Page 1

User's guide

RD4

Position measurement & control

Page 2

This publication was produced by Lika Electronic s.r.l. 2015. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Page 3

General contents

User's guide...............................................................................................................................................................................................1

General contents................................................................................................................................................................................3

Subject Index.......................................................................................................................................................................................7

Typographic and iconographic conventions..........................................................................................................................9

Preliminary information...............................................................................................................................................................10

1 Safety summary.................................................................................................................................. 11

1.1 Safety..........................................................................................................................................................................11

1.2 Electrical safety......................................................................................................................................................11

1.3 Mechanical safety..................................................................................................................................................12

2 Identification....................................................................................................................................... 13

3 Mechanical installation.....................................................................................................................14

4 Electrical connections........................................................................................................................ 17

4.1 Ground connection (Figure 3)..........................................................................................................................17

4.2 Connectors (Figure 3)...........................................................................................................................................18

4.3 Diagnostic LEDs (Figure 3).................................................................................................................................20

4.4 Dip-Switches (Figure 4).......................................................................................................................................21

4.4.1 Setting the node address: Node ID (Figure 4)...................................................................................22

4.4.2 Setting the data transmission rate: Baud rate (Figure 4)............................................................23

4.4.3 RT bus termination (Figure 4)...................................................................................................................23

5 Quick reference................................................................................................................................... 24

6 Functions.............................................................................................................................................. 25

6.1 Working principle..................................................................................................................................................25

6.2 Movements: jog and positioning....................................................................................................................26

6.3 Digital inputs and outputs.................................................................................................................................27

6.4 Objects 3120-00 Distance per revolution, 3114-00 Jog speed, 3115-00 Work speed, 3300-

00 Preset and 310F Delta space.........................................................................................................................28

7 CANopen® interface........................................................................................................................... 32

7.1 EDS files.....................................................................................................................................................................32

7.2 NMT states................................................................................................................................................................33

7.2.1 Initialization.....................................................................................................................................................33

7.2.2 Pre-operational state...................................................................................................................................34

7.2.3 Operational state...........................................................................................................................................34

7.2.4 Stopped state..................................................................................................................................................34

7.3 Communication messages.................................................................................................................................35

7.3.1 Generic pre-defined connection set.....................................................................................................36

7.4 NMT messages.........................................................................................................................................................36

7.6 PDO messages.........................................................................................................................................................37

7.6.1 “RECEIVE PDO1” message sent by the Master to the Slave........................................................38

Control Word............................................................................................................................................................................38

Jog +........................................................................................................................................................................................38

Jog -.........................................................................................................................................................................................38

Stop..........................................................................................................................................................................................39

Alarm reset...........................................................................................................................................................................39

Incremental jog..................................................................................................................................................................39

Start.........................................................................................................................................................................................39

Emergency............................................................................................................................................................................39

Page 4

Axis torque............................................................................................................................................................................40

OUT 1.......................................................................................................................................................................................40

OUT 2.......................................................................................................................................................................................40

OUT 3.......................................................................................................................................................................................40

Target position.........................................................................................................................................................................41

7.6.2 “TRANSMIT PDO1” message sent by the Slave to the Master....................................................42

Status word...............................................................................................................................................................................42

Axis in position....................................................................................................................................................................42

Axis enabled.........................................................................................................................................................................42

SW limit switch +..............................................................................................................................................................42

SW limit switch -...............................................................................................................................................................42

Alarm.......................................................................................................................................................................................42

Axis running.........................................................................................................................................................................42

Executing a command.....................................................................................................................................................42

Target position reached..................................................................................................................................................43

DAC Saturation...................................................................................................................................................................43

IN 1...........................................................................................................................................................................................43

IN 2...........................................................................................................................................................................................43

IN 3...........................................................................................................................................................................................43

Current velocity......................................................................................................................................................................43

Current position......................................................................................................................................................................43

7.7 SDO messages.........................................................................................................................................................45

7.7.1 Command.........................................................................................................................................................45

8 Programming parameters................................................................................................................. 46

8.1 Objects dictionary..................................................................................................................................................46

8.1.1 Standard objects (DS 301).........................................................................................................................46

1000-00 Device type............................................................................................................................................................46

1001-00 Error register.........................................................................................................................................................46

1003 Pre-defined Error Field.............................................................................................................................................47

1005-00 COB-ID SYNC messages....................................................................................................................................47

1008-00 Device name..........................................................................................................................................................47

1009-00 Hardware Version................................................................................................................................................47

100A-00 Software Version.................................................................................................................................................47

100C-00 Guard Time............................................................................................................................................................47

100D-00 Life Time Factor...................................................................................................................................................48

1010-01 Save Parameters..................................................................................................................................................48

1011-01 Restore Default Parameters...........................................................................................................................48

1014-00 COB-ID EMCY........................................................................................................................................................49

1015-00 Inhibit Time Emergency....................................................................................................................................49

1018 Identity Object.............................................................................................................................................................49

1400 Receive PDO Communication Parameter 1.....................................................................................................50

1600 Receive PDO Mapping Parameter 1...................................................................................................................51

1800 Transmit PDO Communication Parameter 1..................................................................................................51

1A00 TPDO Mapping Parameter 1..................................................................................................................................53

8.1.2 Manufacturer's specific objects.............................................................................................................55

3000-00 Baud rate................................................................................................................................................................55

3001-00 Node ID....................................................................................................................................................................55

Device profile objects..............................................................................................................................................56

3108-00 Acceleration...........................................................................................................................................................56

3109-00 Deceleration..........................................................................................................................................................56

310C-00 Max following error...........................................................................................................................................56

Page 5

310D-00 Position window.................................................................................................................................................56

310E-00 Position window time.......................................................................................................................................56

310F Delta space.....................................................................................................................................................................57

3111-00 Kp position loop...................................................................................................................................................57

3112-00 Ki position loop....................................................................................................................................................58

3114-00 Jog speed................................................................................................................................................................58

3115-00 Work speed............................................................................................................................................................58

3116-00 Max speed..............................................................................................................................................................59

3117-00 Jog step length.....................................................................................................................................................59

3118-00 Start Torque current time................................................................................................................................59

3120-00 Distance per revolution....................................................................................................................................59

3300-00 Preset........................................................................................................................................................................60

3301-00 Offset........................................................................................................................................................................60

3302-00 Code sequence.....................................................................................................................................................61

3330-00 Kp current loop....................................................................................................................................................61

3331-00 Ki current loop......................................................................................................................................................61

3340-00 Max current...........................................................................................................................................................61

3341-00 Starting Torque current....................................................................................................................................62

3342-00 Gear ratio................................................................................................................................................................62

3343-00 Positive absolute limit switch........................................................................................................................62

3344-00 Negative absolute limit switch......................................................................................................................62

3005-00 Current value [mA].............................................................................................................................................63

3006-00 Temperature value..............................................................................................................................................63

3100-00 Control word.........................................................................................................................................................63

3101-00 Status word...........................................................................................................................................................63

3102-00 Demanded position value................................................................................................................................63

3103-00 Current position value......................................................................................................................................63

3105-00 Current velocity value.......................................................................................................................................64

3106-00 Target position.....................................................................................................................................................64

3107-00 Target speed..........................................................................................................................................................64

310B-00 Position following error...................................................................................................................................64

3110-00 Cyclic Time.............................................................................................................................................................64

3200-00 Alarms......................................................................................................................................................................65

Machine data not valid...................................................................................................................................................65

Flash memory error...........................................................................................................................................................65

Following error....................................................................................................................................................................65

Axis not synchronized......................................................................................................................................................65

Target not valid...................................................................................................................................................................65

Emergency............................................................................................................................................................................65

Overcurrent..........................................................................................................................................................................65

Overtemperature................................................................................................................................................................66

Undervoltage.......................................................................................................................................................................66

CAN Life guard error........................................................................................................................................................66

8.2 Warning messages................................................................................................................................................67

8.3 Emergency messages...........................................................................................................................................67

No active errors..................................................................................................................................................................67

Generic error........................................................................................................................................................................67

Power surge.........................................................................................................................................................................67

Overvoltage..........................................................................................................................................................................67

Undervoltage.......................................................................................................................................................................67

Overtemperature................................................................................................................................................................67

Page 6

Flash memory......................................................................................................................................................................67

Life Guard..............................................................................................................................................................................67

Following error....................................................................................................................................................................67

8.4 Node guarding protocol.....................................................................................................................................68

9 Programming examples..................................................................................................................... 69

10 Default parameters list................................................................................................................... 70

Page 7

Subject Index

1

1000-00 Device type......................................................46

1001-00 Error register...................................................46

1003 Pre-defined Error Field.......................................47

1005-00 COB-ID SYNC messages.............................47

1008-00 Device name....................................................47

1009-00 Hardware Version.........................................47

100A-00 Software Version..........................................47

100C-00 Guard Time......................................................47

100D-00 Life Time Factor.............................................48

1010-01 Save Parameters............................................48

1011-01 Restore Default Parameters.....................48

1014-00 COB-ID EMCY.................................................49

1015-00 Inhibit Time Emergency.............................49

1018 Identity Object.......................................................49

1400 Receive PDO Communication Parameter 1

.............................................................................................50

1600 Receive PDO Mapping Parameter 1.............51

1800 Transmit PDO Communication Parameter 1

.............................................................................................51

1A00 TPDO Mapping Parameter 1............................53

3

3000-00 Baud rate..........................................................55

3001-00 Node ID.............................................................55

3005-00 Current value [mA].......................................63

3006-00 Temperature value........................................63

3100-00 Control word...................................................63

3101-00 Status word.....................................................63

3102-00 Demanded position value.........................63

3103-00 Current position value................................63

3105-00 Current velocity value.................................64

3106-00 Target position...............................................64

3107-00 Target speed....................................................64

3108-00 Acceleration....................................................56

3109-00 Deceleration....................................................56

310B-00 Position following error.............................64

310C-00 Max following error.....................................56

310D-00 Position window...........................................56

310E-00 Position window time.................................56

310F Delta space..............................................................57

3110-00 Cyclic Time.......................................................64

3111-00 Kp position loop............................................57

3112-00 Ki position loop..............................................58

3114-00 Jog speed..........................................................58

3115-00 Work speed......................................................58

3116-00 Max speed........................................................59

3117-00 Jog step length..............................................59

3118-00 Start Torque current time.........................59

3120-00 Distance per revolution..............................59

3200-00 Alarms................................................................65

3300-00 Preset.................................................................60

3301-00 Offset..................................................................60

3302-00 Code sequence...............................................61

3330-00 Kp current loop..............................................61

3331-00 Ki current loop...............................................61

3340-00 Max current.....................................................61

3341-00 Starting Torque current.............................62

3342-00 Gear ratio.........................................................62

3343-00 Positive absolute limit switch..................62

3344-00 Negative absolute limit switch...............62

A

Alarm.....................................................................................42

Alarm reset..........................................................................39

Axis enabled.......................................................................42

Axis in position..................................................................42

Axis not synchronized....................................................65

Axis running.......................................................................42

Axis torque..........................................................................40

C

CAN Life guard error.......................................................66

Control Word.....................................................................38

Current position...............................................................43

Current velocity................................................................43

D

DAC Saturation.................................................................43

E

Emergency...................................................................39, 65

Executing a command...................................................42

F

Flash memory.....................................................................67

Flash memory error.........................................................65

Following error..........................................................65, 67

G

Generic error......................................................................67

I

IN 1.........................................................................................43

IN 2.........................................................................................43

IN 3.........................................................................................43

Incremental jog.................................................................39

J

Jog -.......................................................................................38

Jog +......................................................................................38

Page 8

L

Life Guard............................................................................67

M

Machine data not valid.................................................65

N

No active errors................................................................67

O

OUT 1.....................................................................................40

OUT 2.....................................................................................40

OUT 3.....................................................................................40

Overcurrent.........................................................................65

Overtemperature.................................................66 e seg.

Overvoltage........................................................................67

P

Power surge........................................................................67

S

Start.......................................................................................39

Status word........................................................................42

Stop........................................................................................39

SW limit switch -.............................................................42

SW limit switch +............................................................42

T

Target not valid.................................................................65

Target position..................................................................41

Target position reached.................................................43

U

Undervoltage........................................................66 e seg.

Page 9

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters and objects both of Lika device and interface are coloured in ORANGE;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee

the safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Page 10

Preliminary information

This guide is designed to provide the most complete information the operator needs to correctly and

safely install and operate the ROTADRIVE positioning units RD4 model.

RD4 units are positioning devices which integrate into one system a brushless motor fitted with gearbox,

a drive, a multiturn absolute encoder and a position controller. They can be used in a variety of

applications in any industrial sector and are suitable to drive secondary axes such as in mold changers,

mobile stops, tools changers, suction cups motion units, conveyor and spindle positioning devices on

packaging & woodworking machineries, among others.

The available interfaces for fieldbus communication are: Modbus RTU, Profibus-DP and CANopen DS

301.

To make it easier to read the text, this guide can be divided into two main sections.

In the first section general information concerning the safety, the mechanical installation and the

electrical connection as well as tips for setting up and running properly and efficiently the unit are

provided.

While in the second section, entitled CANopen Interface, both general and specific information is given

on the CANopen interface. In this section the interface features and the parameters implemented in the

unit are fully described.

Page 11

RD4 CANopen®

1 Safety summary

1.1 Safety

• Always adhere to the professional safety and accident prevention

regulations applicable to your country during device installation and

operation;

• installation and maintenance operations have to be carried out by

qualified personnel only, with power supply disconnected and stationary

mechanical parts;

• device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

• high current, voltage and moving mechanical parts can cause serious or

fatal injury;

• warning ! Do not use in explosive or flammable areas;

• failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture,

and intended use of the equipment;

• Lika Electronic s.r.l. assumes no liability for the customer's failure to

comply with these requirements.

1.2 Electrical safety

• Turn OFF power supply before connecting the device;

• connect according to explanation in section ”Electrical connections”;

• a safety push-button for emergency power off has to be installed to shut

off motor power supply in case of emergency situations;

• in compliance with 2004/108/EC norm on electromagnetic

compatibility, following precautions must be taken:

- before handling and installing the equipment, discharge

electrical charge from your body and tools which may come in touch

with the device;

- power supply must be stabilized without noise; install EMC filters on

device power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive

noise source; shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets

on or near by the unit;

MAN RD4 CB E 1.5 Safety summary 11 of 72

Page 12

RD4 CANopen®

- minimize noise by connecting the shield and/or the connector housing

and/or the frame to ground. Make sure that ground is not affected by

noise. The connection point to ground can be situated both on the device

side and on user’s side. The best solution to minimize the interference

must be carried out by the user.

1.3 Mechanical safety

• Install the device following strictly the information in the section

“Mounting instructions”;

• mechanical installation has to be carried out with stationary mechanical

parts;

• do not disassemble the unit;

• do not tool the unit or its shaft;

• delicate electronic equipment: handle with care; do not subject the device

and the shaft to knocks or shocks;

• respect the environmental characteristics of the product;

• unit with solid shaft: in order to guarantee maximum reliability over time

of mechanical parts, we recommend a flexible coupling to be installed to

connect ROTADRIVE and user's shaft; make sure the misalignment

tolerances of the flexible coupling are respected;

• unit with hollow shaft: ROTADRIVE can be mounted directly on a shaft

whose diameter has to respect the technical characteristics specified in the

purchase order and clamped by means of the collar and the hole into

which an anti-rotation pin has to be inserted.

WARNING

The unit has been adjusted by performing a no-load mechanical running test;

thence default values which has been set refer to an idle device, i.e. running

disengaged from the load. Furthermore they are intended to ensure a standard

and safe operation which not necessarily results in smooth running and

optimum performance. Thus to suit the specific application requirements it may

be advisable and even necessary to enter new parameters instead of the factory

default settings; in particular it may be necessary to change velocity,

acceleration, deceleration and gain values.

WARNING

The counter-electromotive force (back EMF) generated by the motor in case the

shaft is forced to rotate due to a manual external force can cause irreparable

damages to the internal circuitry.

MAN RD4 CB E 1.5 Safety summary 12 of 72

Page 13

RD4 CANopen®

2 Identification

Device can be identified through the ordering code and the serial number

printed on the label applied to its body. Information is listed in the delivery

document too. Please always quote the ordering code and the serial number

when reaching Lika Electronic s.r.l. for purchasing spare parts or needing

assistance. For any information on the technical characteristics of the product

refer to the technical catalogue.

MAN RD4 CB E 1.5 Identification 13 of 72

Page 14

RD4 CANopen®

3 Mechanical installation

WARNING

Installation and maintenance operations have to be carried out by qualified

personnel only, with power supply disconnected. Motor and shaft must be in

stop.

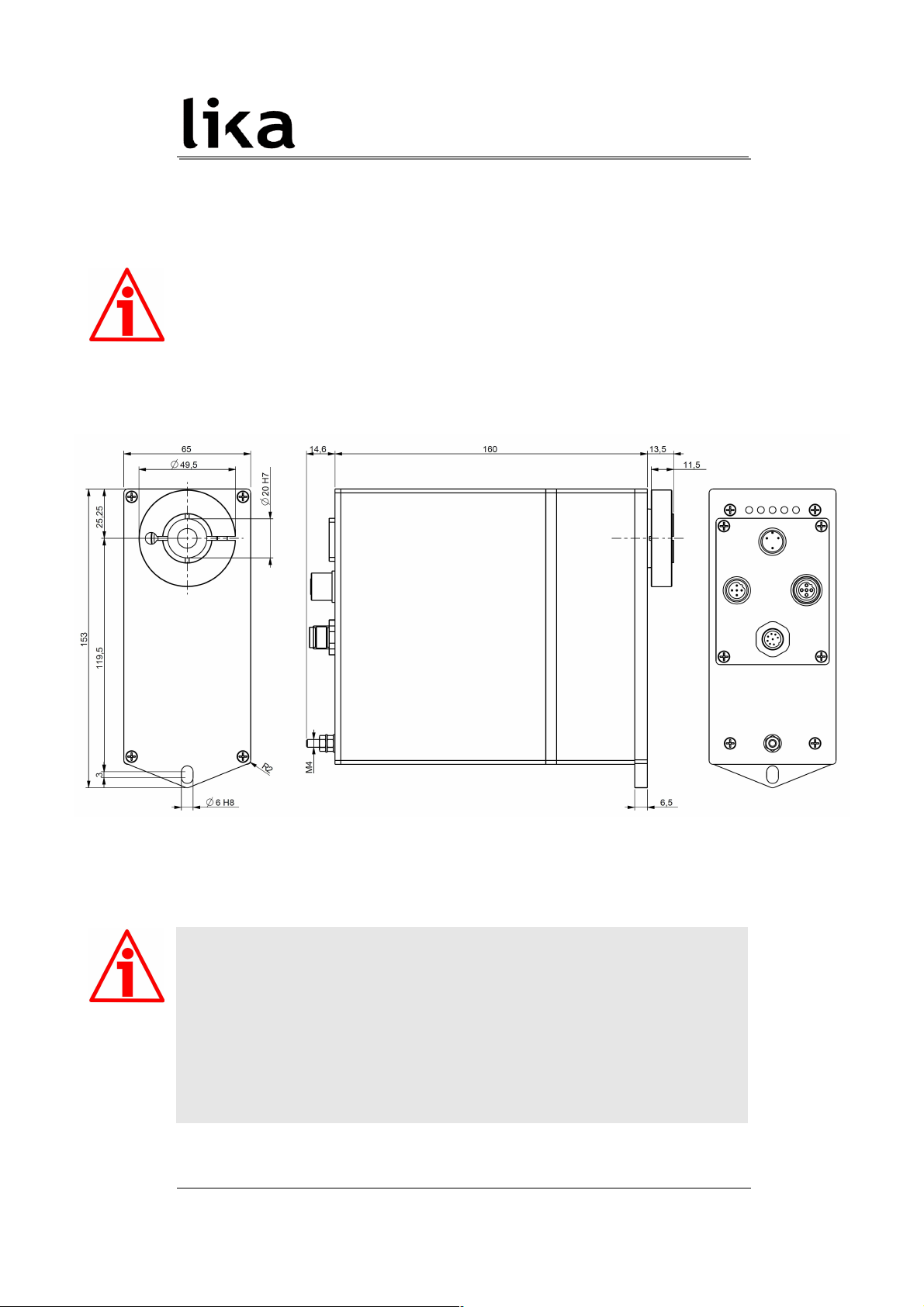

Figure 1 - RD4 unit – Overall dimensions

ROTADRIVE unit must be secured firmly only to the user's shaft using the

provided collar. ROTADRIVE unit is supplied with a screw insulation and an antirotation pin; the anti-rotation pin (TE M5 screw) has to be inserted into the

screw insulation. This will provide to the unit both stability and the mobility

needed to absorb the mechanical tensions produced during operation. Do not

fasten firmly the anti-rotation pin to the flange or the fixed support on user's

side without using the screw insulation! If this occurs, the mechanical tensions

would be transmitted completely to the motor shaft and this would lead to

bearings damages and mechanical breakdowns!

MAN RD4 CB E 1.5 Mechanical installation 14 of 72

Page 15

RD4 CANopen®

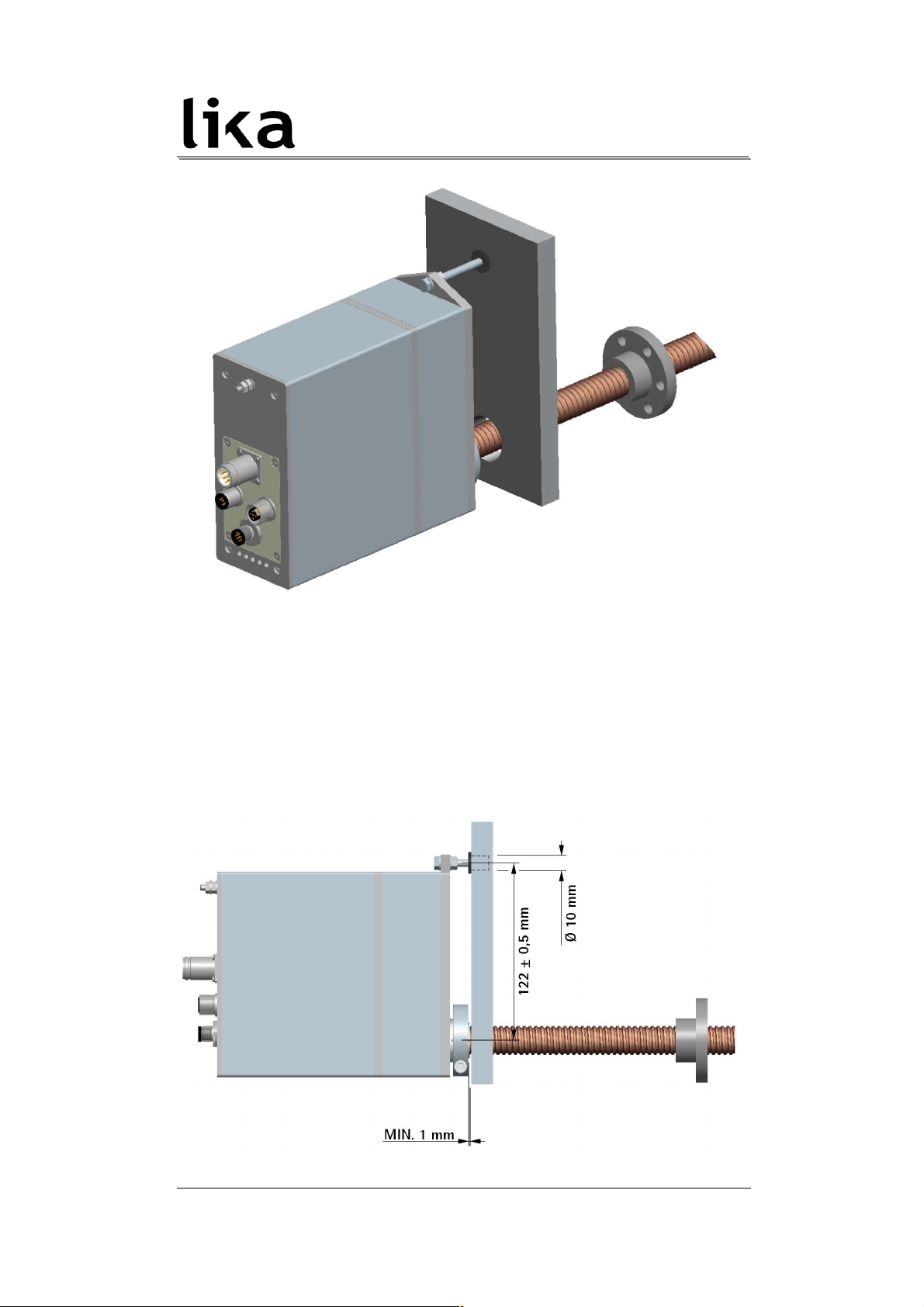

Figure 2 - Typical installation example of RD4 unit on worm screw

To install properly the ROTADRIVE unit please read carefully and follow these

instructions; anyway note that the unit can be installed in several manners and

according to the specific user's application.

• Drill a 10-mm diameter hole in the flange or in the fixed support on user's

side in order to insert the screw insulation and the anti-rotation pin. The

MAN RD4 CB E 1.5 Mechanical installation 15 of 72

Page 16

RD4 CANopen®

distance between the axis of the shaft and the axis of the hole must be 122

± 0,5 mm. Make sure that the hole and the shaft are perfectly aligned on

the vertical axis. If installation is not carried out properly, mechanical

tensions would be produced on the motor shaft and this would lead to

bearings damages and mechanical breakdowns!

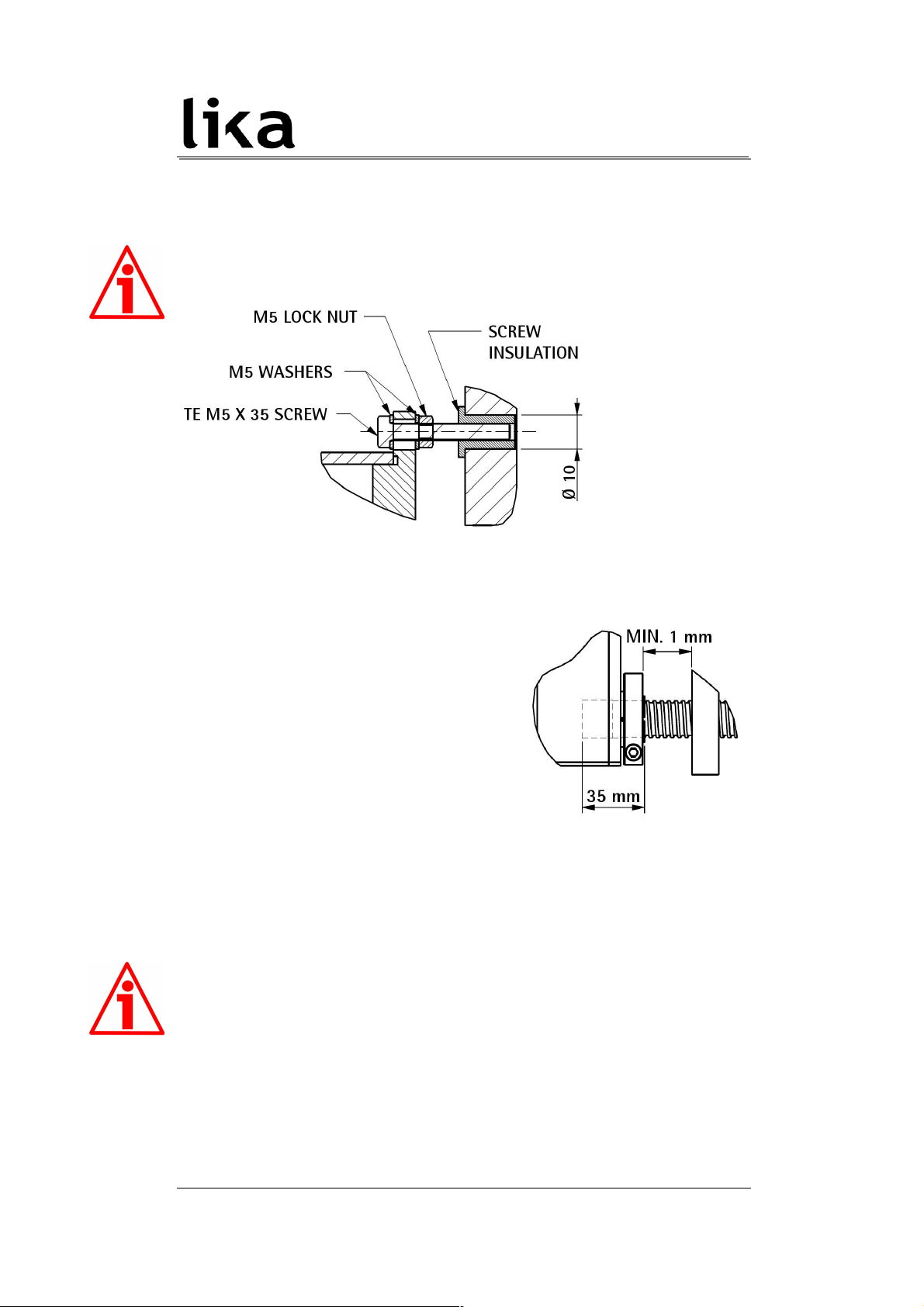

• insert the screw

insulation in the

hole;

• insert the TE M5

x 35 UNI5739

screw and the

two M5 washers

in the hole

designed in the

flange of the

ROTADRIVE

unit; partially

screw the M5 lock nut;

• insert the user's shaft in the hollow shaft of the ROTADRIVE unit; the

maximum depth of the ROTADRIVE shaft is

35 mm; ascertain that the anti-rotation

pin is inserted properly in the screw

insulation; secure the user's shaft through

the collar and the relevant fixing screw;

the minimum distance between the collar

and the fixed support on user's side must

be not less than 1 mm in order to prevent

the fixed parts from coming into contact;

• tighten the anti-rotation pin on the screw

insulation;

• tighten the M5 lock nut in order to secure the anti-rotation pin to the

flange of the ROTADRIVE unit.

ATTENTION

Never force manually the rotation of the shaft not to cause permanent

damages! The counter-electromotive force (back EMF) generated by the motor

in case the shaft is forced to rotate due to a manual external force can cause

irreparable damages to the internal circuitry.

MAN RD4 CB E 1.5 Mechanical installation 16 of 72

Page 17

RD4 CANopen®

4 Electrical connections

WARNING

When you send Start, Jog + or Jog - commands, the unit and the shaft start

moving! Make sure there are no risks of personal injury and mechanical

damages.

Each Start routine has to be checked carefully in advance!

Never force manually the rotation of the shaft not to cause permanent

damages!

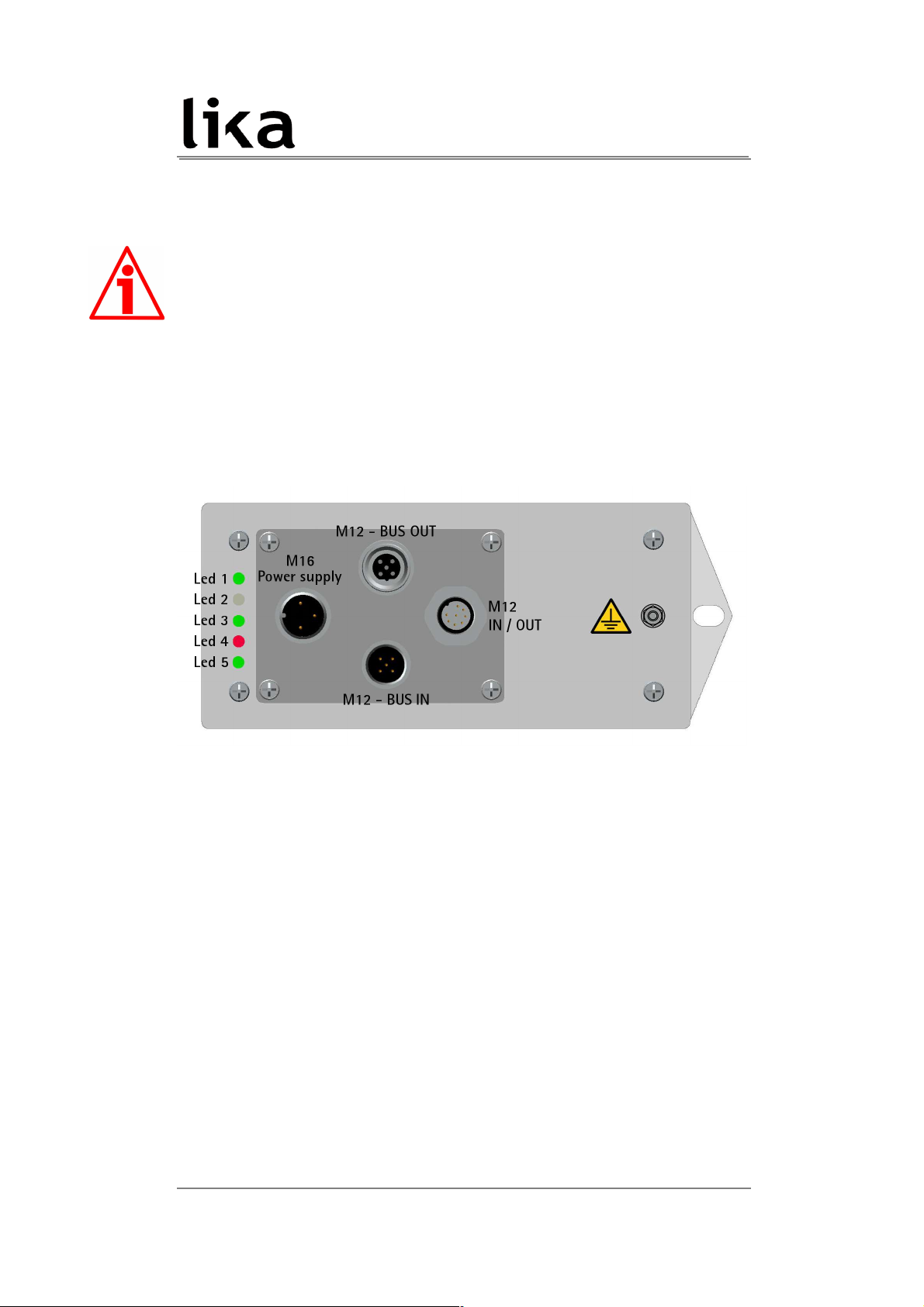

Figure 3: Electrical connections and diagnostic LEDs

4.1 Ground connection (Figure 3)

To minimize noise connect properly the frame to ground; we suggest using the

ground screw provided in the frame (see Figure above). Connect properly the

cable shield to ground on user's side. Lika's EC- pre-assembled cables are fitted

with shield connection to the connector ring nut in order to allow grounding

through the body of the device. Lika's E- connectors have a plastic gland, thus

grounding is not possible. If metal connectors are used, connect the cable shield

properly as recommended by the manufacturer. See also note in the next

paragraph. Anyway make sure that ground is not affected by noise. It is

recommended to provide the ground connection as close as possible to the

device.

MAN RD4 CB E 1.5 Electrical connections 17 of 72

Page 18

RD4 CANopen®

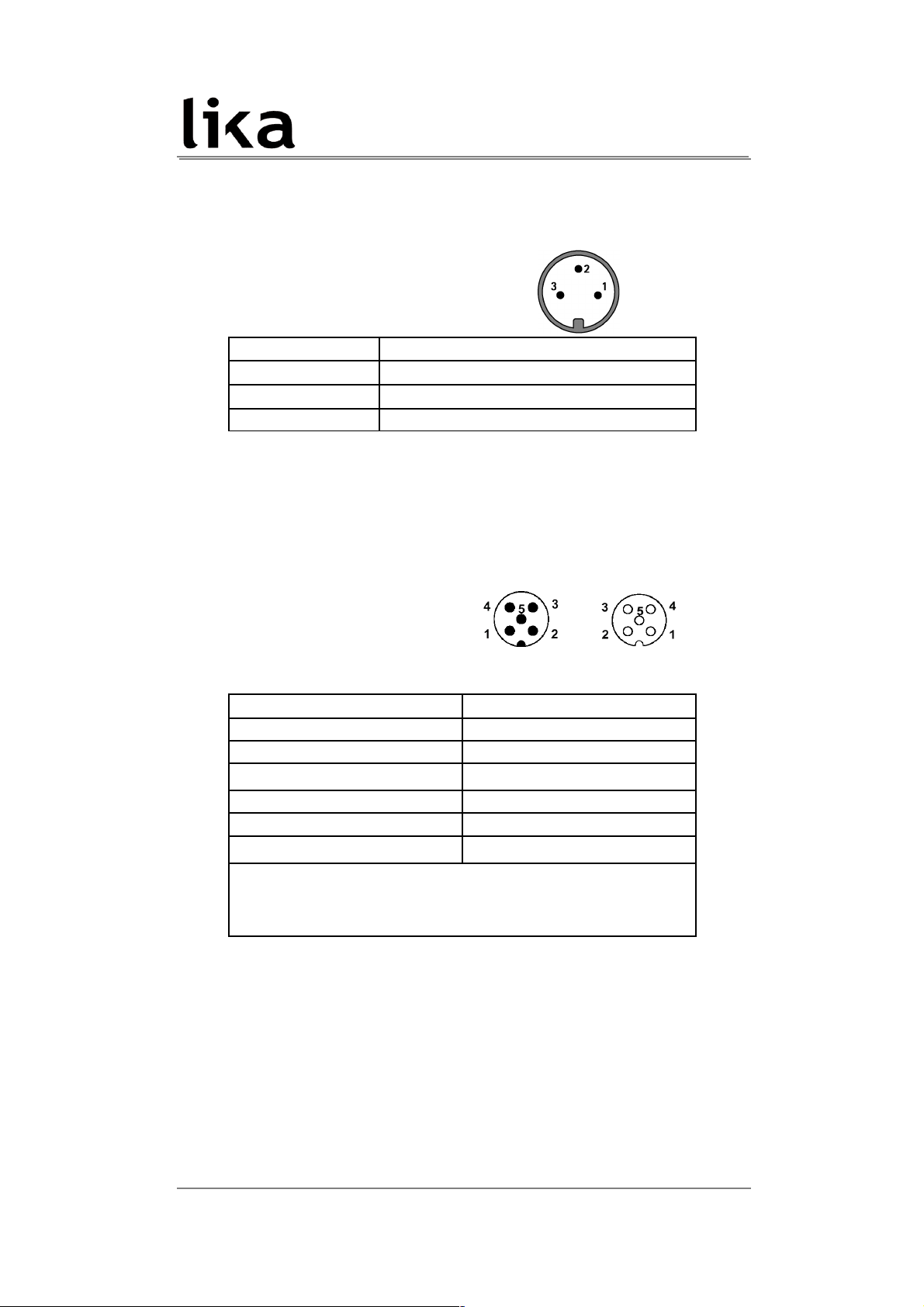

4.2 Connectors (Figure 3)

Power supply

M16 3-pin male connector

(frontal side)

Pin Description

1

+24VDC 10% motor power supply

2

+24VDC 10% controller power supply

3 motor and controller 0 VDC supply voltage

Interface

M12 5-pin connectors

A coding

(frontal side) male

(BUS IN)

female

(BUS OUT)

Pin Description

1 n.c.

2 n.c.

3

CAN GND

1

4 CAN High

5 CAN Low

Case

Shielding

2

1

CAN GND is the 0 VDC reference of CAN signals, it is not connected to 0

VDC supply voltage.

2

Lika's EC- pre-assembled cables only.

n.c. = not connected

We recommend CANopen certified cables to be used.

MAN RD4 CB E 1.5 Electrical connections 18 of 72

Page 19

RD4 CANopen®

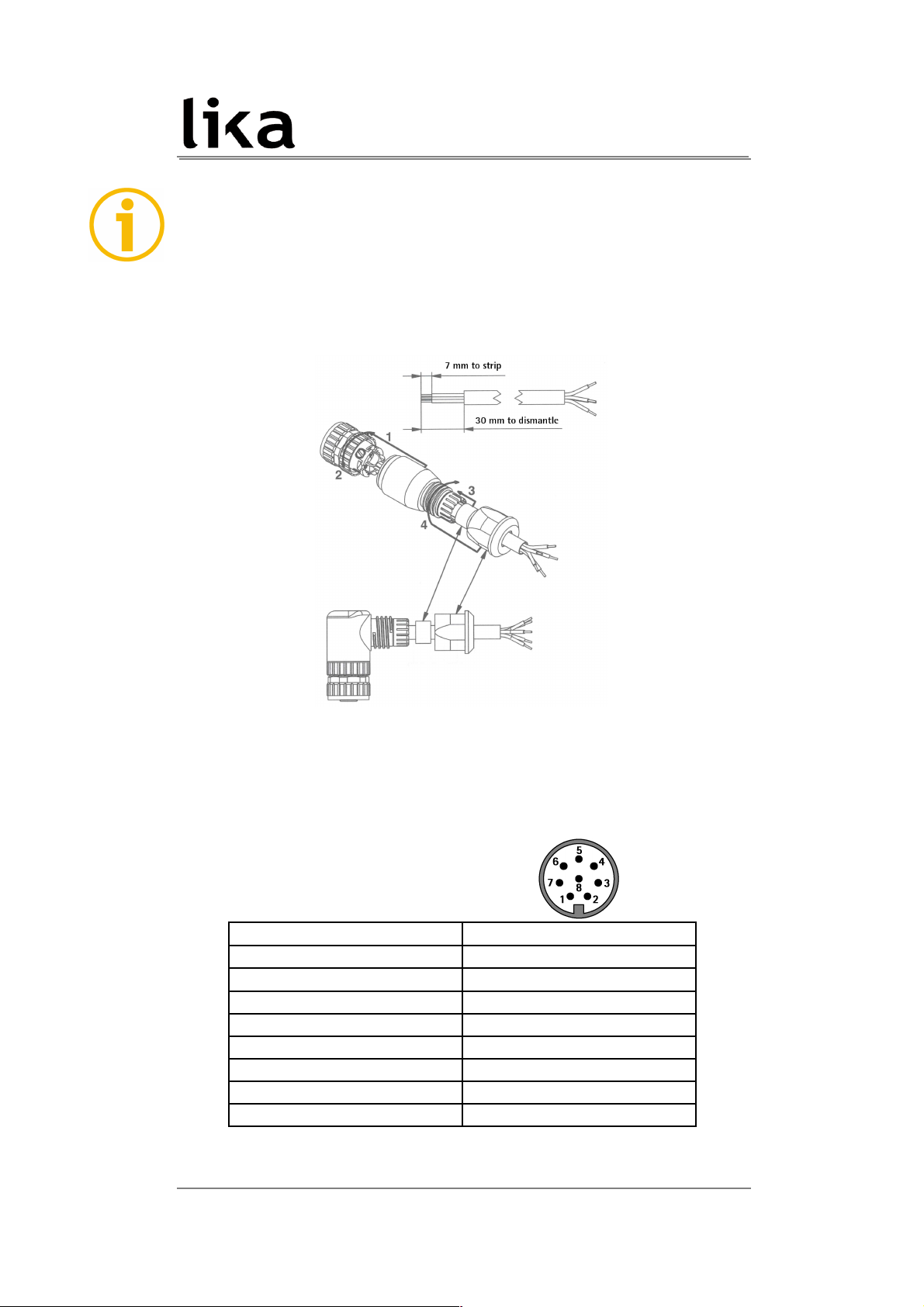

NOTE

We suggest always connecting the cable shield to ground on user's side.

Lika's EC- pre-assembled cables are fitted with shield connection to the

connector ring nut in order to allow grounding through the body of the device.

Lika's E- connectors have a plastic gland, thus grounding is not possible (see

Figure below). If metal connectors are used, connect the cable shield properly as

recommended by the manufacturer.

Inputs / outputs (optional)

M12 8-pin male connector

(frontal side)

Pin Description

1 0 VDC

2 Input 1

3 Input 2

4 Input 3

5 Output 1

6 Output 2

7 Output 3

8 n.c.

n.c.: not connected

MAN RD4 CB E 1.5 Electrical connections 19 of 72

Page 20

RD4 CANopen®

4.3 Diagnostic LEDs (Figure 3)

Five LEDs located next to the M16 power supply connector (see Figure 3) are

meant to show visually the operating or fault status of the CANopen interface

and the device as well. The meaning of each LED is explained in the following

table:

LED 1 GREEN Description

ON

Indicates the power supply of the controller is

turned on

OFF

Indicates the power supply of the controller is

turned off

LED 2

Not used

LED 3 GREEN RUN Description

ON

Device in Operational state

Single flash

Device in Stopped state

Blinking led

Device in Pre-Operational state

LED 4 RED ERR Description

ON Bus off

Double flash Node guarding error (see on page 68)

Single flash Maximum number of warning errors

Blinking led

General error or Flash memory error

OFF No error

LED 5 GREEN Description

ON

Indicates the motor is enabled (control loop

activated)

OFF

Indicates the motor is disabled (control loop

deactivated)

During initialisation, system checks the diagnostic LEDs for proper operation;

therefore they blink for a while.

MAN RD4 CB E 1.5 Electrical connections 20 of 72

Page 21

RD4 CANopen®

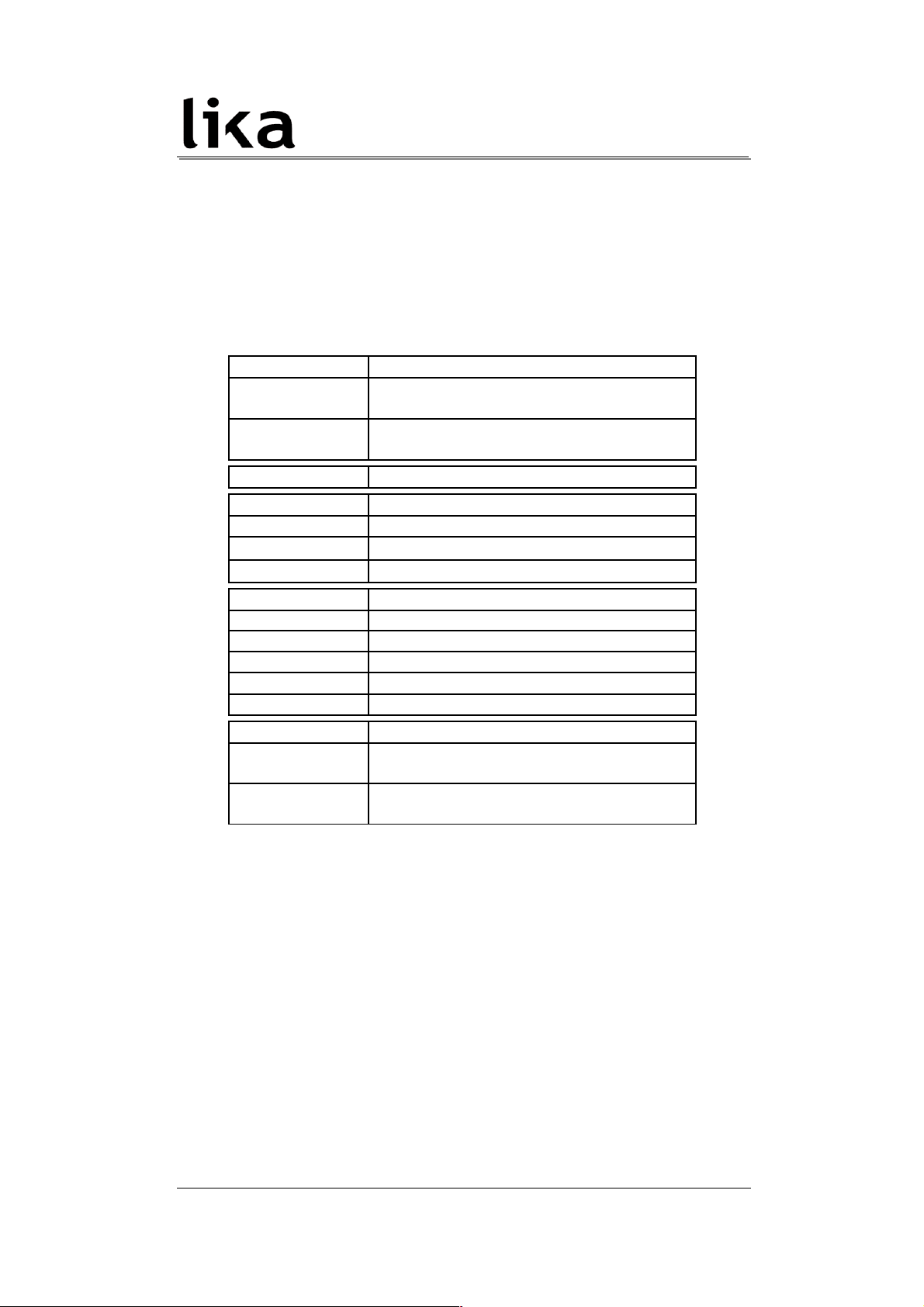

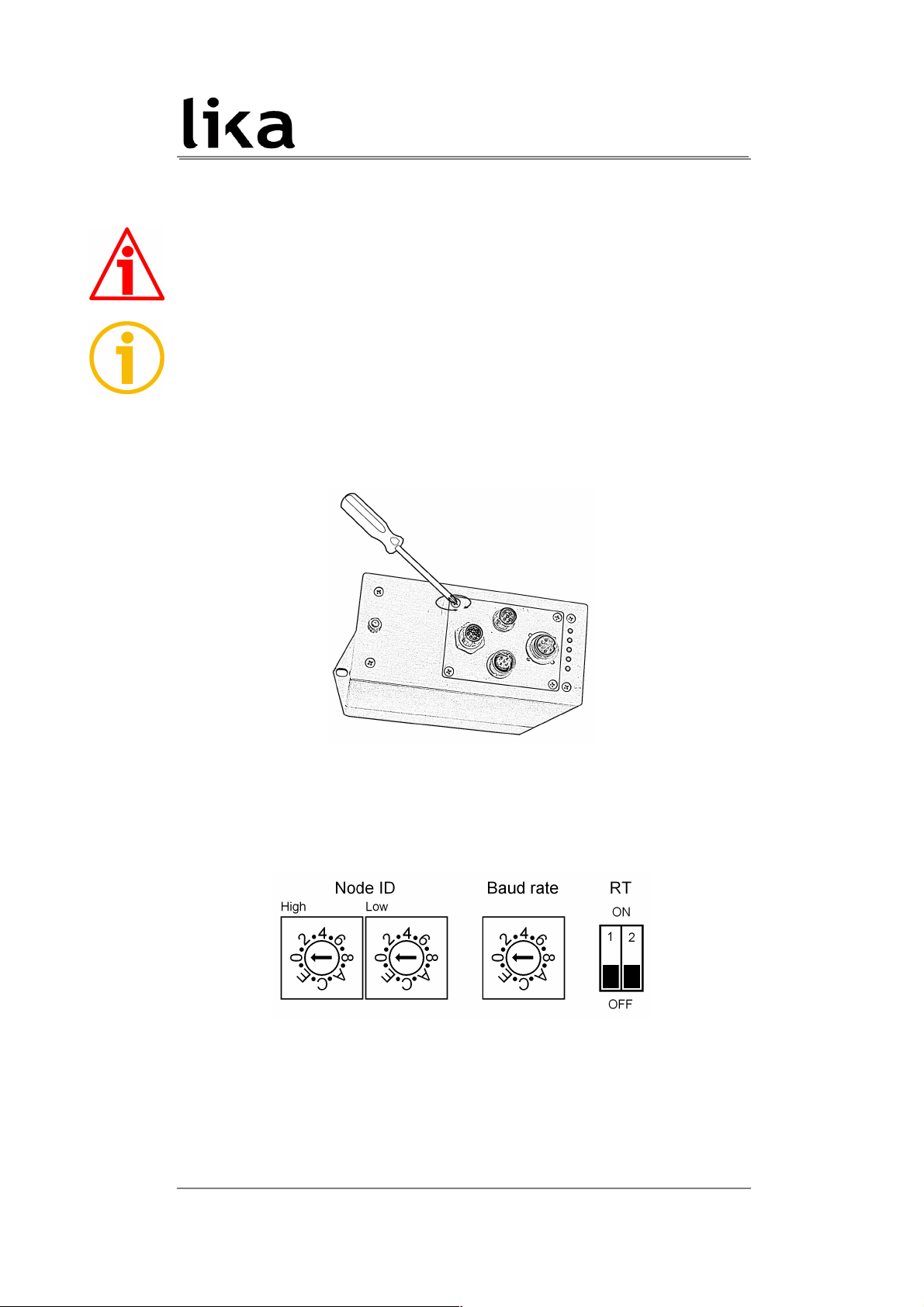

4.4 Dip-Switches (Figure 4)

WARNING

Power supply must be turned off before performing this operation!

NOTE

When performing this operation be careful not to damage the connection wires.

To access DIP-Switches loosen the four screws and remove the connectors metal

cover. Handle the cover with care not to stretch or pull out the connection

wires. Be careful to replace the metal cover at the end of the operation.

The DIP-switches are just beneath.

Figure 4: Dip-Switches

MAN RD4 CB E 1.5 Electrical connections 21 of 72

Page 22

RD4 CANopen®

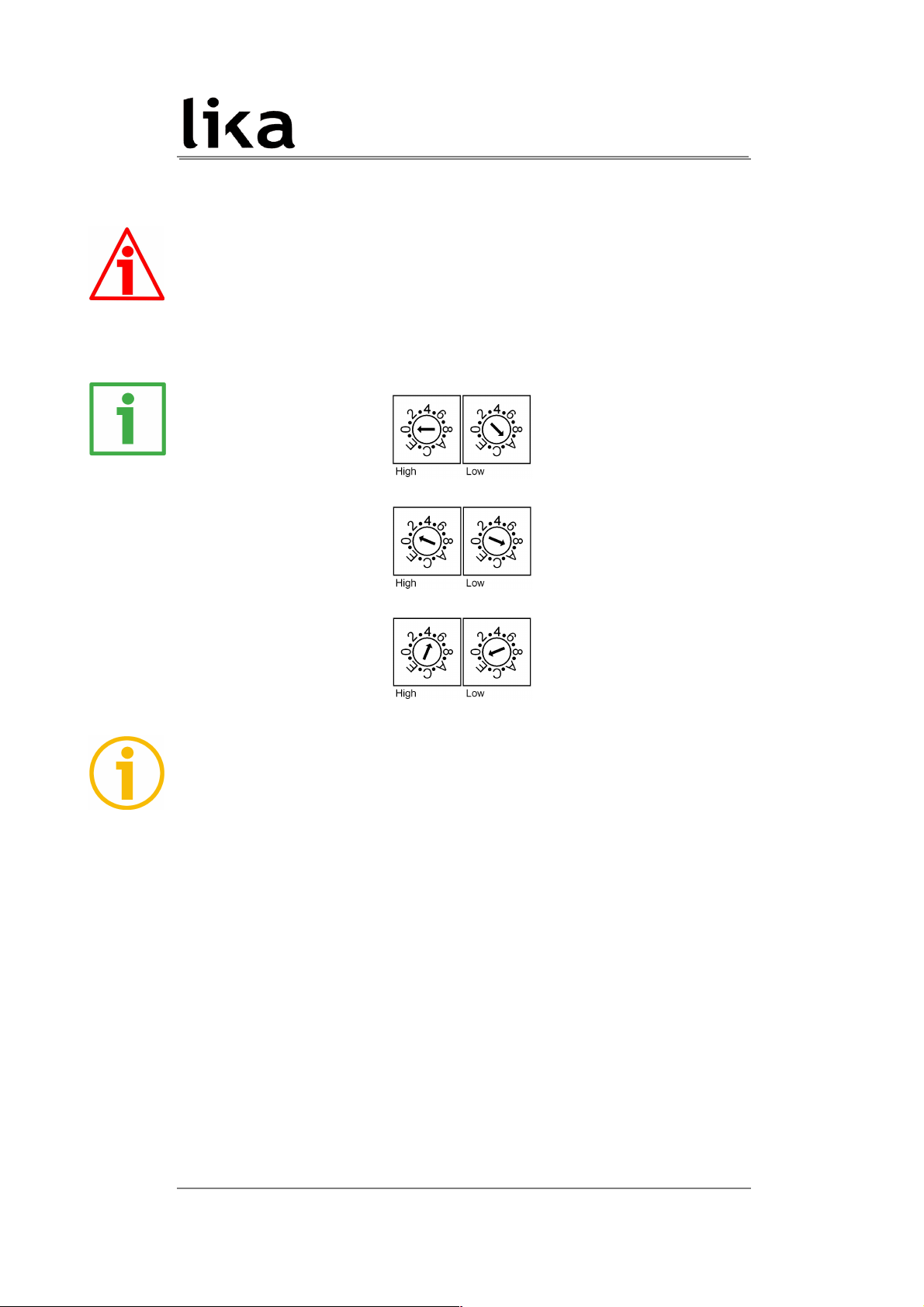

4.4.1 Setting the node address: Node ID (Figure 4)

WARNING

Power supply must be turned off before performing this operation!

Set the node address expressed in hexadecimal notation.

The range of node addresses is between 1 and 127 (127 = 7F hex).

Example

Address 10 = 0A hex:

Address 25 = 19 hex:

Address 95 = 5F hex:

NOTE

The default address is 1.

If you set the address to 0, device will be set to 1 automatically (address 0 is

reserved for Master).

If you set an address higher than 127, device will be set to 127 automatically.

MAN RD4 CB E 1.5 Electrical connections 22 of 72

Page 23

RD4 CANopen®

4.4.2 Setting the data transmission rate: Baud rate (Figure 4)

WARNING

Power supply must be turned off before performing this operation!

Set the hexadecimal value of the transmission rate according to the following

table.

Available baud rate values:

Data byte Baud rate

00h 20 Kbit/s

01h 50 Kbit/s

02h 100 Kbit/s

03h 125 Kbit/s

04h 250 Kbit/s

05h (default) 500 Kbit/s

06h 800 Kbit/s

07h 1000 Kbit/s

4.4.3 RT bus termination (Figure 4)

A bus termination resistor is provided and has to be activated as line

termination in the last device of the transmission line.

Use RT Switch to activate or deactivate the bus termination.

RT Description

1 = 2 = ON

Activated: when the device is at the end of

the transmission line

1 = 2 = OFF

Deactivated: when the device is not at the end

of the transmission line

MAN RD4 CB E 1.5 Electrical connections 23 of 72

Page 24

RD4 CANopen®

5 Quick reference

Following instructions are given to allow the operator to set up the device for

standard operation in a quick and safe manner.

• Mechanically install the device;

• execute electrical connections;

• set data transmission rate (baud rate; see on page 23);

• set the node address (node ID; see on page 22);

• switch +24VDC power supply on (in both motor and controller);

• set a proper value in 3120-00 Distance per revolution (object 3120h;

see on page 59);

• set a proper value in 3114-00 Jog speed (object 3114h; see on page 58);

• set a proper value in 3115-00 Work speed (object 3115h; see on page

58);

• set a proper value in 3300-00 Preset (object 3300h; see on page 60);

• set proper values in 310F Delta space (objects Positive delta 310Fh sub 1

and Negative delta 310Fh sub 2; see on page 57);

• save new setting values (object 1010-01 Save Parameters 1010h sub 1;

see on page 48).

NOTE

Parameters 3120-00 Distance per revolution, 3114-00 Jog speed, 3115-00

Work speed, 3300-00 Preset and 310F Delta space are closely related, hence

you have to be very attentive when you need to change the value in one of

them. For any further information please refer to page 28.

MAN RD4 CB E 1.5 Quick reference 24 of 72

Page 25

RD4 CANopen®

6 Functions

6.1 Working principle

The following scheme is intended to show schematically the working principle

of system control logic.

MAN RD4 CB E 1.5 Functions 25 of 72

Trajectory

generator

PI

position

I2t

control

Temperature

control

PWM

generator

Power

electronics

Absolute

encoder

Motor +

Reductio

n gear

-

+ +

-

Current PI

Current

transducer

Torque

limiter

Page 26

RD4 CANopen®

6.2 Movements: jog and positioning

Two kinds of movement are available in the ROTADRIVE positioning unit, they

are:

Jog: speed control;

Positioning: position and speed control.

Jog: speed control

This kind of control is intended to generate a speed trajectory which is able to

make the maximum rotation speed of the ROTADRIVE unit shaft to be equal to

the value set in 3114-00 Jog speed.

Positioning: position and speed control

This kind of control is a point-to-point movement and the maximum reachable

speed is equal to the value set in 3115-00 Work speed; set speed can be

reached only if space is long enough.

MAN RD4 CB E 1.5 Functions 26 of 72

jog=1 jog=0

Jog

speed

speed

time

Work speed

speed

time

start=1

position

time

target

Target + tolerance

Target - tolerance

“Axis in position” delay

“Axis in position”=1

Page 27

RD4 CANopen®

6.3 Digital inputs and outputs

RD4 unit is fitted with three digital inputs and three digital outputs.

Inputs are read by the Slave device and transmitted to the Master through

Status word (bits 13-15; see on page 42) when the device is running in

Operational state.

“High” logic value is read when voltage is equal to +24VDC 10%.

Slave outputs are operated by the Master through Control Word (bits 13-15;

see on page 38) when the device is running in Operational state.

Outputs are “open collector” type having Imax = 150mA.

Example of connection scheme:

MAN RD4 CB E 1.5 Functions 27 of 72

Page 28

RD4 CANopen®

6.4 Objects 3120-00 Distance per revolution, 3114-00 Jog speed, 3115-

00 Work speed, 3300-00 Preset and 310F Delta space

Objects 3120-00 Distance per revolution, 3114-00 Jog speed, 3115-00

Work speed, 3300-00 Preset and 310F Delta space are closely related, hence

you have to be very attentive every time you need to change the value in any of

them.

Should that be necessary, you have to operate in compliance with the following

procedure:

set a proper value in 3120-00 Distance per revolution (object 3120h, see

on page 59);

set a proper value in 3114-00 Jog speed (object 3114h; see on page 58);

set a proper value in 3115-00 Work speed (object 3115h; see on page 58);

set a proper value in 3300-00 Preset (object 3300h, see on page 60);

check the value in 310F Delta space sub 1 Positive delta is set properly

(object 310Fh sub 1, see on page 57);

check the value in 310F Delta space sub 2 Negative delta is set properly

(object 310Fh sub 2, see on page 57);

save new values (object 1010-01 Save Parameters 1010h sub 1, see on

page 48).

WARNING

Each time you change the value in 3120-00 Distance per revolution you

must then set new values also in 3114-00 Jog speed and 3115-00 Work

speed as speed values are expressed in pulses per second (PPS). To calculate the

speed values you have always to adhere to the following ratio:

where:

• Distance per revolution: this is the new value you want to set in 3120-

00 Distance per revolution, expressed in pulses

• Min. speed: minimum speed 1 [PPS] for all RD4 units

• Max. speed: maximum speed 1600 [PPS] for RD4-...-T32-... model

1066 [PPS] for RD4-...-T48-... model

• 1024: this is the maximum value you can set in 3120-00 Distance per

revolution (expressed in pulses).

MAN RD4 CB E 1.5 Functions 28 of 72

Min. speed ∗ Distance per revolution

1024

Speed

Max. speed ∗ Distance per revolution

1024

Page 29

RD4 CANopen®

Each time you change the value in 3120-00 Distance per revolution you

must then update the value in 3300-00 Preset in order to define the zero of

the axis as the system reference has now changed.

After having changed the parameter in 3300-00 Preset it is not necessary to

set new values for travel limits as the Preset function then calculates them

automatically and initializes again the positive and negative limits according to

the values set in 310F Delta space.

The number of revolutions managed by the system is 511 in negative direction

and 511 in positive direction assuming 3300-00 Preset as reference.

Value set in parameter 310F Delta space plus value set in parameter 3300-00

Preset is the maximum forward travel (positive travel) starting from the preset

(value is expressed in pulses).

Value set in parameter 310F Delta space subtracted from value set in

parameter 3300-00 Preset is the maximum backward travel (negative travel)

starting from the preset (value is expressed in pulses).

WARNING

Please note that the parameters listed hereafter are closely related to the 3120-

00 Distance per revolution parameter; hence when you change the value in

3120-00 Distance per revolution also the value expressed by each one is

necessarily redefined. They are: 3108-00 Acceleration, 3109-00

Deceleration, 310C-00 Max following error, 310D-00 Position window,

310F Delta space, 3116-00 Max speed, 3343-00 Positive absolute limit

switch, 3344-00 Negative absolute limit switch, 3103-00 Current

position value, 3105-00 Current velocity value, 3106-00 Target position

and 3107-00 Target speed. See for instance the relationship between 3120-

00 Distance per revolution and the speed values, explained in the previous

page.

MAN RD4 CB E 1.5 Functions 29 of 72

Page 30

RD4 CANopen®

Example 1

Default values:

3120-00 Distance per revolution = 1024 steps per revolution

Max. 3115-00 Work speed:

= 1600 pulses per second for RD4-...T32-... model (1600*1024/1024 = 1600)

= 1066 pulses per second for RD4-...T48-... model (1066*1024/1024 = 1066)

3300-00 Preset = 0

310F Delta space sub 1 Positive delta and 310F Delta space sub 2 Negative

delta max. values = 523263 = (1024 steps per revolution x 511 revolutions) - 1

when 3300-00 Preset value = 0

Max. SW limit switch + = 0 + 523263 = + 523263 pulses (forward travel)

Max. SW limit switch - = 0 - 523263 = - 523263 pulses (backward travel)

Therefore, when 3300-00 Preset = 0, the working stroke of the axis will span

the maximum positive and negative limits range, that is SW limit switch + =

523263 and SW limit switch - = - 523263.

MAN RD4 CB E 1.5 Functions 30 of 72

Page 31

RD4 CANopen®

Example 2

ROTADRIVE RD4-...T32-... positioning unit is joined to a worm screw having a 1

mm pitch and you need to have a hundredth of a millimetre resolution.

3120-00 Distance per revolution = 100 steps per revolution

Max. 3115-00 Work speed = 156 pulses per second (1600*100/1024 = 156,

rounded off to the nearest integer)

3300-00 Preset = -500 (ex. thickness of the tool)

310F Delta space sub 1 Positive delta and 310F Delta space sub 2 Negative

delta max. values = 100 steps per revolution x 511 revolutions = 51100 pulses

Max. SW limit switch + = (-500) + 51100 = + 50600 pulses (forward travel)

Max. SW limit switch - = (-500) - 51100 = - 51600 pulses (backward travel)

Therefore, when 3300-00 Preset = - 500, the working stroke of the axis will

span the maximum positive and negative limits range, that is SW limit switch

+ = + 50600 and SW limit switch - = - 51600.

MAN RD4 CB E 1.5 Functions 31 of 72

Page 32

RD4 CANopen®

7 CANopen® interface

Lika ROTADRIVE positioning units are Slave devices and are designed in

compliance with the “Application Layer and Communication Profile DS301”.

For any further information or omitted specifications please refer to “CiA Draft

Standard 301” document available at www.can-cia.org.

7.1 EDS files

CANopen® devices are supplied with their own EDS file

LIKA_RD4_Tx_I2_Vx.EDS (see enclosed documentation or click www.lika.biz >

ROTARY ACTUATORS > ROTARY ACTUATORS (DRIVECOD) > RD4). EDS file

has to be installed on CANopen® Master device.

Install LIKA_RD4_T32_I2_Vx.EDS file for devices fitted with T32 reduction

gear.

Install LIKA_RD4_T48_I2_Vx.EDS file for devices fitted with T48 reduction

gear.

EDS files are available in both English version (_en) and Italian version (_it).

MAN RD4 CB E 1.5 CANopen® interface 32 of 72

Page 33

RD4 CANopen®

7.2 NMT states

CANopen® devices are designed to operate using different states. Transition

from one state to another is achieved by sending specific NMT messages (see

Figure below).

(1) Power turned on

(2)

Initialization carried out, boot-up message is sent

automatically

(3)

NMT message: Start remote node

(4)

NMT message: Enter pre-operational

(5)

NMT message: Stop remote node

(6)

NMT message: Reset node or Reset communication

7.2.1 Initialization

This is the first state the CANopen® device enters after power is turned on or

after performing a hardware reset by means of a Reset node command. During

initialization, device reads and loads the parameters saved on EPROM. As soon

as the basic CANopen® device initialization is carried out, device sends a bootup message and then switches automatically to Pre-operational state.

MAN RD4 CB E 1.5 CANopen® interface 33 of 72

Initialization

Pre-operational

Operational

Stopped

Boot-up message

(1)

(2)

(3)

(4)

(4)(5)

(5) (3)

(6)

(6)

(6)

Page 34

RD4 CANopen®

7.2.2 Pre-operational state

In this state communication between Master and Slave is possible using SDO

messages. They allow working parameters to be set. Slave cannot send PDO

messages.

To switch the Slave device to Operational state the Master must send a Start

remote node command using a NMT message.

7.2.3 Operational state

In this state the Slave device is active and all communication objects are

available. The Slave device can use the parameters available in the “Object

dictionary” and is allowed to send process data using PDO messages. “Object

dictionary” can be accessed using SDO messages. To switch the Slave device to

Pre-operational state the Master must send an Enter pre-operational

command using a NMT message.

WARNING

For safety reasons, in Operational state the Master must check the Slave device

continuously and in a proper way. For a description of the correct procedure see

section “7.6 PDO messages” on page 37.

7.2.4 Stopped state

In this state the Slave device is forced to interrupt communication with the

Master altogether (except node guarding, if active).

Communication using PDO and SDO messages is not allowed.

To switch the Slave device to Pre-Operational or Operational state the Master

must send the specific commands Enter pre-operational or Start remote

node using a NMT message.

MAN RD4 CB E 1.5 CANopen® interface 34 of 72

Page 35

RD4 CANopen®

7.3 Communication messages

Four different kinds of communication messages are used in a CANopen®

network:

Network management NMT service: through node control services, the NMT

Master controls the NMT state of the NMT Slaves; see “7.4 NMT messages”

section on page 36.

Process Data Object PDO service: the real-time data transfer is performed

by means of “Process Data Objects (PDO)”. The PDOs correspond to entries in

the object dictionary and provide the interface to the application objects;

see “7.6 PDO messages” section on page 37.

Service Data Object SDO service: SDOs used to provide direct access to

entries of a CANopen® device “Object dictionary” (page 46); they allow to

read and set parameters; see “7.7 SDO messages” section on page 45.

Special Function Object services:

- SYNC: synchronization object provides the basic network synchronization

mechanism and is used by the Master to enable the Slave devices to

transmit process data (position and velocity; see on page 47);

- Emergency EMCY: emergency objects are triggered by the occurrence of a

CANopen® device internal error situation, see on page 67;

- Node guarding protocol: it is used to detect remote errors in the network,

see on page 68.

Relation between device states and communication objects:

Initialization Pre-operat. Operational Stopped

NMT X X X

PDO X

SDO X X

SYNC X

EMCY X X

Boot-up X

Nodeguard X X X

MAN RD4 CB E 1.5 CANopen® interface 35 of 72

Page 36

RD4 CANopen®

7.3.1 Generic pre-defined connection set

Broadcast objects of the generic pre-defined connection set

Type of COB (Object)

Function code

(binary)

COB-ID (hex)

NMT 0000 000

SYNC 0001 080

Peer-to-peer objects of the generic pre-defined connection set

EMERGENCY 0001 081 - 0FF

PDO 1 (tx) 0011 181 - 1FF

PDO 1 (rx) 0100 200 - 27F

SDO (tx) 1011 581 - 5FF

SDO (rx) 1100 601 - 67F

Nodeguard 1110 701 - 77F

Boot-up 1110 701 - 77F

The type of COB (tx means COB-ID sent; rx means COB-ID received) is viewed

from the Slave device.

7.4 NMT messages

Structure of NMT messages:

COB-ID (11 bit) 2 CAN Data Bytes

Func.code Node ID Command Slave ID

0000 0 NMT function Slave ID

If Slave ID = 00h, the NMT message is issued to all network nodes.

Command NMT service Node state

01 hex

Start remote node Operational

02 hex

Stop remote node Stopped

80 hex

Enter pre-operational Pre-operational

81 hex

Reset node Pre-operational

82 hex

Reset communication Pre-operational

MAN RD4 CB E 1.5 CANopen® interface 36 of 72

Page 37

RD4 CANopen®

7.5 Boot-up messages

Structure of Boot-up messages:

COB-ID(hex) 1 CAN Data Byte

700+Node ID 00

7.6 PDO messages

WARNING

For safety reasons, when the ROTADRIVE unit is on a continuous data exchange

between the Master and the Slave has to be planned in order to be sure that the

communication is always active; this is intended to prevent danger situations

from arising in case of failures in the communication network.

For monitoring the communication state in the network, among the possible

methods the Node guarding protocol can be implemented (complying with

DS301 specifications, see on page 68).

ROTADRIVE positioning unit sends PDO messages to the Master according to the

set cyclic or synchronous work mode (see object 1800 Transmit PDO

Communication Parameter 1).

PDO messages have always a 8 CAN Data Bytes format. Please note that the

structure of sent messages and received messages is different anyway.

Structure of RECEIVE PDO1 messages received by the Slave device (sent by the

Master):

IDENTIFIER 8 CAN data byte

COB-ID (hex) 0 1 2 3 4 5 6 7

F.C. Node-ID

Control Word Target position

200+ Node ID Low … … High Low … … High

MAN RD4 CB E 1.5 CANopen® interface 37 of 72

Page 38

RD4 CANopen®

Structure of TRANSMIT PDO1 messages sent by the Slave device (received by

the Master):

IDENTIFIER 8 CAN data byte

COB-ID (hex) 0 1 2 3 4 5 6 7

F.C. Node-ID

Status word

Current

velocity

Current position

180+ Node ID Low High Low High Low … … High

Structure of bytes:

bit 7 6 5 4 3 2 1 0

M.S.bit L.S.bit

7.6.1 “RECEIVE PDO1” message sent by the Master to the Slave

Control Word

Index 0x3100-00. 32 bits. It contains the commands to be sent in real time to

the Slave in order to manage it. See also 3100-00 Control word on page 63.

Byte 0

Jog +

bit 0 If bit 4 Incremental jog = 0, as long as Jog + = 1, the Slave

moves toward positive direction; otherwise if bit 4

Incremental jog = 1, the activation of this bit causes at

rising edge the execution of a single step toward positive

direction having the length, expressed in pulses, set next to

the 3117-00 Jog step length item; then the slave stops

and waits for another issue. Velocity, acceleration and

deceleration are set in objects 3114-00 Jog speed, 3108-

00 Acceleration and 3109-00 Deceleration respectively.

For a detailed description of jog control see on page 26.

Jog -

bit 1 If bit 4 Incremental jog = 0, as long as Jog - = 1, the Slave

moves toward negative direction; otherwise if bit 4

Incremental jog = 1, the activation of this bit causes at

rising edge the execution of a single step toward negative

direction having the length, expressed in pulses, set next to

the 3117-00 Jog step length item; then the slave stops

and waits for another issue. Velocity, acceleration and

MAN RD4 CB E 1.5 CANopen® interface 38 of 72

Page 39

RD4 CANopen®

deceleration are set in objects 3114-00 Jog speed, 3108-

00 Acceleration and 3109-00 Deceleration respectively.

For a detailed description of jog control see on page 26.

Stop

bit 2 If set to “=1” the Slave is allowed to execute the movements

as commanded. If, while the unit is running, this bit

switches to “=0” then the Slave must stop executing the

deceleration procedure set in 3109-00 Deceleration. For

an immediate halt in the movement, use bit 7 Emergency.

Alarm reset

bit 3 Setting this bit to “1” causes the normal work status of the

device to be restored. This command is used to reset an

alarm condition of the Slave but only if the faulty condition

has ceased. Using SDO messages you can read further

information about the alarm in the index 1003 Pre-

defined Error Field.

Please note that should the alarm be caused by wrong

object values (Machine data not valid) normal work status

can be restored only after having set proper values. Flash

memory error alarm cannot be reset.

Incremental jog

bit 4 If set to “=0”, the activation of bits Jog + and Jog - causes

the slave to move as long as Jog + / Jog - = 1. Setting this

bit to 1 the incremental jog function is enabled, that is: the

activation of bits Jog + and Jog - causes at rising edge the

execution of a single step toward positive or negative

direction having the length, expressed in pulses, set next to

the 3117-00 Jog step length item; then the slave stops

and waits for another issue.

bit 5 Not used.

Start

bit 6 If set to “=1” device moves in order to reach the set target

position. For a complete description of the position control

see on page 25. For any information on target position see

Target position on page 41.

Emergency

bit 7 This bit has to be normally high (“=1”), otherwise it will

cause the device to stop immediately. For a normal halt (not

immediate) which respects the set deceleration see above

bit 2 Stop.

MAN RD4 CB E 1.5 CANopen® interface 39 of 72

Page 40

RD4 CANopen®

Byte 1

bit 8 … 11 Not used.

Axis torque

bit 12 When the axis has reached the commanded position, it

keeps the torque.

If set to “=0”, when the axis is in position, PWM is

deactivated.

If set to ”=1”, when the axis is in position, PWM is kept

active.

OUT 1

bit 13 This is intended to activate / deactivate the operation of the

digital output 1. The meaning of the available outputs is

described in section “Programming parameters“ on page 46.

OUT 1 = 0 output 1 low (not active)

OUT 1 = 1 output 1 high (active)

OUT 2

bit 14 This is intended to activate / deactivate the operation of the

digital output 2. The meaning of the available outputs is

described in section “Programming parameters“ on page 46.

OUT 2 = 0 output 2 low (not active)

OUT 2 = 1 output 2 high (active)

OUT 3

bit 15 This is intended to activate / deactivate the operation of the

digital output 3. The meaning of the available outputs is

described in section “Programming parameters“ on page 46.

OUT 3 = 0 output 3 low (not active)

OUT 3 = 1 output 3 high (active)

Bytes 2 and 3 Not used.

MAN RD4 CB E 1.5 CANopen® interface 40 of 72

Page 41

RD4 CANopen®

Bytes 4 … 7

Target position

Position to be reached, otherwise referred to as commanded position. When the

Start command is sent while Stop and Emergency bits are “=1” and the alarm

condition is off, device moves in order to reach the target position.

Position override function