Lika SMAG-GA-100-...+MTAG-300, SMAG-GA-100-...+MTAG-370, SMAG-GA-50-...+MTAG-650, SMAG -GA-100-, SMAG-GA-100-... +MTAG-220 User Manual

...Page 1

User's guide

SMAG +

MTAG

• SMAG absolute linear encoder

• MTAG guided profile unaffected by dust and liquids

• Measuring length from 115 to 570 mm

• Resolution range from 0.1 mm to 0.005 mm

• SSI interface, LSB Right Aligned protocol

Suitable for the following models:

• SMAG -GA-100-...

• SMAG -GA-50-...

• SMAG -GA-10-...

• SMAG -GA-5-...

Table of Contents

Preliminary information 5

1 – Safety summary 6

2 - Identification 8

3 – Mechanical installation 9

4 – SSI interface 12

5 - Maintenance 19

Lika Electronic • Tel. +39 0445 806600 • info@lika.biz • www.lika.biz

Smart encoders & actuators

Page 2

This publication was produced by Lika Electronic s.r.l. 2017. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Page 3

Table of contents

User's guide......................................................................................................................................................... 1

Table of contents............................................................................................................................................ 3

Typographic and iconographic conventions..............................................................................................4

Preliminary information................................................................................................................................ 5

1 – Safety summary....................................................................................................................................... 6

1.1 Safety.......................................................................................................................................................................................... 6

1.2 Electrical safety.......................................................................................................................................................................6

1.3 Mechanical safety..................................................................................................................................................................7

2 - Identification............................................................................................................................................ 8

3 – Mechanical installation.......................................................................................................................... 9

3.1 Overall dimensions (Figure 1)...........................................................................................................................................9

3.2 Mounting instructions.........................................................................................................................................................9

3.3 Sensor (Figure 2)..................................................................................................................................................................10

3.4 Profile of the magnetic tape (Figure 2).....................................................................................................................11

3.5 Measuring length (Figure 1)...........................................................................................................................................11

3.6 Standard counting direction (Figure 2).....................................................................................................................11

4 – SSI interface........................................................................................................................................... 12

4.1 Electrical connections.......................................................................................................................................................12

4.1.1 M8 cable specifications............................................................................................................................................12

4.1.2 M12 8-pin connector specifications...................................................................................................................12

4.1.3 Connection of the shield.........................................................................................................................................13

4.1.4 Ground connection....................................................................................................................................................13

4.1.5 Zero setting input.......................................................................................................................................................13

4.1.6 Counting direction input.........................................................................................................................................14

4.2 SSI (Synchronous Serial Interface)...............................................................................................................................15

4.3 LSB Right Aligned protocol.............................................................................................................................................16

4.4 Recommended transmission rates...............................................................................................................................18

4.5 Recommended SSI circuit................................................................................................................................................18

5 - Maintenance........................................................................................................................................... 19

Page 4

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters and objects both of the device and the interface are coloured in GREEN;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee

the safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Page 5

Preliminary information

This guide is designed to provide the most complete information the operator needs to correctly and

safely install and operate the linear encoders with guided profile of the SMAG series that provide SSI

interface and Gray output code.

The SMAG sensors are engineered to measure linear displacements in industrial machines and

automation lines.

The measuring system consists of a magnetic tape mounted on a rigid profile and a magnetic sensor. The

tape has a coded sequence of poles; the distance between two poles is referred to as “pole pitch”. The

sensor moves along the magnetic tape (or, on the contrary, the magnetic tape is moved under the

sensor), thus the sensor detects the displacement and issues an output signal equivalent to the one

generated by an absolute encoder or an optical linear scale.

The sensor must be compulsorily paired with the MTAG magnetic tape. The measuring length is from

115 mm (4.528”) to 570 mm (22.441”), see the order code.

For technical specifications please refer to the product datasheet.

To make it easier to read the text, this guide can be divided into some main sections.

In the first section (from chapter 1 to chapter 3) some general information concerning the safety, the

mechanical installation and the electrical connection as well as tips for setting up and running properly

and efficiently the SMAG linear encoder + MTAG are provided.

In the second section, entitled SSI Interface (chapter 4), you can find detailed information on the SSI

interface.

Page 6

SMAG + MTAG SSI

1 – Safety summary

1.1 Safety

Always adhere to the professional safety and accident prevention regulations

applicable to your country during device installation and operation;

installation and maintenance operations have to be carried out by qualified

personnel only, with power supply disconnected and stationary mechanical

devices;

device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

high current, voltage and moving mechanical parts can cause serious or fatal

injury;

warning ! Do not use in explosive or flammable areas;

failure to comply with these precautions or with specific warnings elsewhere

in this manual violates safety standards of design, manufacture, and

intended use of the equipment;

Lika Electronic assumes no liability for the customer's failure to comply with

these requirements.

1.2 Electrical safety

Turn OFF the power supply before connecting the device;

connect according to the explanation in the ”4.1 Electrical connections”

section on page 12;

connect Zero Setting input to 0Vdc, if not used; to zero set the encoder,

connect Zero setting input to +Vdc for 100 µs at least, then disconnect +Vdc;

normally voltage must be at 0Vdc; zero set must be performed after

Counting direction setting; we suggest performing the zero set when the

encoder is in stop;

connect Counting direction input to 0Vdc, if not used; to have count up

information when the measuring system moves as shown in Figure 2 (see the

arrows) = connect to 0Vdc; to have count up information when the

measuring system moves in the direction opposite to the movement shown

in Figure 2 (see the arrows) = connect to +Vdc;

in compliance with 2014/30/EU norm on electromagnetic

compatibility, following precautions must be taken:

- before handling and installing the equipment, discharge electrical

charge from your body and tools which may come in touch with the device;

- power supply must be stabilized without noise; install EMC filters on device

power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive noise

source; shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets on

or near by the unit;

MAN SMAG GA E 1.3.odt 1 – Safety summary 6 of 20

Page 7

SMAG + MTAG SSI

- minimize noise by connecting the shield or the connector housing to ground.

Make sure that ground is not affected by noise. The connection point to

ground can be situated both on the device side and on user’s side. The best

solution to minimize the interference must be carried out by the user;

do not stretch the cable; do not pull or carry by cable; do not use the cable

as a handle.

1.3 Mechanical safety

Install the device following strictly the information in the “3 – Mechanical

installation” section on page 9;

mechanical installation has to be carried out with stationary mechanical

devices;

do not disassemble the unit;

do not tool the unit;

delicate electronic equipment: handle with care; do not subject the unit to

knocks or shocks;

protect the unit against acid solutions or chemicals that may damage it;

respect the environmental characteristics declared by manufacturer;

we suggest installing the unit providing protection means against waste,

especially swarf as turnings, chips, or filings; should this not be possible,

please make sure that adequate cleaning measures (as for instance brushes,

scrapers, jets of compressed air, etc.) are in place in order to prevent the

sensor and the magnetic scale from jamming.

MAN SMAG GA E 1.3.odt 1 – Safety summary 7 of 20

Page 8

SMAG + MTAG SSI

2 - Identification

Device can be identified through the order code and the serial number printed

on the label applied to its body. Information is listed in the delivery document

too. Please always quote the order code and the serial number when reaching

Lika Electronic for purchasing spare parts or needing assistance. For any

information on the technical characteristics of the product refer to the

technical catalogue.

Warning: devices having order code ending with “/Sxxx” may have

mechanical and electrical characteristics different from standard and

be supplied with additional documentation for special connections

(Technical info).

MAN SMAG GA E 1.3.odt 2 - Identification 8 of 20

Page 9

SMAG + MTAG SSI

3 – Mechanical installation

WARNING

Installation and maintenance operations must be carried out by qualified

personnel only, with power supply disconnected and mechanical parts

absolutely in stop.

3.1 Overall dimensions (Figure 1)

(values are expressed in mm)

Figure 1

L = 195 mm / 7.677” ÷ 650 mm / 25.59” (see the order code of the MTAG

profile)

3.2 Mounting instructions

Install and use the product in conformance with the protection level it has been

designed to. Protect the unit against knocks, frictions and solvents and avoid

temperatures over the allowed range.

Make sure the unit is mounted where hard or sharp objects (e.g. turnings, chips

or filings) do not come into contact with the magnetic tape and the bottom of

the sensor head. If these conditions cannot be avoided provide adequate

cleaning measures (as for instance brushes, scrapers, jets of compressed air, etc.)

in order to prevent the sensor and the magnetic tape from jamming.

The profile of the magnetic tape must be inserted in the track at the bottom of

the sensor enclosure; the shape of the track is univocal in order to prevent

mounting errors.

Two mounting options are allowed:

1. you can fasten the profile of the magnetic tape to a fixed support and

move the sensor;

MAN SMAG GA E 1.3.odt 3 – Mechanical installation 9 of 20

Page 10

SMAG + MTAG SSI

2. or, on the contrary, you can fasten the sensor to a fixed support and

move the profile of the magnetic tape.

It is customer's duty to evaluate the type of installation that is most suitable for

his application. Anyway both the sensor and the profile (according to your

choice) must be able to slide freely and accomplish a smooth linear travel.

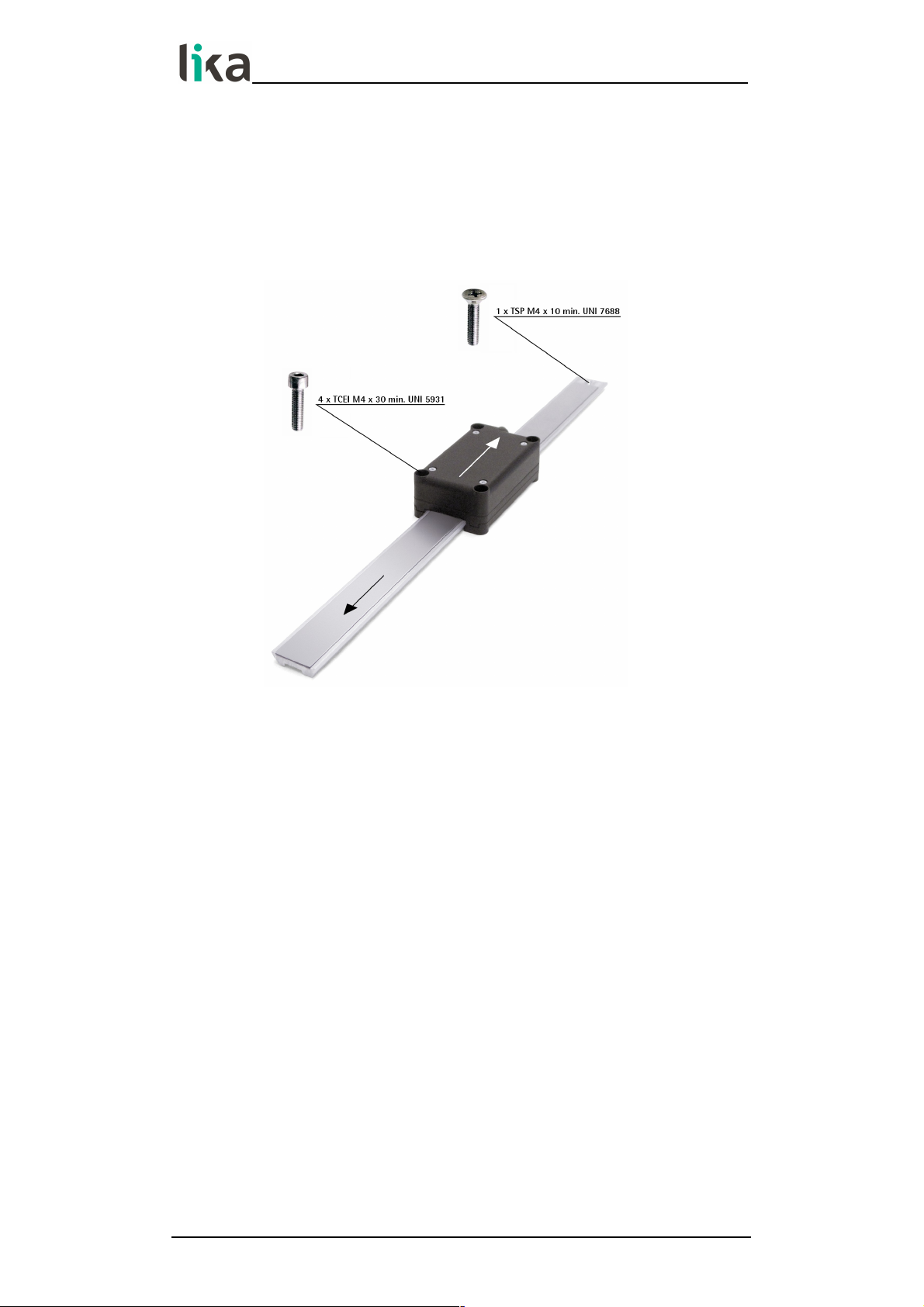

Figure 2

3.3 Sensor (Figure 2)

The sensor can be secured:

1. to a sliding carriage;

2. to an actuator;

3. to a mobile support;

4. or to a fixed support.

Use four TCEI M4 UNI 5931 type cylinder head screws inserted from the top

in the holes provided at the four angles of the enclosure. The screws must be 30

mm min. long (see Figure 1). The maximum tightening torque is 1.2 Nm. We

suggest adding a few drops of threadlocker of medium bond strength.

The fixing support will be placed at the bottom of the sensor case. Make sure

the cable does not block or hamper the movement of the sensor.

MAN SMAG GA E 1.3.odt 3 – Mechanical installation 10 of 20

Page 11

SMAG + MTAG SSI

3.4 Profile of the magnetic tape (Figure 2)

It is mandatory to pair the sensor with the MTAG type magnetic tape.

The profile of the magnetic tape can be secured:

1. to a sliding device driven manually, pneumatically or by a motor; in this

first case the tape will move back and forth while the sensor will be

mounted in a fixed position;

2. or to a fixed support: in this case, the tape will be mounted in a fixed

position while the sensor will move back and forth.

The profile must be installed so that the active magnetic surface (black side) is

turned towards the active surface of the sensor (electronic card).

Use one TSP M4 UNI 7688 type countersunk head screw to secure the

profile of the magnetic tape; insert the screw in the hole provided at one end of

the profile. The screw is 10 mm min. long. The maximum tightening torque is

2.5 Nm.

The length of the profile ranges between 195 mm / 7.677” and 650 mm / 25.59”.

WARNING

Do not expose the sensor and the magnetic tape to magnetic fields. Avoid any

possible interference of the unit with magnetic fields.

WARNING

After having installed the sensor on the magnetic tape a zero setting operation

is compulsorily required. The zero setting operation is further required every

time either the sensor or the tape is replaced. For any information on the zero

setting operation please refer to the “4.1.5 Zero setting input” section on page

13.

3.5 Measuring length (Figure 1)

The maximum tape length L is between 195 mm / 7.677”” and 650 mm /

25.59” (for further information refer the order code in the product datasheet).

As the sensor area has always to be fully within the limits of the tape magnetic

surface, then the maximum measuring length ML is the maximum tape

length minus the sensor length (see the Figure 1) = L – 80 mm / 3.149” (115

mm / 4.528” ÷ 570 mm / 22.441”).

3.6 Standard counting direction (Figure 2)

The positive counting direction (count up information) is achieved when the

sensor moves on the tape according to the white arrow shown in Figure 2; or,

on the contrary, when the tape moves according to the black arrow shown in

Figure 2. For further information see the “4.1.6 Counting direction input” section

on page 14.

MAN SMAG GA E 1.3.odt 3 – Mechanical installation 11 of 20

Page 12

SMAG + MTAG SSI

4 – SSI interface

4.1 Electrical connections

WARNING

Electrical connection must be carried out by qualified personnel only, with

power supply disconnected and mechanical parts compulsorily in stop.

Function M8 cable M12 8-pin

0Vdc

Black 1

+10Vdc +30Vdc

Red 2

Clock IN +

Yellow 3

Clock IN -

Blue 4

Data OUT +

Green 5

Data OUT -

Orange 6

Zero setting

White 7

Counting direction

Grey 8

Shielding

Shield Case

4.1.1 M8 cable specifications

Model : LIKA HI-FLEX sensor cable type M8

Wires : 2 x 0.22 mm2 + 6 x 0.14 mm2 (24/26 AWG)

Jacket : Matt Polyurethane (TPU) halogen free, oil, hydrolysis,

abrasion resistant

Screening : tinned copper braid, coverage 85%

Outer diameter : 5.3 mm ÷ 5.6 mm (0.209” ± 0.220”)

Min. bending radius : Ø x 7.5

Work temperature : -40°C +90°C (-40°F +194°F) – dynamic installation

-50°C +90°C (-58°F +194°F) - fixed installation

Conductor resistance : 90 /km / 148 /km

4.1.2 M12 8-pin connector specifications

Male

Frontal side

A coding

MAN SMAG GA E 1.3.odt 4 – SSI interface 12 of 20

Page 13

SMAG + MTAG SSI

4.1.3 Connection of the shield

For signals transmission always use shielded cables. The cable shielding must be

connected properly to the metal ring nut of the connector in order to ensure a

good earthing through the frame of the device.

4.1.4 Ground connection

Minimize noise by connecting the shield or the connector housing to ground.

Make sure that ground is not affected by noise. The connection point to ground

can be situated both on the device side and on user’s side. The best solution to

minimize the interference must be carried out by the user.

4.1.5 Zero setting input

The output value can be set to zero (reset) via an external signal issued by a PLC

or other controller device. When the internal microprocessor receives the signal

it resets the output information. This can be very useful for setting the zero

position of both the sensor and the machine. To zero set the encoder position,

connect Zero setting input to +Vdc for 100 µs at least, then disconnect +Vdc;

normally voltage must be at 0Vdc; zero set must be performed after Counting

direction setting; we suggest performing the zero set when the encoder is in

stop. Connect to 0Vdc if not used.

WARNING

It is necessary to zero set the sensor after having set a new counting direction.

WARNING

After having installed the sensor on the magnetic tape a zero setting operation

is compulsorily required. The zero setting operation is further required every

time either the sensor or the tape is replaced.

NOTE

Please note that, after setting the zero point, the positive counting will be from

0 towards the max. value (see the table below); if you move the axis before the

0 point, the detected value will be the max. number of information – 1 down.

EXAMPLE

Let's suppose we are using the SMAG-GA-5-... model, it is paired with the

MTAG-650-... profile. If you set the 0 along the path, starting from the 0 point,

the output values will be from 0 towards the max. value (114,000, see the table

below) when the measuring system moves according to the arrows shown in

Figure 2; when the system moves back, the value immediately after 0 will be the

max. number of information – 1 (131,071).

... 131.070 131.071 0 1 2 ... 114.000

MAN SMAG GA E 1.3.odt 4 – SSI interface 13 of 20

Page 14

SMAG + MTAG SSI

Model Max. value

Max. number of

information

SMAG-GA-100-... + MTAG-650

5,700 8,192 (13 bits)

SMAG-GA-100-... + MTAG-370

2,900 4,096 (12 bits)

SMAG-GA-100-... + MTAG-300

2,200 4,096 (12 bits)

SMAG-GA-100-... + MTAG-240

1,600 2,048 (11 bits)

SMAG-GA-100-... + MTAG-220

1,400 2,048 (11 bits)

SMAG-GA-100-... + MTAG-192

1,150 2,048 (11 bits)

SMAG-GA-50-... + MTAG-650

11,400 16,384 (14 bits)

SMAG-GA-50-... + MTAG-370

5,800 8,192 (13 bits)

SMAG-GA-50-... + MTAG-300

4,400 8,192 (13 bits)

SMAG-GA-50-... + MTAG-240

3,200 4,096 (12 bits)

SMAG-GA-50-... + MTAG-220

2,800 4,096 (12 bits)

SMAG-GA-50-... + MTAG-192

2,300 4,096 (12 bits)

SMAG-GA-10-... + MTAG-650

57,000 65,536 (16 bits)

SMAG-GA-10-... + MTAG-370

29,000 32,768 (15 bits)

SMAG-GA-10-... + MTAG-300

22,000 32,768 (15 bits)

SMAG-GA-10-... + MTAG-240

16,000 16,384 (14 bits)

SMAG-GA-10-... + MTAG-220

14,000 16,384 (14 bits)

SMAG-GA-10-... + MTAG-192

11,500 16,384 (14 bits)

SMAG-GA-5-... + MTAG-650

114,000 131,072 (17 bits)

SMAG-GA-5-... + MTAG-370

58,000 65,536 (16 bits)

SMAG-GA-5-... + MTAG-300

44,000 65,536 (16 bits)

SMAG-GA-5-... + MTAG-240

32,000 32,768 (15 bits)

SMAG-GA-5-... + MTAG-220

28,000 32,768 (15 bits)

SMAG-GA-5-... + MTAG-192

23,000 32,768 (15 bits)

4.1.6 Counting direction input

The standard counting direction is to be intended with sensor moving

according to the white arrow in Figure 2; or with magnetic profile moving

according to the black arrow in Figure 2. The counting direction circuit allows to

reverse the counting direction. In other words it allows the count up when the

sensor (or the profile) moves in reverse of the standard direction, i.e. in the

direction opposite to the movement shown by the arrows in Figure 2. Connect

MAN SMAG GA E 1.3.odt 4 – SSI interface 14 of 20

Page 15

SMAG + MTAG SSI

the Counting direction input to 0Vdc if not used. Connect the counting

direction input to 0Vdc to have the count up information when the sensor

moves as shown by the white arrow in Figure 2 (or when the profile moves as

shown by the black arrow in Figure 2); connect the counting direction input to

+Vdc to have the count up information when the sensor moves in reverse of the

standard direction, i.e. in the direction opposite to the movement shown by the

white arrow in Figure 2 (or when the profile moves in reverse of the standard

direction, i.e. in the direction opposite to the movement shown by the black

arrow in Figure 2).

WARNING

After having set the new counting direction it is necessary to zero set the

sensor.

4.2 SSI (Synchronous Serial Interface)

SSI (the acronym for Synchronous Serial

Interface) is a synchronous point-to-point serial

interface engineered for unidirectional data

transmission between one Master and one Slave.

Developed in the first eighties, it is based on the RS422 serial standard. Its most peculiar feature is that data transmission is

achieved by synchronizing both the Master and the Slave devices to a common

clock signal generated by the controller; in this way the output information is

clocked out at each controller's request. Furthermore only two pairs of twisted

wires are used for data and clock signals, thus a six-wire cable is required.

The main advantages in comparison with parallel or asynchronous data

transmissions are:

• less conductors are required for transmission;

• less electronic components;

• possibility of insulting the circuits galvanically by means of

optocouplers;

• high data transmission frequency;

• hardware interface independent from the resolution of the absolute

encoder.

Furthermore the differential transmission increases the noise immunity and

decreases the noise emissions. It allows multiplexing from several encoders, thus

process controls are more reliable with simplified line design and easier data

management.

Data transmission is carried out as follows.

At the first falling edge of the clock signal (1, the logic level changes from high

to low) the absolute position value is stored while at the following rising edge

(2) the transmission of data information begins starting from the MSB.

MAN SMAG GA E 1.3.odt 4 – SSI interface 15 of 20

Page 16

SMAG + MTAG SSI

At each change of the clock signal and at each subsequent rising edge (2) one

bit is clocked out at a time, up to LSB, so completing the data word

transmission. The cycle ends at the last rising edge of the clock signal (3). This

means that up to n + 1 rising edges of the clock signals are required for each

data word transmission (where n is the bit resolution); for instance, a 13-bit

encoder needs 14 clock edges. If the number of clocks is greater than the

number of bits of the data word, then the system will send a zero (low logic

level signal) at each additional clock, zeros will either lead (LSB ALIGNED

protocol) or follow (MSB ALIGNED protocol) or lead and/or follow (TREE FORMAT

protocol) the data word. After the period Tm monoflop time, having a typical

duration of 16 µsec, calculated from the end of the clock signal transmission,

the encoder is then ready for the next transmission and therefore the data

signal is switched high.

The clock signal has a typical logic level of 5V, the same as the output signal

which has customarily a logic level of 5V in compliance with RS-422 standard.

4.3 LSB Right Aligned protocol

“LSB right aligned” protocol allows to right align the bits, beginning from MSB

(most significant bit) to LSB (least significant bit); LSB is then sent at the last

clock cycle. Transmitted bits are always 25, the sensor uses a variable number of

bits according to resolution. Unused bits are set to 0 (zero) and lead the data

word:

Model

Information

per mm

Resolution

Length of the

word

Max. number

of information

SMAG-GA-100-...

10 0.1 mm 25 bits 13 bits (8,192)

SMAG-GA-50-...

20 0.05 mm 25 bits 14 bits (16,384)

SMAG-GA-10-...

100 0.01 mm 25 bits 16 bits (65,536)

SMAG-GA-5-...

200 0.005 mm 25 bits 17 bits (131,072)

* When the profile is 650 mm / 25.59” long

See also the table on page 14

MAN SMAG GA E 1.3.odt 4 – SSI interface 16 of 20

Page 17

SMAG + MTAG SSI

The output code is GRAY.

The measuring step is equal to the resolution (0.1 mm … 0.005 mm).

Structure of the transmitted position value:

SMAG-GA-100-... bits 25 … 14 13 ... 1

SMAG-GA-50-... bits 25 … 15 14 ... 1

SMAG-GA-10-... bits 25 … 17 16 ... 1

SMAG-GA-5-... bits 25 … 18 17 ... 1

value

00 … 00 MSB … LSB

* When the profile is 650 mm / 25.59” long

See also the table on page 14

WARNING

Please note that the position value issued by the sensor is expressed in pulses;

thus you have then to convert the number of pulses into a linear measuring

unit.

To convert the position value into millimetres (mm) or micrometres (µm) you

have to multiply the pulses by the linear resolution of the encoder expressed in

millimetres or micrometres.

EXAMPLE 1

SMAG-GA-50-…

resolution = 50 µm = 0.05 mm

detected pulses = 123

position value = 123 * 50 = 6150 µm = 6.15 mm

EXAMPLE 2

SMAG-GA-10-…

resolution = 10 µm = 0.01 mm

detected pulses = 1569

position value = 1569 * 10 = 15690 µm = 15.69 mm

MAN SMAG GA E 1.3.odt 4 – SSI interface 17 of 20

Page 18

SMAG + MTAG SSI

4.4 Recommended transmission rates

The SSI interface has a frequency of data transmission ranging between 100 kHz

and 1.5 MHz.

The CLOCK signals and the DATA signals are transmitted according to the “EIA

RS-422” standard.

The clock frequency (baud rate) depends on the length of the cables and must

comply with the technical information reported in the following table.

Cable length Baud rate

< 50 m < 400 kHz

< 100 m < 300 kHz

< 200 m < 200 kHz

< 400 m < 100 kHz

The time interval between two consecutive Clock sequence transmissions must

be at least 30 µs (Tp = pause time > 30 µs).

4.5 Recommended SSI circuit

MAN SMAG GA E 1.3.odt 4 – SSI interface 18 of 20

Page 19

SMAG + MTAG SSI

5 - Maintenance

This magnetic measurement system does not need any particular maintenance;

anyway it has to be handled with the utmost care as it is a delicate electronic

equipment. From time to time we recommend the following operations to be

performed:

• periodically check the soundness of the structure and make sure that

there are no loose screws; tighten them if necessary;

• the surface of the magnetic tape has to be cleaned regularly using a soft

and clean cloth to remove dust, chips, moisture etc.

MAN SMAG GA E 1.3.odt 5 - Maintenance 19 of 20

Page 20

Document release Release date Description HW SW

Installation

file version

1.0 15.09.2011 First issue - - -

1.1 11.01.2012 General review, English translation - - -

1.2 18.05.2015

General review, “3 – Mechanical installation”

section updated

- - -

1.3 24.01.2017

General review, Italian and English versions

separated, mounting instructions updated

Lika Electronic

Via S. Lorenzo, 25 • 36010 Carrè (VI) • Italy

Tel. +39 0445 806600

Fax +39 0445 806699

info@lika.biz • www.lika.biz

Loading...

Loading...