Lincoln 1629-00Z-E-K Service Manual

PARTS & SERVICE MANUAL

Impinger Low Profile – Advantage Digital Series (Electric)

International Models

MODELS:

Please note that the model numberi ng system changed

March 2007. The chart below shows the old model

numbering system and its matching new model number.

Old Model Number

1621-000-EA

1628-000-A

1629-000-A

New Model Number

→

1621-00z-E-Kxxxx

→

1628-00z-E-Kxxxx

→

1629-00z-E-Kxxxx

→

P/N: L371152

REV: 10.22.09

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

Telephone: 260.459.8200

Fax: 888.790.8193

Technical Support: 800.678.9511

lincolnfp.com

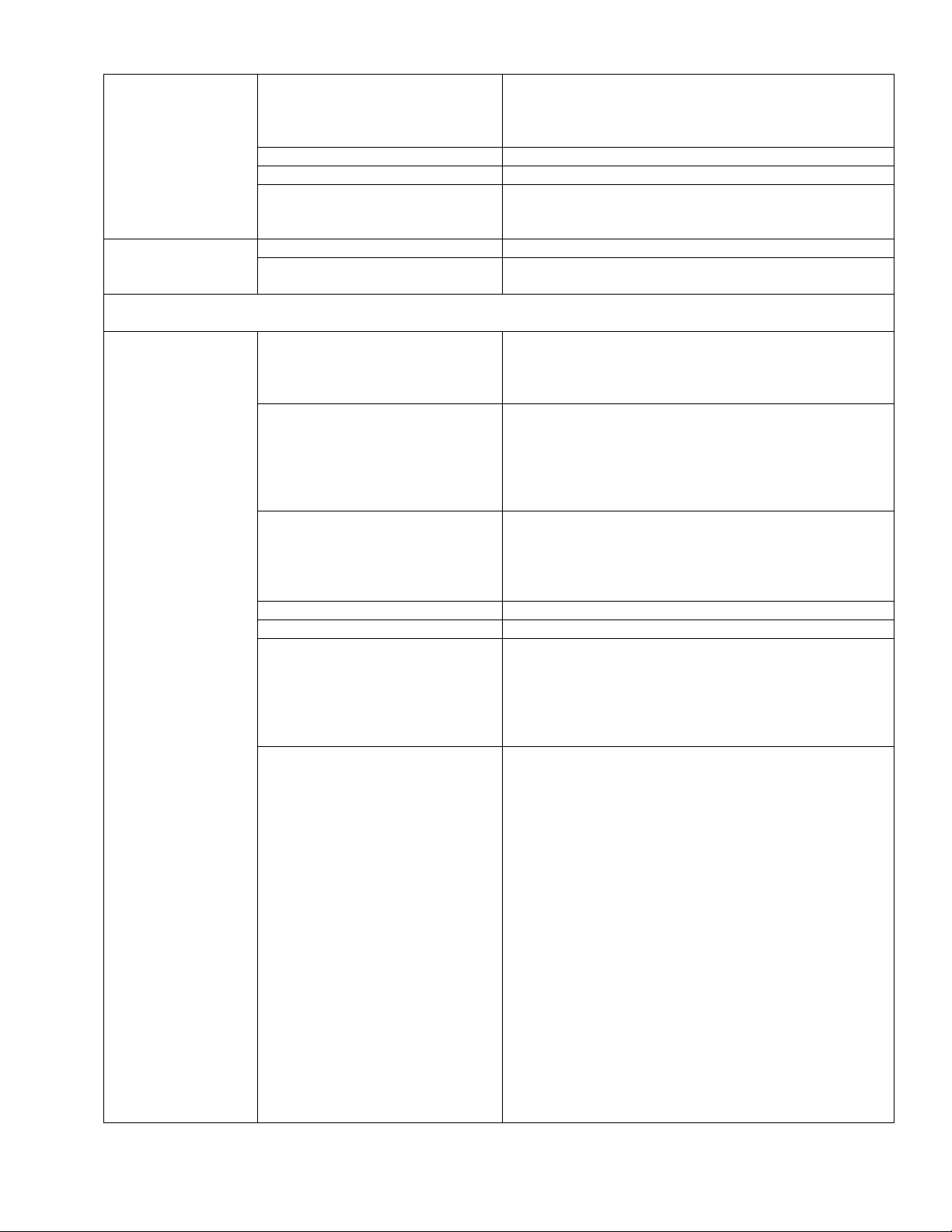

SEQUENCE OF OPERATIONS

IMPINGER ELECTRIC LOW PROFILE ADVANTAGE

(WITH PUSH BUTTON CONTROL)

MODEL 1621-000-EA 230/400 VAC 50HZ

MODEL 1628-000-A 220/380 VAC 50HZ

MODEL 1629-000-A 224/415 VAC 50HZ

POWER SUPPLY Electrical power to be supplied to the oven by a five conductor service.

Brown conductor is hot.

Black conductor is hot.

Black conductor is hot.

Blue conductor is neutral.

Green conductor is ground.

CONTROL BOX

AUTO COOL DOWN

When the temperature in either one of the control boxes reaches 120°F ±3° (49°C ±

1.7°), the cooling fan thermostats will switch power to the cooling fans. The thermostats

will interrupt power to the cooling fans when the temperature falls to 100°F ± 3° (37°C ±

1.7°)

MAIN FAN CIRCUIT Line voltage is permanently supplied (through a power filter) to a normally open contact of

the oven power switch. Line voltage is permanently supplied to the two normally open

cooling fan thermostats. Closing the oven power switch supplies line voltage, through both

normally closed control box hi-limit thermostats, to the oven power relay. Its contacts now

close supplying line voltage to the two main fan motors. Closing the oven power switch also

supplies line voltage to the control box cooling fans, the oven control, the control

transformer, and the conveyor motor.

TEMPERATURE

CONTROL

Closing the oven power switch supplies line voltage, through the 10 amp. fuse, through the

oven power relay, to the primary of the control transformer. 24VAC is supplied to the oven

control. The oven control is set to desired temperature. The thermocouple will provide

varying millivolts to the oven control. The oven control supplies line voltage to the contactor

at intermittent intervals to maintain desired temperature. The display on the oven control

will indicate when the contactor is energized.

NOTE: The display also indicates oven temperature.

CONVEYOR DRIVE Closing the oven power switch supplies line voltage, through the 10 Amp fuse, through the

oven power relay to the conveyor motor and to the primary of the control transformer.

Secondary voltage, 24VAC, is supplied to the oven control. Setting the oven control to the

desired time, outputs voltage, through a reversing switch, to the conveyor motor

NOTE: The conveyor system uses a magnet and hall effect sensor to prove operation of

the conveyor motor. If the conveyor motor is not running, “BELT JAM” is indicated on the

display.

AUTOMATIC COOL

DOWN

When the oven is started, the time delay relay timing circuit is enabled, permitting the oven

fans to operate for approximately 20 minutes after the oven is shut off, to cool the oven.

The time delay relay will keep the coil of the motor relay closed, maintaining operation of

main fan and cooling motors.

2

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

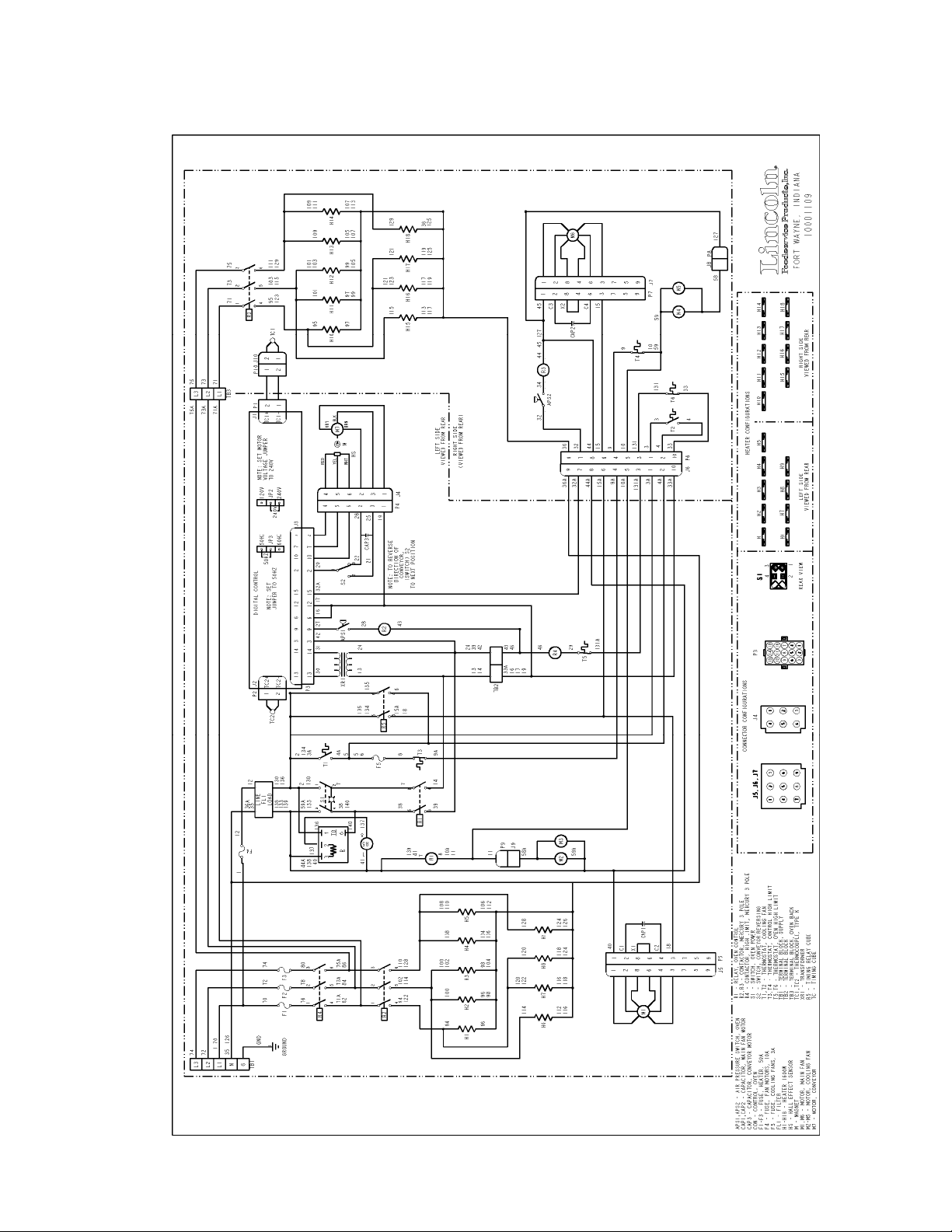

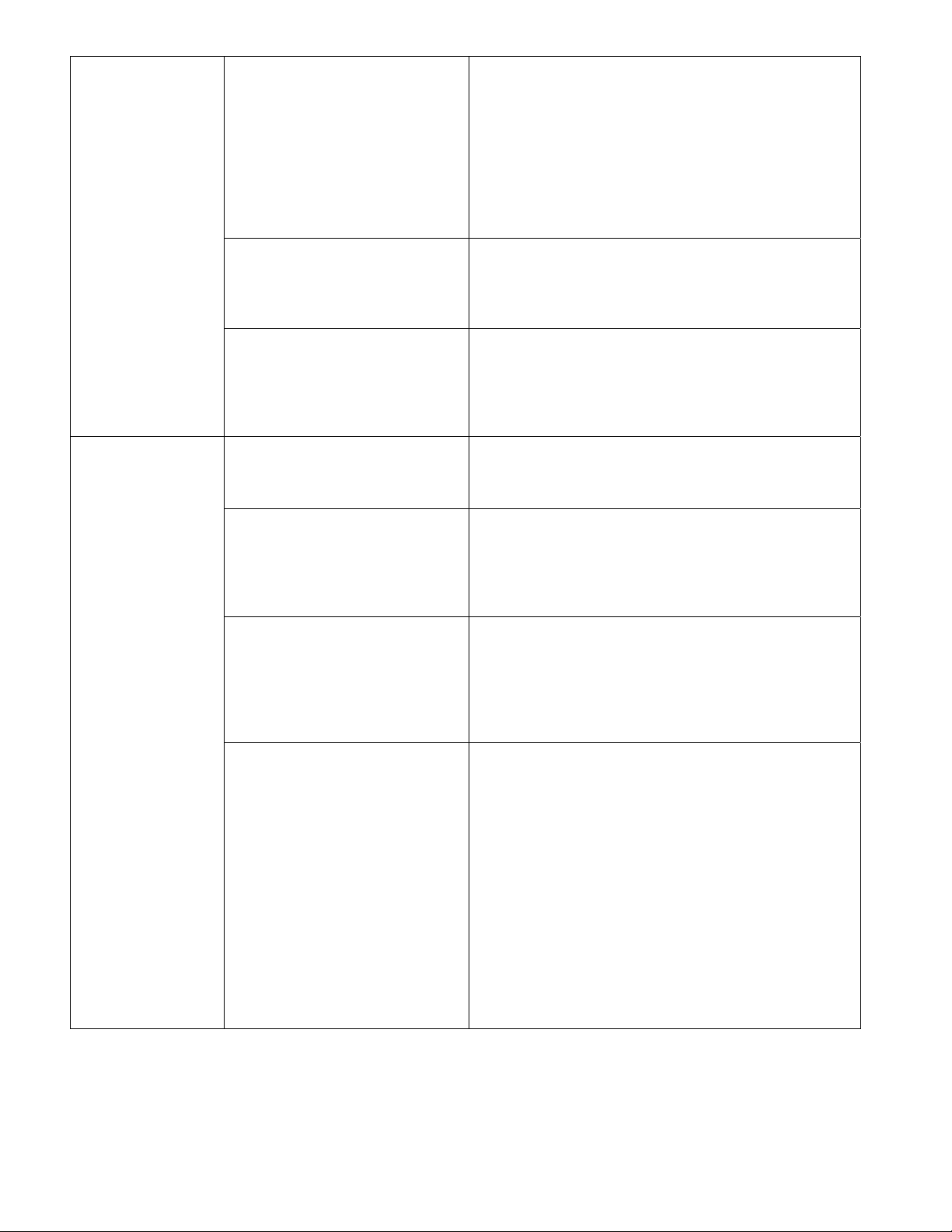

SCHEMATIC

MODEL 1621-000-EA, 1628-000-A, 1629-000-A

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

3

pany

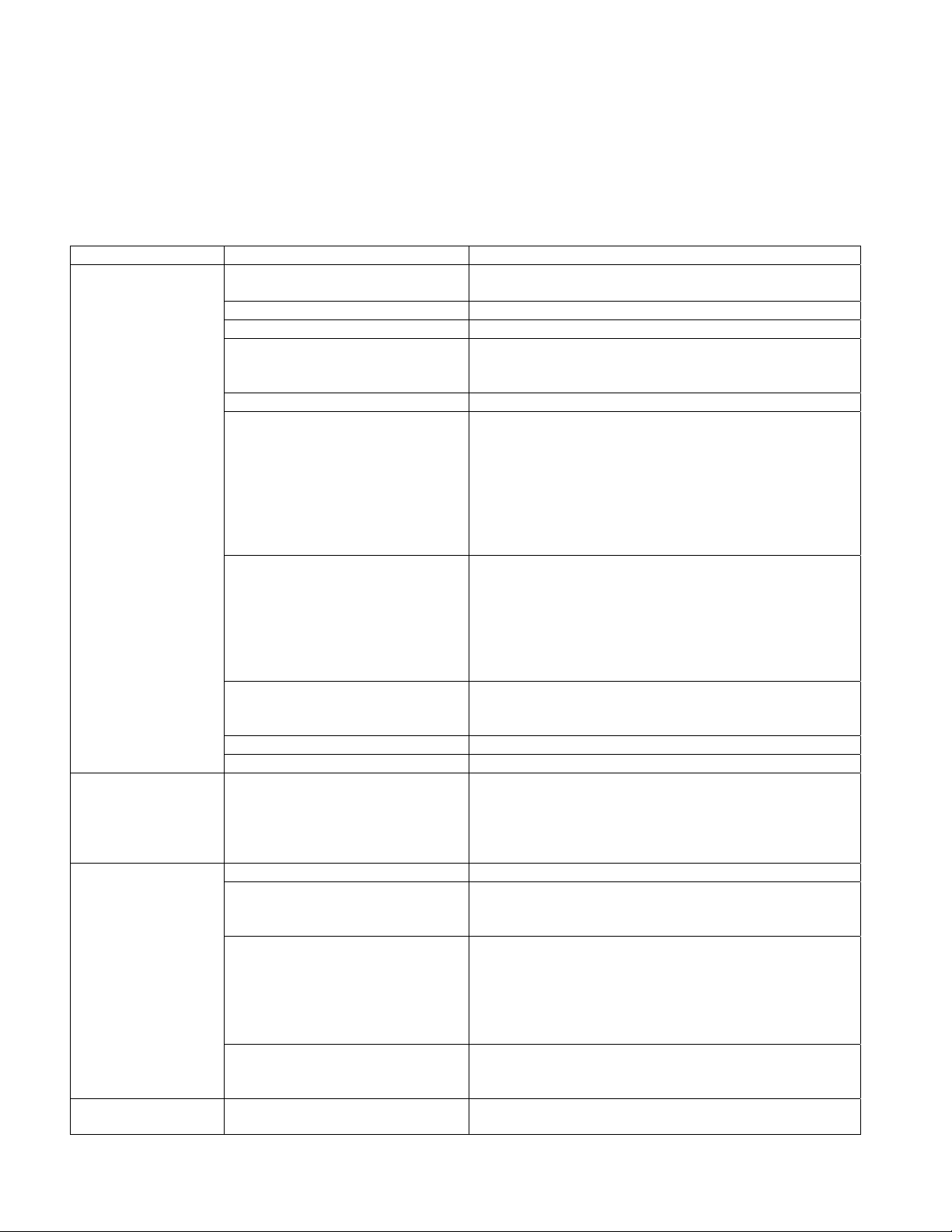

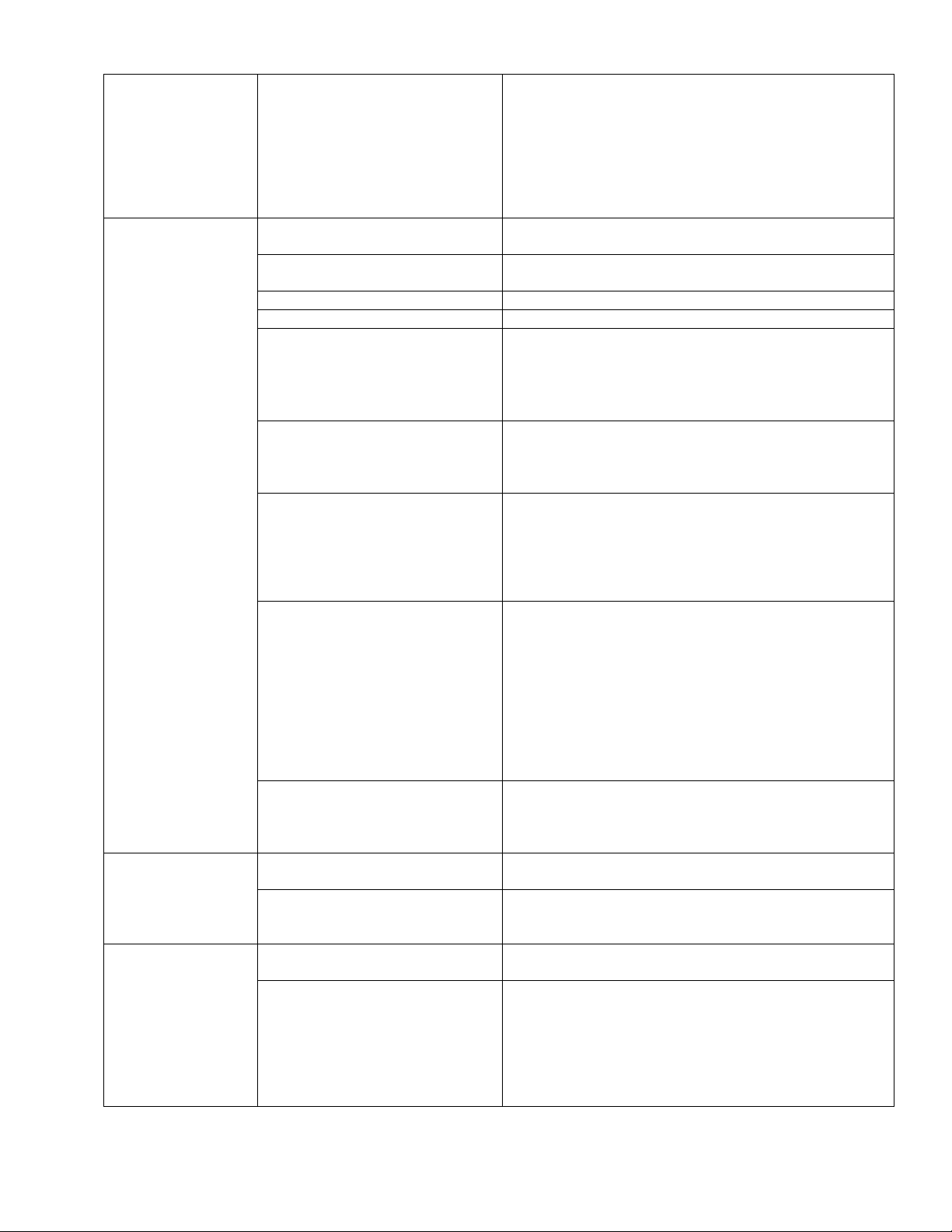

TROUBLESHOOTING GUIDE

MODEL 1621-000 EA 230/400 VAC 50 HZ 3 PHASE

MODEL 1628-000 A 220/380 VAC 50 HZ 3 PHASE

MODEL 1629-000 A 240/415 VAC 50 HZ 3 PHASE

NOTE: When checking components on left side of unit, be sure to check for pro per connections in power

connector, (marked P. C. on schematic diagram) located inside motor cover.

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not

run

No main fan cool

down

No control box

cooling

No automatic

control box cooling

Incoming power supply Check breakers/ reset if required call Power company

if needed.

Fuse, 10 A., main fan Check, replace if necessary.

Fuse holder Check, replace if necessary.

Filter, Power Check for supply voltage to filter. If there is no voltage,

trace wiring back to fuse holder. If there is power in to

the filter, but no power out, replace the filter.

Oven fan switch Check continuity between switch terminals.

20 minute time delay relay Check for supply voltage to terminal #1 and #3, if

there is no voltage, trace wiring back to the power

filter. If voltage is present, check for supply voltage at

terminals #3 to #6, if no voltage is present, trace

wiring back to on/off switch. If there is voltage at #3

and #6, check for voltage at terminals #1 and #2, of

there is no voltage at Terminals #1 and #2, replace

the 20 minute time delay relay.

Relay, main fan motors Check for power to coil of motor relay. If no voltage is

present, trace wiring back to 20 minute time delay

relay. Check for supply voltage to the contact of the

relay. If no voltage is present, trace wiring back to

power filter. If voltage is present, at the relay coil,

check to insure the contacts are closing. Replace

relay as needed.

Hi-limit thermostat(s), control

box

Capacitor(s) Check for opens, shorts, or grounds.

Motor(s), main fan Check for opens, shorts, or grounds.

20 minute time delay relay Check for supply voltage at terminals #1 and #2 while

Fan switch (SEE OVEN FAN WILL NOT RUN.)

Hi-limit thermostat(s) Terminals are normally closed, if open, reset

Relay, main fan motors Check for power to coil of oven fan relay. If no voltage

Cooling fan(s) Supply voltage should now be at these motors. If

Incoming power supply Check circuit breakers, reset if needed. Call power

Terminals are normally closed, if open, reset

thermostat and test oven for proper operation. If it will

not reset, replace thermostat.

is “ON”. Turn “OFF” the main fan switch, supply

voltage should continue to be present for 20 minutes.

If voltage is not present for 20 minutes, replace 20

minute time delay relay.

thermostat and test oven for proper operation. If it will

not reset, replace thermostat.

is present, trace wiring back to hi-limit thermostat.

Check for supply voltage to the contact of the relay. If

no voltage is present, trace wiring back to fuse holder.

If voltage is present, at the relay coil, check to insure

the contacts are closing. Replace relay as needed.

voltage is present, check motor for open, shorts, or

grounds. WITH POWER OFF: check for locked rotor.

com

if needed.

4

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

Cooling fan thermostat(s) Check the cooling fan thermostat. (Thermostat closes

at 49°C and opens at 38°C). With the cooling fan

thermostat preheated, check for continuity. If switch is

open, replace.

Fuse, 3 A., cooling fan Check, replace if necessary.

Fuse holder Check, replace if necessary.

Cooling fan(s) Supply voltage should now be at these motors. If

voltage is present, check motor for opens, shorts or

grounds. WITH POWER OFF: Check for locked rotor.

Fan switch Check to see that the fan switch is on. Oven will not heat

Main oven fan Check if main oven fan is operating. If not, refer to

“Oven fan will not run”.

NOTE: These ovens utilize 2 complete /Temperature control systems. Each system will Follow the same

troubleshooting sequence.

Oven control relay Check for line voltage to the relay coil. If no voltage is

present, trace wiring back to the control box hi-limit

thermostat(s). If voltage is present, check to insure

contacts are closing. Replace relay as needed.

Thermostat, oven cavity hi-limit Terminals are normally closed. If open, reset and test

oven for proper operation. If thermostat will not hold

for maximum oven temperature, and oven is not

exceeding maximum temperature dial setting, check

for proper location of capillary bulb in its spring holder

If above checks OK, replace hi-limit.

Contactor, hi-limit Check for line voltage to the contactor coil. If no

voltage is present, trace wiring back to the oven cavity

hi-limit thermostat(s). If voltage is present, check to

insure contacts are closing. Replace contactor as

needed.

Fuse, heater, 50A. Check, replace if necessary.

Fuseholder Check, replace if necessary.

Control transformer Check for supply voltage to the primary of the control

transformer. If no voltage is present, trace wiring back

to the oven control relay. If primary voltage is present,

check for 24VAC at the transformer secondary. If

there is primary voltage, but no secondary voltage,

replace control transformer.

Oven control Check for 24VAC supply to control. If no voltage is

present, trace wiring back to control transformer. If

24VAC is present, check for a read-out on the control

display. If there is 24VAC supplied, but there is no

read-out on the control display, replace the oven

control.

If there is a read-out on the control, set the control to

maximum temperature (see installation operations

manual for temperature adjustment). With the control

set at maximum temperature, check for line voltage at

the heat relay (mercury contactor). If there is voltage

at the heat relay, proceed to “Heat relay” for next

check. If there is no voltage at the heat relay, trace

wiring back to the oven control. If there is no voltage

output at the oven control, check the read-out on the

control. If the control reads “LP FAIL” or “RP FAIL”,

this indicates that the thermocouple has failed or has

become disconnected from the control. “LP FAIL”

indicates a problem with the left thermocouple probe,

and “RP FAIL” indicates a problem with the right

thermocouple probe.

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

5

Thermocouple probe Check to be sure that the thermocouple is securely

connected to the oven control. If the thermocouple is

connected to the oven control, and the control

indicates “LP FAIL” or “RP FAIL”, disconnect the

thermocouple from the oven control and measure the

resistance of the thermocouple. The left thermocouple

should read approx. 21Ω. The right thermocouple

should read approx. 11Ω. If these readings are not

achieved, replace the thermocouple. If these readings

are correct, proceed.

Oven control If the thermocouple checks good, but the oven control

display indicates that there is a thermocouple failure,

replace the oven control. If the oven control indicates

a temperature reading but the oven will not heat,

proceed.

Thermocouple WITH POWER ON AND THERMOCOUPLE

ATTACHED TO THE OVEN CONTROL: Measure the

DC millivolt output of the thermocouple. Refer to the

thermocouple chart (located in the “Removal” section

of the manual) for proper millivolt readings. If these

readings are not achieved, replace thermocouple.

Oven control If the thermocouple checks good, but there is no

voltage output to the temperature regulation valve,

replace the oven control. If there is voltage output to

the heat relay, proceed.

Oven air pressure switch Check for supply voltage at the air pressure switch, if

no voltage is present, trace wiring back to the oven

control. Check for supply voltage on both sides of

switch. If voltage is present on one side only, check

for air tube blockage. Adjust air pressure switch. If the

above fails, replace air pressure switch.

Heat relay Check for line voltage supplied to the coil of the heat

relay. If no voltage is present, trace wiring back to the

air pressure switch. If voltage is present, check to be

certain that all of the contacts are closing when the

relay is energized.. Also check for opens or shorts in

the operating coil. Replace temperature regulation

valve as needed.

Heating elements Check the Amp draw on each power lead for proper

load. Check the specification plate for proper rating

information.

If the Amp draw is high or low, check the individual

heating elements for opens, shorts and proper

resistance.

To check the resistance of the elements,

TURN OFF THE POWER!

Remove all wiring from the heating elements and use

an accurate digital meter.

The element resistance should be as follows:

220V – 29 ohms approx.

230V – 32 ohms approx.

240V – 34 ohms approx.

If all readings are not correct, replace heating

elements as needed.

6

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

Intermittent heating Thermal overload of main

fan motor(s)

Conveyor will not

Power supply Check for supply voltage at terminals L1 and L2. If

run

Power switch Check continuity between switch terminals. Replace

Fuse, 10 Amp. Check and/or replace.

Fuse holder Check and/or replace.

Hi-limit thermostat(s),

control box

Relay, oven control Check for line voltage to the relay coil. If voltage is not

Control transformer Check for line voltage supply to the primary of the

Conveyor motor Check for line voltage supply to the conveyor motor at

Capacitor, conveyor motor Che c k for shorts or grounds. Replace capacitor as

Switch, conveyor reversing Check continuity between switch terminals, Replace

Oven control If there is supply voltage to the motor. And the motor,

NOTE: Display will indicate

runs, but there is

no speed display

“Belt jam”

Oven control Check for output voltage from the oven control to hall

The main fan motors are equipped with internal

thermal protection and will cease to operate if

overheating occurs. As the motors overheat and then

cool, this will cause the units to cycle on and off

intermittently. Improper ventilation or lack of

preventive maintenance may cause this problem.

Also, most of the problems listed under “Oven will not

heat” can cause intermittent failure.

voltage is not present check breakers.

switch as needed.

Check for voltage on both sides of the switch.

Terminals are normally closed. If open, reset and test

for proper operation. If thermostat will not hold, and

the control box temperature is not exceeding 140°F

(60°C), replace thermostat.

present, trace wiring back to the hi-limit thermostat. If

voltage is present, check to insure contacts are

closing. Replace relay as needed.

control transformer. If no voltage is present, trace

wiring back to the oven power relay. If voltage is

present, check for 24VAC at the transformer

secondary. If there is primary voltage, but no

secondary voltage, replace control transformer.

wire #28 to neutral. If no voltage is present, trace

wiring back to the oven power relay. If voltage is

present and the motor will not run, check the motor

windings for opens or shorts.

WITH POWER OFF: Check the motor windings as

follows:

Grey to black - 116 ohms

Grey to brown - 116 ohms

Brown to black - 230 ohms

needed.

WARNING: Capacitor has a stored charge, discharge

before testing.

switch as needed.

capacitor, and reversing switch check good, replace

the oven control.

Conveyor motor

effect sensor (sensor is located in conveyor motor).

Measure voltage at the motor connector, red wire and

yellow wire. Voltage should be approx. 10VDC. If no

voltage is present, trace wiring back to oven control. If

there is no voltage present at the oven control,

replace the oven control.

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

7

Conveyor motor If there is voltage supplied to the hall effect sensor,

check for a frequency output from the hall effect

sensor. Measure frequency across the yellow and

white wires at the motor connector. Frequency

readings should be approx. 20 – 525 Hz. If these

readings are not achieved, replace the conveyor

motor. If the readings are achieved, proceed.

Oven control If the hall effect sensor readings are correct, but there

is no speed indicated on the display, replace the oven

control.

8

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

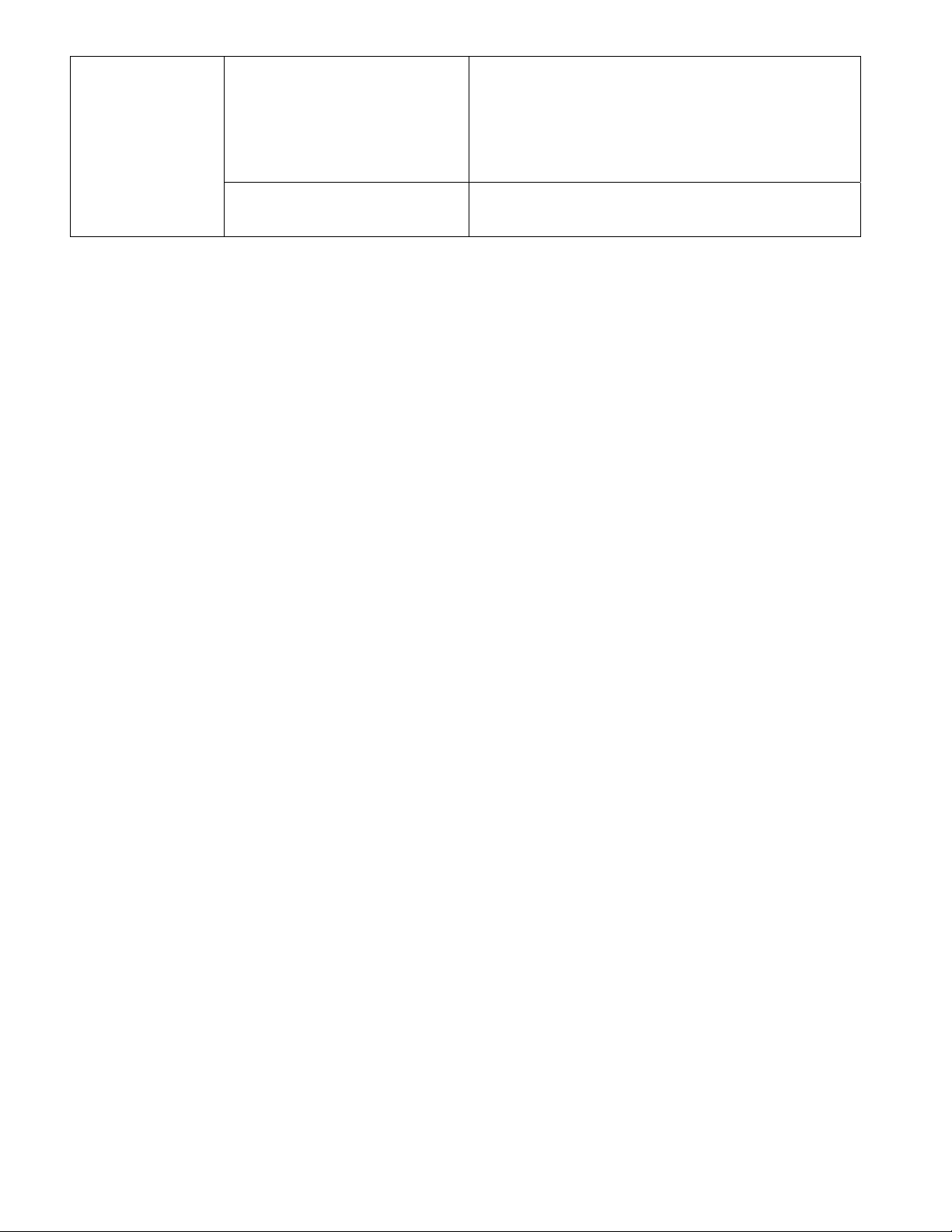

REMOVAL, INSTALLATION & ADJUSTMENTS

MODEL SERIES 1621-000-EA, 1628-000-A, 1629-000-A

CAUTION!

BEFORE REMOVING OR INSTALLING ANY COMPONENT IN THE

IMPINGER OVEN BE SURE TO DISCONNECT ELECTRICAL POWER AND GAS SUPPLY.

AIR PRESSURE SWITCH – REPLACEMENT

A. Remove control panel top.

B. Disconnect wires from switch making note of wire number and location for reinstallation.

C. Remove air tube from switch assembly.

D. Remove switch from control box.

E. Install new switch in reverse, make sure air tube is not blocked or misaligned.

To adjust air pressure switch, remove cover from the switch to expose adjusting screw. To

increase sensitivity, turn screw counter- clockwise; to decrease sensitivity, turn screw

clockwise.

CONVEYOR DRIVE MOTOR – REPLACEMENT

A. Shut off power at main breaker.

B. Remove conveyor.

C. Remove control panel top and front cover.

D. Disconnect wiring from motor and mark for reassembly.

E. Remove sprocket from motor shaft.

F. Remove 4 screws and remove conveyor motor and mounting bracket.

G. Remove mounting bracket from conveyor motor assembly.

H. Reassemble in reverse order.

CAPACITOR, CONVEYOR MOTOR – REPLACEMENT

A. Shut off power at main breaker.

B. Remove control box cover and front panel.

C. Discharge capacitor before removing wires. Mark wires for reassembly.

D. Remove mounting screw and remove capacitor.

E. Reassemble in reverse order.

REVERSING SWITCH – REPLACEMENT

A. Shut off power at main breaker.

B. Remove control box cover and front panel.

C. Disconnect wiring from reversing switch and mark for reassembly.

D. Remove mounting nut and remove reversing switch.

E. Reassemble in reverse order and check system operation.

REVERSING CONVEYOR DIRECTION

A. Shut off power at oven switch.

B. Set reversing switch in the other position.

C. Turn oven “on” and check for proper operation.

FUSEHOLDER – REPLACEMENT

A. Shut off power at main breaker.

B. Remove appropriate control box cover.

Low Profile – 1600 Series Adv Dig Electric S.M. – Int’l

9

Loading...

Loading...