Page 1

Suzhou Lily Tech. Co., Ltd.

www.suzhoulily.com.cn/en Page 1, Total 2 Pages

ZL-6200A Temperature Controller

Instruction Manual A1.0

Introduction

ZL-6200A is for cooling, heating or warning control. Front panel water proof level IP65, control resolution 0.1℃, keypad password

protection. It is suitable to control or audit cold storage, aquarium, water heater, and so on.

Main Function

Cooling, heating or auditing

Over temperature warning

Sensor failure warning

Temperature control

Temp. output energized/de-energized periodically when

sensor fails

Specification

Power supply: 185 ~ 245Vac, 50/60Hz

Sensor: NTC, 1.5 meters long

Display range: -50 ~ 120℃

Setting range: -50 ~ 120℃

Resolution: 0.1℃

Absolute accuracy: 1% at 25℃

Accuracy after calibration: 0.1℃

Temp. output, R1: 7A, 250Vac (pure resistance load)

Warning: Buzzing

(When in warning mode, temp. output as warning output)

Working: -10 ~ 45℃, 5 ~ 90%RH without dew

Dimension: W78 x H34.5 x D71 (mm)

Installation drilling: W71 x H29 (mm)

Case materials: PC + ABS fire proof

Protection level: IP65 (Front side only)

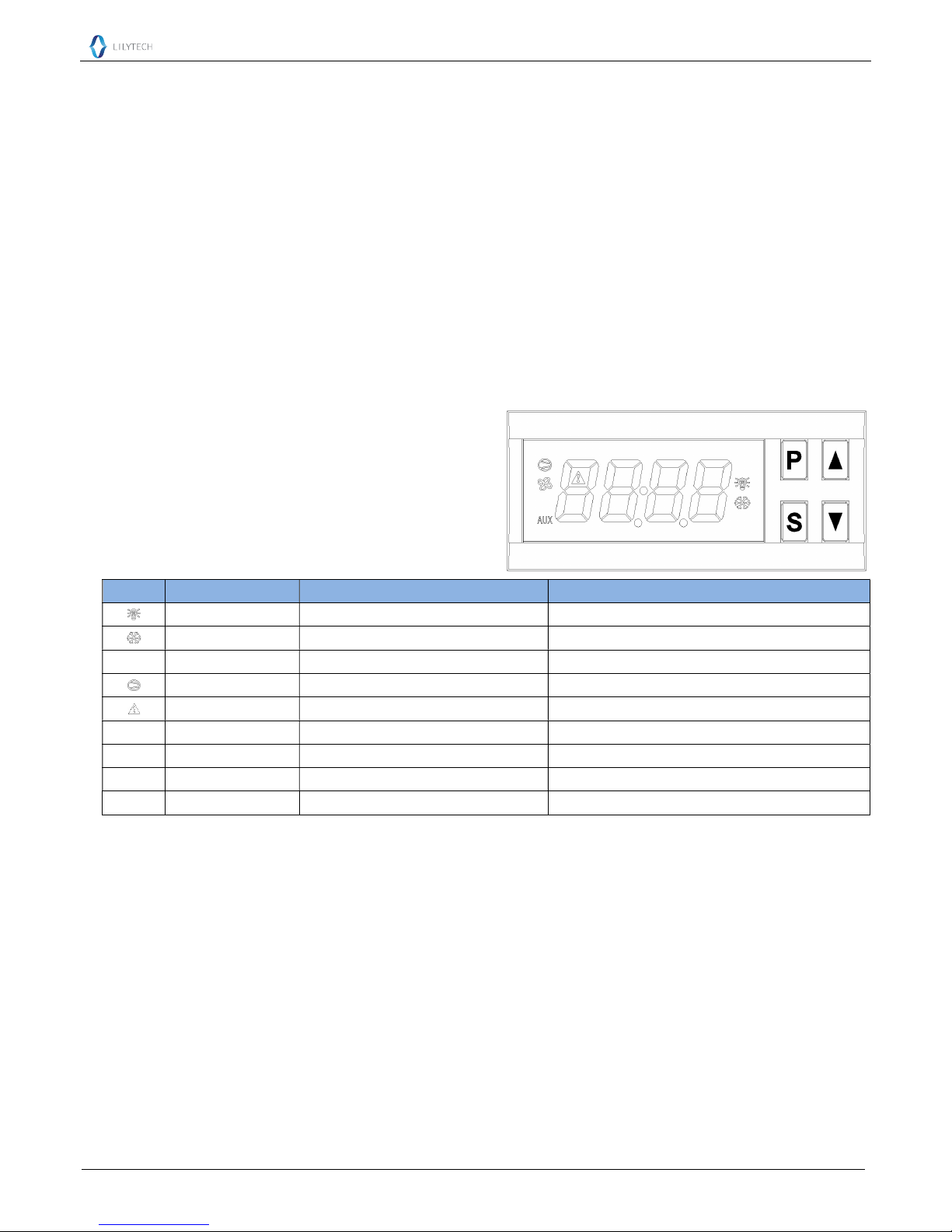

Keypad and Display

Display

Function On Blinking

Heating mode Heating mode Setting set-point

Cooling mode Cooling mode Setting set-point

AUX Warning mode Warning mode Setting set-point

Temp. output, R1 R1 energized Delay protecting

Warning ---- Warning

E1 Warning ---- Sensor open

E2 Warning ---- Sensor short

HH Warning ---- Over high temperature limit

LL Warning ---- Bellow low temperature limit

Operation

On/off: Keep〖S〗depressed for 3 seconds to switch on/off.

Check settings: Press〖▲〗 to check the set-point; Press〖▼〗 to check the hysteresis.

Set Set-Point

Keep〖S〗depressed for 3 seconds to enter into the set status. The current set-point value displays.

Press〖▲〗or〖▼〗 to set the value (keeping depressed can fast set).

Keep〖S〗depressed for 3 seconds to exit, and save the settings.

The status will exit, and the setting will be saved, if no key operation within 30 seconds.

Set System Parameters

Keep〖P〗depressed for 3 seconds: If the password is not “0000”, digits show “---0”, else enter into parameter setting status.

Press〖▼〗to select the digit of the password, press〖▲〗to set the value of the digit.

Press〖S〗 to confirm:

If the password is correct, enter into the parameter setting status, else exit.

Set in parameter setting status:

Press〖▲〗or〖▼〗to select the parameter code (see parameter code table below).

Press〖S〗 to display the value of the code.

Page 2

Suzhou Lily Tech. Co., Ltd.

www.suzhoulily.com.cn/en Page 2, Total 2 Pages

Press〖▲〗or〖▼〗to set the value.

Press〖S〗to return to parameter code selection.

Keep〖P〗depressed for 3 seconds to exit, and save the settings.

The status will exit, and the settings will be saved, if no key operation for 30 seconds.

Parameter Code Table

Code

Function Range Remark Factory set

F0 Hysteresis

0.1 ~ 15.0℃

3.0

F1 Minimum time for R1 to keep de-energized 0 ~ 9 minute 3

F2 Up limit for set-point

-50.0℃~ 120.0℃

-20.0℃

F3 Low limit for set-point

-50.0℃~ 120.0℃

20.0℃

F4 Working mode 1 ~ 3 1: cooling; 2: heating; 3: warning 1

F5 Sensor calibration

-5.0 ~ +5.0℃

0.0℃

F6 Password 0000 ~ 9999 0000: disable password 0000

Control

Cooling Control (F4 = 1)

If Troom ≥ Set-point + F0, and R1 has been de-energized for F1, then R1 energized;

If Troom ≤ Set-point, then R1 de-energized.

Protecting Run When Sensor Fails: R1 will be energized for 15 minutes, and de-energized for 15 minutes, periodically.

Heating Control (F4 = 2)

If Troom ≤ Set-point, and R1 has been de-energized for F1, then R1 energized;

If Troom ≥ Set-point + F0, then R1 de-energized.

Warning Control (F4 = 3)

If Troom ≥ Set-point + F0, or Troom ≤ Set-point, and R1 has been de-energized for F1, then R1 energized;

Temp. Output Load Delay Protection

After power supplied, R1 could be energized after F1 time;

After R1 de-energized, it could be energized again after F1.

Installation

1st: Insert into drilling hole; 2nd: Clamp

Attention

Wiring work should be manipulated by certified technicians.

Wrong connection could damage the controller, and the loads. Power supply to terminal 7 and 8 to check the controller. If there is a

multimeter, check the outputs, as well as input, by the help of settings.

Sensor and input signal wires should not be laid together with power supply wire, and even in same pipe.

Sensor wire is better as short as possible. Not wind the redundant length wire to electrical noise equipment.

The loads should be within the specification of the controller output driving ability. If using ac/dc module as load, or tungsten lamp,

or motor, following the below requirements to avoid surging current damaging or shorten the life time of the controller outputs:

For ac/dc module as load, the rated current should be no more 1/10th of output specification under pure resistance.

For tungsten lamp as load, the rated current should be no more 1/15th of output specification under pure resistance.

For motor, the rate current should be no more 1/5th of output specification under pure resistance.

For example: if drive a 1500W tungsten lamp with 7A

(pure resistance spec.) relay, the relay contactor will

be burnt immediately.

Don’t touch inside components;

Avoid installing controller in the following

environment:

More wet than 90%RH, or easily dew; Vibrating, or will

be shocked; Possible sprayed; Under erosive air; Under

explosive air.

Electrical Wiring

Loading...

Loading...