Page 1

User's guide

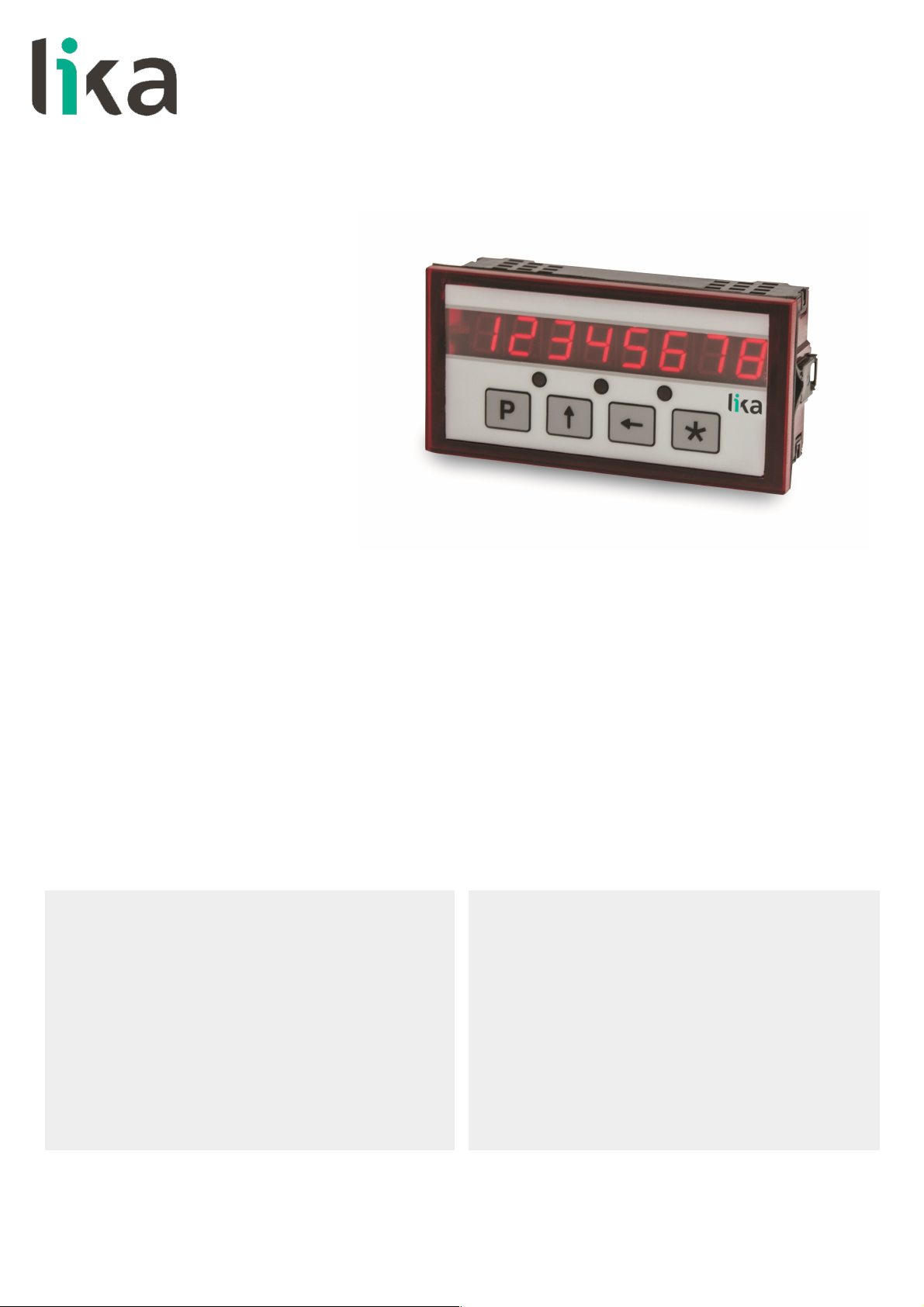

LD200

• Position display, counter, event transmitter, converter

• For HTL/Push-Pull, TTL/Line Driver, Sine/Cosine 1Vpp incremental

encoders/sensors and SSI absolute encoders/sensors

• Linear (mm, inches,...) and angular (degrees) display function

• 1 input and 3 dedicated digital outputs

• RS-232 interface and software tool for easy configuration

Suitable for the following models:

• LD200 universal display

General Contents

Preliminary information 10

1 - Safety summary 11

2 - Identification 13

3 - Mounting instructions 14

4 - Electrical connections 16

5 - Functions 19

6 - Setup 25

7 - RS-232 serial interface 53

8 - Application software for PC 65

Lika Electronic • Tel. +39 0445 806600 • info@lika.biz • www.lika.biz

Smart encoders & actuators

Page 2

This publication was produced by Lika Electronic s.r.l. 2018. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Page 3

General contents

User's guide......................................................................................................................................................... 1

General contents.............................................................................................................................................................................3

Subject index.....................................................................................................................................................................................8

Typographic and iconographic conventions...................................................................................................................9

Preliminary information...........................................................................................................................................................10

1 - Safety summary....................................................................................................................................................................11

1.1 Safety........................................................................................................................................................................................11

1.2 Electrical safety....................................................................................................................................................................11

1.3 Mechanical safety...............................................................................................................................................................12

2 - Identification..........................................................................................................................................................................13

3 - Mounting instructions......................................................................................................................................................14

3.1 Overall dimensions..............................................................................................................................................................14

3.2 Installation.............................................................................................................................................................................15

3.3 Cleaning and maintenance.............................................................................................................................................15

4 - Electrical connections.......................................................................................................................................................16

4.1 CON6 connections (Power supply to the display).................................................................................................16

4.2 CON1 connections (Mini-DIN connector).................................................................................................................16

4.3 CON2 connections (RS-232 serial interface)...........................................................................................................16

4.4 CON3 connections (Sine/Cosine 1Vpp)......................................................................................................................17

4.5 CON5 connections (Push-Pull, Line Driver, SSI).....................................................................................................17

4.6 Jumper J1 (Power supply to the encoder / sensor)..............................................................................................18

4.7 CON4 connections (Outputs and Input)....................................................................................................................18

5 - Functions...................................................................................................................................................................................19

5.1 Start up....................................................................................................................................................................................19

5.2 Function of the LEDs..........................................................................................................................................................19

5.3 Function of the keys...........................................................................................................................................................20

5.4 Default parameters (factory settings)........................................................................................................................20

5.5 Absolute / relative counting mode..............................................................................................................................20

5.6 Memory on power down (for incremental and 1Vpp encoders / sensors).................................................21

5.7 Offset........................................................................................................................................................................................21

5.8 Displaying values in millimetres / degrees / inches / fractional inches.......................................................21

5.9 Zero setting (or Preset setting).....................................................................................................................................21

5.10 Preset Input function (CON4, pins 7 and 8)..........................................................................................................22

5.10.1 Examples of using the input...........................................................................................................................23

5.11 OUT 1, OUT 2, OUT 3 output function (CON4, pins 1 … 6)..............................................................................23

5.11.1 Examples of using the outputs......................................................................................................................24

6 - Setup...........................................................................................................................................................................................25

6.1 Access to setup menus......................................................................................................................................................25

6.2 Basic settings........................................................................................................................................................................26

Ad..................................................................................................................................................................................................26

L_int............................................................................................................................................................................................26

6.3 Parameter settings..............................................................................................................................................................26

d_tyPE........................................................................................................................................................................................26

6.4 AB0 incremental rotary encoder..................................................................................................................................27

PPr................................................................................................................................................................................................27

diSt_r..........................................................................................................................................................................................27

Page 4

MOd 360...................................................................................................................................................................................27

Unit..............................................................................................................................................................................................27

EnAbLE 0...................................................................................................................................................................................27

dir..................................................................................................................................................................................................28

dEciMALS..................................................................................................................................................................................28

PrESEt.........................................................................................................................................................................................28

LIMIt P.......................................................................................................................................................................................28

LIMIt N.......................................................................................................................................................................................28

OFFSEt........................................................................................................................................................................................29

EnAb. In.....................................................................................................................................................................................29

6.5 1Vpp Sine/Cosine rotary encoder.................................................................................................................................30

PPr................................................................................................................................................................................................30

diSt_r..........................................................................................................................................................................................30

MOd 360...................................................................................................................................................................................30

Unit..............................................................................................................................................................................................30

EnAbLE 0...................................................................................................................................................................................30

dir..................................................................................................................................................................................................31

dEciMALS..................................................................................................................................................................................31

PrESEt.........................................................................................................................................................................................31

LIMIt P.......................................................................................................................................................................................31

LIMIt N.......................................................................................................................................................................................31

OFFSEt........................................................................................................................................................................................32

EnAb. In.....................................................................................................................................................................................32

6.6 Absolute rotary encoder with SSI interface.............................................................................................................33

ForMAt.......................................................................................................................................................................................33

PPr................................................................................................................................................................................................33

n_turnS......................................................................................................................................................................................33

diSt_r..........................................................................................................................................................................................33

Prtcl.............................................................................................................................................................................................34

codE.............................................................................................................................................................................................34

Unit..............................................................................................................................................................................................34

dir..................................................................................................................................................................................................34

dEciMALS..................................................................................................................................................................................34

PrESEt.........................................................................................................................................................................................35

LIMIt P.......................................................................................................................................................................................35

LIMIt N.......................................................................................................................................................................................35

OFFSEt........................................................................................................................................................................................35

EnAb. In.....................................................................................................................................................................................36

6.6.1 Connecting an SSI encoder with “MSB Left Aligned” protocol..........................................................36

6.7 Lika's SM2, SM25, SM5 magnetic sensors................................................................................................................40

Pitch............................................................................................................................................................................................40

rES................................................................................................................................................................................................40

Unit..............................................................................................................................................................................................40

dir..................................................................................................................................................................................................40

PrESEt.........................................................................................................................................................................................40

LIMIt P.......................................................................................................................................................................................41

LIMIt N.......................................................................................................................................................................................41

OFFSEt........................................................................................................................................................................................41

EnAb. In.....................................................................................................................................................................................41

Page 5

6.8 AB0 incremental linear encoder/sensor....................................................................................................................43

rES................................................................................................................................................................................................43

Unit..............................................................................................................................................................................................43

EnAbLE 0...................................................................................................................................................................................43

dir..................................................................................................................................................................................................43

PrESEt.........................................................................................................................................................................................44

LIMIt P.......................................................................................................................................................................................44

LIMIt N.......................................................................................................................................................................................44

OFFSEt........................................................................................................................................................................................44

EnAb. In.....................................................................................................................................................................................44

6.9 1Vpp Sine/Cosine linear encoder/sensor...................................................................................................................46

Pitch............................................................................................................................................................................................46

rES................................................................................................................................................................................................46

Unit..............................................................................................................................................................................................46

EnAbLE 0...................................................................................................................................................................................46

dir..................................................................................................................................................................................................47

PrESEt.........................................................................................................................................................................................47

LIMIt P.......................................................................................................................................................................................47

LIMIt N.......................................................................................................................................................................................47

OFFSEt........................................................................................................................................................................................47

EnAb. In.....................................................................................................................................................................................48

6.10 Absolute linear encoder/sensor with SSI interface............................................................................................49

ForMAt.......................................................................................................................................................................................49

StEPS...........................................................................................................................................................................................49

rES................................................................................................................................................................................................50

codE.............................................................................................................................................................................................50

Unit..............................................................................................................................................................................................50

dir..................................................................................................................................................................................................50

PrESEt.........................................................................................................................................................................................50

LIMIt P.......................................................................................................................................................................................51

LIMIt N.......................................................................................................................................................................................51

OFFSEt........................................................................................................................................................................................51

EnAb. In.....................................................................................................................................................................................51

7 - RS-232 serial interface....................................................................................................................................................53

7.1 Connection to a PC.............................................................................................................................................................53

7.2 Setting the serial port.......................................................................................................................................................53

7.3 Communication protocol.................................................................................................................................................53

7.3.1 Protocol structure..................................................................................................................................................54

SOF......................................................................................................................................................................................54

ADD.....................................................................................................................................................................................54

CMD....................................................................................................................................................................................54

ACK.....................................................................................................................................................................................54

DATA..................................................................................................................................................................................54

CHK.....................................................................................................................................................................................55

EOF......................................................................................................................................................................................55

7.3.2 Commands.................................................................................................................................................................55

TPOS...................................................................................................................................................................................56

TDEV...................................................................................................................................................................................56

RDEV...................................................................................................................................................................................56

Page 6

TFOR...................................................................................................................................................................................57

RFOR...................................................................................................................................................................................57

TPPR....................................................................................................................................................................................57

RPPR...................................................................................................................................................................................57

TREV....................................................................................................................................................................................57

RREV...................................................................................................................................................................................57

TDST....................................................................................................................................................................................57

RDST...................................................................................................................................................................................57

T360...................................................................................................................................................................................57

R360...................................................................................................................................................................................57

TSTE....................................................................................................................................................................................57

RSTE....................................................................................................................................................................................57

TPIT.....................................................................................................................................................................................58

RPIT.....................................................................................................................................................................................58

TRES....................................................................................................................................................................................58

RRES...................................................................................................................................................................................58

TPRO...................................................................................................................................................................................58

RPRO..................................................................................................................................................................................58

TCOD..................................................................................................................................................................................59

RCOD..................................................................................................................................................................................59

TUNI....................................................................................................................................................................................59

RUNI...................................................................................................................................................................................59

TETZ....................................................................................................................................................................................59

RETZ....................................................................................................................................................................................59

TDIR....................................................................................................................................................................................59

RDIR....................................................................................................................................................................................59

TDEC...................................................................................................................................................................................60

RDEC...................................................................................................................................................................................60

TREF....................................................................................................................................................................................60

RREF................................................................................................................................................................................... 60

TLIP.....................................................................................................................................................................................60

RLIP.....................................................................................................................................................................................60

TLIM....................................................................................................................................................................................60

RLIM...................................................................................................................................................................................60

TOFF....................................................................................................................................................................................60

ROFF...................................................................................................................................................................................60

TEIN....................................................................................................................................................................................60

REIN....................................................................................................................................................................................60

TADR...................................................................................................................................................................................61

RADR..................................................................................................................................................................................61

TRLA................................................................................................................................................................................... 61

RRLA...................................................................................................................................................................................61

TVER....................................................................................................................................................................................61

ZERO...................................................................................................................................................................................61

STAR...................................................................................................................................................................................62

STOP...................................................................................................................................................................................62

“Null”.................................................................................................................................................................................62

7.3.3 Examples of using the protocol and the commands..............................................................................63

Setting the Device type..........................................................................................................................................63

Page 7

Setting the Pulses per revolution......................................................................................................................63

Reading the position of the decimal separator...........................................................................................63

Reading the current position..............................................................................................................................63

Zero setting the position value..........................................................................................................................64

Starting the cyclic transmission.........................................................................................................................64

Reading the current position cyclically..........................................................................................................64

Stopping the cyclic transmission.......................................................................................................................64

8 - Application software for PC..........................................................................................................................................65

8.1 Serial communication settings......................................................................................................................................65

8.2 Selecting the encoder type.............................................................................................................................................66

8.3 Reading the encoder parameters.................................................................................................................................67

8.4 Setting the encoder parameters...................................................................................................................................67

8.5 Reading the position..........................................................................................................................................................68

8.6 Setting the absolute / relative counting mode......................................................................................................68

8.7 Reading the position cyclically......................................................................................................................................68

Page 8

Subject index

A

Ad............................................................................................26

C

codE................................................................................34, 50

D

d_tyPE...................................................................................26

dEciMALS..............................................................28, 31, 34

dir..............................................28, 31, 34, 40, 43, 47, 50

diSt_r......................................................................27, 30, 33

E

EnAb. In...................................29, 32, 36, 41, 44, 48, 51

EnAbLE 0.......................................................27, 30, 43, 46

F

ForMAt..........................................................................33, 49

L

L_int.......................................................................................26

LIMIt N.....................................28, 31, 35, 41, 44, 47, 51

LIMIt P.....................................28, 31, 35, 41, 44, 47, 51

M

MOd 360.......................................................................27, 30

N

n_turnS................................................................................33

O

OFFSEt......................................29, 32, 35, 41, 44, 47, 51

P

Pitch...............................................................................40, 46

PPr...........................................................................27, 30, 33

PrESEt......................................28, 31, 35, 40, 44, 47, 50

Prtcl........................................................................................34

R

rES....................................................................40, 43, 46, 50

S

StEPS.....................................................................................49

U

Unit...........................................27, 30, 34, 40, 43, 46, 50

Page 9

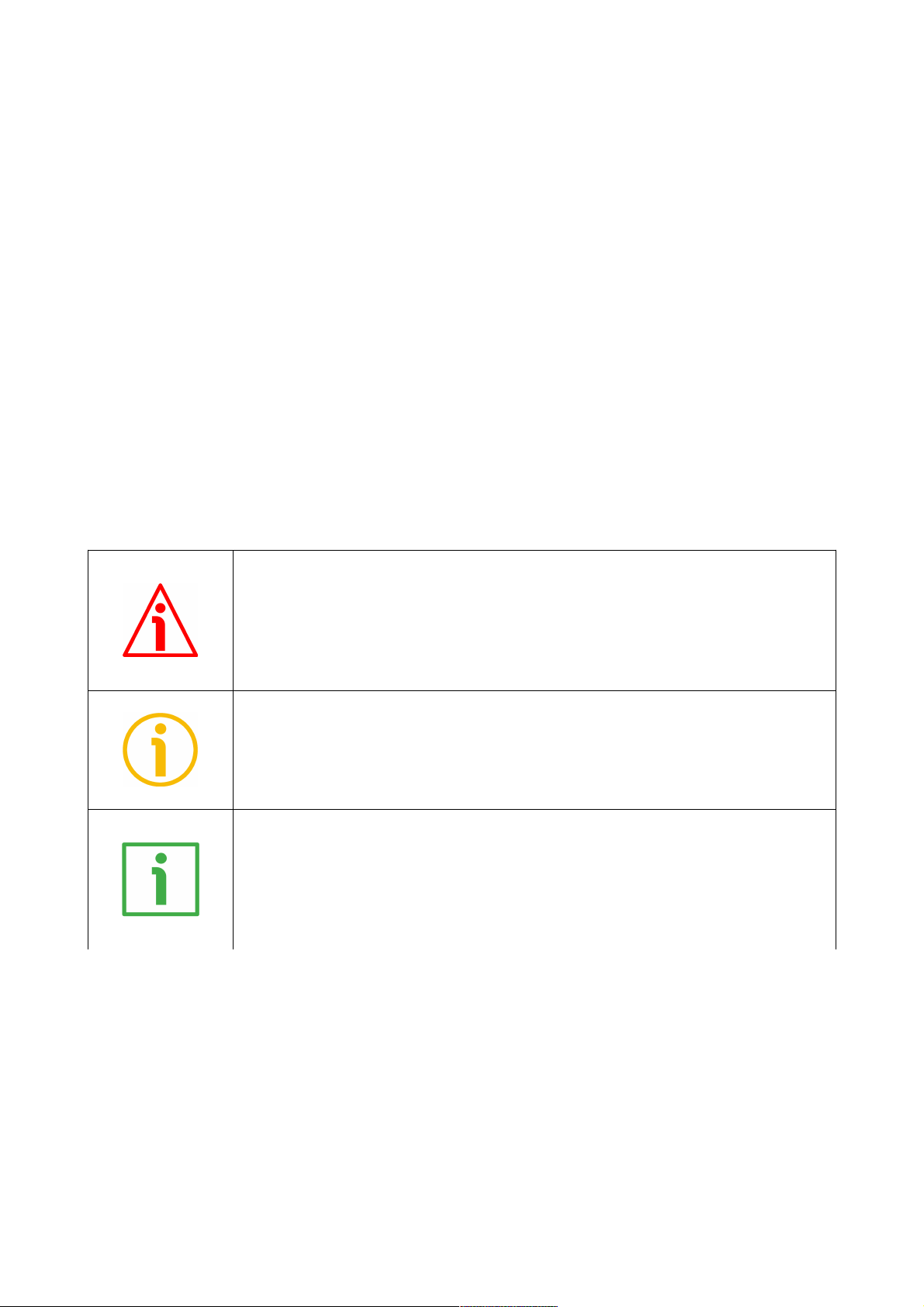

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters and objects both of the device and the interface are coloured in GREEN;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee

the safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Page 10

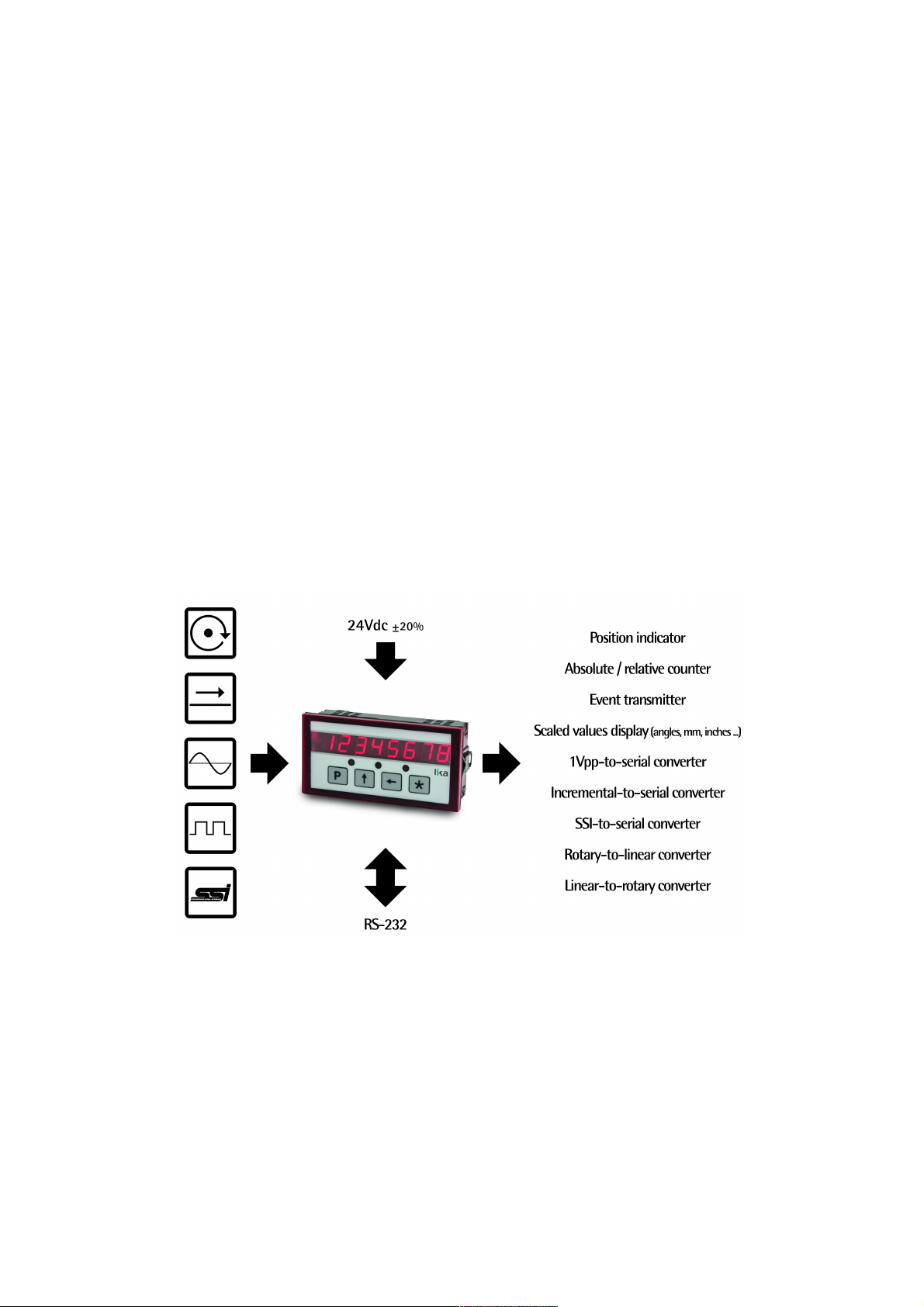

Preliminary information

This guide is designed to provide the most complete information the operator needs to correctly and

safely install and operate the LD200 universal display.

LD200 is a position display which allows to connect a variety of encoders / sensors, they can be

incremental (HTL/Push-Pull, TTL/Line Driver, Sine/Cosine 1Vpp) and absolute (SSI) as well as rotary and

linear.

User's interface is a scratch resistant polycarbonate keyboard fitted with 4 multifunction keys and a 7

segment 8 digit high brightness LED display. The device is also equipped with 3 status LEDs, 1 input and 3

digital outputs designed to operate dedicated functions.

The display provides an RS-232 interface for connection to a PC and configuration via free software tool.

Among the available functions:

• position indicators;

• absolute / relative counter;

• event transmitter.

It allows to display and scale both linear (millimeters, inches, fractional inches) and angular (degreses)

measurement values.

For technical specifications please refer to the product datasheet.

To make it easier to read the text, this guide can be divided into two main sections.

In the first section (from section 1 to section 4) general information concerning the safety, the

mechanical installation and the electrical connection.

In the second section (from section 5 to section 8) both general and specific information is given on the

operator's menu, the use of the keys, the setup procedure and the serial interface.

Page 11

LD200

1 - Safety summary

1.1 Safety

Always adhere to the professional safety and accident prevention

regulations applicable to your country during device installation and

operation;

installation and maintenance operations have to be carried out by qualified

personnel only, with power supply disconnected and stationary mechanical

parts;

device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

high current, voltage and moving mechanical parts can cause serious or

fatal injury;

warning ! Do not use in explosive or flammable areas;

failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture,

and intended use of the equipment;

Lika Electronic assumes no liability for the customer's failure to comply with

these requirements.

1.2 Electrical safety

Turn OFF power supply before connecting the device;

connect following to explanation in the ”4 - Electrical connections” section

on page 16;

in compliance with 2014/30/EU norm on electromagnetic

compatibility, the following precautions must be taken:

- before handling and installing the equipment, discharge

electrical charge from your body and tools which may come in

touch with the device;

- power supply must be stabilized without noise; install EMC filters on

device power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive

noise source; shield the device from noise source if needed;

- minimize noise by connecting the unit to ground (GND). Make sure

that ground (GND) is not affected by noise. The connection point to

ground can be situated both on the device side and on user’s side.

The best solution to minimize the interference must be carried out

by the user.

MAN LD200 E 2.3.odt 1 - Safety summary 11 of 72

Page 12

LD200

1.3 Mechanical safety

Install the device following strictly the information in the “3 - Mounting

instructions” section on page 14;

do not disassemble the unit;

do not tool the unit;

delicate electronic equipment: handle with care;

do not subject the device to knocks or shocks;

respect the environmental characteristics of the device.

MAN LD200 E 2.3.odt 1 - Safety summary 12 of 72

Page 13

LD200

2 - Identification

Device can be identified through the order code and the serial number printed

on the label applied to its body. Information is listed in the delivery document

too. Please always quote the order code and the serial number when reaching

Lika Electronic for purchasing spare parts or needing assistance. For any

information on the technical characteristics of the product, refer to the

technical catalogue.

Warning: devices having order code ending with “/Sxxx” may have

mechanical and electrical characteristics different from standard

and be supplied with additional documentation for special

connections (Technical info).

MAN LD200 E 2.3.odt 2 - Identification 13 of 72

Page 14

LD200

3 - Mounting instructions

WARNING

Installation and maintenance operations have to be carried out by qualified

personnel only, with power supply disconnected and mechanical parts

compulsorily in stop.

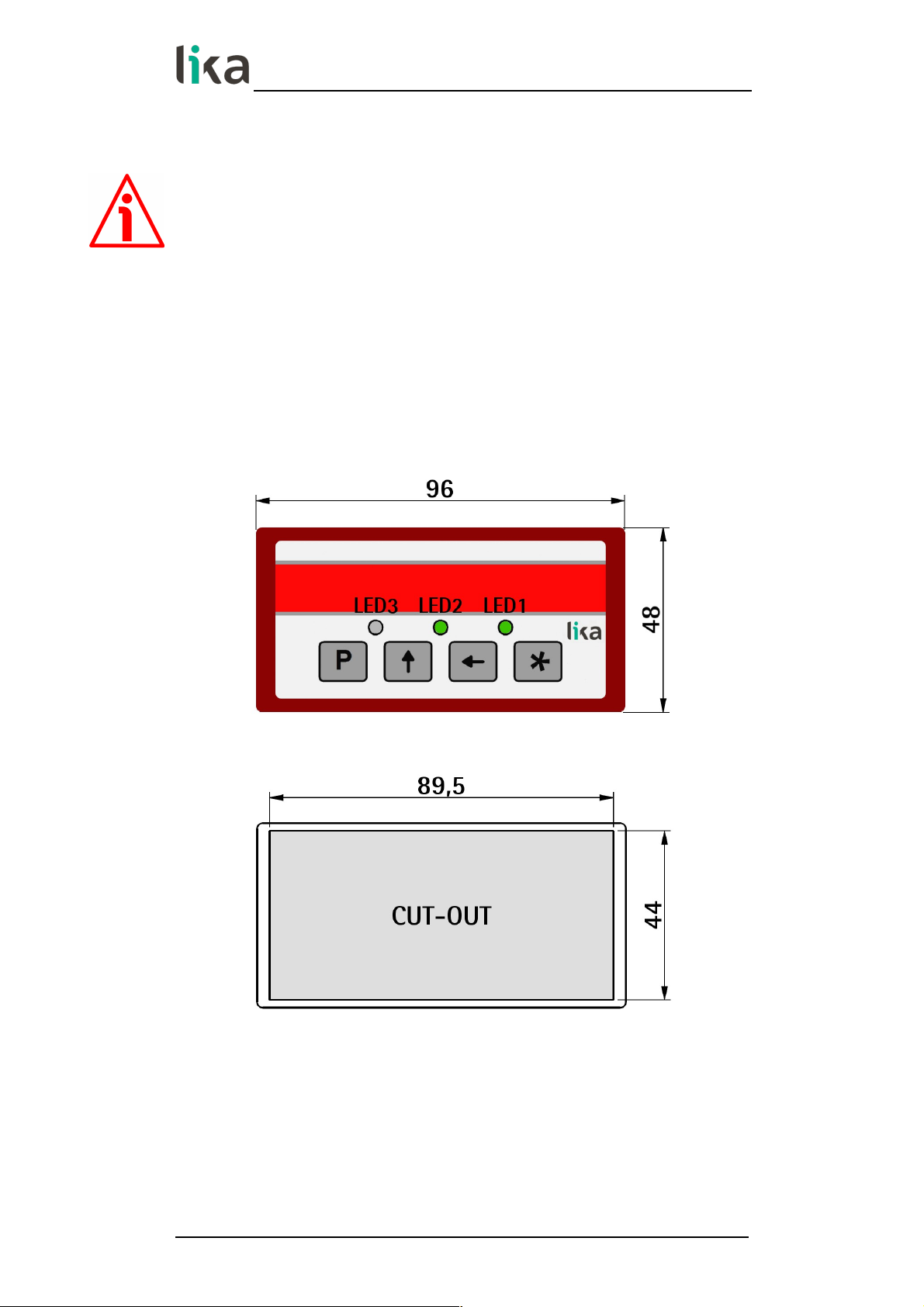

3.1 Overall dimensions

Insert the display without panel clips through the cut-out (approx. 89.5 W x 44

H mm / 3.523” W x 1.732” H) made in the panel.

Mount the panel clips on the sides of the display housing and tighten the

screws until fixed.

Values are expressed in millimeters

MAN LD200 E 2.3.odt 3 - Mounting instructions 14 of 72

Page 15

LD200

3.2 Installation

The device is allowed to be installed and operated only within the permissible

temperature range (0°C +70°C / +32°F +158°F). Please ensure an adequate

ventilation and avoid any direct contact between the device and gases / liquids.

Before installation or maintenance, the unit must be disconnected from all

voltage sources. Furthermore it must be ensured that no danger can arise in the

event of contact with the disconnected voltage sources.

All selected wires and insulations must comply with the provided voltage and

temperature ranges. Furthermore all country and application specific standards

which are relevant for structure, form and quality of the wires must be ensured.

Indications about the permissible wire cross sections for wiring are described in

the product datasheet.

Before starting the unit for the first time it must be ensured that all connections

and wires are firmly plugged in and secured to the screw terminal blocks. All

terminal blocks (including unused ones) must be fastened by turning the

relevant screws clockwise up to the end position.

For placement, wiring, environmental conditions as well as shielding and

earthing/grounding of the supply lines you must comply with the general

standards stated for industrial automation industry and the specific shielding

instructions provided by the manufacturer.

3.3 Cleaning and maintenance

To clean the unit please just use a slightly damp (not wet!), soft cloth. For the

rear side no cleaning is necessary. For an unscheduled, individual cleaning of the

rear side the maintenance technicians or installation operators are selfresponsible.

During normal operation no maintenance is necessary. In case of unexpected

problems, failures or malfunctions the device must be shipped back to the

manufacturer for any checking, adjustment or repair (if necessary).

Unauthorized opening and repair operations can have negative effects or cause

failures to the protection measures of the unit.

MAN LD200 E 2.3.odt 3 - Mounting instructions 15 of 72

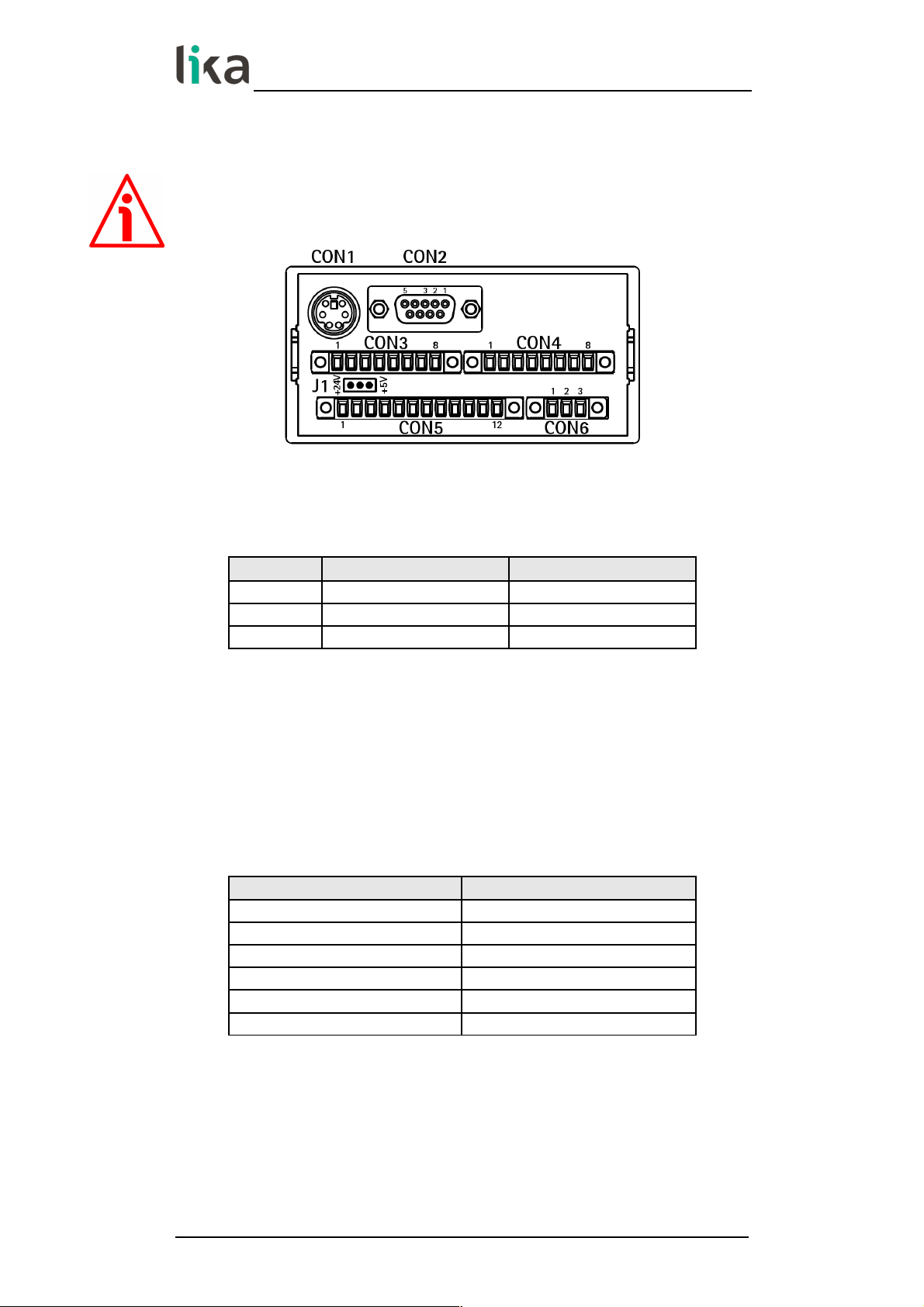

Page 16

LD200

4 - Electrical connections

WARNING

Power supply must be turned off before performing any electrical connection!

4.1 CON6 connections (Power supply to the display)

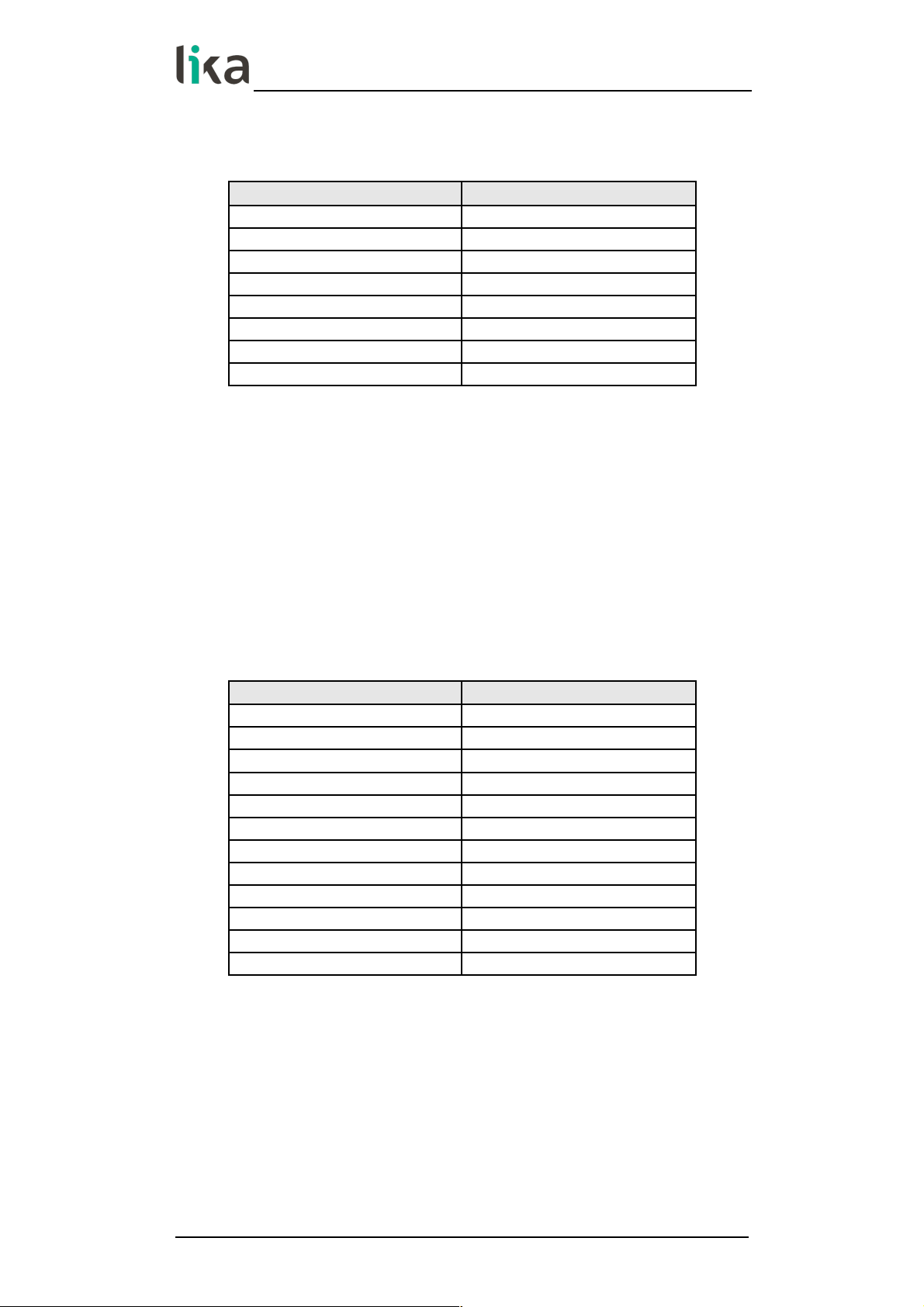

Pin Vdc Vac

1 + 24Vdc ±20% 18Vac

2 0Vdc 18Vac

3 P.E. (GND) P.E. (GND)

4.2 CON1 connections (Mini-DIN connector)

Plug the Mini-DIN circular connector of Lika's SM2, SM25 or SM5 sensors on the

backside of the display. For more information refer to the technical

documentation of the magnetic sensors.

4.3 CON2 connections (RS-232 serial interface)

Pin Description

1

not connected

2 RxD

3 TxD

4

not connected

5 0Vdc

6, 7, 8, 9

not connected

For parameter setup via RS-232 interface and software tool please refer to

sections “7 - RS-232 serial interface” on page 53 and “8 - Application software

for PC” on page 65.

MAN LD200 E 2.3.odt 4 - Electrical connections 16 of 72

Page 17

LD200

4.4 CON3 connections (Sine/Cosine 1Vpp)

It allows to connect a Sine/Cosine 1Vpp encoder.

Pin Description

1 0Vdc

2 +5Vdc

3 SIN + (B)

4 SIN - (/B)

5 COS + (A)

6 COS - (/A)

7 REF + (0)

1

8 REF - (/0)

1

1. Zero signal provided by the encoder can be used to activate the Preset

function. See the “5.9 Zero setting (or Preset setting)” section on page

21. To enable it set the EnAbLE 0 parameter in the specific menu to

“ON”, the counting is zero set at the rising edge of the Zero signal.

4.5 CON5 connections (Push-Pull, Line Driver, SSI)

It allows to connect an HTL/Push-Pull or a TTL/Line Driver incremental encoder /

sensor or an SSI interface absolute encoder / sensor.

Pin Description

1 0Vdc

2 +Vdc

1

3 A

4 /A

5 B

6 /B

7 0

2

8 /0

2

9 Data OUT + (SSI)

10 Data OUT - (SSI)

11 Clock IN + (SSI)

12 Clock IN - (SSI)

1. The voltage level of the power supply provided to the connected

encoder can be selected by means of jumper J1. Refer to the “4.6

Jumper J1 (Power supply to the encoder / sensor)” section in the

following page.

2. Zero signal provided by the encoder can be used to activate the Preset

function. See the “5.9 Zero setting (or Preset setting)” section on page

21. To enable it set the EnAbLE 0 parameter in the specific menu to

“ON”, the counting is zero set at the rising edge of the Zero signal.

MAN LD200 E 2.3.odt 4 - Electrical connections 17 of 72

Page 18

LD200

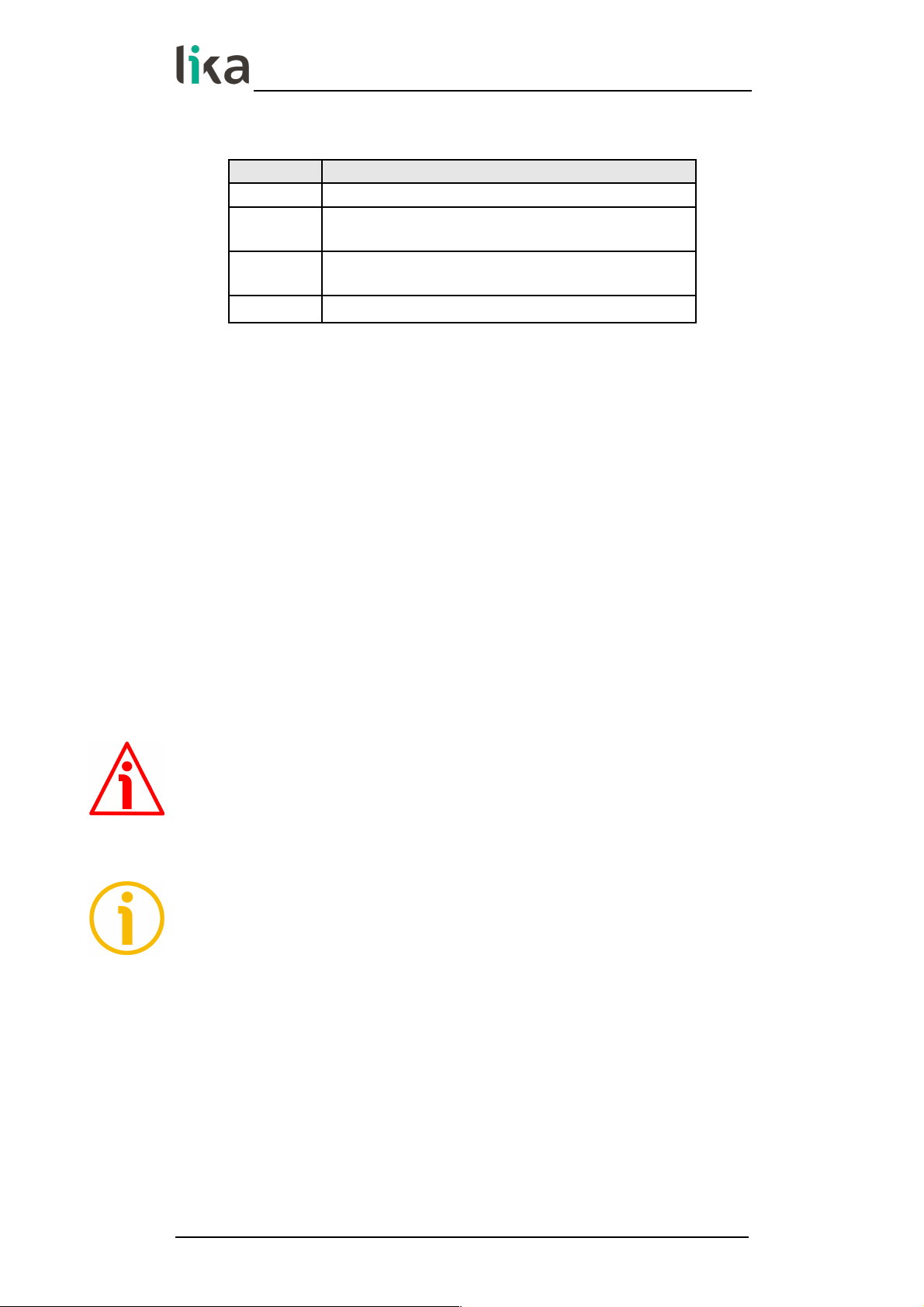

4.6 Jumper J1 (Power supply to the encoder / sensor)

It allows to select the voltage level of the power supply provided to the

connected incremental or SSI encoder / sensor.

Position Description

Left (1-2) +Vdc = +24Vdc @ 1A

Right (2-3) +Vdc = +5Vdc @ 150mA

4.7 CON4 connections (Outputs and Input)

Pin Description

1 OUT1 +

2 OUT1 3 OUT2 +

4 OUT2 5 OUT3 +

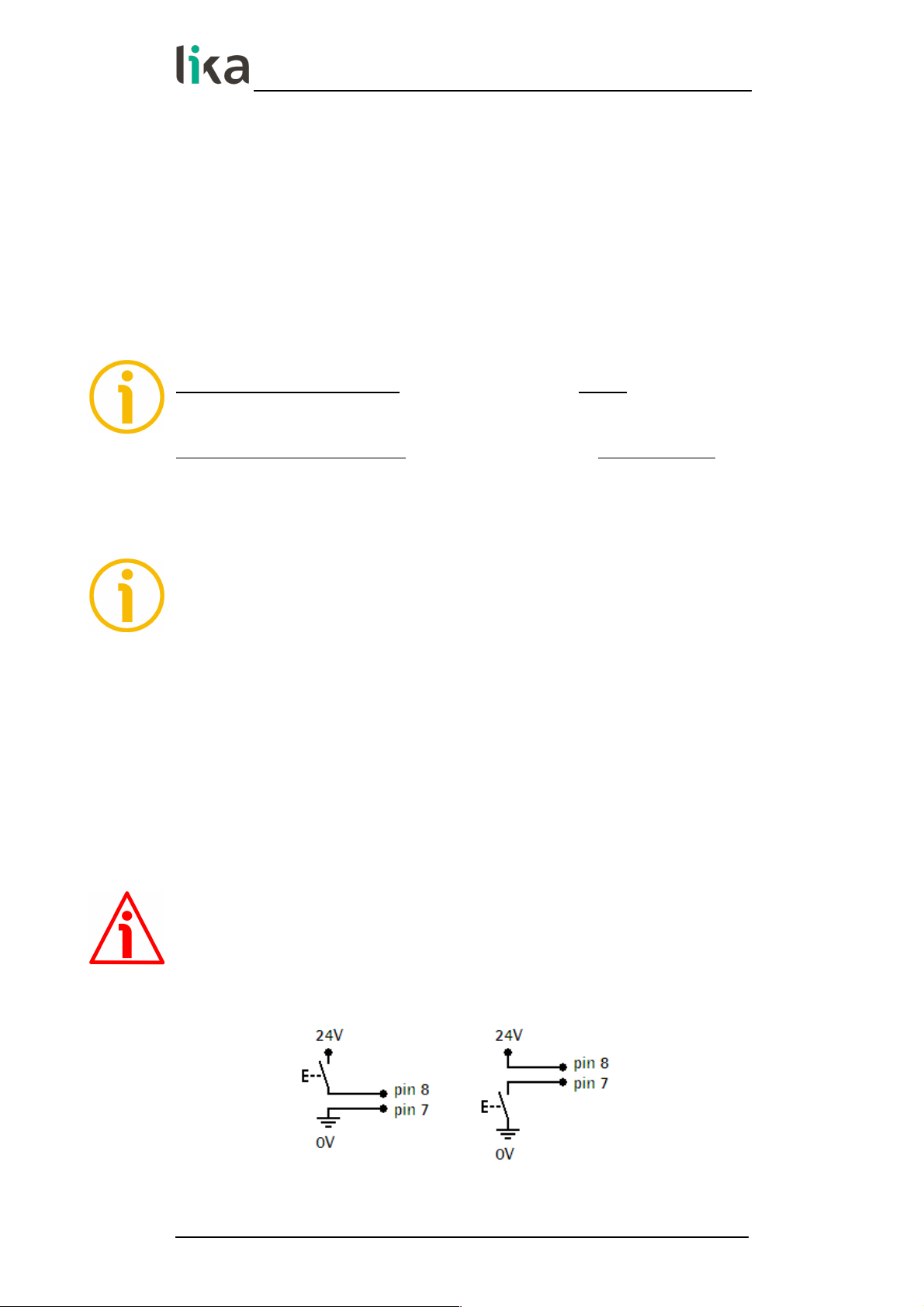

6 OUT3 7 Preset Input 8 Preset Input +

Digital outputs scheme Digital input scheme

Outputs are open collector with optocouplers, Imax = 25 mA.

Input with optocoupler, Vin max = 30Vdc.

NOTE

Some examples of use of the input and the outputs are available in the “5.10

Preset Input function (CON4, pins 7 and 8)” section on page 22 and in the “5.11

OUT 1, OUT 2, OUT 3 output function (CON4, pins 1 … 6)” section on page 23.

MAN LD200 E 2.3.odt 4 - Electrical connections 18 of 72

Page 19

LD200

5 - Functions

5.1 Start up

At switching on the unit shows the hardware/software version followed by the

device address and the current position.

Hardware version Software version

Version: H xx S yy

Device address (0 … 31): Ad zz (see on page 26)

(used for RS-232 interface connection)

5.2 Function of the LEDs

The display is equipped with three LEDs, their function is described in the

following table.

LED 1 GREEN Description

OFF measurement in millimetres or degrees

ON measurement in inches or fractional inches

See the “5.8 Displaying values in millimetres / degrees / inches / fractional inches” section on

page 21

LED 2 GREEN Description

OFF absolute display mode

ON relative display mode

See the “5.5 Absolute / relative counting mode” section on page 20

LED 3 Description

no function

NOTE

During initialisation, system checks the diagnostic LEDs for proper operation;

therefore they light up for a while.

MAN LD200 E 2.3.odt 5 - Functions 19 of 72

Page 20

LD200

5.3 Function of the keys

Key Function

P

Program: it allows to scroll the items in the menu

UP: it allows to change the value of the selected

digit

Shift left: it allows to select the digit and

sometimes also to change it

*

Save: it allows to save data

Sometimes the keys are used in combination to execute specific functions. Refer

to the following sections.

5.4 Default parameters (factory settings)

Default parameter values are set at the factory by Lika Electronic engineers to

allow the operator to run the device for standard operation in a safe mode. They

are highlighted in BOLD characters in the description of the menus.

The unit can be reset to default values following the steps below:

hold down P and keys while switching the device on (“dEFPAr” must

appear);

zero set the unit (see the “5.9 Zero setting (or Preset setting)“ section on

page 21).

WARNING

This action will reset all parameters to factory default values and customised

settings will be lost. After reset you will have to repeat your individual set-up

procedure.

NOTE

When you need to connect a new device to LD200 please upload the default

parameters of the display before configuring it.

5.5 Absolute / relative counting mode

Press P and * keys to switch from absolute (LED2 = OFF) to relative display

mode (LED2 = ON) and vice versa. Default display mode is “absolute”. Absolute /

relative display mode function is not active with SSI encoders / sensors.

MAN LD200 E 2.3.odt 5 - Functions 20 of 72

Page 21

LD200

5.6 Memory on power down (for incremental and 1Vpp encoders / sensors)

On power down the device automatically stores the last position value on

internal memory.

WARNING

If the position of the connected encoder changes while the power of the display

is off, at the next start up the device will display the last position stored before

switching off, not the new position.

5.7 Offset

The offset value is the difference between the value displayed and the value

that is actually measured. It is added to the current position value to indicate,

for example, the thickness of a tool.

When the current position value is displayed, press key to add the OFFSEt

value to it (“OFFSEt” will be displayed); press key again to confirm.

If the OFFSEt value is already used, press key to subtract it from the current

value (“nO OFS” will be displayed); press key again to confirm.

Display value = current position + PrESEt value + OFFSEt value

For more information on the offset value refer to the OFFSEt parameter in the

specific menus.

5.8 Displaying values in millimetres / degrees / inches / fractional inches

When you press key for 3 s. the display switches the engineering unit from

millimeters/degrees (LED1 = OFF) to inches and further to fractional inches

(LED1 = ON). Default display mode is millimetres.

Refer to the Unit parameter in the specific menus.

5.9 Zero setting (or Preset setting)

The Preset function of the display is meant to show a desired value according to

the position value provided by the connected encoder. The chosen position will

get the value set next to the PrESEt parameter (see the specific menus) and all

the previous and the following positions will get a value according to it. This

function is useful, for example, when we want to pair the zero position of the

application with the zero value that is displayed.

Reset/preset function can be activated in the following ways:

via keyboard: press * key for 3 seconds to access the Preset function

("rESEt" will be displayed). Press P key to exit function (no reset operation is

carried out). Press * key twice to confirm the preset execution ("donE" will

be displayed);

via Preset digital input: see the “5.10 Preset Input function (CON4, pins 7

and 8)” section in the following page;

MAN LD200 E 2.3.odt 5 - Functions 21 of 72

Page 22

LD200

via Encoder Zero signal: refer to the EnAbLE 0 parameter in the specific

menus;

by transmitting the zero setting command via serial port; please refer to the

“7 - RS-232 serial interface” section on page 53;

using the software tool via serial port; please refer to the “8 - Application

software for PC” section on page 65.

For more information on the preset / zero setting function please refer to the

description of the PrESEt parameter in the specific menus.

NOTE

In the absolute counting mode setting the preset/reset affects also the relative

counting mode (see the “5.5 Absolute / relative counting mode” section on page

20).

In the relative counting mode setting the preset/reset does not affect the

absolute counting mode (see the “5.5 Absolute / relative counting mode” section

on page 20).

Display value = 0 + PrESEt value

NOTE

See also OUT 3 output in the “5.11 OUT 1, OUT 2, OUT 3 output function (CON4,

pins 1 … 6)” section on the next page to zero set the connected encoder.

5.10 Preset Input function (CON4, pins 7 and 8)

The Preset input function is used to execute the Set Preset function (see the

previous “5.9 Zero setting (or Preset setting)” section). The Preset signal has to

be at logic level HIGH (Vin between +10Vdc and +30Vdc) for 100 msec.

minimum.

Refer to the EnAb. In parameter in the specific menus to enable this function.

Display value = 0 + PrESEt value

WARNING

Input with optocoupler, Vin max = 30Vdc.

Recommended wiring diagrams:

MAN LD200 E 2.3.odt 5 - Functions 22 of 72

Page 23

LD200

5.10.1 Examples of using the input

In both examples the “Enable Preset Input” function has to be enabled: EnAb. In

parameter = ON.

1 Using a remote button to perform the Preset function of the displayed

value (any encoder / sensor connected):

2 Using OUT 1 (positive limit switch) to send a digital output to the PLC

and simultaneously perform a Preset function of the displayed value:

In this case, the high-level signal sent to the PLC has a duration of 160 ms.

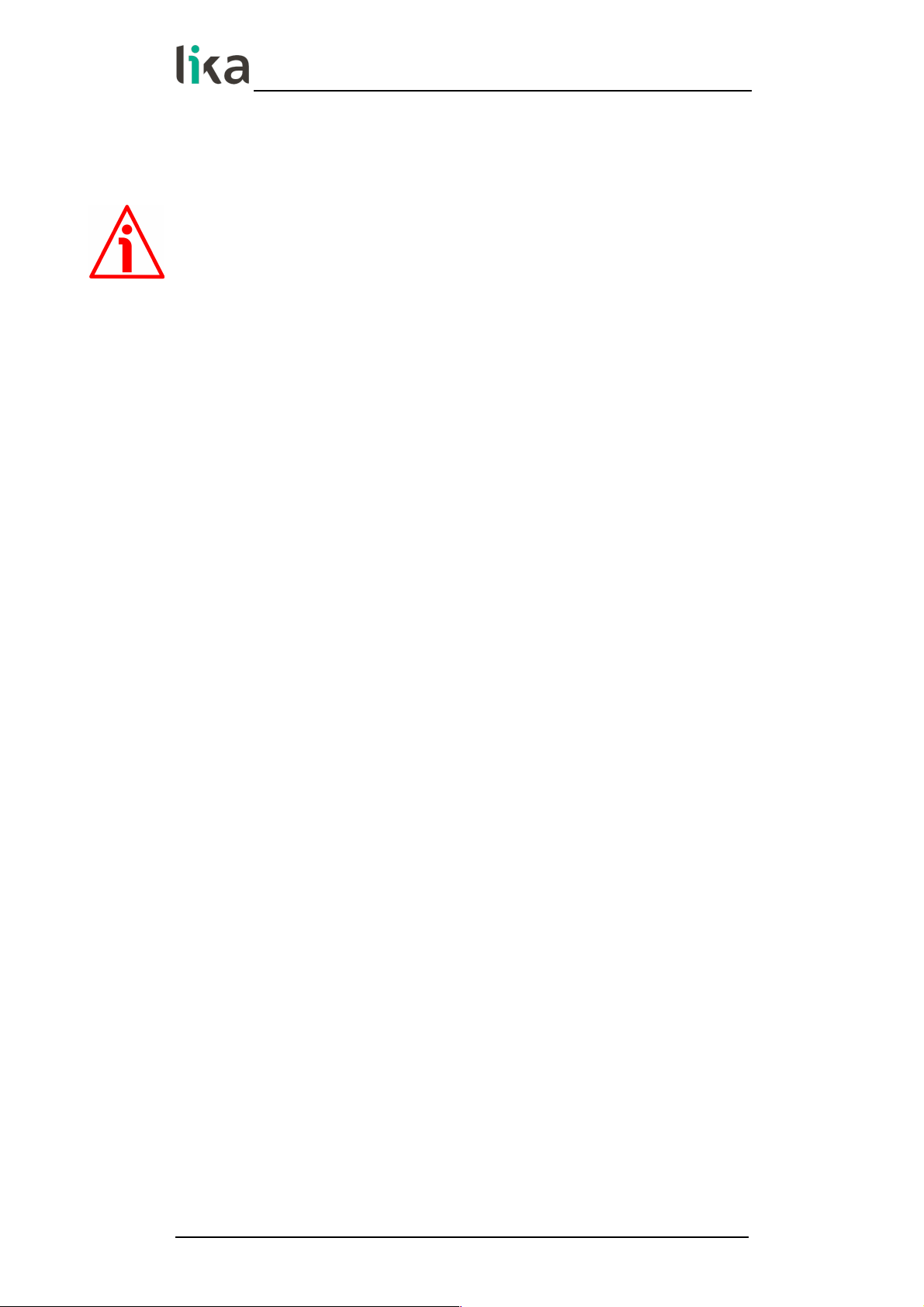

5.11 OUT 1, OUT 2, OUT 3 output function (CON4, pins 1 … 6)

OUT 1 and OUT 2 digital outputs can be used to set upper and lower software

limit switches. See the LIMIt P and LIMIt N parameters in the specific menus.

OUT 3 output can be used for zero setting an SSI absolute encoder / sensor

equipped with zero setting input. When you press the zero setting key or send

the zero setting serial command (see on page 21), OUT 3 is at high logic level for

a duration of 100 ms.

Output Function

OUT 1

HIGH LEVEL if the current position is > LIMIt P

LOW LEVEL if the current position is < LIMIt P

OUT 2

HIGH LEVEL if the current position is < LIMIt N

LOW LEVEL if the current position is > LIMIt N

OUT 3

HIGH LEVEL while the reset command is active

LOW LEVEL during normal operation

MAN LD200 E 2.3.odt 5 - Functions 23 of 72

Page 24

LD200

WARNING

Outputs are open collector with optocouplers, Imax = 25 mA.

Recommended wiring diagrams:

5.11.1 Examples of using the outputs

In the first two examples the “Enable Preset Input” function has to be enabled:

EnAb. In = ON.

1 Using OUT 1 (positive limit switch) to send a digital output to the PLC

and simultaneously perform a Preset function of the displayed value,

the “Enable Preset Input” function has to be enabled: EnAb. In

parameter = ON:

In this case, the high-level signal sent to the PLC has a duration of 160 ms.

2 Using OUT 3 (encoder zero setting output) to send a 24V signal to an

SSI encoder in order to zero set the position by means of the Zero

setting input:

When we use the display zero setting function by means of the zero setting

key or by sending the zero setting serial command (see on page 21), we

contemporaneously transmit to the SSI encoder a 24V signal having a

duration of 100 ms.

MAN LD200 E 2.3.odt 5 - Functions 24 of 72

Page 25

LD200

6 - Setup

6.1 Access to setup menus

Press P key for 3 second to enter the Setup procedure ("SEtUP" will be

displayed):

Then:

press * key to enter the "Basic settings" menu (see the “6.2 Basic settings”

section on page 26);

press key to enter the "Parameter settings" menu (see the “6.3

Parameter settings” section on page 26).

In the "Basic settings" menu both the name of the parameter and the value

appear simultaneously; the value blinks; in the "Parameter settings" menu the

name of the parameter appears first, pressing P key once again the set value

also appears. Press P key to scroll the menu.

Change the value by pressing and/or keys.

Press * to store parameters and values. Displayed value stops blinking if stored

correctly.

Admissible value range for each parameter is listed as follows in the next pages:

[minimum value, maximum value] (default value)

To exit the SETUP procedure scroll the whole list of parameters by pressing P

key.

NOTE

In the LD200 page of Lika's web site www.lika.biz an application software

LD200_Serial_Communication_x_x.exe is available for parameter setup via

RS-232 interface (CON2 connections). Please refer to the “7 - RS-232 serial

interface” section on page 53 and to the “8 - Application software for PC”

section on page 65.

MAN LD200 E 2.3.odt 6 - Setup 25 of 72

Page 26

LD200

6.2 Basic settings

Ad

Device address [0, 31] (def: 0)

It sets the address of the device needed for RS-232 communication. Please refer

to the “7 - RS-232 serial interface” section on page 53 and to the “8 Application software for PC” section on page 65.

L_int

Light intensity of the display [0, 15] (def: 10)

It sets the light intensity of 7 segment LED display. Use and keys to

change the parameter value.

0 = minimum intensity

...

10 = normal intensity

...

15 = maximum intensity

6.3 Parameter settings

d_tyPE

Device type

[E_Incr, E_1VPP, E_SSI_, M_SEnS, M_Incr, M_1VPP, M_SSI_] (def: E_Incr)

It sets the type of encoder/sensor connected to the display.

d_tyPE Type of transducer

E_Incr

AB0 incremental rotary encoder

Refer to “6.4 AB0 incremental rotary encoder“ section on page 27

E_1VPP

1Vpp Sine/Cosine rotary encoder

Refer to “6.5 1Vpp Sine/Cosine rotary encoder” section on page 30

E_SSI_

SSI interface absolute rotary encoder

Refer to “6.6 Absolute rotary encoder with SSI interface” section on on page 33

M_SEnS

SM2, SM25, SM5 magnetic linear sensors

Refer to “6.7 Lika's SM2, SM25, SM5 magnetic sensors” section on on page 40

M_Incr

AB0 incremental linear encoder/sensor

Refer to “6.8 AB0 incremental linear encoder/sensor” section on on page 43

M_1VPP

1Vpp Sine/Cosine linear encoder/sensor

Refer to “6.9 1Vpp Sine/Cosine linear encoder/sensor” section on on page 46

M_SSI_

SSI interface absolute linear encoder/sensor

Refer to “6.10 Absolute linear encoder/sensor with SSI interface” section on on page 49

NOTE

Each device type has appropriate parameters only relevant to the specific type

of encoder/sensor. The choice of the connected device also changes the list of

the available parameters.

MAN LD200 E 2.3.odt 6 - Setup 26 of 72

Page 27

LD200

6.4 AB0 incremental rotary encoder

d_tyPE = E_Incr. List of parameters of incremental rotary encoders with

HTL/Push-Pull or TTL/Line Driver circuit (with or without complementary signals).

For connection refer to the “4.5 CON5 connections (Push-Pull, Line Driver, SSI)”

section on page 17.

PPr

Pulses per revolution [1, 99999999] (def: 4096)

Number of pulses per revolution (PPR) provided by the encoder.

diSt_r

Display value per turn [1, 99999999] (def: 4096)

Value to be displayed after 1 revolution of the encoder.

If diSt_r is > PPr * 4, a “jump” in the display value will occur.

MOd 360

360° display mode [OFF, On] (def: OFF)

It sets the angular display mode (expressed in degrees: ...0.0°...359.9°...0.0°...).

If MOd 360 = ON, the display value per turn (see diSt_r parameter) has to be

set to 360, 3600 or 36000 depending on the required decimal separator

position. Set Unit parameter = U_dEc.

OFF = angular display mode not active

On = angular display mode active

Unit

Unit of measurement [U_dEc, Inch, Inch_F] (def: U_dEc)

It sets the unit of measurement of the display mode to millimeters/degrees,

inches or fractional inches. See also the “5.8 Displaying values in millimetres /

degrees / inches / fractional inches” section on page 21.

U_dEc = mm/degrees (“degrees” only if MOd 360 = On)

Inch = inches

Inch_F = fractional inches (eg. 12.31.64 = 12" 31/64)

EnAbLE 0

Enable Zero signal [OFF, On] (def: OFF)

It is used to activate the Preset function of the display by means of the zero

signal of the encoder (pins 7 and 8 of CON5, see on page 17). See the “5.9 Zero

setting (or Preset setting)” section on page 21.

If EnAbLE 0 is set to “On”, the display value is zero set at the rising edge of the

Zero signal.

OFF = Zero signal not enabled

On = Zero signal enabled

MAN LD200 E 2.3.odt 6 - Setup 27 of 72

Page 28

LD200

dir

Counting direction [uP, dn] (def: uP)

It sets the counting direction of the display value.

uP = standard counting direction = count up when the encoder shaft turns

clockwise (viewed from the shaft side)

dn = inverted counting direction

dEciMALS

Decimal separator [0, 3] (def: 0)

It changes the position of the decimal separator. This setting does not affect

other parameters.

0 = 00000000

…

3 = 00000.000 (0000.0000 if Unit = Inch)

PrESEt

Preset value [-99999999, 99999999] (def: 0)

The Preset function of the display is meant to show a desired value according to

the position value provided by the connected encoder. The chosen position will

get the value set next to this PrESEt parameter and all the previous and the

following positions will get a value according to it. This function is useful, for

example, when we want to pair the zero position of the application with the

zero value that is displayed. To execute the preset see the “5.9 Zero setting (or

Preset setting)” section on page 21. This parameter is always expressed and

calculated in metric measurement unit (millimeters).

LIMIt P

Positive limit switch [-99999999, 99999999] (def: 0)

Value of positive limit switch.

Output OUT 1 (see on page 18) is active (HIGH LEVEL) when the current position

is greater than the set value. This parameter is always expressed and calculated

in metric measurement unit (millimeters). See also the “5.11 OUT 1, OUT 2, OUT

3 output function (CON4, pins 1 … 6)” section on page 23.

LIMIt N

Negative limit switch [-99999999, 99999999] (def: 0)

Value of negative limit switch.

Output OUT 2 (see on page 18) is active (HIGH LEVEL) when the current position

is less than the set value. This parameter is always expressed and calculated in

metric measurement unit (millimeters). See also the “5.11 OUT 1, OUT 2, OUT 3

output function (CON4, pins 1 … 6)” section on page 23.

MAN LD200 E 2.3.odt 6 - Setup 28 of 72

Page 29

LD200

OFFSEt

Offset value [-99999999, 99999999] (def: 0)

The offset value is the difference between the value displayed and the value

that is actually measured. It is added to the current position value to indicate,

for example, the thickness of a tool. This value is added to the current position

by pressing key. This parameter is always expressed and calculated in metric

measurement unit (millimeters). See also the “5.7 Offset” section on page 21.

Position = current position + OFFSEt value

EnAb. In

Enable Preset Input [OFF, On] (def: OFF)

If it is set to “On”, the Preset digital input can be used to activate the Preset

function (see the “5.10 Preset Input function (CON4, pins 7 and 8)” section on

page 22).

OFF = Input not enabled

On = Input enabled

EXAMPLE

An I58-H-500ZCU46L2 encoder (500 PPR) has to display 10,00 mm at each

complete turn, activate the positive limit switch at 30,00 mm and enable the

input function.

d_tyPE = E_Incr dEciMALS = 2

PPr = 500 (encoder feature) PrESEt = 0

diSt_r = 1000 LIMIt P = 2999

MOd 360 = OFF LIMIt N = 0

Unit = U_dec OFFSEt = 0

EnAbLE 0 = OFF EnAb. In = ON

dir = Up

EXAMPLE

We need to connect the following incremental rotary encoder: I28-Y100BNF25Lx (100 PPR) and display 100 mm at each complete turn.

d_tyPE = E_Incr dEciMALS = 0

PPr = 100 (encoder feature) PrESEt = 0

diSt_r = 100 LIMIt P = 0

MOd 360 = OFF LIMIt N = 0

Unit = U_dec OFFSEt = 0

EnAbLE 0 = OFF EnAb. In = OFF

dir = Up

MAN LD200 E 2.3.odt 6 - Setup 29 of 72

Page 30

LD200

6.5 1Vpp Sine/Cosine rotary encoder

d_tyPE = E_1VPP. List of parameters of rotary encoders with 1Vpp Sine/Cosine

output circuit. For connection refer to the “4.4 CON3 connections (Sine/Cosine

1Vpp)” section on page 17.

PPr

Pulses per revolution [1, 99999999] (def: 4096)

Number of pulses per revolution (Sine/Cosine signals) provided by the encoder.

diSt_r

Display value per turn [1, 99999999] (def: 4096)

Value to be displayed after 1 revolution of the encoder.

If diSt_r is > PPr * 1024, a “jump” in the display value will occur. The max.

interpolation factor is 5,000.

MOd 360

360° display mode [OFF, On] (def: OFF)

It sets the angular display mode (expressed in degrees: ...0.0°...359.9°...0.0°...).

If MOd 360 = ON, the display value per turn (see diSt_r parameter) has to be

set to 360, 3600 or 36000 depending on the required decimal separator

position. Set Unit parameter = U_dec.

OFF = angular display mode not active

On = angular display mode active

Unit

Unit of measurement [U_dEc, Inch, Inch_F] (def: U_dEc)

It sets the unit of measurement of the display mode to millimeters/degrees,

inches or fractional inches. See also the “5.8 Displaying values in millimetres /

degrees / inches / fractional inches” section on page 21.

U_dEc = mm/degrees (“degrees” only if MOd 360 = On)

Inch = inches

Inch_F = fractional inches (eg. 12.31.64 = 12" 31/64)

EnAbLE 0

Enable Zero signal [OFF, On] (def: OFF)

It is used to activate the Preset function of the display by means of the zero

signal of the encoder (pins 7 and 8 of CON3, see on page 17). See the “5.9 Zero

setting (or Preset setting)” section on page 21.

If EnAbLE 0 is set to “On”, the display value is zero set at the rising edge of the

Zero signal.

OFF = Zero signal not enabled

On = Zero signal enabled

MAN LD200 E 2.3.odt 6 - Setup 30 of 72

Page 31

LD200

dir

Counting direction [uP, dn] (def: uP)

It sets the counting direction of the display value.

uP = standard counting direction = count up when the encoder shaft turns

clockwise (viewed from the shaft side)

dn = inverted counting direction

dEciMALS

Decimal separator [0, 3] (def: 0)

It changes the position of the decimal separator. This setting does not affect

other parameters.

0 = 00000000

…

3 = 00000.000 (0000.0000 if Unit = Inch)

PrESEt

Preset value [-99999999, 99999999] (def: 0)

The Preset function of the display is meant to show a desired value according to

the position value provided by the connected encoder. The chosen position will

get the value set next to this PrESEt parameter and all the previous and the

following positions will get a value according to it. This function is useful, for