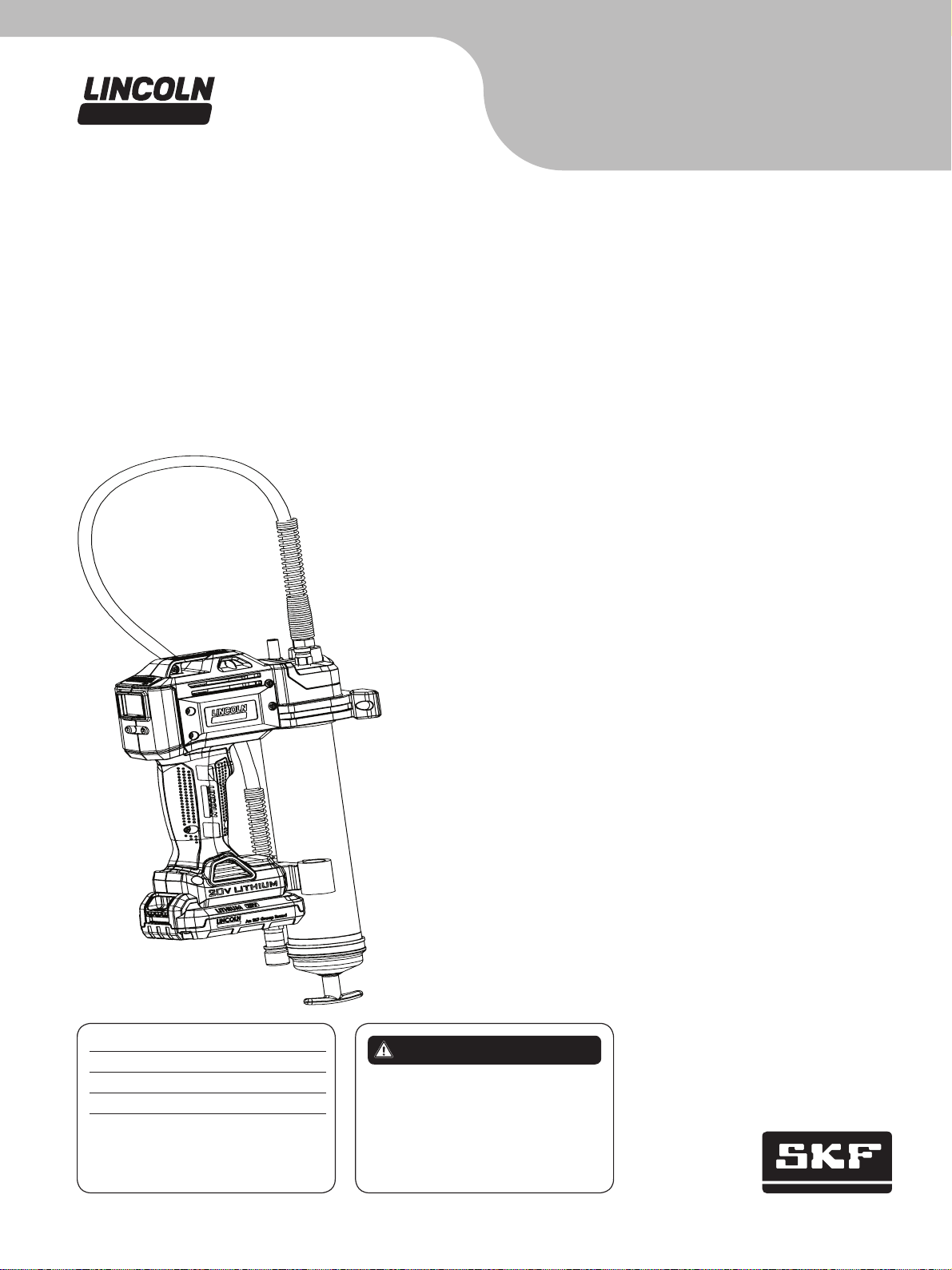

Lincoln A Series, 1880, 1882E, 1882, 1884 Installation And Maintenance Manual

Installation and maintenance guide

PowerLuber grease gun

(lithium ion)

1880, 1882, 1882E, 1884 series “A”

Date of issue January 2014

Form number 423077A

Section D7

Page 86A

DANGER

Read manual prior to installation or use

of this product. Keep manual nearby for

future reference. Failure to follow

instructions and safety precautions may

result in death or serious injury.

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Contents

General power tool safety warnings . 2

Specific safety ................... 3

Inspection ...................... 5

Operation ...................... 5

Charger operation ................ 8

Safety instruction for charger and

batteries ....................... 11

Exploded view and parts list ....... 13

Troubleshooting ................. 15

General power tool

safety warnings

WARNING

Read all safety warnings and instructions. Failure to follow the warnings and

instructions may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power

tool.

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp

location is unavoidable, use a Residual

Current Device (RCD) protected supply.

Notice

!

The term “residual current device

(RCD)” may be replaced by the term

“ground fault circuit interrupter (GFCI)”

or “earth leakage circuit breaker (ELCB)”.

Personal safety

Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

Remove any adjusting key or wrench be-

fore turning the power tool on.

Power tool use and care

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool’s operation.

Use the power tool, accessories and tool

bits in accordance with instructions.

2

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Battery tool use and care

Recharge only with the battery charger

specified by the manufacturer.

Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create risk of

injury and fire.

When battery pack is not in use, keep

it away from other metal objects, like

paper clips, coins, keys, nails, screws or

other small metal objects, that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery; avoid contact.

Liquid ejected from battery may cause

irritation or burns. If contact accidentally

occurs, flush with water. If liquid contacts

eyes, seek medical help.

Specific safety

• Always wear eye protection. The PowerLuber can generate up to 10,000 psi

(689 bar).

• Use only Lincoln 1218, 1224, 1230 or

1236 outlet whip hoses. Grease injection

injuries are a very serious injury. Hold the

hose only in the area of the spring guard.

Avoid accidental starting. Be sure switch

is not depressed when inserting battery

pack.

• Replace the hose at the first sign of wear,

kink or damage to the outside jacket.

• Do not bend the hose so that it becomes

kinked.

• Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enable better control of the

tool in unexpected situations.

• Use safety equipment. Always wear eye

protection.

• Dust mask, non-skid safety shoes, hard

hat or hearing protection must be used

for appropriate conditions.

WARNING

To reduce the risk of injury, the

user must read the instruction

manual.

Separate collection. This product must not be disposed of

with normal household waste.

WARNING

Grease gun can develop high pressure

up to 10,000 psi (689 bar). Use safety

glasses and gloves for protection during

operation. Keep hands clear of exposed

rubber portion of hose.

Service

WARNING

Do not use any hose that has not been

approved by Lincoln. Extreme pressure

may cause nozzle extension or whip

hose to burst.

Replace hose at first sign of wear, kinks,

or damage to outside jacket.

Follow whip hose instructions and

warnings. Failure to comply may result

in serious injury or death.

Tool service must be performed only by

qualified repair personnel. Service or maintenance performed by unqualified personnel

may void warranty and result in a risk of

injury.

When servicing a tool, use only identical

replacement parts.

3

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

The gun uses lubricants, that may be flammable and poisonous if ingested. Do not use

gun near open flame or other fire hazards.

Greases are often marketed as high temperature because it must maintain their lubricating properties in hot areas, but the lubricants may be flammable if the

temperature is too high. Please read all

warnings on lubricants before using this

gun. Do not use flammable greases with this

grease gun.

Tool use and care

Do not use tool if switch does not turn it on

or off. A tool that cannot be controlled with

the switch is dangerous and must be

repaired.

Do not continue to hold down trigger if

grease gun is stalled. This could damage the

motor or cause fire.

Disconnect battery pack from tool before

making any adjustments, changing accessories, or storing the tool. Such preventive

safety measures reduce the risk of starting

the tool accidentally.

Store the tools out of reach of children

and other untrained persons. Tools are dangerous in the hands of untrained users.

When battery pack is not in use, keep it

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together may

cause sparks, burns, or a fire.

Maintain tools with care. Check for misalignment or binding of moving parts,

breakage of parts, and any other condition

that may affect the tool’s operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by Lincoln.

Only accessories that are capable of handling 10,000 psi (689 bar) should be used.

Accessories that may be suitable for one tool

may create a risk of injury when used on

another tool.

Appropriate use

The PowerLuber was exclusively designed to

pump and dispense lubricant using 18 volt

battery power. Do not exceed the maximum

specification ratings.

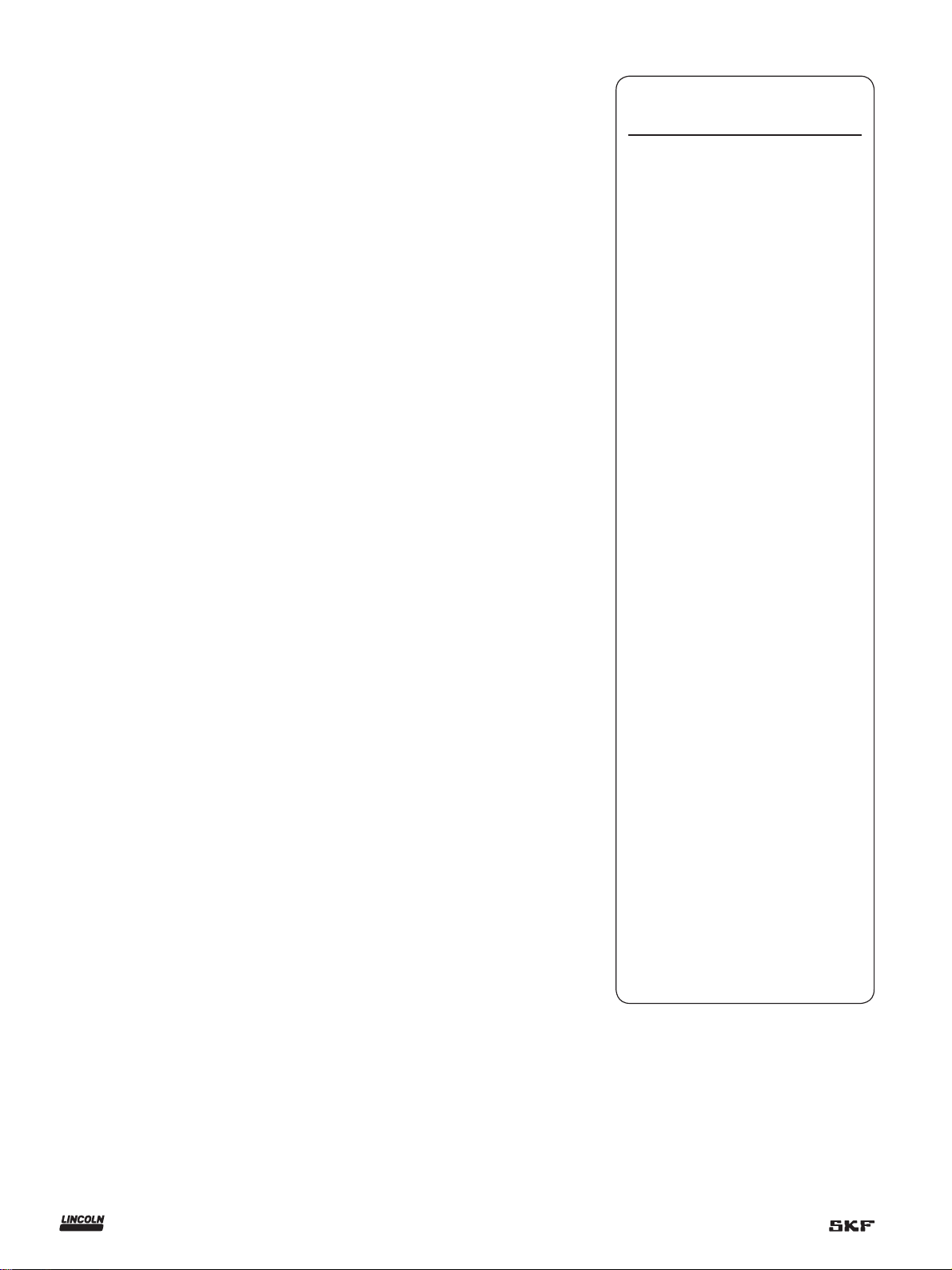

Specifications

Basic PowerLuber model 1880

Operating power 14.5 to 20.5 V DC

Maximum operating

pressure

Low output 6,000 psi (413 bar)

High output 6,000 psi (413 bar)

Grease reservoir

capacity

Maximum peak

pressure

Operating temperature

range

Operating current 4 A at 20 to 130 °F

Rated current 5 A at 20 to 130 °F

Lubricant (grease) up to NLGI #2

Grease output

Low output (L) 3.5 oz./min.

High output (H) 5.5 oz./min.

Weight 6.5 lbs. (2,0 kg)

Accessories

Battery li-ion Model 1871

Output 20 V DC maximum

Capacity 1,500 mAh

Battery charger Model 1870

Charge time 1.5 hours

Input, vac (0.6 A) 120 v, 60 hz

Outlet hose Model 1236

Pressure rating 10,000 psi (689 bar)

Length of the hose 36 in. (914 mm)

Note 1: Operating current and grease output data at

1,000 psi (69 bar).

Note 2: The declared vibration total value has been measured in accordance with a standard test method and may be

used for comparing one tool with another and the declared

vibration total value may also be used in a preliminary assessment of exposure.

Note 3: The vibration emission during actual use of the

power tool can differ from the declared total value depending

on the ways in which the tool is used; and of the need to

identify safety measures to protect the operator that are

based on an estimation of exposure in the actual conditions

of use (taking account of all parts of the operating cycle such

as the times when the tool is switched off and when it is running idle in addition to the trigger time).

14.5 oz. (411 g)

10,000 psi (689 bar)

0 to 120 °F

(–18 to 50 °C)

(–6 to 54 °C)

(–6 to 54 °C)

(0,103 l/min.)

(0,162 l/min.)

4

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Models

General description

Sales model Components included

1880 Grease gun with battery

1882 Grease gun with battery,

charger and carrying

case

1882E Grease gun with battery,

charger 230 V AC

European and carrying

case

1884 Grease gun with battery,

extra battery, charger

and carrying case.

1870E Charger 230 V AC

European

1871 Battery pack

1236 Hose, 36 in. (914 mm)

5852 Coupler, midget hydraulic

251-10124-7 Coupler (European)

The Lincoln PowerLuber is a lithium-ion

battery operated grease gun. The gun was

developed for manual lubrication of grease

points and includes a light emitting diode

(LED) and electronic control center.

The PowerLuber is driven by a small, low

voltage electric motor connected to a gear

transmission. The rotary motion of the

motor is converted into a reciprocating

motion of the plunger using a yoke

mechanism. The PowerLuber is a positive

displacement single acting pump.

Control center

Technology incorporated into the 1880

series PowerLuber includes:

• Motor protection preventing overload due

to excessive current draw. The display will

flash red when this occurs.

• An LCD showing battery charge, pump

speed and grease output.

• An illuminating LED light to help locate

grease fittings in dim light.

5

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

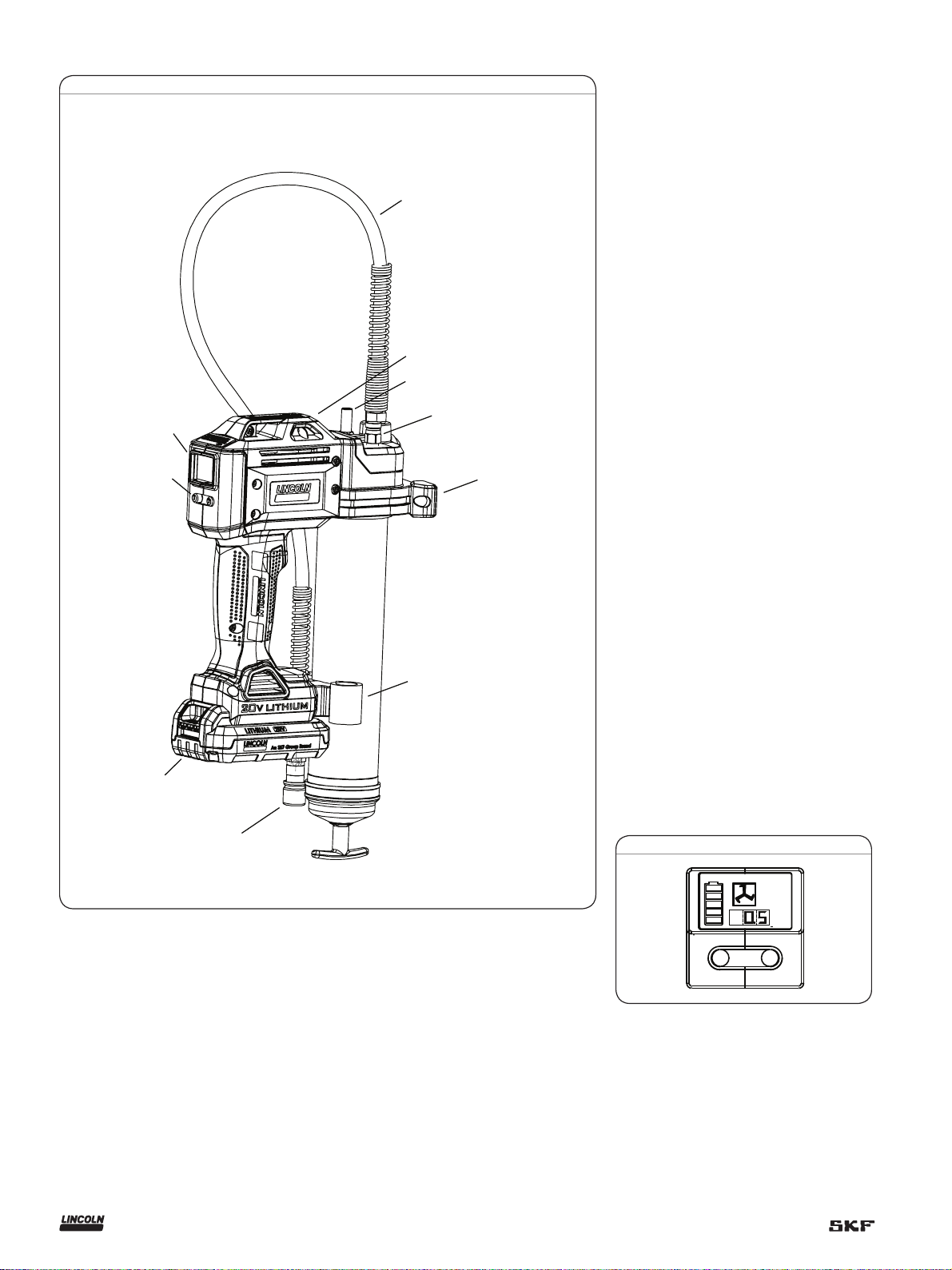

1880 Grease gun

Control

Button

Displ ay

Hose

LED ligh t

Bulk

valve

Vent valve

Suppo rt

Fig. 1

Inspection

Visually inspect for damaged, loose or missing parts. If equipment is worn or damaged,

remove from service. Contact an authorized

service center for damage assessment or

repair.

Operation

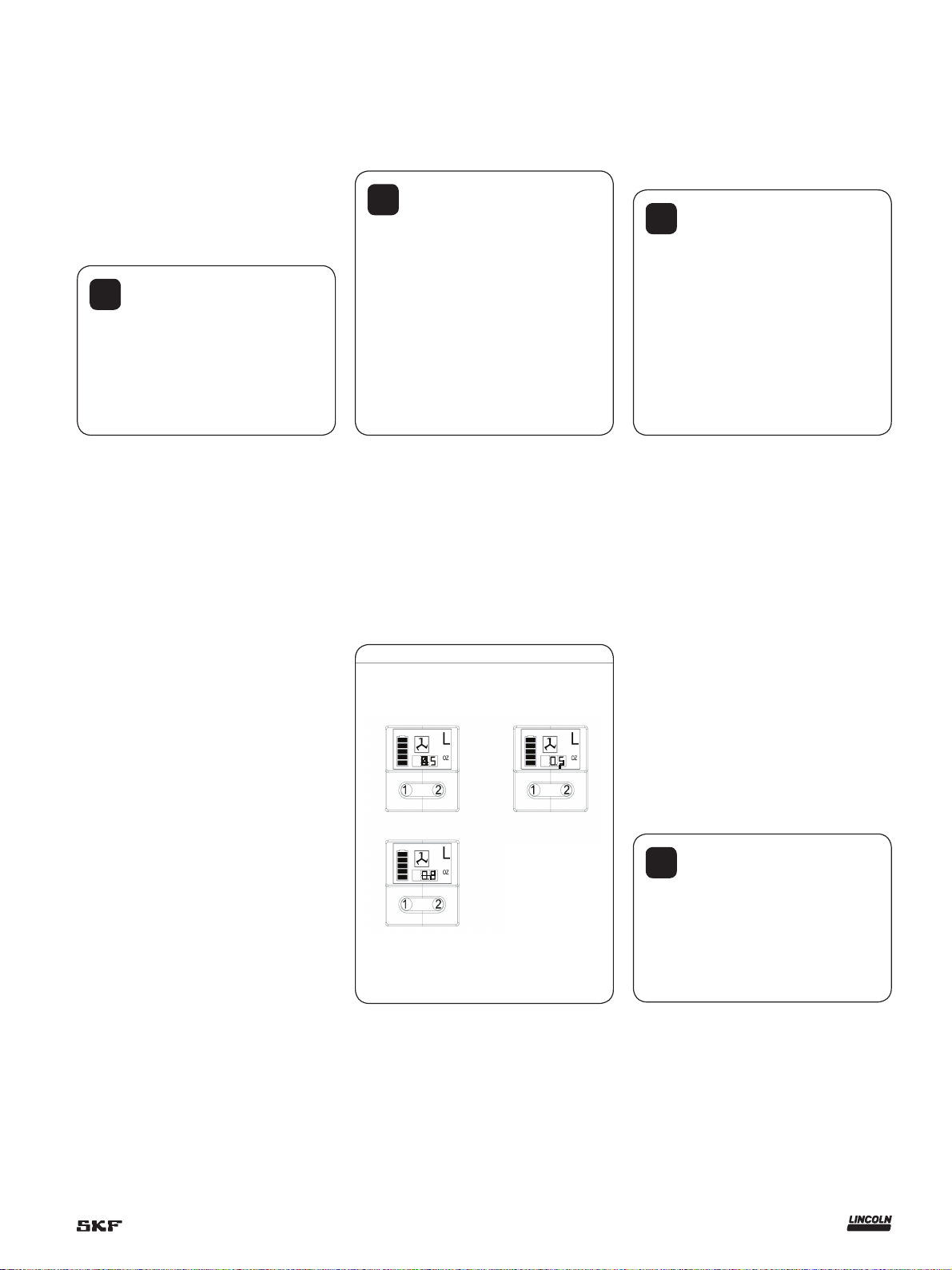

Speed selection

Pressing button 2 switches the tool between high and low pump speed. The letter

“L” or “H” will be displayed on the screen.

High delivers 5.5 ounces (0,162 l) per

minute at 1,000 psi (68 bar) back pressure.

Low delivers 3.5 oz. (0, 103 l) per minute

at 1,000 psi (68 bar) back pressure.

High output is recommended if the tool is

used to lubricate large bearings. Also, high

output is recommended if tool is used to refill small reservoirs.

Low output is recommended if the tool is

used in construction, mining applications

and general lubrication.

Battery

5852 or 251-10124-7

coupler

LCD display and LED

light

Hose hold er

• Button number 1 turns on/off the display

and LED:

• The tool’s trigger also turns on the display

and LED:

• The LCD and display will turn off after 30

seconds if not turned off manually.

Fig. 2

L

OZ

1

2

6

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Grease flow

Priming instructions

Install grease

monitoring

• LCD shows the output of grease delivered

in ounces or grams.

• Clear grease output by holding button 1

for 3 seconds.

• Change grease output by holding button

1 for 15 seconds.

Notice

!

Grease meter is very accurate and

does not show output if prime is lost.

Replace grease

cartridge or refill tube

1 Prime the PowerLuber after each refill or

grease cartridge change. To prime, operate the gun until grease flows from hose.

Use vent valve († fig.1, page 4) to expel

air pockets.

2 Press set key 1 for 3 seconds to clear dis-

play of previous reading.

1 Open vent valve († fig.1, page 8).

Notice

!

Nach jedem Ersetzen der Kartusche das Entlüftungsventil öffnen.

Dadurch kann die Luft aus der Kartusche entweichen und die Fettpresse

vorgefüllt werden.

Den PowerLuber nach jeder Befüllung

bzw. jedem Wechsel der Fettkartusche

vorfüllen.

2 Operate the gun until grease flows from

the vent valve.

3 Close vent valve.

4 Press button “1” 3 seconds to clear dis-

play of previous reading.

Fig. 3

or

Current display

reading

Press 1 for 3 seconds

to clear display of

previous reading

cartridge

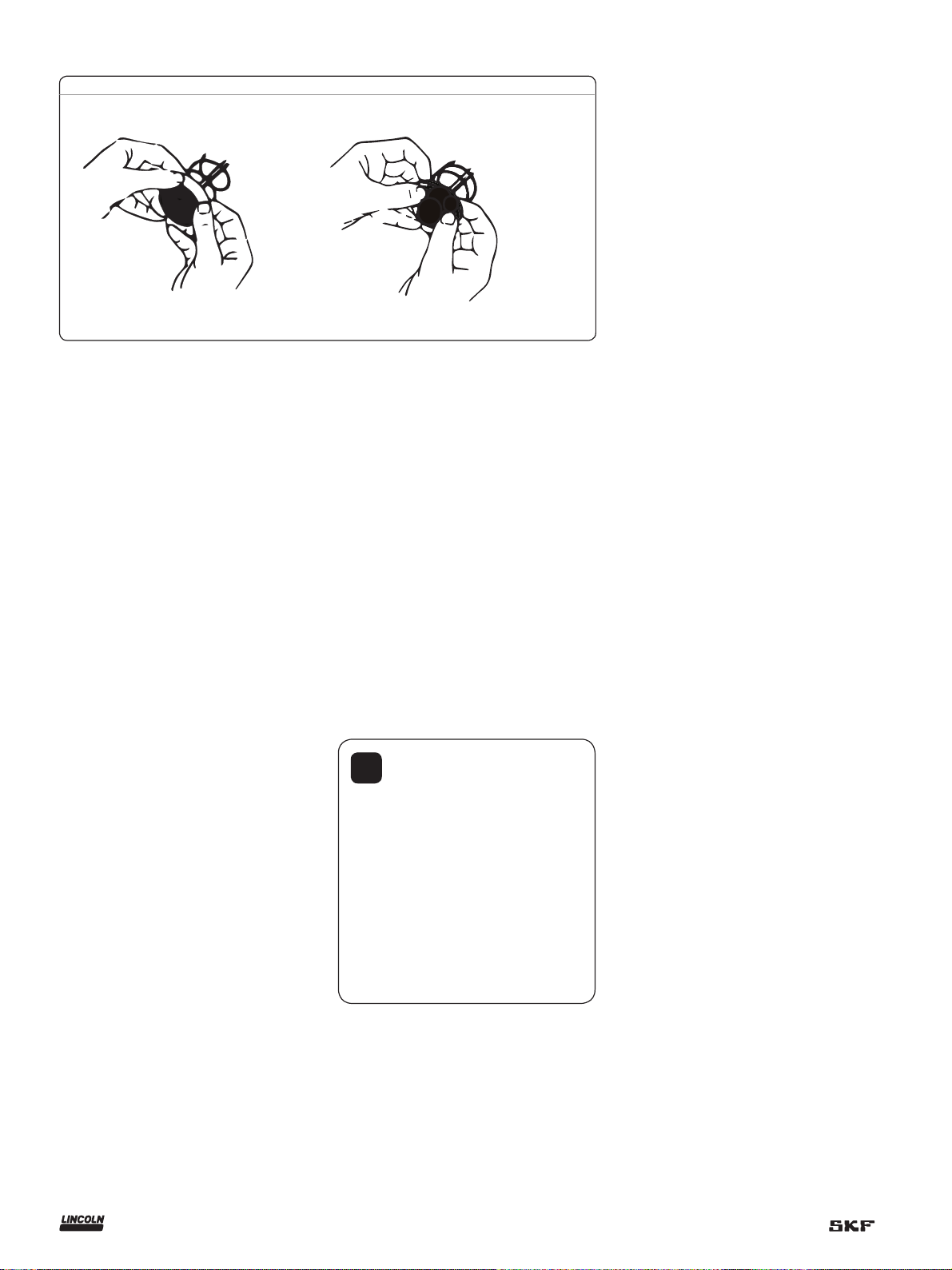

1 Unscrew the grease tube assembly from

the PowerLuber.

Notice

!

The follower seal lip must be directed toward the follower handle or

rear side for cartridge loading

(† figs. 4, page 12).

To change the direction of the follower

seal, unscrew tube cap from grease tube

assembly and pull on the handle to remove follower seal from tube. Flip follower seal over and reassemble.

2 Visually check the follower seal lip direc-

tion before loading a new cartridge.

3 Pull back on the follower handle and latch

the follower rod groove into the slot on

the tube cap.

4 Remove the plastic cap from the grease

cartridge and insert cartridge into the

container tube.

5 Remove the pull tab from the grease

cartridge and screw the grease tube

assembly into the pump assembly.

6 Thread grease tube assembly back onto

the power head.

7 Release follower rod from slot. Purge air

from pump. Refer to page 13 for air

purging instructions.

8 Reset display reading after purging air.

9 Refer to the section titled LCD display

and LED light, page 9.

Notice

!

Air pockets in the cartridge

lubricant will cause the gun to lose its

prime and will cause grease output

measurements and cartridge level

readings to be inaccurate.

7

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

To fill gun from bulk

container

1

Remove pump assembly from grease tube

assembly.

2 Pack lubricant into cavity of the pump

assembly.

3 Insert the open end of the grease tube

assembly into lubricant. Slowly pull the

follower handle back while pushing the

grease tube assembly deeper into the lubricant to prevent air pockets from being

pulled into the grease tube.

4 With the follower rod fully extended, pull it

sideways to latch the rod groove into the

slot in the grease tube assembly cap.

5 Loosely assemble the pump to the grease

tube assembly. Release the follower rod

from the grease tube assembly cap and

disengage the follower rod from the follower by rotating the follower handle.

6 Push the follower rod into the grease tube

assembly.

7 Unscrew the grease tube assembly from

the pump until lubricant oozes from the

interface. Tighten grease tube assembly

into the pump assembly.

8 Reset display reading after purging air.

9 Refer to the section titled

LCD display and LED light, († page 6).

Fig. 4

BulkCartridge

To fill gun with filler

pump

1 Engage the follower rod with the follower

by rotating the follower handle.

2 Insert the gun bulk fill valve into the filler

pump socket.

3 Operate the filler pump to fill the contain-

er. When the follower rod groove is exposed, the grease tube assembly is filled.

The follower rod will be extended approximately 20 cm (8 in.). Do not overfill!

4 Disengage the follower rod from the

follower by rotating the follower handle.

5 Push the follower rod into the grease tube

assembly.

6 Reset display reading after purging air.

Notice

!

Remove air pocket! Air pocket at

grease inlet will prevent grease from

being pumped. Unscrew the vent valve

three to four turns to remove small air

pockets trapped in this area. If the air

pocket is substantial and no grease

flows from coupler after trigger is pulled

for 15 seconds, refer to the following

steps.

To expel air pockets

(air purging)

1 Withdraw the follower rod from the

grease tube assembly cap and engage it

with the follower by rotating the follower

handle.

2 Unscrew the plug of vent valve 3 to 4

turns. Exert force on the follower handle

until grease flows through the small hole

in the side of the vent valve.

3 Tighten the vent valve.

4 Pull the trigger in short bursts to operate

gun until trapped air is expelled. Disengage the follower rod from the follower by

rotating the follower handle. Push the follower rod into the grease tube assembly.

5 If step 2 fails, unscrew the grease tube

assembly 3 turns from the pump

assembly.

6 Exert force on the follower handle until

lubricant oozes from the grease tube

assembly and pump assembly interface.

7 Retighten grease tube into the pump

assembly. Disengage the follower rod

from the follower by rotating the follower

handle. Push the follower rod into the

grease tube assembly.

Charger operation

Charging battery pack

Before using your PowerLuber for the first

time, the battery pack should be fully

charged. If the battery pack is installed in the

PowerLuber, remove it and follow charging

procedure below.

Lincoln chargers are designed to charge

Lincoln lithium-ion batteries in 30 to

90 minutes depending on the battery’s state

of charge and temperature.

8

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Charging procedure

Make sure power circuit voltage is the same

as that shown on the charger specification

plate.

1 Plug the charger into an appropriate

outlet before inserting battery pack.

2 Insert the battery pack into the charger.

The green (charging) light will blink continuously indicating that the charging

process has started.

3 The completion of charge will be indicated

by the green light remaining on continuously. The pack is fully charged and may

be used at this time.

4 Disconnect charger from power source

when not in use.

CAUTION

Do not probe with conductive objects.

120/230 V AC present at charging terminals. Failure to comply may result in

death or personal injury.

Indicator light operation

The charge is complete (solid green).

Battery is charging (flashing green).

Red, at a fast rate. Replace battery.

Charger detected a weak or damaged

battery. Stop charging battery.

Hot/cold pack delay.

Charger detected a battery that is

excessively hot or cold. It

automatically starts a hot/cold pack

delay, suspending charging until

temperature of battery has

normalized. After this, charger

automatically switches to battery

charging mode.

Notice

!

Battery temperature will increase

during and shortly after use. Batteries

may not accept a full charge if they are

charged immediately after use. Allow the

battery pack to cool to room temperature before charging for best results.

Notice

!

Vent slots in top and bottom of

charger must not be obstructed.

Do not charge battery when temperature is below 5 °C (40 °F) or above 40 °C

(104 °F).

Important charging

Notices

Longest life and best performance can be

obtained if the battery is charged when the

air temperature is between 18 and 24 °C

(65 and 75 °F). Do not charge the battery in

an air temperature below 5 °C (40 °F) or

above 41 °C (105 °F). This is important and

will prevent serious damage to the battery.

1 The charger and battery may become

warm to the touch while charging. This is

a normal condition, and does not indicate

a problem.

2 If the battery does not charge properly:

2.1 Check current at receptacle by plug-

ging in a lamp or other appliance.

2.2 Check to see if the receptacle is con-

nected to a light switch which turns

power off when you turn out the

lights.

2.3 Move charger and battery to a loca-

tion where the surrounding air temperature is between approximately

18 to 24 °C (65 to 75° F).

2.4 If charging problems persist, take the

tool, battery and charger to your local

service center.

3 The battery should be recharged when it

fails to produce sufficient power on jobs.

Do not continue to use under these conditions. Follow the charging procedure.

You may also charge a partially used pack

whenever you desire with no adverse affect on the battery.

Under certain conditions, with the charger

4

plugged into the power supply, the exposed charging contacts of the charger

can be shorted by foreign material. Foreign materials of a conductive nature

such as, but not limited to, steel wool, aluminium foil, or any buildup of metallic

particles should be kept away from

charger cavities. Always unplug the

charger from the power supply when

there is no battery in the cavity. Unplug

charger before attempting to clean.

5 Do not freeze or immerse charger in

water or any other liquid.

WARNING

Do not allow any liquid to get inside

charger. Electric shock may result.

To facilitate cooling of battery pack after use, avoid placing charger or battery

pack in a warm environment such as a

metal shed or an un-insulated trailer.

Failure to comply may result in serious injury or death.

9

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Safety instructions for charger

and batteries

Save these instructions

This manual contains important safety and

operating instruction for the Lincoln model

1870E battery charger.

DANGER

Do not probe with conductive objects.

Do not charge damaged battery.

Risk of Electric Shock 120 V AC or

230 V AC present at charger terminals.

Replace immediately.

Failure to comply may result in seri-

ous injury or death.

Read all instructions

• Do not incinerate the battery pack even if

it is severely damaged or is completely

worn out. The battery pack can explode in

a fire. Toxic fumes and materials are created when lithium ion battery packs are

burned.

• Do not charge or use battery in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Inserting or removing the battery from the

charger may ignite the dust or fumes.

• If battery contents come into contact with

the skin, immediately wash area with mild

soap and water. If battery liquid gets into

the eye, rinse water over the open eye for

15 minutes or until irritation stops.

If medical attention is needed, the battery

electrolyte for lithium-ion batteries is

composed of a mixture of liquid organic

carbonates and lithium salts.

• Contents of opened battery cells may

cause respiratory irritation. Provide fresh

air. If symptoms persists, see a doctor for

treatment.

DANGER

Do not expose battery to spark or flame.

Battery liquid may burn.

Do not splash or immerse in water or

other liquids. This may cause premature

cell failure.

Failure to comply may result in serious injury or death.

• Do not store or use the tool and battery in

locations where the temperature may

reach or exceed 40 °C (105 °F) such as

outside sheds or metal buildings in the

summer.

DANGER

Never attempt to open the battery pack

for any reason. If the plastic housing of

the battery pack breaks or cracks, return

to a service center for recycling.

Failure to comply may result in serious

injury or death.

1 Before using a battery charger, read all

instructions and cautionary markings on

battery charger, battery pack, and product using battery.

CAUTION

Do not charge Lincoln model 1871

battery packs with any other charger.

To reduce risk of injury, Lincoln model

1870 or 1870E chargers should only be

used to charge Lincoln battery pack

model 1871. Other types of batteries

may burst.

Failure to comply may result in

serious personal injury

2 Do not expose charger to rain, snow or

frost.

3 Do not abuse cord. Never carry charger

by cord or pull on it to disconnect from

receptacle. Pull by plug rather than cord

when disconnecting charger. Have damaged or worn power cord and strain reliever replaced immediately. Do not attempt to repair power cord.

4 Make sure cord is located so that it will

not be stepped on, tripped over, or otherwise subjected to damage or stress.

5 Do not use an extension cord unless ab-

solutely necessary. Use of improper extension cord could result in a risk of fire

and electric shock.

6 Do not operate charger with damaged

cord or plug. Replace immediately, to

avoid a hazard. Do not attempt to repair

power cord.

7 Do not operate charger if it has received

a sharp blow, been dropped, or otherwise damaged in any way, take it to a

qualified service center.

10

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

8 Do not disassemble charger or battery

pack. Take it to a qualified service centre

when service or repair is required. Incorrect reassembly may result in risk of

electrical shock or fire.

9 Unplug charger from outlet before

attempting any cleaning to reduce risk of

electric shock.

10 Charge the battery pack in a well venti-

lated place; do not cover the charger and

battery with anything while charging.

11 Do not store the charger or battery packs

in locations where the temperature may

reach or exceed 122 °F (50 °C) such as a

metal tool shed, or a car in the summer

which can lead to deterioration of the

storage battery.

12 Do not charge battery pack when the

temperature is below 40 °F (5 °C) or

above 105 °F (40 °C). This is very impor-

tant for proper operation.

13 Do not incinerate battery pack. It can

explode in a fire.

14 Do not charge battery in damp or wet

locations.

15 Do not attempt to charge any other

cordless tool or battery pack with the

Lincoln model 1870 series charger.

16 Do not short across the terminals of the

battery pack. Extremely high temperatures could cause personal injury or fire.

17 This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge.

18 Dispose of expended batteries properly.

The Lincoln model 1871 battery pack

contains rechargeable, lithium-ion batteries. These batteries must be recycled

or disposed of properly. Drop off

expended battery packs at your local replacement battery retailer, or your recycling centre.

11

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

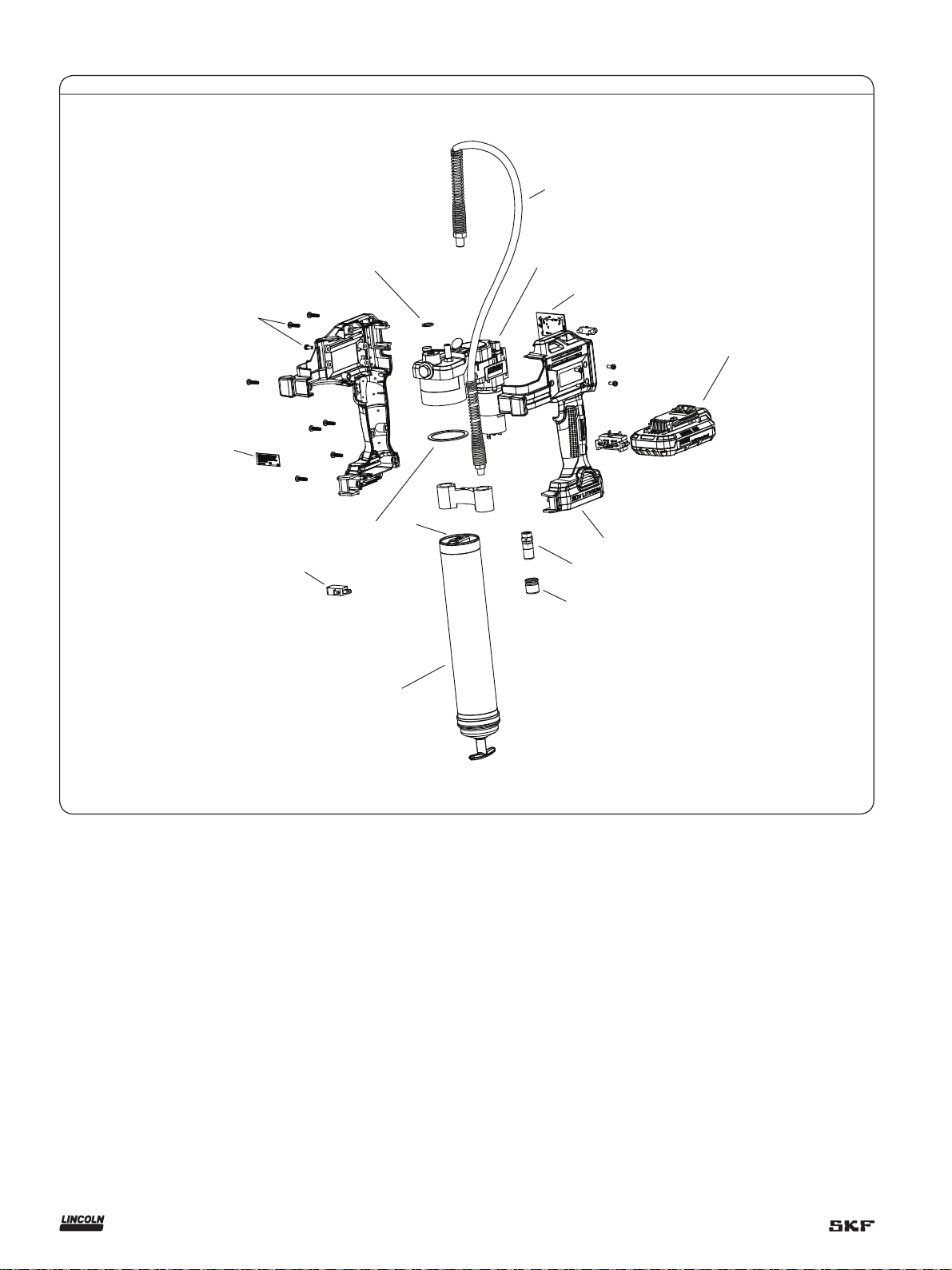

Fig. 6

1

6

11

9

4

3

12

5

13

8

17

10

2

7

12

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

7

16

/

UNEF thread

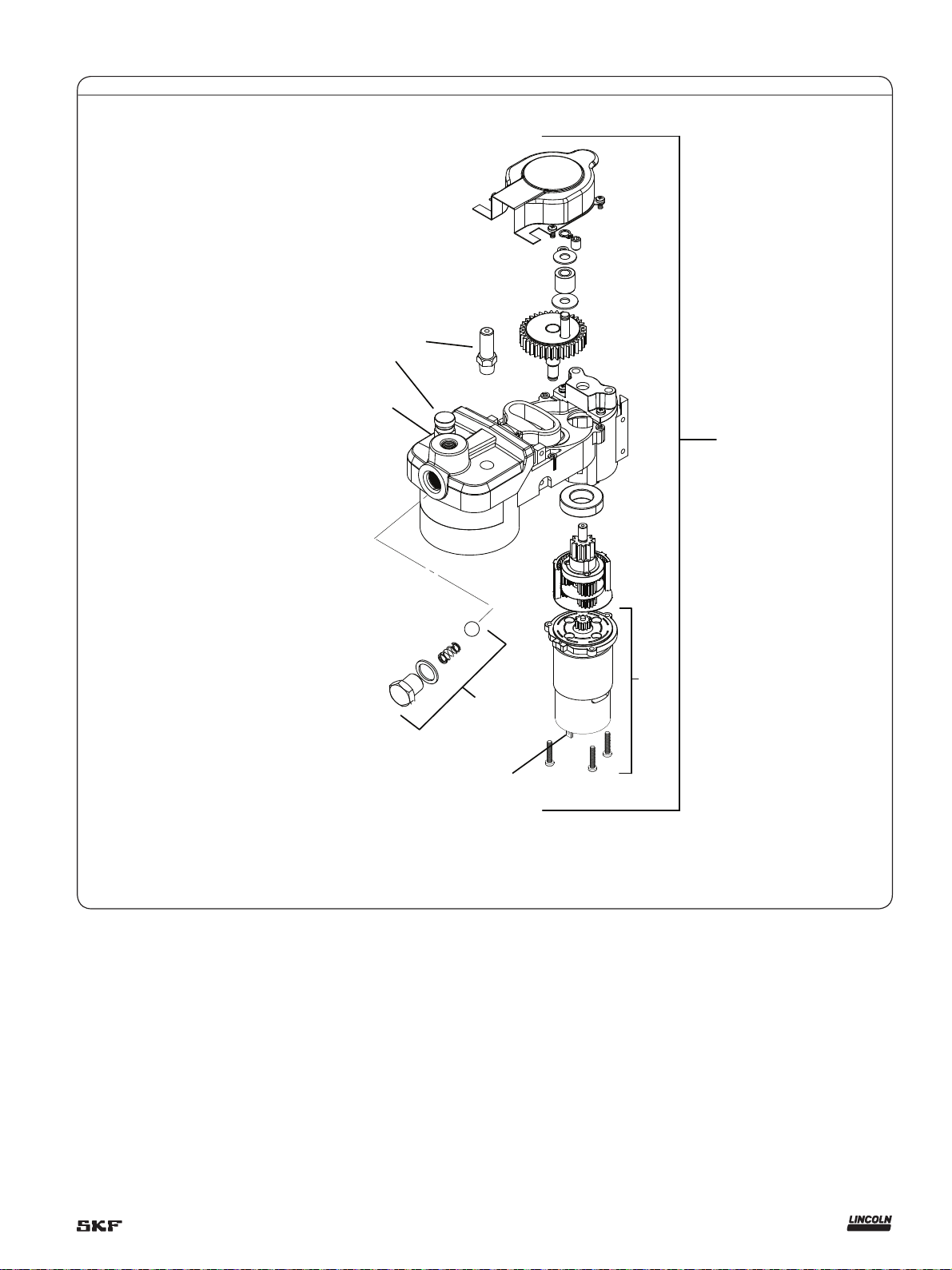

Fig. 7

18

16

- 28

13

14

Positive (red) wire must be

connected to the positive

terminal on the motor. A small

plastic dot identifies the positive

terminal.

15

13

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Service parts list

Item Description Part number

1 Flexible hose 36 in.(914 mm)

with gasket

2 Coupler (model 1880) 5852

Coupler (model 1880E) 251-10124-7

3 Packing 34793

4 Follower assembly kit 272072

5 Grease tube assembly 271882

6 Gasket kit (hose) 271884

7 Coupler cap kit 286093

8 Electrical components kit 280067

9 Decal kit 280068

10 Handle with electrical

component kit

11 Handle with screw kit 280070

12 Switch kit 280071

13 Pump assembly kit 280072

14 Check valve kit 280073

15 Motor with adapter kit 280074

16 Vent valve kit 286315

17 Battery 18 V (lithium) 1871

18 Filler nipple 91108

Not shown Charger (lithium) 1870

Not shown Strap 1414

Not shown Case kit 280085

1236

280069

14

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Troubleshooting

Condition Possible cause Corrective action

Motor fails to run. Battery needs charging. Recharge battery.

Faulty wiring to motor. Remove battery, disassemble handle and check

PowerLuber fails to dispense grease. Grease tube assembly is out of grease. Check that grease tube assembly has grease.

Loss of prime. Repeat priming operation.

Ball check (14) is not functioning. Remove ball check (14), clean and inspect ball

PowerLuber continues to lose prime. Air may be trapped in several locations in container

after bulk filling.

Follower may be binding in grease tube assembly. Replace grease tube assembly (5). Disassemble

Check ball seat and check ball dirty. Clean check ball and check ball seat.

Battery fails to take a charge. Charger may not have power. Check that receptacle has power.

Battery may be bad. Replace battery.

wiring for loose connection.

seat area.

Empty grease tube assembly, refill and repeat

priming instructions.

grease tube assembly and clean. Be sure that

follower has properly entered the grease

cartridge.

or

Verify that the follower is not caught on the rim

of the grease cartridge.

15

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Declaration of Confomrity as defined by

Machinery Directive 2006/42/EC.

The manufacturer Lincoln Industrial, hereby

declares that the model of the PowerLuber

Grease Gun in the version supplied by us

complies with the provision of the above

mentioned directive.

Complies with the following EC-Directives

and standards

2006/42/EC, 2009/98/EC, 2004/108EC,

2006/66/E, EN ISO 12100:2011,

EN 55014-1, EN 55014-2, EN 61000-7,

EN 60745-1

St. Louis, MO January 2014 Paul Conley,

Chief Engineer

16

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Lincoln industrial

standard warranty

Standard limited warranty

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free

from defects in material and workmanship

for a period of one (1) year following the

date of purchase, excluding there from any

special, extended, or limited warranty published by Lincoln. If equipment is determined to be defective during this warranty

period, it will be repaired or replaced, within

Lincoln’s sole discretion, without charge.

This warranty is conditioned upon the

determination of a Lincoln authorized representative that the equipment is defective.

To obtain repair or replacement, you must

ship the equipment, transportation charges

prepaid, with proof of purchase to a Lincoln

Authorized Warranty and Service Center

within the warranty period.

This warranty is extended to the original

retail purchaser only. This warranty does not

apply to equipment damaged from accident,

overload, abuse, misuse, negligence, faulty

installation or abrasive or corrosive material,

equipment that has been altered, or equipment repaired by anyone not authorized by

Lincoln. This warranty applies only to equipment installed, operated and maintained in

strict accordance with the written specifications and recommendations provided by

Lincoln or its authorized field personnel.

This warranty is exclusive and is in lieu

of any other warranties, express or

implied, including, but not limited to, the

warranty of merchantability or warranty

of fitness for a particular purpose. War-

ranty on items sold by Lincoln, but not

manufactured by Lincoln are subject to

the warranty consideration, if any, of

their manufacturer (such as hoses,

hydraulic and electric motors, electrical

controllers, etc.) Assistance in making

such warranty claims can be offered as

required.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s

liability for any claim for loss or damages

arising out of the sale, resale or use of any

Lincoln equipment shall in no event exceed

the purchase price. Some jurisdictions do

not allow the exclusion or limitation of incidental or consequential damages, therefore

the above limitation or exclusion may not

apply to you.

This warranty gives you specific legal

rights. You may also have other rights that

vary by jurisdiction.

Customers not located in the Western

Hemisphere or East Asia: Please contact

Lincoln GmbH and Co. Kg, Walldorf,

Germany, for your warranty rights.

Special limited warranties

Special limited 2 year warranty

SL-V series, single injectors – 85772,

85782, and replacement injectors –

85771, 85781

Lincoln warrants the SL-V Injector series to

be free from defects in material and workmanship for two (2) years following the date

of purchase. If an injector model (single or

replacement) is determined to be defective

by Lincoln, in its sole discretion, during this

warranty period, it will be repaired or

replaced, at Lincoln’s discretion, without

charge.

Special limited 5 year warranty

series 20, 25, 40 bare pumps, pmv bare

pumps, heavy duty and 94000 series bare

reels

Lincoln warrants series 20, 25, 40 bare

pumps, PMV bare pumps, heavy duty

(82206), mini bench (81133, 81323), and

all 94000 LFR series (single arm and dual

arm) bare reels to be free from defects in

material and workmanship for five (5) years

following the date of purchase. If equipment

is determined by Lincoln, in its sole discretion, to be defective during the first year of

the warranty period, it will be repaired or

replaced at Lincoln’s discretion, without

charge. In years two (2) and three (3), the

warranty on this equipment is limited to repair with Lincoln paying parts and labor

only. In years four (4) and five (5), the warranty on this equipment is limited to repair

with Lincoln paying for parts only.

Special limited 5 year warranty

limited oil meters, limited fluid control

valves, aod (air-operated diaphragm

pumps)

Lincoln warrants the 712 series control

valves, 912 series lube meters, electronic

lube meters (980, 981, 982 series), our

universal inline digital meters (812/813

series), and our AOD pump offering to be

free from defects in material and workmanship for five (5) years following the date of

purchase. If either is determined to be

defective by Lincoln, in its sole discretion,

during the warranty period, they will be

repaired or replaced, at Lincoln’s discretion,

without charge.

Special DEF (diesel exhaust fluid) limited

warranty

DEF products are warranted to be free from

defects in material and workmanship for a

period of one (1) year following the date of

purchase. The following exceptions to the

standard warranty period are in effect:

• 85700-30/85700-50 DEF hose reels

(bare reel only),

277251/277252 AC DEF pumps, and

277256 and 277257 DEF meters are

warranted for two (2) years from date of

purchase.

• 85623 DEF AOD

(air operated diaphragm) pumps

are covered under the standard five (5)

year AOD pump warranty.

If either is determined to be defective by

Lincoln, in its sole discretion, during the

warranty period, they will be repaired or

replaced, at Lincoln’s discretion, without

charge.

Lincoln Industrial contact information

To find Lincoln Industrial’s nearest service

center call the following number;

customer service 314-679-4200

(international number 01-314-679-4200)

or you may also use our website

www.lincolnindustrial.com

17

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

This page left intentionally blank

18

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

This page left intentionally blank

19

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

® SKF is a registered trademark of the SKF Group.

® Lincoln is a registered trademark of Lincoln Industrial Corp.

© SKF Group 2014

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

SKF PUB LS/I4 14386 EN · January 2014 · Form 423077A

lincolnindustrial.com skf.com/lubrication

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

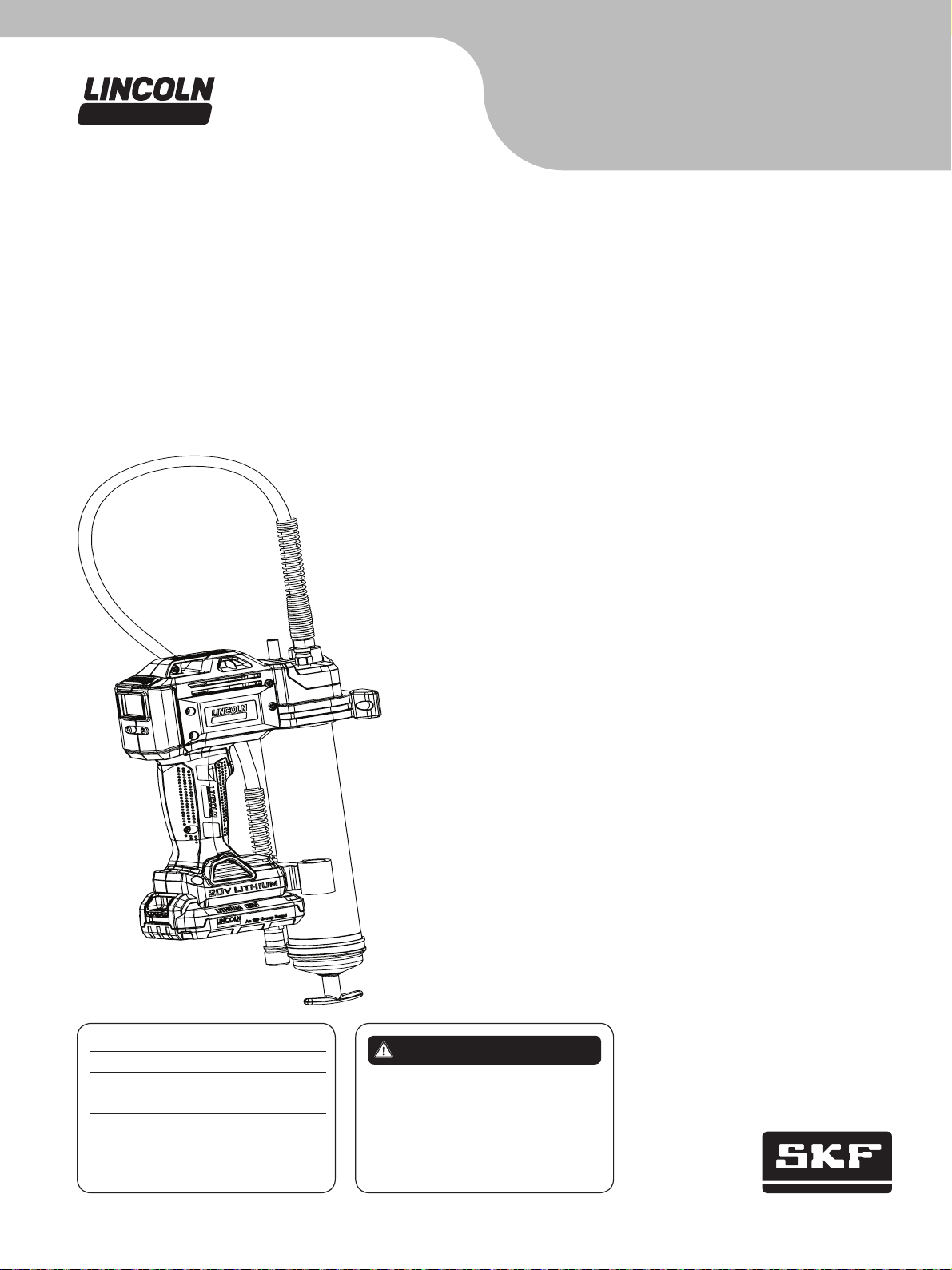

Guide d’installation et de maintenance

Pistolet graisseur PowerLuber

(lithium-ion)

1880, 1882, 1882E, 1884 série « A »

Date de publication Janvier 2014

Numéro de publication 423077A

Section D7

Page 86A

DANGER

Lisez le manuel avant l’installation ou

l’utilisation de ce produit. Conserver le

manuel à proximité pour référence

future. Le non-respect des instructions et

des consignes de sécurité peut entraîner

la mort ou des blessures graves.

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Table des matières

Consignes générales de sécurité .... 2

Consignes particulières de sécurité . . 3

Contrôle ....................... 5

Utilisation ...................... 5

Fonctionnement du chargeur ....... 8

Instructions de sécurité relatives au

chargeur et aux batteries .......... 11

Vue éclatée et liste des pièces ...... 13

Dépannage ..................... 15

Consignes générales

de sécurité pour

l’outillage électrique

AVERTISSEMENT

Lire toutes les consignes et instructions

de sécurité. Leur inobservation risque

d’entraîner une électrocution, un incendie et/ou des blessures graves.

Conserver toutes les consignes et instructions pour pouvoir s’y référer à l’avenir.

Le terme « outil électrique » mentionné

dans les consignes se réfère à un outil branché sur secteur (à fil) ou alimenté par batterie (sans fil)

Sécurité des lieux de

d’électrocution en cas de mise à la terre du

corps.

Ne pas exposer les outils électriques à la

pluie ni à l’humidité. La pénétration d’eau

dans un outil électrique accroîtra le risque

d’électrocution.

Ne pas maltraiter le cordon. Ne jamais se

servir du cordon pour transporter, tirer ou

débrancher l’outil électrique. Ne pas

approcher le cordon d’une source de

chaleur, de l’huile, des arêtes vives ou de

pièces mobiles. Un cordon endommagé ou

emmêlé accroît le risque d’électrocution.

Lorsqu’on se sert d’un outil électrique à

l’extérieur, utiliser un cordon prolongateur

conçu à cet effet. L’utilisation d’un tel cordon

réduit le risque d’électrocution.

Si on ne peut éviter d’utiliser un outil

électrique dans un endroit humide, employer une alimentation protégée par dispositif

différentiel résiduel (DDR).

Avis

!

Le terme « dispositif différentiel

résiduel (DRR) » peut être remplacé par

« disjoncteur différentiel de fuite à la

terre (DDFT) » ou « disjoncteur différentiel résiduel (DDR) ».

travail

Maintenir les lieux de travail propres et bien

éclairés. Les lieux encombrés ou sombres

invitent les accidents.

Ne pas utiliser d’outils électriques dans

les at¬mosphères explosibles, par exemple

en présence de liquides, gaz ou poussière

inflam¬mables. Les outils électriques produisent des étincelles pouvant enflammer la

poussière ou les vapeurs.

Ne pas laisser des enfants ni des spectateurs s’approcher lorsqu’on se sert d’un outil

électrique. Les distractions peuvent causer

une perte de contrôle.

Sécurité électrique

La fiche d’un outil électrique doit s’adapter à

la prise. Ne jamais modifier la fiche en quoi

que ce soit. N’utiliser aucun adaptateur avec

les outils électriques à mise à la terre.

Les fiches et prises correspondantes non

modifiées réduiront le risque d’électrocution.

Éviter tout contact du corps avec les surfaces mises à la terre telles que celles des

canalisations, radiateurs, cuisinières et

réfrigérateurs. Il y a un risque accru

Sécurité personnelle

Utiliser un équipement de protection

individuelle. Toujours porter des lunettes de

protection. L’utilisation d’un équipement de

protection, tel que masque antipoussière,

chaussures de sécurité à semelle antidérapante, casque de chantier ou protecteurs

d’oreilles, adapté aux conditions réduira le

risque de blessures.

Retirer toute clé de réglage avant de met-

tre l’outil en marche.

Utilisation et entretien d’un

outil électrique

Ne pas forcer l’outil électrique. Utiliser l’outil

électrique adapté à l’application. Un tel outil

fera mieux son travail plus en sécurité à la

vitesse pour laquelle il a été conçu.

Ne pas se servir de l’outil si le commutateur ne le met pas sous et hors tension. Tout

outil électrique qui ne peut être commandé

au moyen du commutateur est dangereux

et doit être réparé.

2

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Débrancher la fiche de la prise et/ou la batterie de l’outil avant d’effectuer tout réglage,

de changer d’accessoire ou de ranger des

outils électriques.

Ranger les outils électriques inactifs hors

de la portée des enfants et ne laisser personne qui n’est pas familiarisé avec l’outil ou

ses instructions s’en servir.

Entretenir les outils électriques.

Vérifier les pièces mobiles pour voir si elles

sont désaxées ou grippées, les autres pièces

pour voir si elles sont cassées ou dans tout

autre état susceptible d’affecter le fonctionnement de l’outil.

Utiliser l’outil, ses accessoires et ses embouts conformément aux instructions.

Utilisation et entretien d’un

outil à batterie

Ne recharger les batteries qu’à l’aide du

chargeur spécifié par le fabricant.

N’utiliser les outils électriques qu’avec les

batteries spécifiées. L’emploi de toute autre

batterie peut créer un risque de blessures et

d’incendie.

Lorsqu’une batterie n’est pas en service,

ne pas l’approcher d’objets métalliques tels

que trombones, pièces de monnaie, clés,

clous, vis ou autres petits objets métalliques

pouvant relier une borne à une autre.

La mise en court-circuit des bornes de la

batterie peut entraîner des brûlures ou un

incendie.

Si la batterie est maltraitée, du liquide

peut en être expulsé ; éviter tout contact.

En cas de contact fortuit, rincer à l’eau. Si du

liquide touche les yeux, consulter un

médecin. Le liquide expulsé de la batterie

peut causer une irritation ou des brûlures.

Consignes

particulières de

sécurité

• Toujours porter des lunettes de protection. Le PowerLuber peut produire une

pression allant jusqu’à 689 bar

(10,000 psi).

• N’utiliser que des flexibles courts de sortie Lincoln 1218, 1224, 1230 ou 1236.

Les injections accidentelles de graisse

causent des blessures très graves.

Ne tenir le flexible que dans la zone de la

protection par ressort. Éviter une mise en

marche intempestive. Veiller à ne pas

appuyer sur le commutateur lors de

l’insertion de la batterie.

• Remplacer le flexible au premier signe

d’usure, de pincement ou

d’endommagement de la gaine

extérieure.

• Ne pas recourber le flexible pour qu’il ne

se pince pas.

• Remplacer le flexible au premier signe

d’usure, de pincement ou

d’endommagement de la gaine

extérieure.

• Ne pas trop se pencher en avant.

Garder un bon équilibre en permanence.

Cela permet un meilleur contrôle de l’outil

dans les situations imprévues.

• Utiliser un équipement de sécurité.

Toujours porter des lunettes de

protection.

• Porter un masque antipoussière, des

chaussures de sécurité à semelle antidérapante, un casque de chantier ou des

protecteurs d’oreilles adaptés aux

conditions.

AVERTISSEMENT

L’utilisateur doit lire de manuel

d’utilisation pour réduire les

risques de blessures

Collecte séparée. Ce produit ne

doit pas être ajouté aux ordures

ménagères normales.

AVERTISSEMENT

Le pistolet graisseur peut produire une

pression élevée - jusqu’à 689 bar

(10,000 psi). Porter des lunettes de sécurité et des gants pour se protéger

pendant l’utilisation. Ne pas approcher

les mains de la partie dénudée en caoutchouc du flexible.

Réparation

La réparation de l’outil ne doit être effectuée

que par des réparateurs qualifiés. Une réparation ou un entretien effectué par du personnel non qualifié peut annuler la garantie

et entraîner des risques de blessures.

Lors de la réparation d’un outil, n’utiliser

que des pièces de rechange identiques à

celles d’origine.

AVERTISSEMENT

N’utiliser aucun flexible non agréé par

Lincoln. Une pression très élevée risque

d’entraîner l’éclatement de la rallonge de

buse ou du flexible court.

Remplacer le tuyau au premier signe

d’usure, de déformation ou de détérioration enveloppe extérieure.

Suivre les instructions et les consignes concernant le flexible court. Leur

inobservation peut entraîner des blessures graves, voire mortelles.

3

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Le pistolet utilise des lubrifiants qui peuvent

être inflammables et toxiques en cas

d’ingestion. Ne pas se servir du pistolet près

d’une flamme nue ni de quoi que soit d’autre

susceptible de présenter des risques

d’incendie.

Les graisses sont souvent commercialisées comme convenant aux hautes

tem¬pératures parce qu’elles doivent conserver leurs propriétés lubrifiantes dans les

endroits chauds mais les lubrifiants peuvent

être inflammables si la température est trop

élevée. Lire toutes les mises en garde figurant sur les contenants de lubrifiant avant

de se servir de ce pistolet. Ne pas utiliser

des graisses inflam¬mables avec ce pistolet

graisseur.

N’utiliser que des accessoires recommandés

par Lincoln.

N’utiliser que des accessoires capables

d’accepter une pression de 689 bar

(10,000 psi). Des accessoires adaptés à un

outil peuvent créer des risques de blessures

lorsqu’ils sont utilisés avec un autre outil.

Utilisation correcte

Le PowerLuber est spécialement conçu pour

pomper et distribuer du lubrifiant en étant

alimenté par batterie 18 volts. Ne pas dépasser les spécifications nominales maxima.

Caractéristiques techniques

Modèle PowerLuber 1880 de base

Tension de

fonctionnement

Pression maximum de fonctionnement

Bas débit 413 bar (6,000 psi)

Haut débit 413 bar (6,000 psi)

Contenance du

réservoir de graisse

Pression de crête

maximum

Plage de température

de fonctionnement

Intensité de

fonctionnement

Intensité nominale 5 A à –6 à 54 °C

Lubrifiant (graisse) jusqu’à NLGI n° 2

14,5 à 20,5 V c.c.

411 g (14,5 oz.)

689 bar (10,000 psi)

–18 à 50 °C

(0 à 120 °F)

4 A à –6 à 54 °C

(20 à 130 °F)

(20 à 130 °F)

Utilisation et entretien

de l’outil

Ne pas se servir de l’outil si son commutateur ne le met pas sous et hors tension.

Tout outil qui ne peut être commandé au

moyen du commutateur est dangereux et

doit être réparé.

Ne pas continuer à presser la détente si le

pistolet graisseur est bloqué. Cela pourrait

endommager le moteur ou causer un

incendie.

Débrancher la batterie de l’outil avant

d’effectuer tout réglage, de changer

d’accessoire ou de ranger l’outil. De telles

mesures préventives de sécurité réduisent

le risque de mise en marche intempestive

de l’outil.

Ranger les outils hors de la portée des

enfants ou d’autres personnes non formées

à leur emploi. Les outils sont dangereux

dans les mains des utilisateurs non formés.

Lorsqu’une batterie n’est pas en service,

ne pas l’approcher d’objets métalliques tels

que trombones, pièces de monnaie, clés,

clous, vis ou autres petits objets métalliques

pouvant relier une borne à une autre.

La mise en court-circuit des bornes de la

batterie peut entraîner des étincelles, des

brûlures ou un incendie.

Entretenir soigneusement les outils.

Vérifier les pièces mobiles pour voir si elles

sont désaxées ou grippées, les autres pièces

pour voir si elles sont cassées ou dans tout

autre état susceptible d’affecter le fonctionnement de l’outil. Si l’outil est endommagé, le faire réparer avant de s’en resservir. De nombreux accidents sont causés par

des outils mal entretenus.

Débit de graisse

Bas débit (l) 99 g/mn

Haut débit (h) 1 526 g/mn

Poids 4,0 kg (8.8 lbs.)

Accessories

Battery li-ion Modèle 1871

Tension de sortie 20 V c.c. maximum

Capacité 1,500 mAh

Chargeur de batterie Modèle 1870

Temps de charge 1,5 heure

Tension à l’entrée,

V c.a. (0,6 A)

Flexible de sortie Modèle 1236

Pression nominale 689 bar (10,000 psi)

Longueur du flexible 914 mm (36 po)

Note 1 : Données d’intensité de fonctionnement et de débi

de graisse à ().

Note 2 : La valeuNote 1 : r totale des vibrations déclarée a

été mesurée conformément à une méthode d’essai normalisée et peut être utilisée pour comparer un outil à un autre.

Elle peut également être utilisée dans une évaluation

préliminaire d’exposition.

Note 3 : L’émission de vibrations pendant l’utilisation effective de l’outil électrique peut différer de la valeur totale déclarée suivant les méthodes d’utilisation de l’outil ; elle

dépend également du besoin d’identifier les mesures de sécurité devant être prises pour protéger l’opérateur, qui sont

basées sur une estimation de l’exposition dans les conditions

réelles d’utilisation (en tenant compte de toutes les phases

du cycle de fonctionnement telles que les périodes pendant

lesquelles l’outil est hors tension et celles pendant lesquelles

il tourne à vide, en plus du temps de marche).

(3,5 oz./mn)

(5,5 oz./mn)

120 v, 60 hz

4

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Loading...

Loading...