Page 1

MC150

User manual

MC150

Description

This manual describes the MC150 display series. The

purpose of this device is to display linear or

angular displacements on industrial machines and

automation systems. The device can be connected

to standard Push-Pull or Line Driver incremental

encoders or magnetic sensors.

Chapters

1 Safety summary

2 Identification

3 Installation

4 Mounting recommendations

5 Electrical connections

6 Functions

7 Set up

8 RS232 interface

9 Dimensional drawing and cut-out

1 - Safety summary

For the electrical connections, we recommend to

closely follow these electrical instructions. In

particular, according to the 89/336/EEC norm on

electromagnetic compatibility, following

precautions must be taken:

• Measurement system (sensor) should be

installed as close as possible to the display.

• Always use shielded and twisted cables if

possible.

• Avoid running the sensor cable near high

voltage power cables (e.g. drive cables).

• Install EMC filters on sensor power supply if

needed.

• Avoid mounting sensor near capacitive or

inductive noise sources such as relays, motors,

and switching power supplies.

• Static discharge can damage internal sensitive

electronic components. Before handling and

installing, discharge electrical

charge from your body and tools

which may come in touch with

the device.

Connect according to the chapter 5: “Electrical

connections”.

2 - Identification

The device can be identified by the label's data

(ordering code, serial number). This information is

listed in the delivery document. For technical

features of the product to make reference at the

technical catalogue.

3 - Installation

Install the device according to the protection level

provided. Protect the system against knocks,

friction, solvents and respect the environmental

characteristics of the product.

4 - Mounting recommendations

Push the display into the cut-out (approx. 90 x 66

mm2) without panel clips.

Install panel clips on the display's housing and

screw until fixed.

MAN MC150 I_E 1.7 9 www.lika.it

www.lika.biz

Page 2

+24V / GND

(see P13)

MC150

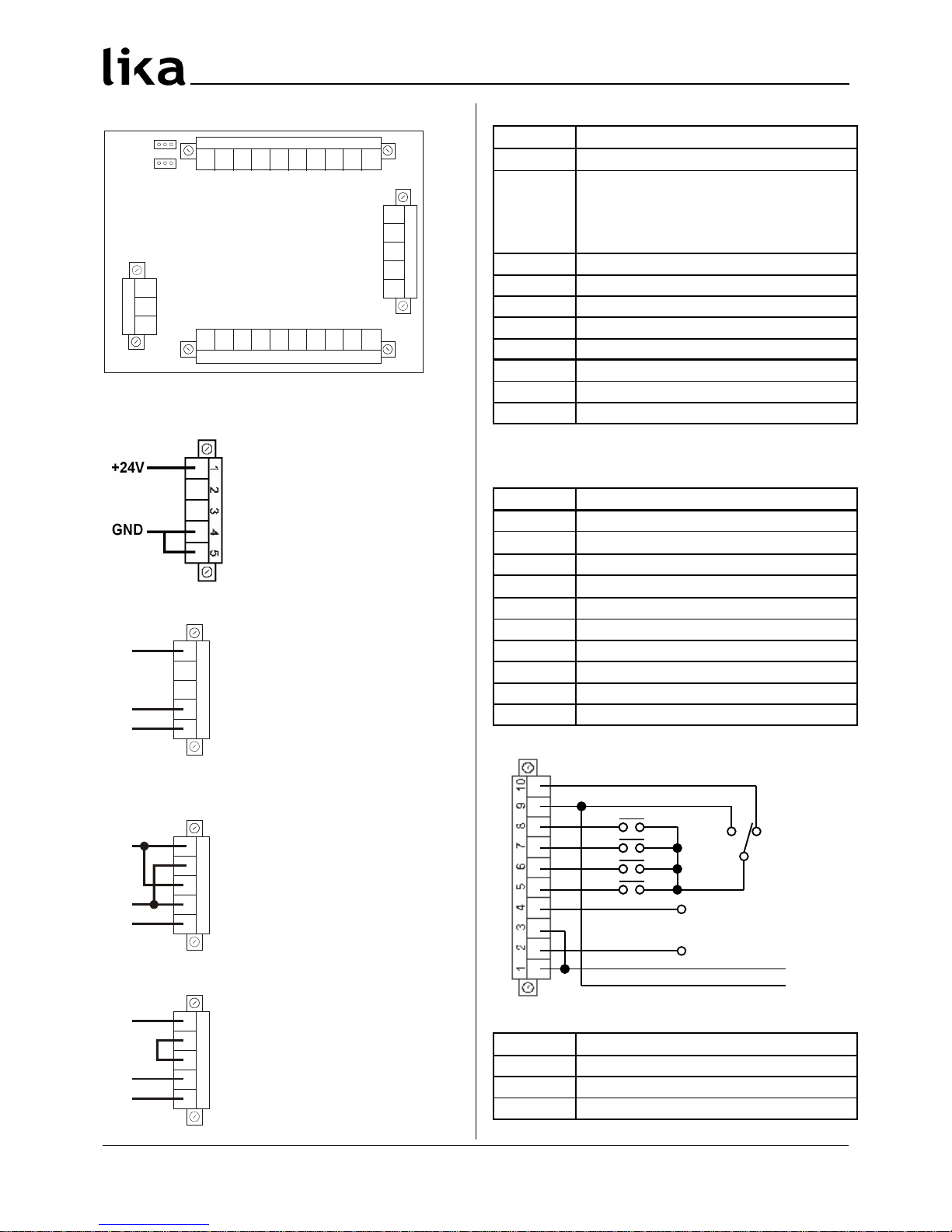

5 - Electrical connections

1 2

3 4 5 6 7 8 9 10

Con1

Con2

Con3

24V 5V

low high

J1

J2

1 2 3

Con4

1 2 3 456 7 8 9 10

1 2

3

4 5

5.1 CON1 connections (power supply)

Power supply 24Vdc

Pin 1 +24Vdc, max. 150 mA

Pin 2 n.c.

Pin 3 n.c.

Pin 4 GND

Pin 5 GND

Power supply 24Vac

1 2

3

4 5

L

N

PE

Pin 1 L

Pin 2 n.c.

Pin 3 n.c.

Pin 4 N, max. 150 mA

Pin 5 P.E.

n.c. = Not connected

Power supply 115Vac

1 2

3

4 5

L

N

PE

Pin 1 L

Pin 2 N

Pin 3 L

Pin 4 N, max. 100 mA

Pin 5 P.E.

Power supply 230Vac

1 2

3

4 5

L

N

PE

Pin 1 L

Pin 2 Connect to pin 3

Pin 3 Connect to pin 2

Pin 4 N, max. 100 mA

Pin 5 P.E.

5.2 CON2 connections (sensor input)

Pin Function

1 *

GND

2 *

+24Vdc (J1: left, power supply: 24Vdc)

+12Vdc (J1: left, power supply: 115Vac

230Vac)

+5Vdc (J1: right, any power supply)

3 A

4 /A (see parameter P22)

5 B

6 /B (see parameter P22)

7 0

8 /0 (see parameter P22)

9 P.E.

10 P.E.

*: output power supply for measuring system

5.3 CON3 connections (Inputs and Outputs)

Pin Function

1 +24Vdc input supply for output 2

2

Output 2 (PNP) *

3 +24Vdc input supply for output 1

4

Output 1 (PNP) *

5 Input 4 - OFFSET function

6 Input 3 - FREEZE/STOP function

7 Input 2 - SET function

8 Input 1 - RESET function

9 GND output for function inputs

10 +24Vdc output for function inputs

*: available only with “MC150-P1-…”

5.4 CON4 connections (RS232)

Pin Function

1 RxD

2 TxD

3 GND

MAN MC150 I_E 1.7 10 www.lika.it

www.lika.biz

Page 3

MC150

5.5 J1 jumper (encoder power supply)

Position Function

Left

+10Vdc +30Vdc *

Right +5Vdc

*: see chapter “5.2 CON2 connections”.

5.6 J2 jumper (input signal level)

Position Function

Left Input connected with GND (CON3/Pin9)

Right

Input connected with +24Vdc

(CON3/Pin10)

6 - Functions

6.1 Start up

At start up the unit shows the software version

followed by actual position.

Software version: SOF xx

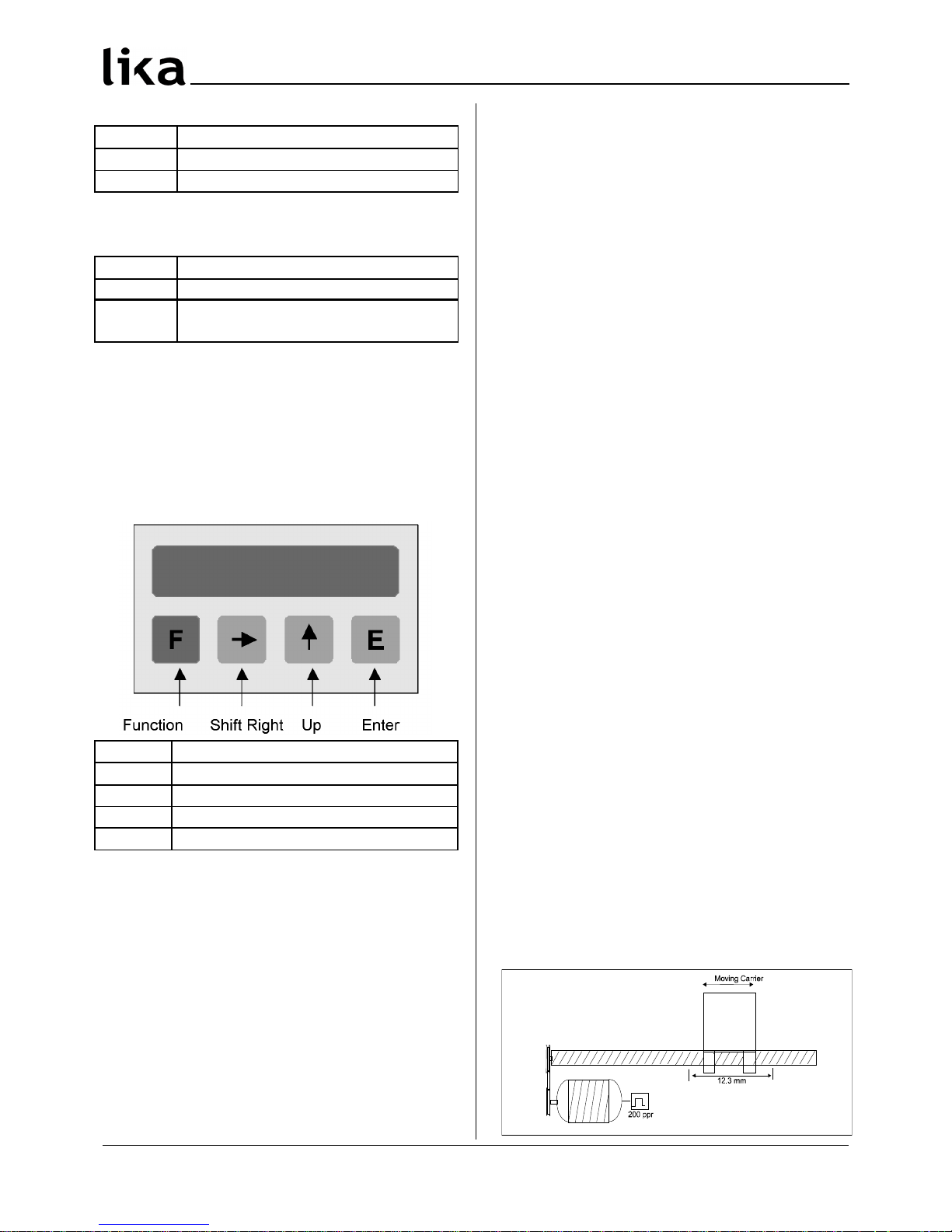

6.2 Key functions

Key Function

F

Function (save + exit setup)

Shift Right (select parameter / digit)

Up (change value)

E

Enter (save + scroll menu)

6.2.1 Default parameter (factory settings)

Default parameter values are written in BOLD

characters. The unit can be reset to default values

by pushing F, and E key while switching on.

6.2.2 Direct functions

To set direct functions, such as reset, reset with

datum value, tool correction (offset value),

absolute/relative display mode and mm/Inch display

mode, program P07 parameter.

7 - Set up

7.1 Access to setup menus

Push F key to enter setup.

• push to select Func 1 or Func 2

• push E to scroll parameters

• push F to exit setup

Admissible value range for each parameter is listed

as follows: [min. value, max. value]

7.2 Parameter setting

In order to activate modified parameters, switch off

and on the device.

Level 1: Func1

P00 Datum value / Eich [-99999, 999999]

Display can be set to datum value (or preset) by

activating SET input or pushing key.

Default value: 50.0

Level 2: Func2

P00 Display value per distance moved [1, 10000]

Enter the value to be displayed when the unit

receives the number of pulses per distance moved

in parameter P01. Note this value is entered

without decimal.

Default value: 100

P01 Nr. of pulses per distance moved [1, 65000]

Enter the number of pulses per distance. This same

distance unit is used to determine the Display value

per distance moved.

Default value: 100

Example:

A ball screw moves 12.3mm per revolution. The

system uses a rotary encoder with 200 PPR (pulses

per revolution).

In this case:

P00 should be set to 123 (value without decimals)

P01 is 200

MAN MC150 I_E 1.7 11 www.lika.it

www.lika.biz

Page 4

MC150

P02 Encoder edge counting mode [1, 3]

1 = x 1 (1 edge counting mode)

2 = x 2 (2 edge counting mode)

3 = x 4 (4 edge counting mode)

For linear magnetic measurement systems set 3.

Example:

A magnetic sensor SME5 with 0,01mm resolution

has to be displayed. The measurement length is

100,00 mm. The sensor outputs 10000 pulses (after

quad.).

P00 is 10000 (100,00mm without decimals)

P01 is 10000 (pulses)

P02 is 3 (signal quadrature)

P03 Counting direction [0, 1]

Sets counting direction of display.

0 = standard counting direction

1 = inverted counting direction

P04 Decimal point [1, 4]

Modification of decimal point position. This setting

has no influence on other parameters.

0 = 000000

1 = 00000.0

….

4 = 00.0000

P05 Password Level 1 [0, 999999]

Enter desired code number here to prevent

operator from entering the "Datum value mode"

(Level 1).

Default value: 0

Attention: Datum value can be set only after

digiting the correct password.

To cancel password and restore default value see

chapter “Default parameter” (6.2.1).

P06 Password Level 2 [0, 999999]

Enter desired code number here to prevent

operator from entering the "Parameter mode"

(Level 2).

Default value: 0

Attention: Datum value can be set only after

digiting the correct password.

To cancel password and restore default value see

chapter “Default parameter” (6.2.1).

P07 Function of the push buttons [0, 6]

The function of the , and the E buttons in

operating mode can be selected.

0 = no functions

1 = E will set actual value to zero

2 = will set actual value to Preset (Func1, P00)

4 = E activates Offset (P12)

8 = will set absolute/incremental mode

16 = E will set Inch/mm mode

To combine more than one function add up the

totals of the different functions and enter the sum

(amount):

3 = function 1 and 2 activated

6 = function 2 and 4 activated

9 = function 1 and 8 activated

11 = function 1, 2 and 8 activated

14 = function 2, 4 and 8 activated

18 = function 2 and 16 activated

P08 Input 1: Reset function [0, 1]

Sets function of Reset input.

0 = static reset. Sets actual value to 0 until input is

activated (high).

1 = dynamic reset. Edge triggered Reset input.

P09 Encoder Index function [0, 2]

Sets function of encoder index pulse 0, /0.

0 = no function

1 = Rising edge triggered Index pulse

2 = Falling edge triggered Index pulse

P10 Input2: SET function [0, 1]

Sets function of SET input.

0 = static SET input. Sets display to Preset value

until input is activated (high).

1 = dynamic SET. Edge triggered SET input.

P11 Input 3:

Freeze/ Stop/ Absolute-incremental function [0, 2]

Sets function of Freeze/Stop input.

0 = freeze actual value while internal counter is

still active.

1 = stop encoder pulse counting.

2 = change absolute/incremental mode

MAN MC150 I_E 1.7 12 www.lika.it

www.lika.biz

Page 5

MC150

P12 Offset [0, 65000]

Value entered here will be subtracted from actual

value by activating OFFSET function (Input 4).

By deactivating OFFSET input, Offset value will be

added to actual value.

Enter the Offset dimension in units of length, such

as xx.x mm or x.xx inches.

Default value: 10.0

P13 Function input configuration [0, 15]

Chose from NO (Normally Open) or NC (Normally

Closed), low active (connected with GND) or high

active (connected with +24Vdc).

P13 CON3

Con. with

GND

Con. with

+24Vdc

Pin 5Pin 6Pin 7Pin

8

0 15 NO NO NO NO

1 14 NC NO NO NO

2 13 NO NC NO NO

3 12 NC NC NO NO

4 11 NO NO NC NO

5 10 NC NO NC NO

6 9 NO NC NC NO

7 8 NC NC NC NO

8 7 NO NO NO NC

9 6 NC NO NO NC

10 5 NO NC NO NC

11 4 NC NC NO NC

12 3 NO NO NC NC

13 2 NC NO NC NC

14 1 NO NC NC NC

15 0 NC NC NC NC

P14 Output 1 [-99999, 999999]

Output 1 will be activated when actual value is

more (or less) than Output 1 value, see P21.

Default value: 10.0

P15 Output 2 [-99999, 999999]

Output 2 will be activated when actual value is

more (or less) than Output 1 value, see P21.

Default value: 20.0

P16 Output configuration [0, 1]

0 = static output

1 = with output dwell time (see P17 and P18)

P17 Output 1 dwell time [0, 2.50]

Enter output dwell time between 0 and 2.50

seconds. P16 must be 1.

Default value: 0

P18 Output 2 dwell time [0, 2.50]

Enter output dwell time between 0 and 2.50

seconds. P16 must be 1.

Default value: 0

P19 Memory on power down [0, 1]

0 = actual value will be stored on power down

1 = after turning power off and on Display shows

"Cal". Display has to be Datumed again before

use (see Func1,P00).

P20 Saw blade offset [-10000, +10000]

Here a value can be stored which is subtracted

from the display value when the Set or Reset

function is activated in incremental mode.

Default value: 0

P21 Output logic [0, 3]

Enter output logic of Output 1 and Output 2.

0 = Output 1 activated when Actual value > P14

Output 2 activated when Actual value > P15

1 = Output 1 activated when Actual value < P14

Output 2 activated when Actual value > P15

2 = Output 1 activated when Actual value > P14

Output 2 activated when Actual value < P15

3 = Output 1 activated when Actual value < P14

Output 2 activated when Actual value < P15

P22 Select CON2 input signals [0, 1]

0 = measuring system with A, B and Z tracks.

1 = measuring system with A, /A, B, /B, Z and /Z

tracks.

MAN MC150 I_E 1.7 13 www.lika.it

www.lika.biz

Page 6

MC150

Setup for devices with RS232 serial interface

(option I1)

P60 Display address [11, 99]

Enter here the serial address of the readout when

using the serial interface option RS232. Don't use

addresses 20, 30, 40,….., 90.

Default value: 11

P61 Baud rate [0, 4]

0 = 2400

1 = 4800

2 = 9600

3 = 19200

4 = 38400

P62 RS232 mode [0, 3]

0 = RS232 protocol according to DIN66019

1 = Printer mode. To transmit actual value

periodically to a printer at a time interval set in

parameter P63.

2 = Printer mode. To transmit actual value to a

printer when pushing E button (attention to

P07: do not use 1, 4 and 16 functions).

3 = Printer mode. To transmit actual value to a

printer when activating Input CON3/ pin 5

(attention: set P12 = 0).

P63 Transmission time interval [0.01, 650.00]

Enter the time interval for periodic actual value

transmission in sec. (P62 must be =1).

Default value: 1.00

P99 Actual value for RS232 [-99999, 999999]

This parameter shows the actual value for serial

transmission via RS232 Interface if parameter

P62=0.

NOTE:

In order to activate modified parameters, switch off

and on the device.

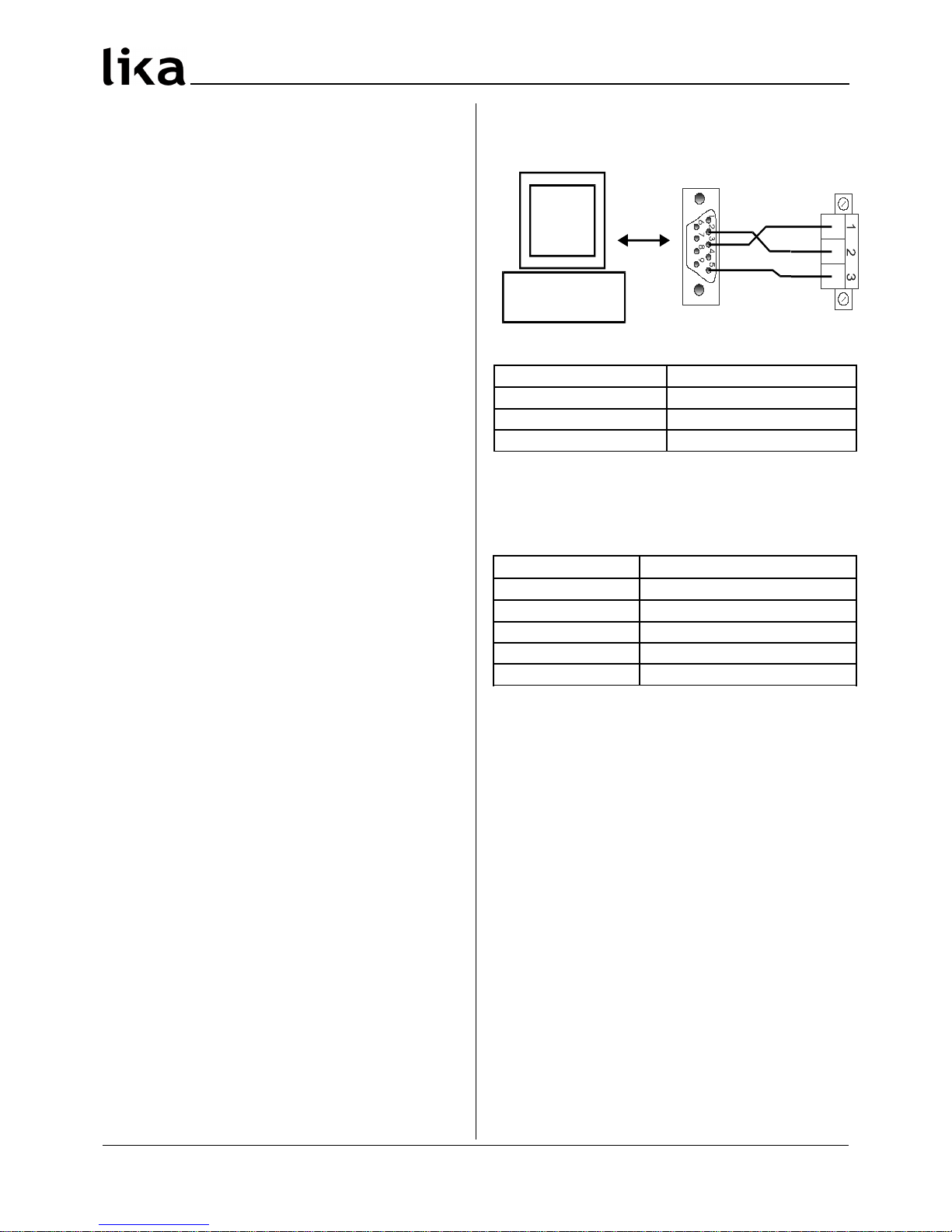

8 - RS232 interface

8.1 PC connection

Use 9 pin DSub connector and connect with CON4

of the MC150 readout.

Pin Function

1 RxD Reception data

2 TxD Transmission data

3 GND Ground

Make sure that RxD on PC side is connected with

TxD on MC150 side and TxD / PC is connected with

RxD / MC150.

8.2 Technical data

Function Data

Baud rate

2400,4800,9600,19200,38400

Data bits 8 bit ASCII

Parity bit No

Stop bit 1

Flow control No

8.3 Communication protocol

The RS232 protocol is according to DIN 66019, ISO

1765, ANSI X3.28.

The PC is the master and the MC150 is the slave

with individual serial address to be entered in

Parameter P60.

There are 3 ways of communication:

• Send

• Receive

• Broadcast

MAN MC150 I_E 1.7 14 www.lika.it

www.lika.biz

Page 7

MC150

8.3.1 Protocol structure

Field Value Function

EOT 04 H End Of Transmit

AD1 ascii Unit address, MSByte

AD2 ascii Unit address, LSByte

STX 02 H Start of TeXt

C1,C2 ascii

Level code = 20 : Level 1

21: Level 2

C3,C4 ascii Parameter code = 00…99

DATA

n byte

ascii

Process data

ETX 03 H End of TeXt

BCC ascii Block Check Character

ENQ 05 H ENQuiry

NAK 15 H Not Acknowledge

ACK 06 H Acknowledge

NOTE:

• BCC (block-check-character) is a character used

for check the correct transmission. It is

generated by XOR-ing characters C1, C2, C3,

C4, DATA and ETX (including). If BCC < 20 Hex,

BCC must be added up with 20 Hex, this avoids

BCC to have values in the range of control

character values.

• DATA field can contain any number of

numerical characters, a sign and can be filled

up with zeros. All DATA are sent in ASCII Code.

8.3.2 Send data from Master to Slave

PC MC150

EOT AD1 AD2 STX C1 C2 C3 C4

DATA ETX BCC

When transmission is correct slave replies with ACK

in any other cases with NAK.

MC150 PC

ACK

or

NAK

All parameters sent to the slave are stored in a data

buffer. Parameters have to be activated by the

"activate parameter" command (see chap. 8.3.4).

Example:

Sets the parameter P01 = 100 (unit address = 11).

PC MC150

EOT AD1 AD2 STX C1 C2 C3 C4

ascii

1 1 2 1 0 1

Hex

04 31 31 02 32 31 30 31

DATA ETX BCC

ascii

1 0 0

Hex

31 30 30 03 30

MC150 PC

ACK

ascii

Hex

06

8.3.3 Receive data from slave

PC MC150

EOT AD1 AD2 STX C1 C2 C3 C4 ENQ

The correct reception of the string is acknowledged

with the following message:

MC150 PC

STX C1 C2 C3 C4 DATA ETX BCC

The reception of a incorrect string is followed by a

negative acknowledgment like:

MC150 PC

STX C1 C2 C3 C4 EOT

in any other cases with “NAK”:

MC150 PC

NAK

Example:

Read actual value (unit address = 11).

PC MC150

EOT AD1 AD2 STX C1 C2 C3 C4 ENQ

ascii

1 1 2 1 9 9

Hex

04 31 31 02 32 31 39 39 05

If actual value = 12 acknowledge message will be:

MC150 PC

STX C1 C2 C3 C4 DATA ETX BCC

ascii

2 1 9 9 1 2

Hex

02 32 31 39 39 31 32 03 23

MAN MC150 I_E 1.7 15 www.lika.it

www.lika.biz

Page 8

MC150

8.3.4 Serial commands

All commands are sent with parameter P52 (C1, C2,

C3, C4 fields = 2152). See “Send data from Master

to Slave” (chap. 8.3.2)

The following commands are available:

- Activate data: DATA=137

- Save data to EEProm: DATA=138

- Set datum: DATA=139

Example:

Send “Activate data” (unit address = 11).

PC MC150

EOT AD1 AD2 STX C1 C2 C3 C4

ascii

1 1 2 1 5 2

Hex

04 31 31 02 32 31 35 32

DATA ETX BCC

ascii

1 3 7

Hex

31 33 37 03 32

MC150 PC

ACK

ascii

Hex

06

8.3.5 Printer mode

When a printer is connected to the MC150 the

following data string will be transmitted:

MC150 printer

AD1 AD2 DATA LF CR

xx xx xx 0A Hex 0D Hex

The MC150 is sending its serial address followed by

the actual value and Line Feed (LF) and Carriage

Return (CR).

9 - Dimensional drawing and cut-out

Check details on product catalogue.

Provide a 90 x 66 mm2 (w x h) cut-out.

Rev HW-SW Man. Vers. Description

0 1.0 1st issue

- 1.- Manual update

6 03-08 1.6 Chap.5, 6, 7 and 8 corrections

7 03-10 1.7

Chap. 5, 8.2 and parameter P62

corrections.

Add parameter P22.

Lika Electronic

Via S. Lorenzo, 25 - 36010 Carrè (VI) - Italy

Tel. +39 0445 382814

Fax +39 0445 382797

Italy: eMail info@lika.it - www.lika.it

World: eMail info@lika.biz - www.lika.biz

MAN MC150 I_E 1.7 16 www.lika.it

www.lika.biz

Loading...

Loading...