Page 1

SERVICE MANUAL

(DOMESTIC AND INTERNATIONAL)

IMPINGER CONVEYOR OVENS

MODEL 1400 SERIES ADVANTAGE

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Phone : (800) 374-3004

U.S. Fax: (888) 790-8193 • Int’l Fax: (260) 436-0735

Technical Service Hot Line

(800) 678-9511

www.lincolnfp.com

1450DomExptSvc REV: 6/11/09

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS..........................................................................................................................................................2

SEQUENCE OF OPERATION................................................................................................................................................ 4

MODEL 1450 / 120 VAC / 60 HZ / NATURAL GAS ........................................................................................................4

MODEL 1451 / 120 VAC / 60 HZ / LP GAS.....................................................................................................................4

MODEL 1480 / 120 VAC / 60 HZ / TOWN GAS..............................................................................................................4

SEQUENCE OF OPERATIONS .............................................................................................................................................4

MODEL 1452 120/208 VAC 3 PHASE 60 HZ................................................................................................................4

MODEL 1453 120/240 VAC 3 PHASE 60 HZ................................................................................................................4

SEQUENCE OF OPERATIONS .............................................................................................................................................5

MODEL 1454 / 380/220 VAC / 50 HZ / 3 PHASE ...........................................................................................................5

MODEL 1455 / 415/240 VAC / 50 HZ / 3 PHASE ...........................................................................................................5

SEQUENCE OF OPERATIONS .............................................................................................................................................6

MODEL 1456 / 220-240 VAC / 50 HZ / NATURAL GAS.................................................................................................6

MODEL 1457 / 220-240 VAC / 50 HZ / L.P. GAS ...........................................................................................................6

MODEL 1474 / 220-240 VAC / 50 HZ / NATURAL GAS.................................................................................................6

MODEL 1475 / 220-240 VAC / 50 HZ / L.P. GAS ...........................................................................................................6

MODEL 1476 / 220-240 VAC / 50 HZ / TOWN GAS.......................................................................................................6

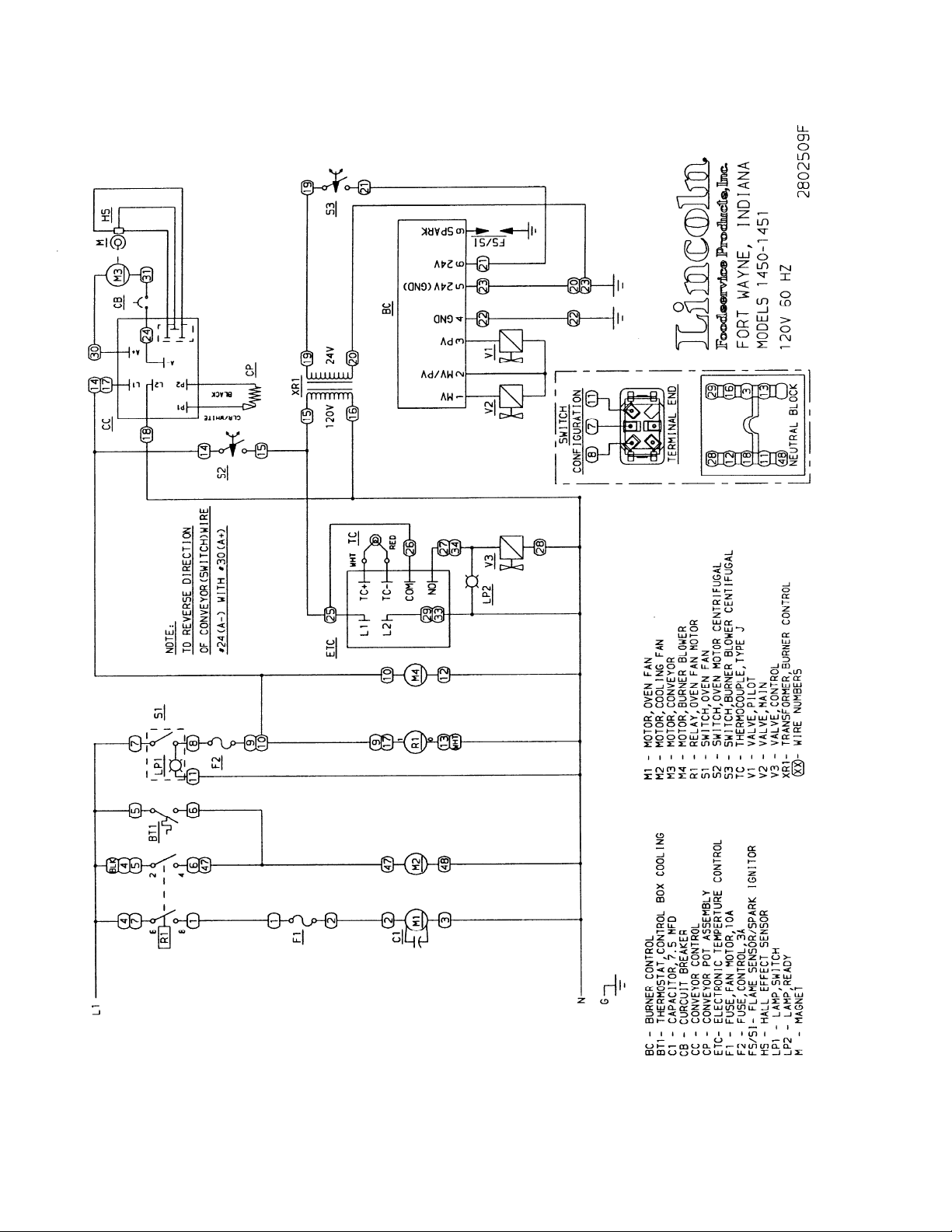

SCHEMATIC 1450 / 1451 / 1480............................................................................................................................................7

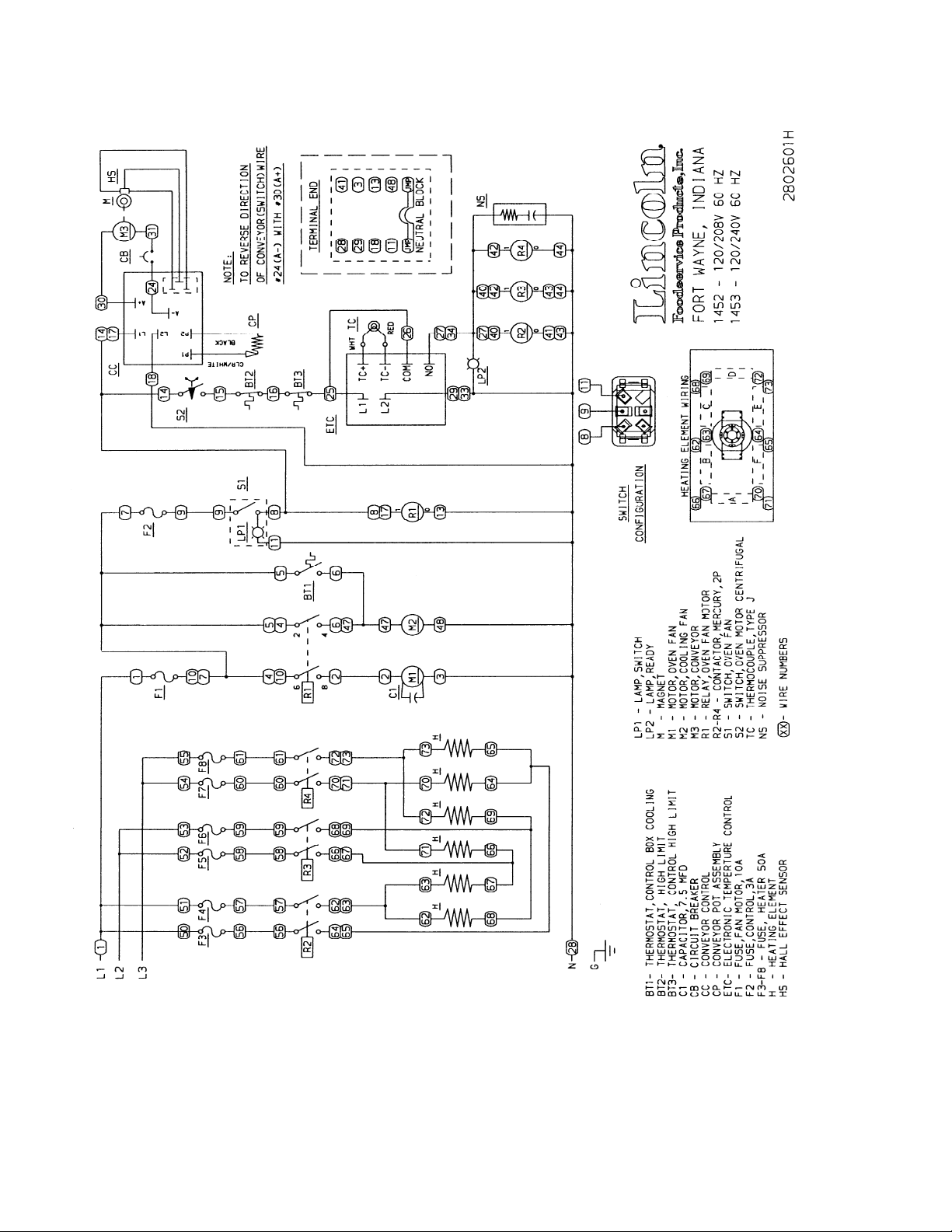

SCHEMATIC 1452 / 1453.......................................................................................................................................................8

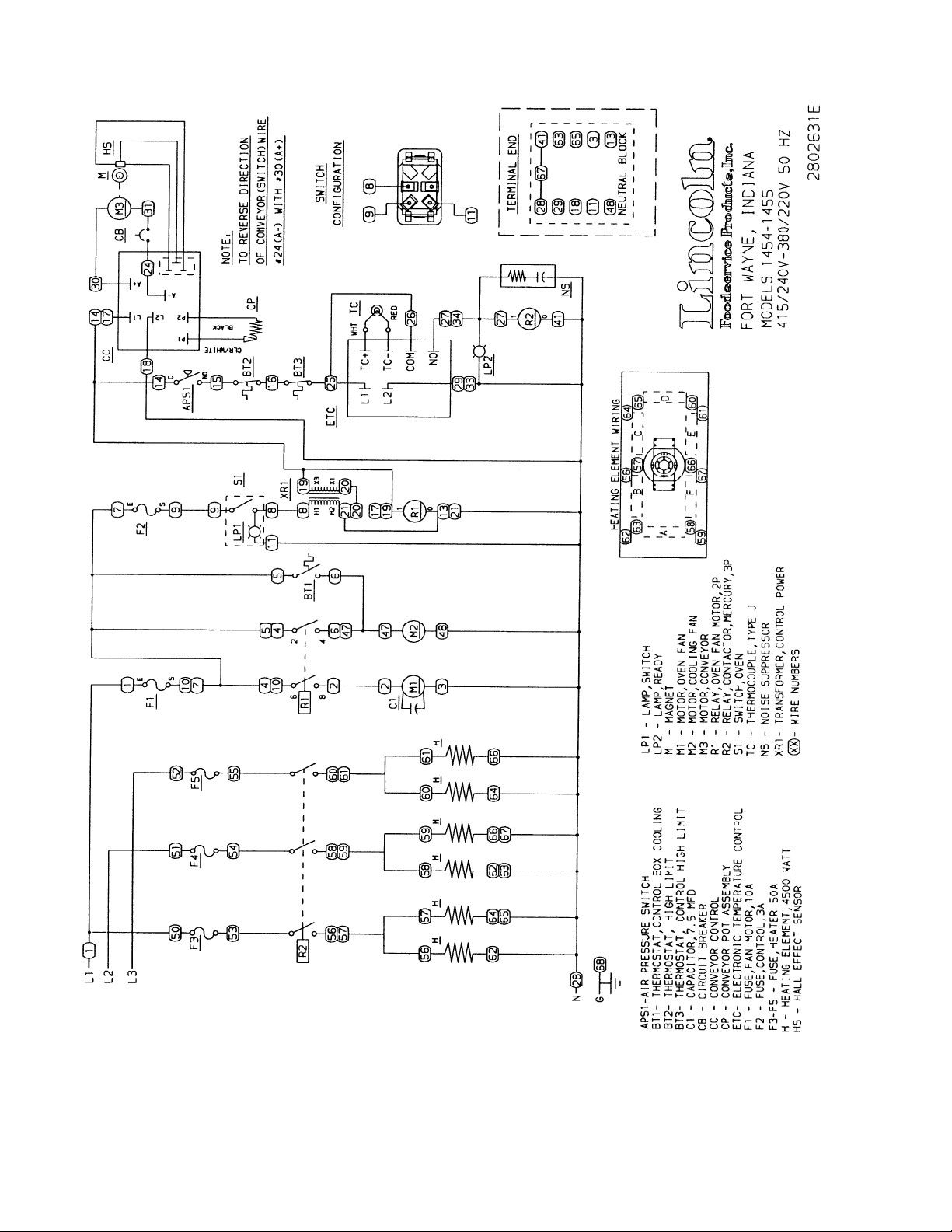

SCHEMATIC 1454 / 1455.......................................................................................................................................................9

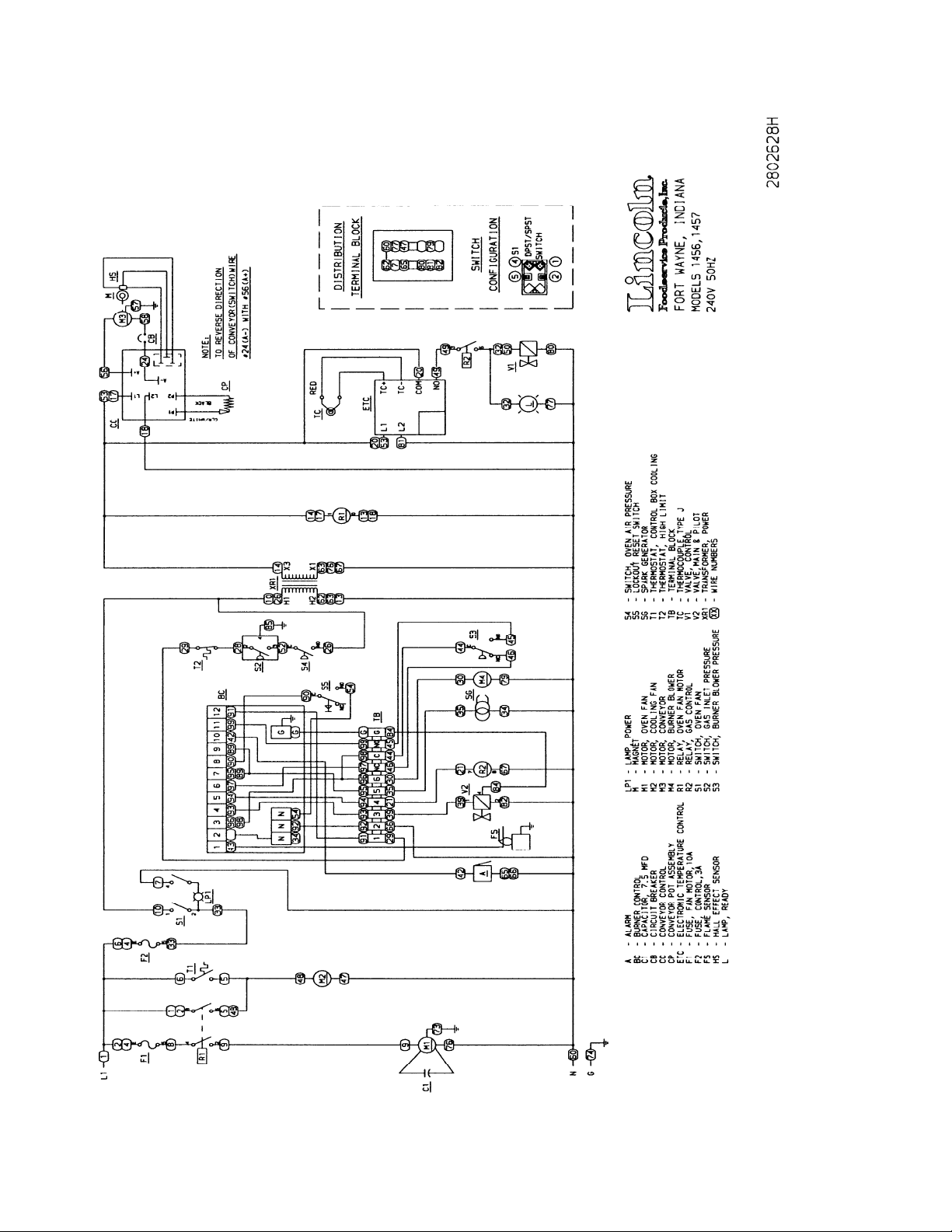

SCHEMATIC 1456 / 1457.....................................................................................................................................................10

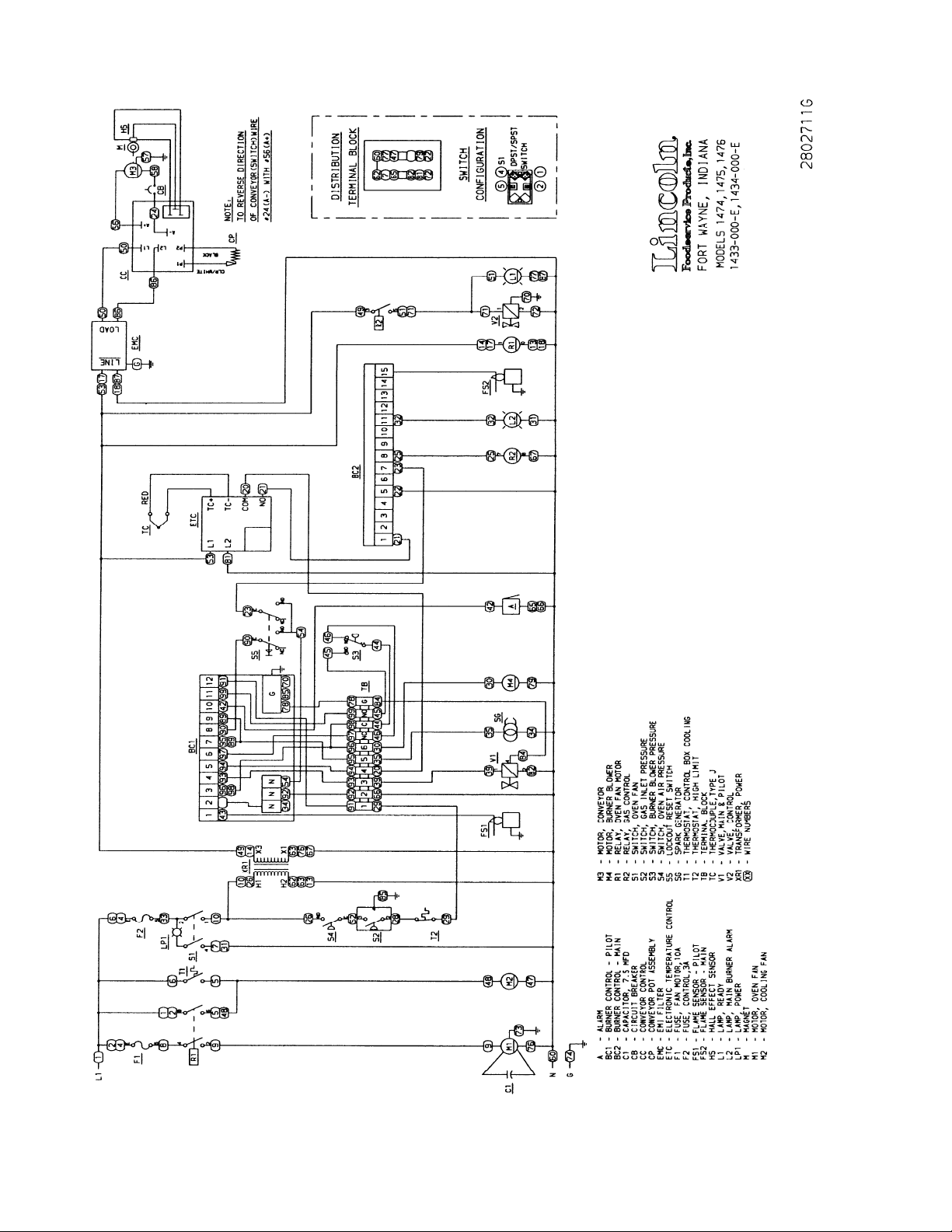

SCHEMATIC 1474 / 1475 / 1476..........................................................................................................................................11

TROUBLESHOOTING GUIDE..............................................................................................................................................12

GAS OVENS..................................................................................................................................................................12

TROUBLESHOOTING GUIDE..............................................................................................................................................19

ELECTRIC OVENS........................................................................................................................................................19

REMOVAL INSTALLATION & ADJUSTMENTS..................................................................................................................22

CONVEYOR CONTROL BOARD ASSEMBLY - REPLACEMENT...............................................................................28

GENERAL – 1450 SERIES..........................................................................................................

GENERAL - 1450 SERIES BLOW-UP..................................................................................................................................31

CONTROL BOX – 1450, 1451, 1480....................................................................................................................................32

CONTROL BOX – 1450, 1451, 1480 BLOW-UP..................................................................................................................33

CONTROL BOX – 1452, 1453..............................................................................................................................................34

CONTROL BOX – 1452, 1453 BLOW-UP............................................................................................................................35

CONTOL BOX – 1454, 1455.................................................................................................................................................36

CONTROL BOX – 1454, 1455 BLOW-UP............................................................................................................................37

CONTROL BOX – 1456, 1457, 1474, 1475, 1476................................................................................................................ 38

CONTROL BOX – 1456, 1457, 1474, 1475, 1476 BLOW-UP..............................................................................................39

OVEN BACK, GAS – ELECTRIC.......................................................................................................................................... 40

OVEN BACK, GAS – ELECTRIC BLOW-UP........................................................................................................................41

CONVEYOR – 1450 SERIES ...............................................................................................................................................42

CONVEYOR 1450 SERIES BLOW-UP ................................................................................................................................ 43

.........................................30

2

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 3

SEQUENCE OF OPERATION

MODEL 1450 / 120 VAC / 60 HZ / NATURAL GAS

MODEL 1451 / 120 VAC / 60 HZ / LP GAS

MODEL 1480 / 120 VAC / 60 HZ / TOWN GAS

POWER SUPPLY Electrical power is supplied to the oven by a three-conductor cordset. Voltage from the

black conductor to white conductor is 120 VAC. The white conductor is neutral. The green

conductor is ground.

CONTROL BOX When the temperature in the control box reaches 120°F±3°

AUTO COOL DOWN (48.9°C±1.7°C), the cooling fan thermostat will switch power to the control box-cooling fan.

The thermostat will interrupt power to the fan when the control box temperature falls to

100°F±3°(37.0°C±1.7°C).

MAIN FAN CIRCUIT Electrical power is permanently supplied to the normally open contacts of the double pole

main fan relay, the cooling fan thermostat and the normally open switch. Closing the on/off

switch energizes the coil of the relay through the 3A fuse. The normally open cont acts now

close, energizing the main fan motor through the 10A fuse, and the control box-cooling fan.

Closing the on/off switch also supplies 120 VAC to the burner blower motor, the conveyor

control board and to the normally open centrifugal switch of the main fan motor.

BURNER CIRCUIT Closing the on/off switch supplies 120 VAC to the burner blower motor and the normally

open centrifugal switch of the main fan motor. As the fan motor reaches approximately

(900 RPM) the centrifugal switch closes supplying120 VAC to the electronic temperature

control board and the primary of the burner control transformer. The transformer secondary

supplies 24 VAC through the normally open centrifugal switch (inside the burner blower

motor, this switch closes at approximately 1600 RPM) to the burner control. The igniter

circuit is now energized.

IGNITION CONTROL When the burner control is supplied with 24 VAC, the pilot valve and spark igniter is

energized. Ignition should now occur, after the pilot flame is proven, the main gas valve is

energized.

TEMPERATURE

CONTROL

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC to the conveyor control board. AC volts are

When the centrifugal switch of the main fan motor closes, 120 VAC is applied to the

temperature controller. The temperature dial is adjusted to the desired temperature. The

thermocouple will provide varying millivolts to the temperature controller. The temperature

controller supplies 120 VAC to the solenoid valve (and the yellow cycling lamp on the front

panel) at intermittent intervals to maintain desired temperatures.

converted to DC volts and are supplied to the conveyor motor at terminals A+ and A-

Adjustment of the speed control potentiometer will change resistance at terminals P1 & P2,

varying the DC voltage to the motor. The speed of the conveyor motor will increase or

decrease as the DC voltage from the board increases or decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor motor

that senses the motor speed. Any change in motor load (± RPM) is detected by the sensor

and the voltage to the motor is adjusted accordingly.

SEQUENCE OF OPERATIONS

MODEL 1452 120/208 VAC 3 PHASE 60 HZ

MODEL 1453 120/240 VAC 3 PHASE 60 HZ

POWER SUPPLY Electrical power is to be supplied to the oven by a 5-conductor service.

Black conductor is hot.

Red conductor is hot.

Orange conductor is hot.

White conductor is dedicated neutral.

Green conductor is ground.

CONTROL BOX AUTO

COOL DOWN

MAIN FAN CIRCUIT Electrical power is permanently supplied through 6, 50A fuses to the normally open

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

When the temperature in the control box reaches 120°F ± 3°, (49°C ± 1.7°C), the cooling

fan thermostat will switch power to the cooling fan. The thermostat will interrupt power to

the cooling fan when the temperature falls to 100°F±3° (37°C ± 1.7°C).

contacts of the mercury contactors. Power is also supplied through 1, 10A fuse to the

normally open contacts of the main fan relay, to the normally open cooling fan thermostat,

and through a 3A fuse to the normally open single pole main fan switch. Closing the main

fan switch supplies 120 VAC to the coil of the main fan relay. The coil of the relay is

3

Page 4

energized, the normally open contacts close, energizing the main fan motor and coolin g

fan. Closing the main fan switch also supplies power to the conveyor control and the

centrifugal switch of the main fan motor.

HEAT CIRCUIT Closing the on/off switch supplies 120 VAC to the normally open centrifugal switch (inside

the main fan motor). As the motor reaches approximately (900 RPM) the centrifugal switch

closes supplying 120 VAC through the normally closed oven cavity and control box hi-limit

thermostats, to the electronic temperature control board

TEMPERATURE

CONTROL

When the centrifugal switch (inside the main fan motor) closes, 120 VAC is applied to the

temperature controller. The temperature dial is adjusted to the desired temperature. The

thermocouple will provide varying millivolts to the temperature controller. The temperature

controller supplies 120 VAC to the contactor coils at intermittent intervals (closing the

contactors and supplying 208 or 240 VAC to the heating elements) to maintain desired

temperature. The ready lamp is energized with the contactors.

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC to the motor control board. AC volts are

converted to DC volts and are supplied to the conveyor motor at terminals A+ and A-.

Adjustment of the speed control potentiometer will change resistance at terminals P1 & P2

varying the DC voltage to the motor. The speed of the conveyor motor will increase or

decrease as the DC voltage from the board increases or decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor motor

that senses the motor speed. Any change in motor load (± RPM) is detected by the sensor

and the voltage to the motor is adjusted accordingly.

SEQUENCE OF OPERATIONS

MODEL 1454 / 380/220 VAC / 50 HZ / 3 PHASE

MODEL 1455 / 415/240 VAC / 50 HZ / 3 PHASE

POWER SUPPLY Electrical power is to be supplied to the oven by a 5-conductor service.

Black conductor is hot.

Red conductor is hot.

Orange conductor is hot.

White conductor is dedicated neutral.

Green conductor is ground

CONTROL BOX AUTO

COOL DOWN

MAIN FAN CIRCUIT Electrical power is permanently supplied through three 50A fuses to the normally open

HEAT CIRCUIT Upon closure of the on/off switch 120 VAC is supplied through the air pressure switch,

TEMPERATURE

CONTROL

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC to the conveyor control board. AC volts are

When the temperature in the control box reaches 120°F ± 3°, (49°C ± 1.7°C), the cooling

fan thermostat will switch power to the cooling fan. The thermostat will interrupt power to

the cooling fan when the temperature falls to 100°F ± 3° (37°C ± 1.7°C).

contacts of the mercury contactor. Power is also supplied through 1, 10A fuse to the

normally open contacts of the main fan relay, to the normally open cooling fan thermostat,

through a 3A fuse to the normally open single pole main fan switch. Closing the main fan

switch supplies 220/240 VAC to the primary of the control circuit step down transformer.

(The transformer steps the voltage down to 120 VAC for the control circuit.) 120 VAC is

supplied to the coil of the main fan relay. The coil of the relay is energized, the normally

open contact close, energizing the main fan motor and cooling fan. Closing the main fan

switch also supplies power to heat and conveyor control.

through the normally closed oven cavity and control box hi-limit thermostats to the

electronic temperature control.

When 120 VAC is supplied to the temperature controller and the temperature dial is

adjusted to the desired temperature, the thermocouple will provide varying millivolts to the

temperature controller. The temperature controller supplies 120 VAC to the contactor coil

at intermittent intervals, (closing the contactor and supplying 220 or 240 VAC to the heating

elements) to maintain desired temperature.

converted to DC volts and are supplied to the conveyor motor at terminals A+ and A-.

Adjustment of the speed control potentiometer will change resistance at terminals P1 & P2

varying the DC voltage to the motor. The speed of the conveyor motor will increase or

decrease as the DC voltage from the board increases or decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor motor

that senses the motor speed. Any change in motor load (± RPM) is detected by the sensor

and the voltage to the motor is adjusted accordingly.

4

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 5

SEQUENCE OF OPERATIONS

MODEL 1456 / 220-240 VAC / 50 HZ / NATURAL GAS

MODEL 1457 / 220-240 VAC / 50 HZ / L.P. GAS

MODEL 1474 / 220-240 VAC / 50 HZ / NATURAL GAS

MODEL 1475 / 220-240 VAC / 50 HZ / L.P. GAS

MODEL 1476 / 220-240 VAC / 50 HZ / TOWN GAS

POWER SUPPLY Electrical power is to be supplied to the oven by a three-conductor service.

Brown conductor is hot.

Blue conductor is neutral.

Green conductor is ground.

CONTROL BOX AUTO

COOL DOWN

MAIN FAN CIRCUIT Electrical power is permanently supplied to the normally open contacts of the double pole

BURNER CIRCUIT Closing the oven fan switch supplies line voltage through the main fan air pressure switch,

TEMPERATURE

CONTROL

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC (through the step down transformer) to the

When the temperature in the control box reaches 120°F ± 3° (48.9°C ± 1.7°C), the cooling

fan thermostat will switch power to the control box cooling fan. The thermostat will interrupt

power to the cooling fan when the control box temperature falls to 100°F ± 3° (37.0°C ±

1.7° C).

main fan relay, the cooling fan thermostat and, through a 3A fuse to the normally open

double pole main fan switch. Closing the oven fan switch supplies line voltage to the

primary of the control circuit step down transformer. The transformer steps the voltage

down to 120 VAC for the control circuit. 120 VAC is supplied to the coil of the double pole

main fan relay. The coil of the relay is energized. The normally open contacts now close,

energizing the main fan motor through one 10A fuse, and the cooling fan motor.

through the gas pressure proving switch, through the normally closed Hi-Limit Thermostat,

to the ignition control. The combustion motor is now energized The normally open

combustion air switch closes upon sensing air. After a pre-purge period of between 30 and

60 seconds, the spark generator and the main gas valve are energized. Ignition should

now occur, after proving, gas control relay is energized.

Closing the oven power switch supplies 120 VAC (through the step-down transformer) to

the temperature control board. The temperature dial is adjusted to desires temperature.

The thermocouple will provide varying millivolts to the temperature controller. The

temperature controller supplies120 VAC through contact of gas control relay to the

solenoid valve at intervals to maintain desired temperature. The ready lamp is energized

with the solenoid valve (an electronic flame monitor proves main flame operation in the

1474, 1475, 1476 models.)

conveyor control board. AC volts are converted to DC volts and are supplied to the

conveyor motor at terminals A+ and A-. Adjustment of the speed control potentiometer will

change resistance at terminals P1 & P2 varying the DC voltage to the motor. The speed of

the conveyor motor will increase or decrease as the DC voltage from the board increases

or decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor motor

that senses the motor speed. Any change in motor load (± RPM) is detected by the sensor

and the voltage to the motor is adjusted accordingly.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

5

Page 6

SCHEMATIC 1450 / 1451 / 1480

6

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 7

SCHEMATIC 1452 / 1453

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

7

Page 8

SCHEMATIC 1454 / 1455

8

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 9

SCHEMATIC 1456 / 1457

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

9

Page 10

SCHEMATIC 1474 / 1475 / 1476

10

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 11

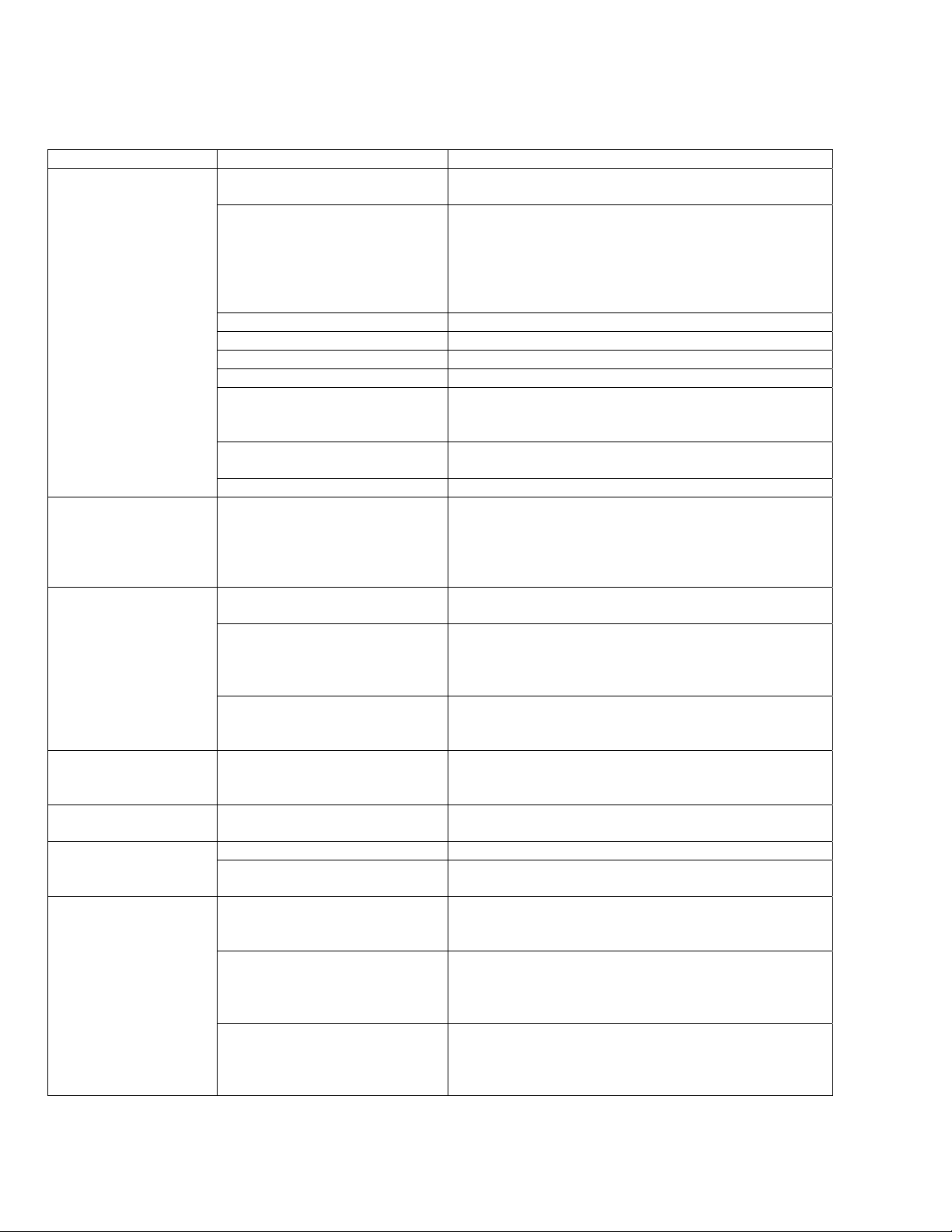

TROUBLESHOOTING GUIDE

GAS OVENS

IMPINGER ADVANTAGE SERIES

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run

NOTE:

No control box

cooling

No automatic control

box cooling

Control box cooling

fan continues to run

Oven will not heat

Model 1450-1451

For 1456, 1457,

1475, 1476 See

Page 14.

Incoming Power Supply Check breakers, reset if required. Call Power Co. if

needed

(Export Ovens) For some export ovens, there is a control circuit step-

down transformer. This transformer steps down

supply voltage to 120 VAC. If main fan will not run,

the secondary of this transformer must be checked

for 120 VAC output. Check specific oven model

schematic for circuit location.

Oven Fan Fuse Check and/or Replace

Control Fuse Check and/or Replace

Fuse Holder Check and/or Replace

Fan Switch Check continuity between switch terminals

Main Relay Chec k continuity to 120 VAC coil. Check for power to

relay coil (120VAC). Check for supply voltage to

relay contacts. Visually check for contact pull-in.

Fan Motor Check for opens, shorts, or ground. WITH POWER

OFF: Turn Fan Blade to check for locked rotor.

Capacitor Check for opens, shorts, or grounds.

Main Fan Relay Check for power to main fan relay. Visually check for

contact pull-in. Axial Cooling Fan. Check for power

(120 VAC or 240 VAC, check specific model) to

cooling fan. If voltage is present at the fan motor and

the fan does not run, replace fan assembly.

Incoming Power Supply Check breakers/Reset if needed. Check for incoming

power at cooling fan thermostat.

Cooling Fan Thermostat Check cooling fan thermostat (thermostat closes at

120°F and opens at 100°F). With cooling fan

thermostat pre-heated, check for continuity. If switch

is open, replace.

Axial Cooling Fan WITH POWER OFF: check for locked rotor. Check

for proper voltage to the cooling fan, if present and

fan does not run, replace the fan.

Cooling Fan Thermostat See "Cooling Fan Thermostat" (NOTE: Thermostat

will remain closed if control box temperature

exceeds 120°F)

Gas Supply Check for adequate gas supply to oven

Manual Gas Shut-off Valve Check to see that manual shut-off valve is open

Main Oven Fan Check if main oven fan is operating. If not, refer to

"Oven fan will not run" on page 11.

Centrifugal Switch Check for 120 VAC on both sides of (Main Fan)

switch. If voltage present on one side only, and motor

is running, replace motor.

Transformer, 24 VAC Check for 120 VAC to primary of transformer. Check

for 24 VAC from secondary of transformer. If there is

primary voltage, but no secondary voltage, replace

transformer.

Burner Blower Motor Check for 120 VAC supply to burner blower motor. If

120 VAC is present and motor does not run, replace

motor. WITH POWER OFF: turn blower wheel to

check for locked rotor.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

11

Page 12

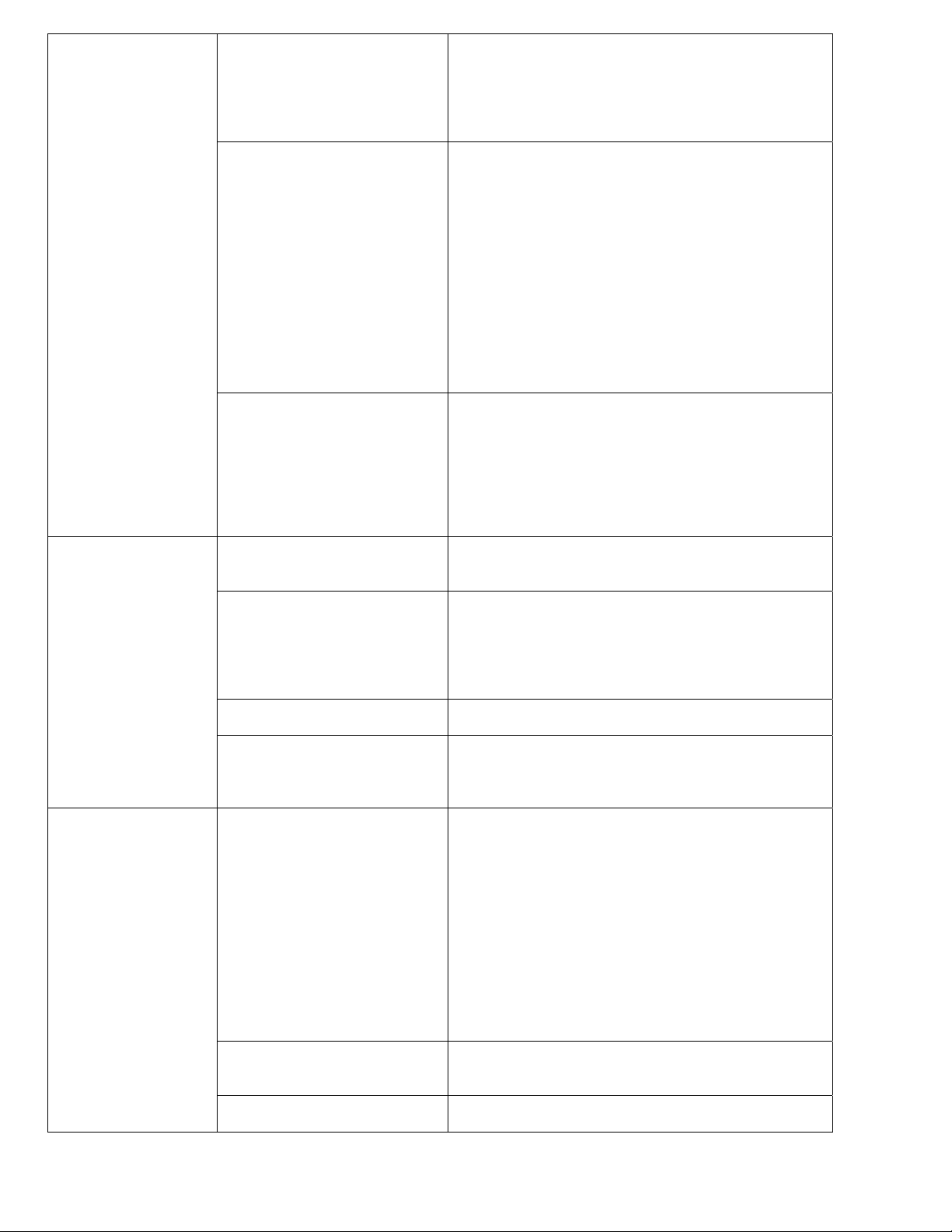

Pilot flame but no

main flame

Centrifugal Switch of Burner

Blower Motor

Check for 24 VAC output from secondary of

transformer. If voltage is present, check for 24 VAC

at pin 6 and ground on ignition control. If the burner

blower motor is running and there is no voltage at pin

6 and the ground on the ignition control, replace the

burner blower motor.

Ignition Control Check for 24 VAC supply to the ignition control at pin

6 and the ground. If voltage is present, check for 24

VAC across pin #3 and ground (pilot valve). NOTE:

The Honeywell ignition control has a 30 sec. pre-

purge (Time Delay) built in. If voltage is not present,

replace electronic control package. If the pilot valve

is energized, check to see that the high voltage

igniter circuit is also energized. To check, disconnect

the igniter lead from the ignition control. Place female

terminal of igniter lead approximately 1/8" from

terminal post on ignition control. Spark should jump

the 1/8" gap. If no spark is present, replace ignition

control. NOTE: control will try for ignition for 15

seconds only.

No Pilot If the ignition control is supplied with 24 VAC and the

pilot valve (internal to valve assembly) and igniter

circuits are energized, visually check for pilot flame.

This may be done by opening the small inspection

door on the end of the burner, or by opening the

main oven door and looking under the lower finger

housings on the right side of the oven. If no pilot

flame is visible, check pilot shut-off valve.

Pilot Shut-off Valve Check to see that pilot shut-off valve is open (shut-off

valve is located between valve assembly and

burner).

Pilot Tube Check for gas pressure at pilot tube. Disconnect pilot

tube at burner and connect manometer to pilot tube.

If no gas pressure is present, check for blockage in

pilot tube or pilot shut-off valve. If these are clear,

and there is gas supplied to the oven, replace the

gas valve.

Pilot Orifice If there is gas pressure at the pilot tube, check the

pilot orifice for obstructions. Replace as needed.

Burner Igniter Check the burner igniter head for any obstructions,

also check for frayed or broken wire, (spark gap .100

in. 2.5 mm). If there is visible damage, replace igniter

assembly.

Ignition Control If there is a pilot flame, check for 24 VAC across

terminals #1 and the ground (main valve). If there is

no voltage present, replace the ignition control.

NOTE: The Honeywell ignition control has a 15-sec.

lockout built in. If pilot flame is not proven, turn off

switch, wait 30 sec. and restart. If power is supplied

to terminal #1 but there is no main flame, verify that

the main valve (internal to valve assembly) has

opened. Connect a manometer to the manifold gas

pressure tap located on the back of the valve

assembly. If no gas is present, replace valve

assembly. Check for temperature control set above

300°F.

Main Orifice Check for blockage of main orifice. If there is no

blockage to the main orifice, check the temperature

control.

Temperature Control

(Electronic)

Check for 120 VAC across L1 and L2 on temperature

control board.

12

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 13

Thermocouple Probe Remove thermocouple leads from the temperature

control board, and measure the millivolt output of

these leads. Refer to charts on page 25 in the

adjustment section for proper readings.

Temperature Control Turn temperature control dial to full "on" position.

NOTE: Thermocouple must be connected. Measure

for 120 VAC across terminals "N.O." and Com., if

voltage is not present; replace control.

Solenoid Valve If voltage is present at terminals "N.O." and Com.,

check for voltage at solenoid valve. If voltage is

present, listen for valve to open and close. Also,

check for opens and shorts in coil. If solenoid valve is

defective, replace.

Intermittent Heating AS FOLLOWS Both the main fan motor and burner blower motor are

equipped with thermo-protection and will cease to

operate when not cooled properly. This can cause

the units to cycle on and off intermittently. Also, most

of the problems listed under "oven will not heat" can

cause intermittent failures.

For continuing intermittent problems, a series of test lights may be made and installed in the ovens. The lights will allow the

customer to advise the service technician a trouble code when the oven fails

The lights should be connected in the following manner:

Light#1 attached in 120 VAC line after oven fan switch.

Light #2 attached after 120 VAC contacts of oven motor centrifugal switch

Light #3 in 24 VAC Burner Transformer Secondary.

Light #4 in 24 VAC at terminal #6 of Ignition control valve.

Light #5 in 24 VAC at terminal #3 of Ignition control valve.

Light #6 in 24 VAC at terminal #1 of Ignition control valve.

CODE:

All lights off - lights of main power, main fan off, oven fan switch out.

1 on 2 off 3 off 4 off 5 off 6 off - Oven Motor Centrifugal Switch open

1 on 2 on 3 on 4 off 5 off 6 off - Burner Motor Centrifugal Switch bad.

1 on 2 on 3 on 4 on 5 0ff 6 off - Ignition Control bad

1 on 2 on 3 on 4 on 5 on 6 off - Pilot Shield missing or warped, no flame rectification, Pilot

- Orifice plugged, or Gas Control Valve bad.

1 on 2 on 3 on 4 on 5 on 6 on - Unit still not working Main Orifice plugged, Gas Valve bad,

- Temperature Control bad.

- However, Main Orifice would not be intermittent problem.

Conveyor will not run

Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 120 VAC. If not

present, check breakers.

3 Amp Fuse This control fuse is located on the front panel. Replace

if defective.

Fuseholder Check and/or replace.

Fan Switch See procedure for checking on page 11.

Speed Adjustment

Potentiometer

This is a 0 to 10 K ohm, 1 turn potentiometer. With

power off, remove the black and white pot leads from

the motor control board at terminals P1, P2. Place the

meter leads on the black lead (P2) and on the white

lead (P1). Rotating the pot., slowly, from low to high,

the meter reading should show an even transition from

0 to 10K ohms ± 5%. There should be no dead or

open spots through out the 1 turn of the pot. Check

both leads to ground. There should be no continuity to

ground. If any of the above checks fail, replace the

pot.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

13

Page 14

DC Motor Control Board Check for 120 VAC input to the control board at

Conveyor Gear Motor If DC voltage is present at A+ and A-and the motor

Conveyor Check for any mechanical mis-alignment . Also check

Conveyor speed

Power Supply Check power supply at the DC control board for the

varying or intermittent

D.C. Motor Control Board Place the test meter probes on terminals A+ and A- .

DC Gearmotor If the DC control board is steady then the problem

Magnet Check to insure that the magnet (cemented to shaft of

Hall Effect Sensor Check for any physical damage to Hall Effect Sensor

MODELS 1456 - 1457-1474-1475-1476

Oven will not heat

Gas Supply Check for adequate gas supply to oven.

Manual Gas Shut-Off Valve Check to see that manual shut-off valve is open.

Fan Switch Check to see that the fan switch is on.

Main Oven Fan Check if main oven fan is operating. If not, refer to

Air Pressure Switch Check for supply voltage on both sides of switch. If

terminals L1 and L2. If not present, check the oven

fan switch and wiring back to 3 amp fuse and then

back to power source if necessary. If 120 VAC is

present at L1 and L2, check both fuses on control

board (4A line) and (1A armature), check the VDC

output at terminals A+ and A-. If 120 VAC is present

at terminals L1 and L2, and DC voltage is present A+

and A-, but motor does not run, check gear motor as

follows.

does not run, first check the mini breaker and then the

conveyor. Refer to the next possible cause. Check the

leads to the motor for evidence of any shorts or

opens, and each lead to ground. If the motor fails the

above tests, replace motor. From the top of the motor,

rotate motor shaft to determine if there is a locked

rotor or a locked gear box (use care so magnet and

the H.S. board are not damaged). Replace as needed.

for worn bearings. A conveyor belt that is over

tightened may cause excessive bearing wear and

sometimes, irregular speed.

120 VAC at board terminals L1 and L2

(With speed potentiometer set to maximum speed (

Approx. 2 min.) The meter reading should be

approximately 100 VDC (±3%). The board output is

steady. If the board voltage output is unsteady beyond

limits (±3%) then the board is probably bad. Always

check the speed pot. , be sure it is okay before

changing a board. This test is not always 100%

accurate as this test is not performed at operating

speeds. However, this test is the best method

currently available.

may be the motor or gearbox. Check the brushes in

the motor for excessive arching and/or unusual wear.

Check the motor and gearbox from instruction located

on page 14 under "possible cause" Listing "conveyor

gear motor."

conveyor drive motor) has not been damaged, or

come loose from motor shaft. Replace as needed.

(mounted on conveyor drive motor Check all wiring

and connections for damage. Check all connections

for tightness or proper location and check all wiring for

visible damage. Replace as needed. Connect new

Hall Effect to system and check for steady operation.

"Oven fan will not run."

voltage present on one side only, check for air tube

blockage or misalignment, adjust air switch. Replace

as needed.

14

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 15

Gas Pressure Switch This switch is located inside the gas valve and should

close when gas pressure is present. WITH POWER

OFF: remove 3 prong plug (on gas valve) and

measure continuity between terminals 2 and 3.NOTE:

Remove insulation pad below plug to read numbers. If

no continuity, check the following:

1. Proper gas pressure supply to the gas valve as

marked on the oven specification plate.

2. Check for proper adjustment of gas pressure

switch. 8.8 on dial for natural gas, 23 for LP, and 4.5

for Town Gas.

3. Check gas filter in gas valve for blockage or

damage. (See Adjustment Section on page 28). If

above checks are okay, but pressure switch is still not

closed, replace gas valve.

Hi-Limit Thermostat Thermostat is normally closed, opens at 368°C

(695°F). If open, reset and test oven for proper

operation. If thermostat will not hold for maximum

oven temperature, and oven is not exceeding

temperature dial setting, check for proper location of

capillary bulb in its spring holder. If above checks

okay, replace hi-limit thermostat.

Ignition Control Check for proper line voltage supply to ignition control,

terminal #1.Check for proper line voltage to the Burner

Blower Motor. If voltage is present, proceed with next

step, if not, wait 30 seconds, push reset button, and

try to restart. If this fails, check wires from thermostat

and burner blower motor to the ignition control. If all

above fails and wires are okay, replace ignition

control.

Burner Blower Motor Check for line voltage to motor. WITH POWER OFF:

turn blower wheel to check for locked rotor or blower

wheel slippage. If proper line voltage is present at

motor connecting plug, terminal 2 and 5, and motor

does not run, replace motor.

Air Pressure Switch (Burner

Blower)

Check for proper line voltage switching from "N.C." to

"N.O." as air pressure switch closes. Check for air

switch adjustment, air tube blockage, or misalignment,

and if these fail, replace air pressure switch.

Spark Generator A pre-purge time of 30 to 60 seconds occurs after

blower motor starts, check for proper line voltage at

spark generator. If voltage is not present, check reset

button for the Ignition Control. If voltage is still not

present, replace ignition control. If voltage is present,

visually check for spark at igniter head located in end

of burner.

Igniter/Sensor Assembly Check this assembly for visible damage. If there is no

damage, replace the spark generator. If there is

damage, replace the Igniter/Sensor Assembly. Also

check for frayed or damaged wires in the burner tube.

Check spark gap (should be .100 inch 2.5 mm).

Replace as needed.

Gas valve This solenoid is located inside the gas valve and

should open when proper line voltage is present. If no

voltage is present, check the reset button on the

ignition control, and all connections for tightness. If

there is still no voltage present at gas valve, replace

ignition control. If there is voltage present, check for

gas pressure at the gas pressure tap located in the

gas piping just prior to the burner. If there is no gas

pressure, replace gas valve.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

15

Page 16

Flame will not stay on

Flame Sensor To check for flame sensor operation, connect a digital

multimeter (capable of measuring D.C. micro amps)

between the flame sensor wire and Ignition Control.

Sensor current from sensor control is 3 micro amps

minimum. If these readings are not achieved replace

igniter/sensor assembly. Also check for any type of

damage to flame sensor wire and connections.

Ignition Control If there is sufficient flame sensor current, but the

burner will not remain ignited, check the reset button

on ignition control. If all above are okay, replace

ignition control.

No Pilot Pilot Orifice If all above are operating properly, but there is no pilot

flame, check for any obstructions in pilot orifice.

Pilot flame, but burner

will not stay ignited

Flame Sensor (There should be a visible pilot flame at this time.) To

check for flame sensor operation, connect a digital

multimeter (capable of measuring D.C. micro

amperes) between the flame sensor wire and the

ignition control. NOTE: this is a current measurement

and the meter must be connected in series. Proper

current readings should be minimum of 3 micro AMP.

D.C. If these readings are not achieved, replace

igniter/sensor assembly. Also check for any type of

damage to flame sensor wire and connections.

Power Supply If there is sufficient micro-amp current, but the flame

will not stay lit, check for proper polarity of the input

power supply.

Ignition Control If there is sufficient flame sensor current, but the

burner will not remain ignited, check reset button on

ignition control, if all above are okay, replace ignition

control.

Indicator light is on,

but no main

flame(Model 1456-

1457)

Gas Control Relay Check for 220 VAC to relay coil. If no voltage is

present, trace wiring back to ignition control. If voltage

is present, check to insure contacts are closing.

Temperature Control Check for 120 VAC across L1 and L2 on temperature

control board. If no voltage is present, retrace wiring

back to power supply. Turn the temperature

adjustment knob to the maximum temperature position

and check for 120 VAC at the load terminal to neutral.

If 120 VAC is not present, proceed as follows: If 120

VAC is present and unit is not heating, see "Solenoid

Valve."

Thermocouple Probe Remove thermocouple leads from the temperature

control board and measure the millivolt output of these

leads. Refer to chart in page 25 for proper readings.

If the thermocouple probe checks good, then the

problem is usually with the temperature control board.

Solenoid Valve If output voltage is present at temperature control

board, check for voltage at solenoid valve. If voltage

is present, listen for valve to open and close. Also

check for opens, shorts in coil. Replace as needed.

Indicator light is on,

but no main flame

(1474-1475-1476)

Temperature Control Check for 120 VAC across L1 and L2 on temperature

control board. If no voltage is present, retrace wiring

back to power supply. Turn the temperature

adjustment knob to the maximum temperature position

and check for 220 VAC at the load terminal to

neutral. If 220 VAC is not present, proceed as follows:

If 220 VAC is present, and unit is not heating, see

"Flame Monitor". Check for 220 VAC at terminal

"COM" on temperature control board. If no voltage is

present, trace wiring back to ignition control.

16

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 17

Thermocouple Probe Remove thermocouple leads from the temperature

control board and measure the millivolt output of these

leads. Refer to chart on Page 25 for proper readings.

If the thermocouple probe checks good, replace

temperature control.

Flame Monitor Check for 220 VAC at terminal #1. If no voltage is

present, trace wiring back to temperature control.

Check for 220 VAC output at terminal #8. NOTE:

There is a delay of up to 2 seconds for 220 VAC

output at terminal #8. If there is no voltage output at

terminal #8, check the reset button. Replace control

as needed.

Relay, Main Burner Check for 220 VAC at relay coil, if no voltage is

present, trace wiring back to flame monitor. Check for

120 VAC to relay contacts. If no voltage is present,

trace wiring back to power supply. Check to ensure

contacts are closing

Valve, Temperature

Regulation

Replace relay as needed. Check for 120 VAC at

valve, if no voltage is present, trace wiring back to

relay. If voltage is present, listen for valve to open and

close. Check for opens or shorts in coil. Replace as

needed.

Main Flame will not

stay lit

Flame Monitor (There should be a visible main flame at this time.) To

check for flame monitor operation, connect a digital

voltmeter (capable of measuring D.C. microamperes)

between the flame sensor and terminal #15 on the

flame monitor. The flame monitor requires a minimum

of 4 micro amp. D.C. for proof of flame. If these

readings are not achieved, replace sensor assembly.

Also check for any type of damage to flame sensor

wire and connections. If the reading is above the

minimum required, and the flame monitor will not

supply 220 VAC to the relay coil, replace the flame

monitor.

Intermittent heating As Follows Both the main fan motor and burner blower motor are

equipped with thermal protection and will cease to

operate if overheating occurs. This can cause the

units to cycle on and off intermittently. This may be

caused by improper ventilation. Also most of the

problems listed under "oven will not heat" can cause

intermittent failure. See page 13 for test lights.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

17

Page 18

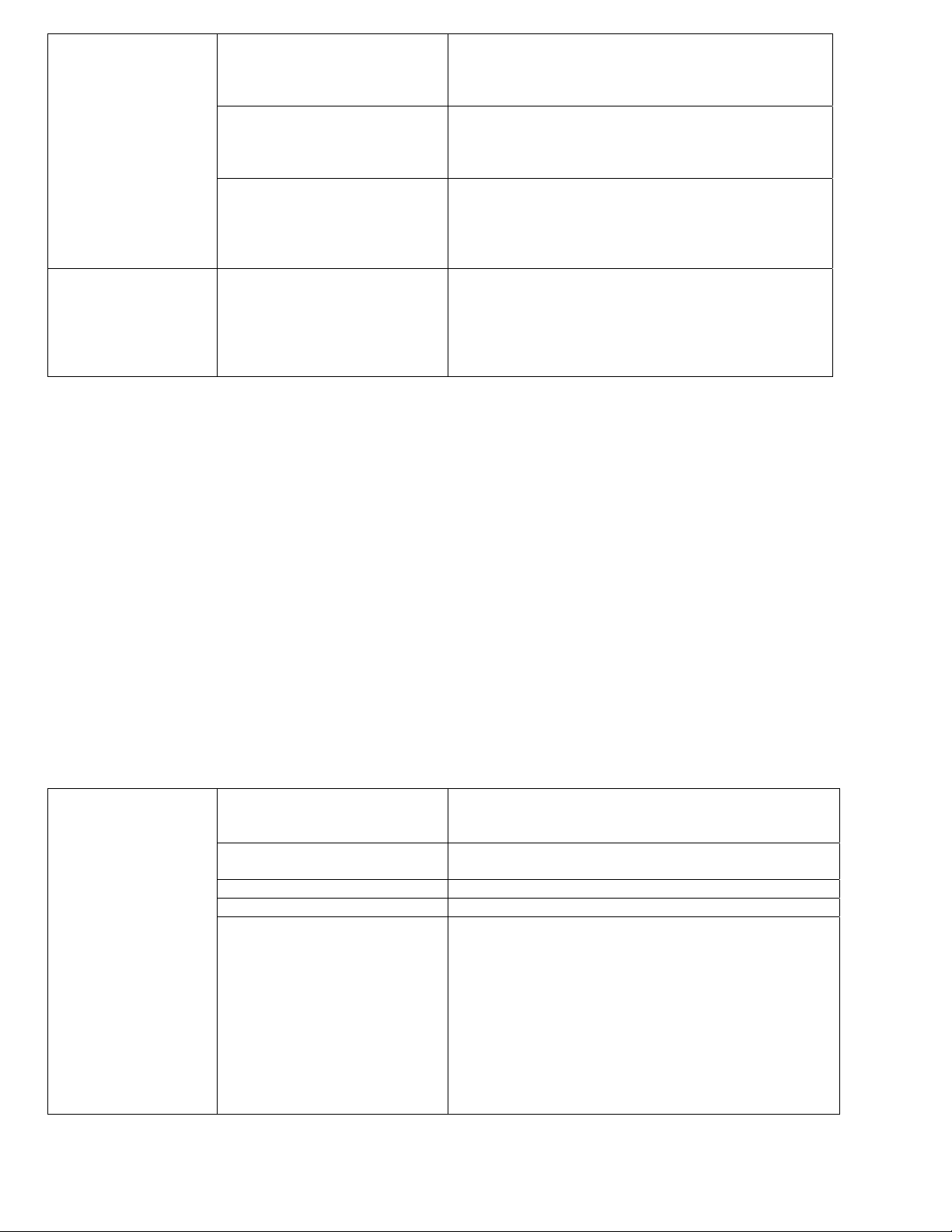

TROUBLESHOOTING GUIDE

ELECTRIC OVENS

IMPINGER ADVANTAGE SERIES

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run

No control box

cooling

No automatic control

box cooling

Oven will not heat

Incoming Power Supply Check breakers/Reset if required. Call Power Co. if

needed.

Oven Fan Fuse Check and/or Replace

Fuse Holder Check and/or Replace

Fan Switch

1454-1455

Main Relay Check continuity to 120 VAC coil. Check for power to

Fan Motor Check for opens, shorts, or ground. WITH POWER

Capacitor Check for opens, shorts, or grounds.

Main Fan Relay Check for power to main fan relay. Visually check for

Axial Cooling Fan WITH POWER OFF: turn fan blade to check for

Incoming Power Supply Check circuit breakers, reset if required, call Power

Cooling Fan Thermostat Thermostat is normally open and closes at 120°F ± 3

Main Oven Fan Check if main oven fan is operating. If not, refer to

Centrifugal Switch (Main Fan)

Model 1452-1453

Air Pressure Switch

(1454-1455)

Hi Limit Thermostat (Oven

Cavity)

Control Box High Limit

Thermostat

Check continuity between switch terminals.

For these oven models, there is a control circuit step-

down transformer. This transformer steps down supply

voltage to 120 VAC. If main fan will not run, the

secondary of this transformer must be checked for

120 VAC output. Check specific oven model

schematic for circuit location.

the relay coil,(120 VAC). Check for 120/208/220/240

VAC to relay terminals. Visually check for contact pull-

in.

OFF: Turn Fan Blade to check for locked rotor.

contact pull-in.

locked rotor. Check for power to cooling fan. If voltage

is present at the fan motor and the fan does not run,

replace fan assembly.

Company if needed.

(48.9°C ± 7°), and opens at 100°F ± 3°F (37.8°C ±

1.7°C).

"Oven fan will not run". Page 18.

Check for 120 VAC on both sides of switch. If voltage

is present on one side only and motor is running,

replace motor.

This normally open switch should close when the main

fan is activated. If adjustment is necessary (Refer to

page 28). Check tube for blockage. Replace if

defective.

Terminals are normally closed. If open, reset and test

oven for proper operation. If thermostat will not hold

for maximum oven temperature, and oven is not

exceeding temperature dial setting, replace

thermostat.

Terminals are normally closed, but open at 130°F ±

5°F (53.9°C ± 2.8°C). Check for over heating and

reset thermostat. Test for proper operation. If it will not

reset and hold, then replace.

18

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 19

Oven heats with

switch off

Conveyor will not run

Temperature Control Board Check for 120 VAC input to temperature control

board. If not present, check wiring from Hi-Limit to

temperature control board. Turn the temperature

adjustment dial to the maximum temperature position.

Check for 120 VAC at coil of mercury contactor(s).

Next, short the leads of thermocouple on the

temperature control board, check for 120 VAC at coil

of mercury contactor(s). If voltage is not present,

replace temperature control board. If voltage is

present, proceed.

Thermocouple Probe Remove thermocouple leads from the temperature

control board, and measure the millivolt output of the

leads. Refer to chart (page 25) in adjustment section

for proper millivolt readings.

Mercury Contactor(s) Check for 120 VAC to the contactor coil. If voltage is

present and contactor will not activate, replace the

contactor(s). Also check each contactor for proper

high voltage input and output.

50 Amp Fuses If there is no high voltage input to the mercury

contactor(s), check the 50 amp fuses and replace if

necessary.

Heater Elements Check the Amp. draw on each hot leg for proper load.

Check the specification plate for rating information. If

the Amp. draw is low or high, check the individual

elements for opens, shorts, and proper resistance. To

check resistance of the elements, turn off the power!

Remove all leads from the elements and use an

accurate digital VOM. The element resistance should

be as follows: 208V - 9.8 ohms approx. 220V - 10.5

ohms approx. 240V - 13 ohms approx. If all readings

are not correct, replace elements as needed.

Mercury Contactor(s) The mercury contactor has probably malfunctioned in

the closed position. If there is no voltage to the

operating coil, but there is high voltage at the

contactor output, replace the mercury contactor.

Voltage Supply (Export Ovens) Check incoming voltage supply, check breakers and

reset if required. For some export ovens there is a

control circuit step down transformer. This transformer

steps down supply voltage to 120 VAC. If conveyor

will not run, the secondary of this transformer must be

checked for 120 VAC output. Check specific oven

model schematic for circuit location.

Speed Adjustment

Potentiometer

This is a 0 to 10K ohm, 1 turn potentiometer. With

power off, remove the black and white pot leads from

the motor control board at terminals P1 and P2 with a

digital multimeter, check the ohm reading on the black

lead (P2) and the white lead (P1). Rotating the pot,

slowly, from low to high, the meter reading should

show an even transition from 0 to 10K ohms ± 5%.

There should be no dead or open spots through out

the 1 turn of the pot. Check both leads to

ground.There should be no continuity to ground. If any

of the above checks fail, replace the pot.

DC Motor Control Board Check for 120 VAC input to the control board at

terminals L1 and L2.If not present, check back to

power source if necessary. If 120 VAC is present at L1

and L2, check the VDC output at terminals A+ and A-.

If 120 VAC is present at terminals L1 and L2, but DC

voltage is not present at A+ and A-, verify fuses are

not blown, if fuses check ok, replace the board. If DC

voltage is present at A+ and A-, but motor does not

run, check gear motor as follows:

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

19

Page 20

Conveyor Gear Motor If DC voltage is present A+ and A- and the motor does

not run, first check the mini breaker and then the

conveyor. Refer to the next possible cause. Check

motor brushes for excessive or abnormal wear,

replace as needed. Check the leads to the motor for

evidence of any shorts or opens, and each lead to

ground. If the motor fails the above tests, replace

motor.

Conveyor Check for any mechanical mis-alignment or improper

adjustment. Also check for worn bearings. The

Installation and Operations Manual shows proper

conveyor belt adjustment. A conveyor belt that is over

tightened will cause excessive bearing wear and

sometimes, irregular speed.

Conveyor speed

varying

Power Supply Check power supply at the DC control board for the

120 VAC at board terminals L1 and L2. If voltage is

not present, check main circuit breakers

DC Gearmotor If the DC control board is steady, then the problem

may be the motor or gearbox: Check the brushes in

the motor for excessive arching and/or unusual wear.

Check the motor and gearbox from instruction located

on page 20 under "possible cause" listing "Conveyor

gear motor".

Magnet Check to insure that the magnet cemented to shaft of

conveyor drive motor) has not been damaged, or

come loose from motor shaft. Replace as needed.

Hall Effect Sensor Check for any physical damage to Hall Effect Sensor

(mounted on conveyor stepper drive motor. Check all

wiring and connections for damage. Check all

connections for tightness or proper location and check

all wiring for visible damage. Replace as needed.

20

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 21

REMOVAL INSTALLATION & ADJUSTMENTS

IMPINGER ADVANTAGE SERIES

CAUTION!

BEFORE REMOVING OR INSTALLING ANY COMPONENT IN THE IMPINGER

OVEN BE SURE TO DISCONNECT ELECTRICAL POWER AND GAS SUPPLY

MOTOR, MAIN FAN

1. Shut off power at main breaker.

2. Remove louvered motor cover from back of oven.

3. Remove wire-way by taking out the (5) five hex screws.

4. Disconnect wiring from motor.

5. Remove the twelve (12) hex head bolts from the oven back and slide back straight out of the oven.

6. Remove two (2) bolts from fan hub and remove fan from motor shaft.

NOTE: Measure distance from fan blade to rear wall assembly before removal to aid in reassembly.

7. Remove the eight (8) hex head bolts from the motor mount and slide the motor assembly out of the oven back.

8. Remove motor by taking off motor clamp and removing the four (4) mounting nuts and washers.

9. Reassemble in reverse order. Whe n motor mount assembly is set on the oven back, align motor shaft in the center

of the hole. Set fan assembly on the motor shaft.

NOTE: A. Torque specs on bolts (150 in/lb. torque)

B. It is recommended that an anti-seize compound be brushed on to the bolts around

the back and motor mount bracket before assembly.

FAN, MAIN

Shut off power at main breaker.

Remove back assembly. (See MOTOR, MAIN FAN))

Reinstall and locate fan so that the bottom of the fan spider is 1 1/2" from the top of the oven back cone. (See Drawing)

FAN SPIDER

NOTE: MEASUREMENT MUST BE

MADE FROM CONE TO FAN SPIDER

FAN HUB

CONE

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

1 1/2 INCH

21

Page 22

CAPACITOR, MOTOR

1. Shut off power at main breaker.

2. Remove motor cover from back of oven.

3. Discharge capacitor.

4. Remove and replace.

RELAY, D.P.S.T.

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove cover from relay box.

4. Disconnect all wire s and mark for replacement.

5. Remove relay by removing two (2) mounting screws.

6. Reassemble in reverse order.

COOLING FAN, CONTROL BOX

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove four (4) screws fro m the fan frame.

4. Disconnect cord and plug and remove fan.

5. Reassemble in reverse order.

THERMOSTAT, COOLING FAN

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove lead wires and m ark for reassembly.

4. Remove two (2) screws and remove thermostat.

5. Reassemble in reverse order.

MERCURY CONTACTOR

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Disconnect contactor wires and mark for reinstallation.

4. Remove screws from mounting brac ket and replace contactor.

NOTE: Be sure contactor is not mounted upside down as this will cause a constant on

5. Reassemble in reverse order.

HEATING ELEMENTS

1. Shut off power at main breaker.

2. Remove back cover.

3. Disconnect heater element wire and mark for reassembly.

4. Disconnect motor wiring and mark for reassembly.

5. Remove oven back from oven.

6. Remove fan shroud.

7. Heater element may now be unbolted an d removed.

8. Check heater elements to be sure they are the proper voltage replacement.

9. Reassemble in reverse order.

NOTE: Be sure the heating element connections are tight.

condition.

22

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 23

URNER BLOWER MOTOR - REPLACEMENT

B

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Unplug motor connector.

4. Remove three (3) screws from blower tube at burner housing.

5. Remove air shutter assem bly from old motor for installation on new

motor assembly.

6. Reassemble in reverse ord er and check system operation.

NOTE: Check air shutter adjustment and adjust if necessary

Set air shutter at approx. 1/4" and adjust to get a blue flame

with an occasional tip of yellow under high flame. A view

port in the burner assembly should be used to observe flame.

BLOWER WHEEL, BURNER

This is part of the burner blower motor assembly.

TO REMOVE THE BLOWER WHEEL FOR PERIODIC CLEANING:

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove air shutter held by 3 screws.

4. Loosen set screws on blower wheel hub and pull straight out.

5. Reassemble in reverse order.

NOTE: There is no critical placement of the blower wheel on the motor shaft. Just back as far as it will go and

then spin the blower to be sure it is not rubbing.

BURNER CONTROL - HONEYWELL - REPLACEMENT

1. Remove control panel top and front cover.

2. Remove wires from control, note wire nu mbers and location for reassembly.

3. Remove Two (2) screws from control Shut off power at main breaker. and replace.

4. Reassemble in reverse ord er and check system operation.

BURNER ASSEMBLY

1. Shut off power at main breaker.

2. Shut off gas supply.

3. Remove control panel top and front pa nel.

4. Remove gas control valve (See "GAS CONTROL VALVE")

5. Disconnect pilot tube.

6. Remove solenoid valve. (See "SOLENOID VALVE")

7. Remove four (4) screws that secure the burner backing plate.

8. Remove burner assembly from housi ng, the main and pilot orifice, flame target, pilot shield

(main and extension), burner ignitor can now be changed or serviced as needed.

9. Reassemble in reverse order.

GAS CONTROL VALVE

1. Shut off power at main breaker.

2. Shut off gas supply.

3. Remove control panel top and front cover.

4. Disconnect the gas piping f rom the ba ck of the unit.

5. Remove the four (4) screws from the in coming nipple mounting bracket.

6. Remove incoming nipple.

7. Remove pilot tube assembly from control valve.

8. Disconnect pipe union just above solenoid valve.

9. Disconnect wiring from control valve making note of wire numbers and location.

Remove piping from old valve for installation on new valve.

10. Reassemble in reverse order - after assembly is complete, be sure to check manifold pressure

(3.5" W.C. NAT GAS 10" W.C. LP) and adjust if necessary. (See Section "MANIFOLD

PRESSURE - ADJUSTMENT")

NOTE: Check all gas line fittings for leaks after installation.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

23

Page 24

PILOT

R

LINE

CONNECTION

MANIFOLD ADJUSTMENT

SCREW LOCATED UNDER

COVER SCREW

FRONT VIEW

MANIFOLD PRESSURE

ADJUSTMENT CONNECTION

MANIFOLD ADJUSTMENT

SCREW LOCATED UNDE

COVER SCREW

TOP VIEW

MANIFOLD PRESSURE - ADJUSTMENT

1. Remove control panel top and front cover.

2. WITH ELECTRIC POWER AND GAS OFF: remove the outlet pressure tap plug from the gas

control valve and install the adapter fitting and manometer.

3. Turn on electric power an d gas and start-up oven.

4. With oven at full fire, manifold pressure should be (3.5" W.C. NAT/ 10" W.C. LP)

If adjustment is needed, remove cover screw from valve body and adjust by turning regulator

screw. (C.W. to increase, C.C.W. to decrease).

5. Turn off electric power and gas, replace cover screw, remove manometer and adapter; replace

pressure tap plug.

6. Check pressure tap for gas leaks before closing panel.

7. Close control panel and check system operation.

SOLENOID VALVE

1. Shut off power at main breaker.

2. Shut off gas supply.

3. Remove control panel top and front cover.

4. Remove gas control valve (See "GAS CONTROL VALVE")

5. Disconnect wires from solenoid valve.

6. Remove two (2) hex nuts that hold main orifice bracket in place.

7. Remove solenoid valve assembly.

8. Remove piping from solenoid valve.

9. Reassemble in reverse order.

10. Check all fittings for leaks.

ELECTRONIC TEMPERATURE CONTROL - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove one screw from control knob guard and move guard to one side.

4. Remove knob and lock nut on control pot. shaft and push out.

5. Remove six (6) wires from temperature control. Note wire numbers and location.

6. Reassemble in reverse order.

NOTE: All electronic temperature controls are preset and calibrated at the factory and no field adjustment is

required other than aligning the temperature control knob to the scale on front panel. Place a temperature sensor

in the center of the oven between top two middle fingers and set temperature control to 500°F, allow temperature

to stabilize (approx. 30 min.) and adjust knob to actual temperature.

24

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 25

BURNER IGNITOR

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Remove burner assembly. (SEE "BURNER ASSY.")

4. Remove pilot shield and pilot shield extensio n.

5. Remove burner igniter.

6. Reassemble in reverse order (spark gap approx. .100 in. 2.5 mm)

NOTE: Be sure to reconnect burner igniter cable to ignition control.

THERMOCOUPLE - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front cover.

3. Slide thermocouple out of oven chamber.

NOTE: Remove conveyor and bottom fingers to aid in removal and installation of thermocouple.

4. Remove two (2) wires from temperatu re control. Make note of wire numbers or color and

location for reinstallation.

5. Reassemble in reverse order making sure the metal end on the thermocouple is securely held

in the wire form in the oven chamber.

THERMOCOUPLE MEASUREMENT CHART:

When two wires composed of dissimilar metals are joined together and one of the ends is heated, a continuous current

flow is generated. We use an iron constant (Type J) thermocouple. The iron wire increases the number of dissimilar

junctions in the circuit.

It is possible to check a thermocouple with a properly calibrated D.C. millivolt meter. At 32°F, the millivolt reading should

be 0.00. Inserting the thermocouple into an ice bath can check this.

The millivolt reading at 72°F should be 1.134.

When using the following chart, the temperature at the terminal connections must be noted. This temperature is called the

Junction Temperature.

The following chart lists the thermocouple millivolt readings from 200°F to 600°F.

The junction temperature is the ambient air temperature where the thermocouple fastens to the electronic temperature

control.

J

U

N

C

T

I

O

N

T

E

M

P

200°F 250°F 300°F 325°F 350°F 400°F 425°F 450°F 500°F 550°F 600°F

90°F 3.26 4.77 6.30 7.06 7.83 9.37 10.14 10.91 12.46 14.00 15.53

88°F 3.32 4.83 6.36 7.12 7.89 9.43 10.20 10.97 12.51 14.05 15.59

86°F 3.37 4.88 6.41 7.17 7.94 9.49 10.26 11.03 12.57 14.11 15.65

84°F 3.43 4.94 6.47 7.23 8.00 9.54 10.31 11.09 12.63 14.19 15.71

82°F 3.49 5.00 6.53 7.29 8.06 9.60 10.37 11.14 12.69 14.23 15.76

80°F 3.55 5.06 6.59 7.35 8.12 9.66 10.43 11.20 12.74 14.28 15.82

78°F 3.60 5.11 6.64 7.40 8.17 9.72 10.49 11.26 12.80 14.34 15.86

76°F 3.66 5.17 6.70 7.46 8.23 9.77 10.55 11.32 12.86 14.40 15.94

75°F 3.69 5.20 6.73 7.49 5.26 9.80 10.57 11.35 12.89 14.43 15.97

74°F 3.72 5.23 6.76 7.52 8.29 9.83 10.60 11.37 12.92 14.46 15.99

72°F 3.78 5.29 6.82 7.58 8.35 9.89 10.66 11.43 12.97 14.51 16.05

70°F 3.83 5.34 6.87 7.63 8.40 9.95 10.72 11.49 13.03 14.57 16.11

68°F 3.89 5.40 6.93 7.69 8.46 10.00 10.78 11.55 13.09 14.63 16.17

66°F 3.95 5.46 6.99 7.75 8.52 10.06 10.83 11.61 13.15 14.69 16.23

64°F 4.01 5.52 7.05 7.81 8.58 10.12 10.89 11.66 13.20 14.74 16.28

62°F 4.06 5.57 7.10 7.86 8.63 10.18 10.95 11.72 13.26 14.80 16.34

60°F 4.12 5.63 7.16 7.92 8.69 10.24 11.01 11.78 13.32 14.86 16.40

O V E N T E M P

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

25

Page 26

BURNER CONTROL TRANSFORMER -REPLACEMENT

1. Shut power off at main breaker.

2. Remove control panel top and front cover.

3. Remove two (2) wires on primary side, note color and location.

4. Remove two (2) wires on secondary side, note color and location.

5. Remove two (2) screws from transformer base and replace assembly.

6. Reinstall in reverse order and check system operation.

HEAT LIGHT

1. Shut off power at main breaker.

2. Remove control panel top and front pa nel.

3. Remove the two wires fro m burner light, note number and location.

4. Grasp body of light assembly and slide sideways to remove.

5. Reassemble in reverse order and check.

CONVEYOR CONTROL POTENTIOMETER (10K OHM) - REPLACEMENT

1. Shut power off at main breaker.

2. Remove control panel top and front cover.

3. Remove the access cover.

4. Loosen two (2) allen screws and remove knob by sliding off shaft.

5. Remove mounting nut from potentiometer shaft and push out.

6. Unplug wire connector fro m conveyo r control bo ard.

7. Reassemble in reverse order and check system operation. Recalibrate knob as needed.

CONVEYOR CONTROL BOARD ASSEMBLY - REPLACEMENT

1. Shut power off at main breaker.

2. Remove control panel top and front cover.

3. Remove two (2) top screws and loosen one (1) bottom screw from control assembly.

4. Disconnect wiring (Push on connectors) from control board, note proper location of connectors for reinstallation and

exchange boards on the mounting bracket before reinstallation.

5. Reassemble in reverse ord er and check system operation.

NOTE: Control boards are calibrated at the factory and no board adjustment is require d.

CONVEYOR DRIVE MOTOR - REPLACEMENT

1. Shut power off at main breaker.

2. Remove control panel top and front cover.

3. Loosen set screw on conveyor drive sprocket and slide sprocket off shaft.

4. Disconnect motor plug and wiring for hall effect sensor board.

5. Remove four (4) screws from motor frame, on control box side, and remove motor assembly.

6. Remove sensor board. * See Note

7. Reassemble in reverse order making sure to align chain sprockets and adjust motor for proper chain tension

( 1/2" SAG).

NOTE: When replacing the drive motor it will be necessary to also install a new magnet on the

shaft up against the shoulder and cement in place.

REVERSING CONVEYOR DIRECTION

All ovens leaving our plant are wired to operate conveyors from left to right. To reverse conveyor

direction, use the following procedure.

1. Shut off power at main breaker.

2. Remove control panel top.

3. Remove cover from relay box.

4. Reverse wires fastened to terminals A+ and A- on conveyor control board

5. Reassemble in reverse order.

26

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 27

HALL EFFECT SENSOR - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box cover.

3. Remove three- (3) wire connector from hall effect sensor board.

4. Remove two (2) screws fro m conveyor drive motor.

5. Remove sensor board fro m mounting bracket.

6. Reassemble in reverse order.

7. Reinstall plug on hall effect sen sor b oard.

8. Replace control box covers and check system operation.

CIRCUIT BREAKER - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front pa nel.

3. Disconnect two (2) wi res from circuit breaker.

4. Remove knurled mounting nut and push out.

5. Reassemble in reverse order.

NOTE: Be sure to reset breaker before operating.

MAIN ORIFICE - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control panel top and front pa nel.

3. Remove gas valve assy.

4. Remove two (2) nuts from burner orifice bracket.

5. Disconnect pipe union.

6. Remove assembly and replace main orifice.

7. Reassemble in reverse ord er and check system operation.

NOTE: Check all gas line fittings for leaks.

PILOT ORIFICE - BURNER

1. Shut off power at main breaker.

2. Shut off gas supply.

3. Remove burner assembly (See "Burner Asse mbly").

4. Remove pilot line from pilot orifice.

5. Remove pilot orifice from burner igniter.

6. Reassemble in reverse order.

NOTE: Check all gas line fittings for leaks.

ON-OFF SWITCH - REPLACEMENT

1. Shut off power at main breaker.

2. Remove control box cover.

3. Remove the access cover.

4. Depress spring clips on side of switch and push out.

5. Remove wires from back of switch, note wire number and location.

6. Reassemble in reverse ord er and check system operation.

NOTE: Make sure switch housing is fully seated in control box housing.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

27

Page 28

THE FOLLOWING ITEMS ARE USED IN THE MODEL 1456, 1457, 1474, 1475, 1476 IMPINGER OVENS

R

R

AIR PRESSURE SWITCHES - REPLACEMENT AND ADJUSTMENT

1. Remove control panel top.

2. Disconnect wires from switch ma king note of wire number and location for reinstallation.

3. Remove air tube from switch assembly.

4. Remove switch from wire hanger.

5. Install new switch in reverse order, make sure air tube is not blocked or miss-ali gned. Adjust as needed.

To adjust the air pressure switch, remove snap on cover on the side of the switch to

expose adjusting screw. To increase sensitivity, turn screw counter clockwise; to

decrease sensitivity, turn screw clockwise. Check for proper line voltage switching from

N.C. to N.O. as the air pressure switch closes.

GAS VALVE - REPLACEMENT AND ADJUSTMENTS

1. Remove control panel top and front cover.

2. Disconnect the gas piping f rom the ba ck of the unit.

3. Remove the four(4) screws from the incoming nipple mounting bracket.

4. Remove incoming nipple.

5. Disconnect two (2) plu gs, (1) 3 prong and (1) 4 prong - Note location.

6. Disconnect pipe union just above gas valve and remove assembly.

7. Reassemble in reverse order (check all pipe fittings for leaks). After assembled, check

for proper adjustment of gas pressure switch, 8.8 on dial for natural gas, 23 for L.P. Gas and

4.5 for town gas.

8. Check and adjust manifold pressure. remove pressure tap lo cated in gas piping above the

gas valve prior to the burner orifice and install manometer. Adjustment screw is located on the

front of the valve, remove plastic cap and adjust as needed: 3.5" WC for Natural Gas and 10" WC for L.P.

9. Check gas filter by removing cover plate (located on either side of valve). Remove four (4) screws and slide filter out

of valve housing and inspect. Reassemble in reverse order and check

10. for leaks around the cover.

TOP VIEWSIDE VIEW

FILTER

COVER

PLATE

PRESSURE

CONTROLLER

ADJUSTMENT

FILTER

COVER

PLATE

OUTPUT

MANIFOLD

PRESSURE

ADJUSTMENT

+

gnd

-

3

2

gnd

12

3

ELECTRICAL

CONNECTO

ELECTRICAL

CONNECTO

28

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 29

IGNITION CONTROL - REPLACEMENT

1. Remove control panel top and front cover.

2. Depress two (2) locking clips on front cover of relay.

3. Remove control portion of relay by pulling straight out (rocking motion).

4. Remove wires from plug-in terminal strip, note wire numbers and location.

5. Remove two (2) screws from mounting bracket an d remove.

6. Reassemble in reverse order. Check system operation.

HIGH LIMIT THERMOSTAT - REPLACEMENT

1. Remove control panel top and front cover.

2. Remove conveyor and fingers.

3. Remove capillary bulb from wire form in oven ch amber and pull through tube into control box.

4. Remove two (2) wires from thermo stat, not e wire numbers and location for reinstallation.

5. Remove screws from bracket and remove thermostat.

6. Reassemble in reverse ord er making sure capillary tube is placed securely in the wire form.

NOTE: Depress reset button to insure thermostat is set for operation.

SPARK GENERATOR - REPLACEMENT

1. Remove control panel top and front cover.

2. Remove two (2) wires for spark generator.

3. Unplug spark lead on bottom of spark generator from i gnition control.

4. Remove two (2) mounting screws and remove generator assembly.

5. Reassemble in reverse ord er and check system operation.

SOLENOID VALVE - REPLACEMENT

1. Remove control panel top and front cover.

2. Disconnect pipe union just above gas valve assembly.

3. Disconnect two (2) wi res from solenoid, note wire number and location for reinstallation.

4. Remove four (4) nuts from main orifi ce b urner bracket and remove assembly.

5. Replace valve and reassemble in reverse order.

6. After assembly, check all fittings for leaks and check system operation.

BURNER ALARM - REPLACEMENT

1. Remove control panel top and front cover.

2. Remove two (2) wires from alarm, note wire numbers and location.

3. Remove retainer cover from alarm and remove assembly from mounting bracket.

4. Reassemble in reverse order and check.

LIGHT (220V) - REPLACEMENT

1. Remove control panel top and front cover.

2. Remove two (2) wires from light assembl y , note wire number and location.

3. Grasp body of light assembly and slide sideways to remove.

4. Reassemble in reverse order and check.

TRANSFORMER, STEP DOWN/120 VAC

1. Shut off power at main breaker.

2. Remove control compa rtment covers.

3. Remove wires from transformer and mark for reassem bly.

4. Remove 4 mounting screws from transformer base and replace.

5. Reassemble in reverse order.

NOTE: Voltage output of the secondary is to be 120 VAC ± 10%. Check for this output

at the secondary before installing leads to the secondary. If voltage above or below

is measured, recheck the position of the primary leads.

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

29

Page 30

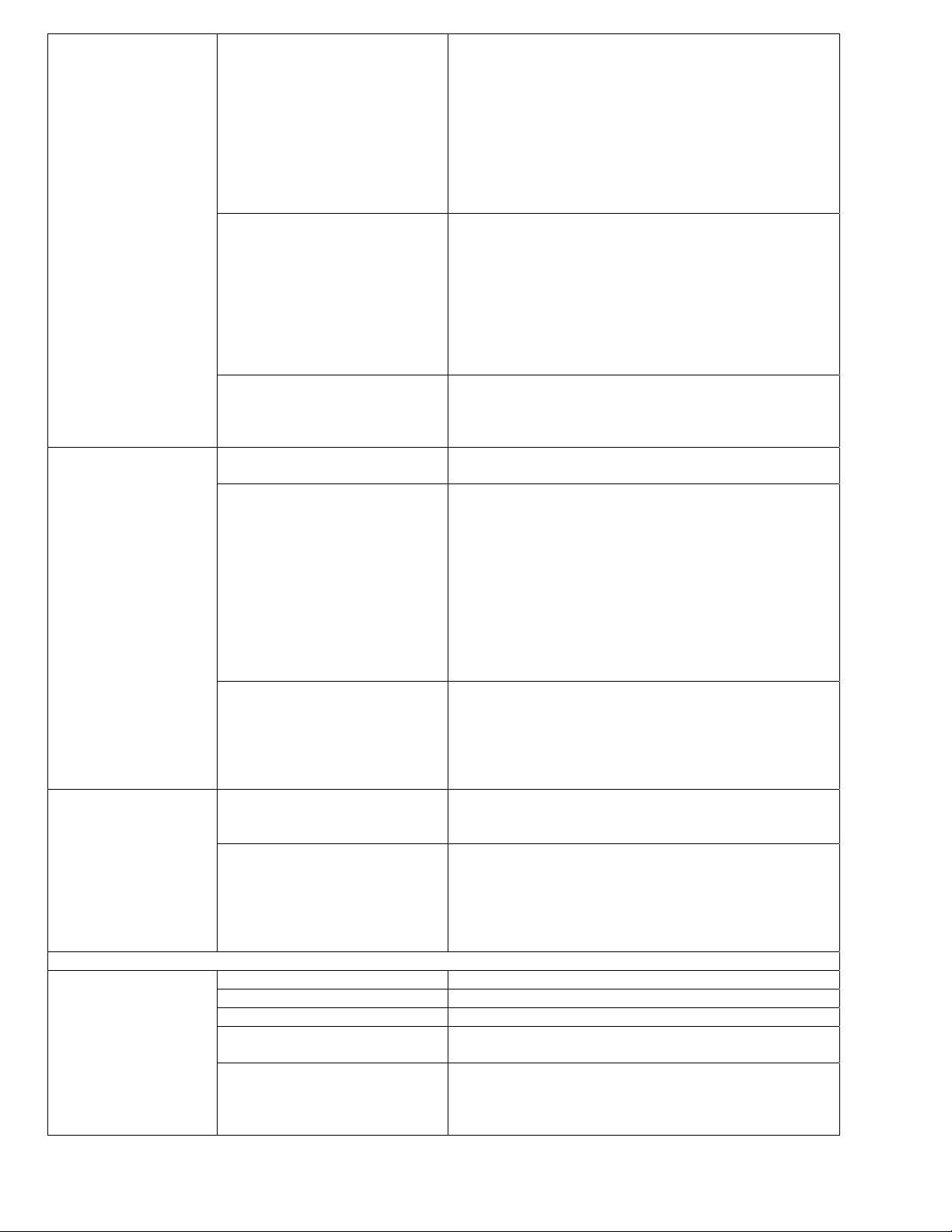

GENERAL – 1450 SERIES

LETTER PART # DESCRIPTION

A 369003 Door Hinge

B 369110 Access Window Assy.

C 369337 Retainer (Old Style)

369929 Retainer (New Style)

D 369828 Handle, Spacer

E 369209 Latch & Strike

F 369310 Screw 6-32 x 3/16”

G 369308 Access Window Assy. Bottom

H 369334 Access Door Glass

J 369309 Access Window Assy. Top

K 350638 Handle

L 369311 Handle Spacer (2 Required)

M 369336 Door Latch

N 369906 Screw 8-32 x 5/8”

O 370110 Door Assy. (Solid)

P 369157 Door Assy. W/Window

Q 1534 Finger Support Assy.

R 369057 Support Bracket Pins

S 369643 Strike Assy.

T 1009 Oven Top

U 369062 Top, Control Panel

V 369140 Compression Spring

W 369903 Washer, Flat

X 369141 Conveyor Hold Do wn Bracket

Y 369139 Shoulder Screw

Z 369058 Baffle, Inlet and Outlet

* 369211 Thumb Screw (Not Shown)

AA 369203 Stud Wing Head

BB 369749 Chain Cover Kit (Includes AA, CC)

CC 369204 Split Ring Retainer

DD 369373 Receptacle, Snap-In

EE 369748 Bracket, Chain Cover

FF 369328 Stand, Leg

GG 369052 Adjustable Leg

HH 369030 Caster 6”

JJ 369904 Insulation Holder Assy.

KK 369053 Finger Housing

LL Columnating Panels – See Installation Manual

MM 369055 Finger Cover

NN 369218 Crumb Pan, Internal

OO 369926 Window Frame, Bottom

PP 369925 Glass, Access Window

QQ 369927 Window Frame, Top

30

Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

Page 31

GENERAL - 1450 SERIES BLOW-UP

Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

31

Page 32

CONTROL BOX – 1450, 1451, 1480

LETTER PART # DESCRIPTION

A 369012 Fuse Holder

B 369014 Fuse, 10 AMP

C 369013 Fuse, 3 AMP

D 369872 Instruction Plate

E 369805 Switch, On/Off

F 369809 Conveyor Control Pot.

G 369507 Cooling Fan Thermostat

H 369154 .7 AMP Circuit Breaker

J 369523 Relay, Motor

K 369803 Control, Conveyor

L 369531 Transformer

M 369393 Ignition Control NAT/LP

N 369125 Terminal Block

O 369131 Thermocouple with Terminals

P 369366 Burner Blower Motor Kit

Q 369131 Finger Guard, Cooling Fan

R 369801 Thermostat (Temperature Control)

S 369128 Neon Pilot Light

T 350224 Lens, Yellow

U 369804 Knob, Clear Skirt

V 369202 Pilot Shield, Main

W 369144 Pilot Shield Extension

X 369263 Gas Valve (Body only) NAT/LP for 1450 & 1451