Page 1

SERVICE MANUAL

(DOMESTIC)

IMPINGER CONVEYOR OVENS

MODEL 1100 SERIES

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Phone : (260) 459-8200

U.S. Fax: (888) 790-8193 • Int’l Fax: (260) 436-0735

Technical Service Hot Line

(800) 678-9511

www.lincolnfp.com

1100svcdom REV 11/4/08

Page 2

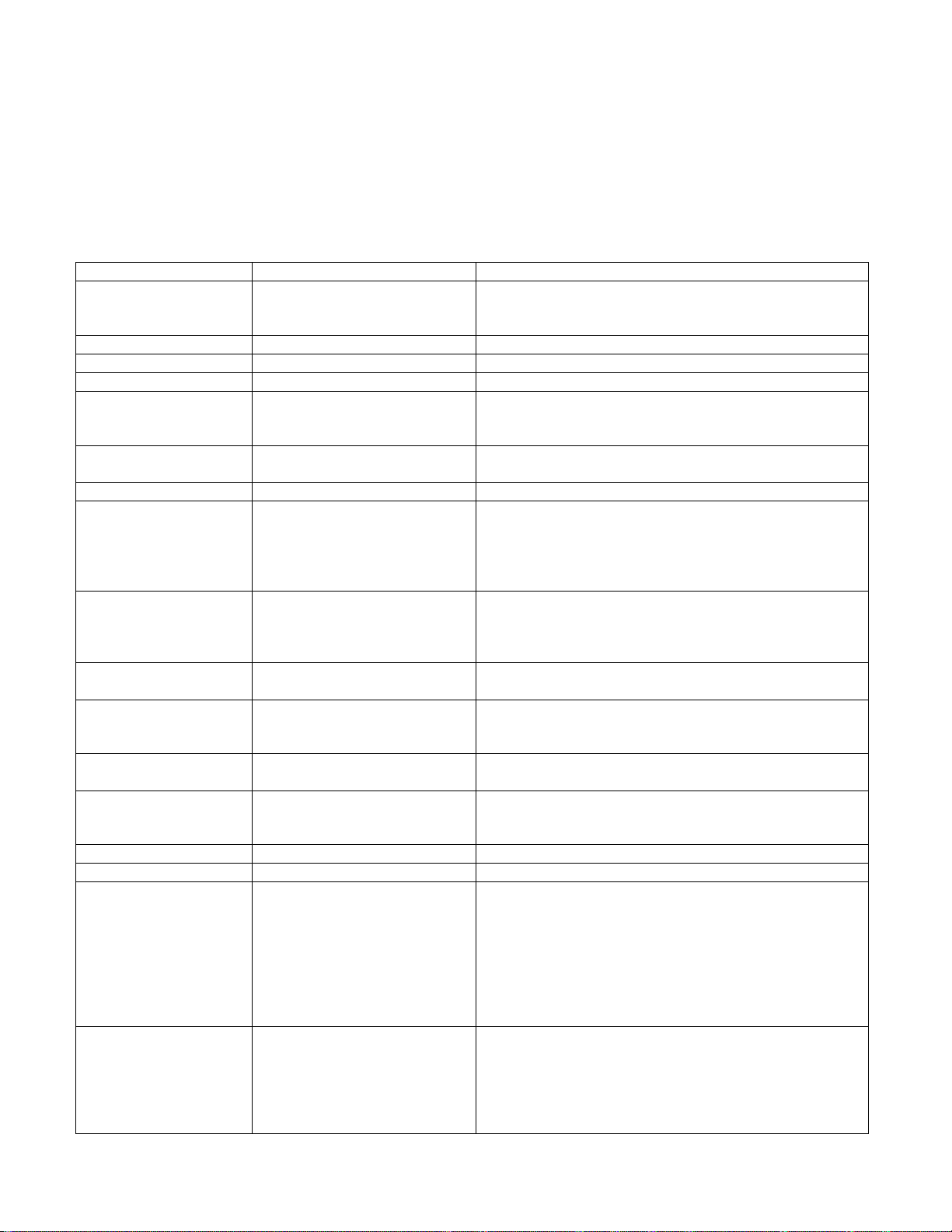

TABLE OF CONTENTS

SEQUENCE OF OPERATIONS 1100 thru 1103 .....................................................................................................3

SEQUENCE OF OPERATIONS 1116 - 1117 ..........................................................................................................4

SEQUENCE OF OPERATIONS 1130 - 1133 & 1160 - 1163................................................................................... 6

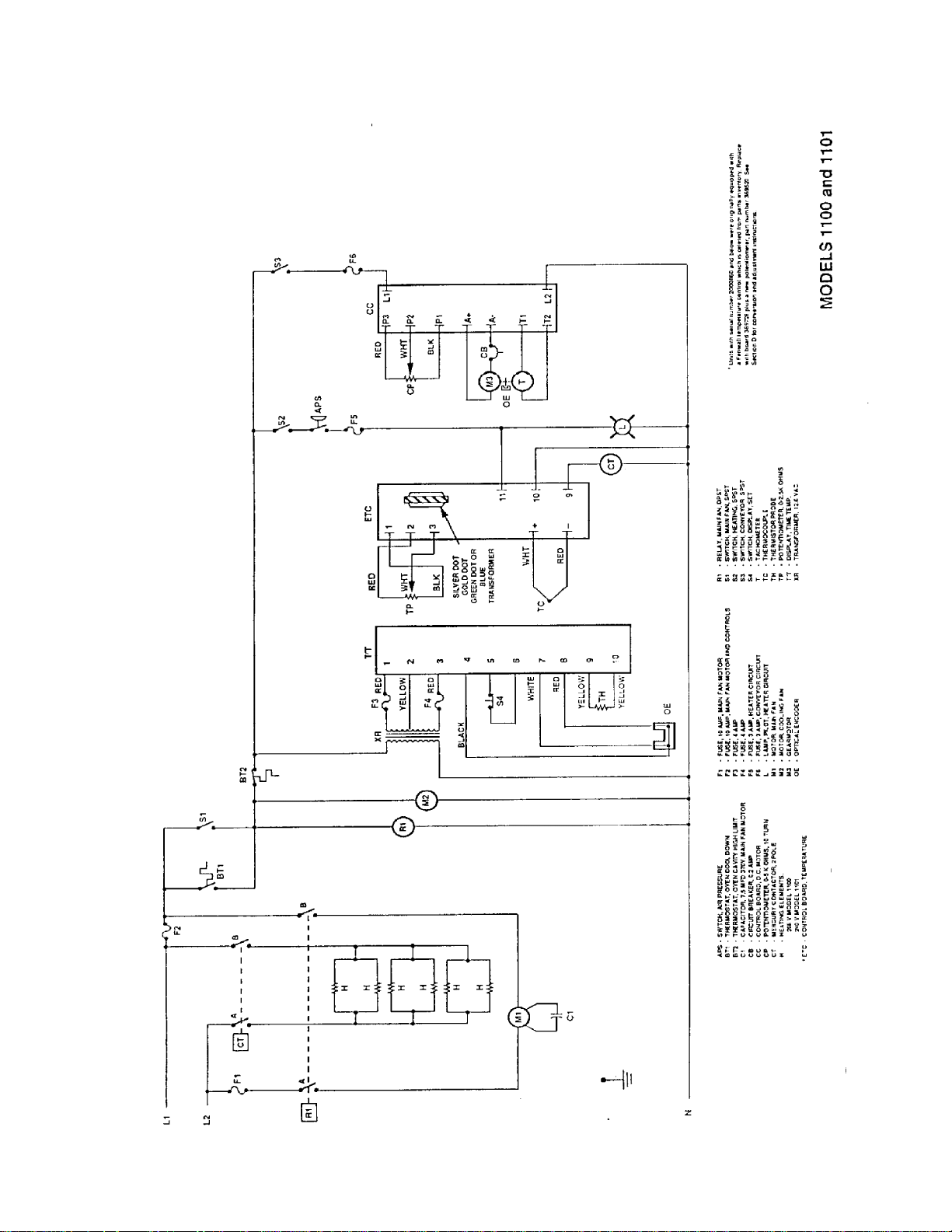

SCHEMATIC 1100 – 1101 .......................................................................................................................................8

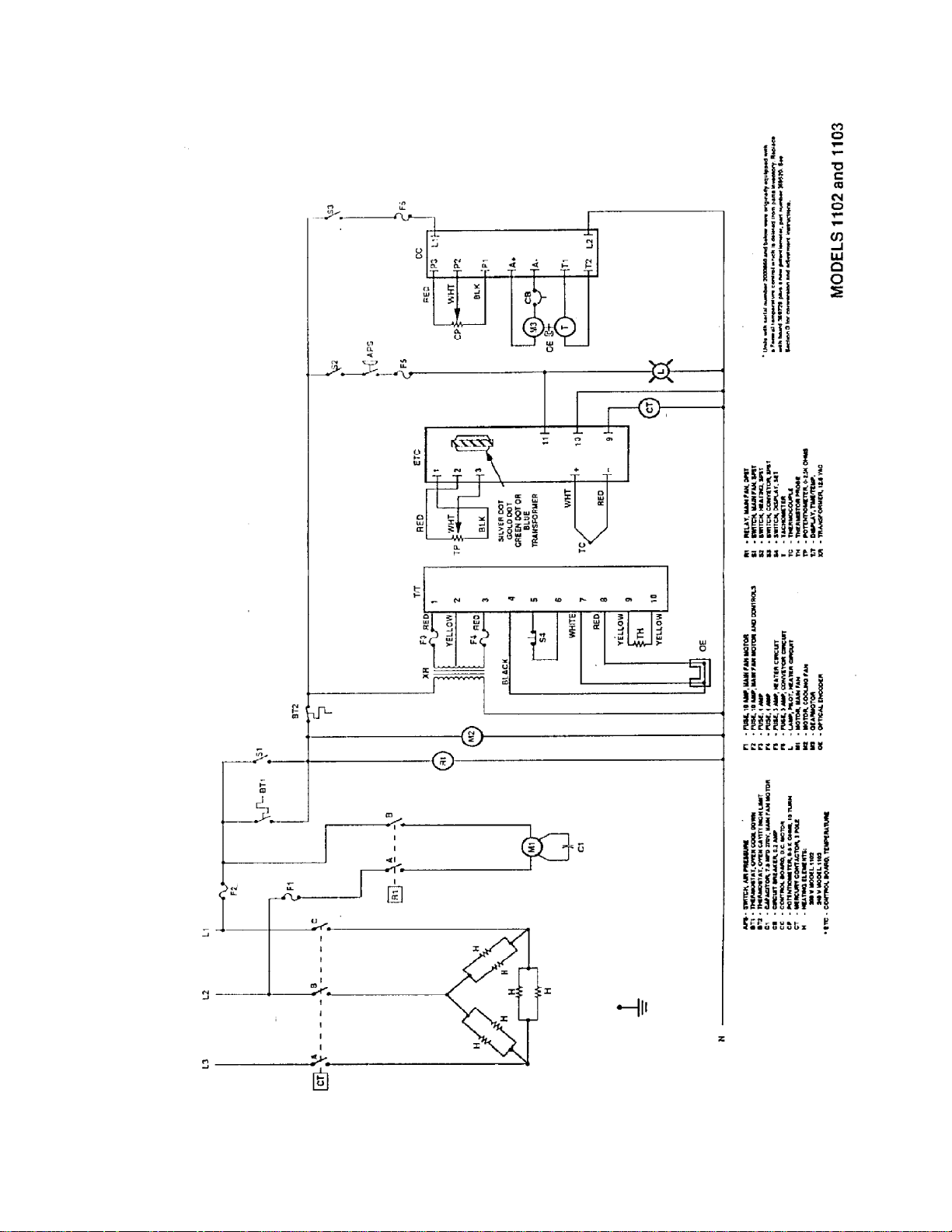

SCHEMATIC 1102-1103 ..........................................................................................................................................9

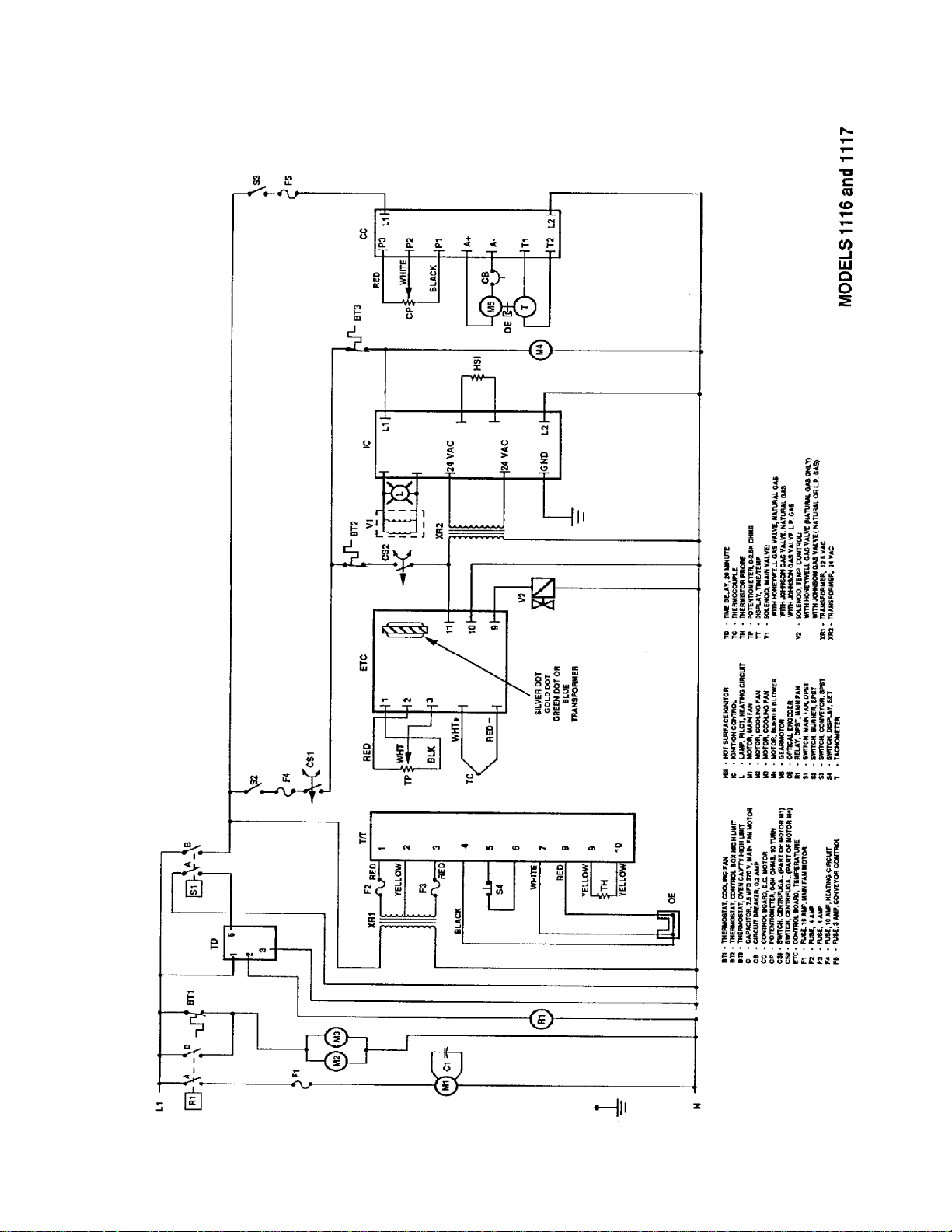

SCHEMATIC 1116 – 1117 S/N 2011383 & BELOW.............................................................................................. 10

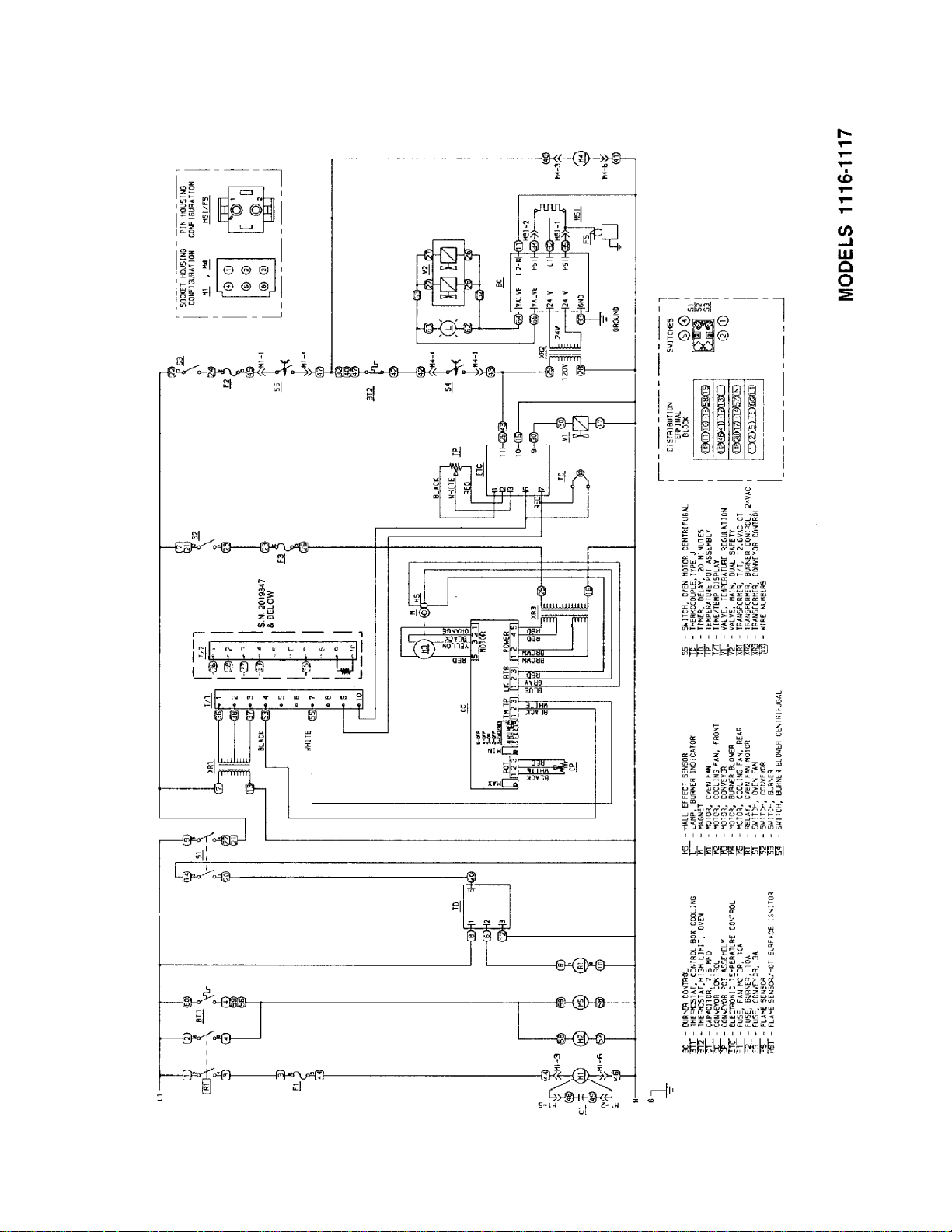

SCHEMATIC 1116 – 1117 S/N 2011384 & ABOVE ..............................................................................................11

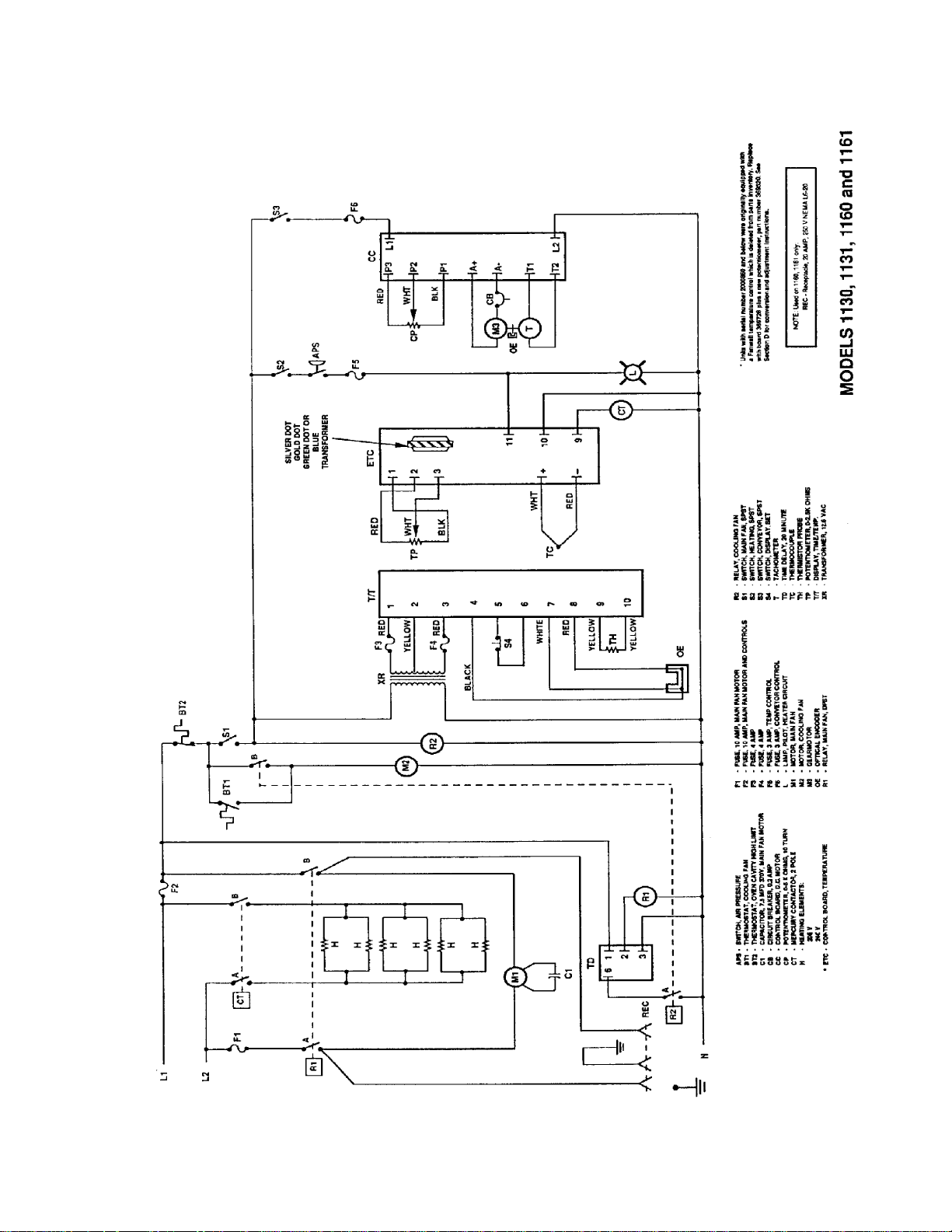

SCHEMATIC 1130 – 1131 S/N 2011383 & BELOW & 1160 – 1161 S/N 2011978 & BELOW..............................12

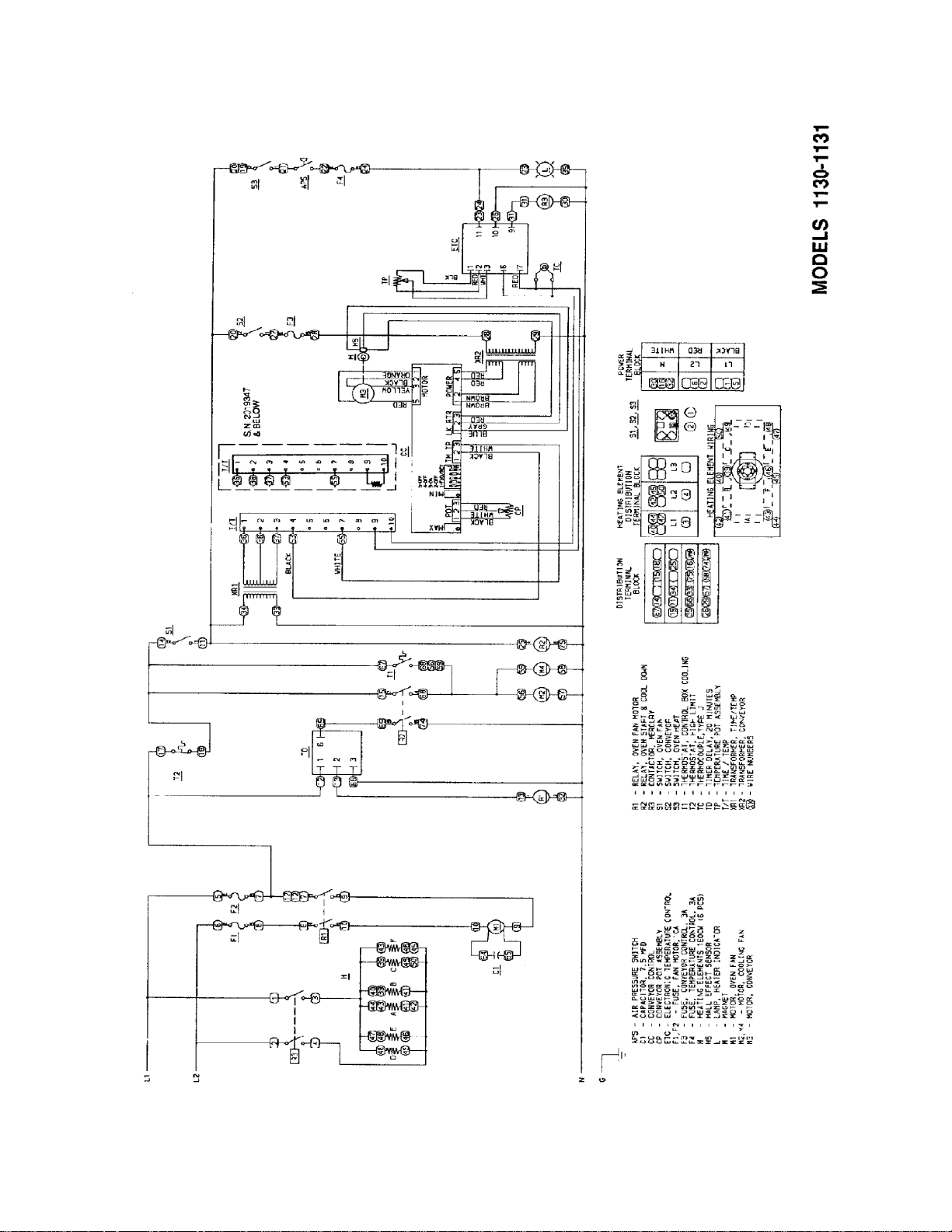

SCHEMATIC 1130 – 1131 S/N 2011384 & ABOVE ..............................................................................................13

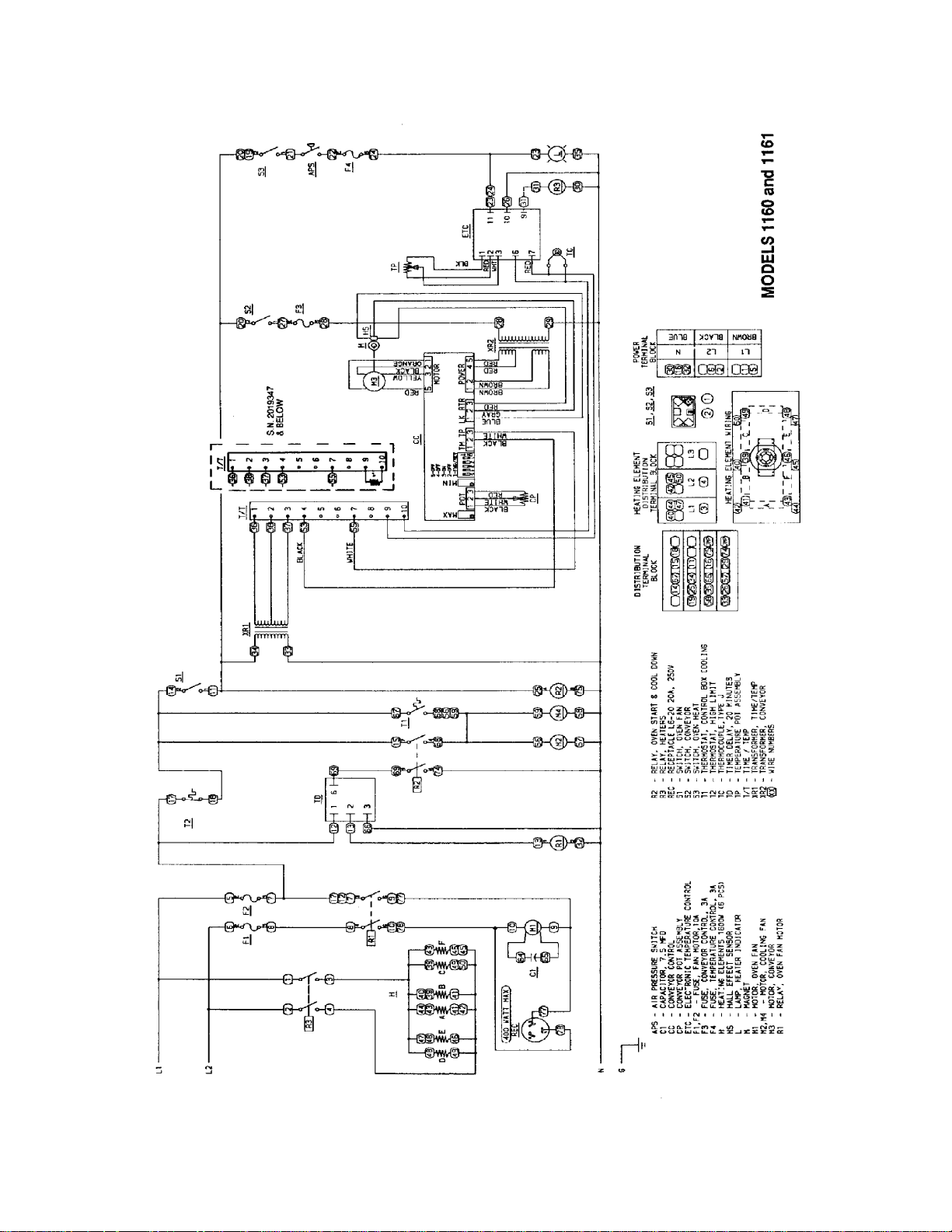

SCHEMATIC 1160 – 1161 S/N 2011978 & ABOVE ..............................................................................................14

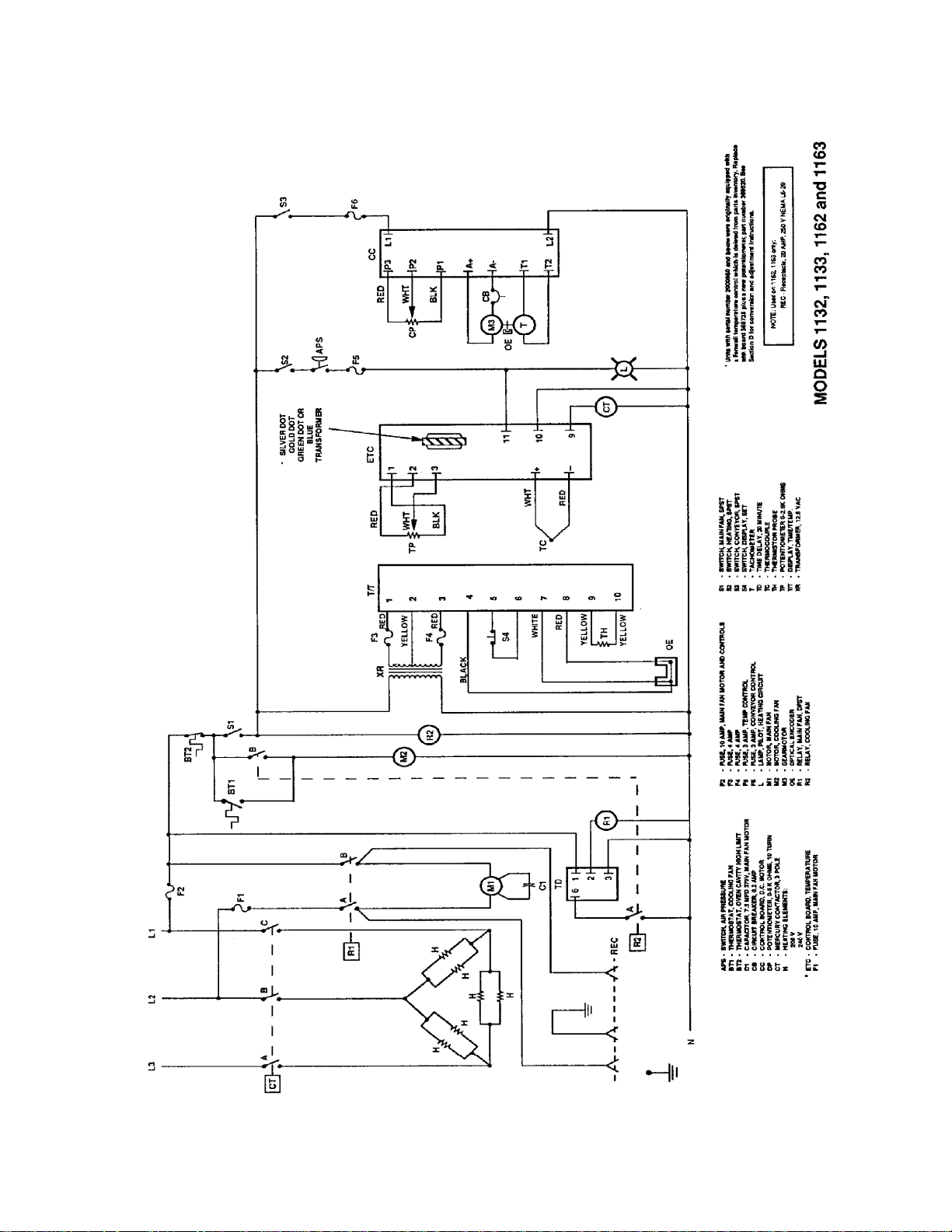

SCHEMATIC 1132 – 1133 S/N 2011383 & BELOW & 1162 – 1163 S/N 2011979 & BELOW..............................15

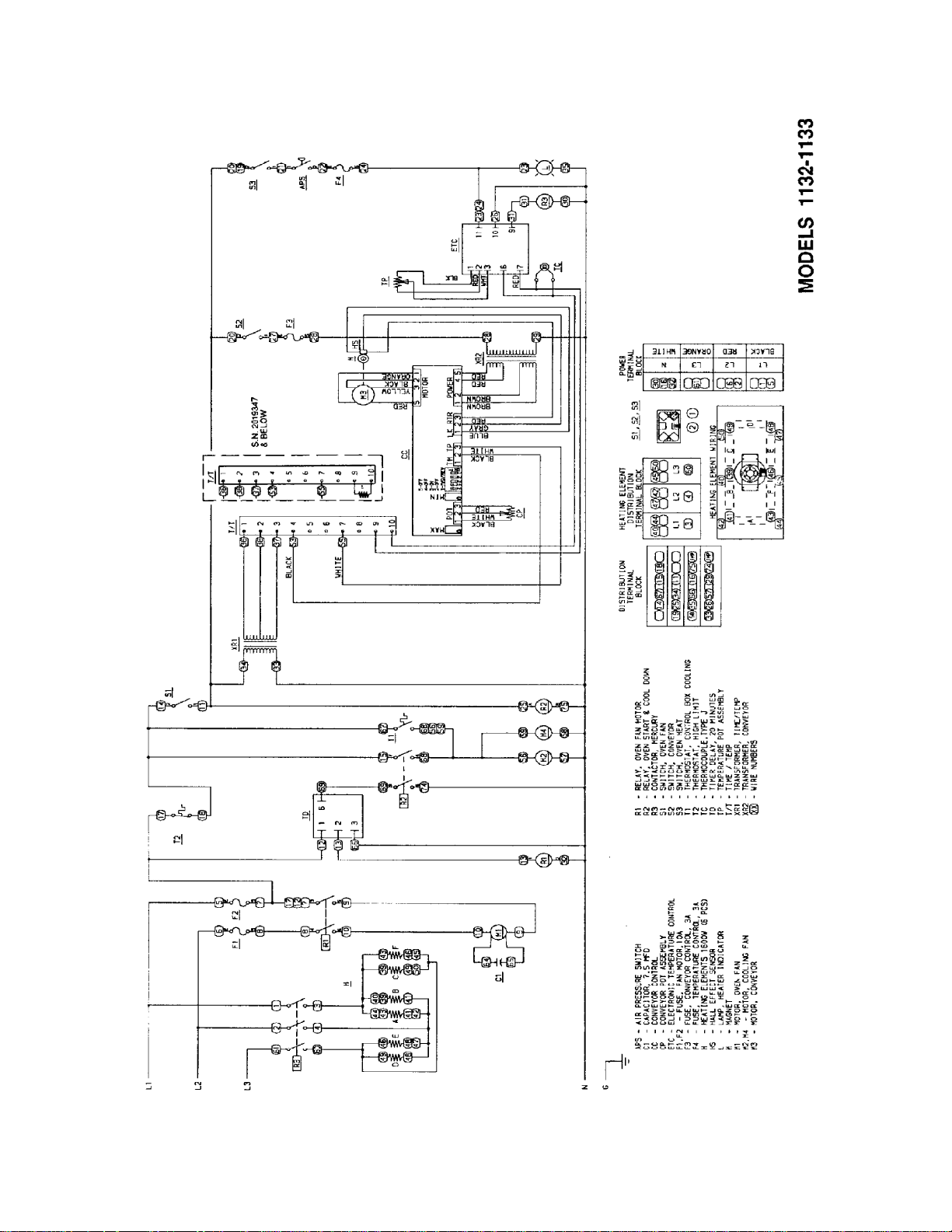

SCHEMATIC 1132 – 1133 S/N 2011384 & ABOVE ..............................................................................................16

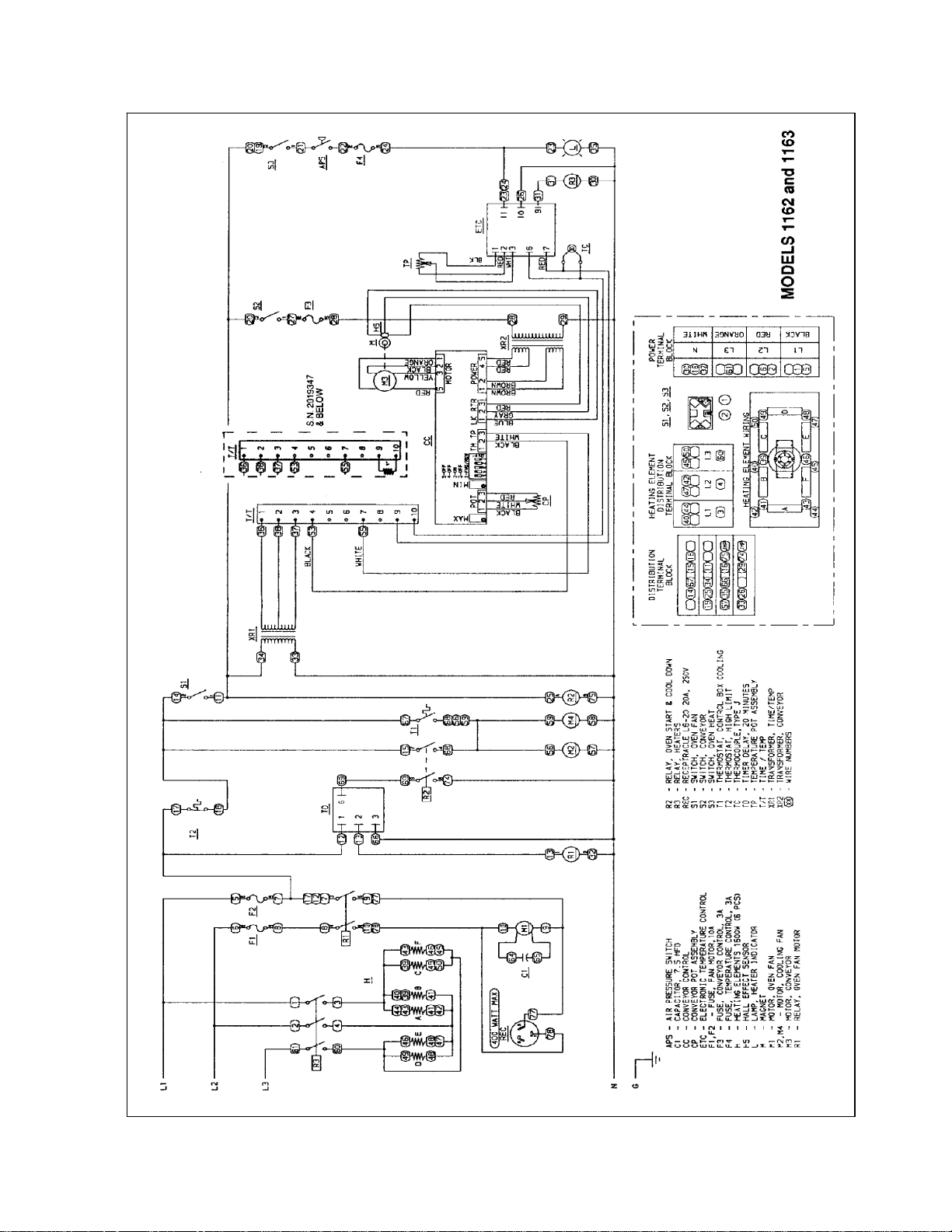

SCHEMATIC 1162 – 1163 S/N 2011978 & ABOVE ..............................................................................................17

TROUBLESHOOTING GUIDE 1116 - 1117........................................................................................................... 18

TROUBLESHOOTING GUIDE 1100 THRU 1103..................................................................................................22

TROUBLESHOOTING GUIDE 1130 THRU 1133 / 1160 THRU 1163................................................................... 24

REMOVAL, INSTALLATION, AND ADJUSTMENT ...............................................................................................31

PARTS / GENERAL –1100 SERIES ......................................................................................................................50

BLOW UP / GENERAL – 1100 SERIES.................................................................................................................51

PARTS / CONTROL COMPARTMENT FRONT 1100 - 1106, 1130 - 1136, 1150,1151,1160 – 1163 ..................52

BLOW UP / CONTROL COMPARTMENT FRONT 1100 – 1106,1130 – 1136, 1150,1151,1160 – 1163 ............. 53

PARTS / CONTROL. COMPARTMENT FRONT 1116,1117 .................................................................................54

BLOW UP / CONTROL COMPARTMENT FRONT 1116, 1117............................................................................. 55

PARTS / CONTROL COMPARTMENT REAR 1100 – 1106, 1130 – 1136, 1150,1151, S/N 2011373 & BELOW, 1160

– 1163 S/N 2011978 & BELOW .............................................................................................................................56

BLOW UP / CONTROL COMPARTMENT REAR 1100 – 1106, 1130 – 1136, 1150,1151, S/N 2011373 & BELOW,

1160 – 1163 S/N 2011978 & BELOW ....................................................................................................................57

PARTS / CONTROL COMPARTMENT REAR 1130 - 1136, 1150, 1151, S/N2011383 AND ABOVE, 1160 – 1163 S/N

3011978 AND ABOVE............................................................................................................................................ 58

BLOW UP / CONTROL COMPARTMENT REAR 1130 - 113

S/N 3011978 AND ABOVE.....................................................................................................................................59

PARTS / CONTROL COMPARTMENT REAR 1116, 1117, S/N 2000200 TO 2011383 .......................................60

BLOW UP / CONTROL COMPARTMENT REAR 1116, 1117, S/N 2000200 TO 2011383................................... 61

PARTS / CONTROL COMPARTMENT REAR 1116, 1117 S/N 2011383 & ABOVE ............................................62

BLOW UP / CONTROL COMPARTMENT REAR 1116, 1117 S/N 2011383 & ABOVE ........................................ 63

PARTS / OVEN BACK ASSEMBLY 1100 SERIES................................................................................................64

BLOW UP / OVEN BACK ASSEMBLY 1100 SERIES ...........................................................................................65

PARTS / GEARMOTOR ASSEMBLY 1100 SERIES .............................................................................................66

BLOW UP / GEARMOTOR ASSEMBLY 1100 SERIES.........................................................................................67

PARTS / CONVEYOR & DOOR 1100 SERIES .....................................................................................................68

BLOW UP / CONVEYOR & DOOR 1100 SERIES................................................................................................. 69

6, 1150, 1151, S/N2011383 AND ABOVE, 1160 – 1163

2

Impinger II –1100 Series Service Manual - Domestic

Page 3

SEQUENCE OF OPERATIONS 1100 THRU 1103

MODEL 1100 / ELECTRIC / 120/208 VAC / 60 HZ / 1 PHASE

MODEL 1101 / ELECTRIC / 120/240 VAC / 60 HZ / 1 PHASE

MODEL 1102 / ELECTRIC / 120/208 VAC / 60 HZ / 3 PHASE

MODEL 1103 / ELECTRIC / 120/240 VAC / 60 HZ / 3 PHASE

POWER SUPPLY Electrical Power to be supplied to the oven by a four conductor cord set on single

phase and a five conductor cord set on three phase.

Voltage from the black conductor to the white conductor is120 VAC.

Black conductor is Hot.

Red conductor is Hot.

Orange conductor is Hot. (Used on 3Ø only)

White conductor is dedicated neutral.

Green conductor is ground.

MAIN FAN CIRCUIT Power is permanently supplied to the normally open contacts of the main fan

relay, through a 10A fuse, to the normally open cool down thermostat, and to the

normally open main fan switch. Closing the main fan switch energizes the coil of

the main fan relay. Its normally open contacts now close energizing the main fan

motor. Closing the main fan switch energizes the cooling fan, the time/temp

transformer, the heat and conveyor switches.

HEATER CIRCUIT Closing the Heater Switch provides power through the normally open Air

Pressure Switch, through the 3 Amp Fuse, to the Temperature Control Board

and to the Heater Lamp.

TEMPERATURE CONTROL Closing the Heat Switch supplies 120 VAC to the Electronic Temperature

Control. The 2.5K ohm Potentiometer is adjusted to achieve the desired

temperature. The Thermocouple will provide varying millivolts to the Temperature

Control. The temperature control board then supplies 120 VAC to the coil of the

Contactor at intermittent intervals to maintain the desired temperature.

NOTE: Units with Serial Number prior to 2000782 were equipped with a Fenwall

Temperature Control and used a Temperature Control Potentiometer rated at 5K

ohms.

CONVEYOR DRIVE Closing the Conveyor Switch supplies 120 VAC to the DC Motor Control Board at

terminals L1 and L2. A.C.volts are converted to DC volts and are supplied to the

Conveyor Motor at terminals A+ and A-. Adjustment of the Speed Control

Potentiometer (5,000 ohm, 10 turn) will change resistance at terminals P1, P2,

and P3varying the DC voltage to the Conveyor Motor. The speed of the conveyor

motor will increase or decrease as the DC voltage from the board increases or

decreases respectively. As the motor turns, it drives both the reducer gear box

and the tach. generator. The tach. generator is a DC voltage generator which

supplies a voltage to the DC Motor Control Board which is used as a reference

for maintaining a constant conveyor speed.

TIME/TEMP DISPLAY The secondary output of the Transformer, is supplied to terminals 1, 2, and 3 of

the Time/Temp. Display. The secondary output of the Transformer is nominally

12.5 to 15 VAC with a center tap. The voltage from the center tap to each leg is

1/2 the secondary voltage. The speed side of the Time/Temp. Display uses a

slotted disc (cemented to tach. coupling) to break the infra-red light beam of the

optical encoder (mounted on gear motor), producing electrical pulses that are

transmitted to the display. The display converts these pulses into a read-out of

minutes and seconds. The temperature portion of the Time/Temp Display

thermistor outputs a resistance proportional to the oven temperature. This

resistance is then converted by the display into a temperature reading.

AUTOMATIC COOL DOWN When the oven reaches operating temperature the normally open Oven Cool

Down Thermostat closes. After oven is switched OFF, the Thermostat bypasses

the Fan Switch , keeping the Cooling Fan and Main Fan operating until the oven

cools down to approximately 200°F (93.3°C).

Impinger II –1100 Series Service Manual - Domestic

3

Page 4

SEQUENCE OF OPERATIONS 1116 - 1117

MODEL 1116 / NATURAL GAS / 120 VAC / 60 HZ / 1 PHASE

MODEL 1117 / L.P GAS / 120 VAC / 60 HZ / 1 PHASE

POWER SUPPLY

CONTROL BOX AUTO When the temperature in the control box reaches 120°F ± COOL DOWN 3°(48.9°C

MAIN FAN CIRCUIT Power is permanently supplied to the normally open contacts of the oven fan relay,

BURNER CIRCUIT Closing the Burner Switch supplies 120 VAC thro ugh the 1 0 Amp Fu se, through

IGNITION CONTROL The Ignition Control operates on both 24 VAC and 120 VAC. When the control is

TEMPERATURE CONTROL When the Ce ntrifigual Switch of the Bu rner Blower Motor closes, power is applied

CONVEYOR DRIVE Closing the Fan S witch and the Conveyor Switch, supplies 120 VAC through 3

TIME/TEMP DISPLAY The secondary output of the Transformer, is supplied to terminals 1, 2, and 3 of the

Electrical power is supplied to the oven by a three conductor cord set. Voltage from

the bla ck conductor t o th e white conductor is 120 VAC. Th e white cond uctor i s

neutral. The green conductor is ground.

± 1.7°C), the Cooling Fan Thermostat will switch power to the Control Box Cooli ng

Fans. T he thermostat will interru pt p ower to the fans when t he control box

temperature falls to100°F ± 3° (37.8°C ± 1.7°C).

the normally open cooling fan thermostat, terminal #1 of the time delay relay and

the no rmally open main fa n switch. Closing the mai n fan switch enables the 20

minutes time delay relay. The time delay relay supplies 120 VAC to the coil of the

main fan rela y. These normally open contac ts now close energizing the main fan

motor and th e coolin g fan s. Cl osing th e fan switch also en ergizes the time/te mp

display, the heat and conveyor switches.

the Main F an Motor Centrifugal Switch, and oven cavity High Limit Thermostat to

terminal L1 of the Ignition Control. The Centrifugal Switch of the Main Fan Mo tor

closes when the fan motor reaches 1600 RPM. The High Limit Thermostat opens

at 662°F (350°C) and m ay be man ually reset after the se nsing b ulb tempe rature

drops 18°F(10°C).Power (120 VAC) i s also supplied to the Burner Blowe r Motor.

As this moto r rea ches a pproximately 1600 RPM, i ts Intern al Centrifugal Switch

closes, suppl ying 12 0 VA C th rough th e no rmally cl osed Control Box Hi gh Li mit

Thermostat, to the prima ry of the 24 VAC Tran sformer and t he Temp erature

Control. The Control Box High Limit Thermostat is manually re-settable and opens

when the co ntrol box re aches 17 0°F ± 5°(76°C ± 3° C). (Discontinue d at S/N

2011383)

energized by 24 VAC fro m the Tra nsformer, 120 V AC is switched by the Ign ition

Control to the Hot Surfac e Ignitor for 45 seconds for Hot Surface Ignitor warm up.

The Ig nitor g lows red, 24 VAC i s switched to the gas valve which op ens, and

ignition should now occur. If ignition do es not occur in 6 second s, the co ntrol will

lock out. To recycle after lock out, turn off the bu rner switch fo r 4 5 second s and

then turn the switch back on.

to the Temperature Control. The 2.5K ohm Temperature Pot is adjusted to desired

temperature. The Thermocouple will provide varying millivolts to the Tem perature

Controller. The Temperature Controller supplies 120 VAC to the Solenoid Valve at

intermittent intervals to maintain desired temperature.

Amp Fuse to L1and L2 of the Motor Control Board. AC volts are converted to DC

by the Control Board and are supplied to the Motor from Board terminals A+ and A. Adjustment of the Spe ed Cont rol Pot (5,000 o hm 10 turn pot) will ch ange

resistance at terminal s P1 , P2, and P3 varying S/N 2011 383 and above th e DC

voltage to th e motor. T he sp eed of t he Conveyor Motor Refer to page 26 will

increase o r d ecrease a s t he DC voltag e from the board i ncreases o r de creases

respectively. As the motor turns, it drives both the Reducer Ge ar Box and the

Tach. Generator. The Tach. Generator is a DC voltage Generator that sup plies a

voltage to the DC Motor Control Board and is used as a reference for maintaining a

constant conveyor speed.

Time/Temp. Display. The secondary output of Transformer is nominally 12.5 to 15

VAC with a cente r tap. The voltag e from cent er tap to ea ch leg i s 1/ 2 the

secondary voltage.

4

Impinger II –1100 Series Service Manual - Domestic

Page 5

S/N 2011383 and above The speed side of the Time/Temp. Display uses a sl otted disc Re fer to page 2 7

(cemented to tach. coupling) to b reak t he infra-re d light b eam of the optical

encoder (mounted on gear motor), producing electrical pulses that are transmitted

to the display. The displa y converts these p ulses into a read-out of minutes a nd

seconds.

The temp erature portion o f the Time/T emp Display uses a Thermistor P robe to

sense oven temperature. The thermistor This resistance is then converted by the

display into a temperature reading.

AUTOMATIC COOL DOWN When this oven is started, the time delay relay timing circuit is enabled, permitting

the oven fans to run for approximately 20 minutes after the oven is shutoff, to cool

the oven. The Time Delay Relay will keep the coil of the Main Fan Relay closed,

maintaining operation of main fan and Cooling Fan Motors.

Impinger II –1100 Series Service Manual - Domestic

5

Page 6

SEQUENCE OF OPERATIONS 1130 - 1133 & 1160 - 1163

MODEL 1130 / ELECTRIC / 120/208 VAC / 1 PHASE

MODEL 1131 / ELECTRIC / 120/240 VAC / 1 PHASE

MODEL 1132 / ELECTRIC / 120/208 VAC / 3 PHASE

MODEL 1133 / ELECTRIC / 120/240 VAC / 3 PHASE

MODEL 1160 / ELECTRIC / 120/208 VAC / 1 PHASE

MODEL 1161 / ELECTRIC / 120/240 VAC / 1 PHASE

MODEL 1162 / ELECTRIC / 120/208 VAC / 3 PHASE

MODEL 1163 / ELECTRIC / 120/240 VAC / 3 PHASE

POWER SUPPLY Electrical Power to be supplied to the oven by a four conductor service on

single phase and a five conductor service on three phase.

Voltage from the black conductor to the white conductor is 120 VAC.

Black conductor is Hot.

Red conductor is Hot.

Orange conductor is Hot. (Used on 3Ø only)

White conductor is dedicated neutral.

Green conductor is ground.

NOTE: A 20 Amp Receptacle, NEMA STYLE L6-20, is provided on Models

1160, 1161, 1162, and 1163 for accessory plug in. Rated at 208 or 240 VAC.

CONTROL BOX AUTO COOL

DOWN

MAIN FAN CIRCUIT Electrical power is permanently supplied through a 10 amp fuse to terminal 1 of

HEATER CIRCUIT Closing the Heat Switch supplies 120 V AC through the normally open Air

TEMPERATURE CONTROL Closing the Heat Switch supplies 120 VAC to the Electronic Temperature

CONVEYOR DRIVE

(S/N 2011383 and above

Models 1130 through 1133).

S/N 2011978 and above

Models 1160 through 1163

Refer to Page 26)

TIME/TEMP DISPLAY The secondary output of the Transformer, is supplied to terminals 1, 2, and 3

6

When the temperature in the control box reaches 120°F ±3°F(48.9°F ± 1.7°C),

the Cooling Fan Thermostat will switch power to the Cooling Fans. The

thermostat will interrupt power to the fans when the temperature falls to 100°F

± 3°F(37°C ± 1.7°C).

the 20 Minute Timer, through the normally closed Hi Limit Thermostat to the fan

switch. Closing fan switch energizes the coil of the oven start relay, its contacts

close enabling the 20 minute time delay module. The 20 minute time delay

module supplies 120 VAC to the oven fan relay, these normally open contacts

now close supplying 208/240 VAC to the main fan motor. The cooling fans are

also energized. Closing the fan switch also supplies 120 VAC to the Heater

Switch/Conveyor Switch, and the display Transformer.

Pressure Switch (closed by air pressure from the Main Fan), the 3 Amp Fuse, to

L1 terminal of the Temperature Control Board, and the Heat Indicator Light.

Control. The 2.5K ohm Potentiometer is adjusted to achieve the desired

temperature. The Thermocouple will provide varying millivolts to the

Temperature Control. The temperature control board then supplies 120 VAC to

the coil of the Contactor at intermittent intervals to maintain the desired

temperature.

Closing the Conveyor Switch supplies 120 VAC to the DC Motor Control Board

at terminals L1 and L2. AC volts are converted to DC volts and are supplied to

the Conveyor Motor at terminals A+ and A-. Adjustment of the Speed Control

Potentiometer (5,000 ohm, 10 turn) will change resistance at terminals P1, P2,

and P3 (varying the DC voltage to the Conveyor Motor. The through speed of

the conveyor motor will increase or decrease as the DC voltage from the board

increases or decreases respectively. As the motor turns, it drives both the

reducer gear box and the tach. generator. The tach. Generator is a DC voltage

generator which supplies a voltage to the DC Motor Control Board and is used

as a reference for maintaining a constant conveyor speed.

of the Time/Temp. Display. The secondary output of Transformer is nominally

12.5 to 15 VAC with a center tap. The voltage from center tap to each leg is

1/2 the secondary voltage. The speed side of the Time/Temp. Display uses a

slotted disc (S/N 2011383 and above on (cemented to tach. coupling) to

break the infra-red light beam Models 1130 through 1133 of the optical

encoder (mounted on gear motor), producing electrical pulses that are

Impinger II –1100 Series Service Manual - Domestic

Page 7

transmitted to the display. The display converts these pulses into a read-out

of minutes and seconds. The temperature portion of the Time/Temp Display

uses a thermistor probe to sense oven temperature. The thermistor outputs a

resistance proportional to the oven temperature. This resistance is then

converted by the display into a temperature reading.

AUTOMATIC COOL DOWN When this oven is started, the time delay relay timing circuit is enabled,

permitting the oven fans to run for approximately 20 minutes after the oven is

shut off, to cool the oven. The Time Delay Relay will keep the coil of Relay

closed, maintaining operation of main fan and Cooling Fan Motors.

Impinger II –1100 Series Service Manual - Domestic

7

Page 8

SCHEMATIC 1100 – 1101

8

Impinger II –1100 Series Service Manual - Domestic

Page 9

SCHEMATIC 1102-1103

Impinger II –1100 Series Service Manual - Domestic

9

Page 10

SCHEMATIC 1116 – 1117 S/N 2011383 & BELOW

10

Impinger II –1100 Series Service Manual - Domestic

Page 11

SCHEMATIC 1116 – 1117 S/N 2011384 & ABOVE

Impinger II –1100 Series Service Manual - Domestic

11

Page 12

SCHEMATIC 1130 – 1131 S/N 2011383 & BELOW & 1160 – 1161 S/N 2011978 & BELOW

12

Impinger II –1100 Series Service Manual - Domestic

Page 13

SCHEMATIC 1130 – 1131 S/N 2011384 & ABOVE

Impinger II –1100 Series Service Manual - Domestic

13

Page 14

SCHEMATIC 1160 – 1161 S/N 2011978 & ABOVE

14

Impinger II –1100 Series Service Manual - Domestic

Page 15

SCHEMATIC 1132 – 1133 S/N 2011383 & BELOW & 1162 – 1163 S/N 2011979 & BELOW

Impinger II –1100 Series Service Manual - Domestic

15

Page 16

SCHEMATIC 1132 – 1133 S/N 2011384 & ABOVE

16

Impinger II –1100 Series Service Manual - Domestic

Page 17

SCHEMATIC 1162 – 1163 S/N 2011978 & ABOVE

Impinger II –1100 Series Service Manual - Domestic

17

Page 18

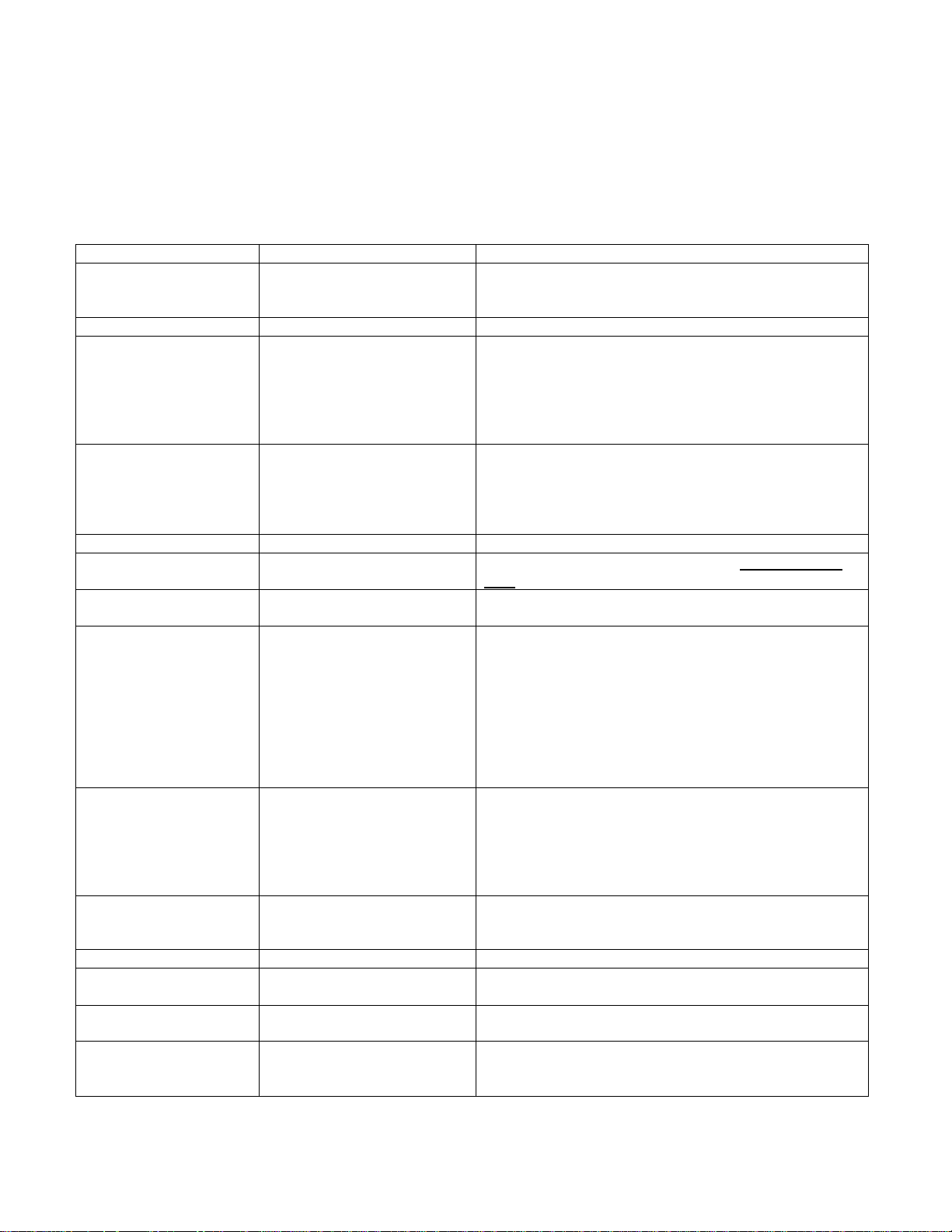

TROUBLESHOOTING GUIDE 1116 - 1117

n

r

r

GAS OVENS

MODEL 1116 / NATURAL GAS / 120VAC / 60 HZ / 1 PHASE

MODEL 1117 / L.P. GAS / 120VAC / 60 HZ / 1 PHASE

REFER TO PROPER SCHEMATIC FOR IDENTIFIED COMPONENTS

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run Incoming Power Supply Check breakers/Reset if required Check power plug to

be sure it is firmly in receptacle. Measure incoming

power/call Power Co. if needed.

No main fan cool down

Main fan runs after 20

minute cool down

20 minute cool down

Time Delay Relay 120 VAC at terminal 2 should discontinue

No control box cooling Incoming Power Check main circuit breakers, reset if required, call powe

Main Fan Switch Check continuity between switch terminals.

20 Minute Time Delay With fan switch on, check for 120 VAC at terminal 2 of

Main Fan Relay Check continuity of 120 VAC coil. Check for power to

Cooling Fans 120 VAC should now be at the fan motors. If voltage is

Main Fan Switch Check continuity between switch terminal.

20 Minute Time Delay Check for 120 VAC at terminal #1 to neutral on 20

minute Time Delay Relay. If no voltage is present,

trace wiring back to power source. If voltage is present

at terminal #1, check for 120 VAC at terminal #2 to

neutral. If no voltage is present, and Main Fan Switch

is closed, replace Time Delay

Main Fan Relay Check for 120 VAC to coil of the Relay, if no voltage

is present, trace wiring back to 20 minute Time

Delay Relay. If voltage is present, check to insure

contacts are closing.Fuse, 10 Amp Check, replace if

necessary

Fuse Holder Check, replace if necessary.

Main Fan Motor Check for opens, shorts, or grounds. WITH POWER

: turn fan blade to check for locked rotor.

OFF

Capacitor Check for shorts or grounds. WARNING: Capacitor

has a stored charge, discharge before testing.

20 Minute Time Delay Relay

Main Fan Relay

Check for 120 VAC at pin #2 and #3 while main fan is

running. Turn off main fan switch and 120 VAC should

continue to be present for 20 minutes at terminal 2.

Check if relay is operating and terminals are remaining

closed for main fan cool down of 20 minutes

NOTE: The time delay relay will keep the coil of main fa

closed, maintaining main fan operation for cool down fo

approximately 20 minutes.

approximately 20 minutes after the main fan switch is

switched off. If the switch is open and voltage

continues at terminal 2, replace Time Delay. When

voltage at terminal 2 of Time Delay ceases ,the main

fan relay must open.

company if needed.

Time Delay.

the relay coil (120 VAC).

present, check motors for shorts or opens WITH

POWER OFF: Check for locked rotor.

18

Impinger II –1100 Series Service Manual - Domestic

Page 19

d

Cooling fans continue to

run after 20 minute cool

Cooling Fan Thermostat Thermostat should close at 120°F± 5°F and open at

100°F± 5°F.

Main Fan Relay Check to insure that contacts of main fan relay are

opening after 20 minute cool down

Oven will not heat Gas Supply Check for adequate gas supply and manual gas shut

off valve is open. Also, check flexible gas line

connection.

Main Fan If not operating, refer to "Oven fan will not run".

Heat Switch Check for continuity, replace if necessary

Fuse 10 amp Replace if necessary.

Fuseholder Replace if necessary

Centrifigual Switch of Main

Fan Motor

Check for 120 VAC at lead #47 (located at 6 pin

connector in raceway near the main fan motor) to

neutral. If no voltage is present, and motor is running,

replace motor.

(Oven Cavity) High Limit Terminals are normally closed, opens at Thermostat

660°F (350°C). If open, push in reset button and

retest. If thermostat will not hold for maximum oven

temperature, and oven is not exceeding temperature

dial setting, check for proper location of capillary bulb

in its spring holder. If above checks okay, replace hi-

limit thermostat.

Burner Blower Motor Visually check to see if motor is running. If not, check

for 120 VAC to motor at motor connector (wire #40

and #41). If voltage is not present, trace wiring back

to oven cavity High Limit. If voltage is present and

motor is not running, check for opens, shorts, or

grounds. Also, WITH POWER OFF: check for locked

rotor.

Control Box High Limit

thermostat

NOTE: Discontinued S/N

Terminals are normally closed, and open at 170°F ±

5°F (76.6°C ± 2.8°C). Check for proper operation. If it

will not reset and hold, replace thermostat.

2011383

Centrifigual Switch of Burner

Blower Motor

Check for 120 VAC at motor connector wire #42 to

neutral. If voltage is not present, trace wiring back to

control box High Limit . If voltage is present, check #43

to neutral. If voltage is not present and motor is

running, replace the Burner Blower Motor.

Burner Transformer Primary is 120 VAC with 24 VAC secondary. If 120

VAC is not present, trace wiring back to Burner Blower

Centrifugal Switch. If 120 VAC is present, check for 24

VAC at secondary of transformer. If no voltage is

present, replace transformer.

Ignition Control Note: The ignition control contains a safety lock-out

circuit. If a flame is not detected within 6 seconds after

the gas control valve is energized, the ignition control

will lock-out. To reset, turn the burner switch "off", wait

45 seconds and switch the burner system "on" to retry

ignition. 24 volts should be present at 24 volt terminals.

If not present, trace wiring back to burner transformer.

When 24 VAC is supplied, the control switches 120

VAC from L1 and L2 to the Hot Surface Ignitor. If 120

VAC is not present at L1 and L2, trace wiring back to

oven cavity High Limit Thermostat. If 24 VAC and 120

VAC are present and 120 VAC is not across the Hot

Surface Igniter terminals, replace the ignition control

Impinger II –1100 Series Service Manual - Domestic

19

Page 20

Hot Surface Igniter If 120 VAC is present at Hot Surface Igniter terminals,

visually check to see that the igniter is heating. (Igniter

may be viewed through the port glass in end of the

burner tube.) The Igniter should glow bright red. If the

igniter does not heat, replace the Igniter.

Ignition Control After 45 seconds of hot surface igniter pre-heat, the

ignition control will switch 24 VAC to the gas control

valves. Check for 24 VAC output from ignition control,

across terminals marked "valve" and "valve ground". If

no voltage is present, replace ignition control

Gas Control Valves When 24 VAC is supplied to the gas control valve, the

valves should open Check for gas pressure at the

manifold tap located just before the burner. If there is no

pressure, check the incoming gas supply to be sure all

manual valves are open and flexible gas hose is

properly connected. If gas is present at the oven and

coils of gas valve are energized, the gas valve is

defective. When 24 VAC is supplied to the gas control

valve the red burner indicator.

Flame will not stay lit Hot Surface Igniter/ Flame

Sensor

Six seconds after the gas valve opens, ignition must

occur. If flame is not detected, the ignition control will

shutoff and lock out. To reset the ignition control, turn off

the burner switch for 45 seconds then turn on the burner

switch to retry ignition. The ignition control requires a

minimum of 0.8 D.C. microamps To check flame

sensing operation, connect a digital multimeter (capable

of measuring D.C. micro-amps) between the "ground"

terminal on ignition control and the ground lead.

NOTE: This is a current measurement and the meter

must be connected in series. If these readings are not

achieved, check bypass orifice for obstructions. If

bypass orifice is clear, replace the hot surface

igniter/flame sensor.

NOTE: The D.C. micro amp test must be conducted

with the oven in low flame (bypass) operation. Turn the

temperature control to the lowest setting.

Power Supply If there is sufficient micro-amp current, but the flame will

not stay lit, check for proper polarity of the 120 VAC

power supply.

Ignition Control If there is sufficient micro-amp current, and the 120 VAC

polarity is correct, but the flame will not stay lit, replace

ignition control.

NOTE: check for proper ground connection on ignition

control.

Low flame is on, but no

main flame

NOTE: flame should be

present at this time

Check for 120 VAC at terminal #11 to neutral on

temperature control. If no voltage, trace voltage back to

Centrifugal Switch.

Tempe rature Control Turn the temperature adjustment knob to maximum

temperature position and check for 120 VAC at the load

terminal (#9) and neutral. If 120 VAC is present and unit

is not heating, refer to "Temperature Solenoid Valve" for

next check. If 120 VAC is not present, proceed.

20

Impinger II –1100 Series Service Manual - Domestic

Page 21

Thermocouple Probe WITH POWER ON AND THERMOCOUPLE LEADS

ATTACHED TO THE TEMPERATURE CONTROL

BOARD: Measure the D. C. millivolt output of these

leads. Refer to thermocouple chart on page 36 for

proper readings. If these readings are not achieved,

replace the thermocouple

Tempe rature Control

Potentiometer

WITH POWER OFF: remove the potentiometer leads

from the temperature control board and measure ohms

from black to white leads. The reading should be from

approximately 0 to 2.5 K ohms as the dial of the

potentiometer is turned throughout its full rotation.

From black to red leads, the reading should be

approximately 2.5 K ohms (constant) throughout the full

rotation of the dial. If these readings are not achieved,

replace potentiometer. If the thermocouple probe and

the control potentiometer check good, then the problem

is usually with the temperature control board.

Temperature Solenoid If 120 VAC is present on the Valve temperature control

board at load terminal (#9) to neutral, check for voltage

at temperature regulation valve. If voltage is present,

listen for valve to open and close. Also check for opens

or shorts in the coil. Replace as necessary.

Intermittent Heating Thermal/Overload of Main

Fan and Burner Blower

Motors

.

Conveyor will not run REFER TO PAGE 26

From S/N 2011383 and up REFER TO PAGE 29

Conveyor speed varying or intermittent REFER TO PAGE 26

From S/N 2011383 and up REFER TO PAGE 29

Time/Temp Display inoperative REFER TO PAGE 27

From S/N 2011383 and up REFER TO PAGE 29

Temp Display out or erratic REFER TO PAGE 27

From S/N 2011383 and up REFER TO PAGE 29

Impinger II –1100 Series Service Manual - Domestic

21

Page 22

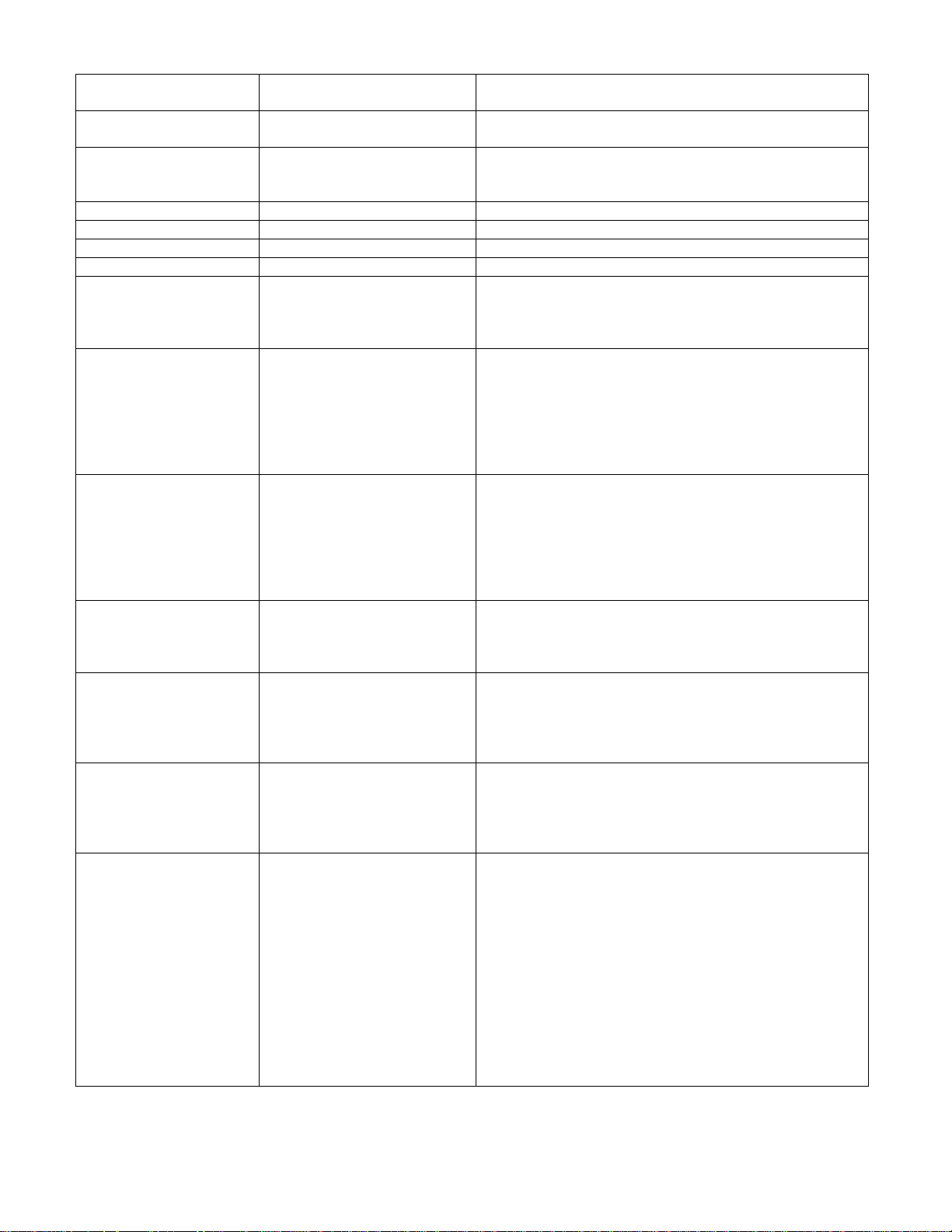

TROUBLESHOOTING GUIDE 1100 THRU 1103

t

f

t

T

t

W

A

T

f

T

t

V

T

W

A

t

ELECTRIC OVENS

MODEL 1100 / 120/208 VAC / SINGLE PHASE / 60 HZ

MODEL 1101 / 120/240 VAC / SINGLE PHASE / 60 HZ

MODEL 1102 / 120/208 VAC / THREE PHASE / 60 HZ

MODEL 1103 / 120/240 VAC / THREE PHASE / 60 HZ

REFER TO PROPER SCHEMATIC FOR IDENTIFIED COMPONENTS

SYMPTON POSSIBLE CAUSE EVALUATION

Oven fan will not run Incoming Power Supply Check circuit breakers. Reset if required. Call Power Co.

needed.

Fuses, 10 Amp, Check, replace if necessary

Fuseholder Check, replace if necessary

Switch, Main Fan Check for continuity between switch terminals.

Main Fan Relay Check continuity of 120 VAC coil. Check for power to

relay coil (120 VAC). Check for 208/240 VAC to the relay

erminals

Main Fan Motor Check for opens, shorts, or grounds. WITH POWER

OFF: Turn fan blade to check for locked rotor

Capacitor Check for opens, shorts, or grounds.

No control box cooling Check for main fan operation. If not operating, refer to

"Oven fan will not run". Cooling Fan Motor 120 VAC

should be present at the fan motor. If voltage is present,

check for opens or shorts. .WITH POWER OFF: Check

or locked rotor of the fan motor.

No main fan cool down Cool Down Thermostat Check cool down thermostat (thermostat closes at 160°F

and opens at 140°F). Check for power (120 VAC) at cool

down thermostat. With cool down thermostat preheated,

check for continuity. If switch is open, replace.

Oven will not heat Main Fan Motor Check for main fan operation. If it is not operating, refer

o "Oven fan will not run".

High Limit Thermostat, Oven

Cavity

Switc h, Heat

Fuse, 3 Amp Check, replace if necessary.

Fuseholder Check, replace if necessary

ir Pressure Switch

emperature Control Check for 120 VAC supply at terminal #11 to neutral on

hermocouple Probe

erminals are normally closed. If open, reset the

hermostat and test for proper operation. If it will not

reset and hold, then replace.

ith switch on, check for 120 VAC on both terminals to

neutral. Replace if defective

his normally open switch should close when the main

an is activated. If adjustment is necessary (Refer to

Section D). Replace if defective.

emperature control. If no voltage is present, trace wiring

back to 3 amp fuse. Turn the temperature adjustment

knob to maximum temperature position and check for

120 VAC at the load terminal (#9) and neutral. If 120

AC is present and unit is not heating, refer to "Mercury

Contactor" for next check. If 120 VAC is not present,

proceed.

ITH POWER ON AND THERMOCOUPLE LEADS

TTACHED TO THE TEMPERATURE CONTROL

BOARD: measure D. C. millivolt output of these leads.

Refer to thermocouple chart on page 36 for proper

readings. If these readings are not achieved, replace

hermocouple.

22

Impinger II –1100 Series Service Manual - Domestic

Page 23

T

W

f

f

w

v

T

t

T

T

emperature Control

Potentiometer

ITH POWER OFF: remove the potentiometer leads

rom the temperature control board and measure ohms

rom black to white leads. The reading should be from

approximately 0 to 2.5k ohms as the dial of the

potentiometer is turned throughout its full rotation. From

black to red leads, the reading should be approximately

2.5k ohms (constant) throughout the full rotation of the

dial. If these readings are not achieved, replace

potentiometer. If the thermocouple probe and the control

potentiometer checks good, then the problem is usually

ith the temperature control board.

Mercury Contactor Check for 120 VAC to the contactor coil. If voltage is

present and contact will not activate, replace the

contactor. Also, check each contactor for proper high

oltage input and output

Heater Elements Check the Amp. draw on each leg for proper load.

Check the specification plate for rating information. If

the Amp. draw is low or high, check the individual

elements for opens, shorts, and proper resistance.

WITH POWER OFF: check resistance of the elements,

remove all leads from the elements and use an

accurate digital VOM. The element resistance should

be as follows: 208V - 27 ohms approximately, 240V -

36 ohms approximately.

Oven heats with switch

off

Mercury Contactor

he mercury contactor has probably malfunctioned in

he closed position. If there is no voltage to the

operating coil, but there is high voltage at the contactor

output, replace the mercury contactor.

Intermittent Heating

hermal/Overload of motor

he main fan motor is equipped with internal thermal

protection and will cease to operate if overheating

occurs. As the motor overheats and then cools, this will

cause the ovens to cycle on and off intermittently. This

may be caused by improper ventilation or preventative

maintenance. Also, most of the problems listed under

"Oven will not heat" can cause intermittent failure.

Conveyor will not run / REFER TO PAGE 26

Conveyor speed varying / REFER TO PAGE 26

or intermittent

Time/Temp Display / REFER TO PAGE 27

inoperative

Temp Display out or / REFER TO PAGE 27

inaccurate

Impinger II –1100 Series Service Manual - Domestic

23

Page 24

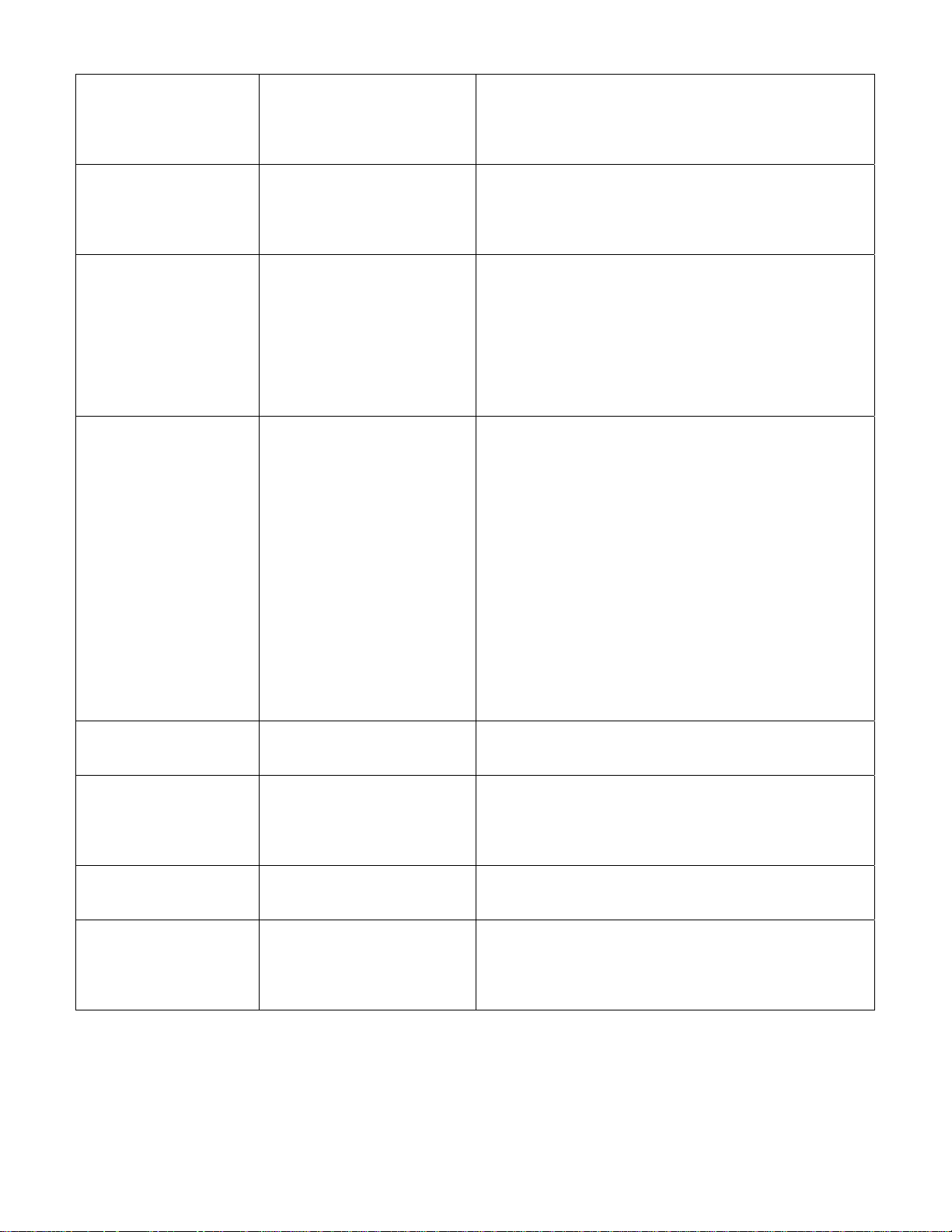

TROUBLESHOOTING GUIDE 1130 THRU 1133 / 1160 THRU 1163

ELECTRIC OVENS

MODEL 1130, 1160 / 120/208 VAC / SINGLE PHASE / 60 HZ

MODEL 1131, 1161 / 120/240 VAC / SINGLE PHASE / 60 HZ

MODEL 1132, 1162 / 120/208 VAC / THREE PHASE / 60 HZ

MODEL 1133, 1163 / 120/240 VAC / THREE PHASE / 60 HZ

REFER TO PROPER SCHEMATIC FOR INDENTIFIED COMPONENTS

SYMPTON POSSIBLE CAUSE EVALUATION

Oven fan will not run Incoming Power Supply Check circuit breakers. Reset if required. Call Power

Co. if needed.

NOTE: On Models 1160, 1161, 1162 and 1163,

disconnect any accessory from receptacle in the rear

of the oven and check for shorts or overloads.

Fuses, 10 Amp, Check, replace if necessary

Fuseholder Check, replace if necessary

High Limit Thermostat, Oven

Cavity

Switch, Main Fan Check for continuity between switch terminals.

Relay, Oven Start Check for continuity at relay coil, and visually check

20 Minute Time Delay Check for 120 VAC at terminal #1 to neutral on 20

Main Fan Relay Check for 120 VAC to coil of the Relay. If no voltage is

Main Fan Motor Check for opens, shorts, or grounds. WITH POWER

Capacitor Check for opens, shorts, or grounds

No main fan cool down 20 Minute Time Delay Check for 120 VAC at terminal #2 to neutral while

Oven Fan Relay Check if relay is operating and that the contacts

Main fan runs after 20

minute cool down

20 Minute Time Delay 120 VAC at terminal #2 should discontinue

Oven Fan Relay Check to insure that the contacts are opening after the

20 Minute Time Delay NOTE: ON/OFF operation of the fan switch will set the

Oven Start Relay Contacts should open when main fan switch is turned

Terminals are normally closed. If open, reset the

thermostat and test for proper operation. If it will not

reset and hold, replace thermostat.

for pull in of contacts.

minute Time Delay Relay. If no voltage is present,

trace wiring back to 10A fuse. If voltage is present

at terminal #1, check for 120 VAC at terminal #2 to

neutral. If no voltage is present, and oven start relay is

closed, replace Time Delay.

present, trace wiring back to 20 minute Time Delay

Relay. If voltage is present, check to insure contacts

are closing.

OFF: Turn fan blade to check for locked rotor.

oven is "on". Turn off the main fan switch, 120 VAC

should continue to be present for 20 minutes. If

voltage is not present for approx. 20 minutes, replace

the timer.

remain closed during the 20 minute cool down.

off.

approximately 20 minutes after main fan is switched

off. If the oven start relay contacts are open, and the

voltage continues at terminal #2 of the 20 minute

timer, for more than 20 minutes, replace the timer.

coil is de-energized

timer to 20 minutes. If the timer is accidentally reset,

turn off main breaker for 15 seconds to cancel

24

Impinger II –1100 Series Service Manual - Domestic

Page 25

No control box cooling Check for main fan operation. If not operating, refer to

"Oven Fan Will Not Run".

Oven Start Relay Check relay contacts. 120 VAC should be present.

Cooling Fan Motor(s) 120 VAC should be present at the fan motor. If voltage

is present, check for opens or shorts. WITH POWER

OFF: Check for locked rotor of the fan motor.

No automatic control Thermostat, Cooling Check the cooling fan thermostat. box cooling Fan

(Thermostat closes at 120°F and opens at 100°F.).

With the cooling fan thermostat pre-heated, check for

continuity. If switch is open, replace.

Cooling Fan Motor(s) 120 VAC should be present at the fan motor. If voltage

is present, check for opens or shorts. WITH POWER

OFF: check for locked rotor of the fan motor.

Control box cooling fan

continues to run

Thermostat, Cooling Fan This normally open thermostat should close at 120°F

(48.9°C) and reopen at 100°F (37.8°C).

Oven will not heat Main Fan Motor Check for main fan operation. If it is not operating,

refer to "Oven fan will not run".

Heat Switch With switch on, check for 120 VAC on both terminals

to neutral. Replace if defective.

Air Pressure Switch This normally open switch should close when the main

fan is activated. Adjust if necessary (Refer to page

23). Replace if defective.

Fuse, 3 Amp Check, replace if necessary

Fuseholder Check, replace if necessary

Temperature Control Check for 120 VAC supply at terminal #11 to neutral

on temperature control. If no voltage is present, trace

wiring back to 3-amp fuse. Turn the temperature

adjustment knob to maximum temperature position

and check for 120 VAC at the load terminal (#9) and

neutral. If 120 VAC is present and unit is not heating,

refer to "Mercury Contactor" for next check. If 120

VAC is not present, proceed.

Thermocouple Probe WITH POWER ON AND THERMOCOUPLE LEADS

ATTACHED TO THE TEMPERATURE CONTROL

BOARD: measure D. C. millivolt output of these leads.

Refer to thermocouple chart on page 36 for proper

readings. If these readings are not achieved, replace

thermocouple.

Tempe rature Control

Potentiometer

WITH POWER OFF: remove the potentiometer leads

from the temperature control board and measure

ohms from black to white leads. The reading should

be from approximately 0 to 2.5k ohms as the dial of

the potentiometer is turned throughout its full rotation.

From black to red leads, the reading should be

approximately 2.5k ohms (constant) throughout the full

rotation of the dial. If these readings are not achieved,

replace the potentiometer. If the thermocouple probe

and the control potentiometer check good, then the

problem is usually with the temperature control board.

Mercury Contactor Check for 120 VAC to the contactor coil. If voltage is

present and the contactor will not activate, replace the

contactor. Also, check each contactor for proper high

voltage input and output.

Heater Elements Check the Amp. draw on each hot leg for proper load.

Check the specifications plate for rating information. If

the Amp. draw is low or high, check the individual

elements for opens, shorts, and proper resistance.

WITH POWER OFF: To check resistance of the

elements, remove all leads from the elements and use

an accurate digital VOM. The element resistance

should be as follows: 208V - 27 ohms approximately

Impinger II –1100 Series Service Manual - Domestic

25

Page 26

240V - 36 ohms approximately.

Oven heats with switch

off

Mercury Contactor The mercury contactor has probably malfunctioned in

the closed position. If there is no voltage to the

operating coil, but there is high voltage at the

contactor output, replace the mercury contactor.

Intermittent Heating Thermal/Overload of Motor The main fan motor is equipped with internal thermal

protection and will cease to operate if overheating

occurs. As the motor overheats and then cools, this

will cause the units to cycle on and off intermittently.

This may be caused by improper ventilation or

preventative maintenance. Also, most of the problems

listed under "Oven will not heat" can cause intermittent

failure.

Conveyor Will Not Run Conveyor Switch Check for continuity between switch terminals

3 Amp Fuse Check, replace as needed

Fuseholder Check, replace as needed

S/N 2011383 and

above 1130 through

1133 – S/N 2011978

and above Models

1160 through 1163

Refer to Page 29

Speed Adjustment

Potentiometer

This is a 0 to 5 K ohm, 10 turn potentiometer. WITH

POWER OFF: Remove the red, black and white pot

leads from the motor control board at terminals P1, P2

and P3. With a digital multimeter, check the ohm

reading across the red lead (P3) to the black lead

(P1). This reading should be 5 K ohms ± 5% as the

pot is rotated from low to high. Place the meter leads

on the red lead (P3) and on the white lead (P2)

Rotating the pot. slowly, from low to high, the meter

reading should show an even transition from 0 to 5 K

ohms ± 5%. There should be no dead or open spots

through out the 10 turns of the pot. Check all three

leads to ground. There should be no continuity to

ground. If any of the above checks fail, replace the

pot.

DC Motor Control Board Check for 120 VAC input to the control board at

terminals L1 and L2. If not present, check the

conveyor switch and wiring back to 3 amp fuse and

then back to power source if necessary. If 120 VAC is

present at L1 and L2, check the VDC output at

terminals A+ and A-. If a DC voltage is not present,

check the 4 amp and the 1 amp fuses on thecontrol

board. If 120 VAC is present at terminals L1 and L2,

but DC Voltage is not present at A+ and A-, providing

the fuses are good, replace the board. If DC voltage

is present at A+ and A-, but motor does not run, check

gear motor as follows.

Conveyor Gear Motor If DC voltage is present at A+ and A-and the motor

does not run, first check the mini breaker and then the

conveyor. As described below under "conveyor."

WITH POWER OFF: Check the leads to the motor for

evidence of any shorts or opens, and each lead to

ground. Remove dust cover from the top of the motor

and rotate motor shaft to determine if there is a locked

rotor or a locked gear box (use care so encoder disc is

not damaged). If the motor fails the above tests,

replace motor.

Conveyor Check for any mechanical misalignment or improper

adjustment. Also check for worn bearings. The

Installation and Operations Manual shows proper

conveyor belt position. A conveyor belt that is too tight

will contribute to excessive load, bearing wear, and

wearing of slider bed rods.

Conveyor speed

varying or intermittent

Power Supply Check power supply at the DC control board for the

120 VAC at board terminals L1 and L2. If voltage is

not present and steady, check the main circuit

26

Impinger II –1100 Series Service Manual - Domestic

Page 27

breakers and call power company if necessary.

S/N 21011383 and

above Models 1130

through 1133 –

2011978 and above

Models 1160 through

1163 – Refer to page

29

Tach. generator and DC

Motor Control Board

WITH POWER OFF: Remove the leads from terminals

T1 and T2. Place the test leads of a digital test meter

on the tach. leads, turn power on, and the meter

reading should be approximately 20 to 25 VDC. This

reading is normally steady within ± 0.2 to 0.3 VDC. If

this reading is not within required VDC, place the test

meter probes on terminals A+ and A-. The meter

reading should be approximately 150 to 160 VDC and

steady within approximately 4 to 5 VDC. If the tach.

voltage is unsteady, and the board output is steady,

check the coupling for loose set screws or any type of

damage. If the coupling checks good, the tach. is

usually bad. If the board voltage output is unsteady

beyond limits, then the board is probably bad. Always

check the speed pot. Be sure it is okay before

changing a board or tach. This test is not always

100% accurate as this test is not performed at

operating speeds. However, this test is the best

method currently available. Readjustment should

always be attempted at least once before

replacement. See procedure for board adjustment on

page 41.

DC Gearmotor If the problem seems to be the motor or gearbox.

Check the brushes in the motor for excessive arching

and/or unusual wear. Check the motor and gearbox

from instruction located on page 26 under "possible

cause" listing "Conveyor gear motor".

Time/Temp Display

inoperative S/N

2011383 and above

Models 1130 through

1133 Refer to Page 29

12.6 VAC Power Supply Measure the transformer primary for a nominal 120

VAC input. Measure the secondary voltage output

which will be 12.5 to 15 VAC normally. Recheck

secondary output at rear of Time/Temp Display.

Terminals 1 to 3 should read 12.5 to 15 VAC.

Terminals 1 to 2 and 2 to 3 should be 1/2 of the

reading across 1 to 3. If you do not get the above

secondary readings, replace the transformer. If 120

VAC primary voltage is not available, refer to the

schematic and trace circuit for incoming power failure.

The older units have a 4 amp ambient fuse in each red

secondary lead. These may be jumpered to

determine if they are burnt out or intermittent.

Temp Display out or

inaccurate

NOTE: Time/Temp displays

use two types of temperature

sensors thermistor probe-2

yellow wires, thermocouple

Insert the thermocouple of your pyrometer into a finger

hole in the top center of the oven. Be sure the tip of

the thermocouple is not touching metal. The

pyrometer will indicate oven temperature.

probe-1 red wire and 1 white

wire

From S/N 2011383

and up Models 1130

through 1133 S/N

2011978 and up

Models1160

through1163 Refer to

Page 29

Thermistor Probe Disconnect the yellow tipped thermistor leads from the

time/temp. terminals 9 and 10. Measure the resistance

of the thermistor probe and temperature of oven. See

the chart on page 44 for proper resistance readings.

Inspect the thermistor bulb for its proper location in its

spring holder. Check for short in leads where they

enter the sensor bulb. Also check each thermistor lead

for short to ground.

Impinger II –1100 Series Service Manual - Domestic

27

Page 28

Thermocouple Probe Place your pyrometer thermocouple into the center of

top finger. Connect temperature meter to

thermocouple at terminals 9 & 10 on back of the

time/temp display. (Be sure to maintain proper

polarity on thermocouple connections.) Compare

actual oven temperature with the reading at the

time/temp display. If the temperature readings match,

re-calibrate or replace time/temp display. If the

readings do not match, replace thermocouple probe.

Erratic time/temp dispaly If strange or unusual behavior is experienced such as

a rolling of numbers, or lock up at a given number, first

check for a display circuit lock up. This can be caused

by a voltage spike or surge in the incoming power

lines. To eliminate this condition remove power from

the time/temp. display by shutting off the main fan

switch for 15 seconds, or if display stays on, (older

models) circuit breaker interruption may be required.

This should eliminate the problem. If the problem

continues, jumper the two fuses in the red wires

leading from the 12.6 VAC transformer to the display

on older units. If this does not solve the problem, it

may be coming in through the commercial power lines.

Suggest that customer contact his power company for

evaluation.

Temp Display inaccurate,

erratic or inoperative

Perform the power supply check, the thermistor probe

check, and then perform the time/temp simulator test.

Refer to Removal, Installation, and Adjustment section

for instructions (see page 42). Remember, when using

the time/temp simulator, remove all the leads from the

back of the display except the 3 power leads. After

completion of this test and if reinstalling display back

into the oven, the dip switches must be reset for oven

operation.

Time Display inaccurate,

erratic

Perform all checks as in the above evaluation. If the

time check is okay, or inoperative refer to the next

section, optical encoder.

Optical Encoder The above time/temp test should have already been

performed. Remove dust cover from the gear motor

and inspect the coupling and encoder disc. The

coupling set screws should be tight and not slipping on

the motor shaft or the tach. generator shaft. The

encoder disc should be firmly attached to the coupling

and not warped. Check the positioning of the optical

encoder disc. The disc should not be touching the

optical encoder assembly and the encoder assembly

should be mounted so it is squarely facing the

coupling shaft. This is to allow the infrared light

beams to be broken by the encoder disc. If all this is

okay, then replace the optical encoder assembly.

28

Impinger II –1100 Series Service Manual - Domestic

Page 29

STEPPER MOTOR DRIVE

Conveyor will not run Conveyor Switch Check for 120 VAC to conveyor switch. If no voltage is

present, trace wiring back to the oven power source.

WITH POWER OFF: Check continuity between switch

terminals.

Conveyor Fuse 3AMP Check, replace if necessary. (Not used on Model 1151)

Fuse holder Conveyor Control

(Stepper) Transformer

Check, replace if necessary. Check for 120 VAC supply

to primary of transformer, if voltage is not present, trace

wiring back to the fuseholder. If voltage is present,

check for output voltage from the transformer

secondary. NOTE: This control transformer outputs (2)

secondary voltages. Red Leads 29 VAC Brown Leads

10 VAC If BOTH secondary voltages are not present,

replace the transformer.

Speed Adjustment

Potentiometer

This is a 0 to 50k ohm, 10 turn potentiometer. WITH

POWER OFF: remove the 3 pin potentiometer cable

plug from the motor control board. With a digital

multimeter, check the ohm reading across the red lead

to the black lead, this reading should be 50k ohms ± 5%

as the potentiometer is rotated through its 10 turn

rotation. Place the meter leads on the red lead and

white lead. Rotating the potentiometer slowly, from low

to high, the meter should show an even transition from 0

to 50k ohms ± 5% through the 10 turn rotation of the

potentiometer. There should be no dead or open spots

through the 10 turns of the potentiometer. Check all

three leads to ground. There should be no continuity to

ground. If any of the above checks fail, replace the

potentiometer.

Conveyor Motor (Stepper)

Control

NOTE: if the conveyor drive motor becomes jammed,

the motor will stop turning. To reset, turn off conveyor

switch, wait 10 seconds and turn the conveyor switch

on. If the motor does not run, check for 2 to 29 VAC

across the motor terminals 1 to 2 and 3 to 5 on the

conveyor motor control. If voltage is not present at both

sets of terminals, replace control.

Conveyor Drive (Stepper)

Motor

Check the drive sprocket on motor output shaft to insure

that it is tight. WITH POWER OFF: Turn the motor shaft

to check for jammed gear box. Check motor windings.

Ohm readings on motor terminal -1-5, 2-6, 3-7, 4-8,

each reading should be approximately 2 ohms. If motor

shaft will not turn, replace conveyor drive (stepper)

motor.

Time/Temp Display

inoperative

12 VAC Power Supply

(Transformer)

Measure the transformer primary for a nominal 120 VAC

input, if voltage is not present, trace wiring back to the

oven power source. Measure the secondary output,

which will normally be 12-15 VAC. Voltage across

terminals 1 and 3 on the time/temp. display should read

12-15 VAC. Terminals 1-2 and 2-3 should be 1/2 the

voltage reading to 1-3. If the above secondary readings

are not achieved, replace transformer.

Time/Temp Display If proper voltage is present at terminals 1, 2, and 3 on

time/temp display, but the display is not lighted, recheck

all connections for tightness. If time/temp display is still

not operating, replace the time/temp display

Temp display out or

inaccurate

NOTE: Time/Temp displays

use two types of temperature

sensors thermistor probe-2

yellow wires thermocouple

Place the thermocouple of a pyrometer into the center of

the top finger. Be sure the tip of the thermocouple is not

touching metal. The pyrometer will indicate oven

temperature.

probe probe-1 red wire and 1

white wire

Thermistor Probe Disconnect the thermistor probe leads from the

Impinger II –1100 Series Service Manual - Domestic

29

Page 30

time/temp display terminals #9 and 10. Measure the

resistance of the thermistor probe. See chart on page

44 showing probe resistance at various oven

temperatures. If these readings are not achieved,

replace the thermistor probe.

Thermocouple Probe Place your pyrometer thermocouple into the center of

the top finger. Measure D.C. millivolts at terminals 9 and

10 on the time/temp display. See thermocouple chart on

page 36 for proper readings. Connect temperature

meter to thermocouple at terminals 9 & 10 on back of

the time/temp display. (Be sure to maintain proper

polarity on thermocouple connections.) Compare actual

oven temperature with the reading at the time/temp

display. If the temperature readings match, recalibrate or

replace time/temp display. If the readings do not match,

replace thermocouple probe.

Power Supply If a strange or unusual behavior is experienced, such as

a rolling of numbers, or lock-up at a given number, first

check for a display circuit lock-up. This may be caused

by a voltage spike or surge in the incoming power lines.

To eliminate this condition, remove power from the

time/temp display by shutting off the main fan switch for

15 seconds. This should eliminate the problem. If this

does not solve the problem, it may becoming in through

the Commercial power lines. Suggest that customer

contact their power company for evaluation.

Temp display

inaccurate erratic, or

inoperative

Time Display inaccurate

erratic, or inoperative

Conveyor Drive (Stepper)

Magnet Check to insure that the magnet (cemented to shaft of

Hall Effect Sensor Check for any physical damage to Hall Effect sensor

Conveyor Drive (Stepper

Time/Temp Display Perform the power supply check, the thermistor probe

check, and then perform the time/temp simulator test.

Refer to page 45 for instructions. Remember, when

using the time/temp simulator, remove all leads from the

back of the time/temp display except the 3 power leads.

After completion of the test, and if re-installing time/temp

display back in the oven, the dip switches must be reset

for oven operation, and the time/temp display must be

re-calibrated. If readings are not achieved, replace

display

Perform all checks as in the above evaluation. If the time

check is okay, refer to the next section.

Check to see if the conveyor drive (stepper) motor is

Motor

Control)

running. If motor is not running, refer to "Conveyor will

not run" on page 29.

conveyor drive [stepper] motor) has not been damaged,

(mounted on conveyor drive [stepper] motor). Check all

wiring and connections for damage. If the motor is

running, the magnet is in place, but the display shows"--

:--" the Hall Effect Sensor may be defective or

improperly connected.

Check all connections for tightness or proper location

and check all wiring for visible damage. Replace as

needed. If there is still no time display and all the above

have checked out, replace the stepper control.

30

Impinger II –1100 Series Service Manual - Domestic

Page 31

REMOVAL, INSTALLATION, AND ADJUSTMENT

IMPINGER II CONVEYOR OVEN

MOTOR, MAIN FAN

1. Shut off power at main breaker.

2. Disconnect motor wiring of main fan motor, note wire colors for reassembly, and remove entire oven back from

the oven. Refer to "main fan" (See Below) for removal information.

3. Remove the main fan.

4. Remove 4 screws from the motor support assembly.

5. Remove the motor mounting clamp and pull the motor away from the oven back assembly.

6. Remove motor mounting fixture.

7. Install the motor in reverse order insuring that the motor shaft is centered in the

8. Shaft tube of the oven back.

CAPACITOR, MOTOR

Model 1100-1106

Capacitor is located under motor cover in rear of unit and held in place by a plastic wire

tie.

1 Discharge capacitor, remove and replace.

FOR ALL OTHER 1100 MODELS

Capacitor is located under rear control box cover and held in place by a plastic wire tie.

MAIN FAN

1. Shut off power at main breaker.

2. Remove motor cover from back of oven.

3. Disconnect and mark motor wiring of main fan motor and remove entire oven back from oven.

NOTE: Turning the oven back bolts back and forward while applying a spray lubricant or penetrating oil will help

minimize breakage.

4. Loosen and remove set screw in hub of fan.

5. Remove fan. The motor shaft has a flat making removal of fan fairly easy. If trouble is encountered, apply a

spray lubricant or penetrating oil in set screw hole and on motor shaft.

NOTE: This fan is balanced by the manufacturer and must be handled carefully.

Suggested storage is by suspending the fan through the shaft hole.

6. Reinstall fan with the tips of the fan blade closest to the oven back.

7. Position of the fan on the motor shaft will be 1 1/2" (3.81cm) from the top of the oven back cone to the bottom of

the fan hub. Refer to drawing. The oven back must be removed to make this measurement.

8. Align set screw with motor shaft flat and tighten.

9. Reassemble in reverse order.

FAN SPIDER

NOTE: MEASUREMENT MUST BE

MADE FROM CONE TO FAN SPIDER

FAN HUB

CONE

Impinger II –1100 Series Service Manual - Domestic

1 1/2 INCH

31

Page 32

RELAY, DPST

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove control compartment covers.

4. Remove leads from relay and mark for reassembly.

5. Remove mounting screws and lift out relay.

6. Reassemble in reverse order.

TIME DELAY, 20 MINUTE

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove front control compartment cover.

4. Unplug all wires and mark for replacement.

5. Remove center mounting screw.

6. Reassemble in reverse order.

NOTE: Do not over tighten the mounting screw as this may damage the internal potted

electronic components.

COOLING FAN

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove front control compartment cover.

4. Remove 4 screws from fan frame.

5. Remove fan and unplug female cord receptacle.

6. Reassemble in reverse order.

NOTE: All current models have 2 of these cooling fans.

7. The second cooling fan is located in the rear of the rear control compartment. On older models of the

1116,1117,1152 through 1158 the fan was attached to a metal box on rear of oven. Metal box was removed

first. Newer ovens have fan mounted on inside of oven back and are removed from inside.

THERMOSTAT, COOL DOWN

Model 1100-1106 only

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove control compartment covers.

4. Remove 2 screws from holding bracket located in upper rear of the control compartment.

5. Remove the 2 leads and remove thermostat.

6. Reassemble in reverse order.

RELAY, DPST

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove front control compartment cover.

4. Remove leads and mark for reassembly.

5. Loosen mounting screws and remove.

6. Reassemble in reverse order.

THERMOSHETAT, COOLING FAN

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove front control compartment cover.

4. Remove lead wires and mark for reassembly.

5. Remove 2 screws and remove thermostat.

6. Reassemble in reverse order.

32

Impinger II –1100 Series Service Manual - Domestic

Page 33

MOTOR, BURNER BLOWER

This unit comes equipped to be used for other models of ovens. For use on the

Impinger II Series, the mating plug with the loose wires may be discarded.

TO REMOVE BLOWER MOTOR:

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove control compartment covers.

4. Disconnect the plug on blower motor. Plastic locks on side of plug need to be depressed.

5. Remove three screws holding blower horn to burner.

6. Remove air shutter from old unit and install on new unit. If air shutter of old unit is damaged or lost,

replace with new air shutter 369401.

7. Reassemble in reverse order.

8. Adjust air shutter opening if necessary. Set air shutter at 50% open and adjust to get a blue flame with an

occasional tip of yellow under high flame. A glass view port in the burner assembly should be used to

observe flame.

CLEANING OF THE BLOWER FAN IS NECESSARY ON A PREVENTIVE MAINTENANCE SCHEDULE.

See Blower Wheel, Burner below

BLOWER WHEEL, BURNER

This is part of the burner blower motor assembly

TO REMOVE THE BLOWER WHEEL FOR PERIODIC CLEANING:

1. Disconnect power and remove control compartment covers.

2. Remove air shutter held by 3 screws.

3. Loosen set screw on blower wheel hub and pull straight out.

4. Reassemble in reverse order.

NOTE: There is no critical placement of the blower wheel on the motor shaft. Just

back as far as it will go and then spin the blower to be sure it is not rubbing.

AIR PRESSURE SWITCH

1. Shut off power at main breaker.

2. Remove conveyor.

3. Remove front control compartment cover.

4. Remove air switch cover plate.

5. Disconnect wiring and mark for reassembly.

6. Loosen 2 screws and remove air switch.

7. Disconnect 1/4" air tube.

8. Reassemble in reverse order.

9. Turn on power and calibrate air switch as follows:

a) Turn adjusting screw counter clockwise to full out position.

b) Turn main fan and heat switch on.

c) Turn adjusting screw clockwise until heat shuts off.

d) Turn adjusting screw (counterclockwise) 1/4 turn and unit should heat.

NOTE: Test as follows

e) Oven must be tested in heated condition.

f) Remove main fan fuse. Main fan should shut down, deactivating air switch causing

heat to shut off in approximately 5 to 25 seconds.

g) Fine tune adjustment as needed.

Impinger II –1100 Series Service Manual - Domestic

33

Page 34

TEMPERATURE CONTROL BOARD

NOTE: If your unit contains a Fenwal temperature control board, (see below) replace it with a thermologic

control board.

TEMPERATURE CONTROL BOARD CONVERSION - FENWAL TO THERMOLOGIC

(FOUND ONLY IN ELECTRIC UNITS BELOW S/N 2000861)

1. Remove Fenwal board.

2. Remove 5K ohm potentiometer

3. Remove wire #63 from oven. This wire is connected to Fenwall board at terminal #5.

4. Install new thermologic board with 2 screws.

5. Install new 2.5K ohm potentiometer.

6. Attach leads to thermologic board as shown in drawings. See pages 34 & 35.

Located in control compartment below drive end of the conveyor

1. Shut off power at main breaker and remove conveyor.

2. Remove front control compartment cover.

3. Remove the two mounting screws.

4. Remove the electrical leads and replace the control board.

5. Identify the style of thermologic board by looking at the top of the transformer

on the board. There are five styles of boards, each identified by a color marked

on the transformer, either RED, BLUE, GREEN, GOLD, OR A SILVER DOT. Refer to Pages 34 & 35

showing proper wiring connection.

6. NOTE: When mounting a new temperature control board, DO

NOT over tighten the two mounting screws.

7. Turn the potentiometer fully counterclockwise.

8. Loosen the Dial/Knob set screw and position the 50°F mark at the pointer.

NOTE: The thermocouple of your test meter should be inserted through a finger hole

in the top center of the oven, and the oven pre-heated for 30 minutes to stabilize

the oven at set temperature. The thermocouple probe must not touch metal, it must

sense air temperature only.

9. Adjustment of the GREEN, GOLD OR SILVER dot control board may be required when installing a new

board. Adjustment is seldom required on RED and BLUE boards.

10. For RED or BLUE control boards with the temperature control dial at maximum,

the reading on your temperature test meter should be between 555°F (290°C)

and 575°F (302°C). If not at this temperature adjust pot P3 to achieve these

figures. Refer to page 35.

11. For the GREEN, GOLD OR SILVER dot control board, place the test probe of your meter in position as

indicated in prior note. Set the oven temperature control dial 500°F(260°C), adjust pot P6 (see page 34) to

achieve a temperature reading on test meter of 500°F(260°C). CCW to increase, CW to decrease.

12. Adjust Time/Temp Display Pot. "Temp Cal" for 500°F(260°C).

RED

POTENTIOMETER

2.5 K OHMS

TRANSFORMER MARKED

WITH GREEN,GOLD OR

SILVER DOT

34

BLACK

THERMOCOUPLE

TYPE J

WHITE

1

2

3

+

6

7

-

P 3

P 5P 6

L 1 120 VAC

11

L 2

10

9

LOAD

Impinger II –1100 Series Service Manual - Domestic

Page 35

BLACK

THERMOCOUPLE

TYPE J

RED

RED

WHITE

POTENTIOMETER

2.5 K OHMS

POTENTIOMETER

2.5 K OHM

1

2

3

+

6

7

-

P 3

TRANSFORMER

MARKED IN BLUE

L 1 120 VAC

11

L 2

10

9

LOAD

TRANSFORMER

MARKED IN RED

13

12

10

L 1 120 VAC

L 2

LOAD

THERMOCOUPLE

TYPE J

WHITE

BLACK

1

3

4

5

+

6

7

-

THIS BOARD DISCONTINUED

AT S/N 2000932

P 3

TEMPERATURE CONTROL POTENTIOMETER, 0-2.5K OHMS, 1 TURN

1. Shut off power at main breaker.

2. Remove front control box cover.

3. Loosen and remove temperature control knob.

4. Remove hex nut and washer then remove pot from rear of compartment.

5. Remove and mark wiring for replacement.

6. Replace in reverse order.

7. Recalibrate the dial. (See "Temperature Control")

THERMOCOUPLE PROBE

The sensor bulb is located in the oven compartment behind the lower finger, and held

in position by a wire form holder.

CAUTION: ALLOW OVEN TO COOL

1. Shut off power.

2. Remove conveyor and lower finger.

3. Remove control compartment covers.

4. Remove sensor bulb from the wire form holder, pull thermocouple out of the oven through the access tube

and disconnect leads from terminals 6 and 7 of the temperature control board.

5. To install, push thermocouple bulb through the access tube and place in wire form

holder. Be sure that wire form holder is exerting enough pressure on the sensor

bulb to hold it in place. If sensor bulb is not held securely, replace the wire form holder or bend the holder

slightly to hold sensor bulb in place.

6. Reconnect RED lead to terminal 7(-) and WHITE lead to terminal 6(+).

7. Replace conveyor and fingers.

Impinger II –1100 Series Service Manual - Domestic

35

Page 36

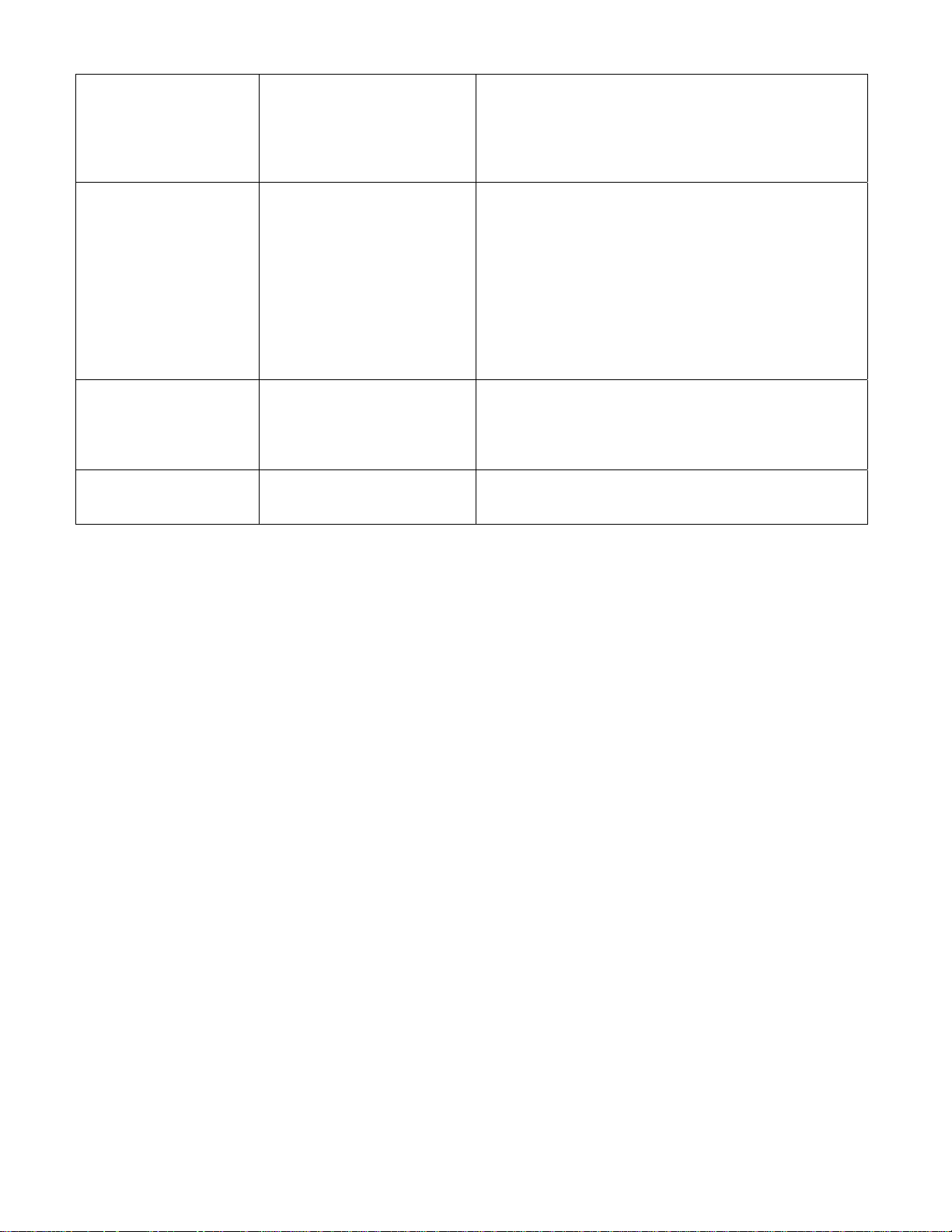

THERMOCOUPLE MEASUREMENT CHART:

EXPLANATION: The junction temperature is the ambient air temperature where the

thermocouple fastens to the electronic temperature control board.

200°F 250°F 300°F 325°F 350°F 400°F 425°F 450°F 500°F 550°F 600°F

90°F 3.26 4.77 6.30 7.06 7.83 9.37 10.14 10.91 12.46 14.00 15.53

J

88°F 3.32 4.83 6.36 7.12 7.89 9.43 10.20 10.97 12.51 14.05 15.59

U

86°F 3.37 4.88 6.41 7.17 7.94 9.49 10.26 11.03 12.57 14.11 15.65

N

84°F 3.43 4.94 6.47 7.23 8.00 9.54 10.31 11.09 12.63 14.19 15.71

C

82°F 3.49 5.00 6.53 7.29 8.06 9.60 10.37 11.14 12.69 14.23 15.76

T

80°F 3.55 5.06 6.59 7.35 8.12 9.66 10.43 11.20 12.74 14.28 15.82

I

78°F 3.60 5.11 6.64 7.40 8.17 9.72 10.49 11.26 12.80 14.34 15.86

O

76°F 3.66 5.17 6.70 7.46 8.23 9.77 10.55 11.32 12.86 14.40 15.94

N

75°F 3.69 5.20 6.73 7.49 5.26 9.80 10.57 11.35 12.89 14.43 15.97

74°F 3.72 5.23 6.76 7.52 8.29 9.83 10.60 11.37 12.92 14.46 15.99

72°F 3.78 5.29 6.82 7.58 8.35 9.89 10.66 11.43 12.97 14.51 16.05

70°F 3.83 5.34 6.87 7.63 8.40 9.95 10.72 11.49 13.03 14.57 16.11

T

68°F 3.89 5.40 6.93 7.69 8.46 10.00 10.78 11.55 13.09 14.63 16.17

E

66°F 3.95 5.46 6.99 7.75 8.52 10.06 10.83 11.61 13.15 14.69 16.23

M

64°F 4.01 5.52 7.05 7.81 8.58 10.12 10.89 11.66 13.20 14.74 16.28

P

62°F 4.06 5.57 7.10 7.86 8.63 10.18 10.95 11.72 13.26 14.80 16.34

60°F 4.12 5.63 7.16 7.92 8.69 10.24 11.01 11.78 13.32 14.86 16.40

O V E N T E M P

MERCURY CONTACTOR

1. Shut off power at the main breaker.

2. Remove conveyor.

3. Remove control compartment covers.

4. Disconnect contactor wires and mark for reinstallation.

5. Remove screws from mounting bracket and replace contactor.

NOTE: Be sure contactor is not mounted upside down at this will cause a constant on

6. Reassemble in reverse order.

GAS VALVE

1. Shut off power at main breaker.

2. Shut off the gas supply in the main line to the oven.

3. Disconnect the flexible gas hose.

4. Remove the control compartment covers.

5. Remove the manual gas shut off valve from piping.

6. Remove screws from the bulkhead plate located on rear of oven at the gas pipe.

7. Remove the section of gas pipe to gas valve.

8. Disconnect the electrical leads from the solenoid valve.

9. Loosen the gas line union located near the burner and remove the gas valve and

solenoid valve assembly.