Bachmann Europe Plc

Operating Manual

Tank Locomotive, class 75

1-3

, Bad VI b /

former Baden State Railway class VI b

L13118x

L13119x

Note on original:

The Baden VIb was the first German tender locomotive with the axle sequence 1‘C1‘. It was developed by

Maffei for the Grand Ducal Baden State Railways in order to improve operations for example on the Höllental

railway rout.

In 1900 there were still 15 serving as saturated steam locomotives. Another eight blocks of about 100

locomotives followed till 1908. Noteworthy on these locos was the connection pipe between the two

steam domes.

Generating 540 hp and a top speed of 80 km/h it soon became too weak for service on the main line routes

and was gradually replaced by the more powerful, faster and also approximately 1000 mm longer successor

the Class VIc. However, despite everything, or perhaps precisely because of this, the locomotives slowly

became distributed throughout Germany.

Of the 131 locomotives, 122 were taken on by the German State Railway and assigned the Class 751-3.

Between 1921 and 1923 another block of 42 locomotives was delivered. The German Federal Railways

obtained 117 of the vehicles. 1962 saw the last representative of this locomotive, the 75 299, finally withdrawn from service. Seven locos served with the German State Railways in Eastern Germany until finally

decommissioned by 1965.

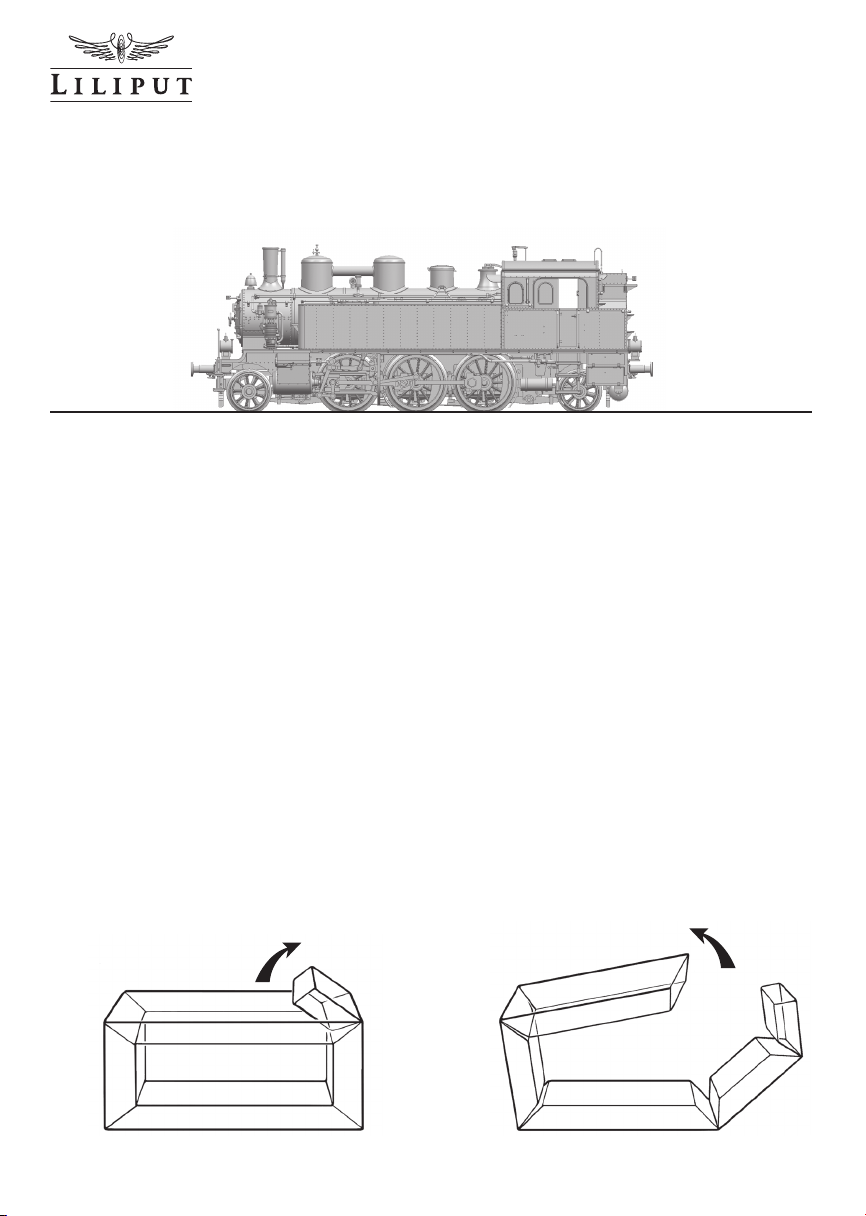

Preparing the model for operation on your layout

Remove your locomotive – encased in the blister pack – carefully from the box. Open the blister pack

according to the illustration in Fig. 1a / 1b, remove the locomotive, and place it on the track. The DC

model is suitable for operation on 14 volts maximum. The AC version is designed as standard for both

analogue operation on 16 volts maximum and for digital operation. First, allow the locomotive to drive

forward and backward for a few minutes at about half the voltage, and then it is ready for operation.

Fig. 1a Fig. 1b

6 H0 1:87

Bachmann Europe Plc

Super-detailing your model

All details are factory fitted with the exception of the two storage compartments SK. These are intended

to complete a static display model or for use when the loco is operated on very large radius curves as

they limit the side play of the rear bogie. Fig. 3 shows how these storage compartments are inserted into

the existing storage unit mouldings from below.

Cornering capability

This model is designed for track systems with even a narrow track radius – minimum radius R 356 mm.

Maintenance and care of your model

To ensure a long useful life, your model should be serviced regularly. For minor service, the model

does not need to be opened. Simply place the model on a soft surface as shown in Fig. 2, clean the

wheel contacts with a cotton swap dipped in denatured alcohol, and then clean the wheels. Under no

circumstances should you turn the drive wheels of the locomotive by hand. After cleaning, apply

a drop of machine oil to the bearing points shown in Fig. 2. Use commercially available oils with a fine

canula or a pin.

Caution: Do not use cooking oils or skin creams!

Fig. 2

H0 1:87 7

Bachmann Europe Plc

Removing the cab

Fig. 3 shows how to detach the cab from the loco body, as follows:

First, using your thumbnails apply gentle pressure to the cab above the forward spectacle plates (forward

view cab windows) and move the cab upwards in a slightly rotating movement; then lift it off. This will

automatically disengage the bunker top TA from its mounting.

Fig. 3

3.

TA

SK

Removing the loco body

Lay the loco upside down

on a soft surface as shown

in Fig. 4 and undo screw S1

and both screws S2. Screw

S1 is accessed by gently

bending the brake rigging

BG upwards, allowing this

to disengage from its fixing

by levering it out with a fine

blade screwdriver.

2.

1.

SK

S2

BG

S1

S2

Fig. 4

8 H0 1:87

Bachmann Europe Plc

Lubrication of the drive mechanism

To access the drive mechanism for lubrication purposes the loco body first needs to be removed from

the chassis (see ”Removing the cab”). Lubricate the worm and toothed gear wheels as shown in Fig. 5.

Apply a commercially available oil with a fine canula or pin. Afterward, move the model slightly forward

and backward to distribute the oil to the transmission components that are situated farther inside. Repeat

this procedure as needed. We recommend this service after every 30 to 40 hours of operation.

KR

S3

SPK

S3

Fig. 5

21-pole digital interface

A built in 21-pole digital interface PL allows conversion to digital operation (Fig. 6). It is accessed by

removing the cab (see ”Removing the cab”) or by removing the complete loco body from the chassis

(see ”Removing the loco body”).

Prior to conversion please ensure

that all functions work correctly in

DC operation. Unplug the bridging

plug JP vertically (Fig. 6) and store

it somewhere safe. Now plug in the

decoder. Please follow exactly the

installation instructions supplied by

the decoder manufacturer. For all

queries regarding decoder function

and installation please contact the

decoder supplier or manufacturer direct. Please note that we can accept

no liability in respect of any decoder

subsequently installed in the model.

Fig. 6

H0 1:87 9

JP

PL

Bachmann Europe Plc

Loco sound system

The loco comes prepared for sound system installation. The installation of the 16 mm speaker requires

the removal of the loco body from the chassis (see ”Removing the loco body”). The boiler backplate

KR (Fig. 5) serves as the speaker securing point. Undo both screws S3 and clip the speaker into place

with the diaphragm facing outwards.

The sound decoder can be plugged vertically into the 21-pole digital interface PL in place of the

bridging plug JP or in place of another decoder. Two connection pins SPK on the circuit board provide

the electrical link for the speaker.

It is essential to follow exactly the instructions supplied by the manufacturer of the decoder and the

speaker. Please note that we can accept no liability in respect of any speaker subsequently installed in

the model.

If you have the AC version of the model...

Please see the following important notes for LILIPUT model operation on the stud contact AC system:

This model is fitted with a decoder (type ESU-LokPilot V 4.0) which allows either analogue 16 volt AC

or digital operation. The mode of operation of the decoder is explained in the accompanying manual

provided by the supplier, ESU.

The stud contact electrical pick up skate is clipped to the chassis by means of support HA, as shown

in Fig. 7. To change the skate, move the securing arms A of support HA laterally slightly outwards with

a small screwdriver. This releases the support and the skate can then be removed.

A

A

HA

Fig. 7

LILIPUT thanks you for purchasing this model

and hopes it brings you a lot of pleasure.

10 H0 1:87

Bachmann Europe Plc

D3

T1G

D4

T1G

R1

2.2K/0603

A

-

+

M1

RIGHT RAILWAY

LEFT RAILWAY

C02

104/1206

C01

104/1206

C1

105/0603

Front

Rear

LED1

W

R3

2.2K/0603

C3

105/0603

LED3

W

R2

2.2K/0603

C2

105/0603

LED2

W

Top Light

M+

M-

R

L

NC

1

NC

11

NC

2

SPEAK2

10

NC

3

SPEAK1

9

NC

4

LEDF

8

NC

5

LEDR

7

NC

6

VDD

12

NC

13

AUX2

14

AUX1

15

V+

16

NC

17

M-

18

M+

19

GND

20

L

21

R

22

CON1

CONNE#10381

R4

2.2K/0603

C4

105/0603

LED4

W

Top Light

L1

22UH

L2

22UH

Low Light

R05

220K/0805

R06

220K/0805

V+

Warm White LEDXX+10205 X 4pcs

Q1

8550

Q2

8550

R04

10K/0805

R02

4.7K/0805

C04

105/0805

C03

105/0805

R01

4.7K/0805

R03

10K/0805

M1+

M1-

D1

T1G

D2

T1G

Low Light

DC Connection Diagram

D3800+PCB03

NC

1

NC

11

NC

2

SPEAK2

10

NC

3

SPEAK1

9

NC

4

LEDF

8

NC

5

LEDR

7

NC

6

VCC

12

NC

13

AUX2

14

AUX1

15

LED+

16

NC

17

M-

18

M+

19

GND

20

L

21

R

22

CON2

CONNE#10341

DIODE#10162

DIODE#10162DIODE#10162

DIODE#10162

SPK

SPEAKER

C05

103/100V

CAPAC#10100

CAPAC#10100CAPAC#10100

CAPAC#10100

AC RAILWAY

AC

CUT

Connect

Connect

(AC)

(AC)

(AC)

BR75 D3118 Circuit Diagram DC AC Circuit Diagram

Circuit Diagram

Warranty Coupon GB

Should your LILIPUT model be faulty or not work properly or require repair, you can either

the dealer from whom you purchased the product or contact the customer services

directly of one of the following addresses below.

GREAT BRITAIN

AND ALL OTHER COUNTRIES

(EXCEPT GERMAN SPEAKING COUNTRIES)

BACHMANN EUROPE PLC

MOAT WAY, BARWELL

GB - LEICESTERSHIRE LE9 8EY

Warranty Conditions:

This LILIPUT model has a warranty of two years from the date of purchase on repairs and parts, as long as it was purchased from an authorised dealer and if this certificate has been stamped with the address of the dealership and the date of

purchase has been entered. The warranty permits Bachmann Europe Plc either to rectify any fault or to replace the faulty

parts. Further claims are excluded.

Please note that no liability can be assumed for any parts subsequently fitted or for any damage caused thereby.

H0 1:87 11

Dealer’s stamp with day of purchasing:

contact

department

Bachmann Europe Plc

Garantie-Schein

Sollte Ihr LILIPUT-Modell einen Mangel oder eine Störung aufweisen oder einmal reparaturbedürftig sein, haben Sie die Möglichkeit, sich diesbezüglich entweder an den Händler, bei dem

Sie das Produkt gekauft haben oder direkt an die Kundendienstabteilung einer der nachfolgend

angegebenen Adressen zu wenden.

DEUTSCHLAND:

BACHMANN EUROPE PLC

NIEDERLASSUNG DEUTSCHLAND

AM UMSPANNWERK 5

D - 90518 ALTDORF BEI NÜRNBERG

ÖSTERREICH:

DOLISCHO MODELLSPIELWAREN

BAHNSTRASSE 4

A - 2340 MÖDLING

Garantiebedingungen:

Dieses LILIPUT-Modell hat ab Kaufdatum zwei Jahre

Garantie auf Reparaturen und Teile, sofern es bei einem

autorisierten Händler gekauft wurde und dieses Zertifikat

vom Händler abgestempelt und das Kaufdatum eingetragen worden ist. Die Garantie umfasst nach Wahl von

Bachmann Europe Plc entweder die Beseitigung eines

eventuellen Mangels oder den Ersatz schadhafter Teile.

Weitergehende Ansprüche sind ausgeschlossen.

Beachten Sie bitte, dass für nachträglich eingebaute Teile

(z.B. Decoder oder Lautsprecher) sowie für dadurch entstandene Schäden keine Haftung übernommen wird.

Wichtig! Wir empfehlen die Originalverpackung aufzubewahren,

sie ist der beste Schutz für Ihr Modell, wenn dieses nicht gerade

auf Ihrer Anlage unterwegs ist. Beim Betrieb der Lok auf Teppichböden kann die feine Mechanik durch Fasern zerstört werden. Änderungen in Konstruktion und Ausführung vorbehalten.

Bitte bewahren Sie diese Beschreibung zum späteren Gebrauch

auf. Dieses Produkt wurde nach Vorschriften der europäischen

Spielzeugrichtlinien (CE) hergestellt. • Important! We recom-

mend that you keep the original box. It is the best place to store

your model, when it is not in use. Please be aware, that carpet

fibres can destroy the fine mechanism of the locomotive. Subject to changes in design, version and technical data. Please

retain these data and instructions for further reference. This

product has been manufactured according to the

European toy Safety Directive (CE). • Importante!

Raccomandiamo di tenere la scatola originale. E’

il posto migliore in cui tenere il tuo modello quando non è in uso. Fibre di tappeti possono distrug-

SCHWEIZ:

MODELLBAU UND

ELEKTRONIK

STETTBACHSTRASSE 193

CH - 8051 ZÜRICH

ALLE ANDEREN LÄNDER:

BACHMANN EUROPE PLC

MOAT WAY, BARWELL

GB - LEICESTERSHIRE LE9 8EY

Kaufdatum mit Händlerstempel:

gere il fine meccanismo della locomotiva. Preghiamo di conservare

questi dati ed istruzioni per altre informazioni. Quest’articolo è stato

prodotto in accordo con la Direttiva Europea Sicurezza giochi (CE).

Achtung! Bei unsachmäßigem Gebrauch besteht Verletzungsgefahr

durch funktionsbedingte scharfe Kanten und Spitzen • Attention! At an

incorrect use there exists danger of hurting because of cutting edges

and tips • Attention! Il y a danger de blessure à un emploi incorrect

à cause des aiguilles et arêtes vives! • Voorzichtig! Bij ondoelmatig

gebruik bestaat verwondigsgevaar door scherpe zijkanten en uitsteek-

sels! • Attenzione! Un uso improprio comporta pericolo di ferimenti

attraverso punte e spigoli taglienti! • Atencion! Un empleo incorrecto

puede causar heridas debido a las puntas y aristas agudas! • Atençao!

Por utilizaçao incorrecta existe o perigo de estragos, em virtude de cor-

tes nas abas e nas pontas! • Προξοχη! Η ακαταλληλη

χρηοη εγκλειει κινδυνουζ μκροτ ραυματιομων, εξ

αιπαξ κοπτερων ακμων και προεξοχωθν • Bemaerk!

Ved ukorrekt brug kan de funktionsbetingede skarpe

kanter og spidser forfolde skade!

Bachmann Europe Plc · Moat Way · Barwell · Leicestershire · LE9 8EY · England Made in China

12 H0 1:87

Loading...

Loading...