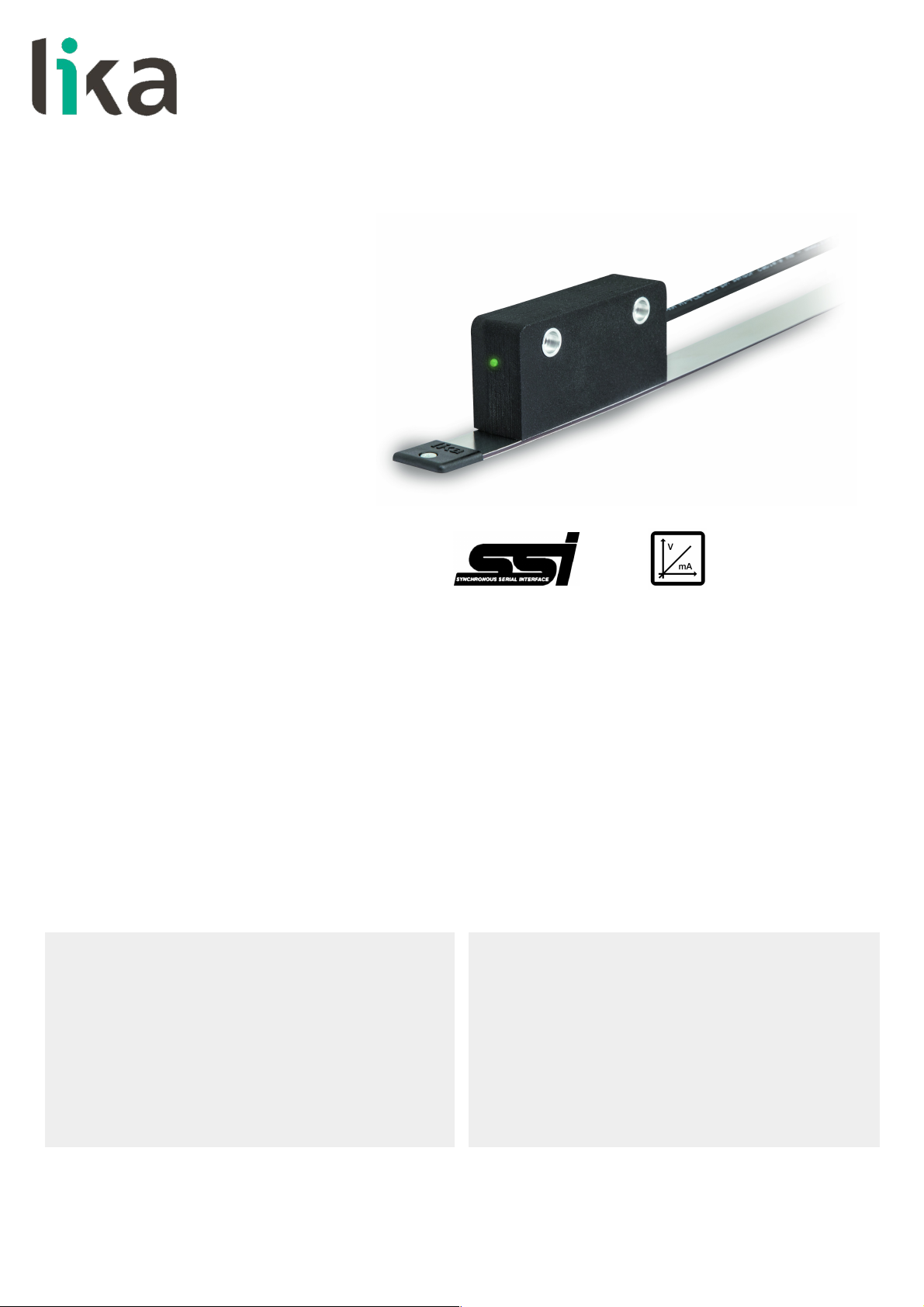

Lika SMAX-BG series, SMAX-AI1 series, SMAX-GG series, SMAX-AV2 series User Manual

User's guide

SMAX

• Cost-effective absolute linear encoder

• Measuring length up to 600 mm / 23.622”

• Resolution down to 0.1 mm

• SSI and voltage/current analogue interfaces

• Up to IP69K protection rate

Suitable for the following models:

• SMAX-BG-...

• SMAX-GG-...

• SMAX-AI1-...

• SMAX-AV2-...

Table of Contents

1 - Safety summary 7

2 - Identification 8

3 - Mounting instructions 9

4 - SSI interface 13

5 - Analogue interface 20

6 - Diagnostic LED 28

7 - Maintenance 29

8 - Troubleshooting 30

Lika Electronic • Tel. +39 0445 806600 • info@lika.biz • www.lika.biz

Smart encoders & actuators

This publication was produced by Lika Electronic s.r.l. 2017. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Table of Contents

User's guide......................................................................................................................................................... 1

Table of Contents............................................................................................................................................... 3

Typographic and iconographic conventions................................................................................................. 5

Preliminary information.................................................................................................................................... 6

1 - Safety summary....................................................................................................................................... 7

1.1 Safety......................................................................................................................................................................................7

1.2 Electrical safety...................................................................................................................................................................7

1.3 Mechanical safety..............................................................................................................................................................8

2 - Identification............................................................................................................................................ 8

3 - Mounting instructions............................................................................................................................ 9

3.1 Overall dimensions............................................................................................................................................................9

3.2 Magnetic tape.....................................................................................................................................................................9

3.3 Mounting the sensor.....................................................................................................................................................10

3.4 Measuring length............................................................................................................................................................12

3.5 Standard counting direction......................................................................................................................................12

4 - SSI interface........................................................................................................................................... 13

4.1 SSI interface electrical connections........................................................................................................................13

4.1.1 M8 cable specifications......................................................................................................................................13

4.1.2 M12 8-pin connector..........................................................................................................................................13

4.1.3 Connection of the shield...................................................................................................................................14

4.1.4 Ground connection..............................................................................................................................................14

4.1.5 Zero setting input.................................................................................................................................................14

4.1.6 Counting direction input...................................................................................................................................15

4.2 SSI (Synchronous Serial Interface)...........................................................................................................................15

4.2.1 MSB left aligned protocol.................................................................................................................................17

4.2.2 Recommended transmission rates................................................................................................................18

4.3 Recommended SSI circuit............................................................................................................................................19

5 - Analogue interface................................................................................................................................ 20

5.1 Analogue interface electrical connections...........................................................................................................20

5.1.1 M8 cable specifications......................................................................................................................................20

5.1.2 M12 8-pin connector..........................................................................................................................................21

5.1.3 Connection of the shield...................................................................................................................................21

5.1.4 Ground connection..............................................................................................................................................21

5.2 Signals description..........................................................................................................................................................21

5.2.1 0Vdc............................................................................................................................................................................21

5.2.2 START input.......................................................................................................................................................21

5.2.3 +Iout current analogue output......................................................................................................................21

5.2.4 +Vout voltage analogue output....................................................................................................................21

5.2.5 STOP input.........................................................................................................................................................22

5.2.6 Fault output............................................................................................................................................................22

5.2.6.1 Fault output connected to a PLC input.............................................................................................22

5.2.6.2 Fault output connected to a relay.......................................................................................................23

5.3 TEACH-IN procedure......................................................................................................................................................24

5.3.1 TEACH-IN procedure...........................................................................................................................................25

5.3.2 Ascending and descending ramp...................................................................................................................26

5.4 Recommended current analogue output circuit...............................................................................................27

5.5 Recommended voltage analogue output circuit...............................................................................................27

6 - Diagnostic LED....................................................................................................................................... 28

7 - Maintenance........................................................................................................................................... 29

8 - Troubleshooting..................................................................................................................................... 30

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters and objects both of Lika device and interface are coloured in GREEN;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee

the safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Preliminary information

This guide is designed to provide the most complete and exhaustive information the operator needs to

correctly and safely install and operate the SMAX absolute linear encoder with SSI and analogue

interfaces.

This encoder is designed to measure linear displacements in industrial machines and automation systems.

The measurement system includes a magnetic tape and a magnetic sensor with conversion electronics.

The tape is magnetized with a coded sequence of North-South poles generating a pseudo-random

absolute pattern. As the sensor is moved along the magnetic tape, it detects the displacement and yields

the absolute position information through the SSI interface (SMAX-BG..., SMAX-GG...) or the voltage

(SMAX-AV2...) / current (SMAX-AI1...) analogue interface or the Modbus interface (SMAX-MB...). The

Modbus sensor is provided with its own technical documentation.

It is mandatory to pair the sensor with the MTAX type magnetic scale. The measuring length can be

200 mm / 7.874”, 300 mm / 11.811” and 600 mm / 23.622”, see the order code.

To make it easier to read and understand the text, this guide can be divided into three main sections.

In the first section some general information concerning the safety, the mechanical installation and the

electrical connection as well as tips for setting up and running properly and efficiently the unit are

provided.

In the second section, entitled SSI interface, both general and specific information is given on the SSI

interface.

In the third section, entitled Analogue interface, both general and specific information is given on the

analogue interface.

SMAX - SSI and analogue

1 - Safety summary

1.1 Safety

• Always adhere to the professional safety and accident prevention

regulations applicable to your country during device installation and

operation;

• installation and maintenance operations have to be carried out by

qualified personnel only, with power supply disconnected and stationary

mechanical parts;

• device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

• high current, voltage and moving mechanical parts can cause serious or

fatal injury;

• warning ! Do not use in explosive or flammable areas;

• failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture,

and intended use of the equipment;

• Lika Electronic assumes no liability for the customer's failure to comply

with these requirements.

1.2 Electrical safety

• Turn OFF power supply before connecting the device;

• connect the unit according to the explanation in the ”Electrical

connections” section;

• connect Zero Setting and Counting direction inputs to 0Vdc, if not used;

- to zero set the encoder, connect Zero setting input to +Vdc for 100 µs at

least, then disconnect +Vdc; normally voltage must be at 0Vdc; zero set

must be performed after Counting direction setting; we suggest

performing the zero set when the encoder is in stop;

- Counting direction: increasing count (count up information) = connect

to 0Vdc; decreasing count (count down information) = connect to +Vdc;

• in compliance with 2014/30/EU norm on electromagnetic

compatibility, following precautions must be taken:

- before handling and installing the equipment, discharge

electrical charge from your body and tools which may come in touch

with the device;

- power supply must be stabilized without noise; install EMC filters on

device power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive

noise source; shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets

on or near by the unit;

- minimize noise by connecting the shield and/or the connector housing

and/or the sensor to ground. Make sure that ground is not affected by

noise. The connection point to ground can be situated both on the device

MAN SMAX SSI_AI1_AV2 E 1.5.odt 1 - Safety summary 7 of 32

SMAX - SSI and analogue

side and on user’s side. The best solution to minimize the interference

must be carried out by the user;

- do not stretch the cable; do not pull or carry by cable; do not use the

cable as a handle.

1.3 Mechanical safety

• Install the device following strictly the information in the “3 - Mounting

instructions” section;

• mechanical installation has to be carried out with stationary mechanical

parts;

• do not disassemble the unit;

• do not tool the unit;

• delicate electronic equipment: handle with care; do not subject the device

to knocks or shocks;

• protect the unit against acid solutions or chemicals that may damage it;

• respect the environmental characteristics of the product;

• we suggest installing the unit providing protection means against waste,

especially swarf as turnings, chips, or filings; should this not be possible,

please make sure that adequate cleaning measures (as for instance

brushes, scrapers, jets of compressed air, etc.) are in place in order to

prevent the sensor and the magnetic scale from jamming.

2 - Identification

Device can be identified through the order code and the serial number printed

on the label applied to its body. Information is listed in the delivery document

too. Please always quote the order code and the serial number when reaching

Lika Electronic for purchasing spare parts or needing assistance. For any

information on the technical characteristics of the product refer to the

technical datasheet.

Warning: devices having order code ending with "/Sxxx" may have

mechanical and electrical characteristics different from standard and

be supplied with additional documentation for special connections

(Technical Info).

MAN SMAX SSI_AI1_AV2 E 1.5.odt 2 - Identification 8 of 32

SMAX - SSI and analogue

3 - Mounting instructions

WARNING

Installation has to be carried out by qualified personnel only, with power supply

disconnected and mechanical parts compulsorily in stop.

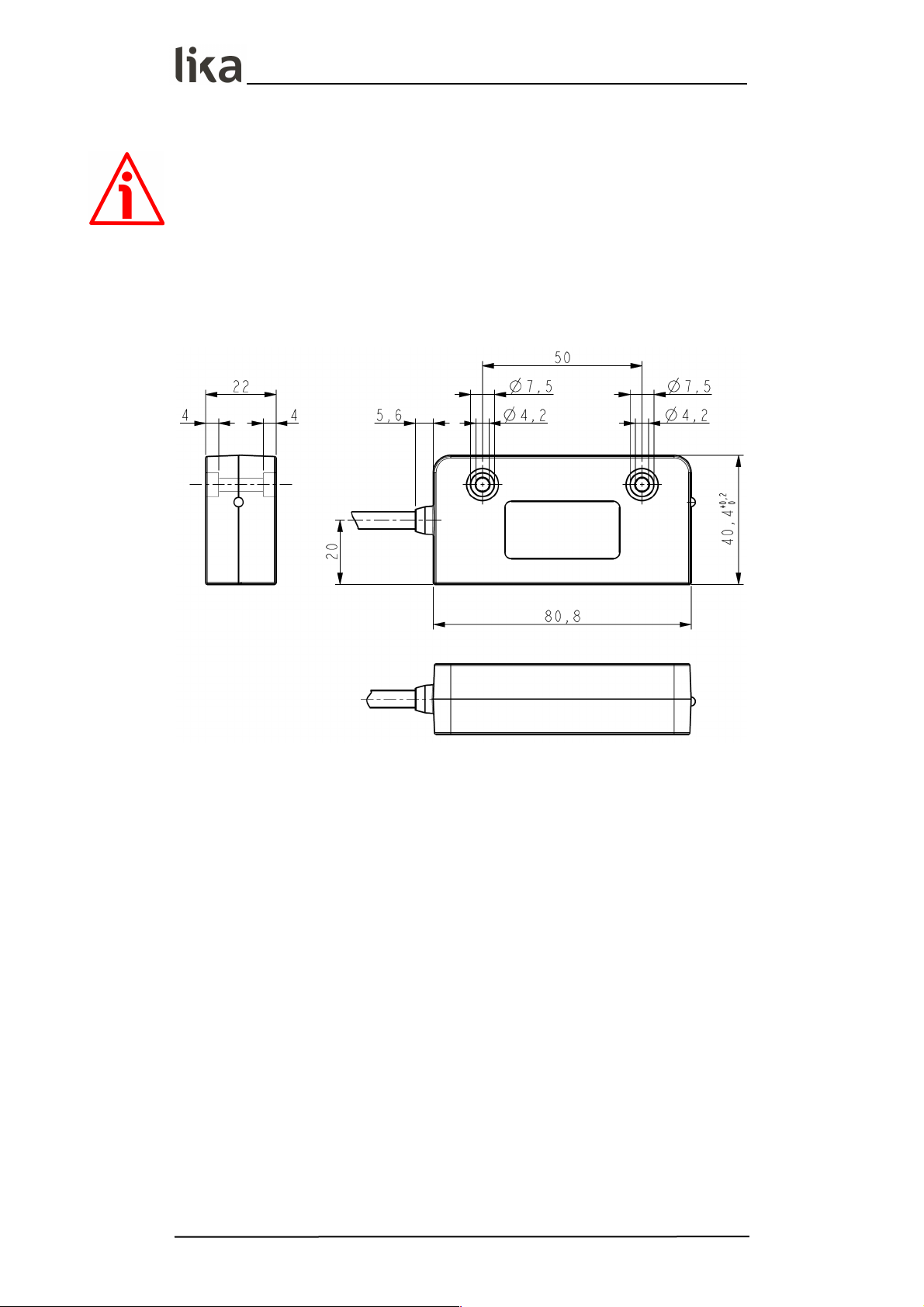

3.1 Overall dimensions

(values are expressed in mm)

3.2 Magnetic tape

The sensor has to be paired with the MTAX type magnetic tape only. For

detailed information on the MTAX type tape and how to mount it properly,

please refer to the specific technical documentation.

Install the unit providing protection means against waste, especially swarf as

turnings, chips or filings; should this not be possible, please make sure that

adequate cleaning measures (as for instance brushes, scrapers, jets of

compressed air, etc.) are in place in order to prevent the sensor and the

magnetic scale from jamming.

Make sure the mechanical installation meets the system's requirements of

distance, planarity and parallelism between the sensor and the scale indicated in

Figure 2 all along the whole measuring length.

MTAX magnetic scale can be provided with a cover strip to protect its magnetic

surface (see the order code).

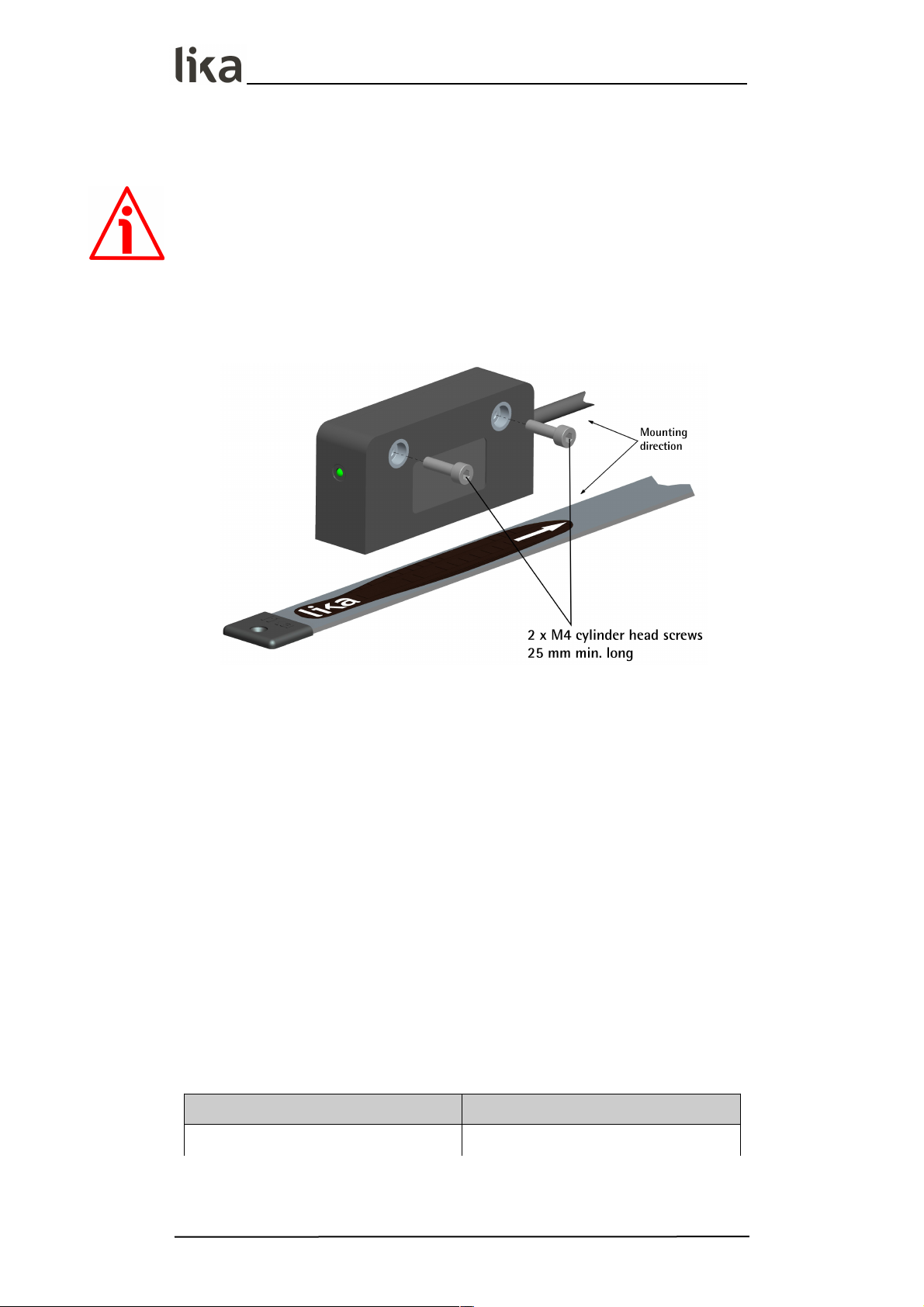

Figure 1 shows how the sensor and the scale must be installed; the arrow

indicates the standard counting direction (increasing count when the sensor

MAN SMAX SSI_AI1_AV2 E 1.5.odt 3 - Mounting instructions 9 of 32

SMAX - SSI and analogue

moves in the direction indicated by the arrow; further information in the “4.1.6

Counting direction input” section on page 15).

WARNING

The system cannot operate if mounted otherwise than illustrated in Figure 1.

3.3 Mounting the sensor

Figure 1

Make sure the mechanical installation complies with the system requirements

concerning distance, planarity and parallelism between the sensor and the scale

as shown in Figure 2. Avoid contact between the parts. Fix the sensor by means

of two M4 25 mm min. long cylinder head screws inserted in the provided

holes. Recommended minimum bend radius of the cable: R 25 mm. Install

the sensor and the magnetic scale as shown in the Figure. The system does not

operate if mounted otherwise than illustrated in the Figure. The arrow is

intended to indicate the standard counting direction (count up information).

Please note that the MTAX magnetic scale can be provided with a cover strip to

protect its magnetic surface (see the order code). Therefore the distance

between the sensor and the magnetic scale is different whether the cover strip

is applied.

The distance D (see Figure 2) between the centre of the screw fixing

holes and the MTAX magnetic scale has to be as follows:

without cover strip with cover strip

31.7 mm 33.2 mm (1.248” 1.307”) 31.3 mm 32.8 mm (1.232” 1.291”)

For better operation the suggested distance D is 32.2 mm (1.267”).

MAN SMAX SSI_AI1_AV2 E 1.5.odt 3 - Mounting instructions 10 of 32

Loading...

Loading...