Page 1

User's guide

XAC80 PB

ATEX certification category 3

for use in zones 2, 22

and temperature class T5 (T100°C)

• 18-bit singleturn encoder for high precision demands

• 27-bit multiturn encoder for standard purposes

• 30-bit multiturn encoder for high end applications

• Profibus DP configurable as Class 1, Class 2 or Class 2(+VEL) Slave

• Heavy-duty construction for harsh environments

Suitable for the following models:

• XAC8018/1PB

• XAC8013/16384PB

• XAC8016/16384PB

General Contents

1 - Safety summary 17

2 - Identification 19

3 – Certificates 20

4 - Mounting instructions 25

5 - Electrical connections 27

6 - Quick reference 32

7 - Profibus® interface 39

8 - Default parameters list 57

Lika Electronic • Tel. +39 0445 806600 • info@lika.biz • www.lika.biz

Smart encoders & actuators

II 3GD, Ex nA IIB T5 Gc

II 3GD, Ex tc IIIC T100°C Dc, IP65

Profibus-DP profile for encoders

Page 2

This publication was produced by Lika Electronic s.r.l. 2018. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Page 3

Table of Contents

User's guide......................................................................................................................................................... 1

Table of Contents............................................................................................................................................ 3

Subject Index................................................................................................................................................... 5

Typographic and iconographic conventions.............................................................................................6

Preliminary information................................................................................................................................ 7

Glossary of Profibus terms........................................................................................................................... 8

1 - Safety summary..................................................................................................................................... 17

1.1 Safety........................................................................................................................................................................................17

1.2 Electrical safety....................................................................................................................................................................17

1.3 Mechanical safety...............................................................................................................................................................18

1.4 Operational safety...............................................................................................................................................................18

2 - Identification.......................................................................................................................................... 19

3 – Certificates............................................................................................................................................. 20

3.1 Declaration of ATEX Conformity...................................................................................................................................20

3.2 EU Declaration of Conformity.......................................................................................................................................22

3.3 Safety instructions..............................................................................................................................................................23

4 - Mounting instructions......................................................................................................................... 25

4.1 Encumbrance sizes..............................................................................................................................................................25

4.2 Mounting the encoder......................................................................................................................................................26

5 - Electrical connections........................................................................................................................... 27

5.1 Connection cap....................................................................................................................................................................27

5.2 Connection cap with PG gland (cable output).......................................................................................................28

5.3 Ground connection............................................................................................................................................................28

5.3.1 Connection of the shield.........................................................................................................................................29

5.4 Setting the node number: DIP A (Figure 2)..............................................................................................................29

5.5 Baud rate................................................................................................................................................................................ 30

5.6 Bus termination resistance (Figure 2)........................................................................................................................31

6 - Quick reference...................................................................................................................................... 32

6.1 STEP7 configuration...........................................................................................................................................................32

6.1.1 Importing the GSD file..............................................................................................................................................32

6.1.2 Adding a node to the project.................................................................................................................................33

6.1.3 Encoder configuration parameters.....................................................................................................................34

6.2 Reading the diagnostic information...........................................................................................................................35

6.3 Setting the Preset value...................................................................................................................................................37

7 - Profibus® interface................................................................................................................................ 39

7.1 GSD file....................................................................................................................................................................................39

7.2 Classes of the Device profile...........................................................................................................................................39

7.3 Modes of operation............................................................................................................................................................40

7.3.1 Types of communication..........................................................................................................................................40

7.4 DDLM_Set_Prm....................................................................................................................................................................41

7.4.1 Byte 10 - Operating parameters...........................................................................................................................43

Code sequence..................................................................................................................................................................43

Class 2 functionality.....................................................................................................................................................43

Scaling function control.............................................................................................................................................44

Exchange type...................................................................................................................................................................44

7.4.2 Bytes 11 … 14...............................................................................................................................................................45

Page 4

Counts per revolution..................................................................................................................................................45

7.4.3 Bytes 15 … 18...............................................................................................................................................................46

Total resolution................................................................................................................................................................46

7.4.4 Byte 19.............................................................................................................................................................................48

Velocity measure unit..................................................................................................................................................48

7.5 DDLM_Chk_Cfg....................................................................................................................................................................49

7.6 DDLM_Data_Exchange.....................................................................................................................................................49

Position value....................................................................................................................................................................49

Position and velocity values.....................................................................................................................................50

Preset value........................................................................................................................................................................50

7.7 DDLM_Slave_Diag..............................................................................................................................................................52

Station_Status_1..........................................................................................................................................................52

Station_Status_2..........................................................................................................................................................53

Station_Status_3..........................................................................................................................................................53

Master_Add.....................................................................................................................................................................53

Ident_Number................................................................................................................................................................53

Extended diagnostic header.....................................................................................................................................53

Alarms................................................................................................................................................................................53

Operating status............................................................................................................................................................54

Encoder type...................................................................................................................................................................54

Singleturn resolution...................................................................................................................................................54

Number of distinguishable revolutions...............................................................................................................54

7.8 "Dead Zone"...........................................................................................................................................................................55

8 - Default parameters list........................................................................................................................ 57

Page 5

Subject Index

A

Alarms...................................................................................53

C

Class 2 functionality.......................................................43

Code sequence..................................................................43

Counts per revolution....................................................45

E

Encoder type......................................................................54

Exchange type...................................................................44

Extended diagnostic header........................................53

I

Ident_Number...................................................................53

M

Master_Add........................................................................53

N

Number of distinguishable revolutions..................54

O

Operating status...............................................................54

P

Position and velocity values........................................50

Position value....................................................................49

Preset value........................................................................50

S

Scaling function control...............................................44

Singleturn resolution......................................................54

Station_Status_1.............................................................52

Station_Status_2.............................................................53

Station_Status_3.............................................................53

T

Total resolution.................................................................46

V

Velocity measure unit....................................................48

Page 6

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters and objects of both Lika device and interface are coloured in GREEN;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee

the safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Page 7

Preliminary information

This guide is designed to provide the most complete information the operator needs to correctly and

safely install and operate the following encoders fitted with Profibus interface:

XAC8018/1PB-xx (18 bit singleturn encoder)

XAC8013/16384PB-xx (13 +14 bit multiturn encoder)

XAC8016/16384PB-xx (16 +14 bit multiturn encoder)

For technical specifications please refer to the product datasheet.

To make it easier to read the text, this guide can be divided into some main sections.

In the first section (from chapter 1 to chapter 4) general information concerning the safety, the

mechanical installation and the electrical connection.

In the second section (chapter 5) information on how to install and configure the encoder under the

Siemens STEP7 development environment as well as tips for setting up and running properly and

efficiently the unit are provided.

In the third section (chapters 6 and 7) both general and specific information is given on the Profibus

interface. In this section the interface features and the parameters implemented in the unit are fully

described.

Page 8

Glossary of Profibus terms

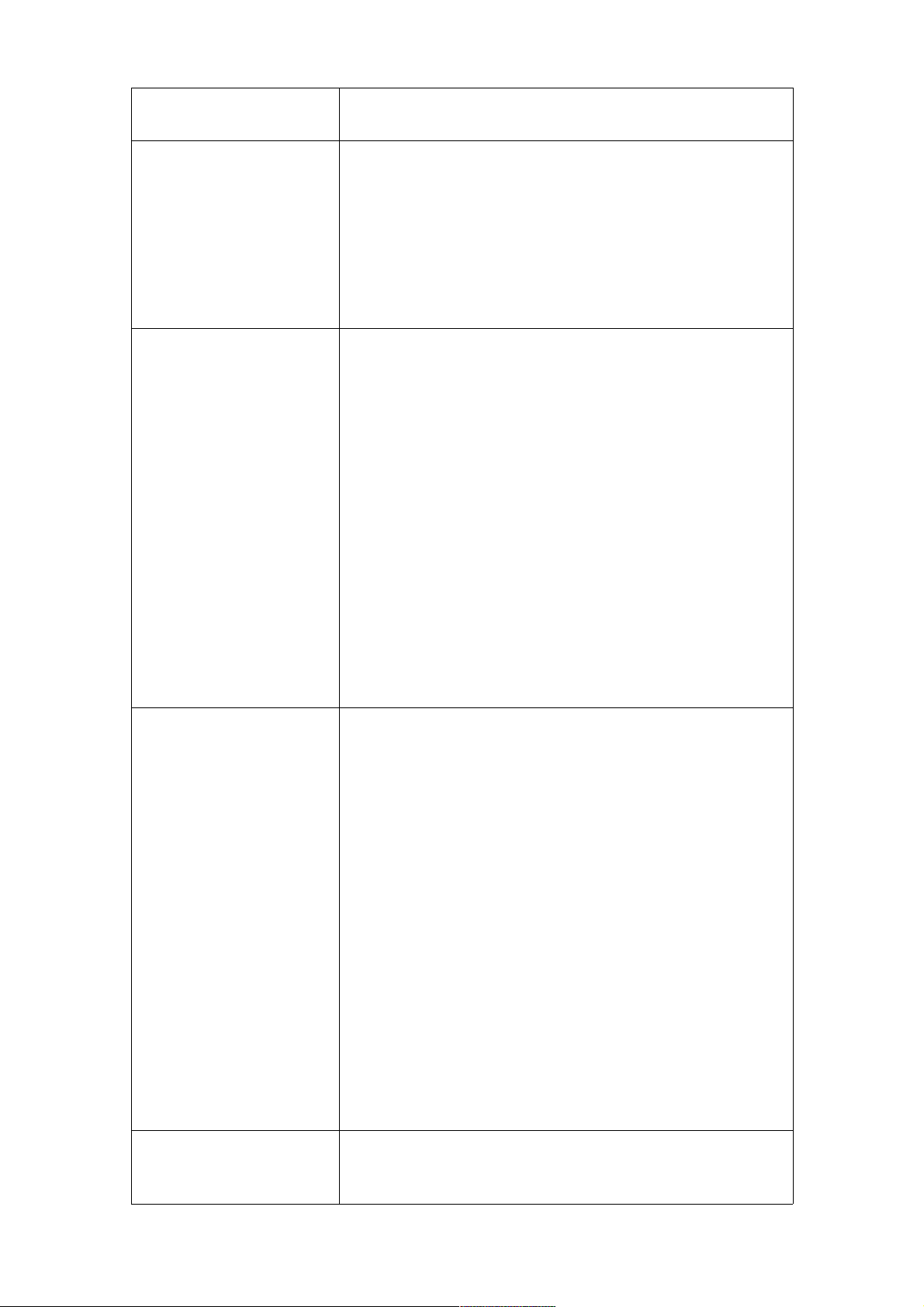

Profibus, like many other networking systems, has a set of unique terminology. Table below contains a

few of the technical terms used in this guide to describe the Profibus interface. They are listed in

alphabetical order.

Address (Station)

IEC 61158-2: Medium attachment unit identification - unique

number of a station connected to a segment (participant).

Address Space

Within PROFIBUS DP the maximum possible number of

addressable network nodes per segment, e.g. 127.

Alarm

Notification of an abnormal or unexpected event within a

system. Alarms in PROFIBUS DP require in addition to the

standard diagnosis event mechanism within the cyclic data

exchange a separate acyclic acknowledgement procedure

between a host and a Slave application. Since DP-V1, "Device

related diagnosis" is the basis for the "Alarm" and "Status"

types of diagnosis events (GSD: "DPV1"=1). PROFIBUS DP

defines the following alarm types: Diagnosis, Status, Process,

Update, Pull and Plug Alarm. See "Device Related Diagnosis".

The PNO maintains a Profile Guideline, Part3: Diagnosis,

Alarms and Time Stamping, order no. 3.522.

Alert

Alert is a generic term for two different types of notifications

within a PROFIBUS DP/PA network especially arranged but not

exclusively for the process automation:

• alarm;

• event.

Both alert types may be used with or without a user

acknowledgement mechanism. The PNO maintains a PROFIBUS

guideline "Time Stamp", order no. 2.192.

Application Profile

Within PROFIBUS a specified agreement within families of

field devices on how to use the general PROFIBUS

communication platform and its subsystems (e.g. device

integration via GSD, EDD, FDT/DTM and Communication

Function Blocks). Communication profiles are not a part of the

PROFIBUS DP application profiles. See "Profile".

Baud rate (Data Rate)

Other common terms are "data transfer rate" and

"transmission rate". Within PROFIBUS DP this is the amount of

data transferred across a fieldbus segment per second. A data

rate is measured in units of bits per second ( "b/s" or "bps"), or

baud.

Bus Cycle

The period of time the bus Master needs to poll every

participant (Slave) once. More bus Masters can be activated by

using the token principle which consequently prolong the bus

cycle.

Page 9

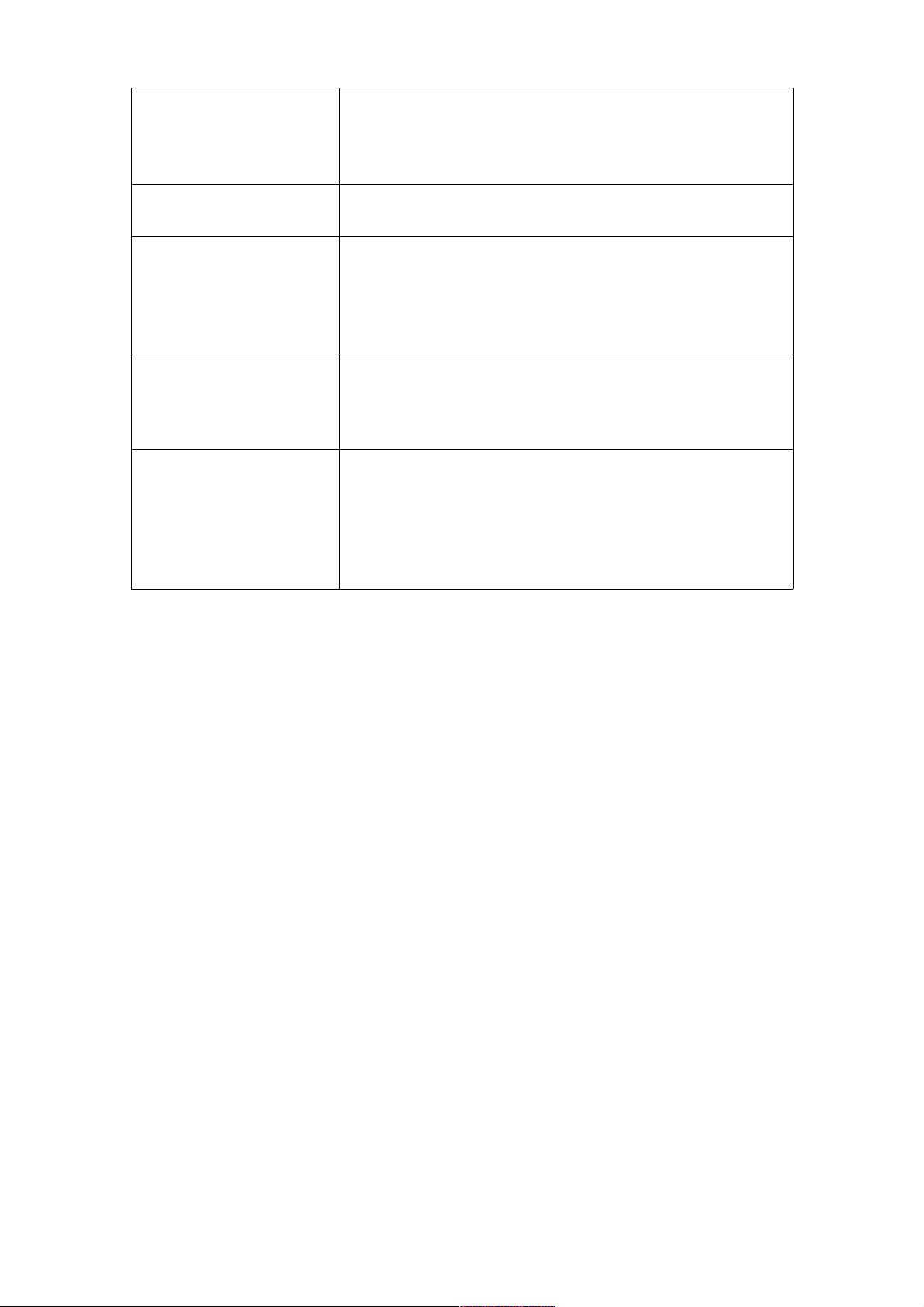

Class

See “DP Master”, “DP Master Class 1 (DPM1)” and “DP Master

Class 2 (DPM2)”.

Class 1 encoder

Encoder class must be set when you configure the device.

Mandatory Class 1 provides the basic functions of the device

and can be used for:

• sending the position value (see Position value

parameter);

• changing the counting direction (see Code sequence

parameter);

• setting the preset value (see Preset value parameter);

• acquiring reduced diagnostic information (see

Diagnostic type parameter = “16 bytes fixed (6+10)”).

Class 2 (+VEL) encoder

Encoder class must be set when you configure the device.

Class 2 (+VEL) provides all the Class 1 and Class 2 functions

and additional velocity-related functions:

• transmission of the velocity value (see Position and

velocity values parameter);

• setting of the velocity measuring unit (see Velocity

measure unit parameter).

Class 2 encoder

Encoder class must be set when you configure the device.

Class 2 provides all the Class 1 functions and additional

advanced functions such as:

• scaling function (see Scaling function control,

Counts per revolution and Total resolution

parameters);

• extended diagnostic information (see Diagnostic type

parameter = “16 bytes (6+10)” or “63 bytes (6+57)”).

Communication Function

Block (Comm FB)

A basic function block defined for PROFIBUS DP and supplied

by the PLC manufacturer for the standardized access of user

programs to field devices. The standardization is based on IEC

61131-3. The PNO maintains a guideline "PROFIBUS

Communication and Proxy Function Blocks acc. to IEC 611313", order no. 2.182.

Communication

Parameter

Communication parameters are parameters, which adjust the

communication protocol function to the current net

configuration. Communication parameters exist for all phases

of the communication protocols. Examples are bus address,

token rotation time, idle time. See "Slave parametrization" and

"Device parametrization".

Communication Profile

IEC 61158 comprises a summary of layer stacks of several

different fieldbusses. IEC 61784 defines the useful

combinations of these stacks via communication profiles

CPF3/1 up to CPF3/3 (PROFINET). One of these is PROFIBUS DP.

Within this communication profile three different physical

profiles are defined:

• RS 485 (RS 485-IS);

• MBP-IS (MBP-LP, MBP);

Page 10

• Fibre Optics.

Cyclic Data Exchange

IEC 61158-3: Term used to describe events which repeat in a

regular and repetitive manner. The MS0 services of PROFIBUS

DP are based on cyclic data exchange. See "State machine".

Cyclic Redundancy Check

(CRC)

Error-checking technique in which the frame recipient

calculates a remainder by dividing frame contents by a prime

binary divisor and compares the calculated remainder to a

value stored in the frame by the sending node.

Data Rate (Baud rate)

Other common terms are "data transfer rate" and

"transmission rate". Within PROFIBUS DP this is the amount of

data transferred across a fieldbus segment per second. A data

rate is measured in units of bits per second ("b/s" or "bps"), or

baud.

Decentralized Peripherals

(DP)

The term "Decentralized Peripherals" and the acronym "DP"

stand for the simple, fast, cyclic and deterministic I/O data

exchange between a bus Master and its assigned Slave devices.

The corresponding PROFIBUS communication protocol is

called PROFIBUS DP.

Device Identifier

Ident number: The primary device identification is an ident

number of data type Unsigned16. This number is unique and

assigned by the PNO business office upon application. It is

stored within the device and defined in the corresponding

GSD file via keyword. In addition it is part of the GSD file

name. At runtime the ident number is used within:

• the set Slave address procedure;

• the parametrization telegram (octet 5 + 6);

• the standard part of a diagnosis message (octet 5 + 6).

The ident number explicitly cannot be retrieved from a device.

Its main purpose is to make sure that a GSD file and

configuration/parametrization data between Master Class 1

and its Slave are matching. The PNO maintains a technical

guideline "Specification for PROFIBUS device description and

device integration, Volume 1: GSD", Version 5.0, order no.

2.122. For a secondary identification possibility see the

identification & maintenance functions (I&M). See "Ident

Number".

Device Parametrization

The device parametrization within PROFIBUS DP consists of

three phases. The first phase takes place during start-up of the

communication system and provides basic communication

parametrization and simple additional device parameters. Both

are defined within the GSD file of a device, stored within a

Master Class 1 after configuration in an engineering tool, and

transmitted to the Slave at start-up time. Most of the

automation cases in factory automation are covered by this

method. More complex devices such as drives, laser scanners,

scales, robots, transmitters, etc. require further individual

parametrization before final production start. This is done in a

second phase. In process automation certain device

Page 11

parameters such as value limits, value range, gain, etc. need to

be adjusted even at run-time. For this second and third phase

PROFIBUS DP provides two ways to accomplish the task:

DTM/FDT and EDD. See "Slave parametrization" and

"Communication parameter".

Device Profile

See "Profile".

DP Master

IEC 61158-5: Within PROFIBUS DP a fieldbus node that can be

either Master Class 1 or Master Class 2. A Master Class 1 is a

controlling device which controls several DP Slaves (field

devices). NOTE: This is usually hosted by a programmable

controller or a process controller.

A Master Class 2 is a controlling device which manages

configuration data (parameter sets) and diagnosis data of a DP

Master Class 1, and that additionally can perform all

communication capabilities of a DP Master Class 1.

DP Master Class1 (DPM1)

IEC 61158-5: A controlling device which controls several DPSlaves (field devices). Usually programmable (logic) controllers

or process control systems are hosts for Master Class 1.

DP Master Class2 (DPM2)

IEC 61158-5: A controlling device which manages

configuration data (parameter sets) and diagnosis data of a

DP-Master (Class 1). Additionally the DP-Master (Class 2) can

perform all communication capabilities of a DP-Master (Class

1). Usually personal computers are hosts for DP Master Class 2

for programming, parametrizing, diagnosing and monitoring

purposes.

DP Slave

IEC 61158-5: A field device that is assigned to one DP Master

Class 1 as a provider for cyclic I/O data exchange. In addition

acyclic functions and alarms could be supported.

Event

Within PROFIBUS DP/PA this is a signal or I/O data or process

value within a certain field device at that point in time where

a trigger condition arises. The values are associated with a

time stamp and stored in a buffer. The time-stamped sample

values are used to archive and visualize significant changes

over the course of the production process. Such an event

mechanism does not prevent from the cyclic transmission of

these signals. A separate event alarm is requesting the transfer

of the events to the main system.

Frame

A single set of data transmission from a device.

General Station

Description (GSD)

A GSD is an electronically readable ASCII text file and contains

both general and device-specific parameters for

communication and network configuration. By means of

keywords, a configuration tool allows to:

• read device information (manufacturer, type, versions,

bitmaps, etc.);

• read texts for comfortable and easy to use

configuration;

• select transmission rates;

Page 12

• select modules and their I/O data length

(configuration identifier);

• read texts to assign diagnosis IDs to HMI displays;

• select supported services (freeze, sync, etc.);

from the GSD for the configuration of the device. A GSD

replaces the previously conventional manuals or data sheets

and thus already supports plausibility checks during the

configuration phase. Distinction is made between a device

GSD (for an individual device only) and a profile GSD, which

may be used for devices that comply exactly with a profile

such as a "PA device". GSDs for different languages may be

provided in separate files with corresponding file extensions

(*.gse for English, *.gsg for German, etc.) or altogether in one

file (*.gsd). The device manufacturers are responsible for the

scope and quality of the GSD of their devices.

Ident Number

See "Device Identifier".

Notes:

• the ident number is necessary for all DP devices except

for Master Class 2;

• the same ident number may be used for modular

devices as long as the device can be described in the

GSD file as a modular device.

Identifier

In general: a symbol that establishes the identity of the one

bearing it. Within this context here it represents an absolute

value of a parameter such as a physical address. It is intended

for systematic and performance handling capabilities within

computer systems, e.g. sorting, consistency checking, physical

localization and alike. Usually an absolute value is associated

with a logical value to represent the particular deployment of

the identifier. Typical abbreviation for identifier is ID.

IEC 61131-3: A combination of letters, numbers and underline

characters, which begins with a letter or underline and which

names a language element. Some of the major identifiers

within PROFIBUS DP are:

- Data type numeric identifier;

- Configuration identifier (Cfg);

- Device identifier (ident number);

- Manufacturer identifier (MANUFACTURER ID);

- Profile ident number (PROFILE ID).

Index

IEC 61158-5: Address of an object within an application

process.

The permitted range in PROFIBUS DP is 0 - 255. Indexes are

used to address records of data (parameters, variables, state

information, commands, etc.) within modules of a field device.

PDU (Protocol Data Unit)

A packet of data passed across a network via telegrams. The

term implies a specific layer of the OSI seven layer model and

a specific protocol. Each layer has its own PDU that is

extended subsequently from the physical layer up to the

application layer:

Page 13

• Physical layer protocol data unit (PhPDU);

• Data link protocol data unit (DLPDU);

• Application protocol data unit (APDU).

PI

The

PROFIBUS Nutzerorganisation e.V.

(PROFIBUS User

Organisation, or PNO) was created in 1989. This group was

composed mainly of manufacturers and users from Europe. In

1992, the first regional PROFIBUS organization was founded

(PROFIBUS Schweiz in Switzerland). In the following years,

additional Regional PROFIBUS & PROFINET Associations (RPAs)

were added. In 1995, all the RPAs joined together under the

international umbrella association PROFIBUS & PROFINET

International (PI). Today, PROFIBUS is represented by 25 RPAs

around the world (including PNO) with over 1400 members,

including most if not all major automation vendors and

service suppliers, along with many end users.

PNO

The

PROFIBUS Nutzerorganisation e.V.

(PROFIBUS User

Organisation, or PNO) was created in 1989. This group was

composed mainly of manufacturers and users from Europe. In

1992, the first regional PROFIBUS organization was founded

(PROFIBUS Schweiz in Switzerland). In the following years,

additional Regional PROFIBUS & PROFINET Associations (RPAs)

were added. In 1995, all the RPAs joined together under the

international umbrella association PROFIBUS & PROFINET

International (PI). Today, PROFIBUS is represented by 25 RPAs

around the world (including PNO) with over 1400 members,

including most if not all major automation vendors and

service suppliers, along with many end users.

PROFIBUS

PROcess FIeldBUS. PROFIBUS is a manufacturer independent

fieldbus standard for applications in manufacturing, process

and building automation. The PROFIBUS family is composed of

three types of protocol, each of which is used for different

tasks. The three types of protocols are: PROFIBUS FMS, DP and

PA.

IEC 61784-1: Communication network according to

communication profile family 3 (CPF3); incorporating

application profiles and system integration aspects like

interfaces and languages for engineering tools and HMI.

PROFIBUS is an open, digital communication system with a

wide range of applications, particularly in the fields of factory

and process automation. PROFIBUS is suitable for both fast,

time-critical applications and complex communication tasks.

The PROFIBUS logo is a registered trademark.

PROFIBUS DP

Acronym for "PROFIBUS for Decentralized Peripherals".

Specification of an open fieldbus system with the following

characteristics:

• polling Master-Slave-system (cyclic communications,

MS0);

• flying Masters with robin round token passing

coordination (MM);

Page 14

• connection based (MS1) and connectionless (MS2,

MS3) acyclic communication between Masters and

Slaves.

Options (e.g.):

• Data exchange broadcast (DXB), i.e. Slave to Slaves

communication;

• isochronous mode of Slaves;

• clock synchronization;

• redundancy.

PROFIBUS DP is standardized within IEC 61158 and IEC 61784,

communication profile families 3/1 and 3/2. The term

"PROFIBUS DP" is also a synonym for the RS-485 based

deployments within factory automation.

PROFIdrive

Communication technology especially adopted to the

requirements of position and speed controlled drive

applications (e.g. speed synchronized axis). Within the scope of

PROFIBUS, "PROFIdrive" is used for the application of the

PROFIBUS DP protocol (DP-V2) in motion control automation

together with the corresponding application profiles

("PROFIdrive - Profile for variable speed drives" and

"PROFIdrive - Profile drive technology") for the transmission

technology RS-485.

Profile

Besides other things profiles in common define agreements on

how to use communication means in a standardized manner.

Within the context of fieldbusses several types of profiles are

known:

• communication profiles (e.g. IEC 61784);

• physical profiles (MBP-IS, RS-485);

• application profiles (see PROFIBUS TC3);

• device profiles (e.g. robots);

• branch profiles (e.g. extruder).

Profile Ident Number

Identifier of a particular profile definition. The profile ident

number is taken from the pool of ident numbers handled by

the PNO. It plays a role within the following scenarios.

(1) In cases where the device of a manufacturer A should be

replaceable by an equivalent device, the PNO is assigning

number ranges to dedicated device types (Profile specific IDs)

in combination with certain "Profile GSDs". Profiles using this

methodology are e.g. "PA Devices" and "PROFIdrive".

(2) Usually these Slave devices are designed to communicate

with a Master Class 2 application (e.g. profile application or

profile DTM). In order to ensure a Master application is

communicating with an appropriate Slave, it is sending a

profile specific ID during the establishment of the connection

(MS2 Initiate Service). The Slave may answer with the same

profile specific ID (if it is supporting this profile), with another

ID (if it is supporting another profile) or with "0000h" if it is

not supporting any profile.

(3) I&M functions: Besides its basic I&M information devices -

Page 15

following a certain profile - are enabled to provide more

detailed profile specific information.

Protocol Data Unit (PDU)

A packet of data passed across a network via telegrams. The

term implies a specific layer of the OSI seven layer model and

a specific protocol. Each layer has its own PDU that is

extended subsequently from the physical layer up to the

application layer:

• Physical layer protocol data unit (PhPDU);

• Data link protocol data unit (DLPDU);

• Application protocol data unit (APDU).

Slave Parametrization

For a DP Slave several levels of parametrization exist.

(1) The parameters on the DP communication level can be

defined via a GSD file and comprise features such as baud

rates, timing constraints, identification, options, transferable

data structures, publisher subscriber links, etc. This level

supports parametrization of simple modular Slaves and also

special common additional communication layers such as

PROFIsafe. This parametrization is fixed for a given operational

life cycle after start-up.

(2) More complex devices may be parametrized via EDD and/or

FDT/DTM technology via an acyclic communication service

(MS2).

(3) For parameter changes at run-time such as batch

operation (recipes) or motion control, special "parameter

channels" associated with the cyclic data structures may be

added or the MS1 services together with proxy function blocks

may be used.

State Machine (DP)

An abstract machine consisting of a set of states (including

the initial state), a set of input events, a set of output events,

and a state transition function. A state machine describes the

behaviour of a field device how to react in different situations.

The state machine for DP Slaves comprises the following

states/actions:

- Power_On_Reset --> Set Slave address --> if successful, a

transition follows to:

- Wait_Prm --> Parametrization, diagnosis (optional) --> if

successful, a transition follows to:

- Wait_Cfg --> Configuration, diagnosis (optional) --> if

successful, a transition follows to:

- Data_Exch --> Normal operation: cyclic data exchange.

On top of this basic communication layer state machine

application profiles are defining their own additional state

machines, e.g. PA devices, PROFIdrive, PROFIsafe, Ident

Systems, Weighing and Dosage Systems.

State machines are best modelled and documented with the

help of the "Unified Modelling Language (UML)".

Station Address

Within PROFIBUS DP the address of a communication

participant (Master or Slave). The permitted range is 0 to 127,

with:

Page 16

- 126 intended to be used for the "soft" addressing of Slave

devices;

- 127 intended to be used for broadcast messages to all the

Slaves.

Topology

In a communication network, the pattern of interconnection

between network nodes; e.g. bus, ring, star configuration.

Transmission Rate (Baud

rate)

The signalling rate of a digital communication line. It is the

switching speed, or number of transitions (voltage or

frequency changes) that are made per second. Within

PROFIBUS DP the possible transmission rates depend on the

MAU (Medium Attachment Unit) in use.

Watchdog Control

IEC 61158-6: This timer is part of the DP layer within a Slave.

It is restarted by received requests from the bus Master and

will set the outputs of a Slave to a fail-safe state after the

expiration of the timer.

Watchdog Time (Twd)

IEC 61158-5: The watchdog timer is part of the DP layer

within a Slave. The watchdog time is set by parametrization at

run-up and consists of a watchdog time base (1 or 10 ms) and

2 factors. A selection can be made during configuration via

the GSD file of a Slave. This is a Slave parameter. See

"Watchdog control".

Page 17

XAC80 Profibus-DP

®

1 - Safety summary

1.1 Safety

Always adhere to the professional safety and accident prevention regulations

applicable to your country during device installation and operation;

installation and maintenance operations have to be carried out by qualified

personnel only, with power supply disconnected and stationary mechanical

parts;

device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

high current, voltage and moving mechanical parts can cause serious or fatal

injury;

failure to comply with these precautions or with specific warnings elsewhere

in this manual violates safety standards of design, manufacture, and

intended use of the equipment;

Lika Electronic assumes no liability for the customer's failure to comply with

these requirements.

1.2 Electrical safety

Turn off power supply before connecting the device;

connect according to explanation in the “5 - Electrical connections” section

on page 27;

in compliance with the 2014/30/EU norm on electromagnetic

compatibility, following precautions must be taken:

- before handling and installing, discharge electrical charge from

your body and tools which may come in touch with the device;

- power supply must be stabilized without noise, install EMC filters on device

power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive noise

source, shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets on

or near by the unit;

- minimize noise by connecting the shield and/or the frame to ground. Make

sure that ground is not affected by noise. The connection point to ground

can be situated both on the device side and on user’s side. The best solution

to minimize the interference must be carried out by the user. Provide the

ground connection as close as possible to the encoder. We suggest using the

ground screw provided in the cap (see Figure 1);

the rated supply voltage must not exceed 30Vdc;

in classified areas the electrical connection of the device must be carried out

in compliance with the methods stated in the EN 60079-0 regulation;

MAN XAC80 PB E 1.0.odt 1 - Safety summary 17 of 60

Page 18

XAC80 Profibus-DP

®

the user has to take suitable measures in order to prevent longer or

continuous disturbances that cause the supply voltage to exceed by 10% or

more;

the product must be protected against overheating due to mechanical or

electrical overloading.

1.3 Mechanical safety

Install the device following strictly the information in the section “4 -

Mounting instructions”;

mechanical installation has to be carried out with stationary mechanical

parts;

do not disassemble the encoder;

do not tool the encoder or its shaft;

delicate electronic equipment: handle with care; do not subject the device

and the shaft to knocks or shocks;

respect the environmental characteristics declared by manufacturer.

1.4 Operational safety

The described products are category 3 certified and are designed for use in

potentially explosive zones 2 (according to EN60079-15) and 22 (according

to EN60079-31). They are suitable for a safe use and a normal level of

protection in areas in which explosive atmospheres caused by mixture of

gases and vapors (zone 2) or dust (zone 22) are unlikely to occur and if they

do occur do so for a short period of time. They comply with the

constructional safety requirements of the temperature class T5 (T100°C =

+212°F). They are not to be used in Zones 0, 1, 20 and 21;

protection requirements: Zone 2, gas explosion protection (G): protection by

non sparking equipment: the construction minimizes the occurrence of

sparks, arcs or hot surfaces, which in normal operation might give the risk of

explosion; Zone 22, dust explosion protection (D): the construction of the

product protects against the penetration of dust in hazardous quantities

(min. IP5x) and guarantees that the surface temperature is under the ignition

temperature of dust/air mixture as well as under the smoldering temperature

of dust deposits;

the manufacturer's specifications (temperature, speed, …) must under no

circumstances be exceeded;

max. permissible environmental temperature: -20°C +40°C (-4°F +104°F) at

continuous rotational speed of max. 6000 rpm;

the maximum surface temperature (in °C) of the product must not exceed

2/3 of the ignition temperature of the dust/air mixture;

in continuous operation the plastic parts must be able to withstand a

temperature 10°C higher than the maximum temperature that can be

reached in the hottest point of the product while the environmental

temperature is the highest allowed during operation.

MAN XAC80 PB E 1.0.odt 1 - Safety summary 18 of 60

Page 19

XAC80 Profibus-DP

®

2 - Identification

Device can be identified through the order code and the serial number printed

on the label applied to the enclosure. Information is listed in the delivery

document too. Please always quote the order code and the serial number when

reaching Lika Electronic for purchasing spare parts or needing assistance. For

any information on the technical characteristics of the product refer to the

technical catalogue.

Warning: encoders having order code ending with "/Sxxx" may have

mechanical and electrical characteristics different from standard and

be supplied with additional documentation for special connections

(Technical Info).

MAN XAC80 PB E 1.0.odt 2 - Identification 19 of 60

Page 20

XAC80 Profibus-DP

®

3 – Certificates

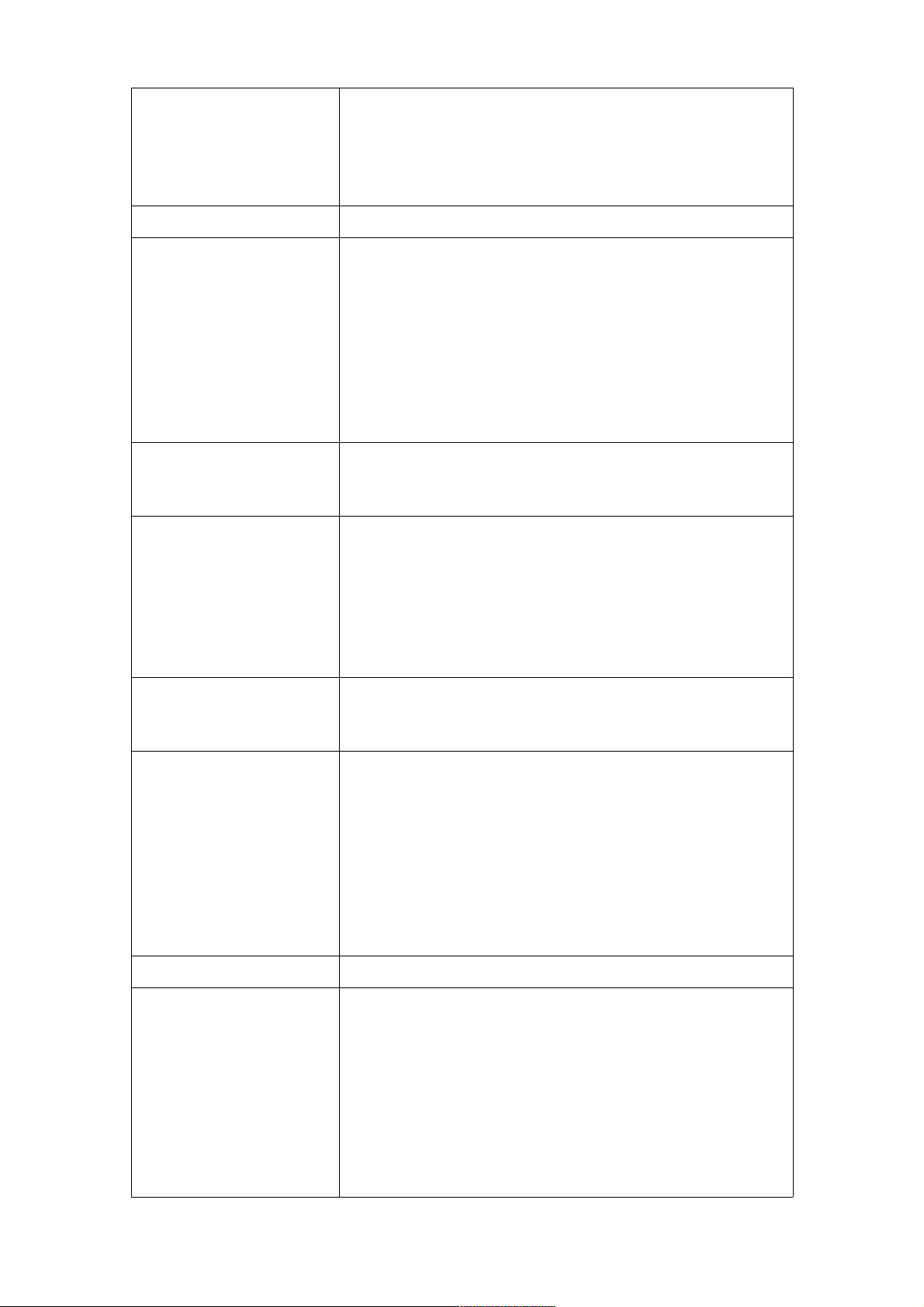

3.1 Declaration of ATEX Conformity

MAN XAC80 PB E 1.0.odt 3 – Certificates 20 of 60

Page 21

XAC80 Profibus-DP

®

MAN XAC80 PB E 1.0.odt 3 – Certificates 21 of 60

Page 22

XAC80 Profibus-DP

®

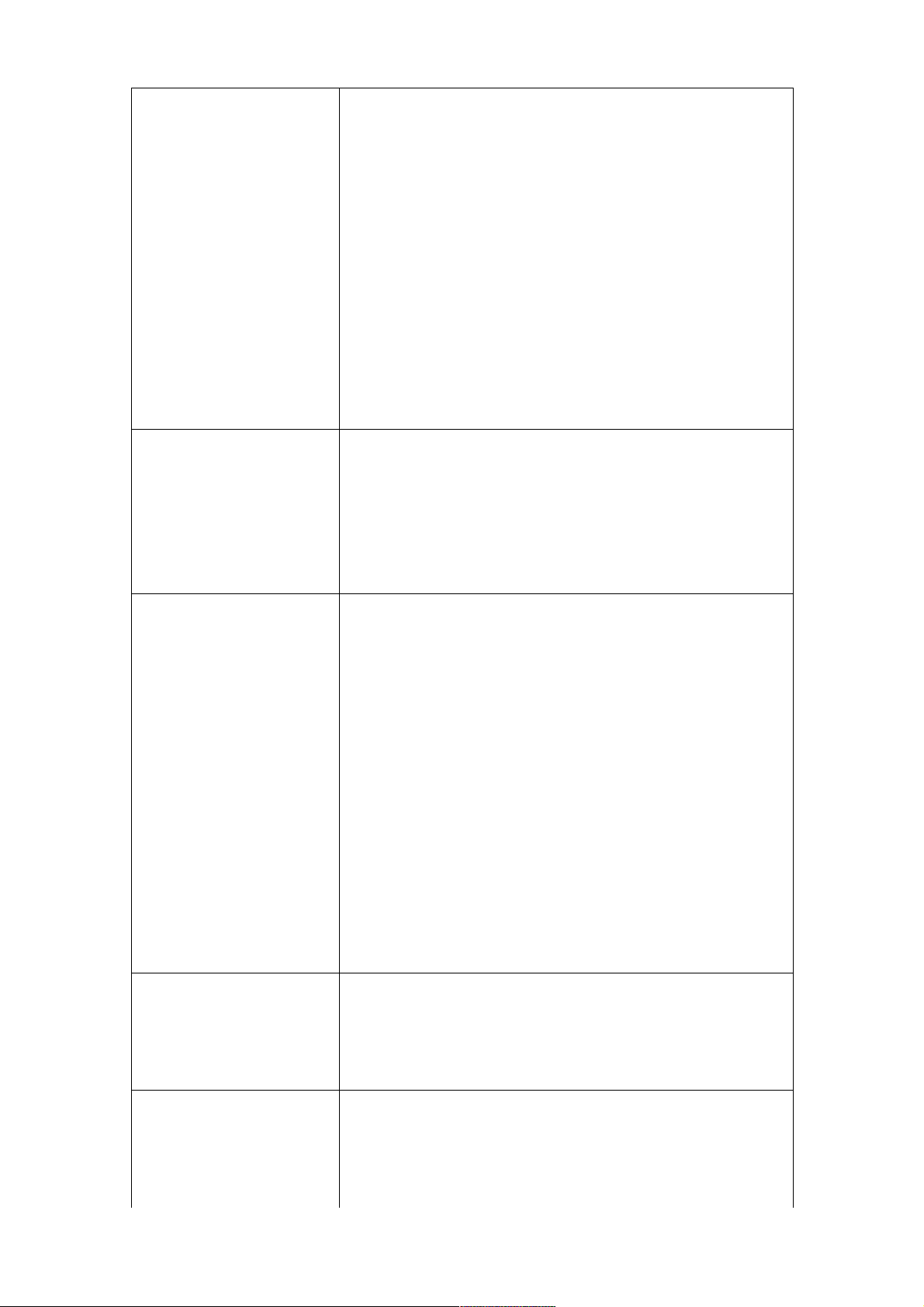

3.2 EU Declaration of Conformity

MAN XAC80 PB E 1.0.odt 3 – Certificates 22 of 60

Page 23

XAC80 Profibus-DP

®

3.3 Safety instructions

MAN XAC80 PB E 1.0.odt 3 – Certificates 23 of 60

Page 24

XAC80 Profibus-DP

®

MAN XAC80 PB E 1.0.odt 3 – Certificates 24 of 60

Page 25

XAC80 Profibus-DP

®

4 - Mounting instructions

WARNING

Installation and maintenance operations must be carried out by qualified

personnel only, with power supply disconnected and mechanical parts

compulsorily in stop.

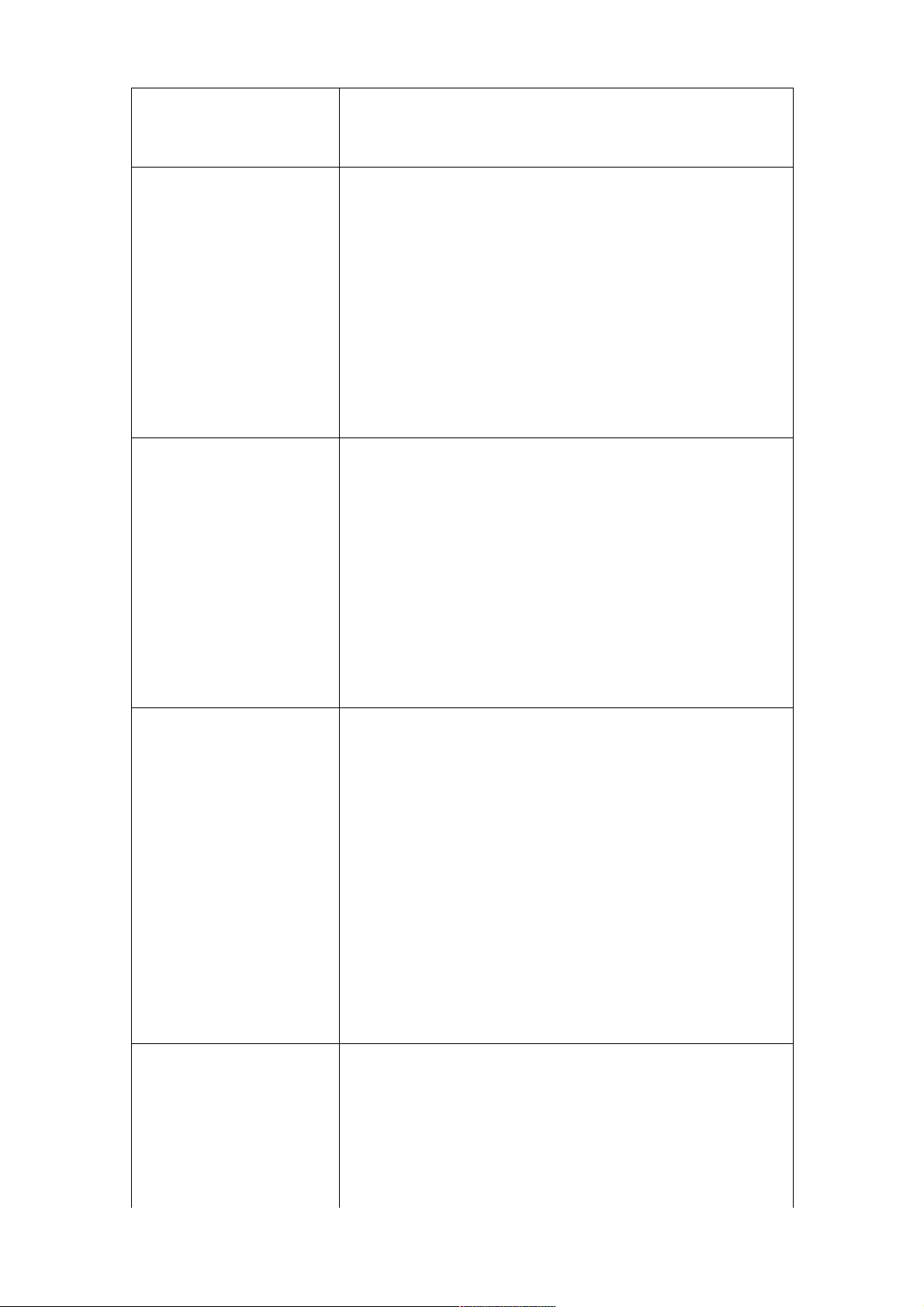

4.1 Encumbrance sizes

(values are expressed in mm)

MAN XAC80 PB E 1.0.odt 4 - Mounting instructions 25 of 60

Page 26

XAC80 Profibus-DP

®

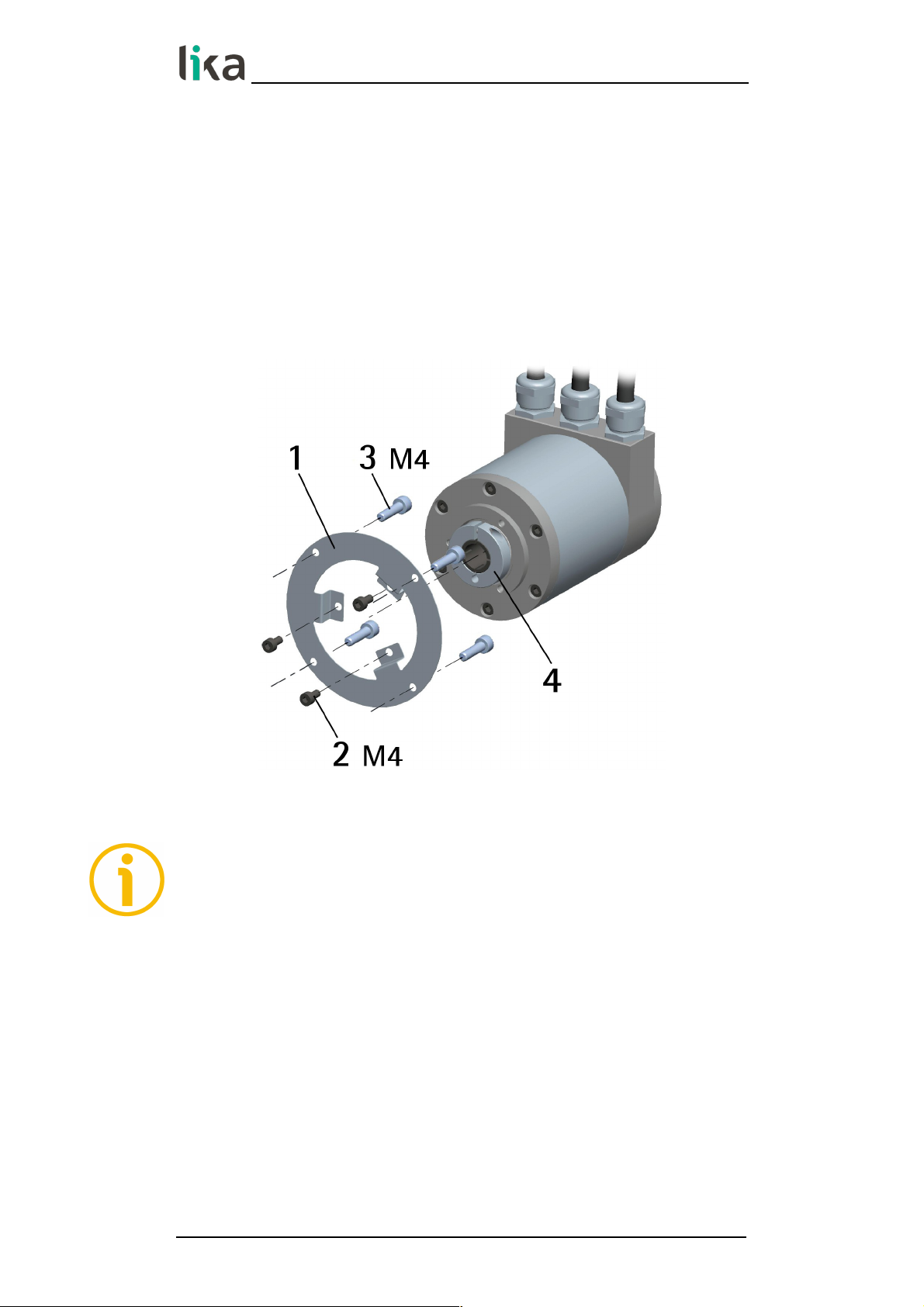

4.2 Mounting the encoder

• Fasten the fixing plate 1 to the encoder using the three M4 screws 2

provided with the device;

• mount the encoder on the motor shaft using the reducing sleeve (if

supplied); avoid forcing the encoder shaft;

• fasten the fixing plate 1 to the rear of the motor using four M4 cylindrical

head screws 3;

• fix the collar 4 to the encoder shaft (apply threadlocker to screw).

NOTE

You are strongly advised not to carry out any mechanical operations (drilling,

milling, etc.) on the encoder shaft. This could cause serious damages to the

internal parts and an immediate warranty loss. Please contact out technical

personnel for the complete availability of custom made shafts.

MAN XAC80 PB E 1.0.odt 4 - Mounting instructions 26 of 60

Page 27

XAC80 Profibus-DP

®

5 - Electrical connections

WARNING

Electrical connections must be carried out by qualified personnel only, with

power supply disconnected and mechanical parts compulsorily in stop.

5.1 Connection cap

WARNING

Do not remove or mount the connection cap with power supply switched ON.

Damage may be caused to internal components.

The terminal connector for connecting the power supply and the BUS IN and

BUS OUT cables as well as the DIP switches meant to set the node ID and

activate the termination resistance are located inside the encoder connection

cap. Thus you must remove the connection cap to access any of them.

NOTE

Be careful not to damage the internal components when you perform this

operation.

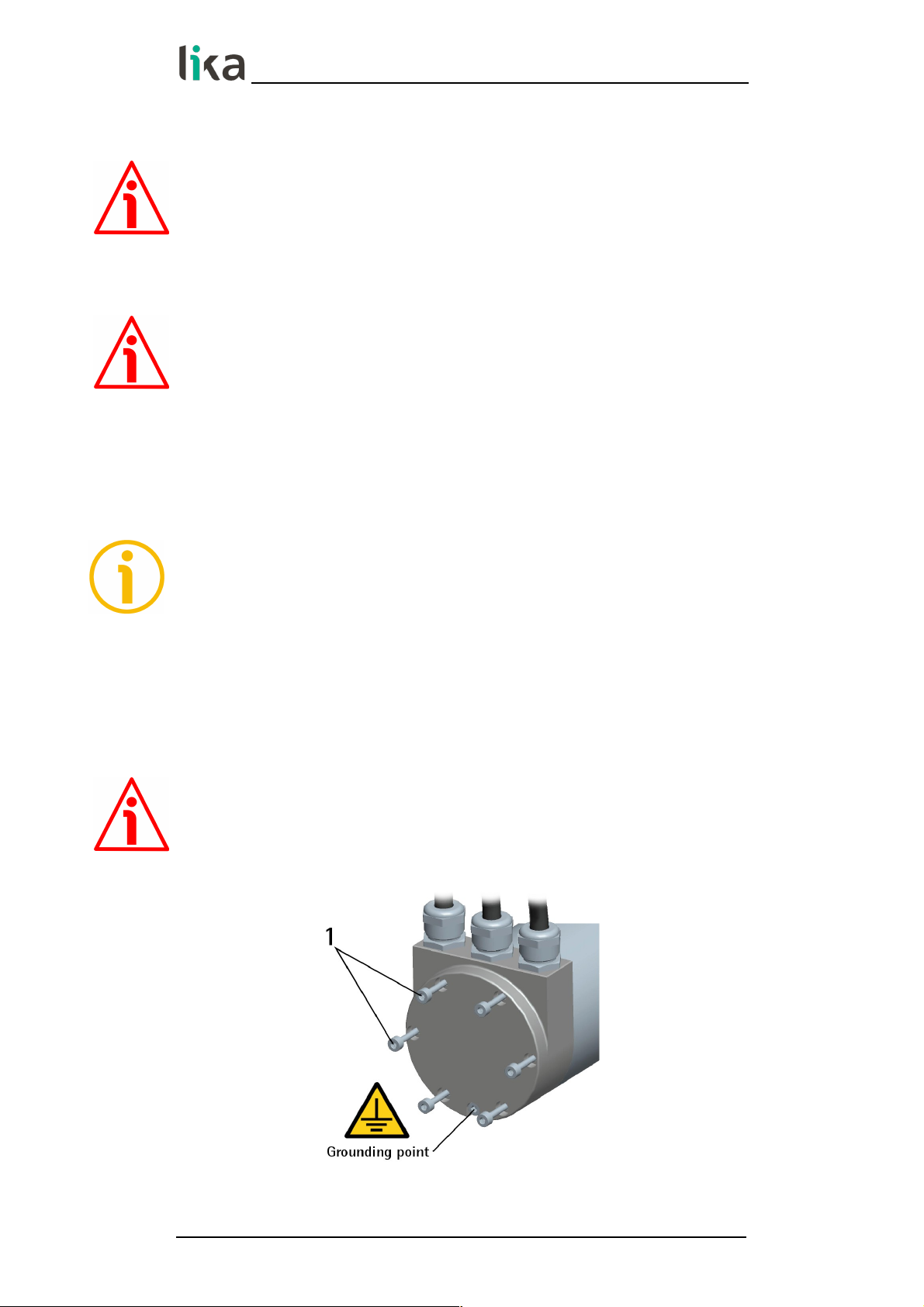

To remove the connection cap loosen the six screws 1. Please be careful with

the internal 15-pin D-SUB connector.

Always replace the connection cap at the end of the operation. Take care in reconnecting the internal 15-pin D-SUB connector. Tighten the screws 1 using a

tightening torque of approx. 2.5 Nm.

WARNING

You are required to check that the encoder body and the connection cap are at

the same potential before replacing the connection cap!

Figure 1 - Removing the connection cap

MAN XAC80 PB E 1.0.odt 5 - Electrical connections 27 of 60

Page 28

XAC80 Profibus-DP

®

5.2 Connection cap with PG gland (cable output)

Figure 2 - Connection cap

The connection cap is fitted with three PG9 cable glands for BUS IN and BUS

OUT connections and power supply connection. The bus cables can be connected

directly to the terminal connectors located in front of each cable gland.

We recommend Profibus-DP certified cables to be used. Core diameter should

not exceed Ø 1.5 mm (0.06 inches). Please note that BUS IN and BUS OUT

connections are actually the same and so interchangeable.

Terminal connector Description

- 0Vdc Supply voltage

+ +10Vdc +30Vdc Supply voltage

B Profibus B (Red)

A Profibus A (Green)

PG

Shield

1

1

Connect the cable shield to cable gland

5.3 Ground connection

Minimize noise by connecting the shield and/or the encoder frame to ground

(GND). Make sure that ground (GND) is not affected by noise. The connection

point to ground can be situated both on the device side and on user's side. The

MAN XAC80 PB E 1.0.odt 5 - Electrical connections 28 of 60

Page 29

XAC80 Profibus-DP

®

best solution to minimize the interference must be carried out by the user. It is

recommended to provide the ground connection as close as possible to the

encoder. We suggest using the ground screw provided in the cap (see Figure 1).

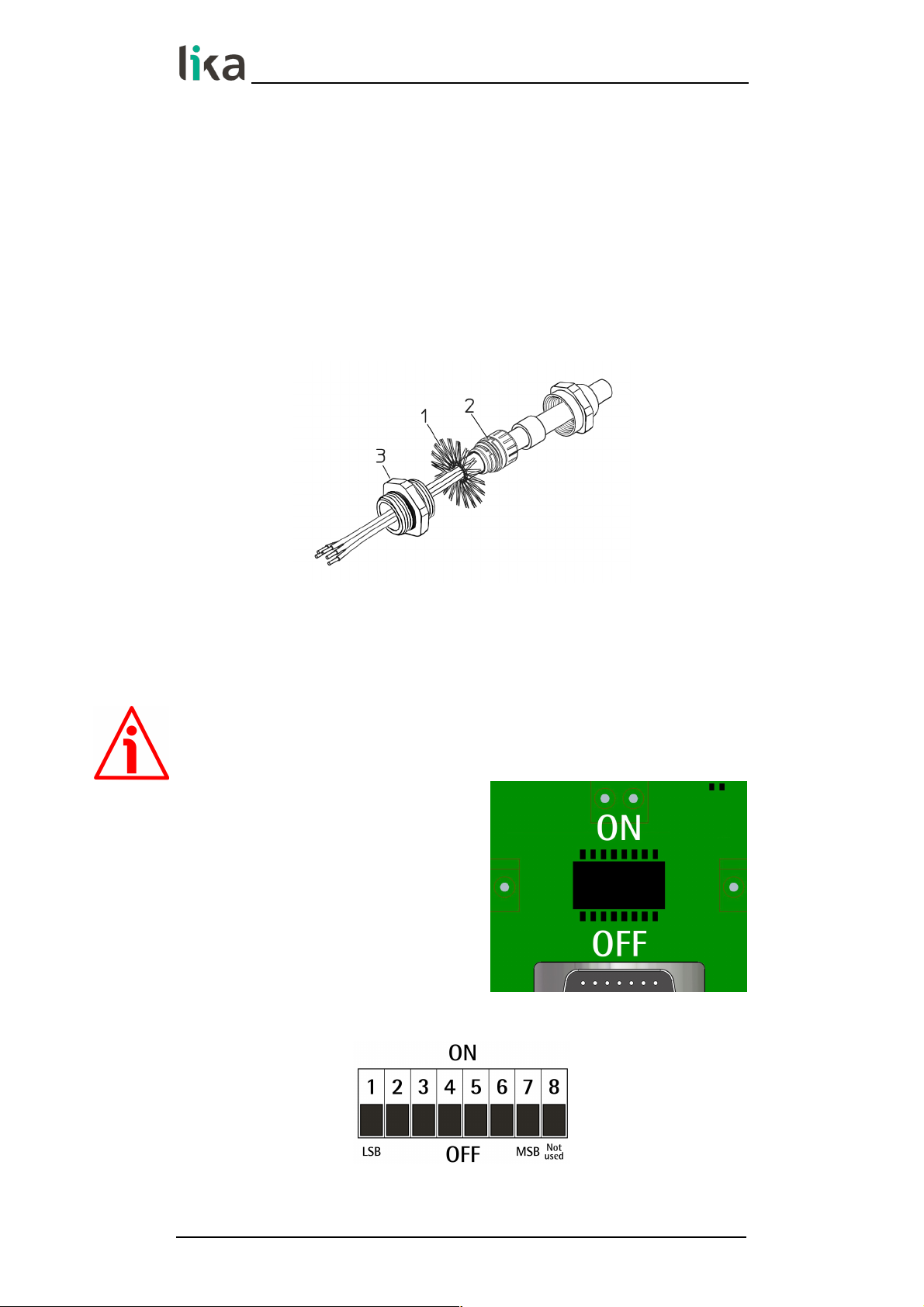

5.3.1 Connection of the shield

Disentangle and shorten the shielding 1 and then bend it over the part 2; finally

place the ring nut 3 of the connector. Be sure that the shielding 1 is in tight

contact with the ring nut 3.

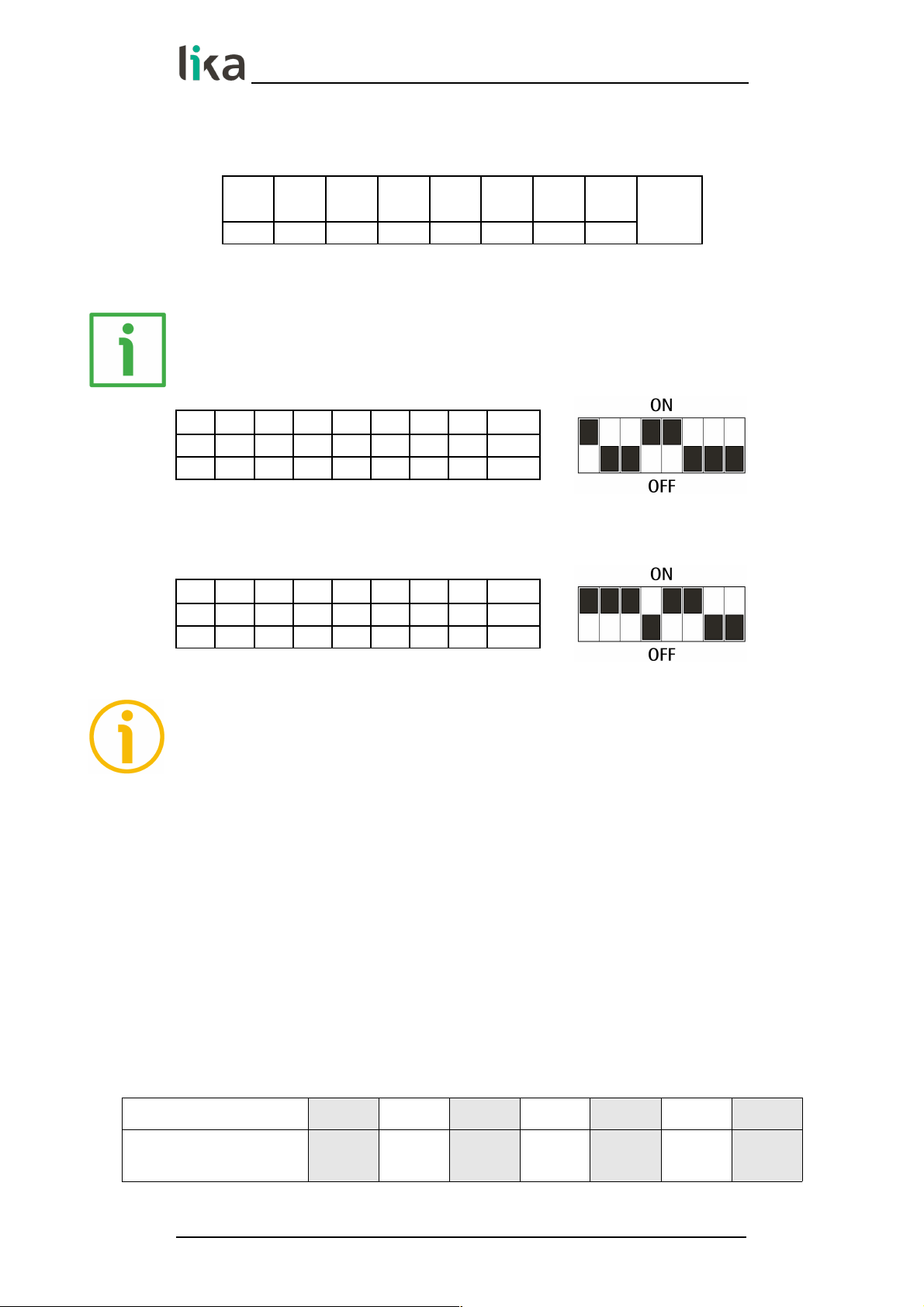

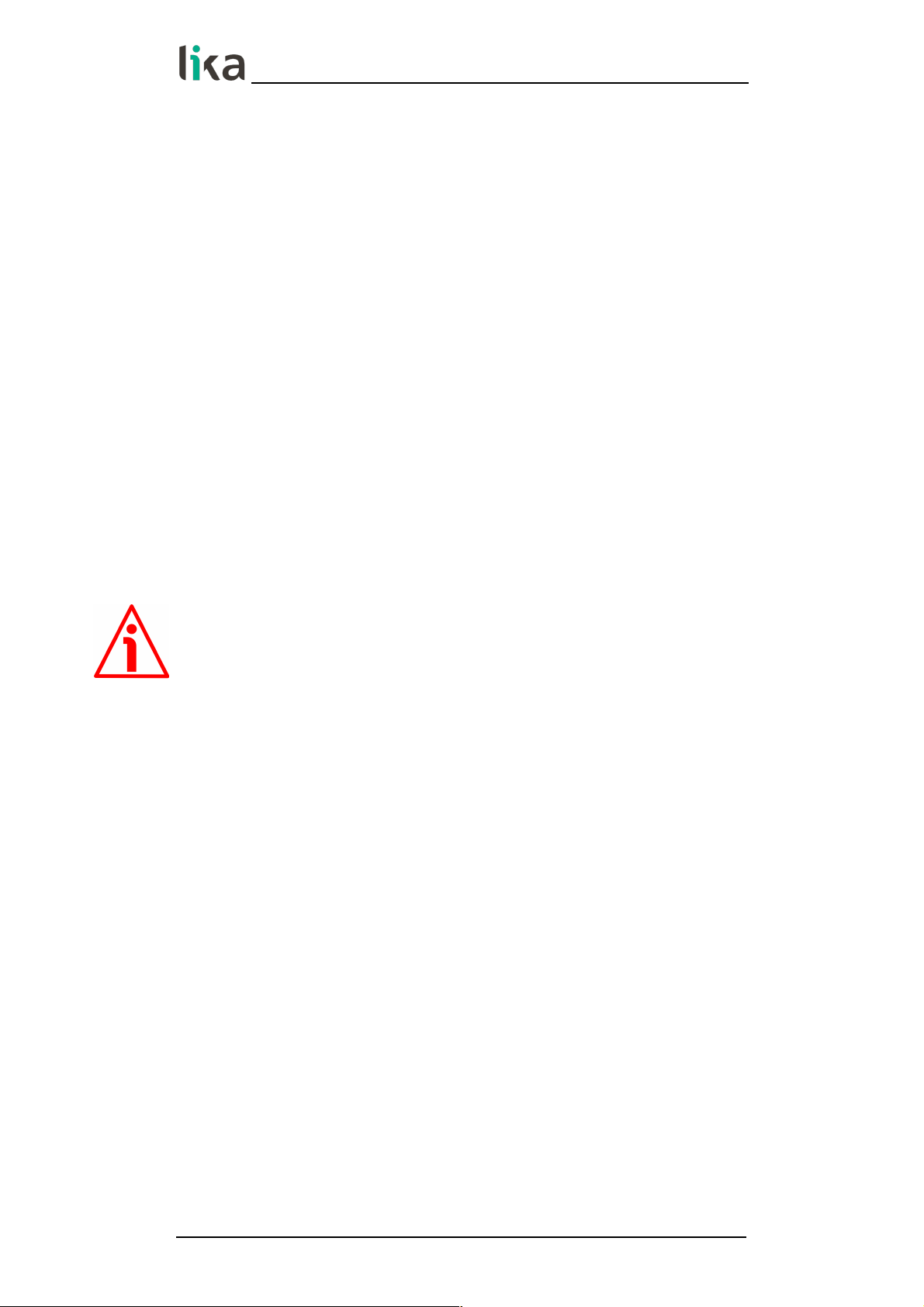

5.4 Setting the node number: DIP A (Figure 2)

WARNING

Power supply must be turned off before performing this operation!

The node number must be set via

hardware using DIP A dip-switches.

Allowed addresses are from 0 to 125. The

default value is 1.

DIP A:

MAN XAC80 PB E 1.0.odt 5 - Electrical connections 29 of 60

Page 30

XAC80 Profibus-DP

®

Turn the power supply off and set the node number in binary value; consider

that: ON=1, OFF=0

bit 1

LSB

2 3 4 5 6 7

MSB8not

used

2

0

2

1

2

2

2

3

2

4

2

5

2

6

EXAMPLE

Set node address = 25:

2510 = 0001 10012 (binary value)

bit 1 2 3 4 5 6 7 8

2021222324252

6

ON OFF OFF ON ON OFF OFF OFF

Set node address = 55:

5510 = 0011 01112 (binary value)

bit 1 2 3 4 5 6 7 8

2021222324252

6

ON ON ON OFF ON ON OFF OFF

NOTE

After having set the device address, please check the position of the bus

termination switch (see the “5.6 Bus termination resistance (Figure 2)” section

on page 31).

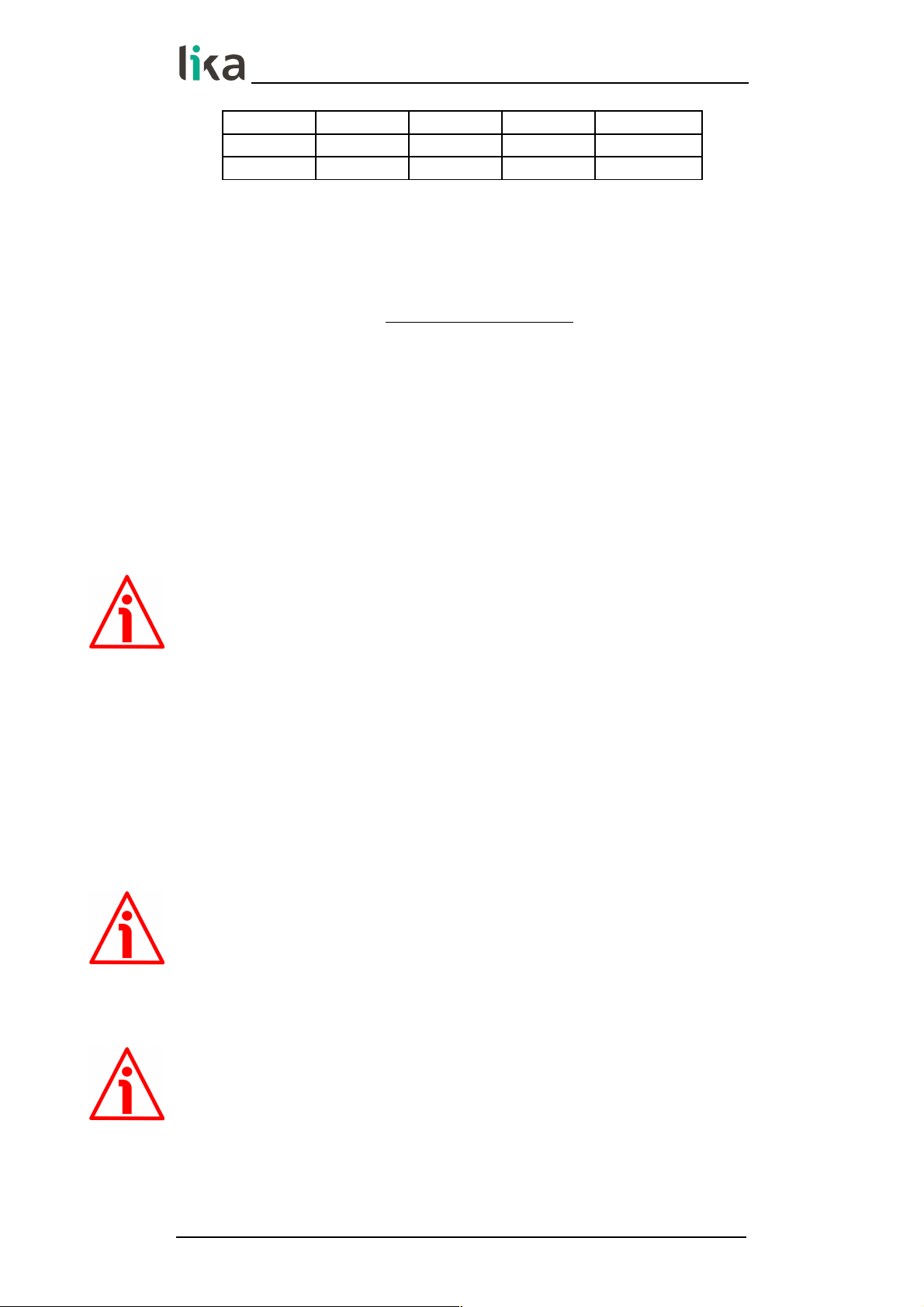

5.5 Baud rate

The baud rate is set by the Master via software at configuration of the node

(Slave).

The device supports the following baud rates (they are listed in the .GSD file

too):

9.6 kbit/s, 19.2 kbit/s, 93.75 kbit/s, 187.5 kbit/s, 500 kbit/s, 1.5 Mbit/s, 3 Mbit/s, 6

Mbit/s, 12 Mbit/s.

The following table shows the maximum transmission rates in relation to

permissible line length:

Baud rate [Kbit/s]

9.6 19.2 93.75 187.5 500 1,500 12,000

Max. cable length

1200 m

4000 ft

1200 m

4000 ft

1200 m

4000 ft

1000 m

3300 ft

400 m

1300 ft

200 m

660 ft

100 m

330 ft

MAN XAC80 PB E 1.0.odt 5 - Electrical connections 30 of 60

Page 31

XAC80 Profibus-DP

®

5.6 Bus termination resistance (Figure 2)

WARNING

Power supply must be turned off before performing this operation!

A bus termination resistance is provided inside the connection cap and must be

activated as line termination if the encoder is at the ends of the transmission

line (i.e. it is either the first or the last device in the transmission line).

Use RT Switch to activate or deactivate the bus termination.

RT Description

1 = 2 = ON

Activated: if the encoder is either the first or the

last device in the transmission line

1 = 2 = OFF

Deactivated: if the encoder is not either the first

or the last device in the transmission line

MAN XAC80 PB E 1.0.odt 5 - Electrical connections 31 of 60

Page 32

XAC80 Profibus-DP

®

6 - Quick reference

6.1 STEP7 configuration

6.1.1 Importing the GSD file

Profibus encoders are supplied with their own GSD file, they are specific for

each encoder model. To download the file enter www.lika.biz > ROTARY

ENCODERS > ABSOLUTE ENCODERS > PROFIBUS).

The GSD file must be installed in the Profibus Master device.

The available GSD files are:

xac80_18.GSD: XAC8018/1PB (18 bit singleturn encoder)

xac80_27.GSD: XAC8013/16384PB (13 + 14 bit multiturn encoder)

xac80_30.GSD: XAC8016/16384PB (16 + 14 bit multiturn encoder)

WARNING

Please pay attention to install the right GSD file in the matching encoder model.

In the menu bar of the HW Config window, press Options and then Install

New GSD… command.

Select the correct GSD file in the installation window and install it.

MAN XAC80 PB E 1.0.odt 6 - Quick reference 32 of 60

Page 33

XAC80 Profibus-DP

®

6.1.2 Adding a node to the project

In the left pane of the HW Config window, open the directory tree and select

Catalog\PROFIBUS_DP\Additional Field Devices\Encoders; drag the required

module (for instance “LIKA XAC8016/16384PB” module to the window on the

left and drop it on “PROFIBUS(1): DP master system (1)”.

Then drag the desired submodule (Class 1, Class 2 or Class 2(+VEL)) to the

variables table in the bottom; in this way you set the class of the device (for

further details on the available classes see the “7.2 Classes of the Device profile“

section on page 39).

MAN XAC80 PB E 1.0.odt 6 - Quick reference 33 of 60

Page 34

XAC80 Profibus-DP

®

6.1.3 Encoder configuration parameters

To enter the Encoder configuration parameters window, select the device in the

submodule page in bottom of the HW Config window and right-click to open

the menu; then choose the Object Properties… command.

The Properties – DP slave window will appear; in the Parameter Assignment

page the list of all encoder parameters is available.

For any information on using and setting each parameter refer to the “7.4

DDLM_Set_Prm“ section on page 41.

Class 2 example

MAN XAC80 PB E 1.0.odt 6 - Quick reference 34 of 60

Page 35

XAC80 Profibus-DP

®

Class 2(+VEL) example

After having set new parameter values, press the OK button to close

the Properties – DP slave window and then press the Download

button (see the icon on the left) in the toolbar of the HW Config window to

download the set parameters.

6.2 Reading the diagnostic information

The system implements 16-byte diagnostic messages, for any further

information refer to the “7.7 DDLM_Slave_Diag” section on page 52.

Before entering the diagnostic page, it is necessary to connect to the

unit (enter online status). To do this, select Station\Open online in

the HW Config window or click the Online<->Offline button (see

the icon on the left). Then select PLC\Module information… to enter the

Module information window. Finally open the DP Slave Diagnostics page.

MAN XAC80 PB E 1.0.odt 6 - Quick reference 35 of 60

Page 36

XAC80 Profibus-DP

®

Press the Hex. Format… button to display diagnostic information:

16-byte Diagnostic:

NOTE

Refer to the “7.7 DDLM_Slave_Diag” section on page 52 for a complete list and

meaning of each diagnostic byte.

MAN XAC80 PB E 1.0.odt 6 - Quick reference 36 of 60

Page 37

XAC80 Profibus-DP

®

6.3 Setting the Preset value

EXAMPLE

The encoder having device address 1 transmits the position value to the Master.

The Position value is loaded into variables ED 100…103 (4 bytes).

The Velocity value is loaded into variables ED 104…107 (4 bytes).

The Preset value is sent to the encoder using the variables AD 100…103 (4

bytes).

The current Position value of the encoder is 0003 7AA1hex.

To set the Preset value = 0000 0500hex, set the bit 31 of variable AD 100 = “1”

(8000 0500hex).

MAN XAC80 PB E 1.0.odt 6 - Quick reference 37 of 60

Page 38

XAC80 Profibus-DP

®

Finally press the Command variables button in the Toolbar (see the

icon here on the right).

Now the position of the encoder is 0000 0500hex.

To close the “Preset” procedure set bit 31 of variable AD 100 back to ”0” and

then press the "Command variables" button again.

NOTE

It may occur that data variables having index higher than 127 or data greater

than 4 bytes are not treated properly in STEP7 software. Should this happen, we

recommend "MD" reference operators (pointers) for encoder position, speed and

Preset to be used.

MAN XAC80 PB E 1.0.odt 6 - Quick reference 38 of 60

Page 39

XAC80 Profibus-DP

®

7 - Profibus® interface

Lika encoders are Slave devices and comply with “Profibus-DP Profile for

Encoders”; they can be set as Class 1, Class 2 or Class 2(+VEL) devices (see the

“7.2 Classes of the Device profile“ section on page 39).

For any omitted information refer to the official Profibus website

www.profibus.com.

7.1 GSD file

Profibus encoders are supplied with their own GSD file, they are specific for

each encoder model. To download the file enter www.lika.biz > ROTARY

ENCODERS > ABSOLUTE ENCODERS > PROFIBUS).

The GSD file must be installed in the Profibus Master device.

The available GSD files are:

xac80_18.GSD: XAC8018/1PB (18 bit singleturn encoder)

xac80_27.GSD: XAC8013/16384PB (13 + 14 bit multiturn encoder)

xac80_30.GSD: XAC8016/16384PB (16 + 14 bit multiturn encoder)

WARNING

Please pay attention to install the right GSD file in the matching encoder model.

7.2 Classes of the Device profile

Encoder class must be set when you configure the device.

Mandatory Class 1 provides the basic functions of the device and can be used

for:

sending the position value (refer to the Position value parameter on page

49);

changing the counting direction (refer to Code sequence parameter on

page 43);

setting the preset value (refer to Preset value parameter on page 50).

Class 2 provides all the Class 1 functions and additional advanced functions

such as:

scaling function (see Scaling function control parameter on page 44;

Counts per revolution parameter on page 45; and Total resolution

parameter on page 46).

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 39 of 60

Page 40

XAC80 Profibus-DP

®

Class 2(+VEL) provides all the Class 1 and the Class 2 functions and additional

velocity-related functions:

transmission of the velocity value (see the Position and velocity values

parameter on page 50);

setting of the unit of measurement for velocity (see the Velocity measure

unit parameter on page 48).

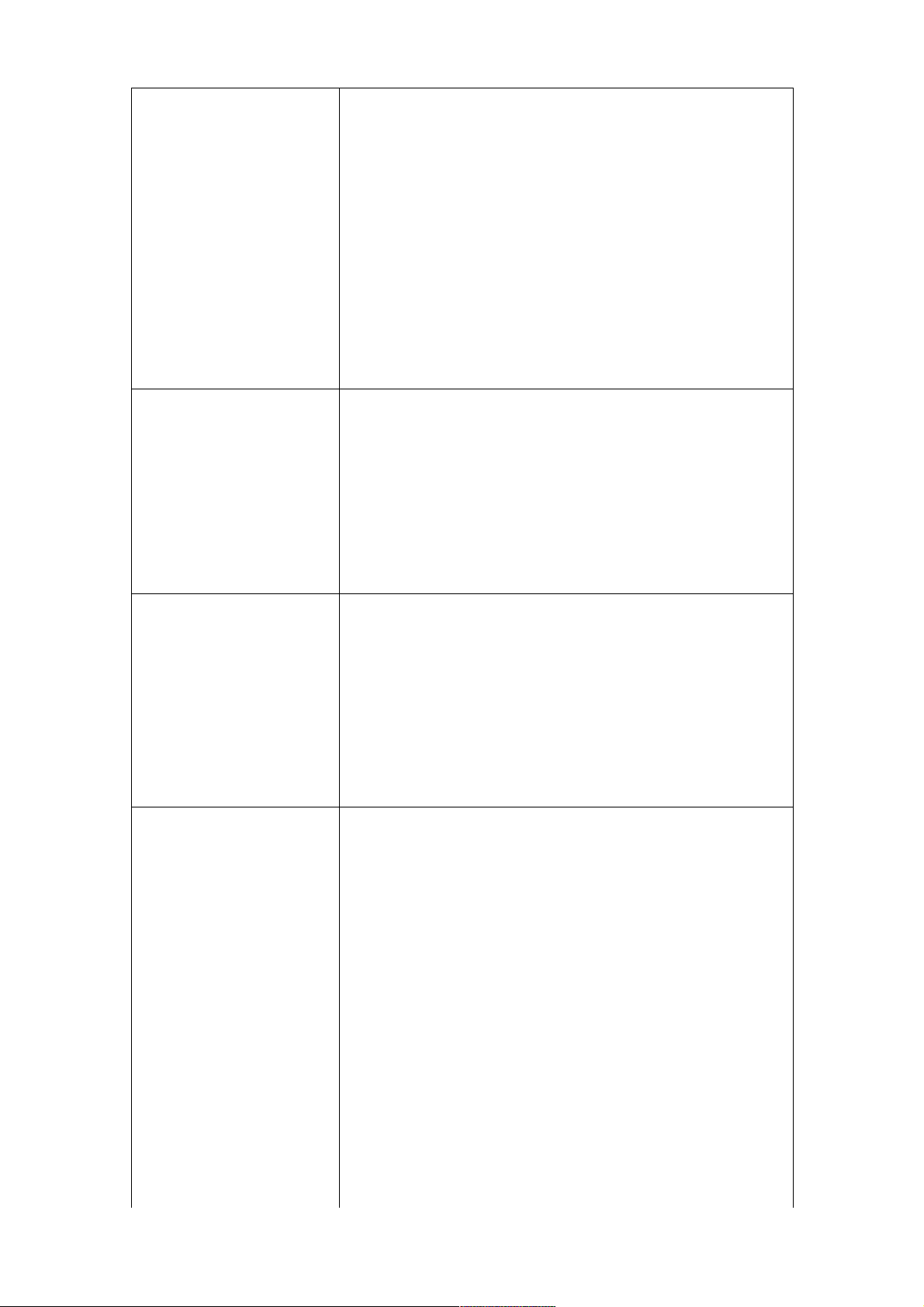

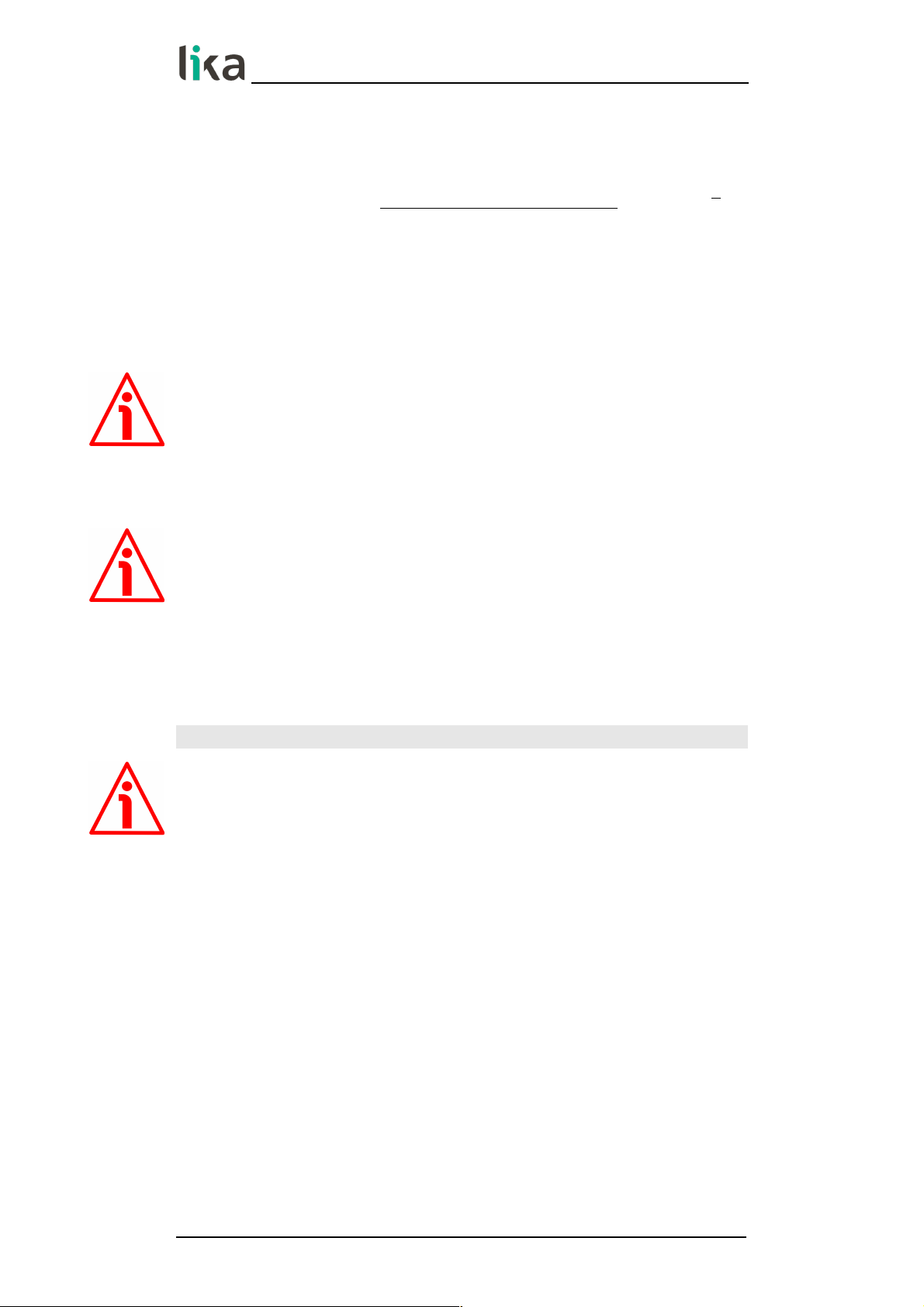

7.3 Modes of operation

Profibus-DP devices allow operation using different communication modes (see

the Figure below):

NOTE

All parameters -except Preset value- are transmitted in Set_Prm mode.

Preset value is transmitted only in Data_Exchange mode.

7.3.1 Types of communication

Transmission of data between the Master and the Slave is carried out using the

following types of messages:

DDLM_Set_Prm:

It is used to configure the Slave. This communication mode is active

immediately after the power is turned ON and used to send parameters

from the Master to the Slave (see the “7.4 DDLM_Set_Prm“ section on page

41).

DDLM_Chk_Cfg:

It sets the number of bytes used for data transmission in Data_Exchange

mode (see the “7.5 DDLM_Chk_Cfg“ section on page 49).

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 40 of 60

Power-ON

Wait_Prm

Wait_Cfg

Data_Exchange

Chk_Cfg_OK

Set_Prm_OK

Set_Prm_FAIL

Chk_Cfg_FAIL

Init_OK

Page 41

XAC80 Profibus-DP

®

DDLM_Data_Exchange:

It is used as "standard operation mode".

Used by the Master to send the Preset value; used by the Slave to transmit

the position and velocity values (see the “7.6 DDLM_Data_Exchange“ section

on page 49).

DDLM_Slave_Diag:

It is used when the power is turned ON and whenever the Master needs

diagnostic information from the Slave device (see the “7.7

DDLM_Slave_Diag“ section on page 52).

7.4 DDLM_Set_Prm

When the system is turned ON, configuration data set by the operator is sent to

the absolute encoder by the controller. Transmission of parameters depends on

the configuration chosen by the operator. Customarily data is sent

automatically while data setting is carried out through a user's interface

available in the controller's software (for instance, STEP7, see the “6.1 STEP7

configuration“ section on page 32).

However sometimes it is necessary to set some bits and bytes according to the

working specifications you want to set.

Data transmission is carried out in compliance with values set for the encoder

profile and shown in the following tables.

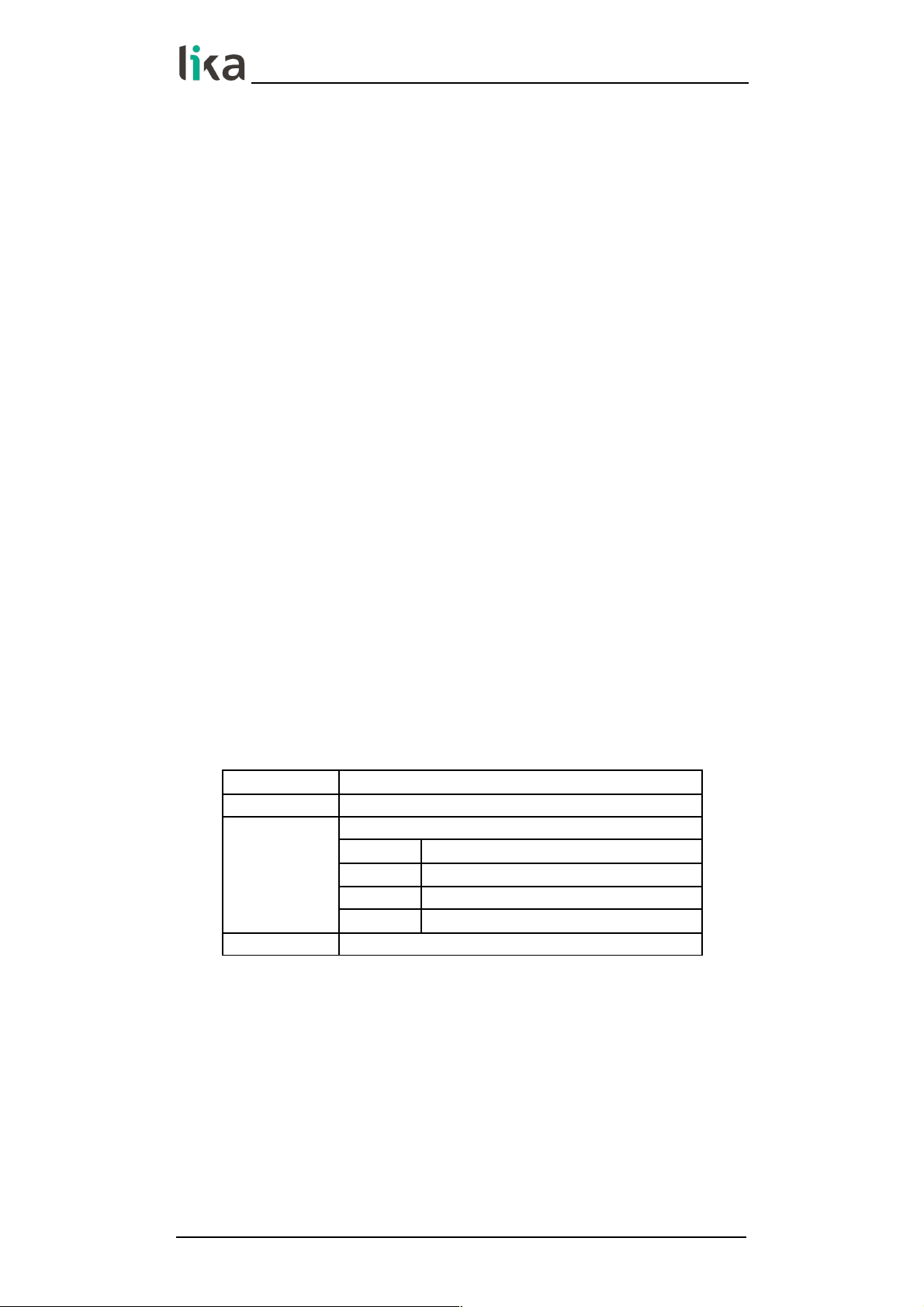

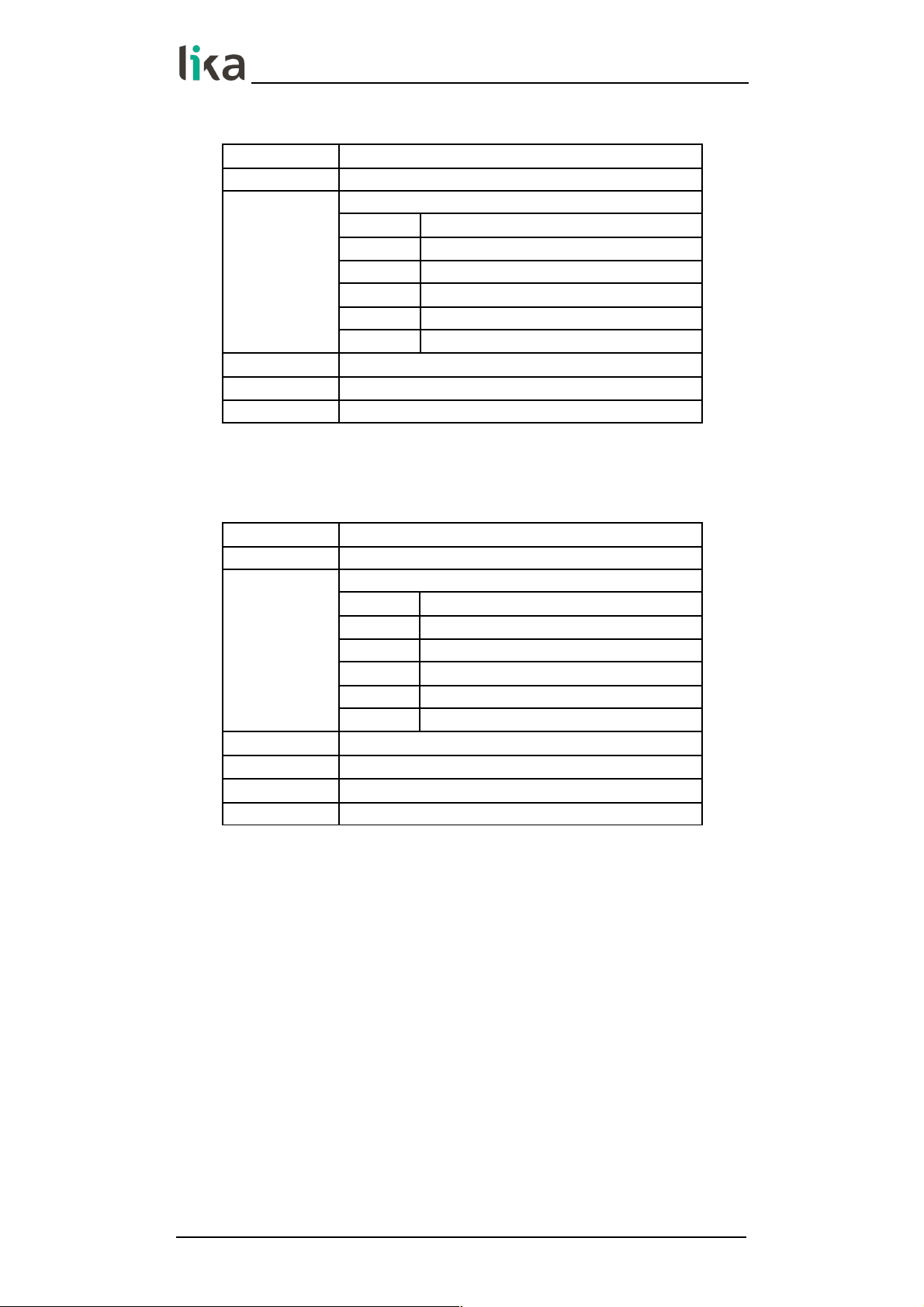

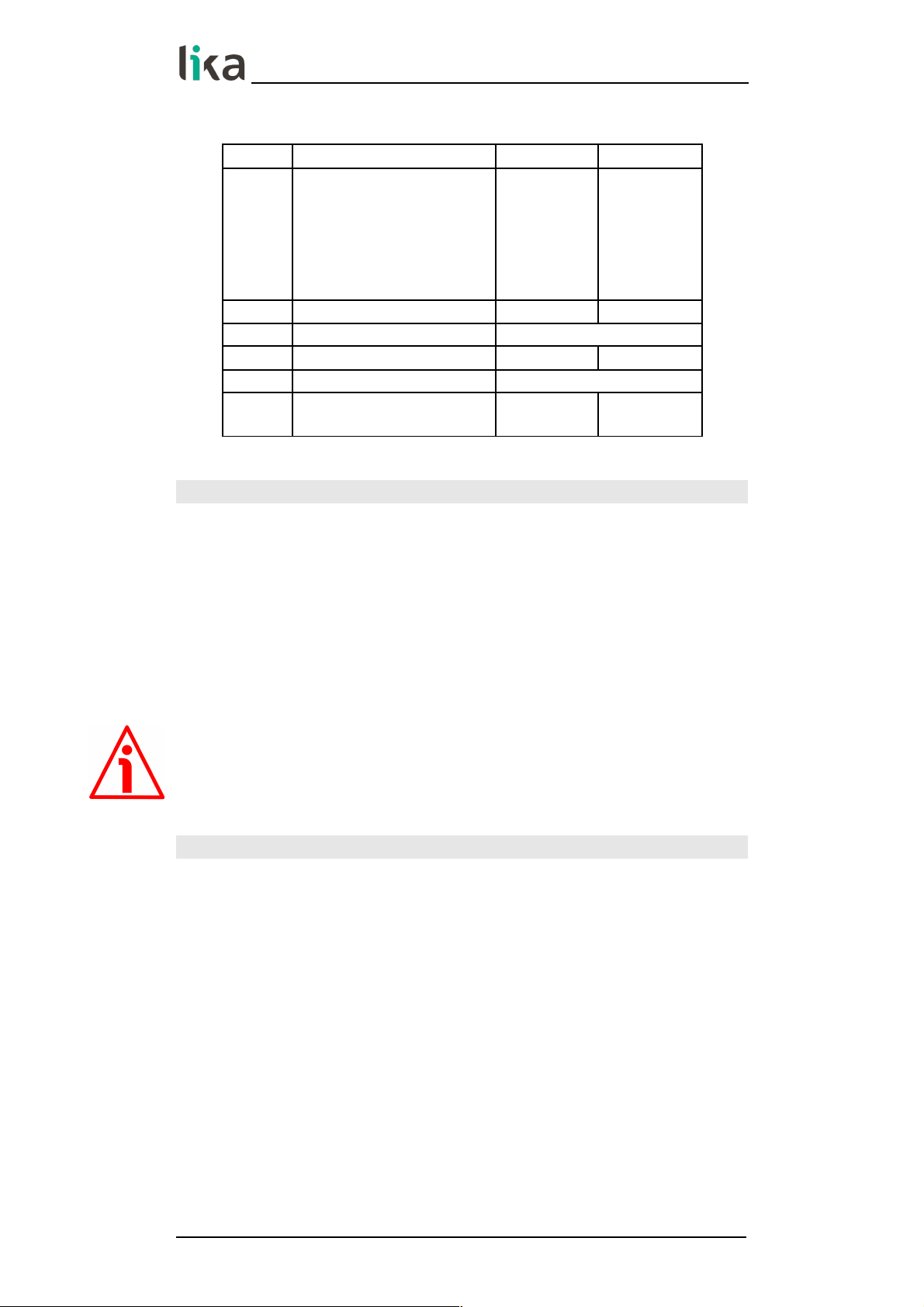

DDLM_Set_Prm with Class 1

Byte Parameter

0 … 9 Reserved for PROFIBUS network

10

Operating parameters

bit 0

Code sequence

bit 1

Class 2 functionality

bits 2 … 6 Reserved

bit 7

Exchange type

11 … 20 Reserved

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 41 of 60

Page 42

XAC80 Profibus-DP

®

DDLM_Set_Prm with Class 2

Byte Parameter

0 … 9 Reserved for PROFIBUS network

10

Operating parameters

bit 0

Code sequence

bit 1

Class 2 functionality

bit 2 Reserved

bit 3

Scaling function control

bits 4 … 6 Reserved

bit 7

Exchange type

11 … 14

Counts per revolution

15 … 18

Total resolution

19 and 20 Reserved

DDLM_Set_Prm with Class 2 (+VEL)

Byte Parameter

0 … 9 Reserved for PROFIBUS

10

Operating parameters

bit 0

Code sequence

bit 1

Class 2 functionality

bit 2 Reserved

bit 3

Scaling function control

bits 4 ... 6 Reserved

bit 7

Exchange type

11 … 14

Counts per revolution

15 … 18

Total resolution

19

Velocity measure unit

20 Reserved

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 42 of 60

Page 43

XAC80 Profibus-DP

®

7.4.1 Byte 10 - Operating parameters

Bit Function bit = 0 bit = 1

0

Code sequence

Count up

information

with

clockwise

rotation

Count up

information

with

counter-

clockwise

rotation

1

Class 2 functionality

disabled

enabled

2 Reserved

3

Scaling function control

disabled

enabled

4 ... 6 Reserved

7

Exchange type

position

position +

velocity

Code sequence

This is intended to set whether the position value output by the transducer

increases (count up information) when the encoder shaft rotates clockwise (CW)

or counter-clockwise (CCW). When Code sequence = 0, the position value

increases when the encoder shaft rotates clockwise; on the contrary, when

Code sequence = 1, the position value increases when the encoder shaft

rotates counter-clockwise. CW and CCW rotations are viewed from the shaft

end.

Default = 0 (min. = 0, max. = 1)

WARNING

Every time you change the Code sequence, then you are required to set a new

preset value (see the Preset value parameter).

Class 2 functionality

This is only available when the encoder Class 2 or the encoder Class 2(+VEL) are

installed.

Two device classes are defined in the encoder profile, one mandatory class (Class

1) and one class with optional functions (Class 2). This encoder implements

functions of both Class 1 and Class 2 for encoders. For any information on the

available encoder classes see the “7.2 Classes of the Device profile” section on

page 39.

0 = Disabled = Encoder Class 1 is set.

1 = Enabled = Encoder Class 2 (or Class 2(+VEL)) is set.

Default = 1 (min. = 0, max. = 1)

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 43 of 60

Page 44

XAC80 Profibus-DP

®

Scaling function control

This is only available when the encoder Class 2 or the encoder Class 2(+VEL) are

installed.

When this option is disabled (bit 3 Scaling function control = 0 = DISABLED),

the device uses the hardware resolution, i.e. the hardware counts per revolution

and the hardware number of revolutions to arrange the absolute position

information, see the encoder data on the label applied to the device.

On the contrary, when it is enabled (bit 3 Scaling function control = 1 =

ENABLED), the device uses the custom resolution transmitted through the bytes

from 11 to 18 to calculate the position information (see the Counts per

revolution and Total resolution parameters).

For a correct use of this function see the “7.4.2 Bytes 11 … 14“ and “7.4.3 Bytes

15 … 18“ sections.

Default = 1 (min. = 0, max. = 1)

WARNING

When you enable the scaling function (Scaling function control = 1), please

enter scaled values next to the Counts per revolution and Total resolution

parameters that are consistent with the physical values. In the case of

inconsistent values, the system does not go online.

WARNING

Every time you enable the scaling function and/or change the scaled values (see

the Counts per revolution and Total resolution parameters), then you are

required to set a new preset value (see the the Preset value parameter).

WARNING

You can activate the custom values set next to the Counts per revolution and

Total resolution parameters only if Class 2 functionality = ENABLED.

If Scaling function control = ENABLED the set custom resolution values are

enabled and used by the encoder; on the contrary, if Scaling function control

= DISABLED you are allowed to set new resolution values, however they are not

enabled even if sent to the encoder: the encoder still goes on using the physical

values, NOT the new entered values, until you enable the Scaling function

control.

Exchange type

0 = Position = the device transmits only the position value (Class 1 and Class 2).

1 = Position + velocity = the device transmits both position and velocity values

(Class 2(+VEL)).

Default = 0 (min. = 0, max. = 0) for Class 1 and Class 2

Default = 1 (min. = 1, max. = 1) for Class 2 (+VEL)

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 44 of 60

Page 45

XAC80 Profibus-DP

®

7.4.2 Bytes 11 … 14

Counts per revolution

WARNING

This is only available when the encoder Class 2 or the encoder Class 2 (+VEL) are

installed.

You can activate a new value next to the Counts per revolution parameter

only if Class 2 functionality = ENABLED. If Scaling function control =

ENABLED the set resolution values are enabled and used by the encoder; on the

contrary, if Scaling function control = DISABLED you are allowed to set new

resolution values, however they are not enabled even if sent to the encoder: the

encoder still goes on using the physical values, NOT the new entered values,

until you enable the Scaling function control. See the “7.4.1 Byte 10 Operating parameters” section on page 43.

If Class 2 functionality = DISABLED or Scaling function control = DISABLED,

then the system uses the physical values to arrange the position information.

The Counts per revolution parameter allows to program a user specific

singleturn resolution (i.e. the desired number of information -distinguishable

steps- per revolution).

Byte 11 12 13 14

Bit 31-24 23-16 15-8 7-0

Data 231 to 2

24

223 to 2

16

215 to 2

8

27 to 2

0

The custom singleturn resolution value must be less than or equal to the

physical singleturn resolution (hardware counts per revolution value).

Setting a value greater than allowed causes the resolution to be forced to the

Hardware counts per revolution value.

You are allowed to set any integer value less than or equal to the Hardware

counts per revolution. However we suggest setting a value that is a power of 2

(1, 2, 4, … 2,048, 4,096, …). This is meant to avoid counting errors (refer also to

the “7.8 "Dead Zone"” section on page 55).

Default = 262,144 (min. = 1, max. = 262,144) for XAC8018/1

Default = 8,192 (min. = 1, max. = 8,192) for XAC8013/16384

Default = 65,536 (min. = 1, max. = 65,536) for XAC8016/16384

WARNING

When you set a new value next to the Counts per revolution parameter, please

always check also the Total resolution parameter value and be sure that the

resulting number of revolutions complies with the Hardware number of

revolutions of the device (1 or 16,384, see the order code).

Let's suppose that our encoder is programmed as follows:

Counts per revolution: 8,192 cpr

Total resolution = 134,217,72810 = 8,192 (cpr) * 16,384 (rev.)

Let's set a new singleturn resolution, for instance: Counts per revolution =

360.

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 45 of 60

Page 46

XAC80 Profibus-DP

®

If we do not change the Total resolution value at the same time, we will get

the following result:

Number of revolutions =

134,217,728 (Total resolution)

= 372,827.02

360 (Counts per revolution)

As you can see, the encoder is required to carry out almost 373,000 revolutions,

this cannot be as the hardware number of revolutions is, as stated, max. 16,384.

When this happens, the encoder falls into an error.

WARNING

When you enable the scaling function (Scaling function control = 1), please

enter scaled values next to the Counts per revolution and Total resolution

parameters that are consistent with the physical values. In the case of

inconsistent values, the system does not go online.

WARNING

Every time you change the value in this parameter, then you are required to set

a new preset value (see the the Preset value parameter).

7.4.3 Bytes 15 … 18

Total resolution

WARNING

This is only available when the encoder Class 2 or the encoder Class 2 (+VEL) are

installed.

You can activate a new value next to the Total resolution item only if Class 2

functionality = ENABLED. If Scaling function control = ENABLED the set

resolution values are enabled and used by the encoder; on the contrary, if

Scaling function control = DISABLED you are allowed to set new resolution

values, however they are not enabled even if sent to the encoder: the encoder

still goes on using the physical values, NOT the new entered values, until you

enable the Scaling function control. See the “7.4.1 Byte 10 - Operating

parameters” section on page 43.

If Class 2 functionality = DISABLED or Scaling function control = DISABLED,

then the system uses the physical values to arrange the position information.

This parameter is intended to set a custom number of distinguishable steps over

the total measuring range. The total resolution of the encoder results from the

product of Counts per revolution by the required Number of revolutions.

MAN XAC80 PB E 1.0.odt 7 - Profibus® interface 46 of 60

Page 47

XAC80 Profibus-DP

®

Byte 15 16 17 18

Bit 31-24 23-16 15-8 7-0

Data 231 to 2

24

223 to 2

16

215 to 2

8

27 to 2

0

Allowed values are less than or equal to the Total hardware resolution value.

Setting a value greater than allowed causes the resolution to be forced to the

Total hardware resolution value.

Number of revolutions =

Total resolution

Counts per revolution

We recommend the Number of revolutions to be set to a power of 2. This is

meant to avoid problems when using the device in endless operation (when

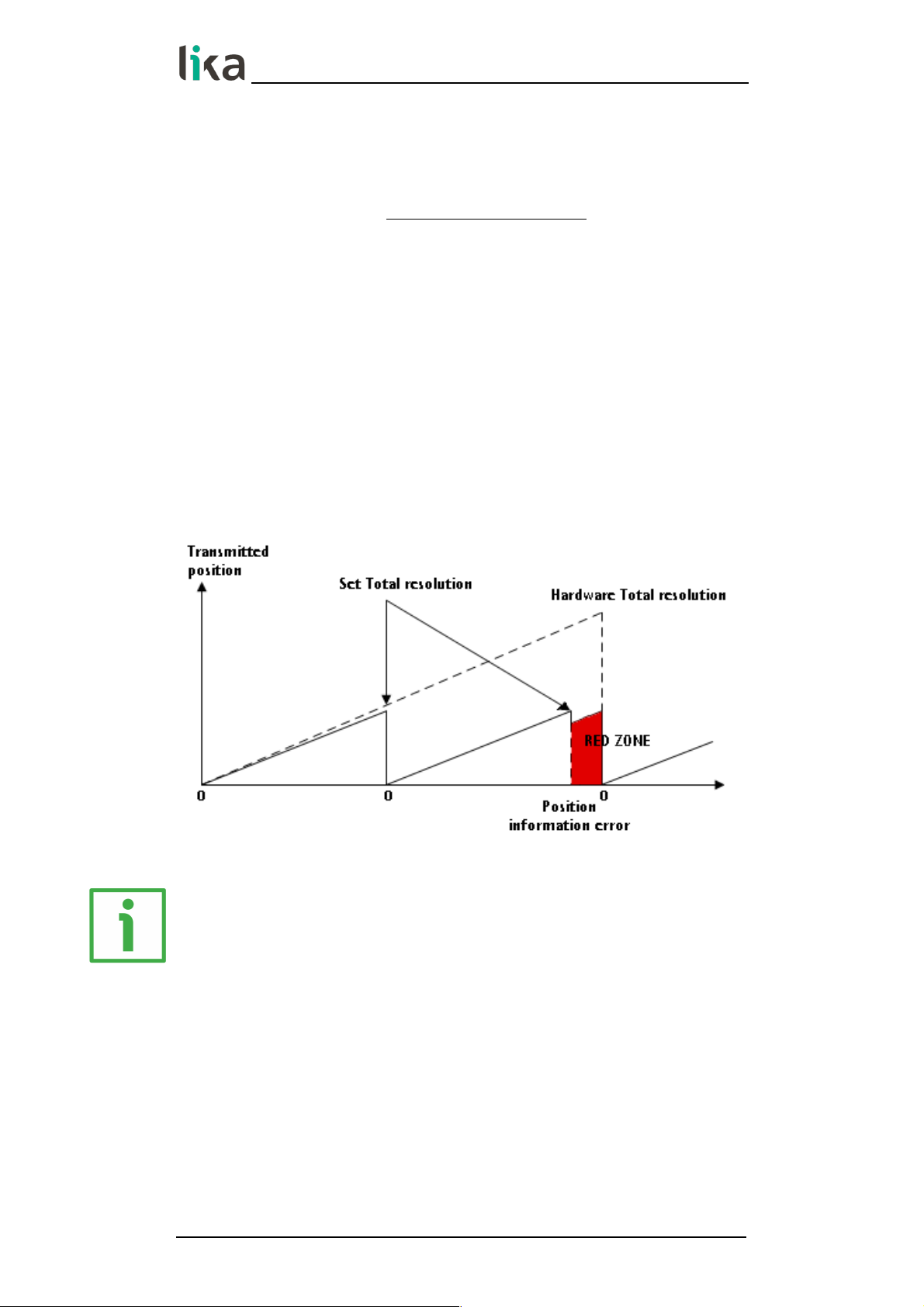

crossing the physical zero) and entering the "Red Zone" (see the “7.8 "Dead

Zone"” section on page 55).