Lincoln 1312-020-E User Manual

Global

Countertop Impinger® (CTI)

Conveyorized Electric Oven

Models:

1301 1302 1303 1304 1305

1308 1309 1310 1312-000-E 1312-020-E

Countertop Impinger

Specications:

Ge ne ra l : El ectric B aki ng/Finishing

Oven is s elf-contained, conveyorized

and stack abl e up to two (2) h igh.

It is d esigned for counter top u se

and must be used with approp riate

four-inc h (4” ) legs for proper coo ling.

Temperature is adjust able from 20 0°F

(93°C) to 550° F (28 8°C ). Conve yor

speed is ad justa ble f ro m one (1)

minute to t wenty -four ( 24) minutes

cook ing time. Conveyor and air

distribut ion fingers are remov able

throug h the side -ac cess panels

for easy clea ning. The co nveyor is

offered in either th e 31” ( 787 m m)

standard length or 50” (1 270 m m)

exte nded model. Crumb pans are

locate d bel ow the conveyo r belt

outside the baking chamb er on the

exte nded conveyor only.

Standard Features:

AIR IMPINGE MENT uses hot

•

air under p ressure which

surrou nds foo d wit h small

jets of hot air. This allow s

for rapid hea ting, c ook ing,

baking and crisping of

foods, t wo to four tim es

faster than conventional

ovens, d epend ing on food

produc t coo ked.

Unifor m hea ting/cooking of

•

food pro ducts offer a wid e

tolera nce for rapid bak ing at

a variety of t emperatures.

Safety of c onveyor ized

•

produc t movement i s a

definite ad vantage over

bath type ovens, a s it

eliminates the need for

constant te nding.

Cont ro ls : The ov en controls are

locate d on the fro nt of the oven.

It incl udes a power o n/off switch,

temper ature c ontrol and c onveyor

speed control. A heating indi cator

light illum inates when heati ng to let

you know when the oven is ca lling

for heat.

Cons tr uct io n : Ex terior is fabricated

from N o. 4 fini sh st ainle ss stee l. The

air distr ibution syst em consists of an

axial typ e fan powered by 1/10 hp

AC motor. Th e heate d air is force d

throug h four (4) dis tribution finge rs

locate d in the baki ng chamber w ith

two (2) above the conveyo r belt

and two (2) belo w. Each finger has

required numb er of holes to crea te

the air imp ingem ent e ffect o n the

food pro duct passi ng th ro ugh t he

baking chamber on t he co nv eyor

Oven has one self-

•

contained h eatin g sys te m.

Customer specific air f ingers

•

on top and bottom allow

for heat to b e adjusted a nd

contro lled by zoning.

belt. The conveyor belt is a flexib le

stainless s teel design with capacit y

for 16” (406 mm) wid e produ ct and

a travel distance of 31 ” (787 mm) on

the standard conveyo r or 50” (1270

mm) on the extended c onveyor, of

which 20” (508 mm) is i n the baking

chamber. T he dire ct dr ive c onveyor

is pow ered by a DC m otor. The f uses

for the controls and blower motor are

locate d on the side of the

contro l box.

(CTI) Conveyorized Electric Oven

1309 1310 1312-000-E

1312-020-E

®

Models:

1304 1305 1308

1301 1302 1303

1111 Nor th Hadley Road

P.O. Box 1229

Fort Wayne, Indiana 46801-1229

Tel 1.260.459.8200

Fax 1.260.436.0735

E mail info@lincolnfp.com

web www.lin colnfp.com

www.lincolnfp.com

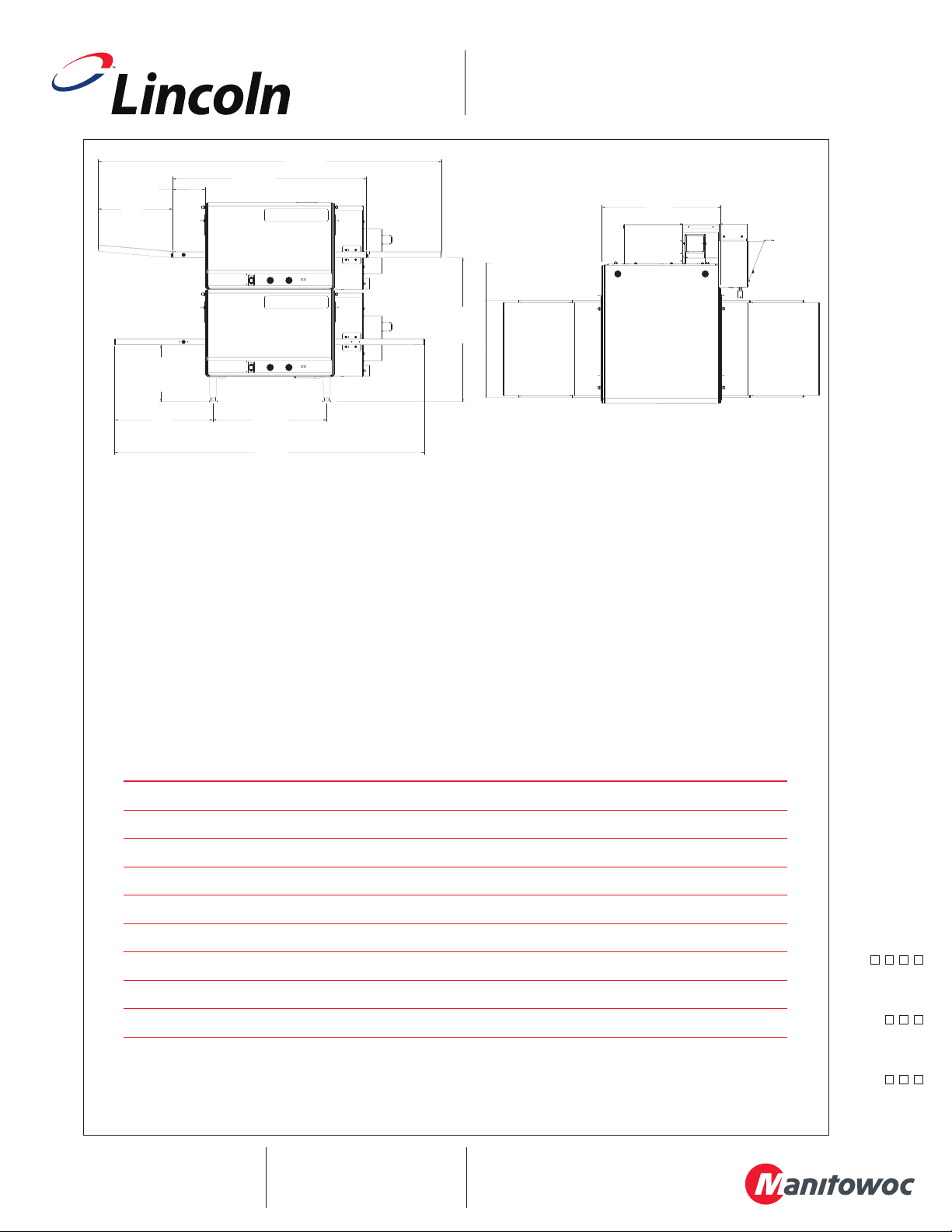

18.93”

(481 mm)

LEG DEPTH

31.25”

(794mm)

OVERALL

OVEN DEPTH

17”

(432 mm)

CONVEYOR WIDTH

20.69”

(525 mm)

12”

(305 mm)

5.25”

(133 mm)

9.13”

(232 mm)

TO BOTTOM OF

CONVEYOR

31.1”

(790 mm)

CONVEYOR LENGTH

55.13”

(1400 mm)

CONVEYOR

W/SHELVES LENGTH

23.06”

(586 mm)

TO BOTTOM OF

CONVEYOR

Global

17”

(432 mm)

CONVEYOR WIDTH

20.69”

(525 mm)

Countertop Impinger

®

(CTI) Conveyorized Electric Oven

15.75”

(400 mm)

18.25”

(464 mm)

LEG WIDTH

49.75”

(1264 mm)

CONVEYOR

LENGTH

Electrical Service:

Heat is sup plied by one (1) eleme nt at 5600 w atts.

Each ovens is rate d at 6kW. T he oven s are ava ilabl e

in a vari ety o f voltages i n bot h single and three

phase, (refer to table,) with a fa ctory installed co rd

with NEMA 6-5 0 plu g. A se parate circuit breaker i s

required for ea ch oven deck with t he prop er voltage,

amperage, phase an d her tz as ind icated by mo del

number.

Ventilation:

Ven tilat ion is recommended, but no t requi red.

Local codes p revail. Thes e are t he “authority having

juri sdiction” a s sta ted by the National FIRE Pro tecti on

Associ ation , Inc., in NFPA 96- 1994.

Testing

Agency Listing

NSF/UL/CUL 1301

NSF/UL/CUL 1302

NSF 1303

NSF 1304

NSF 1305

NSF 1308

NSF 1309

NSF 1310

NSF/CE 1312-000-E

NSF/CE 1314-000-E

Catalog

Number

Width

(31” Conveyor)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

35/”

*

(899 mm)

Width

(50” Conveyor)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

50”

(1270 mm)

Depth

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

31¼”

(797 mm)

Spacing:

The oven must have 6 ” (152 mm) of clearance from

combustible surfa ces and 24” (610 mm ) cle arance

on both sid es from othe r coo kin g equipment. The

conveyor is rem oved from the control side of

the ov en.

Warranty:

All new Cou ntertop Impinge r (CTI ) ovens installed i n

the United States or Canada come wi th a one (1) year

parts/l abor warra nty. All ovens insta lled in loca tions

other than the U nited S tates or Can ada a re warr anted

for one (1) year on par ts an d ninety ( 90) day s on labor.

Height

Single

Stack

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

18”

(457 mm)

Height

Double

Stack

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

32”

(813 mm)

Input

Volts Amps Phase Hz

Rate

6 kW 208 27 1 60

6 kW 240 24 1 60

6 kW 220 28 1 50

6 kW 240 25 1 50

6 kW 380/220 16 1 50

6 kW 380/220 9 3 50

6 kW 415/240 8 3 50

6 kW 220 28 1 60

6 kW 400/230 19 3 50

6 kW 400/230 15 2 50

1309 1310 1312-000-E

1312-020-E

Models:

1304 1305 1308

1301 1302 1303

NOTES: Specifications subject to change without notification. * For the quieter version of the CTI add a “-4” to the appropriate catalog number (ex. 1301-4 or 1302-4). *For the

Turbo CTI add a “-9” to the appropriate catalog number, (ex. 1301-9 or 1302-9). If double stacked, each oven must be wired separately to carry rated load. Each oven requires a

“dedicated neutral”. U.S. Patent pending.

1111 Nor th Hadley Road

P.O. Box 1229

Fort Wayne, Indiana 46801-1229

Tel 1.260.459.8200

Fax 1.260.436.0735

E mail info@lincolnfp.com

web www.lin colnfp.com

©2009 Lincoln Foodservice Products, LLC.

Manitowoc Foodservice

Printed in the U.S.A.

1166-2.5K-07/09

Loading...

Loading...