Page 1

Impinger® Dual Technology Finisher (DTF-16)

Single Belt Conveyorized Electric Platform

Models:

Impinger

1962 1961

Standard Features:

• Impinger® Dual-Tech Finisher

(DTF-16) combines our patented

Air Impingement with high intensity infrared heating

elements to achieve superior

toasting times and crispness.

• High velocity air impinges

the food for rapid heat transfer,

uniformity and doneness, while

the IR elements provide

superior browning, toasting

and crisping.

• The DTF-16 oers rapid heating,

cooking, baking and crisping

of foods, and is up to two

times faster than conventional

air impingement and up to

four times faster than

convection ovens.

• Cool-Skin exterior stays cool to

the touch during operation.

®

Dual Technology Finisher (DTF-16)

• Variable speed conveyor moves

products through the nisher,

improving product ow during

toasting and virtually

eliminating labor.

• Consistency of conveyorized

product movement is a denite

advantage over batch type

toasters, as it eliminates the

need for constant tending.

Specications:

Ge neral : Th e el ectr ic f inisher is self -con tained,

con veyor ized and sta ckab le up t o tw o hi gh. I t is

des igne d for c ount erto p us e and m ust be u sed

wit h th e ap propriate 4” le gs f or prop er c ooling.

Temp erature is adju stable fr om 2 50°F (93° C) to

650 °F ( 343° C). Conv eyor spee d is adj usta ble fro m

15 seco nds to 15 min utes cooki ng time . C onvey or

and air dis trib ution f inge rs a re re mova ble

thr ough the side- access pane ls f or ea sy c lean ing.

Remov able cru mb pa ns a re l ocate d be low the

con veyor bel t ou tsid e the bak ing cham ber.

Con trol s: Th e con trol s are loc ated on the rea r

right han d si de of the fin ishe r. I t in cludes a po wer

on- off sw itch , te mpera ture cont rol, conv eyor

spe ed c ontrol, and four o ne- touch pre set butto ns.

1111 Nor th Hadley Road

P.O. Box 1229

Fort Wayne, Indiana 46801-1229

Tel 1.260.459.8200

Fax 1.260.436.0735

E mail info@lincolnfp.com

web www.lin colnfp.com

Con stru ctio n: E xter ior is f abricat ed f rom No. 4

fin ish stai nles s ste el. The air d istr ibut ion syste m

con sist s of a mixe d-fl ow t ype fan pow ered by a

fra ctio nal hp AC m otor. The heated air is force d

thr ough air distribu tion fin gers loca ted in t he

bak ing ch ambe r ab ove a nd b elow the co nveyo r.

Eac h fi nger has the requ ired numb er o f ho les

to maxi mize the air impi ngem ent e ffec t on the

foo d pr oduc t passi ng t hrou gh the cham ber on

the con veyor bel t. T he co nveyo r be lt i s a flexi ble

sta inle ss s teel desi gn w ith capacit y fo r 16 ”

(40 6mm) wid e produ ct a nd a tra vel d ista nce of 53 ”

(13 46mm ), o f wh ich 2 3” (584m m) i s i n th e bak ing

cha mber. An AC, brus hles s motor pow ers the

dir ect driv e conve yor.

The fus es f or t he c ontro ls a nd b lowe r mo tor are

lo cated on the back of the cont rol box.

www.lincolnfp.com

Page 2

Impinger

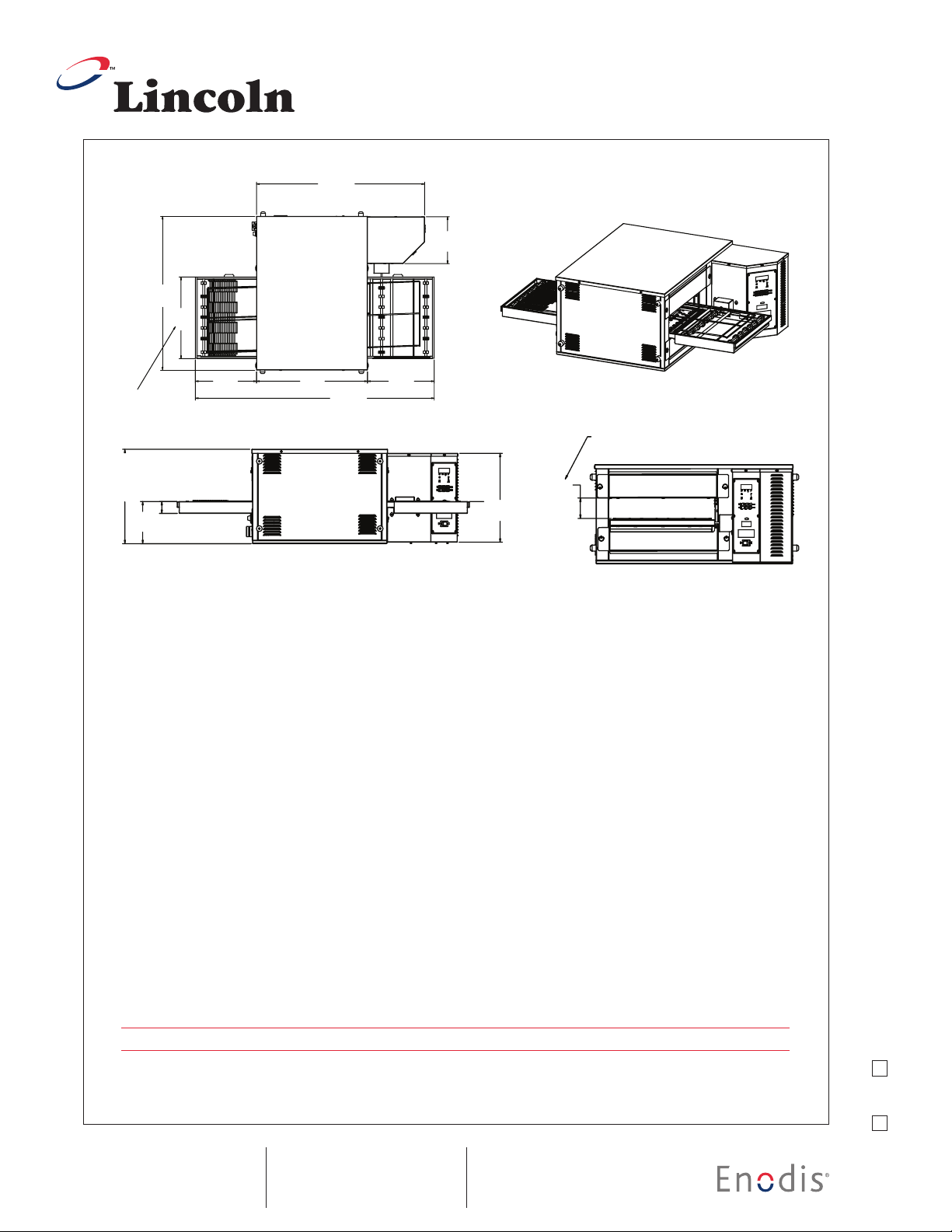

CONVEYOR WIDTH

32”

(813mm)

35”

(889mm)

23”

(584mm)

16”

(406mm)

14”

(356mm)

17”

(432mm)

53”

(1346mm)

9⅞”

(251mm)

CONVEYOR OPENING

3

¾”

(95mm)

CONVEYOR OPENING

32”

(813mm)

35”

(889mm)

23”

(584mm)

16”

(406mm)

14”

(356mm)

17”

(432mm)

53”

(1346mm)

7¼”

(184mm)

16”

(406mm)

3

¾”

(95mm)

15”

(381mm)

9⅞”

(251mm)

®

Dual Technology Finisher (DTF-16)

ELECTRIC AL SERVICE: Heat is supplied by six (6)

infrared elements at 120 0W each, (user may select

any three (3 ) e lem ents to be acti vated at on e t ime,)

one (1) ma in fan el eme nt at 8000W. Each fi nis her is

rated at 12 kW. The DTF- 16 is available in 208V or

240V, 3- phase power. A separate circuit breaker is

required for each finisher with the prope r voltage,

amperag e, phase and hertz as in dic ated by model

number. UN IT REQUIRES 50 AMP SERVI CE. Plug

type NEMA- 15-50P.

VENTILATIO N: Ventil ation is not required but

local codes prevail. These are the “authority

having jur isdiction” as state d by the National Fire

Pro tec tion Asso ciation, Inc. in NFPA 96-1 994 .

Testing

Agency

Listing

UL/CUL 1961 32” 53” 16”

UL/CUL 1962 32” 53” 16”* 32”* 12 kW 240V 32 3 60

NOTE: Specications subject to change without notice.

*Without legs. Legs are 4” tall.

1111 Nor th Hadley Road

P.O. Box 1229

Fort Wayne, Indiana 46801-1229

Cat. # Width Depth

Tel 1.260.459.8200

Fax 1.260.436.0735

E mail info@lincolnfp.com

web www.lin colnfp.com

Height

Single

Stack

*

SPACING: The finisher must have 6” (152mm)

of clea rance from combustible sur face s a nd 24”

(610mm) cl earance on both sides from other

cook ing equipment. The conveyor can be re moved

from either side of the DTF.

WARRANTY: All new Impinger® DTF’s come with

a one year parts/labor warranty. Defective parts

of the origin al equipment on all installed DTF’s are

warranted fo r one year fro m the date of purchase.

Height

Double

Stack

Input

Rate

Volts Amps Phase Hz

32”* 12 kW 208V 36 3 60

©2006 Lincoln Foodservice Products, Inc.

Printed in the U.S.A.

1546-2.5M-04/06-SP

Models:

1961 1962

Loading...

Loading...