Bachmann Europe Plc

Operating Manual

L133920-39

Electric Double Decker Railcar

Information on the original:

Since 2004 the FLIRT railcar, which was developed and built by the Stadler

Company, has been operated by many European railway companies. The

increased passenger volume recorded by many companies and the restricted

length of platforms has led to the development of a “successor” to the FLIRT,

namely the KISS designed by Stadler as a double decker railcar and also

designated as the DOSTO since 2010. A double decker carriage can transport 30 per cent more passengers than a single-deck carriage. This railcar

and the new concept it represents have been employed both for suburban

line services (since 2012 by the SBB on Zurich suburban lines or by the BLS

on suburban lines in Bern) and for main line traffi c (WESTbahn).

The name KISS stands for “komfortabler innovativer spurtstarker S-BahnZug (comfortable, innovative, high-torque suburban train)”. The SBB now

calls the railcar the REGIO-DOSTO; the BLS calls it the MUTZ (the same

name as the bear appearing on the Bern coat of arms, but also standing for

“moderner, universeller Trieb-Zug [modern, universal railcar])”.

A four-part railcar consists of units 100, 200, 400 and 600, a six-part railcar

of the units 100, 200, 300, 400, 500 and 600.

LILIPUT thanks you for purchasing this model

and hopes it brings you a lot of pleasure.

H0 1:87 1

Bachmann Europe Plc

Fig. 1

Unit 600 Unit 500 Unit 400 Unit 300 Unit 200 Unit 100

Preparing the Model

Please carefully remove the individual units from the blister packaging. Units 100 and 600

each come with a motor. However, only unit 100 (Fig. 1) with a coupler retaining collar (H)

can be used on its own for test purposes.

Unit 600 only runs when connected with the other units.

Coupling the Units

The models are fi tted with special electrically conducting couplings. Place the railcar unit 100

and the middle carriage 200 slightly apart on the rails. Always make sure when coupling up

that two non-matching coupling parts (with and without retaining collar H) are facing opposite

each other Fig 2.

Now carefully push the units towards each other until the couplings touch.

We recommend slightly

lifting the two ends of the

carriages by about 2 cm and

to place the retaining collar

(H) on one of your fi ngers

for support as shown in

Fig. 2a. This allows the two

couplings to be gently interconnected until the coupling

collar engages without one

part being pressed downwards.

Fig. 2

H

Repeat this process to

couple up the other units.

Please pay attention to the

correct sequence of units.

Once the units have been coupled, the railcar train is ready to run. The four-part basic model

consists of the units 100, 200, 400 and 600. The SBB and WESTbahn also run six-part

railcar trains. To cater for this LILIPUT offers for each an add-on set; which consists of units

300 and 500.

Please consult the overview in Fig. 1 for the correct sequencing of units.

2 H0 1:87

Fig. 2a

H

Bachmann Europe Plc

Uncoupling the Units

To uncouple (Fig. 2b)

insert a screwdriver

from the side and

press the coupling

collar (H) downwards. You can then

separate the units.

H

Putting your DC Model into Operation

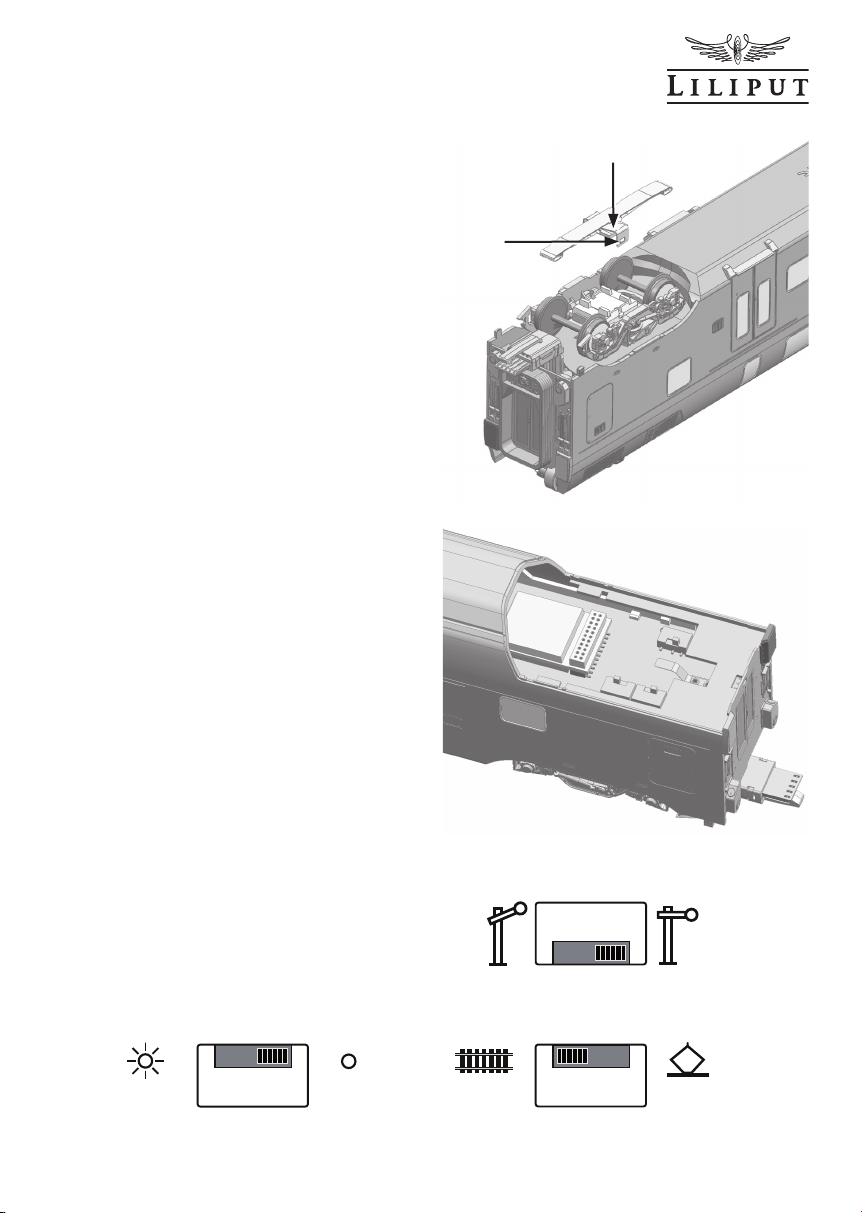

Altering the default settings and opening unit 100

Fig. 2b

The DC model in its default setting has been connected so that the power pick-up is effected

via the wheels of the two end cars. If you would like to alter the default setting a little, please

open the separate roof section near the gangway area of unit 100 as shown in Fig. 3.

To do this fi rst remove the gangway

D

bellows with the moulded retaining

pins (Z). You can then unclip and

remove the roof section (D) by lifting

it upwards.

2.

Apart from the digital interface you

can see three switches S1, S2 and

S3 (Fig. 3a).

S3

S2

S1

Fig. 3

H0 1:87 3

Z

1.

Bachmann Europe Plc

If you wish to run the car in block track

operation or have it automatically stop in a

terminus, please switch the switch S3 to OFF

(Fig. 3a). This will ensure that power pick up

only takes place at the end carriage that is

currently fronting the train.

Switch S2 enables you to switch the power

pick up from wheel contact to overhead

contact operation.

Switch S1 enables you to switch the interior

lighting on and off. For digital operation the

switch is set to AUX1; interior lighting is

activated from the decoder.

ON

TRACK

Fig. 3a

S3

S2

S1

OFF

PAN

AUX1DC

Installing a Decoder

The digital interface (DS) with 21 + 2 plug contacts (Fig. 4) is located on the same circuit

board as the three function switches. The installed interface board (SP) with its total of 23

plug contacts carries the switching for the stop function. If you wish to convert to digital

operation by installing a decoder (DEC), the stop function is deactivated.

SP

1.

Fig. 4

4 H0 1:87

2.

DEC

DS

Bachmann Europe Plc

) shown. It is advisable to carry

L

Installing a Loudspeaker

The railcar already comes completely

prepared for locomotive sound operation.

The 21-pin sound decoder (SD) can be

SD

SPK

plugged in vertically on the interface.

The holder of the loudspeaker (M) and

the two solder pins (SPK) for the wires

are located in unit 100 near the gangway (Fig. 5).

S3

S2

S1

To install, please remove the body. To

do this fi rst remove the two screws (S)

on the underside, then pull the front

part forwards (Fig. 5a). By splaying (A)

the two outer walls of the body you can

then loosen the body from the bogies.

Refi tting is effected by following the

sequence in reverse.

Fig. 5

M

Looking after your Model

In order to ensure that your model has a long service life, the railcar should undergo maintenance at regular intervals. The model need not be opened to do this. It is perfectly suffi cient

to turn the model over on a soft base as shown in Fig. 5a, but please be careful not to

damage the roof parts or the pantograph in the process. Clean the wheel contacts using

cotton wool buds soaked in spirits and then clean the wheels. However, please do not turn

the drive wheels by hand in any circumstances.

After cleaning please use a drop of machine oil to lubricate

the bearing points (L) shown. It is advisable to carry

out maintenance work after approximately

30-40 hours of operation.

L

L

L

A

L

L

L

S

S

L

L

A

H0 1:87 5

Fig. 5a

Bachmann Europe Plc

The railcar also need not be opened to lubricate the gear parts. It is perfectly suffi cient to

swivel the motor bogie to one side as shown in Fig. 6. Then you can look between bogie

and running gear and see the worm and worm wheel (O) and use a pipette to oil all the gear

parts (Z). Then run the railcar up and down a little. This ensures that the oil is distributed

evenly. Use commercially available oils and use a fi ne cannula or a needle.

Caution: Do not use cooking oil or hand cream!

Z

Z

Fig. 6

Z

O

Your Model as an AC Variant

If you have decided on running your

LILIPUT model using a three rail AC

system, please observe the following:

This model has a digital decoder installed

(ESU Lokpilot) located in unit 100, which

can be used to power your vehicle either

on an analogue basis (16 volt AC) or digitally. Please consult the operating manual

supplied by ESU for details on how the

decoder works.

A slider is installed on the turning bogie

of the end carriages 100 and 600 (Fig. 7)

for power pick up from the centre rail.

This picture shows the installed slider.

6 H0 1:87

R

Fig. 7

Bachmann Europe Plc

Fig. 8 shows the removed slider with the

retaining bracket (R). The retaining bracket

snaps simply into two clip-in lugs. When

taking apart, please press the retention

arm (S) slightly outwards using a small

screwdriver.

Naturally, the wheel profi le of the wheel

sets has also been adapted to the track

system commonly in use.

The alternating current version has a

circuit board with three switches in the

roof section of unit 100. Fig. 9 shows the

position of the individual switches.

Please slide switch S3 into the position

OFF (Fig. 10) for the stop function.

For overhead operation using the pantographs please slide the switch S2 to

the PAN position. S1 must be in position

AUX1 for digital operation. The interior

lighting is turned on and off here with the

decoder.

For all other operating information please

consult pages 3 - 6 under

- Altering the default settings and

opening unit 100

- Installing a decoder

- Installing a loudspeaker as well as

- Looking after your model.

R

S

Fig. 8

Fig. 9

S3

S1

S2

S3

Fig. 10

S1

H0 1:87 7

AUX1DC

ON

AC

S2

OFF

PAN

Bachmann Europe Plc

Circuit Diagrams

For all those desiring more information, we have enclosed the complete circuit diagram for the

car units and the power systems.

Circuit Diagram DC: Unit 100

LED13

R13

2K

Y

LED12

R12

Loco B (R Pickup)

Loco B (M+)

Loco B (M-)

Loco B (L Pickup)

Loco B (Pantograph)

Rear Light+

Front Light+

Interior Light+

GND

TOP/name Light+

123

4

5

9

8

6

10

CONNE

Unit A_R

Unit A_R

Unit A_R

Unit A_R

Unit A_R

B

DCC Aux1

Pantograph

A

Track

DC ON

STOP OFF STOP ON

A B

DC STOP

Power Pickup

Function

Interior LEDs

S3

S1

S2

SW

A

S3S2S1

PANTO DC STOP

SW B

A

DC STOP

S3S2S1

SW B

A

PANTO

S3S2S1

SW B

7

Unit A_L

R

LED4

R4

M-

M+

GND

Unit B_L

Unit B_R

Front Light+

Rear Light +

Interior Light+

TOP/name Light+

Unit A_L

Unit B_PAN

Unit A_L

Unit A_L

Unit 100 (A)

DC

Unit A_L

Unit B_R

Unit B_PAN

Unit A_R

Unit A_PAN

PAN TO

S2A

S2

S3A

S3

Unit B_L

Unit A_L

TRACK

PAN TO

TRACK

AAB

B

S2B

ON

OFFONOFF

AAB

B

S3B

2K

LED3

R3

2K

Rear Light +

Q2

8550

VCC

TOP/Front Light+

Q1

8550

VCC

R

C2

105

R06

4.7K

10K

R02

D2

C6 105

LED_R

W

LED5

R5

2K

LED2

W

R2

2K

LED1

R1

2K

W

C1

105

R05

4.7K

C5 105

R01

10K

D1

LED_F

2K

Y

LED11

R11

2K

Y

104

104

LED10

R10

2K

Y

LED9

R9

2K

Y

LED8

R8

2K

C4

105

Interior Light+

Q4

Rear Light X 2PCS(LEDXX+10175)

8550

R04

10K

VCC

PTC1

V+

MISCE#500MA

R7

2K

R6

2K

name Light+

C3

Front Light X 2PCS(LEDXX+10145)

105

TOP LED X 1PCS(LEDXX+10145)

Q3

8550

10K

R03

VCC

AUX_1

V+

LED_F

V+

LED_R

V+

4

2

A

1

3

R1

NC

NC

NC

AUX 4

L1

M+

L

R

GND

D?

B

21

22

20

18

19

M+

M+

L1 4.7uH

Interior Light X 6PCS (LEDXX+10205)

Y

R08

4.7K

C8 105

LED7

Y

LED6

Y

C7 105

S1

B

A

DC

AUX1

Station name Light X 2PCS (LEDXX+10205)

R07

4.7K

D3

D4

D5

LED_F

AUX_1

LED_R

LED_FR

R20 220K

R18 220K

R19 220K

LED_F

LED_R

8

7

11

10

6

9

NC5NC

NC

LEDF

LEDR

SPEAK2

SPEAK1

NC

M-

17

M-

M-

L2 4.7uH

V+

SPK

AUX1

AUX 3

AUX2

VDD

V+

CONN2

13

14

12

16

15

AUX_2

C04

104

+

22UF/35V

C0

1

DC

A

S3S2S1

SW B

1

2

2

MOTOR

C05

104

C04

104

8 H0 1:87

Bachmann Europe Plc

Circuit Diagram DC: Unit 100 / jumper plug

D3392 DOSTO DC TRACK

D1...D16(DIODE#10187)

D1

D8

D6

V+

D3

D2

M+

M-

D4

C0N1

B

22

21

20

19

18

17

16

15

14

13

12

A

L1

R1

1

R

NC

CONN2

2

L

NC

3

GND

NC

4

M+

AUX 4

5

M-

NC

Q2

6

NC

NC

8050

7

V+

LEDR

8

AUX1

LEDF

9

AUX2

SPEAK1

10

AUX 3

SPEAK2

11

VDD

NC

Front R

Front L

D16

R

D7

D5

L

D13

D3392+PCB10 (23Pin Dummy Board)

Circuit Diagram DC: Unit 200, 300, 400, 500 and 600

Unit 200 Unit 300 Unit 400 Unit 500

Front Light+

Interior Light+

GND

TOP/name Light+

Front Light+

Interior Light+

GND

TOP/name Light+

Rear Light+

Loco B (R Pickup)

Loco B (M+)

Loco B (Pantograph)

Loco B (M-)

Loco B (L Pickup)

Interior Light+

CONNE

1

2

3

4

5

10

9

8

7

6

R3

R7

R1

R2

2K

2K

2K

2K

105

Y

Y

Y

Y

LED3

LED2

LED1

LED7

105 105

R4

2K

Y

CONNE

1

2

3

4

5

10

9

8

7

6

R5

2K

Y

LED5

LED4

Front Light+

Interior Light+

GND

TOP/name Light+

Rear Light+

Loco B (R Pickup)

Loco B (M+)

Loco B (Pantograph Pickup)

Loco B (M-)

Loco B (L Pickup)

R8

R6

2K

2K

105

Y

LED6

LED8

Y

Rear Light+

Loco B (R Pickup)

Loco B (M+)

Loco B (Pantograph)

Loco B (M-)

Loco B (L Pickup)

Interior Light x 8pcs

R2

2.2K

R4

2.2K

Q4

8050

Front Light X 2PCS(LEDXX+10145)

TOP LED X 1PCS(LEDXX+10145)

CONNE

Front Light+

W

R1

2.2K

Q1

8050

8050

Unit B_L

1

2

3

4

5

10

9

8

7

6

Unit B_R

R2

R1

2K

2K

LED2

LED1

W

Rear Light +

R3

2K

LED3

R

D15

C1

104

R_1

D12

D11

R3

2.2K

D10

Q3

D9

L_1

D14

C2

104

DC Unit 600 (B)

Unit B_L

B

Unit B_PAN

Unit B_R

name Light+

R5

2K

LED5

R4

2K

LED4

R

R6

R7

2K

2K

LED6

Y

W

Station name Light X 2PCS (LEDXX+10205)

Interior Light+

105

LED7

Y

R8

2K

Y

LED8

Rear R

Rear L

Unit B_L

Unit B_R

C01

104

C02

104

R10

R9

2K

2K

Y

Y

LED9

Unit B_L

Unit B_R

L1

M+

4.7uH

1

1

MOTOR

2

2

L2

M-

4.7uH

R13

R12

R11

2K

2K

2K

105

Y

Y

Y

LED11

LED13

LED12

LED10

Rear Light X 2PCS(LEDXX+10175)

Interior Light X 6PCS (LEDXX+10205)

H0 1:87 9

Circuit Diagram AC: Unit 100

Loco B (AC Pickup)

Rear Light+

Front Light+

Interior Light+

TOP/name Light+

GND

123410

9

5

CONNE

R Wheel

M+

GND

R Wheel

Unit A_R

R Wheel

R Wheel

DCC Aux1

A B

Track Pantograph

DC ON

STOP OFF STOP ON

DC STOP

Power Pickup

Function

Interior LEDs

S3S2S1

SW

ASW B

PAN STOP

S3S2S1

ASW B

AC STOP

S3S2S1

ASW B

PAN

S3S2S1

ASW B

AC

S3S2S1

Unit B_AC

Rear Light +

Front Light+

Interior Light+

TOP/name Light+

AC Unit 100 (A)

A B

Unit A_AC Unit B_AC

Unit A_PAN Unit B_PAN

PAN TO

AC

PAN TO

AC

1

3

4

6

AAB

B

S2A

S2B

S2

2

5

K1A

K1

Bachmann Europe Plc

LED13

R13

2K

Y

LED12

R12

2K

Loco B (Pantograph Pickup)

Loco B (L Pickup)

Loco B (M+)

Loco B (M-)

8

6

7

L Wheel

M-

L Wheel

Unit B_ L

Unit B_PAN

B ACA AC

ON

OFF

4

6

AAB

S3A

S3

5

K1B

Rear Light +

Q2

8550

Unit A_L

L Wheel

VCC

L Wheel

TOP/Front Light+

Q1

8550

VCC

OFF

ON

1

3

B

S3B

2

A

B

RELAY-DPDT

D6

D5

R0

220

V+

R

LED4

R4

2K

LED3

R3

2K

R

C2

105

R06

4.7K

10K

D2

C6 105

R02

W

LED5

R5

2K

LED2

W

R2

2K

LED1

R1

2K

W

C1

105

R05

4.7K

D1

R01

10K

C5 105

Q5

8050

Q6

8050

104

C10

R14

R15

10K

R17

220K

AUX_4

AUX_4

AUX_3

AUX_3

Interior Light+

Rear Light X 2PCS(LEDXX+10175)Front Light X 2PCS(LEDXX+10145)

Q4

VCC

LED_R

PTC1

V+

name Light+

TOP LED X 1PCS(LEDXX+10145)

Q3

LED_F

VCC

AUX_3

104

C9

AUX_3

10K

R16

220K

Y

LED11

R11

2K

Y

104 104

LED10

R10

2K

Y

LED9

R9

2K

Y

LED8

R8

2K

C4

105

8550

R04

10K

MISCE#500MA

R7

2K

R6

2K

C3

105

8550

10K

C7 105

R03

AUX_4

AUX_4

Interior Light X 6PCS (LEDXX+10205)

Y

R08

4.7K

C8 105

S1

B

A

DC

AUX1

LED7

Y

LED6

Y

Station name Light X 2PCS (LEDXX+10205)

R07

4.7K

D4

D5

D3

LED_F

LED_R

AUX_1

LED_FR

AUX_1

V+

LED_F

LED_R

A

R1

L1

D?

B

R20 220K

V+

R18 220K

V+

R19 220K

LED_F

LED_R

8

6

7

2

4

1

3

NC

NC

NC

AUX 4

M+

L

R

GND

21

22

20

19

M+

M+

L1 4.7uH

11

10

9

NC5NC

NC

LEDF

LEDR

SPEAK2

SPEAK1

NC

M-

18

16

17

M-

M-

L2 4.7uH

V+

1

1

C01

104

SPK

AUX1

AUX 3

AUX2

VDD

V+

CONN2

14

12

15

13

AUX_2

C11

104

+

22UF/35V

C0

2

2

MOTOR

C02

104

10 H0 1:87

Bachmann Europe Plc

Circuit Diagram AC: Unit 200, 300, 400, 500 and 600

M+

L1

4.7uH

1

1

MOTOR

Unit B_L

Unit B_L

B

Unit B_AC

Unit B_PAN

Unit B_L

Unit B_L

B AC

AC Unit 600 (B)

Unit B_L

Unit B_R

2

1

41098756

3

CONNE

GND

Front Light+

Interior Light+

TOP/name Light+

Rear Light+

Loco B (AC Pickup)

Unit B_L

Unit B_L

Loco B (Pantograph)

Loco B (L Pickup)

Loco B (M+)

Loco B (M-)

C01

104

R7

2K

R6

2K

R5

2K

R2

2K

R1

2K

Front Light+ name Light+

M-

L2

4.7uH

2

2

LED13

R13

C02

104

Y

LED7

LED6

Y

Station name Light X 2PCS (LEDXX+10205)

W

LED5

W

LED2

LED1

W

Front Light X 2PCS(LEDXX+10145)

2K

Y

LED12

R12

2K

Y

LED11

R11

2K

Y

105

LED10

R10

2K

Y

LED9

R9

2K

Y

LED8

R8

2K

Y

105

Interior Light+

LED4

R4

2K

LED3

R3

2K

Rear Light +

TOP LED X 1PCS(LEDXX+10145)

Interior Light X 6PCS (LEDXX+10205)

R

R

Rear Light X 2PCS(LEDXX+10175)

105

LED8

R8

2K

Y

LED6

R6

2K

Y

LED5

R5

2K

Y

LED4

R4

2K

Y

105 105

LED3

Y

R3

2K

LED2

Y

R2

2K

LED1

Y

R1

2K

LED7

R7

2K

Y

105

Interior Light x 8pcs

Unit 200 Unit 300 Unit 400 Unit 500

Front Light+

Interior Light+

123410

CONNE

2

1

CONNE

Front Light+

Interior Light+

Loco B (Pantograph Pickup)

Loco B (M+)

Loco B (M-)

Loco B (L Pickup)

Loco B (AC Pickup)

Rear Light+

TOP/name Light+

GND

9

5

6

7

8

4

3

9

875

6

10

TOP/name Light+

GND

Rear Light+

Loco B (Pantograph Pickup)

Loco B (AC Pickup)

Loco B (M+)

Loco B (M-)

Loco B (L Pickup)

Interior Light+

H0 1:87 11

Bachmann Europe Plc

Warranty Coupon

Should your LILIPUT model be faulty or not work properly or require repair, you can either

contact the dealer from whom you purchased the product or contact the customer services

department directly of one of the following addresses below.

GREAT BRITAIN:

BACHMANN EUROPE PLC

MOAT WAY, BARWELL

GB - LEICESTERSHIRE LE9 8EY

GERMANY:

BACHMANN EUROPE PLC

NIEDERLASSUNG DEUTSCHLAND

AM UMSPANNWERK 5

D - 90518 ALTDORF BEI NÜRNBERG

Warranty Conditions:

This LILIPUT model has a warranty of two years from the

date of purchase on repairs and parts, as long as it was

purchased from an authorised dealer and if this certificate

has been stamped with the address of the dealership and

the date of purchase has been entered. The warranty permits Bachmann Europe Plc either to rectify any fault or to

replace the faulty parts. Further claims are excluded.

Please note that no liability can be assumed for any parts

subsequently fitted or for any damage caused thereby.

Important! We recommend that you keep the original box. It is

the best place to store your model, when it is not in use. Please

be aware, that carpet fibres can destroy the fine mechanism of

the locomotive. Subject to changes in design, version and technical data. Please retain these data and instructions for further

reference. This product has been manufactured according to the

European toy Safety Directive (CE). • Wichtig! Wir empfehlen die

Originalverpackung aufzubewahren, sie ist der beste Schutz für

Ihr Modell, wenn dieses nicht gerade auf Ihrer Anlage unterwegs

ist. Beim Betrieb der Lok auf Teppichböden kann die feine Mechanik durch Fasern zerstört werden. Änderungen in Konstruktion

und Ausführung vorbehalten. Bitte bewahren Sie diese Beschreibung zum späteren Gebrauch auf. Dieses Produkt wurde nach

Vorschriften der europäischen Spielzeugrichtlinien

(CE) hergestellt. • Importante! Raccomandiamo di

tenere la scatola originale. E’ il posto migliore in cui

tenere il tuo modello quando non è in uso. Fibre di

tappeti possono distruggere il fine meccanismo del-

SWITZERLAND:

MODELLBAU UND

ELEKTRONIK

STETTBACHSTRASSE 193

CH - 8051 ZÜRICH

ALL OTHER COUNTRIES:

( EXEPT GERMAN SPEAKING COUNTRIES )

BACHMANN EUROPE PLC

MOAT WAY, BARWELL

GB - LEICESTERSHIRE LE9 8EY

Dealer’s stamp with day of purchasing:

la locomotiva. Preghiamo di conservare questi dati ed istruzioni

per altre informazioni. Quest’articolo è stato prodotto in accordo

con la Direttiva Europea Sicurezza giochi (CE).

Attention! At an incorrect use there exists danger of hurting because

of cutting edges and tips • Achtung! Bei unsachmäßigem Gebrauch

besteht Verletzungsgefahr durch funktionsbedingte scharfe Kanten

und Spitzen • Attention! Il y a danger de blessure à un emploi in-

correct à cause des aiguilles et arêtes vives! • Voorzichtig! Bij ondo-

elmatig gebruik bestaat verwondigsgevaar door scherpe zijkanten

en uitsteeksels! • Attenzione! Un uso improprio comporta pericolo

di ferimenti attraverso punte e spigoli taglienti! • Atencion! Un em-

pleo incorrecto puede causar heridas debido a las puntas y aristas

agudas! • Atençao! Por utilizaçao incorrecta existe o perigo de es-

tragos, em virtude de cortes nas abas e nas pontas!

• Προξοχη! Η ακαταλληλη χρηοη εγκλειει κινδυνουζ

μκροτ ραυματιομων, εξ αιπαξ κοπτερων ακμων και

προεξοχωθν • Bemaerk! Ved ukorrekt brug kan de funk-

tionsbetingede skarpe kanter og spidser forfolde skade!

Bachmann Europe Plc · Moat Way · Barwell · Leicestershire · LE9 8EY · England Made in China

12 H0 1:87

Loading...

Loading...