Lincoln 1461, 1462 User Manual

Impinger® Tandem Conveyorized Oven

Models:

Impinger

1461/62 with 1481 Solid Conveyor

1461/1462 with 1487 Split Conveyor

Standard Features:

• Air Impingement uses hot

air under pressure w hi ch

surrounds fo od w it h je ts o f

hot air.

• FastBake™ Pa ne l

Configurat io n - De si gn ed

specifically to prod uc e a

bake faster than any o th er

model.

• Tandem-joined Impinger® I

oven s to optimized

capacity and baki ng

per formance.

• Each deck contains two

independent heating

systems.

• Front doors allow access

to chamber for e as ie r

cleaning.

®

Tandem Conveyorized Oven

Specications:

Gen eral: Gas Fired Baki ng/Fin ishing O ven is

sel f-con tained, c onveyo rized and stac kable up t o 2

hig h. Temp eratur e is adjust able from 250 F ( 121C)

to 600 F (316C ). C onveyo r speed is a djust able

fro m 1min ute t o 30 m inute s cookin g time. Front

doo r has acc ess o pening with see- throug h win dow

to allow produ ct to be pla ced o n the movin g

conv eyor inside the b aking cham ber wh en a short er

coo k cyc le is desir ed. A ir di strib ution finge rs are

rem ovable through the f ront d oor f or eas y cle aning.

Cru mb pans a re lo cated below the conv eyor b elt

out side the bak ing cham ber.

Dig ital Contro ls: Two 4-but ton d igital

mic roproc essor contr ol panels are locate d at the

bac k of each si de of the deck and have a powe r on-

off switc h, te mperature controls , and the c onveyo r

1111 Nor th Hadley Road

P.O. Box 1229

Fort Wayne, Indiana 46801-1229

Tel 1.260.459.8200

Fax 1.260.436.0735

E mail info@lincolnfp.com

web www.lin colnfp.com

spe ed con trol. The vacu um flores cent readou ts

dis play a ctual cavi ty te mperat ure in degre es (F or

C), conve yor b elt sp eed, therm ostat indic ator l ight,

and diagn ostic mess ages for easy troubl eshoo ting.

All settings are automa tical ly lo cked o ut to

eli minate acci dental ch anges to d esired sett ings.

All ovens are digi tally cali brated at the fac tory,

red ucing the n eed fo r per iodic calibrat ion.

Cons truc tion: Exterior is fabr icate d from No. 4

fin ish stainles s ste el. E ach d eck c ontain s two air

dis tribu tion s ystem s that cons ist o f an a xial type

fan power ed by 1/3, AC motor. The he ated air is

forc ed th rough sixte en (1 6) distribution fing ers

loc ated i n the baki ng ch amber with e ight (8) a bove

the conve yor be lt an d eig ht (8) belo w. Each fing er

has requi red n umber of holes to c reate the air

imp ingement effec t on the fo od product passin g

www.lincolnfp.com

thr ough t he ba king chamb er on the co nveyor belt .

The conve yor be lt is a flexib le st ainle ss ste el si ngle

pie ce des ign w ith c apacit y for 32” (813mm ) wid e

pro duct and a travel di stanc e of 115”, of whic h 80

3/1 6” is in the bakin g cha mber. T he ch ain drive n

conv eyor syst em is power ed by an AC mo tor

wit h an external reve rsing switch on t he rea r of

the motor cont rol bo x for insta llati ons re quiri ng

opp osite belt travel .

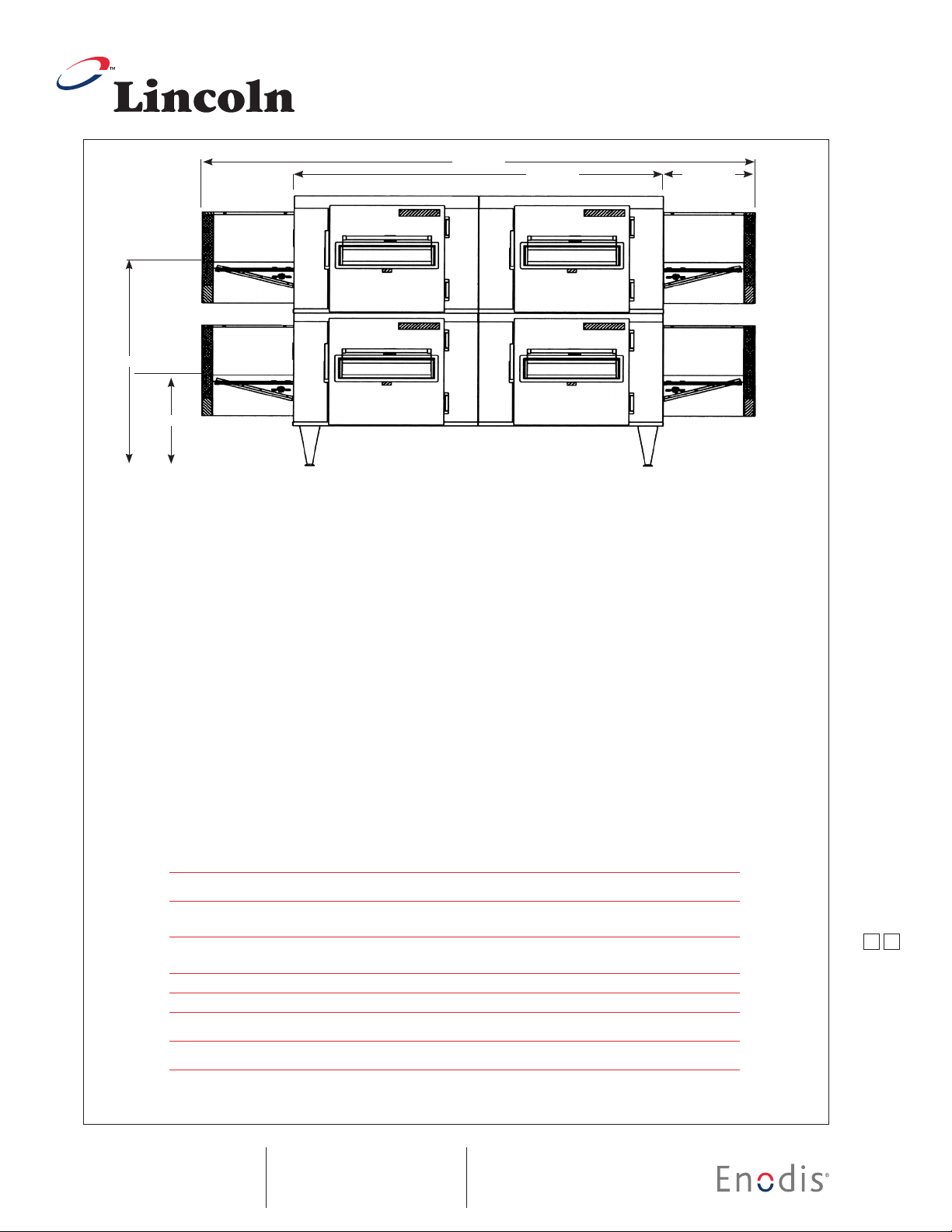

Impinger

48⅝” (1235 mm)

21⅝” (549 mm)

Ga s Se rvic e pe r de ck: Curre ntly availa ble in Natu ral Gas Only.

Each oven de ck c ontains two sep arate gas contro l syste ms w ith

the f ollowin g require ments: Gas cont rol sys tem has a m anua l

shut- off valve, internal pressure regulat or (facto ry pre set at 3

½” wate r co lumn/. 87 k Pa or 8.7 0 mbar fo r Natur al G as), and an

electri c so lenoid op erated main gas valve. Hea t is suppli ed b y

one ( 1) b urner rat ed at 1 20,0 00 BTU/ H. ( 126M J) wit h el ectronic

ign itio n. Natural Gas requir es 7 ” WC/ 1.7 kPa o r 17 .4 mbar inl et

with maxi mum allow able of 14. 5” WC/3.6 kPa o r 36 .05 mbar.

Gas l ine from me ter to oven s should be s ufficie nt t o insure full

vol ume flow of gas to ove ns. AG A/CGA d esign app roved fle xibl e

con nect ion to each o ven mus t be ¾” NP T an d lengt h mu st n ot

exc eed 6 ft. (18 29mm ).

Electri cal Ser vice pe r de ck: Each deck req uires t wo e lect ric

hooku ps w ith the f ollowin g require ments: stan dard 120V ser vice

and c omes with a fac tory i nsta lled co rd with N EMA 5-15 plug. It is

rec omme nded th at a sep arate 20 amp – 1 p ole circuit breaker be

pro vide d with each oven d eck.

120⅝” (3051 mm)

Ventil atio n: Venti lati on is r equi red. Local co des pre vail. The se

are the “aut hori ty h aving jur isdi ctio n” as s tated by the Nat iona l

Fire Protec tion Ass ociatio n, I nc. in NF PA 9 6-19 94. Consul t Mo del

1450, 145 1 In stallat ion and Opera tions Man ual for ven tilatio n

rec omme ndation s.

Spaci ng: T he oven mus t have 5” (12 7mm) of clear ance fr om

com bust ible sur face s and 2 4” (61 0mm) cle arance on b oth sid es

fro m ot her coo king e quip ment. A pe rman ently i nsta lled ov en

deck require s ap proxi mate ly 11 f t of cle arance overall to allow

for remova l of conveyor an d prote ctiv e gu ards for cleanin g. T he

con veyor i s remov ed f rom the contro l si de of t he o ven.

War ranty : Al l ne w Im ping er® ov ens come wi th a one ye ar p arts /

labor war ranty. Defe ctive p arts o f th e or iginal equi pment o n

all i nsta lled ov ens are w arra nted fo r one yea r from the date of

“START- UP/CHEC K-OU T.”

803/16” (2037 mm) 20” (508 mm)

®

Tandem Conveyorized Oven

Tandem Components

Description Cat. # Width Depth

Left Hand*1461 60” 565/8” 52” 645/8”

Right Hand*1462 60” 565/8” 52” 645/8”

Solid Conveyor 1481 115½” 32” -- -- -- -- -- -- --

Split Conveyor 1487 115½” 32” -- -- -- -- -- -- --

Single Deck (Tandem containing 1461 and 1462 with a 1481 tandem conveyor belt)

Cat. # Width Depth

Tandem 1201/8” 565/8” 52” 645/8”

NOTE: Spe cications subj ect to change wi thout notice. * Testi ng Agency Listi ng: NSF/CSA

1111 Nor th Hadley Road

P.O. Box 1229

Fort Wayne, Indiana 46801-1229

Single Stack

Single Stack

Tel 1.260.459.8200

Fax 1.260.436.0735

E mail info@lincolnfp.com

web www.lin colnfp.com

Height

Height

Height

Double Stack

Height

Double Stack

©2007 Lincoln Foodser vice Products, LLC.

Printed in the U.S.A.

1557-2.5M-02/07-SP

Input

Rate

120,000

BTU/Hr

120,000

BTU/Hr

Input

Rate

240,000

BTU/Hr

Volts Amps Phase Hz

120 7 1 60

120 7 1 60

Volts Amps Phase Hz

120 14 1 60

Models:

1461/1 462 with 1481 Solid Conveyor

1461/1 462 with 1487 Split Conveyor

Loading...

Loading...