Page 1

User's guide

SMS12

• Incremental linear encoder for 1-mm pole pitch tape

• Resolution 1 mm / 0.039”

• Measuring length up to 100 m / 328 ft

• IP67 protection rate

• 1Vpp sinusoidal outputs

• With external limit switches to mark off the travel

Suitable for the following models:

• SMS12

Table of Contents

Safety summary 6

Identification 8

Mechanical installation 9

Electrical connection 18

Maintenance and troubleshooting 28

Lika Electronic • Tel. +39 0445 806600 • info@lika.biz • www.lika.biz

Smart encoders & actuators

Page 2

This publication was produced by Lika Electronic s.r.l. 2018. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Page 3

General contents

User's guide............................................................................................................................................................................................1

General contents.............................................................................................................................................................................3

Typographic and iconographic conventions...................................................................................................................4

Preliminary information..............................................................................................................................................................5

1 Safety summary..................................................................................................................................... 6

1.1 Safety.............................................................................................................................................................................6

1.2 Electrical safety.........................................................................................................................................................6

1.3 Mechanical safety....................................................................................................................................................7

2 Identification......................................................................................................................................... 8

3 Mechanical installation....................................................................................................................... 9

3.1 Overall dimensions...................................................................................................................................................9

3.2 Sensor and scale / ring combination.............................................................................................................10

3.3 Magnetic tape.........................................................................................................................................................10

3.4 Magnetic rings........................................................................................................................................................10

3.5 Mounting the sensor with magnetic tape..................................................................................................11

3.6 Mounting the sensor with “R” / “T” Reference..........................................................................................13

3.7 Mounting the sensor with LS1 and LS2 limit switches.........................................................................14

3.8 Measuring length..................................................................................................................................................15

3.9 Mounting the sensor with MRI magnetic rings.......................................................................................15

3.10 Standard counting direction..........................................................................................................................17

3.11 Optional cleaning wipers (Figure 1).............................................................................................................17

4 Electrical connection.......................................................................................................................... 18

4.1 M10 cable connection.........................................................................................................................................18

4.2 M10 cable specifications....................................................................................................................................19

4.3 Connection of the shield....................................................................................................................................20

4.4 Ground connection...............................................................................................................................................20

4.5 AB0, /AB0 output channels...............................................................................................................................21

4.6 Counting direction................................................................................................................................................21

4.7 Reference “R” / “T”.................................................................................................................................................22

4.8 Voltage signals........................................................................................................................................................23

4.9 LS1 and LS2 limit switches................................................................................................................................23

4.10 Diagnostic LEDs (Figure 10).............................................................................................................................25

4.11 Recommended circuit........................................................................................................................................27

5 Maintenance and troubleshooting................................................................................................. 28

Page 4

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters are coloured in GREEN;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee the

safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Page 5

Preliminary information

This guide is designed to provide the most complete and exhaustive information the operator needs to

correctly and safely install and operate the SMS12 incremental linear encoder.

SMS12 linear encoder is designed to measure linear or angular displacements on industrial machines and

automation systems. The measurement system includes a magnetic tape / magnetic ring and a magnetic

sensor. The tape / ring has alternating magnetic north/south poles that are magnetized at a fixed

distance called the pole pitch. The pole pitch is 1 mm. The conversion electronics inside the sensor

translates the magnetic fields of the tape / ring into sinusoidal electrical signals (1Vpp) equivalent to

those of an incremental encoder or a linear scale. The readhead must be paired with the appropriated

magnetic tape / ring (see the “3.2 Sensor and scale / ring combination” section on page 10).

SMS12 encoder is equipped with two sensors for detecting external limit switches (order code LKM1309/LS). They are designed to mark out the travel of the application. The activation of the sensors is

shown through LEDs.

In addition it also integrates a sensor for detecting an external Reference magnet (order code LKM1309/1) and is equipped with four diagnostic LEDs.

The flexibility of the scale allows the sensor to be used for both linear and angular applications.

Furthermore it can be installed also on round surfaces and magnetic rings.

Page 6

SMS12

1 Safety summary

1.1 Safety

• Always adhere to the professional safety and accident prevention

regulations applicable to your country during device installation and

operation;

• installation and maintenance operations have to be carried out by

qualified personnel only, with power supply disconnected and stationary

mechanical parts;

• device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

• high current, voltage and moving mechanical parts can cause serious or

fatal injury;

• warning ! Do not use in explosive or flammable areas;

• failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture,

and intended use of the equipment;

• Lika Electronic assumes no liability for the customer's failure to comply

with these requirements.

1.2 Electrical safety

• Turn OFF the power supply before connecting the device;

• connect according to the explanation in the ”Electrical connection” section

on page 18;

• the wires of unused output signals must be cut at different lengths and

insulated singularly;

• in compliance with 2014/30/EU norm on electromagnetic

compatibility, the following precautions must be taken:

- before handling and installing the equipment, discharge

electrical charge from your body and tools which may come in touch

with the device;

- power supply must be stabilized without noise; install EMC filters on

device power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive

noise source; shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets

on or near by the unit;

MAN SMS12 E 1.1 Safety summary 6 of 32

Page 7

SMS12

- minimize noise by connecting the cable shield and the frame to ground.

Make sure that ground is not affected by noise. The connection point to

ground can be situated both on the device side and on user’s side. The

best solution to minimize the interference must be carried out by the

user;

- do not stretch the cable; do not pull or carry by cable; do not use the

cable as a handle.

1.3 Mechanical safety

• Install the device following strictly the information in the “Mechanical

installation” section on page 9;

• mechanical installation must be carried out with stationary mechanical

parts;

• do not disassemble the unit;

• do not tool the unit;

• delicate electronic equipment: handle with care; do not subject the device

to knocks or shocks;

• protect the unit against acid solutions or chemicals that may damage it;

• respect the environmental characteristics of the product;

• we suggest installing the unit providing protection means against waste,

especially swarf as turnings, chips, or fillings; should this not be possible,

please make sure that adequate cleaning measures (as for instance

brushes, scrapers, jets of compressed air, etc.) are in place in order to

prevent the sensor and the magnetic tape from jamming.

MAN SMS12 E 1.1 Safety summary 7 of 32

Page 8

SMS12

2 Identification

Device can be identified through the order code and the serial number printed

on the label applied to its enclosure. Information is listed in the delivery

document too. Please always quote the order code and the serial number when

reaching Lika Electronic for purchasing spare parts or needing assistance. For

any information on the technical characteristics of the product refer to the

technical catalogue.

Warning: encoders having order code ending with "/Sxxx" may have

mechanical and electrical characteristics different from standard and

be supplied with additional documentation for special connections

(Technical Info).

MAN SMS12 E 1.1 Identification 8 of 32

Page 9

SMS12

3 Mechanical installation

WARNING

Installation must be carried out by qualified personnel only, with power supply

disconnected and mechanical parts compulsorily in stop.

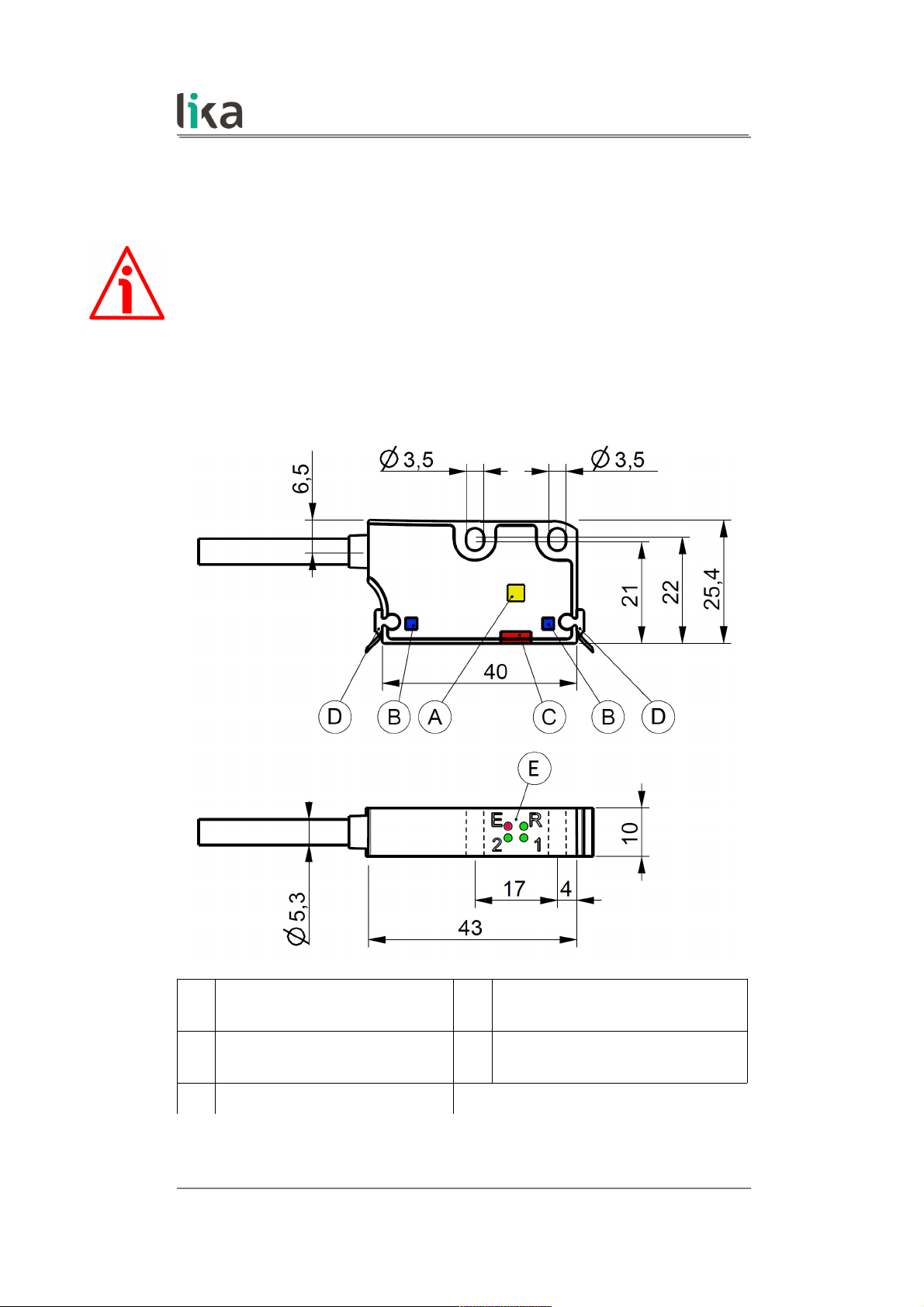

3.1 Overall dimensions

(values are expressed in mm)

A

Reference sensor “R” / “T” (page

22)

D Optional cleaning wipers (page 17)

B

Limit switch sensors “LS” (page

23)

E Diagnostic LEDs (page 25)

C Incremental sensor

MAN SMS12 E 1.1 Mechanical installation 9 of 32

Page 10

SMS12

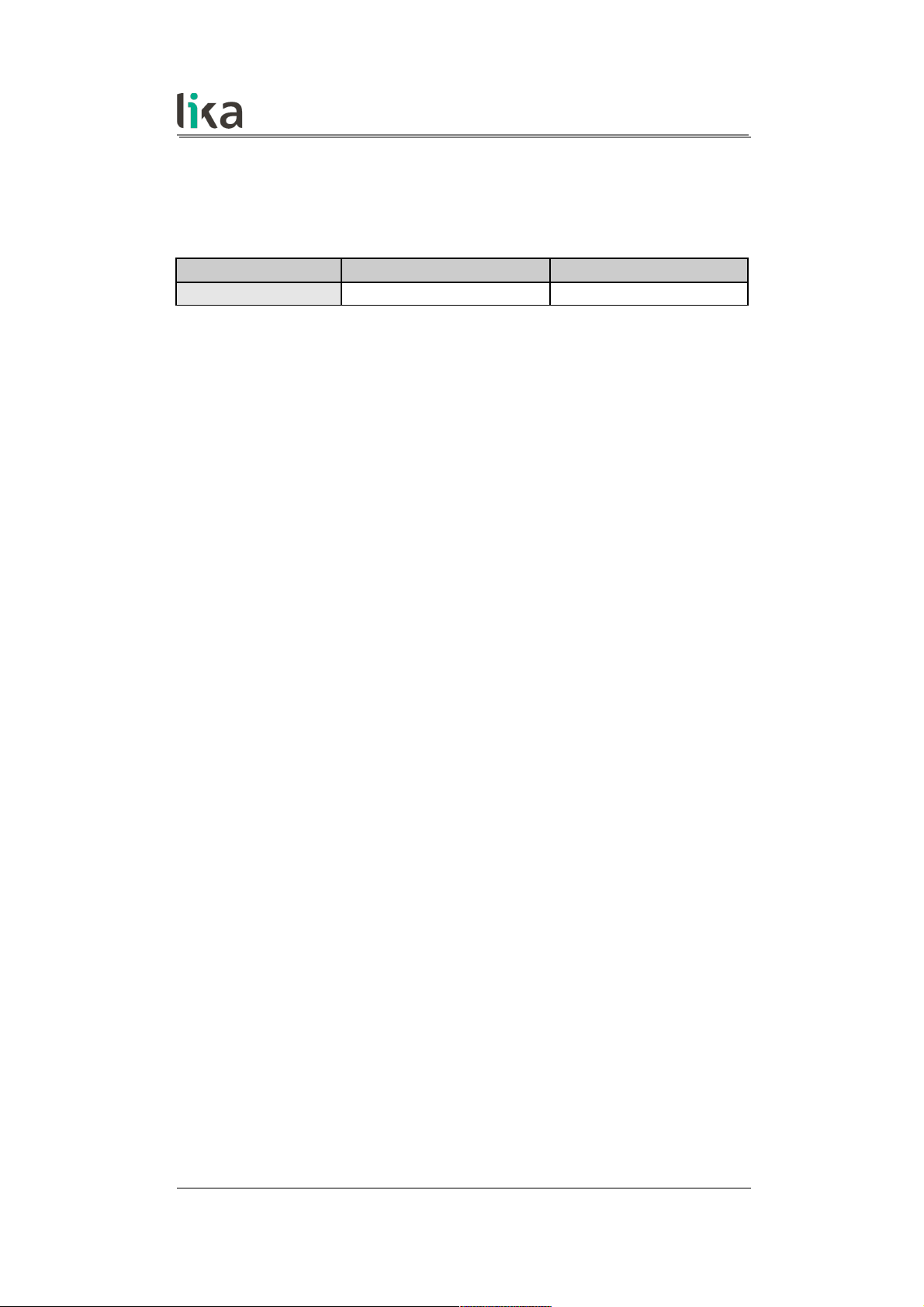

3.2 Sensor and scale / ring combination

The sensor has to be compulsorily paired with its specific type of magnetic scale

or ring as indicated in the table below. For any information on the scale or ring

please refer to the specific documentation.

Sensor MT tape MRI ring

SMS12

MT10 MRI/xxx-xxx-1

3.3 Magnetic tape

As stated, the sensor model must be compulsorily paired with its specific type of

magnetic scale (see the previous section). For detailed information on the tape

and how to mount it properly, please refer to the specific technical

documentation.

Make sure that the mechanical installation complies with the system's

requirements for distance, planarity and parallelism between the readhead and

the scale indicated in Figure 2 all along the whole measuring length.

MT magnetic tape can be provided with a cover strip to protect its magnetic

surface (see the order code of the magnetic tape).

You can mount the readhead in both directions over the tape. The arrow in

Figure 1 indicates the standard counting direction (the rising edge of A signal

leads the rising edge of B signal) when the sensor moves in the direction

indicated by the arrow; further information in the “4.6 Counting direction”

section on page 21.

The external “R” / “T” Reference magnet order code LKM-1309/1 and the limit

switches “LS” order code LKM-1309/LS must be compulsorily installed as

shown in Figure 3 and Figure 4. For complete information please refer to the

“3.6 Mounting the sensor with “R” / “T” Reference” section on page 13; and to

the “3.7 Mounting the sensor with LS1 and LS2 limit switches” section on page

14.

3.4 Magnetic rings

The flexibility of the scale allows the sensor to be used for both linear and

angular applications. Furthermore it can be installed also on round surfaces and

magnetic rings.

As stated, the sensor model must be compulsorily paired with its specific type of

magnetic ring (see the “3.2 Sensor and scale / ring combination” section).

MAN SMS12 E 1.1 Mechanical installation 10 of 32

Page 11

SMS12

3.5 Mounting the sensor with magnetic tape

Figure 1 - Encoder / tape mounting gap

Make sure that the mechanical installation complies with the system

requirements concerning distance, planarity and parallelism between the sensor

and the scale as shown in Figure 2. Avoid contact between the parts.

Install the unit providing protection means against waste, especially swarf as

turnings, chips or filings; should this not be possible, please make sure that

adequate cleaning measures (as for instance brushes, scrapers, jets of

compressed air, etc.) are in place in order to prevent the sensor and the

magnetic scale from jamming. We suggest installing the optional cleaning

wipers order code KIT WIPERS.

Fix the sensor by means of two M3 15 mm min. long cylinder head screws

inserted in the provided slots.

The recommended tightening torque is 1.1 Nm.

The recommended minimum bend radius of the cable is: R 42 mm.

Install the sensor and the magnetic scale as shown in the Figure. As previously

stated, the arrow is intended to indicate the standard counting direction (the

rising edge of A signal leads the rising edge of B signal).

Please note that the MT magnetic scale can be provided with a cover strip to

protect its magnetic surface (see the order code). Therefore the distance

between the sensor and the magnetic scale is different whether the cover strip

is applied.

The distance D (see Figure 1) between the bottom of the encoder and the

MT magnetic scale must be as follows:

Sensor

Distance D between

sensor and MT tape

Distance D between

sensor and cover strip

SMS12

0.1 mm 0.5 mm

0.004” 0.019”

0.1 mm 0.3 mm

0.004” 0.012”

MAN SMS12 E 1.1 Mechanical installation 11 of 32

Page 12

SMS12

For better operation we suggest the following distance D:

Sensor

Recommended distance D between sensor and MT

tape

SMS12

0.25 mm 0.010”

WARNING

Make sure that the mechanical installation complies with the system's

requirements for distance, planarity and parallelism between the readhead and

the scale as shown in Figure 2 all along the whole measuring length.

Figure 2 - Encoder / tape mounting tolerances

MAN SMS12 E 1.1 Mechanical installation 12 of 32

Page 13

SMS12

3.6 Mounting the sensor with “R” / “T” Reference

The Reference signal is available

with "R" order code (RS-422 level

signals) or “T” order code (1Vpp

level signals) and in combination

with LKM-1309/1 Reference pole

support. It provides a single datum

position along the scale for use at

power-up or following a loss of

power. The external Reference

magnet is placed next to the scale

on the side shown in the Figure at

the preferred location to mark a

relevant position in the travel (the

home position, for instance). The R

LED lights up when the sensor

detects the LKM-1309/1 external reference. If the zero signal is not present on

the output or has not the indicated length when the LED is ON, move the

Reference Mark (LKM-1309/1) of about half a pole length to align it with the

scale while keeping the same distance from the sensor. Further information in

the “4.7 Reference “R” / “T”” section on page 22.

Figure 3 - External Reference

D1: gap to be compliant with between the sensor and the LKM-1309/1 external

magnet.

D2: distance from the centre of fixing hole to the edge of the Reference Mark.

MAN SMS12 E 1.1 Mechanical installation 13 of 32

Page 14

SMS12

D1 D2

SMS12 / LKM-1309/1

0.1 – 0.3 mm

0.004” - 0.012”

7.3 mm

0.287”

3.7 Mounting the sensor with LS1 and LS2 limit switches

SMS12 linear encoder integrates two sensors designed to detect external limit

switches (code LKM-1309/LS). They allow to detect the ends in the travel.

External references LS1 and LS2 must be installed at either/both ends of the

sensor's travel on the side shown in the Figure respecting the indicated

tolerances. In this way at power-up or during operation the controller can

determine whether the encoder is at an end-of-travel and in which direction to

drive the axis. Further information on page 23.

Figure 4 - External limit switches

D1: gap to be respected between the sensor and the LKM-1309/LS external

magnet.

D2: distance from the centre of the fixing hole to the edge of Limit Switch

Mark.

D1 D2

SMS12 - LKM-1309/LS

0.5 – 1.0 mm

0.020” - 0.039”

7.5 mm

0.295”

MAN SMS12 E 1.1 Mechanical installation 14 of 32

Page 15

SMS12

3.8 Measuring length

The length of the tape can be theoretically unlimited. The tape is supplied in

rolls up to 100 m / 328 ft long.

The sensor area must always be fully within the limits of the tape magnetic

surface, then the maximum measuring length is the maximum length of the

tape minus the length of the sensor head (and further two safety sections at

both end each one being min. 1-pole pitch long). For instance: if the travel in

your application is 500 mm / 19.685”, then the length of the tape to be installed

will be: 500 mm / 19.685” (measuring length) + 40 mm / 1.575” (length of the

readhead, see the Figure on page 9) + 2 x 1 mm (the length of two pole pitches

of MT10 tape for safety reasons) = 542 mm / 21.338”.

3.9 Mounting the sensor with MRI magnetic rings

As previously stated, the flexibility of the tape allows the sensor to be used also

for angular applications. Furthermore it can be installed also on round surfaces

or MRI type magnetic rings.

When the sensor is installed on magnetic rings having a 10 mm / 0.4” wide

magnetic surface, line up both the sensor and the ring on the central axis. When

magnetic rings having a 5 mm / 0.2” wide magnetic surface are used, line up the

sensor and the ring as shown in Figure 5; please consider that the incremental

sensor is located laterally in the sensing head. With 5 mm rings the mounting

direction of the ring makes no difference (but ascertain that the sensor is

properly aligned on the correct side!).

Install the unit providing protection means against waste, especially swarf as

turnings, chips or filings; should this not be possible, please make sure that

adequate cleaning measures (as for instance brushes, scrapers, jets of

compressed air, etc.) are in place in order to prevent the sensor and the

magnetic scale from jamming.

MAN SMS12 E 1.1 Mechanical installation 15 of 32

Page 16

SMS12

Figure 5 - Sensor / ring alignment

To learn about the mounting tolerances refer to the tables below as well as to

Figure 5 and Figure 6.

Figure 6 - Sensor / ring mounting gap

Sensor Distance DR between sensor and MRI ring

SMS12

0.1 mm 0.5 mm

0.004” 0.019”

MAN SMS12 E 1.1 Mechanical installation 16 of 32

Page 17

SMS12

Sensor

Recommended distance DR between sensor and MRI

ring

SMS12

0.25 mm 0.010”

3.10 Standard counting direction

The positive counting direction (the rising edge of A signal leads the rising edge

of B signal) is achieved when the sensor moves on the tape according to the

arrow shown in Figure 1; or when the ring turns according to the arrow shown

in Figure 6. For further information see the “4.6 Counting direction” section on

page 21.

3.11 Optional cleaning wipers (Figure 1)

This encoder can be optionally provided with rubber cleaning wipers to be

mounted on the sensing head (order code KIT WIPERS). They are designed for

debris removal from the magnetic tape surface in order to ensure a clear path of

motion.

MAN SMS12 E 1.1 Mechanical installation 17 of 32

Page 18

SMS12

4 Electrical connection

WARNING

Electrical connection must be carried out by qualified personnel only, with

power supply disconnected and mechanical parts compulsorily in stop.

WARNING

If wires of unused signals come in contact, irreparable damage could be caused

to the device. Thus they must be cut at different lengths and insulated

singularly.

4.1 M10 cable connection

Function M10 cable

0Vdc

Black

+5Vdc ±5%

Red

A

Yellow

/A

Blue

B

Green

/B

Orange

0

1

White

/0

1

Grey

LS1

2

Brown

LS2

2

Violet

Shield

Shield

1 Reference “R" or “T” signals (see the “4.7 Reference “R” / “T”“ section on page

22), see the order code.

2 LS1 / LS2 limit switch signals (see the “4.9 LS1 and LS2 limit switches”

section on page 23).

NOTE

All sensors can provide inverted signals.

A = A signal;

/A = inverted A signal (or complementary signal).

MAN SMS12 E 1.1 Electrical connection 18 of 32

Page 19

SMS12

All Lika's magnetic sensors can provide AB0, /AB0 output signals. You are advised

to always connect the inverted signals if the receiving device will accept them.

Otherwise each output should be insulated singularly.

4.2 M10 cable specifications

Model : LIKA HI-FLEX sensor cable type M10

Cross section : 2 x 0.22 mm2 + 8 x 0.14 mm2 (24/26AWG)

Jacket : Matt Polyurethane (TPU) halogen free, oil, hydrolysis,

abrasion resistant

Shield : Tinned copper braid, coverage > 85%

Outer diameter : 5.7 ± 0.2 mm (0.224” ± 0.008”)

Min. bending radius : outer diameter x 7.5

Work temperature: dyn -40 +90°C (-40° +194°F) / fix -50 +90°C (-58° +194°F)

Conductor resistance : <90 /Km (0.22 mm2), <148 /Km (0.14 mm2)

The total length of the cable that connects the sensor and the receiving device

should not exceed the values stated in the “Cable lengths” section of the linear

encoders' catalogue; they are specific for each type of output circuit. If you need

to reach greater distances please contact Lika Electronic Technical Dept.

MAN SMS12 E 1.1 Electrical connection 19 of 32

Page 20

SMS12

4.3 Connection of the shield

For signals transmission always use shielded cables. The cable shielding must be

connected properly to the metal ring nut 3 of the connector in order to ensure

a good earthing through the frame of the device. To do this disentangle and

shorten the shielding 1 and then bend it over the part 2; finally place the ring

nut 3 of the connector. Be sure that the shielding 1 is in tight contact with the

ring nut 3.

4.4 Ground connection

Minimize noise by connecting the cable shield and the sensor to ground. Make

sure that ground is not affected by noise. The connection point to ground can

be situated both on the device side and on the user’s side. The best solution to

minimize the interference must be carried out by the user. You are advised to

provide the ground connection as close as possible to the encoder.

MAN SMS12 E 1.1 Electrical connection 20 of 32

Page 21

SMS12

4.5 AB0, /AB0 output channels

Figure 7 - Output signals

The conversion electronics inside the sensor translates the magnetic fields of the

scale / ring into electrical signals equivalent to those of an incremental encoder

or similar incremental optical devices.

The frequency of the output signal is proportional to the measuring speed and

the displacement of the sensor.

NOTE

The standard counting direction (the channel A leads the channel B) is to be

intended with sensor moving as shown in Figure 1 in a linear application; with

ring turning as indicated by the arrow in Figure 6 in a rotary application.

4.6 Counting direction

By default the phase relationship between A and B channels is so that the rising

edge of A channel leads the rising edge of B channel when the encoder moves

in the direction shown by the arrow in Figure 1 in a linear application; or when

the ring turns as indicated by the arrow in Figure 6 in a rotary application (see

the “4.5 AB0, /AB0 output channels” section on page 21). Thus the counter in

the subsequent electronics will get a count up. It cannot be changed.

MAN SMS12 E 1.1 Electrical connection 21 of 32

Page 22

SMS12

4.7 Reference “R” / “T”

Reference signals (0, /0) are available with "R" or “T” order codes and in

combination with LKM-1309/1 support. They provide a single datum position

along the scale for use at power-up or following a loss of power. The external

Reference magnet is placed next to the scale on the side shown in Figure 3 at

the preferred location to mark a relevant position in the travel (the home

position, for instance). The R LED lights up when the sensor detects the LKM1309/1 external reference. Please note that this does not mean that the

Reference pulse is output in the same time: the Reference pulse is synchronized

with A and B channels within the South pole (Figure 8) and has the indicated

duration. Thus, it may be either not output yet or already output while the LED

is lit.

“R” code Reference signals have an amplitude according to RS-422; while “T”

code Reference signals have an amplitude of 1Vpp.

The typical repeatability of the signal is 1% of the period length.

EXAMPLE

SMS12, 1 mm pole pitch: 1000 µm / 100 = 10 µm

The Reference signal has a duration of 70 ±10 electrical degrees.

The accuracy and the duration of the Reference pulse may vary depending on

the alignment of the Reference magnet and the magnetic scale, see the Figure

8. For additional information refer to the “3.6 Mounting the sensor with “R” / “T”

Reference” section on page 13.

Figure 8 - Reference

MAN SMS12 E 1.1 Electrical connection 22 of 32

Page 23

SMS12

4.8 Voltage signals

The voltage level refers to the differential value between normal and inverted

signal (differential).

Level of A, /A, B and /B signals

signals amplitude

A, /A, B, /B Min 0.4Vpp - Max 0.6Vpp

VREF 2.5V

Level of differential signals

signals amplitude

VA, VB 1Vpp: Min 0.8Vpp - Max 1.2Vpp

“R” according to RS-422

“T” 1Vpp: Min 0.5Vpp - Max 1.0Vpp

V

REF

= 2.5V ± 0.5V VA = 1Vpp * Av Av = R2 / R1

4.9 LS1 and LS2 limit switches

SMS12 linear encoder integrates two sensors designed to detect external limit

switches (code LKM-1309/LS). They allow to detect the ends in the travel.

External references LS1 and LS2 must be installed at either/both ends of the

sensor's travel on the side shown in the Figure and according to the indicated

tolerances. In this way at power-up or during operation the controller can

MAN SMS12 E 1.1 Electrical connection 23 of 32

Page 24

SMS12

determine whether the encoder is at an end-of-travel and in which direction to

drive the axis.

Figure 9 - LS limit switches

MAN SMS12 E 1.1 Electrical connection 24 of 32

Page 25

SMS12

Outputs of limit switches LS1 and LS2 are open collector type and have Imax =

50 mA. The signal is normally at logic level high (+Vdc) and switches to logic

level low (0Vdc) as soon as the external limit switch is detected. The signal is

kept at logic level low (0Vdc) as long as the sensor is within the active area of

the external limit switch.

LS1 and LS2 LEDs light up when the sensor detects the relevant LKM-1309/LS

external limit switch.

4.10 Diagnostic LEDs (Figure 10)

Four LEDs located in the upper face of the encoder enclosure are intended to

show visually the work status of the device as explained in the following table.

Figure 10 - Diagnostic LEDs and optional cleaning wipers

1 GREEN LED

(Limit Switch LS1)

Description

ON

Green

It lights up when the LS1 sensor detects the

external LKM-1309/LS1 limit switch. It is

MAN SMS12 E 1.1 Electrical connection 25 of 32

Page 26

SMS12

equivalent to the logic level low (0) of the LS1

open collector signal. Refer to the “4.9 LS1 and

LS2 limit switches” section on page 23. It is on

for the whole period length (Figure 9).

OFF External limit switch not detected.

2 GREEN LED

(Limit Switch LS2)

Description

ON

Green

It lights up when the LS2 sensor detects the

external LKM-1309/LS2 limit switch. It is

equivalent to the logic level low (0) of the LS2

open collector signal. Refer to the “4.9 LS1 and

LS2 limit switches” section on page 23. It is on

for the whole period length (Figure 9).

OFF External limit switch not detected.

E RED LED

(Error status)

Description

ON

Red

It warns of the presence of an error.

• Distance error: the specified mounting

tolerances between sensor and tape (or ring)

are not met; please refer to the “Mechanical

installation” section on page 9.

OFF No error is active currently.

R GREEN LED

(Reference)

Description

ON

Green

It is ON as long as the external Reference is

detected (see Figure 7 and Figure 8). Refer to the

“4.7 Reference “R” / “T”” section on page 22. It is

on for the whole period length (Figure 8).

OFF External Reference not detected.

NOTE

If an error occurs switch off and then on again the encoder and check whether

the problem is cleared up and the LED turns off.

MAN SMS12 E 1.1 Electrical connection 26 of 32

Page 27

SMS12

4.11 Recommended circuit

MAN SMS12 E 1.1 Electrical connection 27 of 32

Page 28

SMS12

5 Maintenance and troubleshooting

The magnetic measurement system does not need any particular maintenance;

please always consider it is a delicate electronic equipment and therefore it

must be handled with care. From time to time we recommend the following

operations:

• Check the mounting tolerances between the sensor and the magnetic

scale / magnetic ring all along the measuring length. Wear of the

machine may increase the tolerances.

• The surface of the magnetic scale / magnetic ring should be cleaned

periodically using a soft cloth to remove dust, chips, moisture etc.

The following list shows some typical faults and errors that may occur during

installation and operation of the magnetic measurement system. Refer also to

the “4.10 Diagnostic LEDs (Figure 10)” section on page 25.

Fault:

The system does not work (no pulse output).

Possible cause:

• The scale or the sensor has been mounted incorrectly (the active part of

the scale does not match the active side of the sensor).

• A magnetic piece or an inappropriate strip is in between the sensor and

the scale / ring. Only non-magnetic materials are allowed between the

sensor and the scale / ring.

• The sensor touches the scale / ring: the mounting tolerances are not

met. Check if the active side of the sensor is damaged.

• The sensor has been damaged by a short circuit or a wrong connection.

Fault:

The measured values are inaccurate.

Possible cause:

• The mounting tolerances between the sensor and the scale / ring are not

met all along the whole measurement length.

• The connection cable runs near to high voltage cable or shield is not

connected correctly. See the “4 -Electrical connection“ section on page

18.

• A section of the magnetic scale / ring has been damaged mechanically

or magnetically along the measuring length.

• The measuring error is caused by torsion of the machine structure.

Check parallelism and symmetry of machine movement.

MAN SMS12 E 1.1 Maintenance and troubleshooting 28 of 32

Page 29

SMS12

NOTE

If an error occurs switch off and then on again the encoder and check whether

the problem is cleared up and the LED turns off.

MAN SMS12 E 1.1 Maintenance and troubleshooting 29 of 32

Page 30

This page intentionally left blank

Page 31

This page intentionally left blank

Page 32

Document release Release date Description HW SW Interface

1.0 16.06.2016 First issue - - -

1.1 10.07.2018 New mechanical version - - -

Lika Electronic

Via S. Lorenzo, 25 • 36010 Carrè (VI) • Italy

Tel. +39 0445 806600

Fax +39 0445 806699

info@lika.biz • www.lika.biz

Loading...

Loading...