Page 1

LD120

User manual

LD120-M7

SM5

Description

This manual describes the LD120 display and the

sensors of the SM5 series. The purpose of this

system is to display displacements on industrial

machines and automation systems. The

measurement system includes a LED display,

magnetic tape and a magnetic sensor. As the sensor

is moved along the magnetic tape, it detects the

displacement which is shown on the display. The

flexibility of the tape allows it to be used for both

linear and angular applications.

Chapters

1 Safety summary

2 Identification

3 Installation

4 Mounting steps

5 Electrical connections

6 Setup

7 RS485 serial interface

8 Dimensional drawing and cut-out

1 - Safety summary

We strongly recommend carefully reading this user

manual and following the installation guidelines:

• Measurement system (sensor) should be installed

as close as possible to the display.

• Always use shielded and twisted cables if

possible.

• Avoid running the sensor cable near high

voltage power cables (e.g. drive cables).

• Install EMC filters on sensor power supply if

needed.

• Avoid mounting sensor near capacitive or

inductive noise sources such as relays, motors,

and switching power supplies.

Connect according to the chapter 5: “Electrical

connections”.

2 - Identification

The display and sensor can be identified by the

label's data (ordering code, serial number). This

information is listed in the delivery document. For

technical features of the product to make reference

at the technical catalogue.

3 - Installation

Install the product according to the protection level

provided. Protect the system against knocks,

friction, solvents, and respect the environmental

characteristics of the device.

4 - Mounting steps

4.1 Display

Push the display into the cut-out (approx. 68 x 33

mm2) without panel clips.

Install panel clips on the display's housing and screw

until fixed.

4.2 Magnetic tape

See manual supply with the magnetic tape.

4.3 Sensor mounting

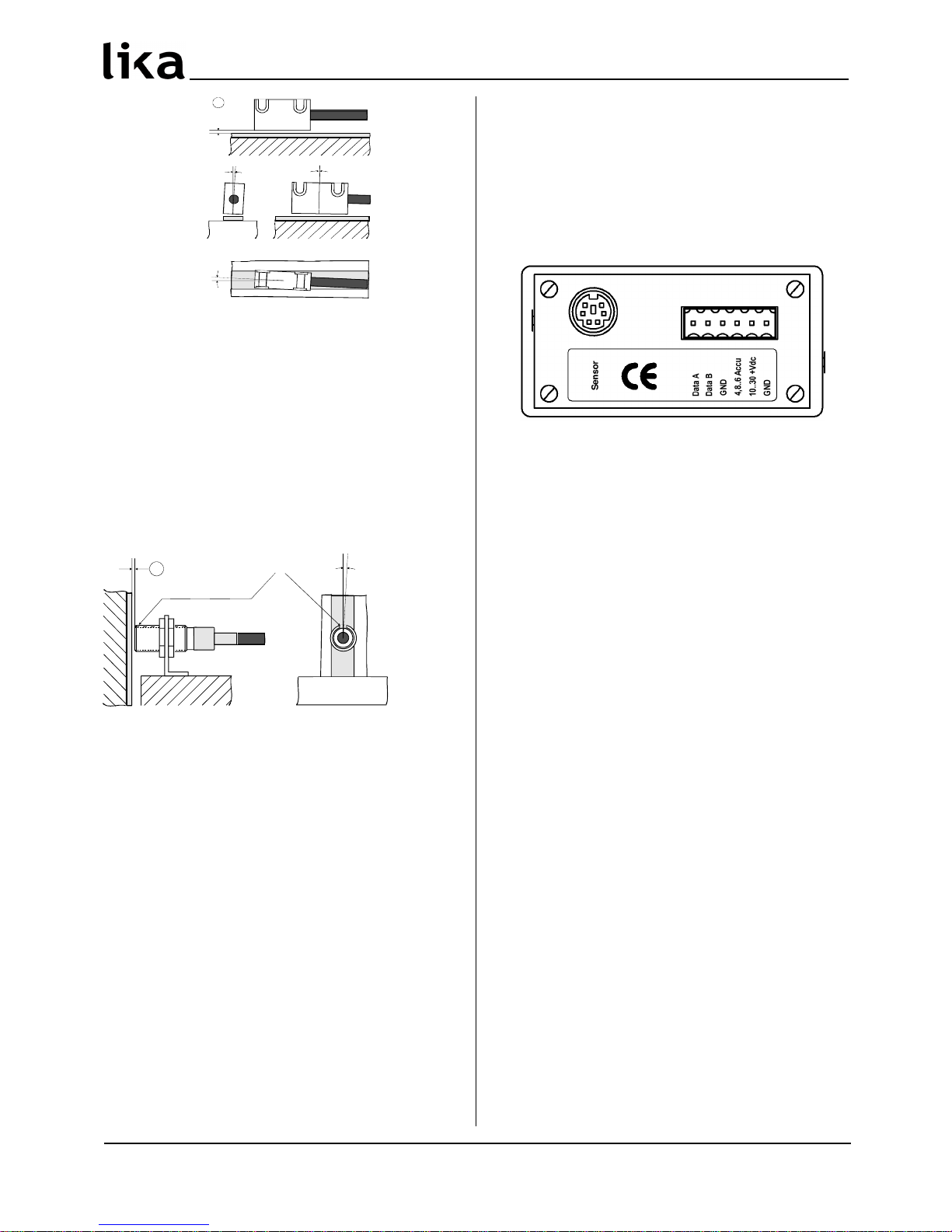

4.3.1 Sensor type SM5-R (rectangular)

Sensor can be fixed by means of two M3 screws

over the buttonholes. Make sure that the gap

between sensor and tape is in respect with (fig. 1)

along the total measuring length. Avoid contact

between the parts. You can check planarity and

parallelism between sensor and magnetic tape using

a feeler gauge.

MAN LD120 I_E 1.5 Pag. 9 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 2

LD120

figure 1

D = 0,1 mm - 2,1 mm

4.3.2 Sensor type SM5-C (circular)

The sensor can be fixed in a corresponding

mounting hole by means of the two nuts. Make sure

that the gap between sensor and tape is in respect

with (fig. 2) along the total measuring length.

Observe the correct alignment of the marker on the

tape. Avoid contact between the parts. You can

check planarity and parallelism between sensor and

magnetic tape using a feeler gauge.

figure 2

D = 0,1 mm - 2,1 mm

5 - Electrical connections

5.1 SM5 sensor

Plug in the sensor's Mini-DIN connector (circular) on

backside of the display.

5.2 Display

Make the clamp connections as follow:

Serial interface is option.

The ACCU input can supply the device in stand-by

mode with a low consumption. In this way the LED’s

are deactivate while the electronics count and the

sensor remain active.

NOTE:

This device is to be supplied by a Class 2 Circuit or

Low-Voltage Limited Energy or Energy Source not

exceeding 30Vdc.

MAN LD120 I_E 1.5 Pag. 10 www.lika.it

www.lika.biz

D

< 1 °

< 3 ° < 3 °

<3°

D

Marker

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 3

LD120

6 - Setup

6.1 Key's function

: UP (select value)

: Shift links (select digit)

* : Save (save data)

P : Program (programming/change parameter)

6.2 Key combinations / Quick functions

6.2.1 Set datum (reference)

Push * key for 3 s to set actual value to datum

value.

Datum value is = rEF + OFS1 + OFSx (where OFSx is

the actually set Offset value).

This function is enabled only if “F_rSt” parameter is

set “on”.

6.2.2 Incremental measurement

Push P and * key simultaneously to switch from

absolute measurement to incremental.

In incremental mode the decimal point flashes.

Zero setting in incremental mode (see 6.2.1) does

not change absolute value in the background.

6.2.3 Mm/inch display modes

Mm/ich display modus can be changed by pushing

key for 3 s.

6.2.4 Offset value modification

Push P and keys simultaneously to display Offset

1 value (OFS1). Use and keys to change value

and save with * key. Further Offset values OFS2 and

OFS3 can be changed only in setup menu.

This function is enable only if “F_oFS” parameter is

set “on”.

key allows to scroll OFS1, OFS2 and OFS3 values.

OFS1 = actual value + OFS1 + rEF

OFS2 = actual value + OFS1 + OFS2 + rEF

OFS3 = actual value + OFS1 + OFS3 + rEF

6.2.5 Datum modification

Push P and keys simultaneously to display datum

value rEF. Use and keys to change value and

save with * key.

This function is enabled only if “F_rEF” parameter is

set “on”.

6.3 Setup / Parameter setting

Push P key for 3 s to enter setup and “SEtUP” is

displayed.

Push key to enter Menu 1 (parameters)

Push * key to enter Menu 2 (RS485 serial I/F)

Push P key to access the next Parameter and

Parameter setting.

Push P key for 3 s to exit the setup at any point.

6.3.1 Default parameters (factory settings)

Default parameter values are written in BOLD

characters. The unit can be reset to default values by

pushing * key while switching on.

6.3.2 Menu 1: Parameters

rES Resolution [10, 50, 100, 1000, InCH, FrEE]

Linear resolution value expressed in µm (microns).

10 = 0,01 mm

50 = 0,05 mm

100 = 0,1 mm

1000 = 1 mm

InCH = sets display mode and measurement unit to

inch (with 3 decimals, e.g. 1.000).

FrEE = allows to input a free resolution factor e.g.

for angle displays (basis of calculation is max.

resolution 0,01 mm).

* = save, P = next parameter, P for 3 s. = exit

FrEE [0.0001, 1.0000]

Only if rES = FrEE.

E.g. angle display with range from 0° to 90° and 0,1°

resolution on a rotating table with circumference of

785,4 mm. Total working range is 785,4 mm : 4 =

196.35 mm.

FrEE = 900 : 19635 = 0,0458

Default value = 0.0001

* = save, P = next parameter, P for 3 s. = exit

dEC Decimal point [0, 1, 2, 3]

Only if rES = FrEE.

Modification of decimal point position.

0 = no decimal point

1 = one decimal (e.g. 1,0)

2 = two decimals (e.g. 1,00)

3 = three decimals (e.g. 1,000)

* = save, P = next parameter, P for 3 s. = exit

MAN LD120 I_E 1.5 Pag. 11 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 4

LD120

dir Counting direction [uP, dn]

uP = up (standard direction)

dn = down (inverted direction)

* = save, P = next parameter, P for 3 s. = exit

F_rEL Incremental measurement function [on, oFF]

Enables incremental measurement function (by

pushing P and * keys).

on = function on

oFF = function off

* = save, P = next parameter, P for 3 s. = exit

F_rSt Datum function [on, oFF]

Enables datum function (by pushing * key).

on = function on

oFF = function off

* = save, P = next parameter, P for 3 s. = exit

F_oFS Offset function [on, oFF]

Enables offset function (by pushing P and keys).

on = function on

oFF = function off

* = save, P = next parameter, P for 3 s. = exit

rEF Datum value [-99999, 99999]

Absolute reference value for the measuring system.

This value is displayed by pushing * key for 3 s.

(displayed value includes previously set offset

values).

Default value = 0

* = save, P = next parameter, P for 3 s. = exit

OFS1 Offset1 value (-99999, 99999)

First offset value (e.g. tool correction). This value is

added to actual value (see 6.2.3.)

Default value = 0

* = save, P = next parameter, P for 3 s. = exit

OFS2 Offset2 value [-99999, 99999]

Second Offset value. This value is added to actual

value and OFS1.

Default value = 0

* = save, P = next parameter, P for 3 s. = exit

OFS3 Offset3 value [-99999, 99999]

Third Offset value. This value is added to actual

value and OFS1.

Default value = 0

* = save, P = next parameter, P for 3 s. = exit

NOTE:

To set negative values, select sign digit with key

and change with key. If “-” sign flashes negative

value is selected, otherwise positive value is

selected. Push * key to save.

F_SAP Save actual value [on, oFF]

Saves the last displayed value after power off.

on = last value memory on

oFF = last value memory off

* = save, P = next parameter, P for 3 s. = exit

When the setup is completed the display shows

"rESEt".

• Push P key to display rEF+OFS1+OFSx

• Push * key to reset the display.

• Push P key twice to quit the setup.

6.3.3 Menu 2: RS485

Ad xx Device address [00, 31]

Setting of device address (only if ordered with serial

interface (option I4).

Default value = 0

* = save, P = next parameter

H_cnt Hourmeter (1/10 h)

Elapsed time indication (display connected to power

supply). Resolution is 1/10 hour (6 minutes).

= hourmeter reset, P = exit

MAN LD120 I_E 1.5 Pag. 12 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 5

LD120

7 - RS485 serial interface (option I4)

If the display is provided with RS485 serial interface,

the following commands can be used.

7.1 RS485 parameters

Baud rate = 9600

Data bits = 8

Parity bit = No

Stop bit = 1

Flow control = Xon/Xoff

7.2 Serial commands

Serial commands must have the following structure:

| A DC M ND = X

where :

| : PC keyboard symbol

AD : device address (00 to 31) 2 digit

CMND : command (see command list)

X : value range (see command list)

Upon receipt of a wrong command the display will

answer with the same command + ? and checksum

(e.g. sent command: |02azs → answer |02azs?EF)

Any common terminal program can be used for

communication with LD120 (e.g. Hyperterminal).

Command will be send after confirmation by ENTER

key (carriage return).

Answers are structured as follow:

ADCMND:SXXXXXCK

where:

AD : device address

CMND : command

XXXXX : value

CK : checksum

The checksum is equal to the least significant byte

of the summing the hex values of all characters

transmitted.

Example:

The displayed position is 8,29. The position of device

with address 01 is read by means of the |01TPOS

command.

The answer is: 01TPOS:+008290F

The sum of hex values of all characters is the

following: 30+31+54+50+4F+53+3A+2B+30+30+

38+ 32+39 = 30F

The least significant byte of 30F is 0F which is the

checksum.

7.2.1 Command list

(below the device address is indicated with AD)

Zeroing of device address

|00RSET

Device address is set to value 0.

Device address [1, 31]

|00INIT=X

Sets device address to value X.

Display device address

|00DADR

Displays device address until P key is pushed.

Change device address [1, 31]

|ADRADR=X

Changes actual device address AD to X.

Answer: ADRADR:+XCHKS (CHKS is checksum and X

is value).

Read actual position

|ADTPOS

Reads actual position of device AD (resolution is

0,01mm).

Change counting direction [0, 1]

|ADRDIR=X

Sets counting direction.

X=0 → uP = standard direction

X=1→ dn = inverted direction

Answer: ADRDIR:+00000XCHKS

Read counting direction

|ADTDIR

Reads the actual counting direction.

X=0→uP , X=1→dn

Answer: ADTDIR:+0000XCHKS

MAN LD120 I_E 1.5 Pag. 13 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 6

LD120

Decimal point [0, 3]

|ADRDEC=X

Modification of decimal point position.

0 = no decimal point

1 = one decimal (e.g. 1,0)

2 = two decimals (e.g. 1,00)

3 = three decimals (e.g. 1,000)

Answer: ADRDEC:+0000XCHKS

ATTENTION: decimal point setting has no influence

on mm/inch display mode (see command |

ADRMMI=0).

Read decimal point position

|ADTDEC

Reads value of actual decimal point position.

X=0→ 0, X=1→ 1, X=2→ 2, X=3→ 3

Answer: ADTDEC:+0000XCHKS

Display mm/inch [0, 1]

|ADRMMI=X

Sets mm or inch display mode.

X=0→ mm

X=1→ inch

Answer: ADRMMI:+0000XCHKS

Read mm/inch display mode

|ADTMMI

Reads value of actual display mode.

X=0→ mm, X=1→ inch

Answer: ADTMMI:+0000XCHKS

Incremental measurement function [0, 1]

Enables incremental measurement function (key

combination P and *).

|ADRRLA=X

X=0→ oFF (function off)

X=1→ on (function on)

Answer: ADRRAE:+0000XCHKS

Read incremental measurement

|ADTRAE

Reads status of incremental measurement function.

X=0→ oFF, X=1→ on

Answer: ADTRAE:+0000XCHKS

Incremental measurement [0, 1]

Sets from absolute display mode to incremental

(relative).

|ADRRLA=X

X=0→ oFF

X=1→ on

Answer: ADRRAE:+0000XCHKS

Read incremental measurement

|ADTRLA

Reads status of absolute/incremental display mode.

X=0→ oFF, X=1→ on

Answer: ADTRLA:+0000XCHKS

Datum function [0, 1]

|ADRRSE=X

Enables datum function (by pushing * key).

X=0→ oFF (function off)

X=1→ on (function on)

Answer: ADRRSE:+0000XCHKS

Read datum function

|ADTRSE

Reads status of datum function.

X=0→ oFF, X=1→ on

Answer: ADTRSE:+0000XCHKS

Datum value modification [0, 1]

|ADRRFE=X

Enables datum value modification (by key

combination P and ).

X=0→ oFF (not enables)

X=1→ on (enabled)

Answer: ADRRFE:+0000XCHKS

Read datum value modification

|ADTRFE

Reads status of datum value modification.

X=0→ oFF, X=1→ on

Answer: ADTRFE:+0000XCHKS

Offset function [0, 1]

|ADROFE=X

Enables offset function (by key combination P and

)

X=0→ oFF (function off)

X=1→ on (function on)

Answer: ADROFE:+0000XCHKS

MAN LD120 I_E 1.5 Pag. 14 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 7

LD120

Read offset function

|ADTOFE

Reads status of offset function.

X=0→ oFF, X=1→ on

Answer: ADTOFE:+0000XCHKS

Resolution [10, 50, 100, 1000]

|ADRRES=X

Sets linear resolution.

X=10→ 0,01 mm

X=50→ 0,05 mm

X=100→ 0,1 mm

X=1000→ 1 mm

Answer: ADRRES:+XCHKS

Read resolution

|ADTRES

Reads value of actual resolution.

X=10→ 0,01 mm, X=50→ 0,05 mm,

X=100→ 0,1 mm, X=1000→ 1 mm

Answer: ADTRES:+XCHKS

Free resolution factor FrEE [0.0001, 1.0000]

|ADRFRE=X

Sets free resolution factor FrEE (see chapter 6.3.2).

Answer: ADRFRE:+XCHKS

Read FrEE factor

|ADTFRE

Reads value of actual FrEE factor.

Answer: ADTFRE:+X.XXXXCHKS

Datum value [-99999, 99999]

|ADRREF=X

Absolute reference value for the measurement

system. Resolution is 0,01.

Answer: ADRREF:XCHKS

Read datum value

|ADTREF

Reads actual datum value.

Answer: ADTREF:XCHKS

Offset1 value [-99999, 99999]

|ADROF1=X

Sets Offset1 (OFSt1) value (resolution 0,01mm).

Answer: ADROF1:XCHKS

Read Offset1 value

|ADTOF1

Reads actual Offset1 value.

Answer: ADTOF1:XCHKS

Offset2 value [-99999, 99999]

|ADROF2=X

Sets Offset2 (OFSt2) value (resolution 0,01mm).

Answer: ADROF2:XCHKS

Read Offset2 value

|ADTOF2

Reads actual Offset2 value.

Answer: ADTOF2:XCHKS

Offset3 value [-99999, 99999]

|ADROF3=X

Sets Offset3 (OFSt3) value (resolution 0,01mm).

Answer: ADROF3:XCHKS

Read Offset3 value

|ADTOF3

Reads actual Offset3 value.

Answer: ADTOF3:XCHKS

Save actual value function [0, 1]

|ADRSPE=X

Saves the last displayed value after power off.

X=0→ oFF

X=1→ on

Answer: ADRSPE:+0000000XCHKS

Read save actual value function

|ADTSPE

Reads status of save actual value function.

X=0→ oFF, X=1→ on

Answer: ADTSPE:+0000000XCHKS

8 - Dimensional drawing and cut-out

8.1 Display Cut-out

Provide a 68 x 33 mm2 (w x h) cut-out.

8.2 SM5 sensor

Check details on product catalogue.

MAN LD120 I_E 1.5 Pag. 15 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Page 8

LD120

Rev. Man.Vers. Description

0 1.0 1^ issue

1.- SW + Manual update

5 1.5 Chap.6 correction

Lika Electronic

Via S. Lorenzo, 25 - 36010 Carrè (VI) - Italy

Tel. +39 0445 382814

Fax +39 0445 382797

Italy: eMail info@lika.it - www.lika.it

World: eMail info@lika.biz - www.lika.biz

MAN LD120 I_E 1.5 Pag. 16 www.lika.it

www.lika.biz

PH SYSTEMS - www.phsystems.be - sales@phsystems.be

Loading...

Loading...