Lincoln 1204 Service Manual

SERVICE MANUAL

(DOMESTIC)

IMPINGER CONVEYOR OVENS

MODEL SERIES 1000 & 1200

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Phone : (800) 374-3004

U.S. Fax: (888) 790-8193 • Int’l Fax: (260) 436-0735

Technical Service Hot Line

(800) 678-9511

www.lincolnfp.com

L-371088 REV: 3/27/09

TABLE OF CONTENTS

TABLE OF CONTENTS............................................................................................................................................. 2

SEQUENCE OF OPERATIONS 1000/1001/1004/1005/1200/1201/1204/1205 ....................................................... 3

SEQUENCE OF OPERATIONS 1022 / 1023 / 1202 / 1203...................................................................................... 4

SEQUENCE OF OPERATIONS 1040 / 1041 / 1240 / 1241...................................................................................... 5

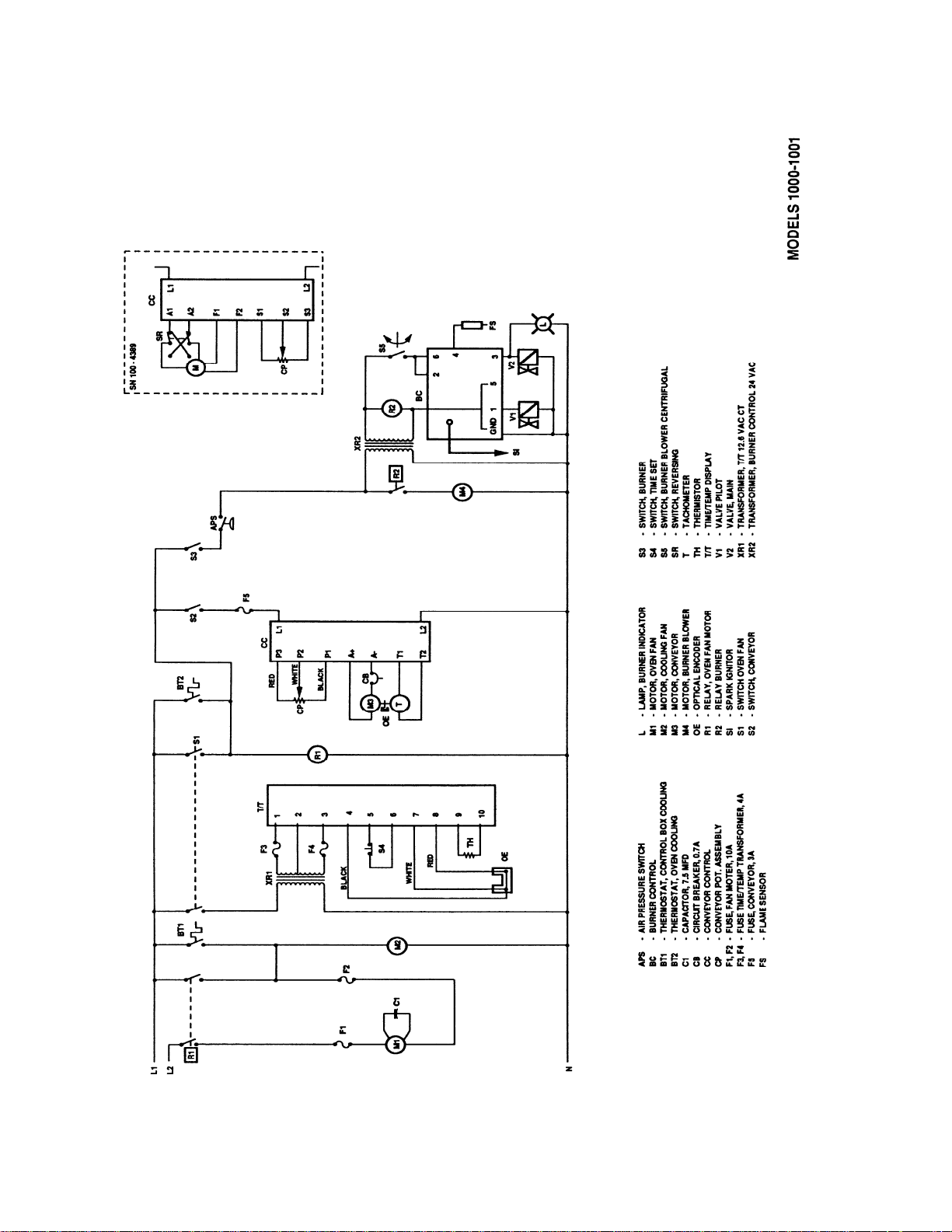

SCHEMATIC / 1000, 1001 ........................................................................................................................................ 8

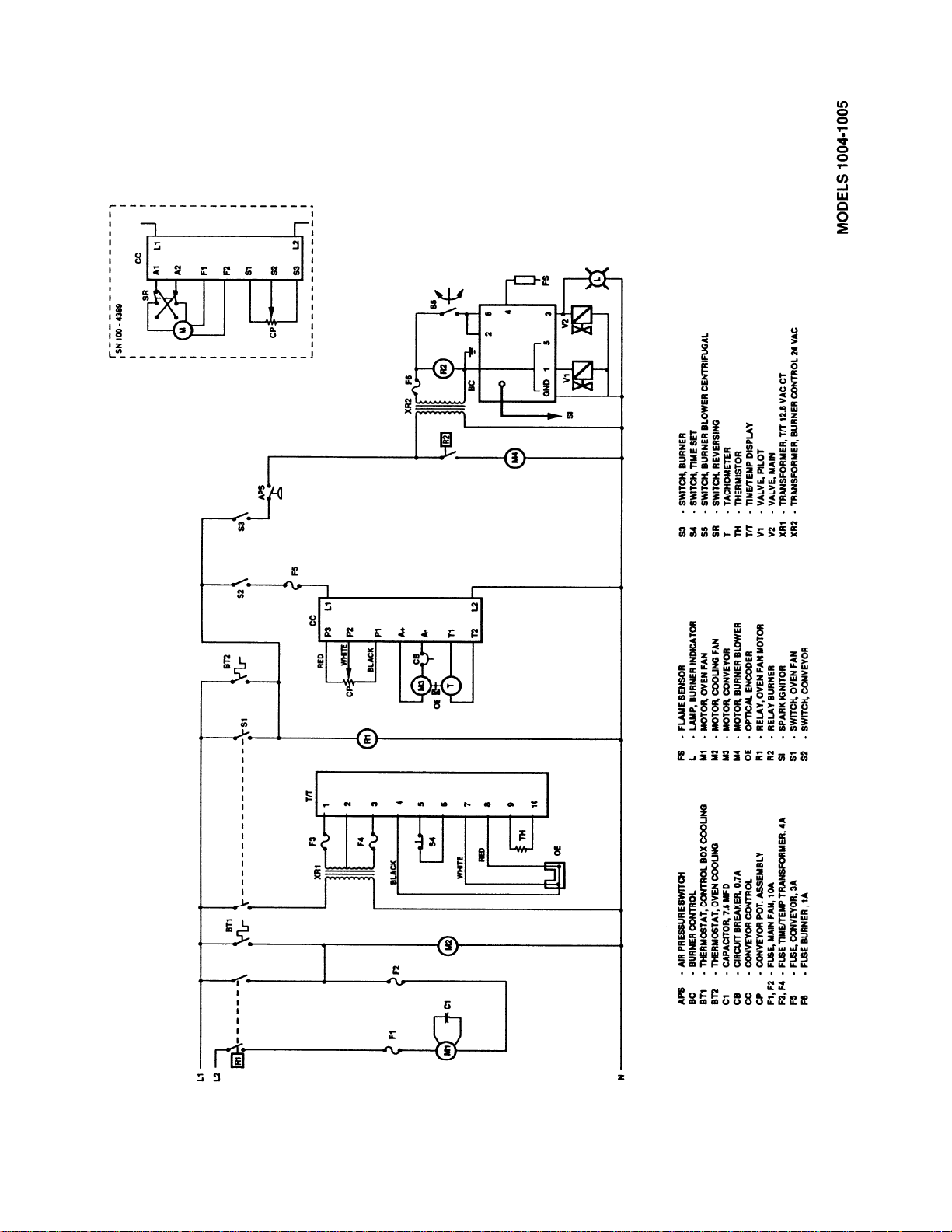

SCHEMATIC / 1004, 1005 ........................................................................................................................................ 9

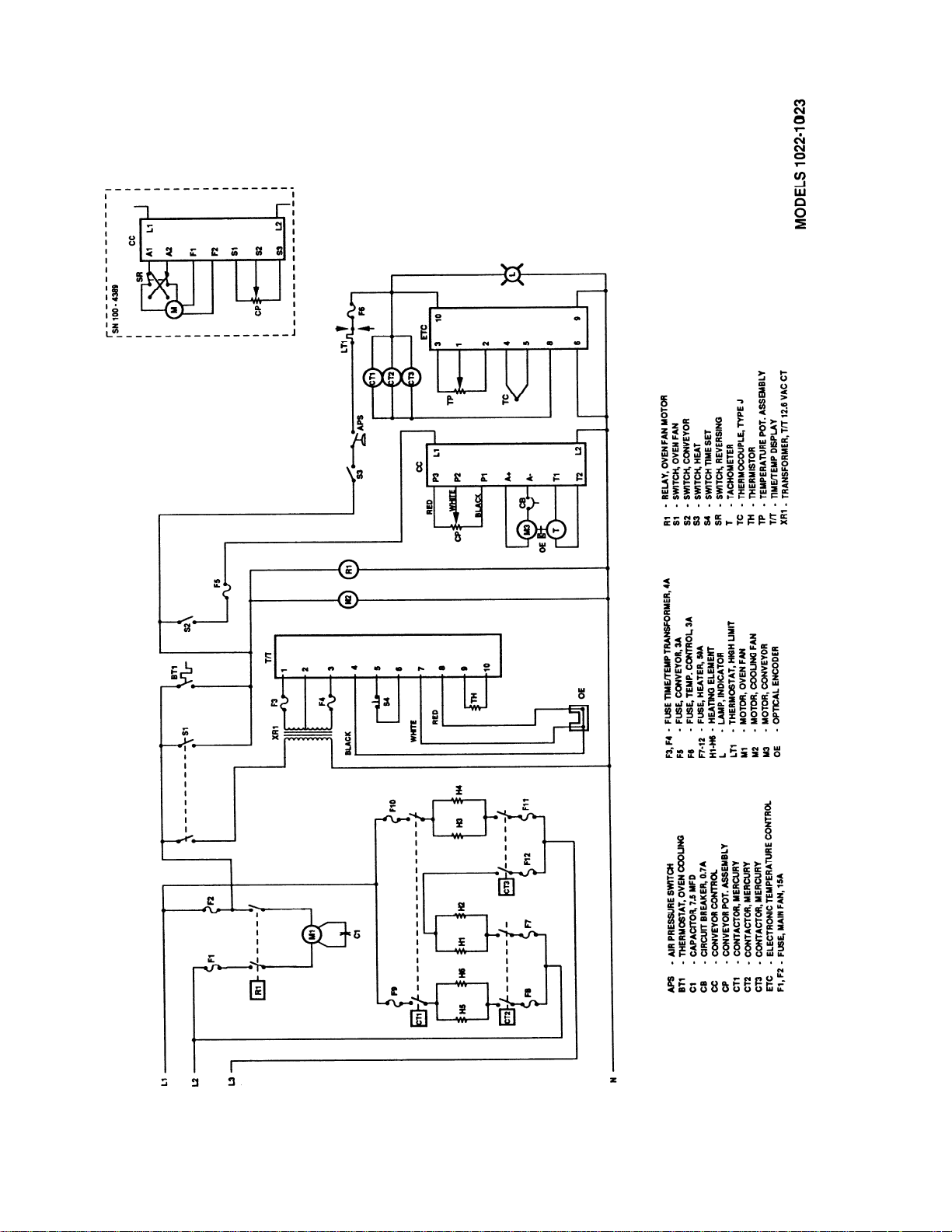

SCHEMATIC / 1022, 1023 – S/N Q19077 & BELOW ............................................................................................. 10

SCHEMATIC / 1022, 1023 – S/N Q19078 & ABOVE.............................................................................................. 11

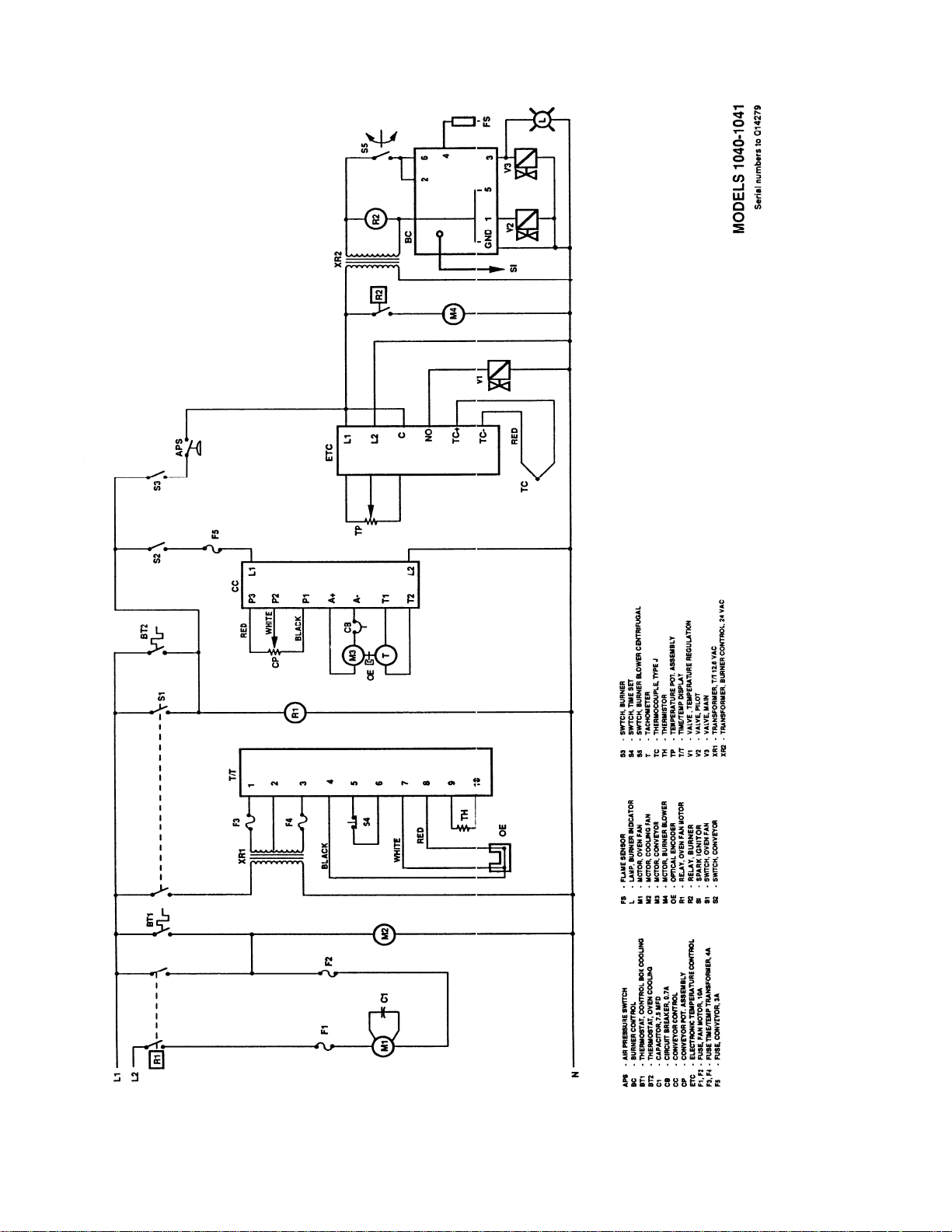

SCHEMATIC / 1040, 1041 – S/N Q14279 & BELOW ............................................................................................. 12

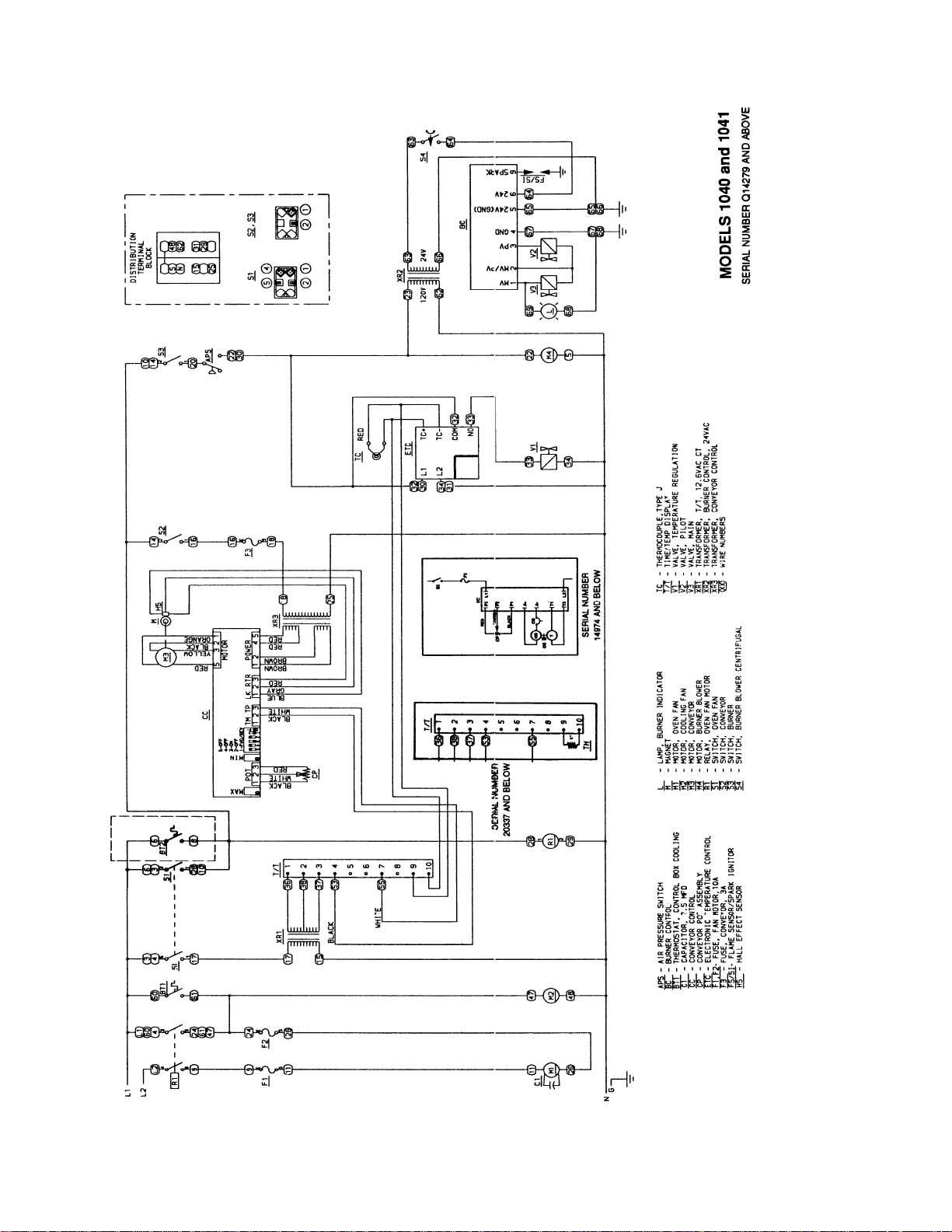

SCHEMATIC / 1040, 1041 – S/N Q14280 & ABOVE.............................................................................................. 13

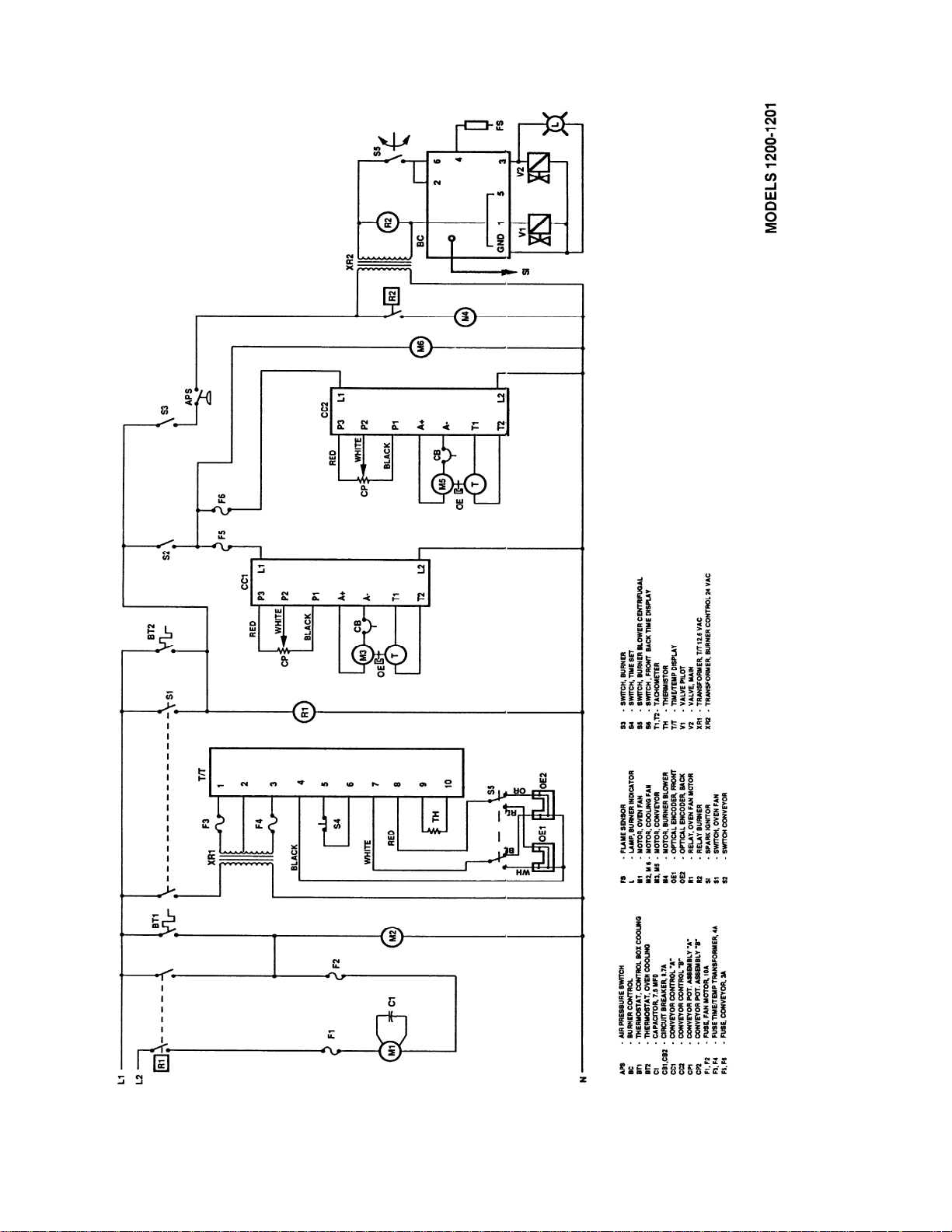

SCHEMATIC / 1200, 1201 ...................................................................................................................................... 14

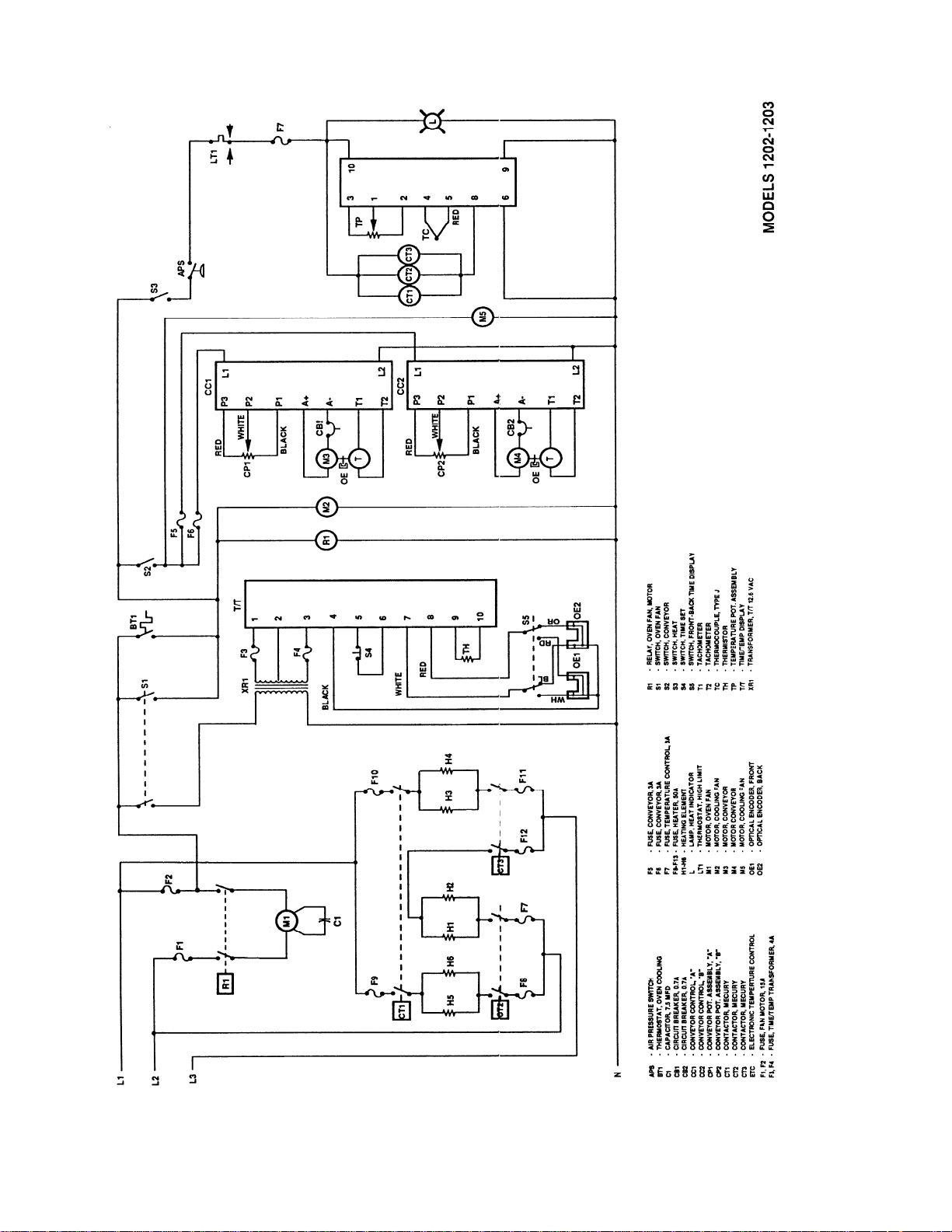

SCHEMATIC / 1202, 1203 S/N Q14790 & BELOW ................................................................................................ 15

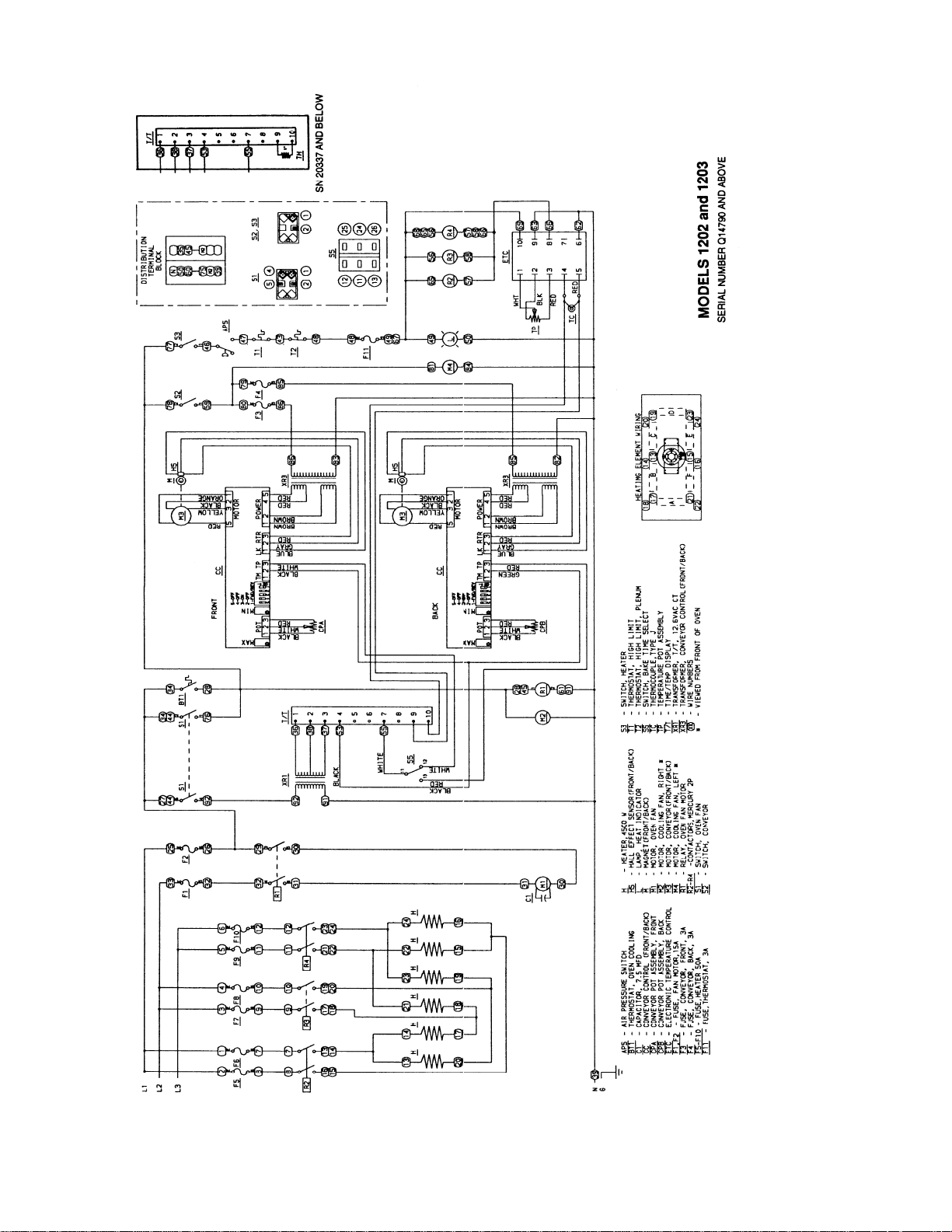

SCHEMATIC / 1202, 1203 S/N Q14791 & ABOVE................................................................................................. 16

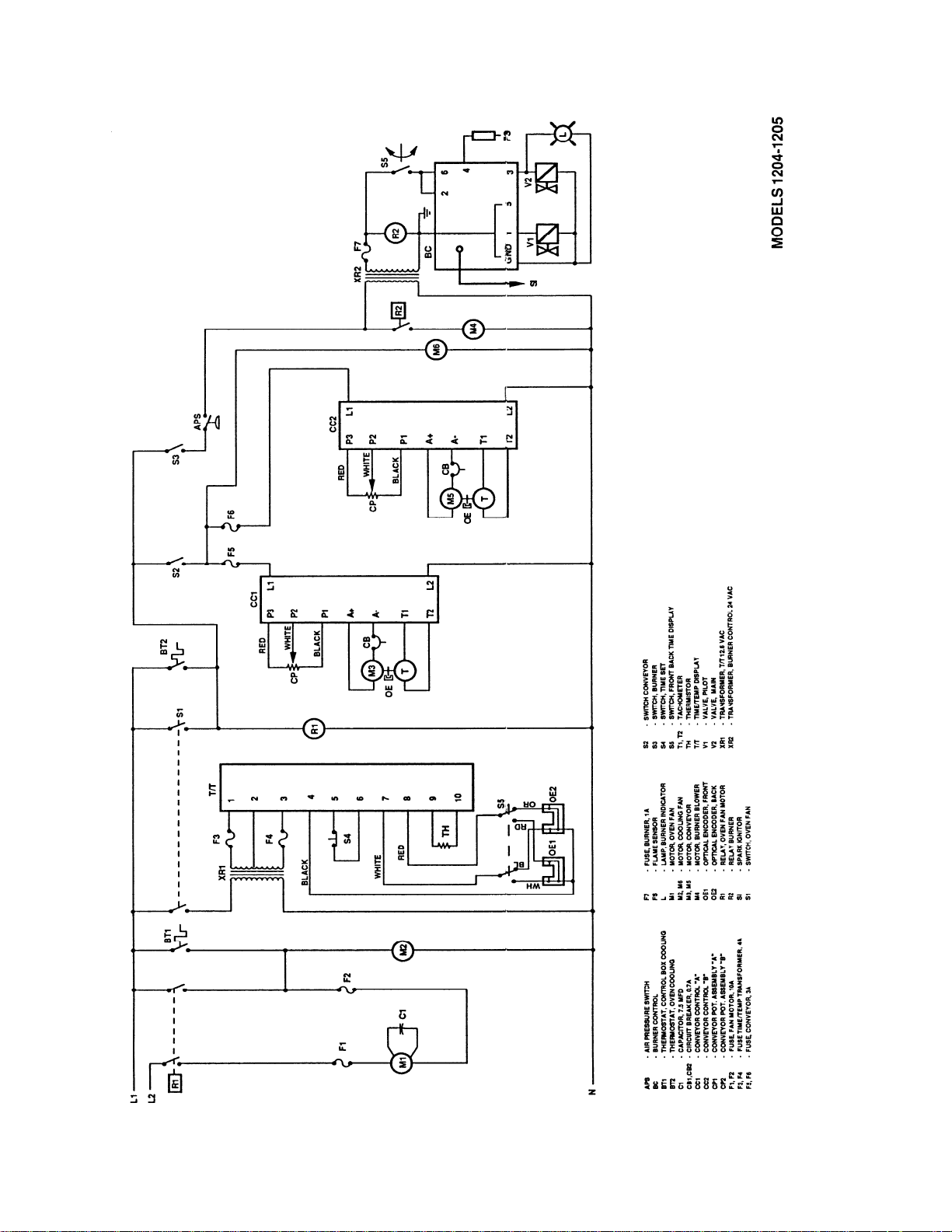

SCHEMATIC / 1204, 1205 ...................................................................................................................................... 17

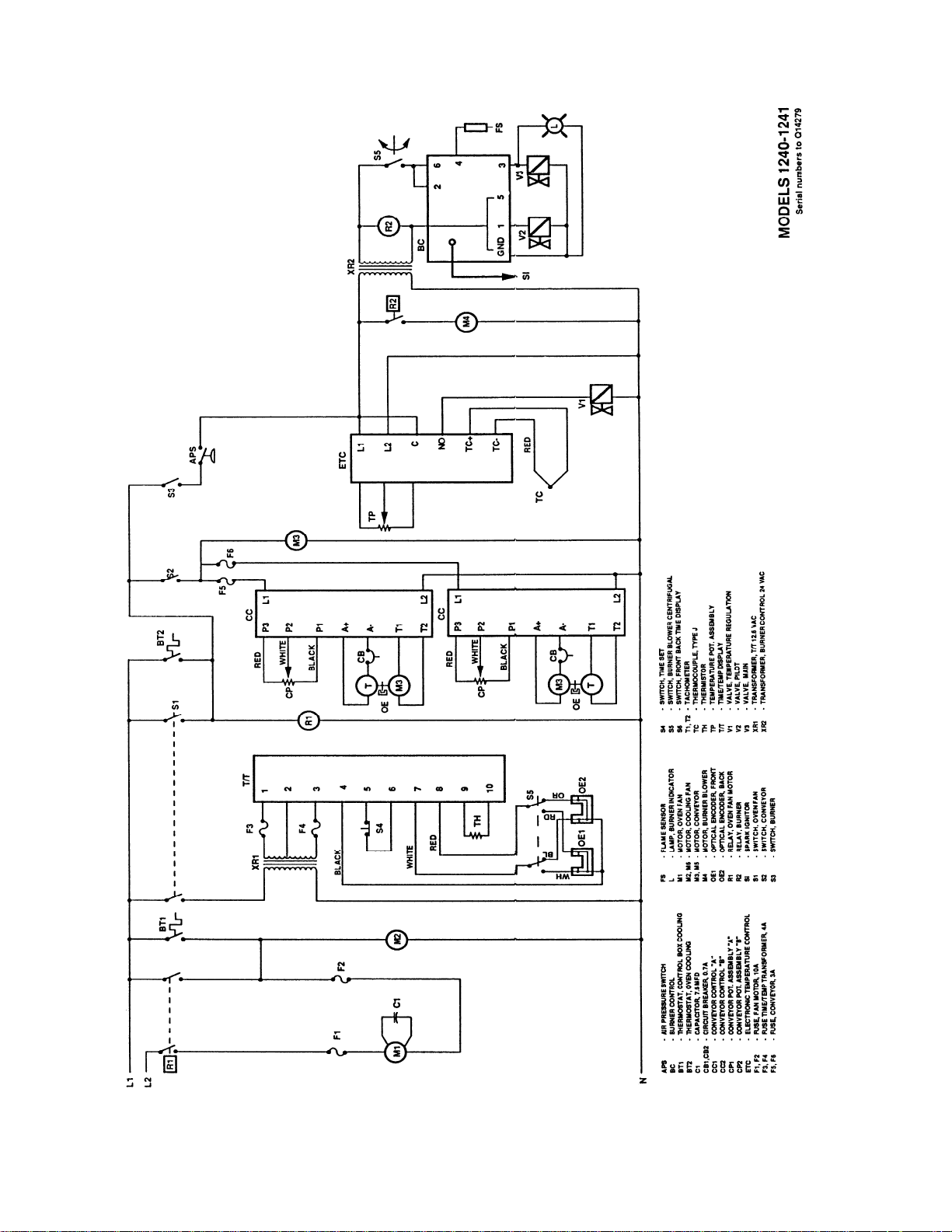

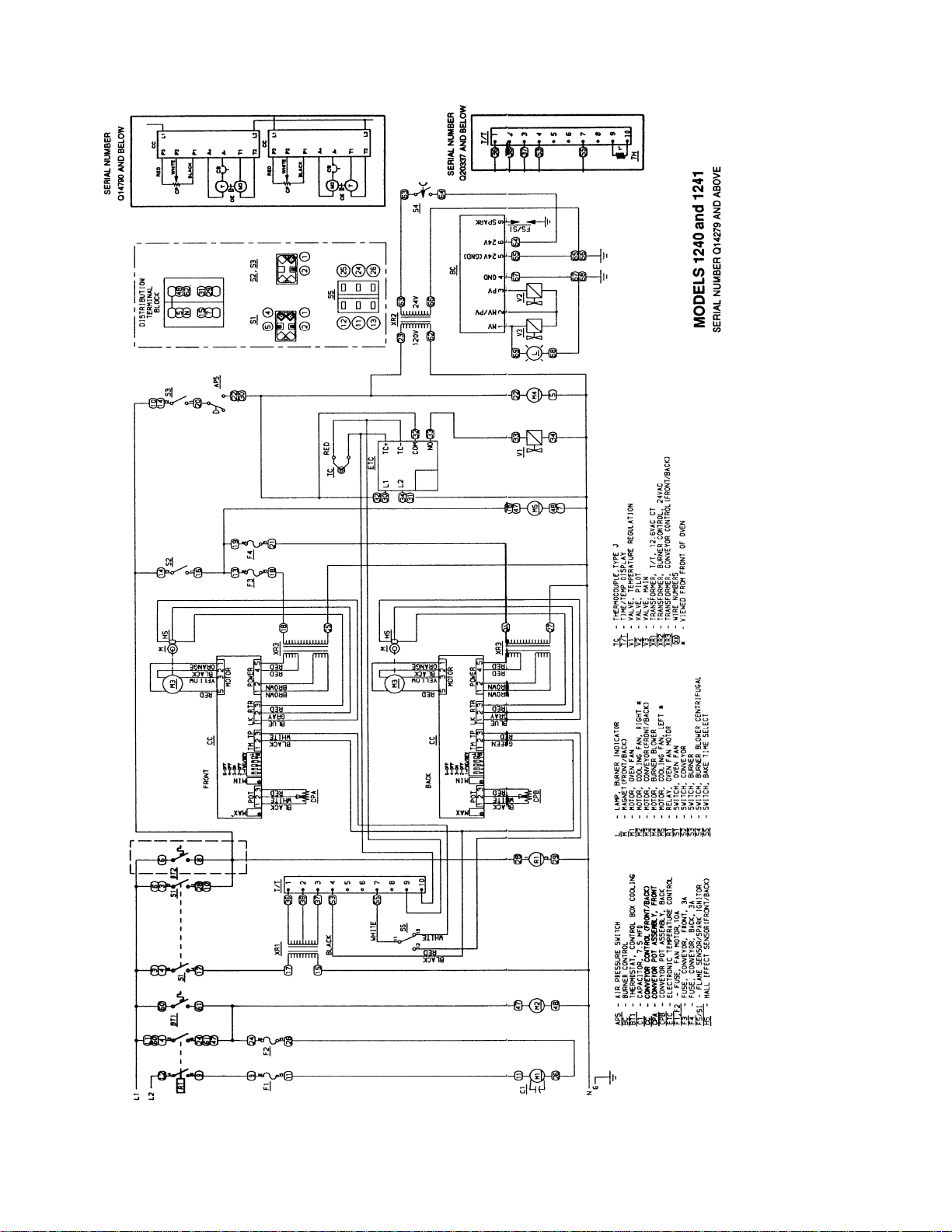

SCHEMATIC / 1240, 1241 – S/N Q14279 & BELOW ............................................................................................. 18

SCHEMATIC / 1240, 1241 – S/N Q14280 & ABOVE.............................................................................................. 19

TROUBLESHOOTING GUIDE 1000 & 1200 .......................................................................................................... 20

GAS OVENS ........................................................................................................................................................ 20

TROUBLESHOOTING GUIDE ................................................................................................................................ 25

ELECTRIC OVENS MODEL SERIES 1000 & 1200............................................................................................ 25

REMOVAL, INSTALLATION & ADJUSTMENTS .................................................................................................... 32

PARTS / MODEL SERIES 1000 & 1200 - GENERAL............................................................................................. 60

BLOW UP / 1000, 1200 – GENERAL...................................................................................................................... 61

PARTS / ACCESS DOOR & 1050 DOOR............................................................................................................... 62

BLOW UP / ACCESS DOOR & 1050 DOOR .......................................................................................................... 63

PARTS / MODEL 1000,1001,1050,1051,1004, &1005 – S/N 100 TO 4389........................................................... 64

BLOW UP / 1000, 1001, 1050, 1051, 1004, & 1005 S/N 100 TO 4389 .................................................................. 65

PARTS / MODEL 1000,1001,1004, AND 1005 S/N 4390 & ABOVE

BLOW UP 1000, 1001, 1004, 1005 S/N 4390 & ABOVE........................................................................................ 67

PARTS / 1022-1023................................................................................................................................................. 68

BLOW UP / 1022, 1023 ........................................................................................................................................... 69

PARTS / 1040-1041................................................................................................................................................. 70

BLOW UP / 1040, 1041 ........................................................................................................................................... 71

PARTS / 1200, 1201, 1204 AND 1205 .................................................................................................................... 72

BLOW UP / 1200, 1201, 1204, 1205....................................................................................................................... 73

PARTS / 1202-1203................................................................................................................................................. 74

BLOW UP / 1202, 1203 ........................................................................................................................................... 75

PARTS / 1240-1241................................................................................................................................................. 76

BLOW UP / 1240, 1241 ........................................................................................................................................... 77

PARTS / OVEN BACK - GAS.................................................................................................................................. 78

BLOW UP / OVEN BACK – GAS ............................................................................................................................ 79

PARTS / OVEN BACK- ELECTRIC......................................................................................................................... 80

BLOW UP / OVEN BACK – ELECTRIC .................................................................................................................. 81

PARTS / CONVEYOR MOTOR ASSEMBLY S/N 4390 & ABOVE ......................................................................... 82

BLOW UP / CONVEYOR MOTOR ASSEMBLY S/N 4390 & ABOVE .................................................................... 83

PARTS / SERIES 1000 – CONVEYOR................................................................................................................... 84

BLOW UP / SERIES 1000 CONVEYOR ................................................................................................................. 85

PARTS / SERIES 1200 - CONVEYOR CONTROL................................................................................................. 86

BLOW UP / SERIES 1200 – CONVEYOR CONTROL ........................................................................................... 87

PARTS / SERIES 1200 – CONVEYOR................................................................................................................... 88

BLOW UP / SERIES 1200 – CONVEYOR .............................................................................................................. 89

......................................................................

66

2

Impinger I -–1000 Series Service Manual - Domestic

SEQUENCE OF OPERATIONS 1000/1001/1004/1005/1200/1201/1204/1205

MODEL 1000 - 120/230 VAC - 60HZ - NATURAL GAS

MODEL 1001 - 120/230 VAC - 60HZ - L.P. GAS

MODEL 1004 - 120/230 VAC - 60HZ - NATURAL GAS

MODEL 1005 - 120/230 VAC - 60HZ - L.P. GAS

MODEL 1200 - 120/230 VAC - 60HZ - NATURAL GAS/DUAL BELT

MODEL 1201 - 120/230 VAC - 60HZ - L.P. GAS/DUAL BELT

MODEL 1204 - 120/230 VAC - 60HZ - NATURAL GAS/DUAL BELT

MODEL 1205 - 120/230 VAC - 60HZ L.P.GAS/DUAL BELT

POWER SUPPLY Electrical Power to be supplied to the Oven by a four conductor service. . Voltage

from the black conductor to the white conductor is 120 VAC.

Black conductor is Hot

Red conductor is Hot

White conductor is Dedicated Neutral

Green conductor is Ground

CONTROL BOX AUTO

COOL DOWN

MAIN FAN CIRCUIT Electrical power is permanently supplied to the normally open contacts of the Double

TRANSFORMER (12.6

VAC)

BURNER CIRCUIT Closing th e Fan Swit ch and the normally open Burner Swit ch su pplies 1 20 VAC

CONVEYOR DRIVE(S/N

100 to 4389)

(S/N 4390 and UP) Closing the fan switch an d the normally open conveyor switch supplies 120 VAC t o

When the te mperature i n the Co ntrol Box rea ches 120°F + 3 °, the Co oling Fan

Thermostat will swit ch power to the Cont rol B ox Cooling Fan. The Thermostat will

interrupt power to the Cooling Fan when the Control Box temperature falls to 100°F +

3°.

Pole Main F an Rel ay, the Cooli ng Fa n Thermo stat, the normall y open Main Fa n

Switch, and the n ormally open Cool Down Thermostat (thermostat closes at 160°F

and opens at 140 °F). Closing the Mai n Fan Switch energizes th e coil of the Relay.

The normally ope n contacts now close, energizing the Mai n Fan Motor thro ugh (2)

10A fuses, and the Coolin g Fan. Closing the Fan S witch also supplies power to the

Hour Meter (hour meter discontinued after S/N 3484), the 12.6 VAC Transformer, the

Burner and Conveyor Switches.

Upon closure of the Fan Switch, 120 VAC is supplied to the primary of the 12.6 VAC

Transformer. The Transformer steps the voltage down to 12.6 VAC (normally 13 to

14 VAC) with a ce nter t ap, and supplies p ower t o the Time/T emp Di splay. The

voltage from each leg of t he Tran sformer's secondary to the cent er tap should be

one half of the secondary voltage.

through the Air Pressure Switch, to th e normally open contacts of the Bu rner Motor

Relay, and t he prim ary o f the 24 VAC Step Do wn Tran sformer. The Tra nsformer

secondary supplies 2 4 VA C (through a 1A fu se on Model 100 4 and 1005) to the

Relay Coil (t he normally open conta cts close within 30 se conds), and the n ormally

open Centrifugal Switch. When the Relay contacts close, the Burner Blower Motor is

energized. As this motor reaches a pproximately1600 R.P.M., its internal centrifugal

switch closes, supplyin g 24 VAC to the Gas Control Valve. Whe n the G as Control

Valve is supplied with 24 VAC the pilot valve is e nergized, and the ignitor circuit is

energized. Ignition should now occur. After pilot flame is proven, the main gas valve

is energized. The Burner Indicator Light is also energized.

Closing the F an Switch an d the normall y open Conv eyor Switch supplies 120 VAC

through a 3A Fuse, to the Motor Control Board. AC volts are converted to D.C. volts

and a re supplied to the Conveyor mo tor at bo ard terminals A1 and A2 th rough a

D.P.D.T. Rev ersing Swit ch. Adjustmen t of the Speed Co ntrol P otentiometer (500

ohm, 10 turn ) will change re sistance a t terminals S1, S2, and S 3 varying the

voltage to the

the D.C. voltage from the Motor Control Board increases or decreases respectively.

the Motor Control Board. AC volts are converted to DC volts and are supplied to the

Conveyor M otor at term inals A+ an d A-. Adj ustment of th e Spee d Control

Potentiometer (5,000 ohm 10 tu rn ) will change resistance at term inals P1, P2, and

P3 varying t he DC volta ge to the m otor. The sp eed of th e conveyor m otor will

increase o r decrea se a s the DC volt age from th e board incre ases o r de creases

respectively. As the motor turns, it driv es both the reducer gearbox and the tach.

motor. The speed of the Conveyor Motor will increase or decrease

D.C.

as

Impinger I -–1000 Series Service Manual - Domestic

3

generator. The tach. generator is a DC voltage generator which supplies a voltage to

the DC moto r control bo ard and i s use d as a refe rence for m aintaining a constant

conveyor speed.

NOTE

TIME TEMP DISPLAY The Time/Temp. Display is energized when the Fan Switch is closed, supplying120

The 1200 Series Ovens utilize 2 complete conveyor drive systems.

VAC to the primary of the 12.6 volt Transformer The secondary output of the

transformer, normally 13 to 14 VAC (depending on input), with a center tap is

supplied at terminals 1,2, and 3 of the Time/Temp. Display. The center tap is

terminal 2. The display works on a balanced input and center tap voltage to each leg

must be 1/2 the total reading.

The speed side of the Time/Temp. Display uses a slotted disc (cemented to tach.

coupling) to break the infra-red light beam of the optical switch (mounted on gear

motor) producing electrical pulses that are transmitted to the display. The display

converts these pulses into a read-out of minutes and seconds. The temperature

portion of the display uses a Thermistor Probe to sense oven temperature. The

thermistor outputs a resistance proportional to the oven temperature. This resistance

is then converted by the display into a temperature reading.

NOTE: The 1200 Series Ovens use a Double Pole Double Throw Switch to connect

the two Opti cal Encode r Assemblies to the Time/Temp Di splay. By activatin g the

switch, either the front or rear belt speed can be shown by the Time/Temp Display.

SEQUENCE OF OPERATIONS 1022 / 1023 / 1202 / 1203

MODEL 1022

MODEL 1023 - 120/240 VAC - 3 PHASE

MODEL 1202 - 120/208 VAC - 3 PHASE - DUAL BELT

MODEL 1203 - 120/240 VAC - 3 PHASE - DUAL BELT

POWER SUPPLY Electrical Power to be supplied to the Oven by a five conductor service. Voltage from

the black conductor to the white conductor is 120 VAC.

MAIN FAN CIRCUIT Electrical power is permanently supplied through 6, 50A fuses to the normally open

contacts of the Mercury Contactors. Power is also supplied through 2, 15A fuses to

the normally open contacts of the Double Pole Main Fan Relay, the Double Pole

Main Fan Switch, and the normally open Cool-Down Thermostat (thermostat closes

at 160°F and opens at 140°F.) Closing the Main Fan Switch energizes the coil of the

Main Fan Relay. The normally open contacts now close, energizing the Main Fan

Motor, and the Control Box Cooling Fan. Closing the Fan Switch also supplies power

to the Hour Meter (hour meter discontinued after S/N 3484), the 12.6 VAC

Transformer, the Heat and Conveyor Switches.

TRANSFORMER (12.6

VAC)

HEAT CIRCUIT Closing the Fan Switch and the normally open Heat Switch supplies 120 VAC

TEMPERATURE

CONTROL

Upon closure of the Fan Switch, 120 VAC is supplied to the primary of the 12.6 VAC

Transformer. The Transformer steps the voltage down to 12.6 VAC (normally 13 to

14 VAC) with a center tap, and supplies power to the Time/Temp Display. The

voltage from each leg of the Transformer's secondary to the center tap should be

one half of the secondary voltage.

through the Air Pressure Switch and the normally closed Hi-Limit Thermostat

(manually re-settable, opens at 190°F) the 3A Fuse, to the L1 terminal of the

Temperature Control Board, the coils of the Mercury Contactors, and to the Heat

Indicator Light.

When the Heat Switch is closed, 120 VAC is supplied to the Temperature Control.

The Temperature Control Potentiometer (2.5K ohm) is adjusted to desired

temperature. The Thermocouple will provide varying millivolts to the Temperature

Controller. The Temperature Controller switches the L2 line of the Contactor coils at

intermittent intervals to maintain desired temperature.

- 120/208 VAC - 3 PHASE

Black conductor is Hot

Red conductor is Hot

Orange conductor is Hot

White conductor is Dedicated Neutral

Green conductor is Ground

4

Impinger I -–1000 Series Service Manual - Domestic

CONVEYOR DRIVE

(S/N 100 to 4389)

(S/N 4390 and UP) Closing the fan switch and the normally open conveyor switch supplies 120 VAC to

NOTE* The 1200 Series Ovens utilize 2 complete conveyor drive systems.

TIME/TEMP DISPLAY The Time/Temp Display is energized when the Fan Switch is closed, supplying 120

NOTE* The 1200 Series Ovens use a Double Pole Double Throw Switch to connect the two

Closing the Fan Switch and the normally open Conveyor Switch supplies 120 VAC

through a 3A Fuse, to the Motor Control Board. AC volts are converted to D.C. volts

and are supplied to the Conveyor Motor at board terminals A1 and A2 through a

D.P.D.T. Reversing Switch. Adjustment of the Speed Control Potentiometer (500

ohm, 10 turn) will change resistance at terminals S1, S2, and S3 varying the D.

voltage to the motor. The speed of the Conveyor Motor will increase or decrease as

the D.C. voltage from the Motor Control Board increases or decreases respectively.

the Motor Control Board. AC volts are converted to DC volts and are supplied to the

Conveyor Motor at terminals A+ and A-. Adjustment of the Speed Control

Potentiometer (5,000 ohm 10 turn) will change resistance at terminals P1, P2, and

P3 varying the DC voltage to the Conveyor Motor. The speed of the conveyor motor

will increase or decrease as the DC voltage from the board increases or decreases

respectively. As the motor turns, it drives both the reducer gearbox and the tach.

generator. The tach. generator is a DC voltage generator which supplies a voltage to

the DC motor control board and is used as a reference for maintaining a constant

conveyor speed.

VAC to the primary of the12.6 volt Transformer. The secondary output of the

transformer, normally 13 to 14 VAC (depending on input), with a center tap is

supplied to terminals 1,2, and 3 of the Time/Temp Display. The center tap is terminal

2. The display works on a balanced input and center tap voltage to each leg must be

1/2 the total reading.

The speed side of the Time/Temp. Display uses a slotted disc (cemented to tach.

coupling) to break the infra-red light beam of the optical switch (mounted on gear

motor) producing electrical pulses that are transmitted to the display. The display

converts these pulses into a read-out of minutes and seconds.

The temperature portion of the display uses a Thermistor Probe to sense oven

temperature. The thermistor outputs a resistance proportional to the oven

temperature. This resistance is then converted by the display into a temperature

reading.

Optical Encoder Assemblies to the Time/Temp. Display. By activating the switch,

either the front or rear belt speed can be shown by the Time/Temp. Display.

C.

SEQUENCE OF OPERATIONS 1040 / 1041 / 1240 / 1241

MODEL 1040

MODEL 1041 - 120/230 VAC - 60HZ - L.P. GAS

MODEL 1240 - 120/230 VAC - 60HZ - NATURAL GAS/DUAL BELT

MODEL 1241 - 120/230 VAC - 60HZ - L.P. GAS/DUAL BELT

POWER SUPPLY Electrical Power to be supplied to the Oven by a four conductor service. Voltage

from the black conductor to the white conductor is 120 VAC.

CONTROL BOX AUTO

COOL DOWN

MAIN FAN CIRCUIT Electrical power is permanently supplied to the normally open contacts of the Double

When the temperature in the Control Box reaches 120°F ± 3°, the Cooling Fan

Thermostat will switch power to the Control Box Cooling Fan. The Thermostat will

interrupt power to the Cooling Fan when the Control Box temperature falls to 100°F +

3°.

Pole Main Fan Relay, the Cooling Fan Thermostat, the normally open Main Fan

Switch, and the normally open Cool Down Thermostat (thermostat closes at 160°F

and opens at 140°F). Closing the Main Fan Switch energizes the coil of the Relay.

The normally open contacts now close, energizing the Main Fan Motor through two

10A fuses, and the Cooling Fan. Closing the Fan Switch also supplies power to the

12.6 VAC Transformer, the Burner and Conveyor Switches.

- 120/230 VAC - 60HZ - NATURAL GAS

Black conductor is Hot

Red conductor is Hot

White conductor is Dedicated Neutral

Green conductor is Ground

Impinger I -–1000 Series Service Manual - Domestic

5

TRANSFORMER (12.6

VAC)

Upon closure of the Fan Switch, 120 VAC is supplied to the primary of the 12.6 VAC

Transformer. The Transformer steps the voltage down to 12.6 VAC (normally 13 to

14 VAC) with a center tap, and supplies power to the Time/ Temp. Display. The

voltage from each leg of the Transformer's secondary to the center tap should be

one half of the secondary voltage.

BURNER CIRCUIT Closing the Fan Switch and the normally open Burner Switch supplies 120 VAC

through the Air Pressure Switch, to the Temperature Control Board, the normally

open contacts of the Burner Motor Relay (Burner Motor Relay discontinued after S/N

14791) and the primary of the 24 VAC Transformer. The transformer's secondary

supplies 24 VAC to the burner motor relay coil (the normally open contacts close

within 30 seconds), and the normally open Centrifugal Switch. When the relay

contacts close, the Burner Blower Motor is energized. As this motor reaches approx.

1,600 R.P.M its internal centrifugal switch closes, supplying 24 VAC to the Gas

Control Valve. When the Gas Control Valve is supplied with 24 VAC, the pilot valve

is energized, and the igniter circuit is energized. Ignition should now occur. After pilot

flame is proven, the Main Gas Valve is energized. The Burner Indicator Light is also

energized.

TEMPERATURE

CONTROL

Closing the Fan Switch and Burner Switch supplies 120 VAC to the Temperature

Control Board. The 1K or 1000 ohm Temperature Potentiometer is adjusted to

desired temperature. The Thermocouple will provide varying millivolts to the

Temperature Controller. The Temperature Controller supplies 120 VAC to the

Solenoid Valve at intermittent intervals to maintain desired temperature.

CONVEYOR DRIVE

(S/N Q14790 & Below,

1200 series

S/N Q14973 & Below

1000 series)

Closing the fan switch and the normally open conveyor Switch supplies 120 VAC to

the Motor Control Board. AC volts are converted to DC volts and are supplied to the

Conveyor Motor, at terminals A+ and A-. Adjustment of the Speed Control

Potentiometer (5,000 ohm 10 turn) will change resistance at terminals P1, P2, and

P3 varying the DC voltage to the Conveyor Motor. The speed of the conveyor motor

will increase or decrease as the DC voltage from the board increases or decreases

(S/N Q14791 & Above,

1200 series refer to Pg.

S/N Q14974 &

5 & 6

Above, 1000 series refer

to Pg. 5 & 6 (STEPPER)

respectively. As the motor turns, it drives both the reducer gearbox and the tach.

generator. The tach. Generator is a DC voltage generator, which supplies a voltage

to the DC motor control board and is used as a reference for maintaining a constant

conveyor speed.

NOTE: The 1200 Series Ovens utilize 2 complete conveyor drive systems.

TIME/TEMP

DISPLAY(S/N Q14790 &

Below, 1200 series

S/N Q14973 & Below

1000 series)

The Time/Temp. Display is energized when the Fan Switch is closed, supplying 120

VAC to the primary of the12.6 volt Transformer. The secondary output of the

transformer, normally 13 to 14 VAC (depending on input), with a center tap, is

supplied to terminals 1,2, and 3 of the Time/Temp. Display. The center tap is

terminal 2. The display works on a balanced input and center tap voltage to each leg

must be 1/2 the total reading.

(S/N Q14791 & Above,

1200 series refer to Pg.

S/N Q14974 &

5 & 6

Above, 1000 series refer

to Pg. 5 & 6 (STEPPER)

The speed side of the Time/Temp. Display uses a slotted disc (cemented to tach.

coupling) to break the infrared light beam of the optical switch (mounted on gear

motor) producing electrical pulses that are transmitted to the display. The display

converts these pulses into a read-out of minutes and seconds. The temperature

portion of the display uses a Thermistor Probe to sense oven temperature. The

thermistor outputs a resistance proportional to the oven temperature. This resistance

is then converted by the display into a temperature reading.

NOTE* The 1200 Series Ovens use a Double Pole Double Throw Switch to connect the two

Optical Encoder Assemblies to the Time/Temp. Display. By activating the switch,

either the front or rear belt speed can be shown by the Time/Temp Display .

CONVEYOR DRIVE Closing the Oven Fan Switch supplies 120 VAC, through the Power Transformer, to

the normally open Conveyor Switch. Closing the Conveyor Switch supplies 120 VAC,

through a 3 AMP Fuse, to the primary of the Conveyor Control Transformer. The

secondary of this Transformer supplies 10 VAC and 29 VAC to the Conveyor

Control. The conveyor control supplies voltage pulses to the Conveyor Control. The

Conveyor Control Potentiometer varies the frequency of these pulses. The motor

speed will increase or decrease, as the frequency of the pulses increase or decrease

respectively.

6

Impinger I -–1000 Series Service Manual - Domestic

TIME TEMP DISPLAY Closing the Oven Fan Switch supplies 120 VAC, through the Power Transformer, to

the primary of the Time/Temp. Transformer. The secondary output of the

Transformers, 12.5to 15 VAC with a center tap, is supplies to terminals 1, 2, and3 of

the Time/Temp. Display. The display works on a balanced input, and the center tap

voltage to each leg must be 1/2 the total reading.

Impinger I -–1000 Series Service Manual - Domestic

7

SCHEMATIC / 1000, 1001

8

Impinger I -–1000 Series Service Manual - Domestic

SCHEMATIC / 1004, 1005

Impinger I -–1000 Series Service Manual - Domestic

9

SCHEMATIC / 1022, 1023 – S/N Q19077 & BELOW

10

Impinger I -–1000 Series Service Manual - Domestic

SCHEMATIC / 1022, 1023 – S/N Q19078 & ABOVE

Impinger I -–1000 Series Service Manual - Domestic

11

SCHEMATIC / 1040, 1041 – S/N Q14279 & BELOW

12

Impinger I -–1000 Series Service Manual - Domestic

SCHEMATIC / 1040, 1041 – S/N Q14280 & ABOVE

Impinger I -–1000 Series Service Manual - Domestic

13

SCHEMATIC / 1200, 1201

14

Impinger I -–1000 Series Service Manual - Domestic

SCHEMATIC / 1202, 1203 S/N Q14790 & BELOW

Impinger I -–1000 Series Service Manual - Domestic

15

SCHEMATIC / 1202, 1203 S/N Q14791 & ABOVE

16

Impinger I -–1000 Series Service Manual - Domestic

SCHEMATIC / 1204, 1205

Impinger I -–1000 Series Service Manual - Domestic

17

SCHEMATIC / 1240, 1241 – S/N Q14279 & BELOW

18

Impinger I -–1000 Series Service Manual - Domestic

SCHEMATIC / 1240, 1241 – S/N Q14280 & ABOVE

Impinger I -–1000 Series Service Manual - Domestic

19

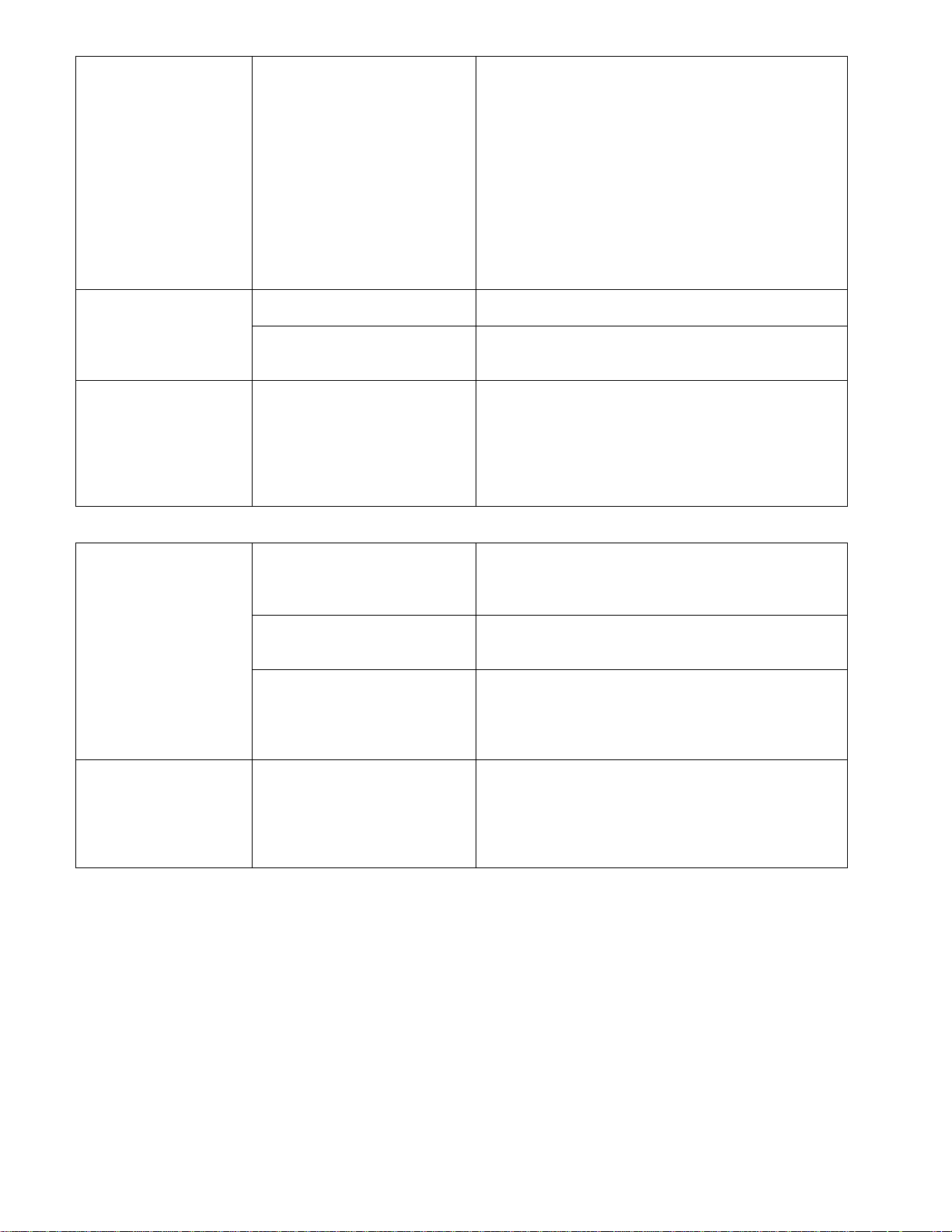

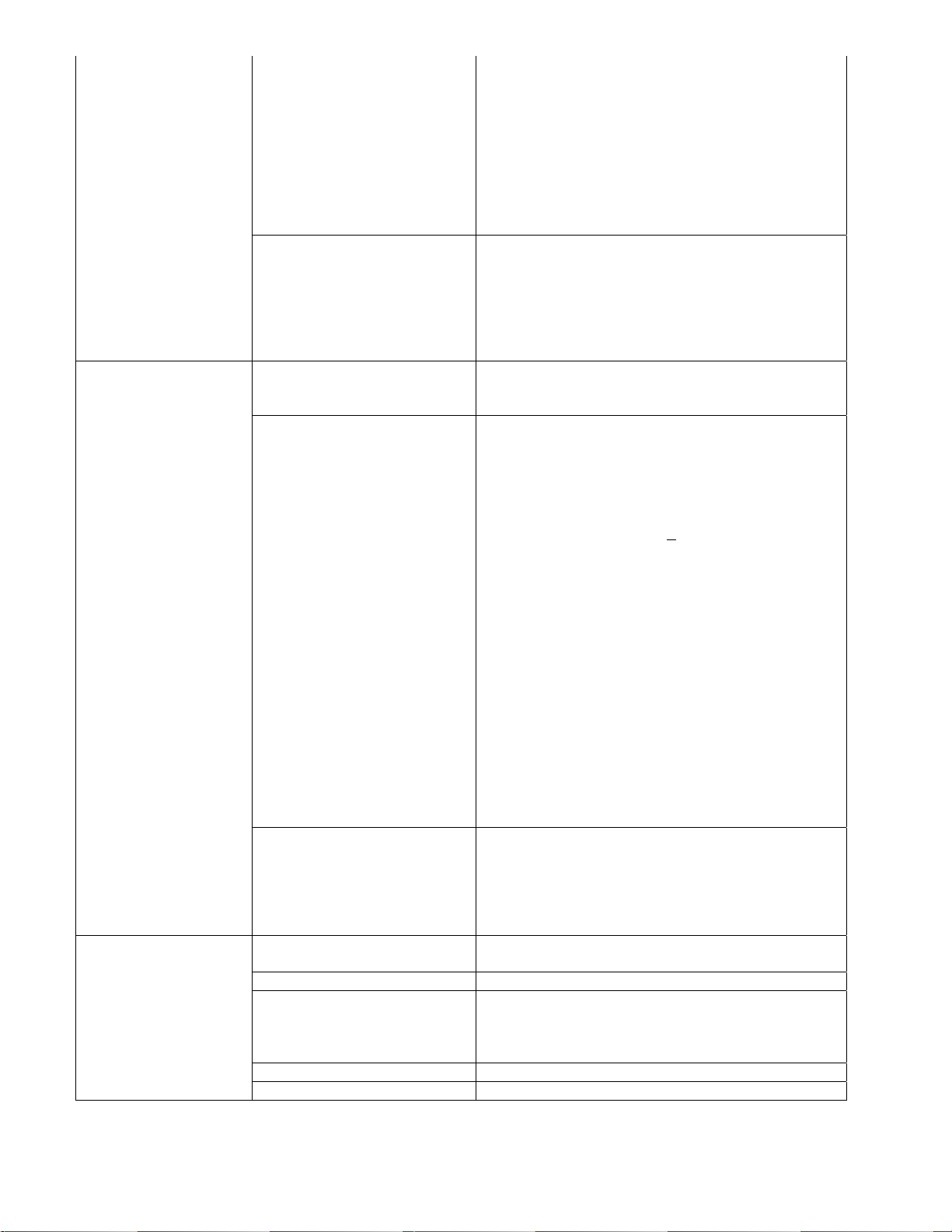

TROUBLESHOOTING GUIDE 1000 & 1200

GAS OVENS

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run

NOTE:

No Main Fan Cool

Down

No Control Box

Cooling(For ovens

equipped with Control

Box Cooling Fan)

NOTE:

No automatic control

box cooling (For ovens

equipped with control

box cooling fan)

Control box cooling fan

continues to run

Oven will not heat

Incoming Power Supply Check breakers/ Reset if required / Call Power Co.

if needed.

(Export Ovens) For some export ovens, there is a control circuit

step-down transformer. This transformer steps

down supply voltage to 120 VAC. If main fan will

not run, the secondary of this transformer must be

checked for 120 VAC output. Check specific oven

model schematic for circuit location.

Oven Fan Fuse(s) Check and/or Replace

Fuse Holder Check and/or Replace

Fan Switch Check continuity between switch terminals.

Main Relay Check continuity to 120 VAC coil. Check for power

to relay coil (120 VAC). Check for 208/240 VAC to

relay terminals. Visually check for contact pull-in.

Fan Motor Check for opens, shorts, or grounds. WITH

POWER OFF: Turn Fan Blade to check for locked

rotor.

Capacitor Check for opens, shorts, or grounds.

Cool Down Thermostat Check cool down thermostat (thermostat closes at

160°F and opens at 140°F). Check for power (120

VAC) at cool down thermostat. With the cool down

thermostat pre-heated, check for continuity. If

switch is open, replace.

Main Fan Relay

(Export Ovens)

Axial Cooling Fan

Incoming Power Supply Check breakers/Reset if needed. Check for

Cooling Fan Thermostat Check cooling fan thermostat (thermostat closes at

Axial Cooling Fan Check for 120 VAC to cooling fan, if present and

Cooling Fan Thermostat See "Cooling Fan Thermostat"

Gas Supply Check for adequate gas supply to oven.

Manual Gas Shut-off Valve Check to see that manual shut-off valve is open.

Fan Switch Check to see that fan switch is "on".

Main Oven Fan Check if main oven fan is operating. If not, refer to

Burner Switch Check for 120 VAC to neutral on both sides of

Check for power to Main Fan Relay. Visually check

for contact pull in.

(For ovens equipped with a control circuit step-

down transformer, the supply voltage for the

cooling fan is 240 VAC.)

WITH POWER OFF: check for locked rotor. Check

for power (120 VAC) to cooling fan. If 120 VAC is

present at the fan motor and the fan does not run,

replace fan assembly.

incoming power (120 VAC)at cooling fan

thermostat.

120°F and opens at 100°F). With cooling fan

thermostat pre-heated, check for continuity. If

switch is open, replace.

fan does not run, replace fan.

"Oven fan will not run". Page 20.

switch. If switch is closed and 120 VAC is present

on one side only, replace the switch.

20

Impinger I -–1000 Series Service Manual - Domestic

Air Pressure Switch Check for 120 VAC on both sides of switch. If

Transformer, 24 VAC Check for 120 VAC to primary of transformer.

NOTE:

(Model 1004 & 1005) For oven models 1004 and 1005, there is a 1 Amp

Burner Motor Relay Delete burner motor relay refer to Section D, Page

Burner Blower Motor Check for 120 VAC supply to burner blower motor.

Centrifugal Switch of Burner

Blower Motor

For ovens with

Johnson Controls

Ignition Control and Valve

Assembly

Ignition Control

(For ovens with

Honeywell Ignition

control, See Pg. 21)

No Pilot If the ignition control is supplied with 24 VAC, and

Pilot Shut-off Valve Check to see that pilot shut-off valve is open (shut-

Pilot Tube Check for gas pressure at pilot tube. Disconnect

Pilot Orifice If there is gas pressure at the pilot tube, check the

Burner

Ignitor Check the burner ignitor head for any obstructions,

Impinger I -–1000 Series Service Manual - Domestic

voltage present on one side only, check for air tube

blockage. Adjust air switch. If above fails, replace

air pressure switch.

Check for 24 VAC from secondary of transformer. If

there is primary voltage, but no secondary voltage,

replace transformer.

fuse located between the 24 VAC output from the

transformer and the coil of the burner motor relay. If

there is 24 VAC output from the transformer, but no

burner motor relay action, check fuse and fuse

holder. Replace as necessary.

34.

If 120 VAC is present and motor does not run,

replace motor. WITH POWER OFF: turn blower

wheel to check for locked rotor.

Check for 24 VAC output from secondary of

transformer. If voltage is present, check for 24 VAC

at pin 6 and the ground bar on ignition control and

valve assembly. If the burner blower motor is

running and there is no voltage at pin 6 and the

ground bar on the ignition control valve, replace the

burner blower motor.

Check for 24 VAC supply to the ignition control and

valve assembly at pin 6 and the ground bar. If

voltage is present, check for 24 VAC across pin #1

and the ground bar (pilot valve). If voltage is not

present, replace electronic control package. If the

pilot valve is energized, check to see that the high

voltage ignitor circuit is also energized. To check,

disconnect the ignitor lead from the bottom of

ignition control. Place female terminal of ignitor

lead approximately 1/8" from terminal post on

ignition control. Spark should jump the 1/8" gap. If

no spark is present, replace ignition control.

the pilot valve (internal to valve assembly) and

ignitor circuits are energized, visually check for pilot

flame. This may be done by opening the small

inspection door on the end of the burner, or by

opening the main oven door and looking under the

lower finger housings on the right side of the oven.

If no pilot flame is visible, check the following.

off valve is located between ignition control and

valve assembly and burner.)

pilot tube at burner and connect manometer to pilot

tube. If no gas pressure is present, check for

blockage in pilot tube or pilot shut-off valve. If these

are clear, and there is gas supplied to the oven,

replace the ignition control and valve assembly.

pilot orifice for obstructions. Replace as need

also check for frayed or broken wire, any type of

damage to spark gap (.100 in. 2.5 m.m.) If there is

visible damage, replace ignitor assembly.

21

Pilot flame but no main

flame

For ovens with

Honeywell ignition

control

No Pilot

Flame Sensor (There should be a visible pilot flame at this time.)

To check for proper flame sensor operation,

connect a digital multimeter (capable of measuring

D. C. microamperes) in series between the flame

sensor wire (normally connected to terminal #4)

and terminal #4. NOTE: This is a current

measurement and the meter must be connected in

series. This procedure is for checking the pilot

flame only. Remove main valve wire (Red) from

terminal #3 on ignition control. With a visible pilo

t

flame, the current readings should be as follows:

Johnson G-65 control, 0.2 micro amp. D.C.

minimum/Johnson G-60 control, 0.7 micro amp.

D.C. minimum. If these values are not achieved,

replace flame sensor. Also check for any type of

damage to flame sensor wire and connections.

Ignition Control and Valve

Assembly

If there is a pilot flame, and there is sufficient micro

amp. current at terminal #4, check for 24 VAC

that the main valve (internal to valve assembly) has

opened. Connect a manometer to the manifold gas

pressure tap located on the back side of the ignition

control and valve assembly. If no gas is present,

replace ignition control and valve assembly.

Centrifugal Switch of Burner

Blower Motor

Check for 24 VAC output from secondary of

transformer. If voltage is present, check for 24 VAC

at terminals marked "24V" and "24V gnd" on

Ignition Control. If the Burner Blower Motor is

running and there is no voltage at terminals 24V

and 24V gnd on the ignition control, replace the

Burner Blower Motor.

NOTE:

These Ignition Controls have a 30 second prepurge(Delay) and a 15 second lock-out time – The

Ignition Control will try for ignition for 15 seconds

and then shut-off. To Re-try for ignition, turn off

burner switch, wait 30 seconds and re-try ignition.

Ignition Control

Check for 24 VAC supply to ignition control at

terminals "24V" and "24V gnd". If voltage is

present, check for 24V at terminal "P.V. (Pilot

Valve) and "gnd". If voltage is not present, replace

Ignition Control. If the pilot valve is energized,

check to see that the high voltage ignitor circuit is

also energized. To check, disconnect the ignitor

lead from the ignition control. Place the terminal of

ignitor lead approximately 1/8" from terminal post

on Ignition Control. Spark should jump the 1/8"

gap. If no spark is present, replace ignition control.

If the ignition control is supplied with 24 VAC and

the pilot valve (in gas valve) and ignitor circuits

Pilot Shut-off Valve If no pilot flame is visible, check to see that the pilot

shut-off valve is open(shut-off valve is located

between gas valve and burner).

Pilot Tube Check for gas pressure at pilot tube. Disconnect

pilot tube at burner and connect manometer to pilot

tube. If no gas pressure is present, check for

blockage in pilot tube or pilot shut-off valve.

Pilot Orifice If there is gas pressure at the pilot tube, check the

pilot orifice for obstructions. Replace as needed.

Burner Ignitor Check the burner ignitor head for any obstructions,

also check for frayed or broken wire, any type of

damage to spark gap (.100 in. 2.5 mm) If there is

visible damage, replace ignitor assembly.

22

Impinger I -–1000 Series Service Manual - Domestic

Spark Ignitor (Flame Sensor) (There should be a visible pilot flame at this time).

Pilot flame but no main

flame

NOTE: The Honeywell Ignition Control uses the

spark ignitor as the flame sensor. If spark

continues, check for proper ground connections at

Ignition Control. Check pilot orifice for any partial

blockage. If the above checks OK, replace ignition

control. If spark stops when pilot is lit, check for 24

VAC across M.V. - M.V/ P.V. terminals, if voltage is

not present, replace ignition control. If voltage is

present at terminals M.V. - M.V./P.V., the indicator

light on the control panel should be on, verify that

the main valve has opened, connect manometer to

manifold gas pressure tap(located on the

Red Indicator Light is

on, but no main

flame(For ovens with

mechanical

thermostat)

(For ovens with

Electronic

Temperature Control)

Temperature Control Valve

(Robert Shaw)

Main Orifice Check for blockage of main orifice. If there is no

Temperature Control

Potentiometer

Check for gas supply at temperature control. Check

for temperature control set above 300°F.

blockage to the main orifice, replace the

temperature control.

Check for 120 VAC across L1 and L2on

temperature control board. Potentiometer (1000

ohm,1 turn) WITH POWER OFF: check ohms

across red and black leads, the ohm reading

should be 0 to1000 ohms as the dial is turned.

From green to red, the reading should be 1000

ohms steady throughout the full turn of the dial.

NOTE: Ovens S/N Q18037 and above, the potentiometer is internal to temperature control. Proceed to next

component.

Thermocouple Probe Remove thermocouple leads from the temperature

control board, and measure the millivolt output of

these leads. Refer to chart on page 38 in the

adjustment section for proper readings.

Temperature Control Turn temperature control dial to full "on" position.

Measure for 120 VAC across terminals "N.O." and

"L2", if voltage is not present; replace control.

Solenoid Valve If voltage is present at terminals "

N.O."and "L2",

check for voltage at solenoid valve. If voltage is

present, listen for valve to open and close. Also,

check for opens and shorts in coil. If solenoid valve

is defective, replace

Intermittent Heating Both the main fan motor and burner blower motor

are equipped with thermo-protection and will cease

to operate when not cooled properly. This can

cause the units to cycle on and off intermittently.

Also, most of the problems listed under "oven will

not heat" can cause intermittent failures.

For continuin

g intermittent problems, a series of test lights may be made and installed in

the ovens. The lights will allow the customer to advise the service technician a trouble code when

the oven fails.

The lights should be connected in the following manner:

Light#l attached in 120VAC line after Air Pressure Switch.

Light#2 attached after 120VAC contacts of Burner Motor Relay (or, refer to Bulletin #028

for Relay Removal).

Light#3 in 24VAC Burner Transformer Secondary.

Light#4 in 24VAC at terminal #6 of Johnson control valve or "24V" on Honeywell Control.

Light#5 in 24VAC at terminal #1 of Johnson control valve or "PV" on Honeywell Control.

Light#6 in 24VAC at terminal #3 of Johnson control valve or "MV" on Honeywell Control.

CODE:

All lights off - lights of main power, main fan off, air pressure switch out.

1 on 2 off 3 on 4 off 5 off 6 off - Burner Motor Relay bad.

Impinger I -–1000 Series Service Manual - Domestic

23

1 on 2 on 3 on 4 off 5 off 6 off - Burner Motor Centrifugal Switch bad.

1 on 2 on 3 on 4 on 5 off 6 off - Ignition Control bad.

1 on 2 on 3 on 4 on 5 on 6 off - Pilot Shield missing or warped, Flame Sensor bad, Pilot

Orifice plu

-

1 on 2 on 3 on 4 on 5 on 6 on - Unit still not working Main Orifice plugged, Gas Valve bad,

-

Temperature Control bad.

However, Mai

-

gged, or Gas Valve

n Orifice would not be intermittent problem.

bad.

24

Impinger I -–1000 Series Service Manual - Domestic

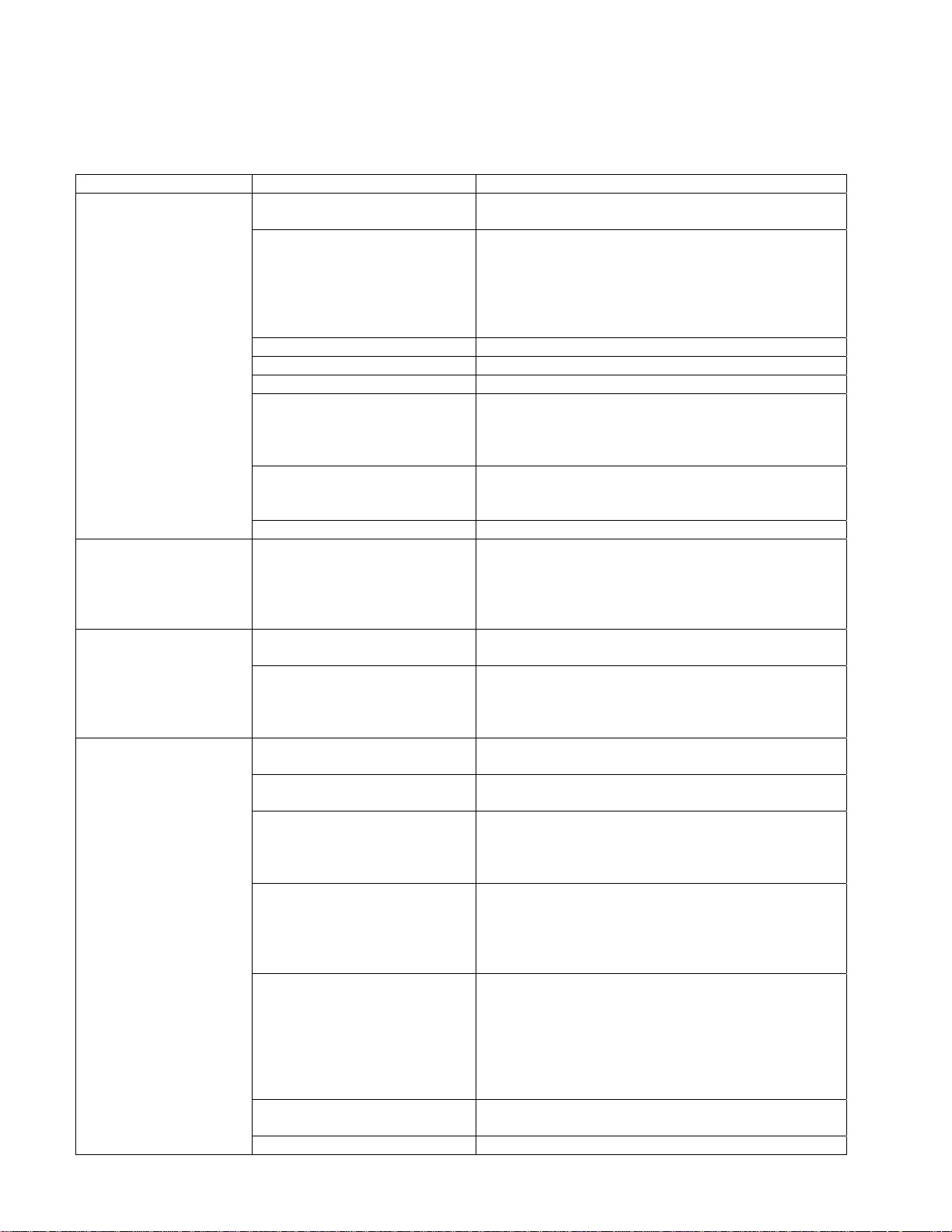

TROUBLESHOOTING GUIDE

ELECTRIC OVENS MODEL SERIES 1000 & 1200

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run

NOTE:

No Main Fan Cool

Down

No control box cooling

Oven will not heat

NOTE:

Incoming Power Supply Check breakers/Reset if required/ Call Power Co. if

needed.

(Export Ovens) For some export ovens, there is a control circuit

step-down transformer. This transformer steps

down supply voltage to 120 VAC. If main fan will

not run, the secondary of this transformer must be

checked for 120 VAC output. Check specific oven

model schematic for circuit location.

Oven Fan Fuse(s) Check and/or Replace

Fuse Holder Check and/or Replace

Fan Switch Check continuity between switch terminals.

Main Relay Check continuity to 120 VAC coil. Check for power

to the relay coil (120 VAC). Check for 208/220/240

VAC to relay terminals. Visually check for contact

pull-in

Fan Motor Check for opens, shorts, or grounds. WITH

POWER OFF: Turn Fan Blade to check for locked

rotor.

Capacitor Check for opens, shorts, or grounds.

Cool Down Thermostat Check cool down thermostat (thermostat closes at

160°F and opens at 140°F). Check for power (120

VAC) at cool down thermostat. With cool down

thermostat pre-heated, check for continuity. If

switch is open, replace.

Main Fan Relay Check for power to main fan relay. Visually check

for contact pull in.

Axial Cooling Fan WITH POWER OFF: turn the fan blade to check for

locked rotor. Check for power (120 VAC) to cooling

fan. If 120 VAC is present at the fan motor and the

fan does not run, replace fan assembly.

Main Oven Fan Check if main oven fan is operating. If not, refer to

"Oven fan will not run."

Heat Switch Check for continuity between switch terminals with

switch on. Replace if defective.

Air Pressure Switch Check for 120 VAC on both sides of switch. If

voltage present on one side only, check for air tube

blockage, adjust air switch. If above fails, replace

air pressure switch.

Hi Limit Thermostat Terminals are normally closed. If open, reset and

test oven for proper operation. If thermostat will not

hold for maximum oven temperature, and oven is

not exceeding temperature dial setting, replace

thermostat (rated at 190°F).

Hi Limit Thermostat

(Model 1032)

3 Amp Temperature Control

Fuse

Fuseholder Check and/or replace.

Terminals are normally closed. If open, reset and

test oven for proper operation. If thermostat will not

hold for maximum oven temperature, and oven is

not exceeding temperature dial setting. Replace

the thermostat. Check for proper location of

sensing bulb in its spring holder. If hi-limit is still

tripping, replace (rated for 368°C).

Check and/or Replace

Impinger I -–1000 Series Service Manual - Domestic

25

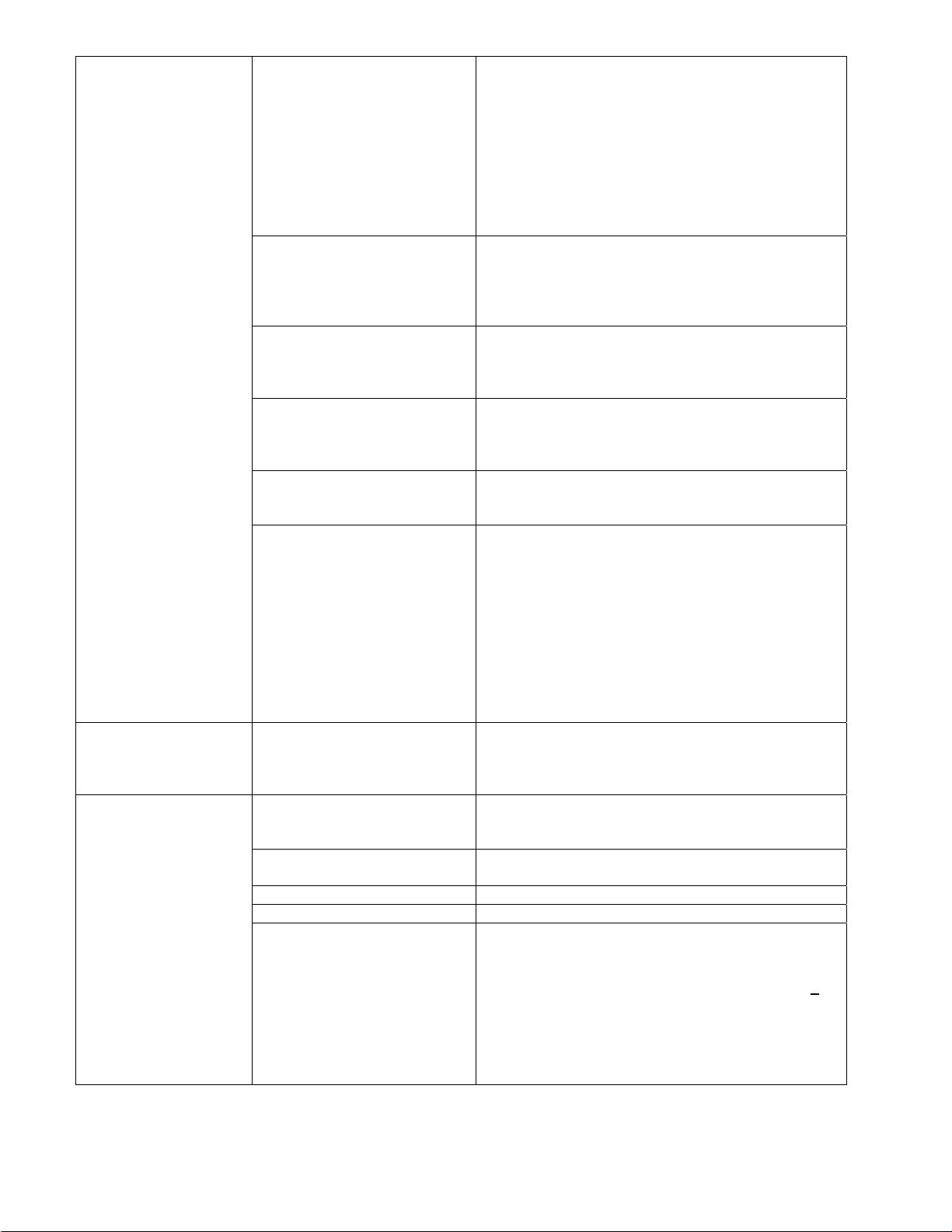

Oven heats with switch

off

Conveyor will not run

(S/N 100-4389)

Temperature Control Board Check for 120 VAC input to temperature control

board. If not present, check wiring from fuse holder

to temperature control board. Turn the temperature

adjustment dial to the maximum temperature

position Check for 120 VAC at coil of mercury

contactor(s). Next, short the leads of thermocouple

on the temperature control board, check for 120

VAC at coil of mercury contactor(s). If voltage is

not present, replace temperature control board. If

voltage is present proceed.

Temperature Control

Potentiometer

Potentiometer is 0 to 2.5K ohm. WITH POWER

OFF: remove the leads from the temperature

control board terminals 1, 2, and 3 and measure

ohms from black to white leads. The ohm reading

should be 0 to approximately 2.5K ohms as the dial

Thermocouple Probe Remove thermocouple leads from the temperature

control board, and measure the millivolt output of

the leads. Refer to chart in adjustment section for

proper millivolt readings.

Mercury Contactor(s) Check for 120 VAC to the contactor coil. If voltage

is present and contactor will not activate, replace

the contactor(s). Also check each contactor for

proper high voltage input and output.

50 Amp Fuses If there is no high voltage input to the mercury

contactor(s), check the 50 amp fuses and replace if

necessary.

Heater Elements Check the Amp. draw on each hot leg for proper

load. Check the specifications plate for rating

information. If the Amp. draw is low or high, check

the individual elements for opens, shorts, and

proper resistance . To check resistance of the

elements, turn off the power! Remove all leads

from the elements and use an accurate digital

VOM. The element resistance should be as

follows: 208V - 9.8 ohms approx. 220V - 10.5 ohms

approx. 240V - 13 ohms approx. If all readings are

not correct, replace elements as needed.

Mercury Contactor(s) The mercury contactor has probably malfunctioned

in the closed position. If there is no voltage to the

operating coil, but there is high voltage at the

contactor output, replace the mercury contactor.

Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 120 VAC. If

not present, check breakers.

3 Amp Fuse This conveyor fuse is located on the front panel.

Replace if defective.

Fuse Holder Check and/or Replace.

Conveyor Switch Same procedure as for fan switch.

D. C. Motor Control Board

Check for 120 VAC input to D. C. control board

across L1 and L2. Check the 3 amp fuse on the D.

C. control board. Check for D. C. voltage at

terminal F1 a

nd F2. Voltage should be 10 VDC +

10 steady. If this voltage is not present, replace D.

C. control board. Check for D. C. voltage output to

the motor across terminals A1 and A2 (this voltage

should be approx. 125 VDC at maximum conveyor

motor speed).

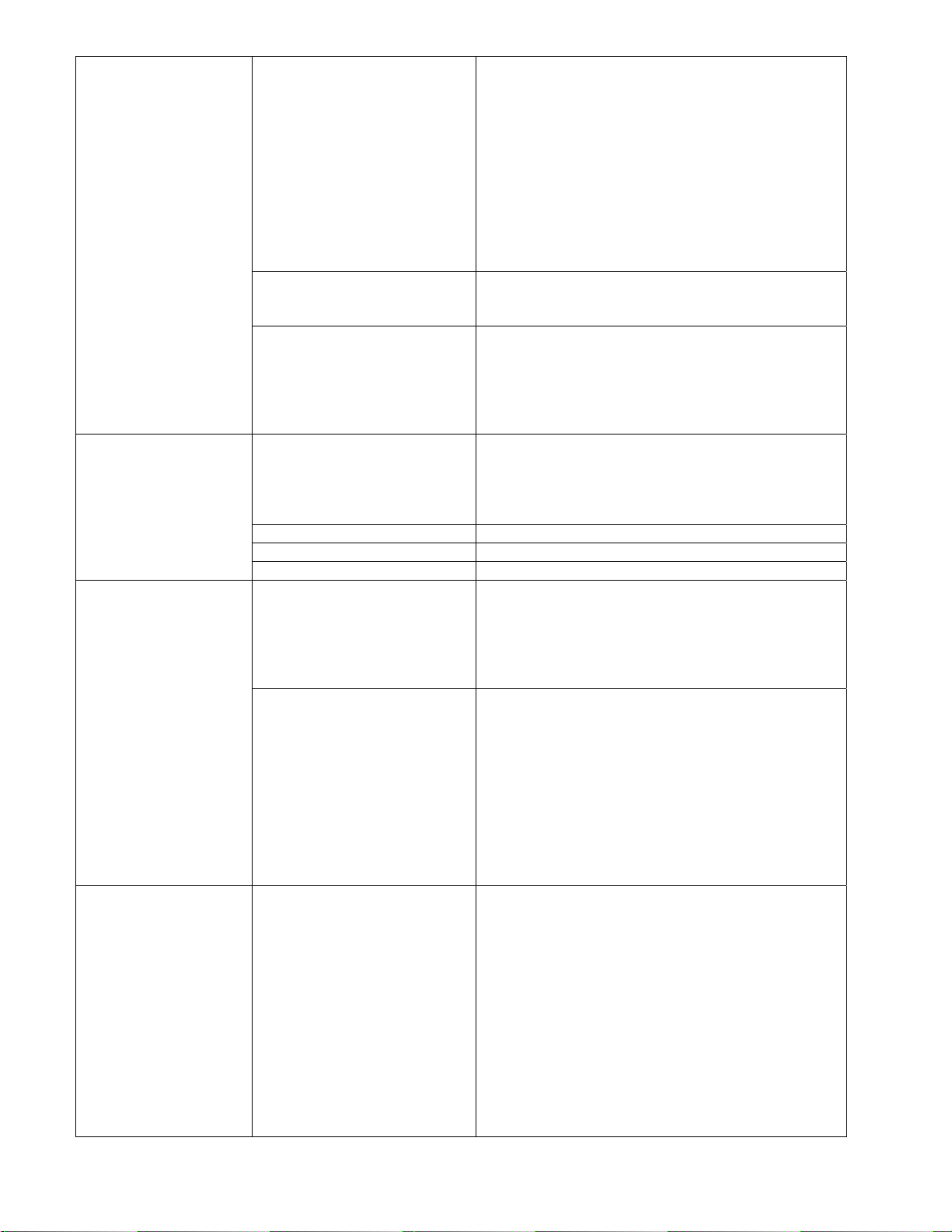

26

Impinger I -–1000 Series Service Manual - Domestic

Speed Control Potentiometer This is a 0 to 400 ohm or 0 to 500 ohm, 10-turn

potentiometer. WITH POWER OFF: remove the

red, white, and black leads from terminals S1, S2,

S3. With a digital multimeter, check the ohm

reading across the red to black leads. This ohm

reading should be a steady 400-ohm, or 500-ohm,

through the entire 10-turn rotation of the

potentiometer. Check for shorts or opens or

unsteady, ohm reading, if potentiometer is

defective, replace. If the potentiometer checks OK,

and there is no output at terminals A1 and A2,

replace the D. C. control board.

Reversing Switch If there is D. C. voltage output from the motor

control board, but the conveyor drive motor is not

running, check the D.P.D.T. reversing switch.

Conveyor Drive Motor Check the conveyor drive sprocket for tightness.

Disconnect the motor, check the red and black

motor leads for opens, shorts or grounds. Check

the brushes for excessive or abnormal wear.

Replace as needed. Reconnect motor. Test for

operation. If motor does not run, replace.

Conveyor will not

run(S/N 4390 to

Q190771000 Series)

(S/N 4390Q147901200 Series)

Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 120 VAC. If

no present, check breakers. 3 Amp Fuse. This

conveyor fuse is located on the front panel.

Replace if defective.

Fuseholder Check and/or Replace.

Fan Switch See procedure for checking on Page 20.

Conveyor Switch Same procedure as for fan switch.

NOTE:

(Dual Belt Ovens) Dual belt ovens utilize 2 complete independent

conveyor drive systems. The trouble shooting

procedures are the same as single belt ovens,

except that the dual belt ovens use one each of the

following: one "A" D. C. control board and one "B"

D. C. control board.

Speed Adjustment

Potentiometer

This is a 0 to 5 K ohm, 10 turn potentiometer With

power off, remove the red, black and white pot

leads from the motor control board at terminals P1,

P2 and P3. With a digital multimeter, check the

ohm reading across the red lead (P3) to the black

lead (P1). This reading should be 5 K ohms ± 5%

as the pot is rotated from low to high. Place the

meter leads on the red lead (P3) and on the white

lead (P2) Rotating the pot. slowly, from low to high,

the meter reading should show an even transition

from O to 5 K ohms ± 5%. There should be

DC Motor Control Board Check for 120 VAC input to the control board at

terminals L1 and L2. If not present, check the

conveyor switch and wiring back to 3-amp fuse and

then back to power source if necessary. If 120 VAC

is present at L1 and L2, check the VDC output at

terminals A+ and A-. If a DC voltage is not present,

check the 4 amp and the 1 amp fuses on the

control board. Also reset and check the mini

breaker in the armature line to the gearmotor. If

120 VAC is present at terminals L1 and L2, but DC

voltage is not present at A+ and A-, providing the 1

amp and 4 amp fuses are good, replace the board.

If DC voltage is present at A+ and A-, but motor

does not run, check gear motor as follows.

Impinger I -–1000 Series Service Manual - Domestic

27

Conveyor speed

varying or intermittent

Conveyor will not

run(S/N Q19078 &

Up1000 Series) (S/N

Q14791 & Up1200

Series)

Conveyor Gear Motor If DC voltage is present at A+ and A- and the motor

does not run, first check the mini breaker and then

the conveyor. Refer to the next possible cause.

Check the leads to the motor for evidence of any

shorts or opens, and each lead to ground. If the

motor fails the above tests, replace motor. Remove

dust cover from the top of the motor and rotate

motor shaft to determine if there is a locked rotor or

a locked gear box (use care so encoder disc is not

damaged).

Conveyor Check for any mechanical misalignment or

improper adjustment. Also check for worn

bearings. The Installation and Operations Manual

shows proper conveyor belt adjustment. A

conveyor belt that is over tightened will cause

excessive bearing wear and sometimes, irregular

speed.

Power Supply Check power supply at the DC control board for the

120 VAC at board terminals L1 and L2. If voltage is

not present, check main circuit breakers.

Tach generator and DC Motor

Control Board

With the power to the DC motor control board

turned off, remove the leads from terminals T1 and

T2.Place the test leads of a digital meter on the

tach leads, turn power on, and the meter reading

should be approximately 30 to 35 VDC. This

reading should be steady within ± 0.2 to 0.3 VDC.

If this reading is not within +

0.5 VDC, place the

test meter probes on terminals A+ and A-. The

meter reading should be approximately 150 to 160

VDC and steady within approximately 2 VDC. If the

tach. voltage is unsteady, and the board output is

steady, check the coupling for loose set screws or

any type of damage. If the coupling checks good,

the tach. is usually bad. If the board voltage output

is unsteady beyond limits, then the board is

probably bad. Always check the speed pot. Be sure

it is okay before changing a board or tach. This test

is not always 100% accurate as this test is not

performed at operating speeds. However, this test

is the best method currently available.

Readjustment should always be attempted at least

once before replacement. See procedure for board

adjustment on page 44.

DC Gearmotor If the DC control board is steady then the problem

may be the motor or gearbox. Check the brushes

in the motor for excessive arching and/or unusual

wear. Check the motor and gearbox from

instruction located on page 27 under "possible

cause" listing "Conveyor gear motor".

Voltage Supply Check incoming voltage supply at Line 1 to neutral.

There should be a voltage reading of 120 VAC.

Fan Switch See procedure for checking on page 20.

Conveyor Switch Check for 120 VAC to conveyor switch. If no

voltage is present, trace wiring back to the fan

switch. WITH POWER OFF: Check continuity

between switch terminals.

Conveyor Fuse (3A) Check, replace if necessary.

Fuseholder Check, replace if necessary.

28

Impinger I -–1000 Series Service Manual - Domestic

Loading...

Loading...