Page 1

1600 Series Impinger® Low Profile

Conveyorized Oven

Models

Global

1600 Series Impinger

1600-000-U

1601-000-U

1621-000-E

1622-000-U

1623-000-U

1624-000-U

1628-000-N

1629-000-N

1633-000-E

Benefits

Faster bake times improve

•

time of service.

Advanced air impingement

•

technology enhances bake

quality and uniformity.

Improved product flow

•

during cooking reduces

operation costs.

Research and applications

•

support for continued

operational success.

Manitowoc STAR Service

•

Support is committed to

ongoing customer satisfaction.

FastBake™ Technology designed

•

to bake up to 35% faster than

other conveyor ovens without

increased noise levels or loss of

product quality! (Optional)

1634-000-E

1635-V00-E

1636-V00-E

Standard Features

Stackable up to three (3) oven

•

cavities high.

32” (812 mm) wide, 73” (1854 mm)

•

long conveyor belt with product

stop.

40” (1016 mm) baking chamber.

•

Temperature is adjustable from

•

250°F (121°C) to 600°F (316°C).

Conveyor speed is adjustable

•

from one (1) minute to thirty (30)

minutes cooking time.

Dual heating systems for

•

maximized cooking efficiency.

Front-loading access door with

•

cool handle.

Customer-specific setups give

•

customers very specific results.

Indirect conveyor drive is powered

•

by an AC motor.

Stainless steel top, front and sides.

•

Oven Start-Up/Check-Out by

•

Manitowoc STAR service agent

included in price.

1637-000-E

®

Low Profile Conveyorized Oven

Specifications

Lincoln Impinger Conveyor Ovens are

the premier continuous cook platform

for the food service industry. Using the

latest advancements in air impingement

technology, Impinger ovens allow for

rapid heating, cooking, baking, and

crisping of foods, typically done two

to four times faster than conventional

ovens.

Easy to Operate:

Digital controls with single on/off

•

power switch.

Microprocessor controlled bake

•

time/conveyor speed.

1111 N. Hadley Rd.

P.O. Box 1229

Ft. Wayne, IN 46801-1229

Tel: 888-417-5462

Fax: 800-285-9511

E mail: info@lincolnfp.com

Improved view vacuum florescent

•

readout displays set temperatures

in degrees (F° or C°), conveyor belt

speed, thermostat indicator light,

and diagnostic messages for easy

trouble shooting.

All settings are automatically

•

locked out to eliminate accidental

changes.

Easy to Clean:

Front door for easy cleaning and

•

removal of finger assemblies.

Conveyor is removable through the

•

right side opening.

www.lincolnfp.com

Optional Features:

FastBake: Improve your bake time

•

by up to 35% without increased

noise levels or loss of product

quality!

Entry and exit shelves.

•

Flexible gas connector.

•

Cleaning kit (#1050)

•

Split belt

•

Page 2

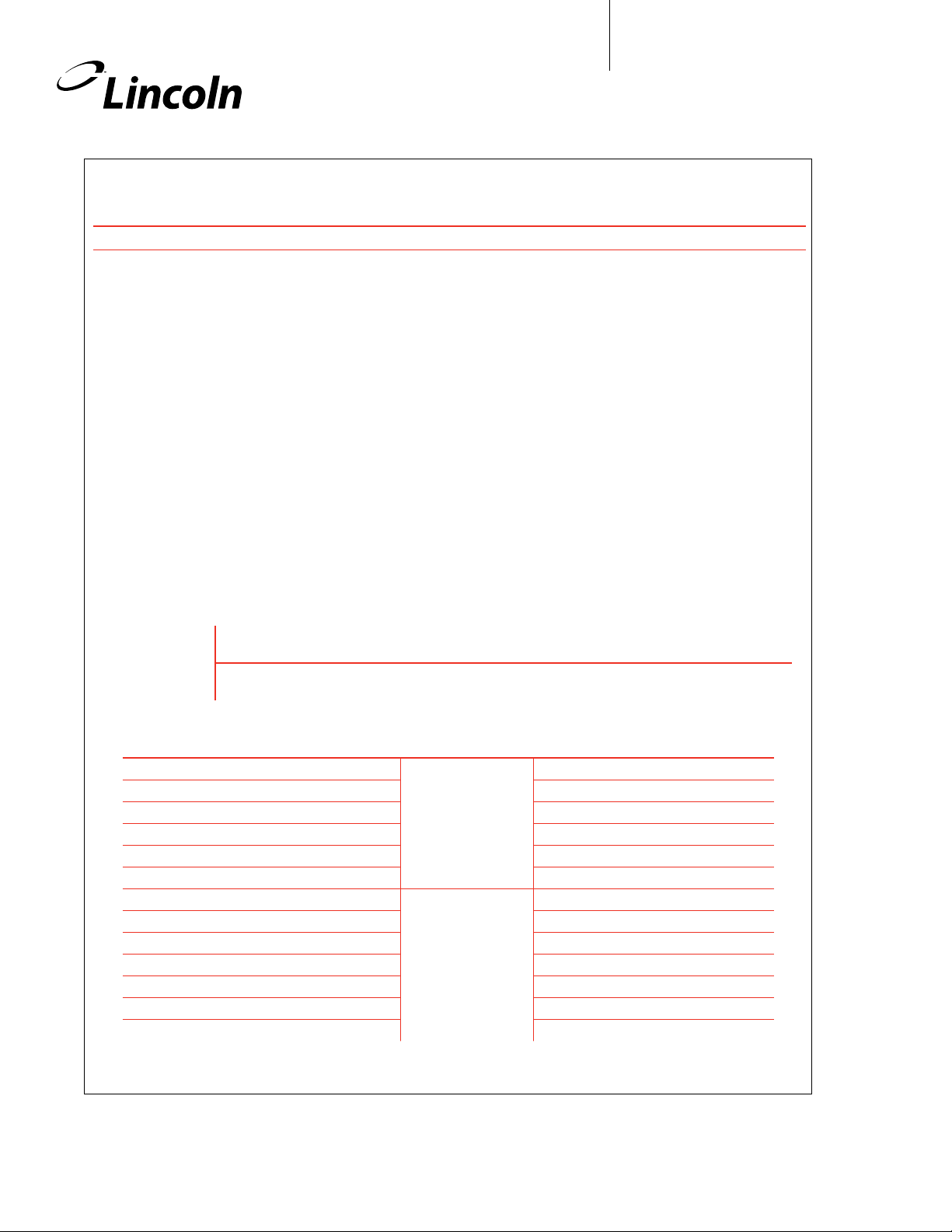

Global

Gas Supply Pressure Recommendations

Gas Type Supply (Inlet) Pressure (mbar)

Natural 7-14” WC (2.2 kPA / 22.4 mbar - 3.5kPa / 34.9 mbar) 2” (51 mm)

LP 11-14” WC (2.7 kPa / 27.36 mbar - 3.5 kPa / 34.9 mbar) 2” (51 mm)

*Gas supply pressures are dependent on local gas type and on all applicable local codes. Agency approved flexible connection to each oven

must be minimum¾” (19 mm) NPT and length must not exceed six (6) feet (1829 mm).

Recommended

Minimum

Gas Pipe Size

Electrical Service

Each oven deck requires voltage, phase and hertz as indicated by model number. Neutral must be grounded at electrical service and

receptacle properly polarized. Gas 120V units have a cord with NEMA 5-15 plug. All other models have terminal block connections. It is

recommended that a separate circuit breaker be provided for each oven deck.

Recommended Minimum Clearances

Rear of oven to combustible surface: 6” (152 mm). Clearance on each side from other cooking equipment: 24” (610 mm). Clearance

required to remove conveyor for cleaning: 11’ (3553 mm).

Warranty

All new Impinger ovens installed in the United States and Canada come with a one (1) year parts and labor warranty starting from the

date of start-up/check-out. All ovens installed in locations other than the US and Canada are warranted for one (1) year parts and ninety

(90) days labor starting from the date of start-up/check-out. Start-up/check-out must occur within 24 months of date of manufacture.

General Information

Length Depth

All 1600 Models

Model

Number

1600-000-U NSF/CSA Natural

1633-000-E NSF/AGA/CE Natural 230 50 1 3

1635-V00-E -- Natural 220 60 1 5

1601-000-U NSF/CSA LP 120 60 1 3

1634-000-E NSF/AGA/CE LP 230 50 1 3

1636-V00-E -- LP 220 60 1 5

1621-000-E CE Electric

1622-000-U UL/NSF Electric 120/208 60 3 5

1623-000-U UL/NSF Electric 120/240 60 3 5

1624-000-U UL/NSF Electric 120/220 60 3 5

1628-000-N -- Electric 380/220 50 3 5

1629-000-N -- Electric 415/240 50 3 5

1637-000-E CE Electric 215/240 50 3 5

NOTE: Panel setups are added as kit numbers to the end of the model number to complete the oven order;

(Example: 1600-000-U-K1819 is a 1600-000-U with standard setup, left to right.)

80”

(2032 mm)

Agency Utility Input Rate Voltage Hertz Phase Supply

60 ¹/₂”

(1537 mm)

Height

Single

44 ¹/₈”

(1121 mm)

110,000 BTU

32.2 kW

(116 MJ)

22 kW

Height

Double Stacked

63 ³/₈”

(1610 mm)

120 60 1 3

400/230 50 3 5

Height

Triple Stacked

66 ³/₈”

(1686 mm)

Page 3

60.5”

(1537mm)

3/4” N.P.T. INLET w/Tee

(19 mm)

120 VOLT

10 FT. LONG

POWER CORD

3/4” N.P.T.

(19 mm)

UNION

GAS

DOOR SWING

(TOP VIEW)

80” (2032 mm)

18”

(457 mm)

40”

(1016 mm)

22”

(585 mm)

7 1/2”

(191 mm)

44 1/8”

(1121 mm)

32 1/8”

(816 mm)

7 1/2”

(191 mm)

32 1/8”

(816 mm)

51 3/8”

(1305 mm)

63 3/8”

(1610 mm)

(1692 mm)

3 1/8”

(79 mm)

OPENING

GAS

60 1/2”

(1537 mm)

58 1/4”

(1479 mm)

33 1/2”

(851 mm)

OPENING

64 1/2”

(1638 mm)

27 5/8”

(702 mm)

7 1/2”

(191 mm)

32 1/8”

(816 mm)

51 3/8”

(1305 mm)

63 3/8”

(1610 mm)

60 1/2”

60.5”

3/4” N.P.T. INLET w/Tee

(19 mm)

120 VOLT

10 FT. LONG

POWER CORD

3/4” N.P.T.

(19 mm)

UNION

GAS

DOOR SWING

(TOP VIEW)

7 1/2”

(191 mm)

32 1/8”

(816 mm)

51 3/8”

(1305 mm)

63 3/8”

(1610 mm)

UNION

3/4” N.P.T.

(19 mm)

3/4” N.P.T. INLET w/Tee

(19 mm)

GAS

120 VOLT

10 FT. LONG

POWER CORD

Global

Conveyor Opening: 3 3/8” (85.7 mm)

1600 Series Impinger

60.5”

(1537mm)

18”

(457 mm)

7 1/2”

(191 mm)

DOOR SWING

80” (2032 mm)

40”

(1016 mm)

22”

(585 mm)

32 1/8”

(816 mm)

(TOP VIEW)

44 1/8”

(1121 mm)

Optional Split Belt (50/50):

7 1/2”

(191 mm)

32 1/8”

(816 mm)

15”

(381mm)

15”

(381mm)

51 3/8”

(1305 mm)

33.5”

(850mm)

63 3/8”

(1610 mm)

®

Low Profile Conveyorized Oven

5 5/8”

(143 mm)

NOTE: Specications subject to change without notication.

(901 mm)

16”

(406 mm)

35 1/2”

54 3/8”

(1387 mm)

66 3/8”

3 1/8”

(79 mm)

OPENING

33 1/2”

(851 mm)

OPENING

(1537 mm)

58 1/4”

(1479 mm)

GAS

(702 mm)

64 1/2”

(1638 mm)

27 5/8”

Page 4

Global

Capacity Estimates | Pies Per Hour

BAKE TIME

Pie Size 3 min. 3½ min. 4 min. 4½ min. 5 min. 5½ min. 6 min. 6½ min. 7 min.

12” (30 cm) 182 155 135 120 108 99 90 84 78

14” (36 cm) 115 99 87 88 69 63 58 53 50

16” (41 cm) 101 87 76 67 61 55 51 47 44

Ventilation Requirements

Ventilation is required. Local codes prevail. These are the “authority having jurisdiction” as stated by the National Fire Protection

Association, Inc., in NFPA 96-1994. Estimates of CFM requirements can vary from 2400 to as high as 6000 CFM exhaust. In all cases

the ambient temperature around the oven must not exceed 95°F (35°C) when the oven is operating. This information is shown as a

guideline for ventilating the Impinger® 1600 Ovens.

1600 Series Impinger

®

Low Profile Conveyorized Oven

18-24”

(457 mm -

610mm)

78”

(1981 mm)

CAPTURE VELOCITY 50 FPM

8”

(203 mm)

94” (2388 mm)

CAPTURE AREA CAPTURE AREA

CAPTURE

VELOCITY

8”

(203 mm)

50 FPM

6”

(153 mm)

70” (1778 mm)

6”

(153 mm)

1. Dimensions shown are for ovens without long extension shelves. The outside end of the conveyor frame must be a minimum

of eight (8) inches (203 mm) inside the canopy as shown.

2. The capture velocity across the lower edge of the canopy is to be 50 FPM at sides and front.

3. Use lters at rear exhaust area of the hood, as shown. Do not just put an opening into a 4 sided canopy.

4. The ovens are to be centered in the canopy space left-to-right and front-to-back if possible.

5. A six (6) inch space at rear of oven is recommended for utilities.

6. Use of a Type I or Type II application and overall nal installation is determined per local codes.

7. Recommended 2400-3000 CFM exhaust, typical, or higher per local codes; as a guideline to obtain adequate capture velocity.

8. Recommended 80% of make-up air provided outside of the canopy through perforated metal diusers directed straight

down... not at the oven; located at front , side or both.

9. Room air diusers must not be directed onto the oven and should be positioned a minimum of three (3) feet from the

perimeter of the hood to keep airow from aecting the oven.

NOTE: Specications subject to change without notication.

1111 N. Hadley Rd.

P.O. Box 1229

Ft. Wayne, IN 46801-1229

Tel: 888-417-5462

Fax: 800-285-9511

E mail: info@lincolnfp.com

www.lincolnfp.com

©2010 Lincoln Foodservice Products, LLC / Printed in the U.S.A. / 1256-6/10

Loading...

Loading...