Lincoln 1441 Installation Manual

operator manual

Impinger® Conveyor Oven

This document includes:

• Safety N otices

• Specifications

• Installation Instructions

• Operating Instructions

• Cleaning Instructions

• Warranty Statement

Revision: J

P/N: 2810197

Series 1400

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Technical Support Hotline: (800) 678-9511

Telephone: (260) 459-8200

www.lincolnfp.com

IMPORTANT WARNING AND SAFETY INFORMATION

WARNING:

!

WARNING:

!

DANGER!

!

DANGER!

!

This appliance is not intended for use by young children or infirm persons unless they have been

adequately supervised by a responsible person to ensure that they can use the appliance safely. Young

children should be supervised to ensure that they do not play with the appliance.

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

Do not work around conveyor belt with long hair, loose clothing, or dangling jewelry. Getting caught in the

belt could result in serious injury.

For your safety, do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or

any other appliance.

DANGER!

!

Do not spray aerosols in the vicinity of this appliance while it is in operation.

DANGER!

!

!

· Obtain from your local gas provider and post in a prominent location instructions to be followed in the event gas

odors are detected.

· It is required that the oven be placed under a ventilation hood to provide for adequate air supply and ventilation.

· Minimum clearances must be maintained from all walls and combustible materials. See “spacing requirements”

section for more information.

· Keep the oven free and clear of combustible material.

· Adequate clearance for air openings to the combustion control chamber on the right side of the oven is required.

· Do not obstruct the ventilation holes in the control panels, as these provide the combustion air for the burner and

cooling air for the controls.

· The oven is to be operated only on the type of gas and/or electricity as shown on the specification plate.

· The power burner will not operate and gas will not flow through the burner without electrical power.

· This manual should be retained for future reference.

· The electrical wiring diagram is located under the control box covers.

DANGER!

If the power supply cord appears to be damaged, do not attempt to operate the unit. Contact a service

agent or qualified electrician to repair!

Do not use parchment paper when placing food product through the oven! Use of such materials may

cause a fire and should never be placed in the oven.

GENERAL OPERATOR

MAINTENANCE AND CLEANING IS

CRITICAL TO OVEN

PERFORMANCE. FAILURE TO

FOLLOW GUIDELINES LISTED IN

THIS MANUAL MAY RESULT IN

COMPONENT FAILURE NOT

COVERED BY WARRANTY.

2

2810197 - Impinger I – Operator Manual

PURCHASER’S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the gas and electric services for the oven are installed on site in accordance with the manufacturers

specification.

2. To unload, uncrate, and install the oven in its proper location; in accordance with this installation / operation

manual.

3. To see that the gas and electric services are connected properly by a qualified installer of your choice. For

installation in the State of Massachusetts: Installation of this oven must be performed by a licensed plumber or

gas fitter. All such connections must be in accordance with applicable code requirements. See “Code

Reference” section for specific code references.

4. To arrange for inspection and operation check-out by an Authorized Service Technician as described below:

Do not attempt to operate the oven until connection of utility service has been fully inspected by an Authorized

Service Technician or a Lincoln Foodservice Products Service Representative. This service is required by Lincoln

Foodservice Products, LLC in order to assist the purchaser in proper start-up of the oven on site. Please note the

specific details on the Warranty and make certain connections are made to proper utility services.

The warranty shall not apply if the oven(s) are started up and operated prior to the utilities and oven being

inspected and check out made by an Authorized Service Technician or a Lincoln Foodservice Products Service

Representative.

TABLE OF CONTENTS

WARNING AND SAFETY INFORMATION……………………………………………………………………...… 2

PURCHASER’S RESPONSIBILITY……………………………………………………………………………...… 3

MODEL NUMBER KEY……………………………………………………………………….……………………… 4

UTILITY SPECIFICATIONS……………………………………………………………………...………………..… 5

EXTERIOR DIMENSIONS……………………………………………………………………………..……………. 6

GENERAL INFORMATION…………………………………………………………………..……………………… 7

UNLOADING & UNCRATING………………………………………………………………..……………………… 7

STAND & FINGER ASSEMBLY……………………………………………………………….……………………. 8

SPACING REQUIREMENTS………………………………………………………………….…………………….. 10

VENTILATION………………………………………………………………………………………...………………. 10

MANUAL GAS VALVE INSTALLATION……………………………………………………………………………. 12

CODE REFERENCES………………………………………………………………………………….……………. 12

RESTRAINT REQUIREMENTS……………………………………………………………………….……………. 13

PROGRAMMING……………………………………………………………………………………….…………….. 13

FUNCTIONS…………………………………………………………………………………………….…………….. 15

FINGER & CONVEYOR REMOVAL / REINSTALLATION………………………………………….……………. 16

OPERATOR MAINTENANCE……………………………………………………………………………………….. 17

CLEANING INSTRUCTIONS……………………………………………………………………………...………… 17

PREVENTIVE MAINTENANCE……………………………………………………………………………..………. 18

STACKING WITH OTHER OVENS………………………………………………………………………….……… 18

HOW TO OBTAIN SERVICE………………………………………………………………………………….…….. 18

APPENDIX A – LABEL DEFINITIONS……………………………………………………………………….…….. 19

WARRANTY STATEMENT………………………………………………………………………………………….. 21

2810197 - Impinger I – Operator Manual

3

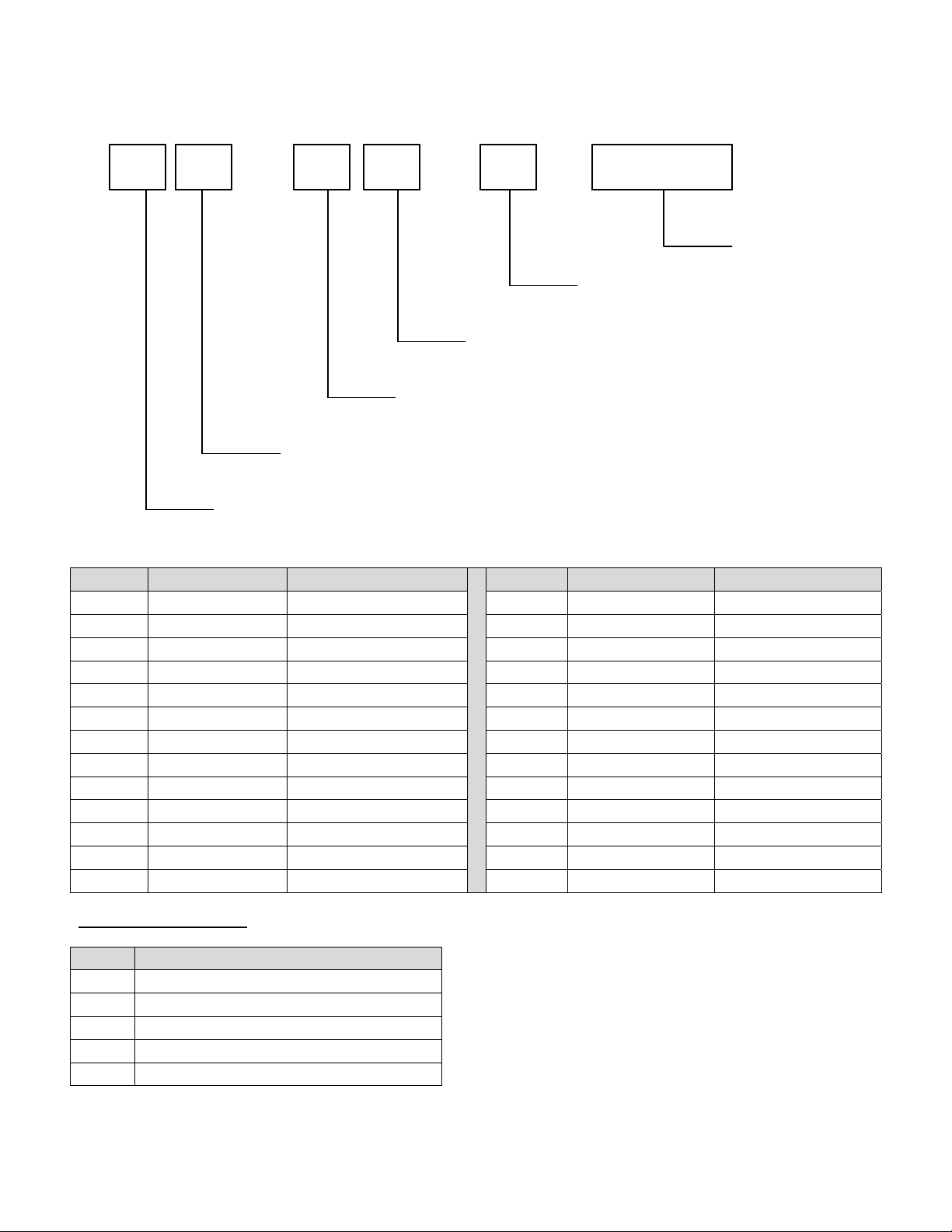

MODEL NUMBER KEY

EXAMPLE: 1433-B00-E-K1801

14 33 - B 00 - E - K1801

Panel Setup Code

Agency Code (i.e. CE & RoHS combined)

Custom Configuration Code (i.e. General Market Version)

Language Code

Indicates change to base assembly (i.e. Natural Gas, 230V, 1 phase, 50 Hz)

Oven Platform Size (i.e. Impinger I)

CODE LANGUAGE COUNTRY

0 English Dom. & Int. Default N Finnish Finland

B French France/Luxembourg O Restricted ---

C German Germany P Norwegian Norway

D Italian Italy Q English Japan

E Spanish Spain R Swedish Sweden

F English UK/India/Africa/Hungary S English Australia

G Spanish Mexico/Latin America T Mandarin China

H Portuguese Portugal U Restricted ---

I Not Used --- V English Pacific Rim/Korea

J Danish Denmark W English Middle East

K Dutch & French Belgium X Not Used ---

L Dutch Netherlands Y Not Used ---

M Greek Greece Z Not Used ---

CODE LANGUAGE COUNTRY

AGENCY CODE TABLE

CODE AGENCY

N No Agency

E CE & RoHS compliance combined

U US & Canada compliance only

A Advantage style oven to be phased-out

B Australia AGA

4

2810197 - Impinger I – Operator Manual

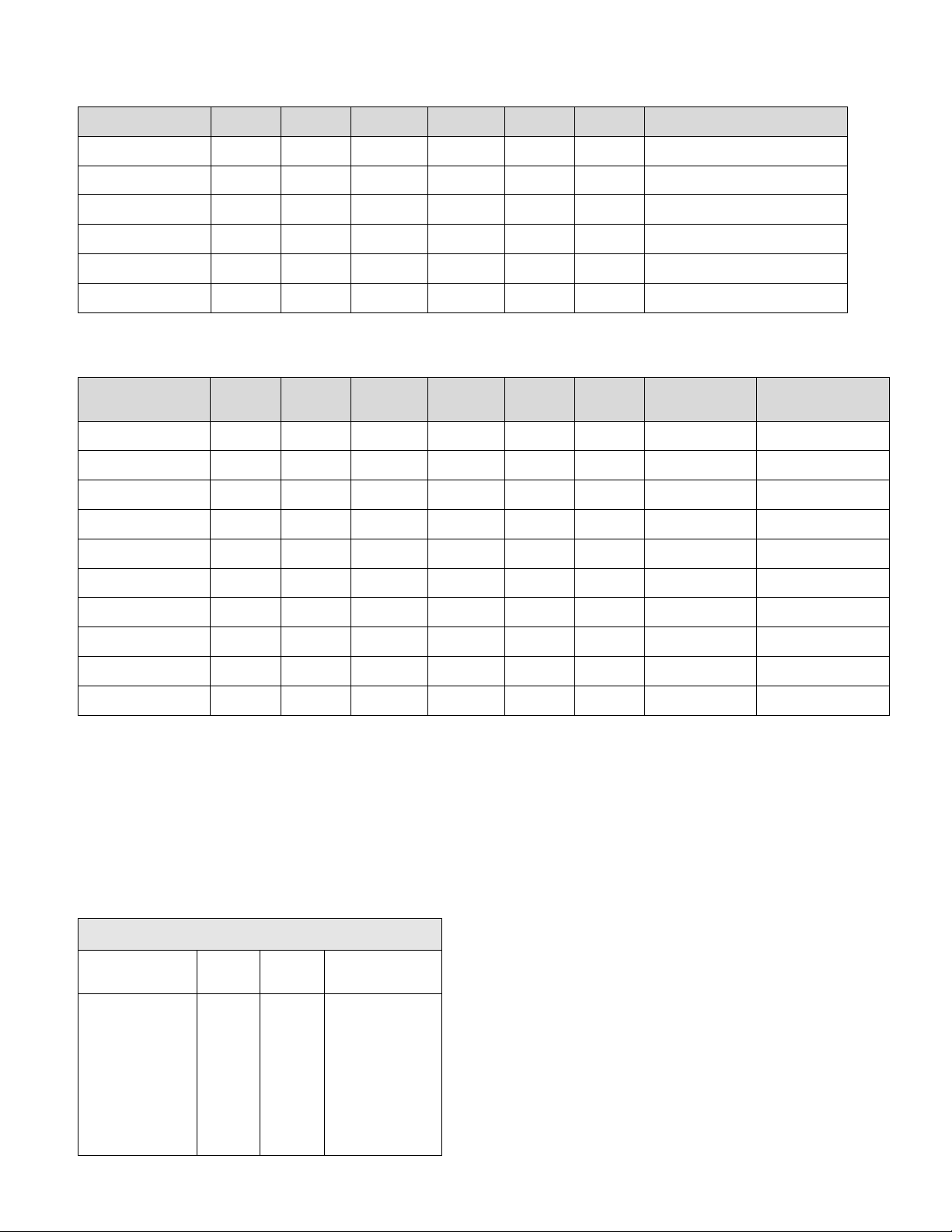

UTILITY SPECIFICATIONS REQUIRED – ELECTRIC

Model Energy Power Voltage Current Phase Hz

*1421-xxx-E-Kxxx Electric 27 kW 400/230V 40 Amps 3 50 Hz

*1452-xxx-E-Kxxx Electric 27 kW 120/208V 80 Amps 3 60 Hz

*1453-xxx-E-Kxxx Electric 27 kW 120/240V 70 Amps 3 60 Hz

*1454-xxx-E-Kxxx Electric 27 kW 380Y/220 41 Amps 3 50 Hz

*1455-xxx-E-Kxxx Electric 27 kW 415Y/240 38 Amps 3 50 Hz

*1458-xxx-E-Kxxx Electric 27 kW 400 38 Amps 3 50 Hz

UTILITY SPECIFICATIONS REQUIRED – GAS

Model Energy Power Voltage Current Phase Hz

*1433-xxx-E-Kxxx Nat. Gas Hs 40 kW 230 VAC 3 Amps 1 50 Hz

*1434-xxx-E-Kxxx L.P. Gas Hs 40 kW 230 VAC 3 Amps 1 50 Hz

*1440-xxx-E-Kxxx Nat. Gas 35 kW 120 VAC 3 Amps 1 60 Hz

*1441-xxx-E-Kxxx L.P. Gas 35 kW 120 VAC 3 Amps 1 60 Hz

1446-xxx-N-Kxxx Nat. Gas

*1450-xxx-E-Kxxx Nat. Gas

*1451-xxx-E-Kxxx L.P. Gas

*1456-xxx-E-Kxxx Nat. Gas

*1457-xxx-E-Kxxx L.P. Gas

*1474-xxx-E-Kxxx Nat. Gas 35 kW 220 VAC 3 Amps 1 50 Hz

* Reference Model Key

120,000

BTU

120,000

BTU

120,000

BTU

120,000

BTU

120,000

BTU

Electrical Supply for Australia:

Single Phase: 240VAC, 50Hz / 20 Amp: one neutral & one earth/ground.

Three Phase: 240/415 VAC / 20 Amp; three active, one neutral & one earth/ground.

** In Australia, use a 10 Amp General Purpose Outlet

All ovens require separate service and dedicated neutral.

GAS PRESSURE CONVERSION CHART

Inches of

Water Column

3.5

4.5

7

10

10.5

11

14

14.5

KPa m-Bar

0.87

1.12

1.74

2.48

2.61

2.73

3.48

3.61

8.70

11.2

17.40

24.87

26.11

27.36

34.81

36.05

2810197 - Impinger I – Operator Manual

220/230

VAC

120 VAC 5 Amps 1 60 Hz

120 VAC 5 Amps 1 60 Hz

220/240

VAC

220/240

VAC

5 Amps 1 50 Hz

5 Amps 1 50 Hz

5 Amps 1 50 Hz

***NOTE: For proper operation, the gas valve

Millimeters of

Water Column

88.9

114.3

177.8

254.0

266.7

279.4

355.6

requires a nominal inlet pressure of 7 inches H

column for natural gas and 11 inches of H

for L.P. gas. A minimum inlet pressure of 1.0 inch of

above the manifold setting (NAT. manifold 3.5”

2O

H

O, L.P. manifold 10” H2O) must be maintained with

H

2

no pressure drop from the no load to full load

condition. The maximum inlet pressure must be

maintained at or below ½ PSIG (14.5 inches H

column). Refer to the chart on the left for pressure

conversions.

368.3

Recommended Electrical

Specifications

5 Wires, 3 Poles

1N-1G

5 Wires, 3 Poles

1N-1G

5 Wires, 3 Poles

1N-1G

5 Wires, 3 Poles

1N-1G

5 Wires, 3 Poles

1N-1G

5 Wires, 3 Poles

1N-1G

Recommended

Electrical

Specification

3 Wires, 1 Pole

1N-1G

3 Wires, 1 Pole

1N–1G

3 Wires, 1 Pole

1N–1G

3 Wires, 1 Pole

1N–1G

3 Wires, 1 Pole

1N–1G

3 Wires, 1 Pole

1N-1G

3 Wires, 1 Pole

1N-1G

3 Wires, 1 Pole

1N-1G

3 Wires, 1 Pole

1N-1G

3 Wires, 1 Pole

1N–1G

120,000 BTU @ 1.7 kPa

inches H2O column***

inches H2O column***

inches H2O column***

inches H2O column***

O column

2

Gas

Hs 40 kW/hr at 17.4

mB H2O column***

Hs 40 kW/hr at 27.4

mB H2O column***

35 kW/hr at 27.4

mB H2O column***

35 kW/hr at 27.4

mB H2O column***

120,000 BTU at 7

120,000 BTU at 11

120,000 BTU at 7

120,000 BTU at 11

35 kW/hr at 27.4

mB H2O column***

O

2

O

2

5

6

2810197 - Impinger I – Operator Manual

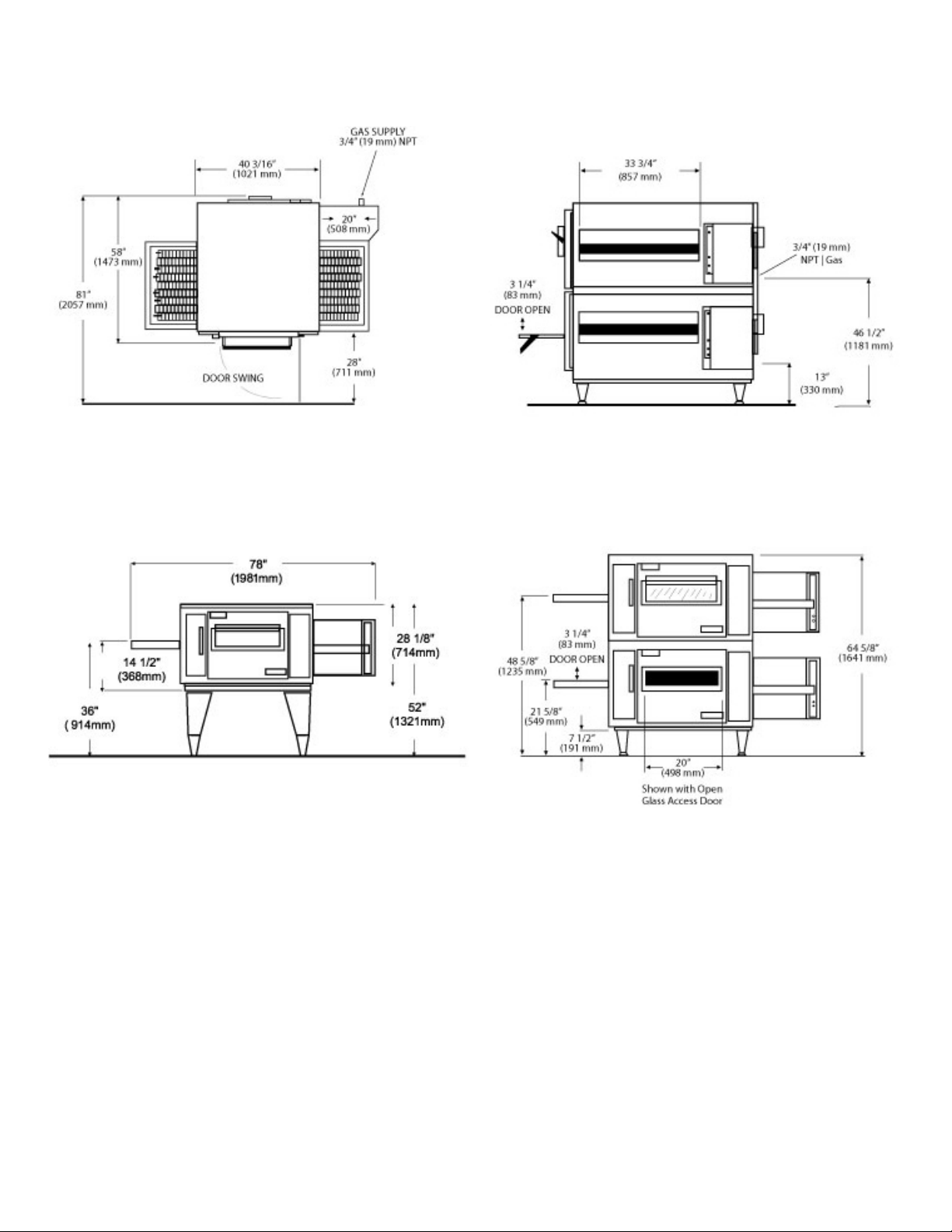

EXTERIOR DIMENSIONS

2810197 - Impinger I – Operator Manual

7

GENERAL INFORMATION

The instructions that follow are intended as a guide for preparing for the installation of the Impinger Conveyor Oven.

First and foremost, each crate should be examined before signing the Bill of Lading to report any visible damage by

the trucker in transit, and to account for the proper number of crates.

The Impinger® oven functions by directing high velocity streams of heated air directly on the food products.

Because air is the heat source, it is effective even on sensitive foods. Compared to conventional ovens and even

convection ovens, the cooking time of products in the Impinger® Conveyor ovens can be as much as two (2) to four

(4) times faster. Several factors may affect the cooking time of any special product such as: 1) oven temperature

setting, 2) conveyor speed, 3) position of columnating plate in oven, and 4) adjustments of the 2 baffles on the

conveyor openings.

We encourage you to experiment with the oven by trying different temperature settings and belt speeds. Also, try

to control the cooking of the product by re-arranging the optional columnating plates.

IF THERE IS APPARENT DAMAGE:

UNITED STATES AND CANADA: Arrangements should be made to file a claim against the carrier. As Interstate

Commerce Regulations require that the claim must be initiated by the consignee.

ALL SHIPMENTS TO OTHER COUNTRIES: Freight terms will be developed and extended on an individual basis.

Proper and secure storage facilities should be arranged for the oven(s) if necessary to protect it from outdoor or

damp conditions at all times before installation.

UNLOADING

When the oven arrives it should consist of:

1. A crate containing oven body, conveyor, fingers, crumb pans, and pan stops. (Some models may have

the conveyor packed separately.)

2. A package containing the stand and top.

It is recommended that you have a material-handling device available to unload.

NOTE: DO NOT LIFT EXCESSIVE WEIGHT!

UNCRATING

When you have all the crates unloaded, open the crates and remove the plastic covers. Inspect at once for

concealed damage. If anything appears to be damaged, contact the appropriate persons immediately to file a

damage claim. After completing this inspection, finish unpacking the oven and all other components. Be sure to

remove the cardboard from the plenum shroud. Move all components inside near the area where they will be

assembled in the order in which they will be assembled.

THE OVEN WILL CLEAR THROUGH A 30” (762 mm) DOORWAY BY USING THE FOLLOWING PROCEDURE:

A. Remove conveyor; see “Conveyor Removal” section for instructions. (Some units may have conveyor

packed separately.)

B. Remove thumb screws and baffle from the left side of the oven.

C. Place the left side on a four wheel moving dolly and it will clear a 30” (762 mm) doorway.

8

2810197 - Impinger I – Operator Manual

Loading...

Loading...