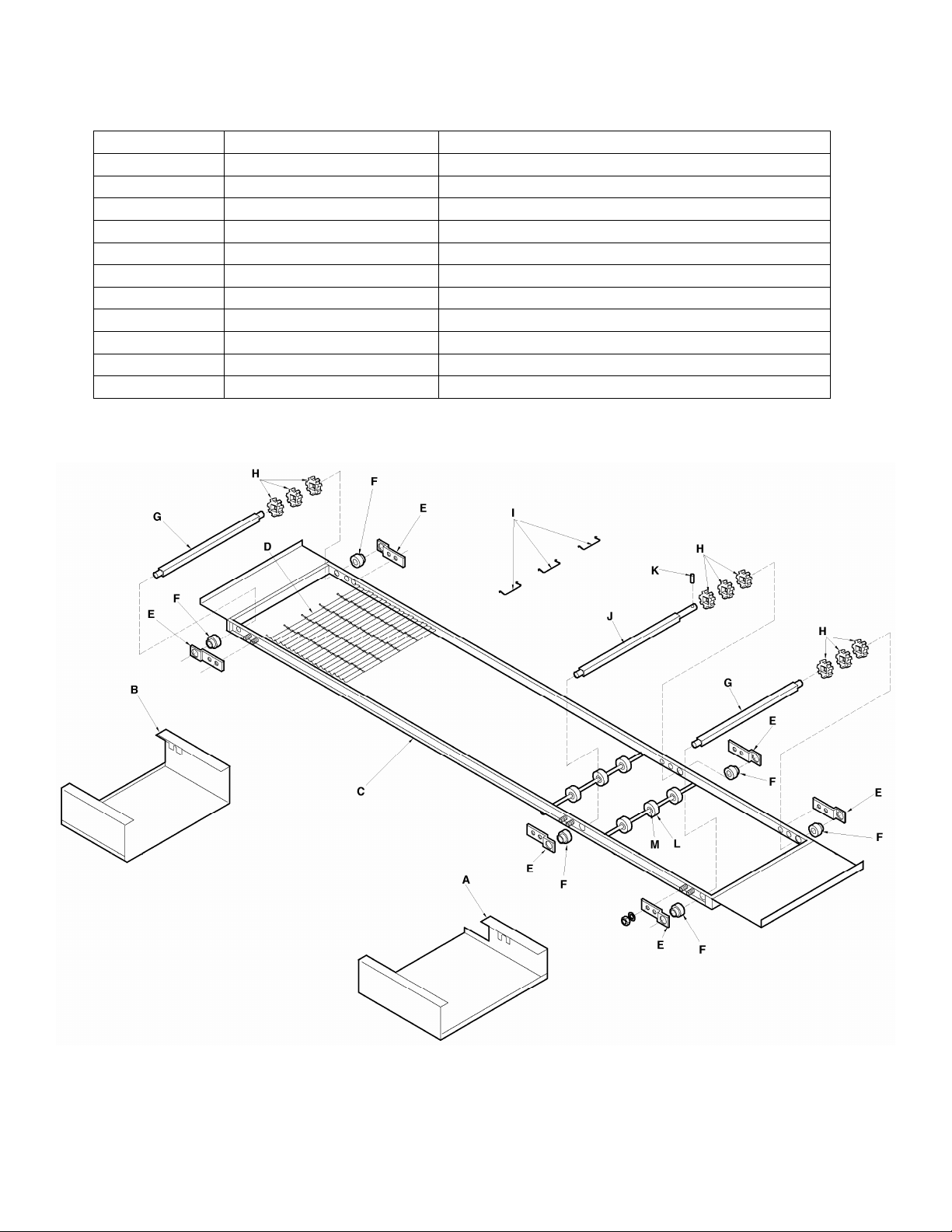

CONVEYOR

MODEL 1921, 1922

S/N 8001199 and Below

A 370477 Crumb pan, right

B 370478 Crumb pan, left

C 370440 Frame, conveyor

D 370479 Belt, conveyor

E 370480 Bracket, conveyor bearing

F 370481 Flanged bearing, conveyor

G 370482 Shaft, idler

H 369515 Drive sprocket

I 369952 Connecting link, conveyor (three required)

J 370483 Shaft, drive

K 369471 Pin

Not shown 370484 Conveyor assembly, complete

22

DTF – 1920 Series Service Manual

Page 23

CONVEYOR

MODEL 1921, 1922

S/N 8001200 and Above

A 370477 Crumb pan, right

B 370478 Crumb pan, left

C 370529 Frame, conveyor

D 370479 Belt, conveyor

E 370480 Bracket, conveyor bearing

F 370481 Flanged bearing, conveyor

G 370482 Shaft, idler

H 369515 Drive sprocket

I 369952 Connecting link, conveyor (three required)

J 370483 Shaft, drive

K 369471 Pin

L 370501 Sprocket, drive

M 370498 Drive chain

N Cover, drive chain

O 370500 Shaft, driven

Not shown Conveyor assembly, complete

DTF – 1920 Series Service Manual

23

Page 24

24

DTF – 1920 Series Service Manual

Loading...

Loading...