Page 1

User's guide

ES58, ES58S

EM58, EM58S

ESC58/59/60

EMC58/59/60

Version RS-485

• Singleturn and multiturn absolute rotary encoder

• MODBUS RTU interface (RS-485) with programming software

• Resolution 4,096 cpr (ES58), 4,096 cpr x 16,384 revolutions (EM58)

• Diagnostic LEDs

• IP67 protection rate

Suitable for the following models:

• ES5812/MB-..., ES58S12/MB-...

• ESC5812/MB-..., ESC5912/MB-...,

ESC6012/MB-...

• EM5812/16384MB-..., EM58S12/16384MB-...

• EMC5812/16384MB-...,

EMC5912/16384MB-...,

EMC6012/16384MB-...

Table of Contents

Safety summary 12

Identification 14

Mechanical installation 15

Electrical connections 20

Quick reference 30

MODBUS® interface 50

Programming parameters 65

Programming examples 85

Lika Electronic • Tel. +39 0445 806600 • info@lika.biz • www.lika.biz

Smart encoders & actuators

Page 2

This publication was produced by Lika Electronic s.r.l. 2019. All rights reserved. Tutti i diritti riservati. Alle Rechte vorbehalten. Todos los

derechos reservados. Tous droits réservés.

This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in

part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies,

film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

The information herein is subject to change without notice and should not be construed as a commitment by Lika Electronic s.r.l. Lika

Electronic s.r.l. reserves the right to make all modifications at any moments and without forewarning.

This manual is periodically reviewed and revised. As required we suggest checking if a new or updated edition of this document is

available at Lika Electronic s.r.l.'s website. Lika Electronic s.r.l. assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation, in order

to make it as clear and complete as possible. Please send an e-mail to the following address info@lika.it for submitting your

comments, suggestions and criticisms.

Page 3

General contents

User's guide......................................................................................................................................................... 1

General contents............................................................................................................................................. 3

Subject Index................................................................................................................................................... 6

Typographic and iconographic conventions..............................................................................................7

Preliminary information................................................................................................................................ 8

Glossary of MODBUS terms.......................................................................................................................... 9

1 Safety summary.................................................................................................................................. 12

1.1 Safety..............................................................................................................................................................................12

1.2 Electrical safety..........................................................................................................................................................12

1.3 Mechanical safety.....................................................................................................................................................13

2 Identification....................................................................................................................................... 14

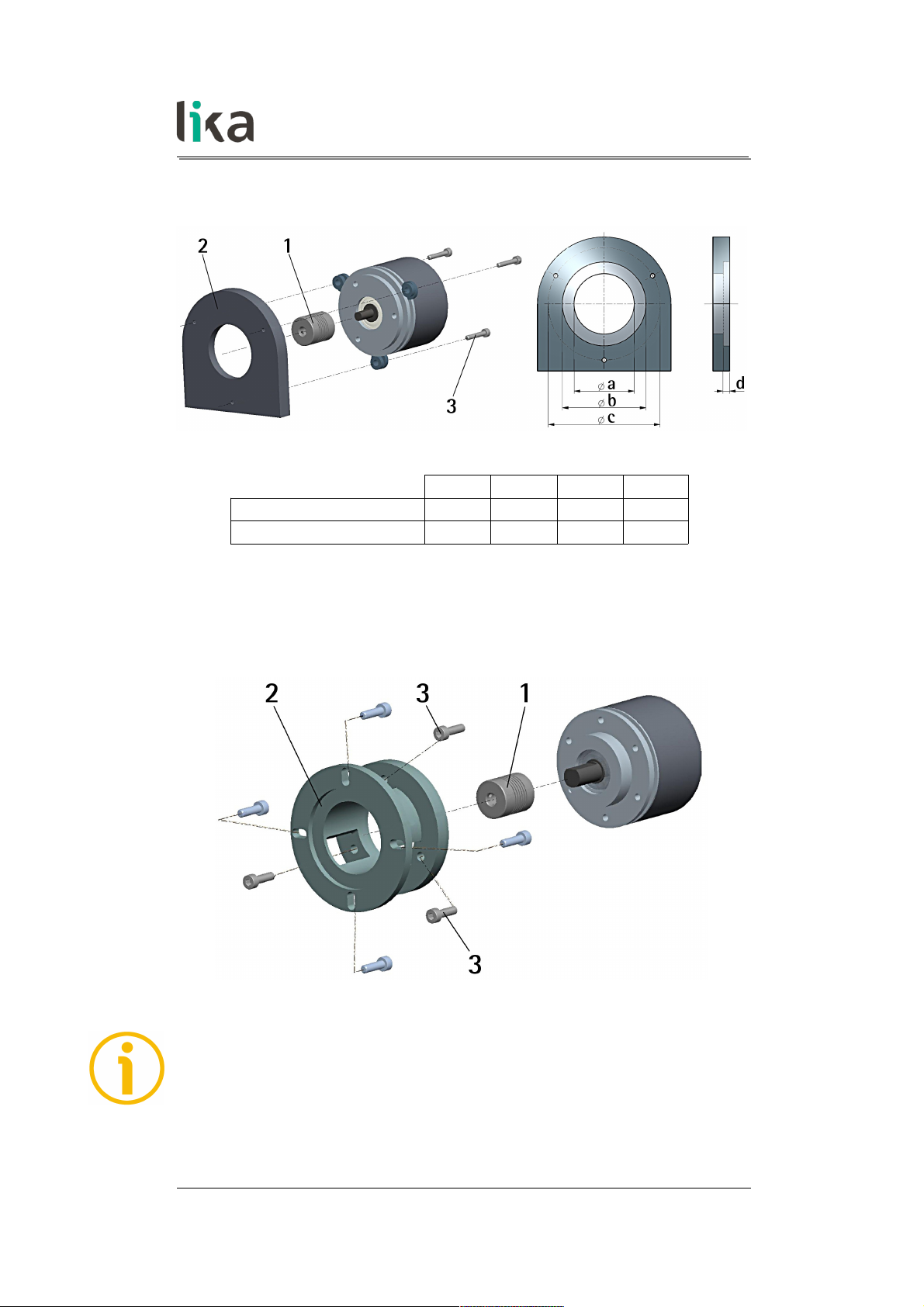

3 Mechanical installation..................................................................................................................... 15

3.1 Solid shaft encoders (ES58, ES58S, EM58, EM58S).....................................................................................15

3.1.1 Customary installation................................................................................................................................15

3.1.2 Installation using fixing clamps (code LKM-386)............................................................................16

3.1.3 Installation using a mounting bell (code PF4256)..........................................................................16

3.2 Hollow shaft encoders (ESC58, EMC58, ESC59, EMC59, ESC60, EMC60)..........................................17

3.2.1 ESC58, EMC58.................................................................................................................................................17

3.2.2 ESC59, EMC59.................................................................................................................................................18

3.2.3 ESC60, EMC60.................................................................................................................................................19

4 Electrical connections........................................................................................................................ 20

4.1 CB cable.........................................................................................................................................................................20

4.1.1 CB cable specifications................................................................................................................................20

4.2 M12 5-pin connector...............................................................................................................................................21

4.3 Ground connection...................................................................................................................................................21

4.4 Diagnostic LEDs (Figure 1).....................................................................................................................................22

4.5 DIP switches (Figure 2 and Figure 3).................................................................................................................25

4.5.1 Setting data transmission rate: Baud rate and Parity bit (Figure 3)........................................26

4.5.2 Setting the node address (Figure 3)......................................................................................................27

4.5.3 Termination resistor (Figure 3).................................................................................................................29

5 Quick reference................................................................................................................................... 30

5.1 Getting started...........................................................................................................................................................30

5.2 Configuring the encoder using the software tool by Lika Electronic.................................................31

5.3 Main page of the interface...................................................................................................................................32

5.3.1 Configuring the serial port – Connection to the encoder...........................................................33

Read Params.......................................................................................................................................................35

Write Holding....................................................................................................................................................35

5.3.2 Reading the Input Registers.....................................................................................................................36

Continuous reading.......................................................................................................................................37

Current position...............................................................................................................................................37

Angle.......................................................................................................................................................................37

Counts....................................................................................................................................................................37

Turns.......................................................................................................................................................................37

Baud rate dip switch.....................................................................................................................................37

Address dip switch.........................................................................................................................................38

Page 4

SW version...........................................................................................................................................................38

HW version..........................................................................................................................................................38

Status word.........................................................................................................................................................38

Alarm register....................................................................................................................................................38

Machine data not valid................................................................................................................................38

5.3.3 Reading the exception responses – Exception error......................................................................39

Exception error.................................................................................................................................................39

5.3.4 Reading / writing the Holding Registers.............................................................................................40

Counts per rev...................................................................................................................................................41

Total resolution.................................................................................................................................................41

Preset value.........................................................................................................................................................41

Offset value.........................................................................................................................................................41

Node address......................................................................................................................................................41

Baud rate..............................................................................................................................................................42

Operating parameters...................................................................................................................................42

Enable scaling function...............................................................................................................................42

Change counting dir.....................................................................................................................................42

Control word......................................................................................................................................................42

Enable watchdog...........................................................................................................................................42

Execute preset.................................................................................................................................................43

Upload defaults..............................................................................................................................................43

Auto save..............................................................................................................................................................44

Save parameters.............................................................................................................................................44

5.4 Update FW page - Firmware upgrade..............................................................................................................45

5.4.1 Information on firmware upgrade.........................................................................................................45

5.4.2 Preliminary operations and connections.............................................................................................46

5.4.3 Launching the firmware upgrade process..........................................................................................46

5.5 Manual frame page – Transmitting PDUs manually..................................................................................48

6 MODBUS® interface........................................................................................................................... 50

6.1 MODBUS Master / Slaves protocol principle.................................................................................................50

6.2 MODBUS frame description..................................................................................................................................51

6.3 Transmission modes.................................................................................................................................................52

6.3.1 RTU transmission mode..............................................................................................................................53

6.4 Function codes............................................................................................................................................................55

6.4.1 Implemented function codes...................................................................................................................55

03 Read Holding Registers........................................................................................................................55

04 Read Input Register................................................................................................................................57

06 Write Single Register.............................................................................................................................59

16 Write Multiple Registers......................................................................................................................61

7 Programming parameters................................................................................................................. 65

7.1 Parameters available................................................................................................................................................65

7.1.1 Machine data parameters (Holding registers)...................................................................................65

Custom counts per revolution [0000-0001 hex]............................................................................65

Custom total resolution [0002-0003 hex].........................................................................................67

Preset value [0004-0005 hex]...................................................................................................................70

Offset value [0006-0007 hex]....................................................................................................................71

Operating parameters [0008 hex]...........................................................................................................72

Scaling function...............................................................................................................................................72

Code sequence..................................................................................................................................................73

Control Word [0009 hex]..............................................................................................................................73

Page 5

Watchdog enable............................................................................................................................................74

Save parameters...............................................................................................................................................74

Load default parameters.............................................................................................................................74

Perform counting preset.............................................................................................................................74

7.1.2 Input Register parameters.........................................................................................................................76

Alarms register [0000 hex]..........................................................................................................................76

Machine data not valid................................................................................................................................76

Flash memory error........................................................................................................................................76

Watchdog.............................................................................................................................................................76

Current position [0001-0002 hex]..........................................................................................................77

Register 4 [0003 hex]......................................................................................................................................77

Wrong parameters list [0004-0005 hex]............................................................................................77

DIP switch baud rate [0006 hex]..............................................................................................................78

DIP switch node ID [0007 hex]..................................................................................................................79

SW Version [0008 hex]...................................................................................................................................79

HW Version [0009 hex]..................................................................................................................................79

Status word [000A hex].................................................................................................................................80

Scaling...................................................................................................................................................................80

Counting direction..........................................................................................................................................80

Alarm......................................................................................................................................................................81

7.2 Exception response and codes.............................................................................................................................82

8 Programming examples..................................................................................................................... 85

8.1 Using the 03 Read Holding Registers function code.................................................................................85

8.2 Using the 04 Read Input Register function code........................................................................................86

8.3 Using the 06 Write Single Register function code.....................................................................................87

8.4 Using the 16 Write Multiple Registers function code...............................................................................88

9 Default parameters list...................................................................................................................... 89

9.1 List of the Holding Registers with default value.........................................................................................89

9.2 List of the Input Registers.....................................................................................................................................89

Page 6

Subject Index

A

Address dip switch...........................................................38

Alarm.....................................................................................81

Alarm register....................................................................38

Alarms register [0000 hex]...........................................76

Angle.....................................................................................37

Auto save.............................................................................44

B

Baud rate.............................................................................42

Baud rate dip switch.......................................................37

C

Change counting dir.......................................................42

Code sequence..................................................................73

Continuous reading.........................................................37

Control word......................................................................42

Control Word [0009 hex]..............................................73

Counting direction..........................................................80

Counts...................................................................................37

Counts per rev...................................................................41

Current position................................................................37

Current position [0001-0002 hex]............................77

Custom counts per revolution [0000-0001 hex]65

Custom total resolution [0002-0003 hex]............67

D

DIP switch baud rate [0006 hex]...............................78

DIP switch node ID [0007 hex]...................................79

E

Enable scaling function.................................................42

Enable watchdog..............................................................42

Exception error..................................................................39

Execute preset...................................................................43

F

Flash memory error.........................................................76

H

HW version..........................................................................38

HW Version [0009 hex]..................................................79

L

Load default parameters...............................................74

M

Machine data not valid..........................................38, 76

N

Node address......................................................................41

O

Offset value.........................................................................41

Offset value [0006-0007 hex].....................................71

Operating parameters....................................................42

Operating parameters [0008 hex].............................72

P

Perform counting preset...............................................74

Preset value.........................................................................41

Preset value [0004-0005 hex].....................................70

R

Read Params.......................................................................35

Register 4 [0003 hex].....................................................77

S

Save parameters........................................................44, 74

Scaling..................................................................................80

Scaling function...............................................................72

Status word........................................................................38

Status word [000A hex].................................................80

SW version..........................................................................38

SW Version [0008 hex]...................................................79

T

Total resolution.................................................................41

Turns......................................................................................37

U

Upload defaults.................................................................43

W

Watchdog............................................................................76

Watchdog enable.............................................................74

Write Holding....................................................................35

Wrong parameters list [0004-0005 hex]................77

Page 7

Typographic and iconographic conventions

In this guide, to make it easier to understand and read the text the following typographic and

iconographic conventions are used:

• parameters and objects both of Lika device and interface are coloured in GREEN;

• alarms are coloured in RED;

• states are coloured in FUCSIA.

When scrolling through the text some icons can be found on the side of the page: they are expressly

designed to highlight the parts of the text which are of great interest and significance for the user.

Sometimes they are used to warn against dangers or potential sources of danger arising from the use of

the device. You are advised to follow strictly the instructions given in this guide in order to guarantee the

safety of the user and ensure the performance of the device. In this guide the following symbols are

used:

This icon, followed by the word WARNING, is meant to highlight the parts of the

text where information of great significance for the user can be found: user must

pay the greatest attention to them! Instructions must be followed strictly in order

to guarantee the safety of the user and a correct use of the device. Failure to heed

a warning or comply with instructions could lead to personal injury and/or damage

to the unit or other equipment.

This icon, followed by the word NOTE, is meant to highlight the parts of the text

where important notes needful for a correct and reliable use of the device can be

found. User must pay attention to them! Failure to comply with instructions could

cause the equipment to be set wrongly: hence a faulty and improper working of

the device could be the consequence.

This icon is meant to highlight the parts of the text where suggestions useful for

making it easier to set the device and optimize performance and reliability can be

found. Sometimes this symbol is followed by the word EXAMPLE when instructions

for setting parameters are accompanied by examples to clarify the explanation.

Page 8

Preliminary information

This guide is designed to provide the most complete information the operator needs to correctly and

safely install and operate the ES58 series singleturn and EM58 series multiturn absolute encoders

equipped with MODBUS interface.

They are:

• ES5812/MB-...

• ES58S12/MB-...

• ESC5812/MB-...

• ESC5912/MB-...

• ESC6012/MB-...

• EM5812/16384MB-...

• EM58S12/16384MB-...

• EMC5812/16384MB-...

• EMC5912/16384MB-...

• EMC6012/16384MB-...

For technical specifications please refer to the product datasheet.

To make it easier to read the text, this guide can be divided into two main sections.

In the first section general information concerning the safety, the mechanical installation and the

electrical connection as well as tips for setting up and running properly and efficiently the device are

provided.

In the second section, entitled MODBUS Interface, both general and specific information is given on the

MODBUS interface. In this section the interface features and the registers implemented in the unit are

fully described.

In the “Quick reference” section on page 30 the software tool designed by Lika Electronic to easily

configure the encoder via RS-485 serial port is fully described.

Page 9

Glossary of MODBUS terms

MODBUS, like many other networking systems, has a set of unique terminology. Table below contains a

few of the technical terms used in this guide to describe the MODBUS interface. They are listed in

alphabetical order.

Address field

It contains the Slave address.

Application Process

The Application Process is the task on the Application Layer.

Application protocol

MODBUS is an application protocol or messaging structure

that defines rules for organizing and interpreting data

independent of the data transmission medium.

ASCII transmission mode

When devices are setup to communicate on a MODBUS serial

line using ASCII (American Standard Code for Information

Interchange) mode, each 8–bit byte in a message is sent as

two ASCII characters. This mode is used when the physical

communication link or the capabilities of the device does not

allow the conformance with RTU mode requirements

regarding timers management.

Bus

A bus is a communication medium connecting several nodes.

Data can be transferred via serial or parallel circuits, that is, via

electrical conductors or fibre optic.

Client

A Client is any network device that sends data requests to

servers.

MODBUS follows the Client/Server model. MODBUS Masters

are referred to as Clients, while MODBUS Slaves are Servers.

Cyclic Redundancy Check

(CRC)

Error-checking technique in which the frame recipient

calculates a remainder by dividing frame contents by a prime

binary divisor and compares the calculated remainder to a

value stored in the frame by the sending node.

Data encoding

MODBUS uses a ‘big-Endian’ representation for addresses and

data items. This means that when a numerical quantity larger

than a single byte is transmitted, the most significant byte is

sent first.

Exception code

Code to be returned by Slaves in the event of problems. All

exceptions are signalled by adding 0x80 to the function code

of the request.

Exception response

MODBUS operates according to the common client/server

(Master/Slave) model: the Client (Master) sends a request

telegram (service request) to the Server (Slave), and the Server

replies with a response telegram. If the Server cannot process

a request, it will instead return a error function code

(exception response) that is the original function code plus

80H (i.e. with its most significant bit set to 1).

Function code

MODBUS is a request/reply protocol and offers services

Page 10

specified by function codes. The function code is sent from a

Client to the Server and indicates which kind of action the

Server must perform. MODBUS function codes are elements of

MODBUS request/reply PDUs.

The function code field of a MODBUS data unit is coded in one

byte. Valid codes are in the range of 1 ... 255 decimal (the

range 128 – 255 is reserved and used for exception responses).

Function code "0" is not valid. Lika devices only implement

public function codes.

Holding register

In the MODBUS data model, a Holding register is the output

data. A Holding register has a 16-bit quantity, is alterable by

an application program, and allows either read-write or readonly access.

IEEE 1588

This standard defines a protocol enabling synchronisation of

clocks in distributed networked devices (e.g. connected via

Ethernet).

Input register

In the MODBUS data model, an Input register is the input

data. An Input register has a 16-bit quantity, is provided by an

I/O system, and allows read-only access.

LRC Checking

In ASCII mode, messages include an error–checking field that

is based on a Longitudinal Redundancy Checking (LRC)

calculation that is performed on the message contents,

exclusive of the beginning ‘colon’ and terminating CRLF pair

characters. It is applied regardless of any parity checking

method used for the individual characters of the message.

Master

A Master is any network device that sends data requests to

Slaves.

Message

The MODBUS messaging service provides a Client/Server

communication between devices connected on the network.

The Client / Server model is based on four types of messages:

• MODBUS Request

• MODBUS Confirmation

• MODBUS Indication

• MODBUS Response

The MODBUS messaging services are used for information

exchange.

MODBUS Confirmation

A MODBUS Confirmation is the Response Message received on

the Client side.

MODBUS Indication

A MODBUS Indication is the Request message received on the

Server side.

MODBUS Request

A MODBUS Request is the message sent on the network by the

Client to initiate a transaction.

MODBUS Response

A MODBUS Response is the Response message sent by the

Server.

Network

Network is a group of computers on a single physical network

segment.

Page 11

PDU

The Protocol Data Unit (PDU) is the MODBUS function code

and data field. It is packed together with the Address Field and

the CRC (or LRC) to form the Modbus Serial Line PDU.

The MODBUS protocol defines three PDUs. They are:

• MODBUS Request PDU, mb_req_pdu

• MODBUS Response PDU, mb_rsp_pdu

• MODBUS Exception Response PDU,

mb_excep_rsp_pdu

Read Holding Registers

(03, 0003hex)

This function code is used to READ the contents of a

contiguous block of holding registers in a remote device; in

other words, it allows to read the values set ina group of work

parameters placed in order.

Read Input Register (04,

0004hex)

This function code is used to READ from 1 to 125 contiguous

input registers in a remote device; in other words, it allows to

read some result values and state / alarm messages in a

remote device.

Register

MODBUS functions operate on memory registers to configure,

monitor, and control device I/O.

RTU transmission mode

Remote Terminal Unit. When devices communicate on a

MODBUS serial line using the RTU mode, each 8–bit byte in a

message contains two 4–bit hexadecimal characters. The main

advantage of this mode is that its greater character density

allows better data throughput than ASCII mode for the same

baud rate. Each message must be transmitted in a continuous

stream of characters.

Server

A Server is any program that awaits data requests to be sent

to it. Servers do no initiate contacts with Clients, but only

respond to them.

MODBUS follows the Client/Server model. MODBUS Masters

are referred to as clients, while MODBUS Slaves are servers.

Service request

It is the MODBUS Request, i.e. the message sent on the

network by the Client to initiate a transaction.

Slave

A Slave is any program that awaits data requests to be sent to

it. Slaves do no initiate contacts with Masters, but only

respond to them.

Transmission rate

Data transfer rate (in bps).

Write Multiple Registers

(16, 0010hex)

This function code is used to WRITE a block of contiguous

registers (1 to 123 registers) in a remote device.

Write Single Register (06,

0006hex)

This function code is used to WRITE a single holding register in

a remote device.

Page 12

ES58 • EM58 MODBUS®

1 Safety summary

1.1 Safety

• Always adhere to the professional safety and accident prevention

regulations applicable to your country during device installation and

operation;

• installation and maintenance operations have to be carried out by

qualified personnel only, with power supply disconnected and stationary

mechanical parts;

• device must be used only for the purpose appropriate to its design: use for

purposes other than those for which it has been designed could result in

serious personal and/or the environment damage;

• high current, voltage and moving mechanical parts can cause serious or

fatal injury;

• warning ! Do not use in explosive or flammable areas;

• failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture,

and intended use of the equipment;

• Lika Electronic assumes no liability for the customer's failure to comply

with these requirements.

1.2 Electrical safety

• Turn OFF the power supply before connecting the device;

• connect according to the explanation in the ”Electrical connections”

section on page 20;

• in compliance with 2014/30/EU norm on electromagnetic

compatibility, following precautions must be taken:

- before handling and installing the equipment, discharge

electrical charge from your body and tools which may come in touch

with the device;

- power supply must be stabilized without noise; install EMC filters on

device power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive

noise source; shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets

on or near by the unit;

MAN ESx58x_EMx58x MB E 1.2 Safety summary 12 of 92

Page 13

ES58 • EM58 MODBUS®

- minimize noise by connecting the shield and/or the connector housing

and/or the frame to ground. Make sure that ground is not affected by

noise. The connection point to ground can be situated both on the device

side and on user’s side. The best solution to minimize the interference

must be carried out by the user.

1.3 Mechanical safety

• Install the device following strictly the information in the “Mechanical

installation” section on page 15;

• mechanical installation has to be carried out with stationary mechanical

parts;

• do not disassemble the unit;

• do not tool the unit or its shaft;

• delicate electronic equipment: handle with care; do not subject the device

and the shaft to knocks or shocks;

• respect the environmental characteristics of the product;

• unit with solid shaft: in order to guarantee maximum reliability over time

of mechanical parts, we recommend a flexible coupling to be installed to

connect the encoder and user's shaft; make sure the misalignment

tolerances of the flexible coupling are respected;

• unit with hollow shaft: the encoder can be mounted directly on a shaft

whose diameter has to respect the technical characteristics specified in the

purchase order and clamped by means of the collar and, when requested,

the anti-rotation pin.

MAN ESx58x_EMx58x MB E 1.2 Safety summary 13 of 92

Page 14

ES58 • EM58 MODBUS®

2 Identification

The device can be identified through the order code and the serial number

printed on the label applied to its enclosure. Information is listed in the delivery

document too. Please always quote the order code and the serial number when

reaching Lika Electronic for purchasing spare parts or needing assistance. For

any information on the technical characteristics of the product refer to the

technical catalogue.

Warning: devices having order code ending with "/Sxxx" may have

mechanical and electrical characteristics different from standard and

be supplied with additional documentation for special connections

(Technical Info).

MAN ESx58x_EMx58x MB E 1.2 Identification 14 of 92

Page 15

ES58 • EM58 MODBUS®

3 Mechanical installation

WARNING

Installation and maintenance operations must be carried out by qualified

personnel only, with power supply disconnected. Shaft and mechanical

components must be in stop.

For any information on the mechanical data and the electrical characteristics of

the encoder please refer to the technical catalogue.

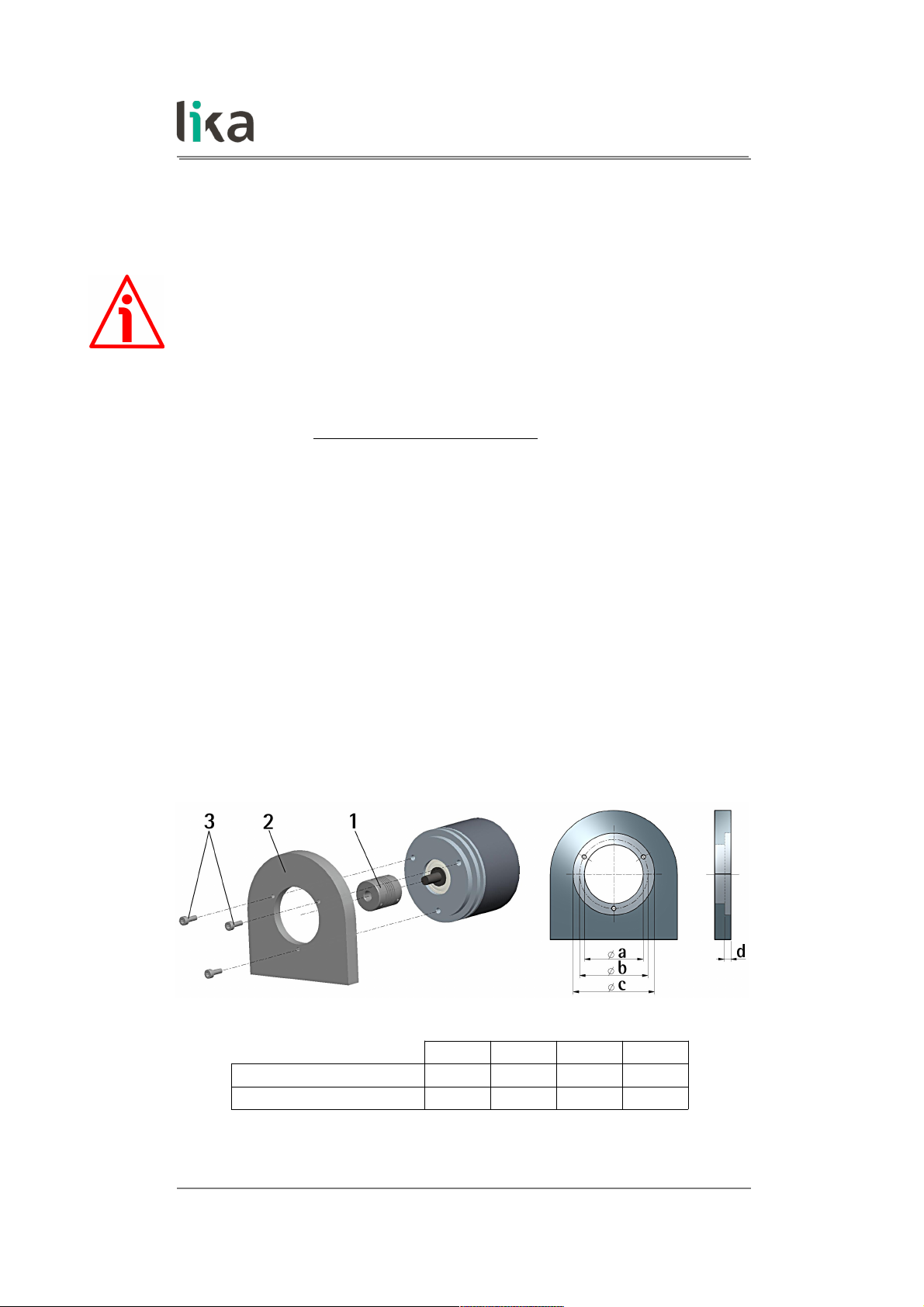

3.1 Solid shaft encoders (ES58, ES58S, EM58, EM58S)

• Mount the flexible coupling 1 on the encoder shaft;

• fix the encoder to the flange 2 (or to the mounting bell) by means of the

screws 3;

• secure the flange 2 to the support (or the mounting bell to the motor);

• mount the flexible coupling 1 on the motor shaft;

• make sure to comply with the misalignment tolerances of the flexible

coupling 1.

3.1.1 Customary installation

a [mm] b [mm] c [mm] d [mm]

ES58, EM58

- 42 50 F7 4

ES58S, EM58S

36 H7 48 - -

MAN ESx58x_EMx58x MB E 1.2 Mechanical installation 15 of 92

Page 16

ES58 • EM58 MODBUS®

3.1.2 Installation using fixing clamps (code LKM-386)

a [mm] b [mm] c [mm] d [mm]

ES58, EM58

- 50 F7 67 4

ES58S, EM58S

36 H7 - 67 -

3.1.3 Installation using a mounting bell (code PF4256) ES58S, EM58S

NOTE

In order to guarantee reliability over time of the encoder mechanical parts, we

recommend a flexible coupling to be installed between the encoder and the

motor shaft. Make sure to comply with the misalignment tolerances of the

flexible coupling.

MAN ESx58x_EMx58x MB E 1.2 Mechanical installation 16 of 92

Page 17

ES58 • EM58 MODBUS®

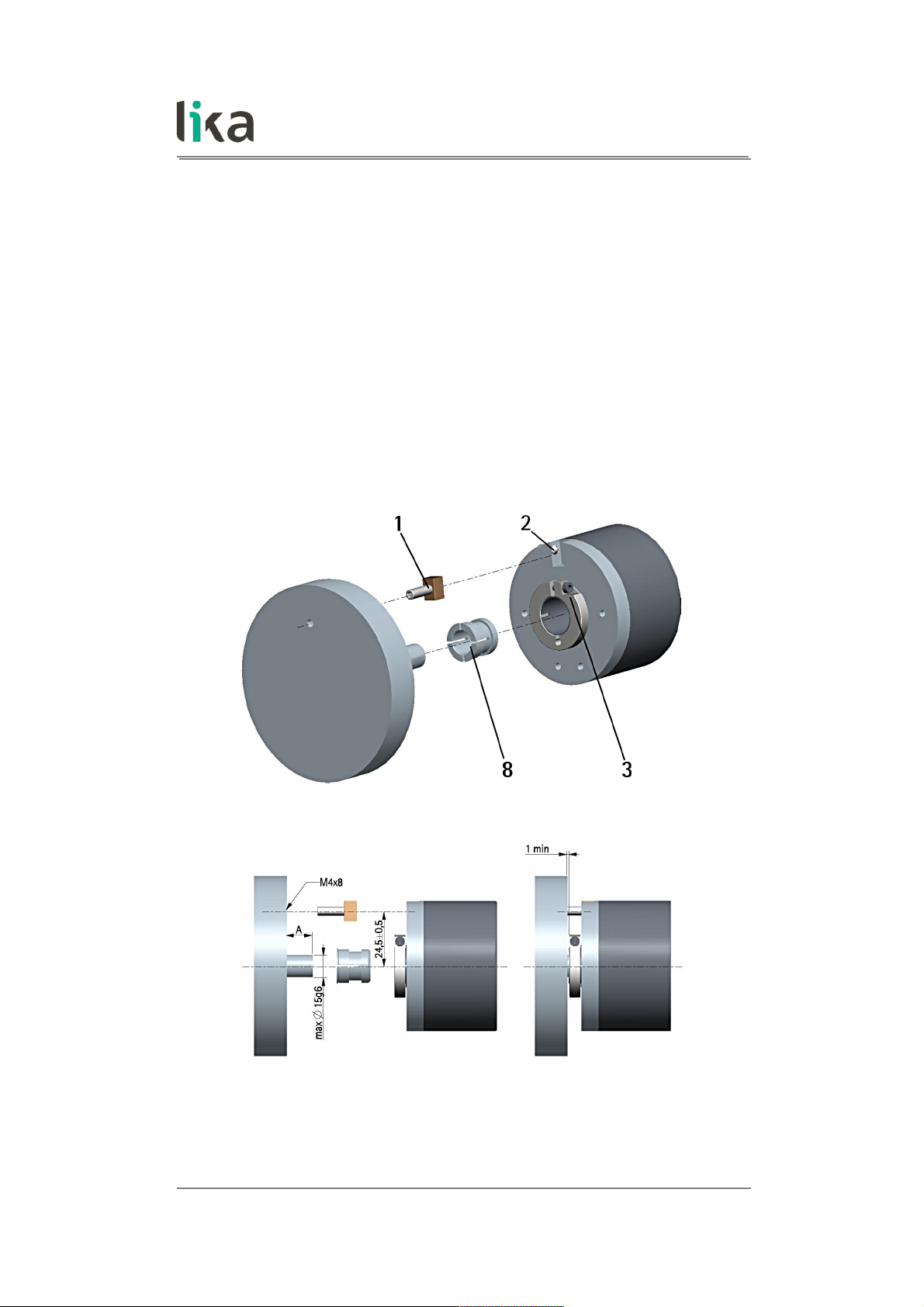

3.2 Hollow shaft encoders (ESC58, EMC58, ESC59, EMC59, ESC60, EMC60)

3.2.1 ESC58, EMC58

• Fasten the anti-rotation pin 1 to the rear of the motor (secure it using a

locknut);

• mount the encoder on the motor shaft using the reducing sleeve 8 (if

supplied). Avoid forcing the encoder shaft;

• insert the anti-rotation pin 1 into the slot on the flange of the encoder; this

secures it in place by grub screw 2, preset at Lika;

• fix the collar 3 to the encoder shaft (apply threadlocker to screw 3).

MAN ESx58x_EMx58x MB E 1.2 Mechanical installation 17 of 92

Page 18

ES58 • EM58 MODBUS®

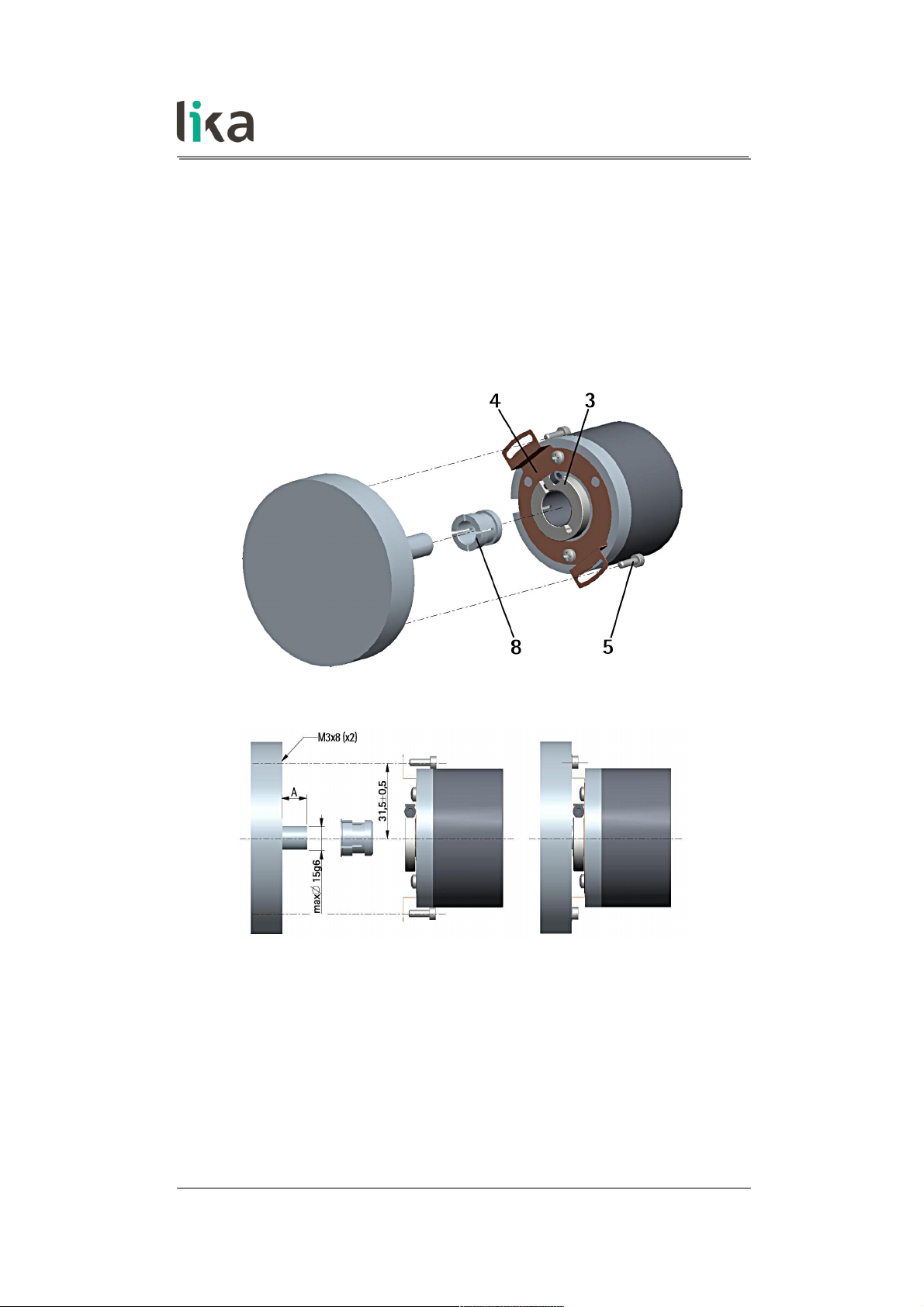

3.2.2 ESC59, EMC59

• Mount the encoder on the motor shaft using the reducing sleeve 8 (if

supplied). Avoid forcing the encoder shaft;

• fasten the fixing plate 4 to the rear of the motor using two M3 cylindrical

head screws 5;

• fix the collar 3 to the encoder shaft (apply threadlocker to screw 3).

MAN ESx58x_EMx58x MB E 1.2 Mechanical installation 18 of 92

Page 19

ES58 • EM58 MODBUS®

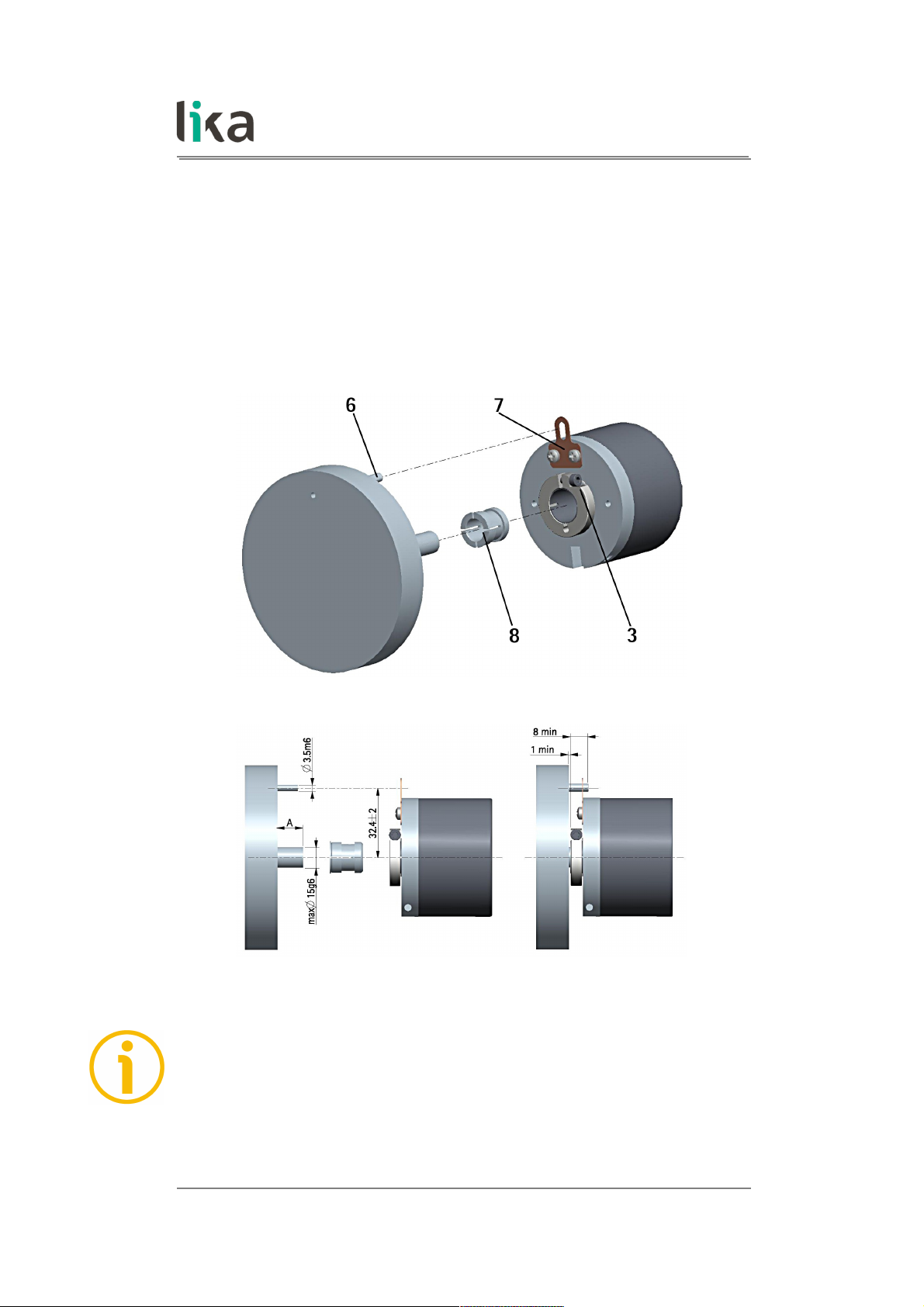

3.2.3 ESC60, EMC60

• Fix the tempered pin 6 to the rear of the motor;

• mount the encoder on the motor shaft using the reducing sleeve 8 (if

supplied). Avoid forcing the encoder shaft;

• make sure the anti-rotation pin 6 is inserted properly into the fixing plate 7;

• fix the collar 3 to the encoder shaft (apply threadlocker to screw 3).

NOTE

You are strongly advised not to carry out any mechanical operations (drilling,

milling, etc.) on the encoder shaft. This could cause serious damages to the

internal parts and an immediate warranty loss. Please contact our technical

personnel for the complete availability of "custom made" shafts.

MAN ESx58x_EMx58x MB E 1.2 Mechanical installation 19 of 92

Page 20

ES58 • EM58 MODBUS®

4 Electrical connections

WARNING

Electrical connections must be carried out by qualified personnel only, with

power supply disconnected. Shaft and mechanical components must be in stop.

For any information on the mechanical data and the electrical characteristics of

the encoder please refer to the technical catalogue.

4.1 CB cable

Colour Description

Red

+10Vdc +30Vdc

power supply voltage

Black

1

0Vdc

power supply voltage

White Modbus A (RS-485)

Blue Modbus B (RS-485)

1 0Vdc of the RS-485 serial connection too.

4.1.1 CB cable specifications

Model : LIKA CB type cable

Wires : 2 x 0.24 mm2 (24/19AWG) + 2 x 0.35 mm

2

(22/19AWG) pair cable

Jacket : PUR flame retardant and halogen free

Shield : tinned copper wire braid 65% nom. coverage

External diameter : 6.9 mm ±0.2 (0.272” ±0.008”)

Min. bend radius : external Ø x 6 (fixed); external Ø x 12 (dynamic)

Operating temperature : -40°C +80°C / -40°F +185°F (fixed); -30°C +70°C /

-22°F +158°F (dynamic)

Max. conductor resistance: 78.0 /km (24AWG) / 54.0 /km (22AWG)

Max. translation speed : 3.0 m/sec

Max. acceleration : 5.0 m/sec

2

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 20 of 92

Page 21

ES58 • EM58 MODBUS®

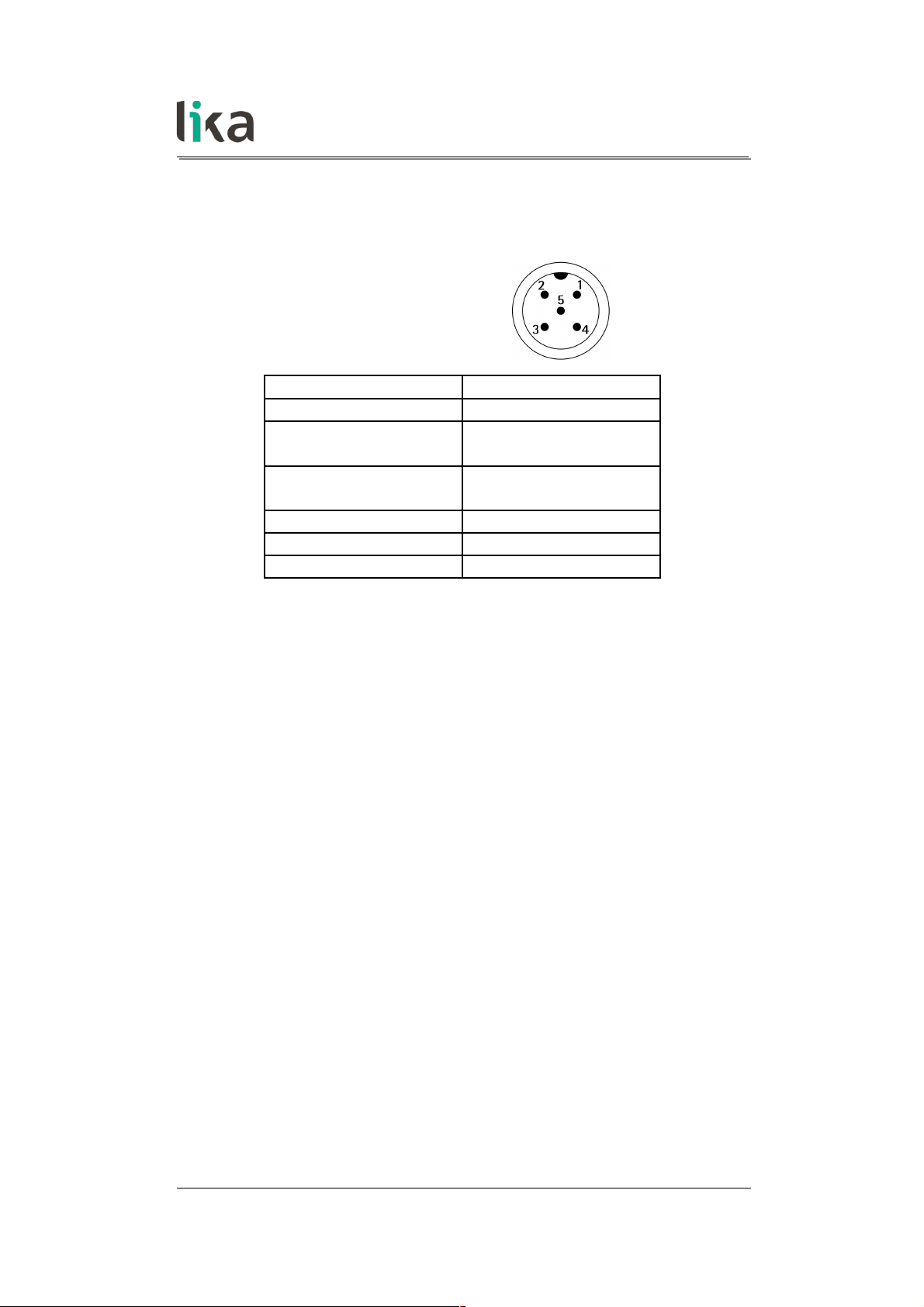

4.2 M12 5-pin connector

M12 5-pin

male connector

A coding

(frontal view)

Pin Description

1

1

Shielding

2

+10Vdc +30Vdc

power supply voltage

3

2

0Vdc

power supply voltage

4 Modbus A (RS-485)

5 Modbus B (RS-485)

Case

3

Shielding

1 Pin 1 is intended to allow the connection of the shield to

ground even if the plug connector has a plastic case.

2 OVdc of the RS-485 serial connection too.

3 Lika's EC- pre-assembled cables only

4.3 Ground connection

To minimize noise connect properly the shield and/or the connector housing

and/or the frame to ground. Connect properly the cable shield to ground on

user's side. Lika's EC- pre-assembled cables are fitted with shield connection to

the connector ring nut in order to allow grounding through the body of the

device. Lika's E- connectors have a plastic gland, thus grounding is not possible.

In the specific case pin 1 of M12 connector is specifically intended to allow the

connection of the shield to ground. If metal connectors are used, connect the

cable shield properly as recommended by the manufacturer. Anyway make sure

that ground is not affected by noise. It is recommended to provide the ground

connection as close as possible to the device.

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 21 of 92

Page 22

ES58 • EM58 MODBUS®

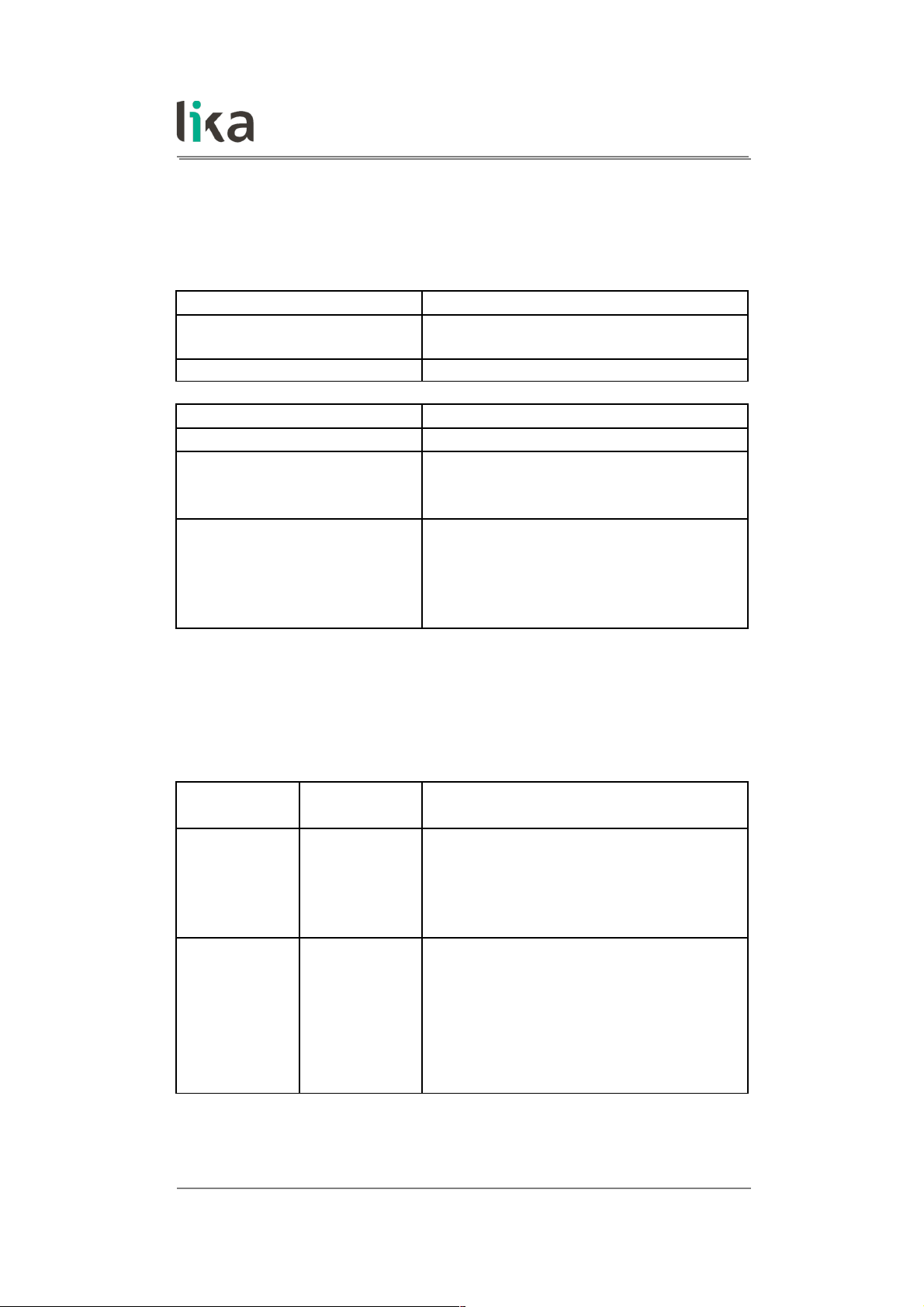

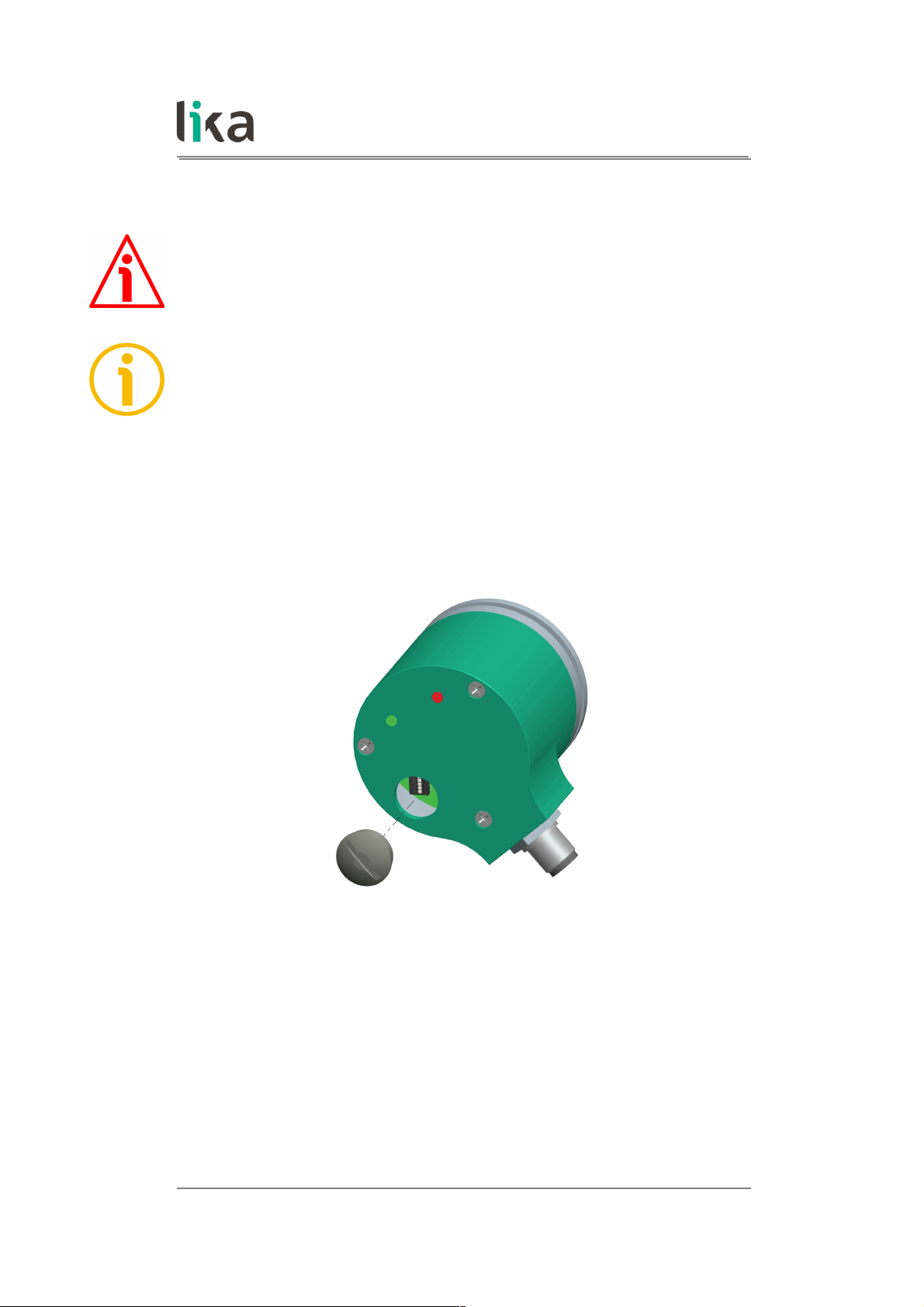

4.4 Diagnostic LEDs (Figure 1)

Figure 1: Diagnostic LEDs

Two bicoloured LEDs located in the rear side of the encoder (see the Figure here

above) are meant to show visually the operating or fault status of the MODBUS

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 22 of 92

Page 23

ES58 • EM58 MODBUS®

interface and the device as well. The meaning of each LED is explained in the

following table. In case of error, to know in detail which alarm has been

triggered, see the Alarms register [0000 hex] variable on page 76.

ACTIVITY LED Description

Blinking GREEN

Indicates the device is sending or receiving a

message.

OFF Indicates there is no send - receive activity.

STATUS/ERROR LED Description

ON GREEN

No active alarm.

Blinking RED

Indicates there are either active alarms or an

internal error. For further information refer to

Alarms register [0000 hex] on page 76.

ON RED

An hardware error has occurred which

prevents the unit from continuing to run.

Please turn the device off and then on again.

If the error is still on, please contact Lika

Electronic After Sales Service.

While performing the firmware upgrade operation (bootloading, refer to the “5.4

Update FW page - Firmware upgrade” section on page 45), the two LEDs operate

in a specific way, as explained in the following table.

ACTIVITY

LED

STATUS/ERROR

LED

Description

Blinking

GREEN at 5 Hz

with duty cycle

= 50%

Blinking

GREEN at 5 Hz

with duty cycle

= 50%

While downloading data to the flash memory

for upgrading the firmware of the unit (see

the “5.4 Update FW page - Firmware

upgrade” section on page 45), both LEDs blink

green at 5 Hz with duty cycle = 50%.

Blinking

RED at 2 Hz with

duty cycle =

50%

Blinking

RED at 2 Hz with

duty cycle =

50%

The operator has pressed the BOOT STATE

button in the Firmware Upgrade page, the

encoder is waiting for the firmware upgrade

operation to start (by pressing the

DOWNLOAD button). For any information

please refer to the “5.4 Update FW page -

Firmware upgrade” section on page 45.

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 23 of 92

Page 24

ES58 • EM58 MODBUS®

ACTIVITY

LED

STATUS/ERROR

LED

Description

Blinking

RED at 5 Hz with

duty cycle =

50%

Blinking

RED at 5 Hz with

duty cycle =

50%

While downloading data to the flash memory

for upgrading the firmware of the unit (see

the “5.4 Update FW page - Firmware

upgrade” section on page 45), if an error

occurs which stops the upgrading process

(for instance: a voltage drop and/or the

switching off of the unit), as soon as the

power is turned on again both LEDs start

blinking red at 5 Hz with duty cycle = 50% as

the user program is not installed in the flash

memory (it has been deleted previously). For

any information on restoring the unit please

refer to the “5.4 Update FW page - Firmware

upgrade” section on page 45.

ON

RED

ON

RED

While downloading data to the flash memory

for upgrading the firmware of the unit (see

the “5.4 Update FW page - Firmware

upgrade” section on page 45), if data

transmission is cut off (for instance, because

of the disconnection of the serial cable), after

5 seconds both LEDs come on solidly red. For

any information on restoring the unit please

refer to the “5.4 Update FW page - Firmware

upgrade” section on page 45.

OFF

ON GREEN

The firmware upgrade operation has been

carried out successfully, the encoder is

operating properly and no error is active. For

any information please refer to the “5.4

Update FW page - Firmware upgrade” section

on page 45.

During initialisation, system checks the diagnostic LEDs for proper operation;

therefore they blink for a while.

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 24 of 92

Page 25

ES58 • EM58 MODBUS®

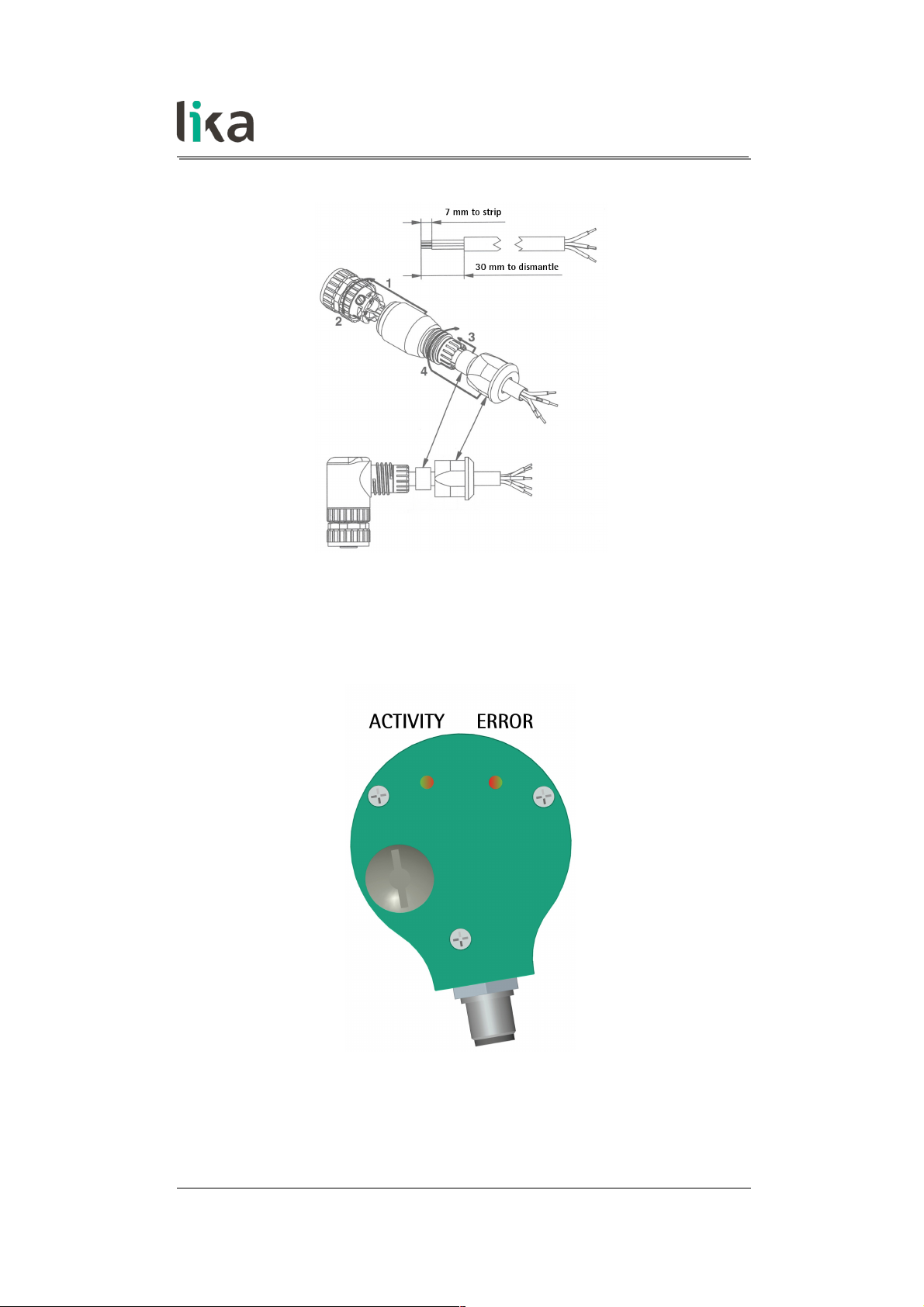

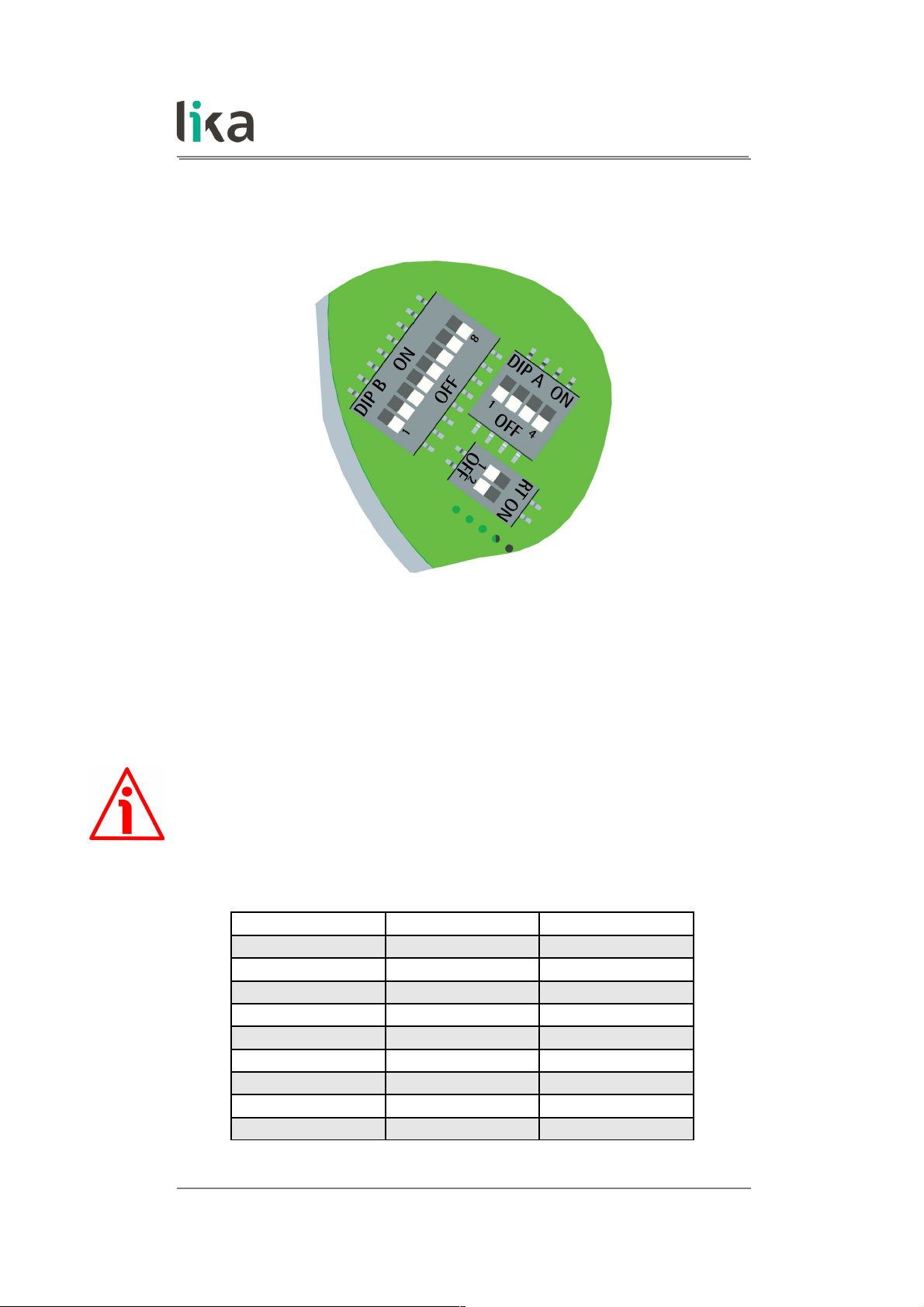

4.5 DIP switches (Figure 2 and Figure 3)

WARNING

Power supply must be turned off before performing this operation!

NOTE

When performing this operation be careful not to damage the internal

components and the connection wires.

To access the DIP switches loosen and remove the M12 metal screw plug in the

rear of the encoder. Be careful to replace the screw plug at the end of the

operation.

Figure 2: Reaching the DIP switches

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 25 of 92

Page 26

ES58 • EM58 MODBUS®

The DIP switches are located just beneath.

Figure 3: DIP switches

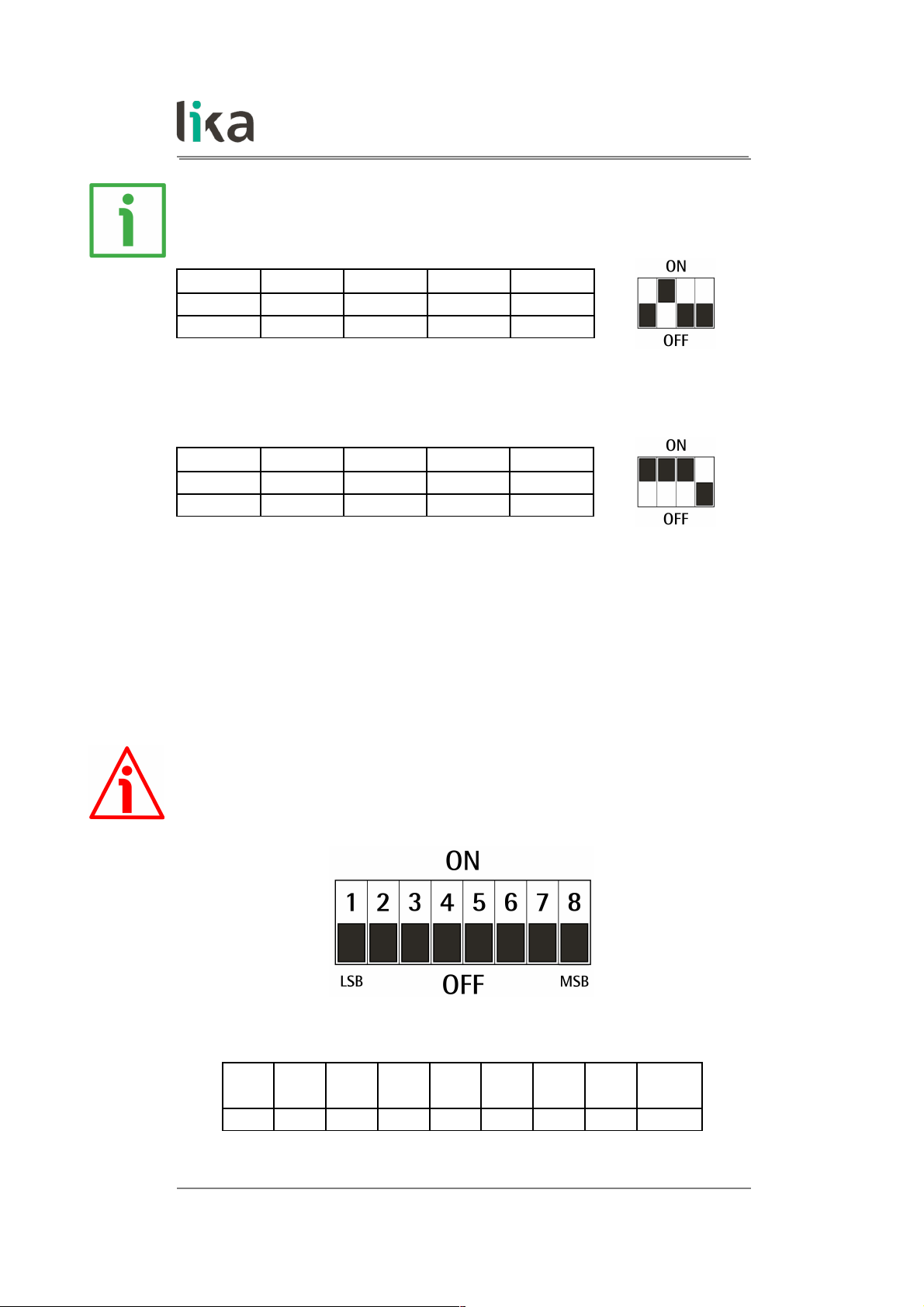

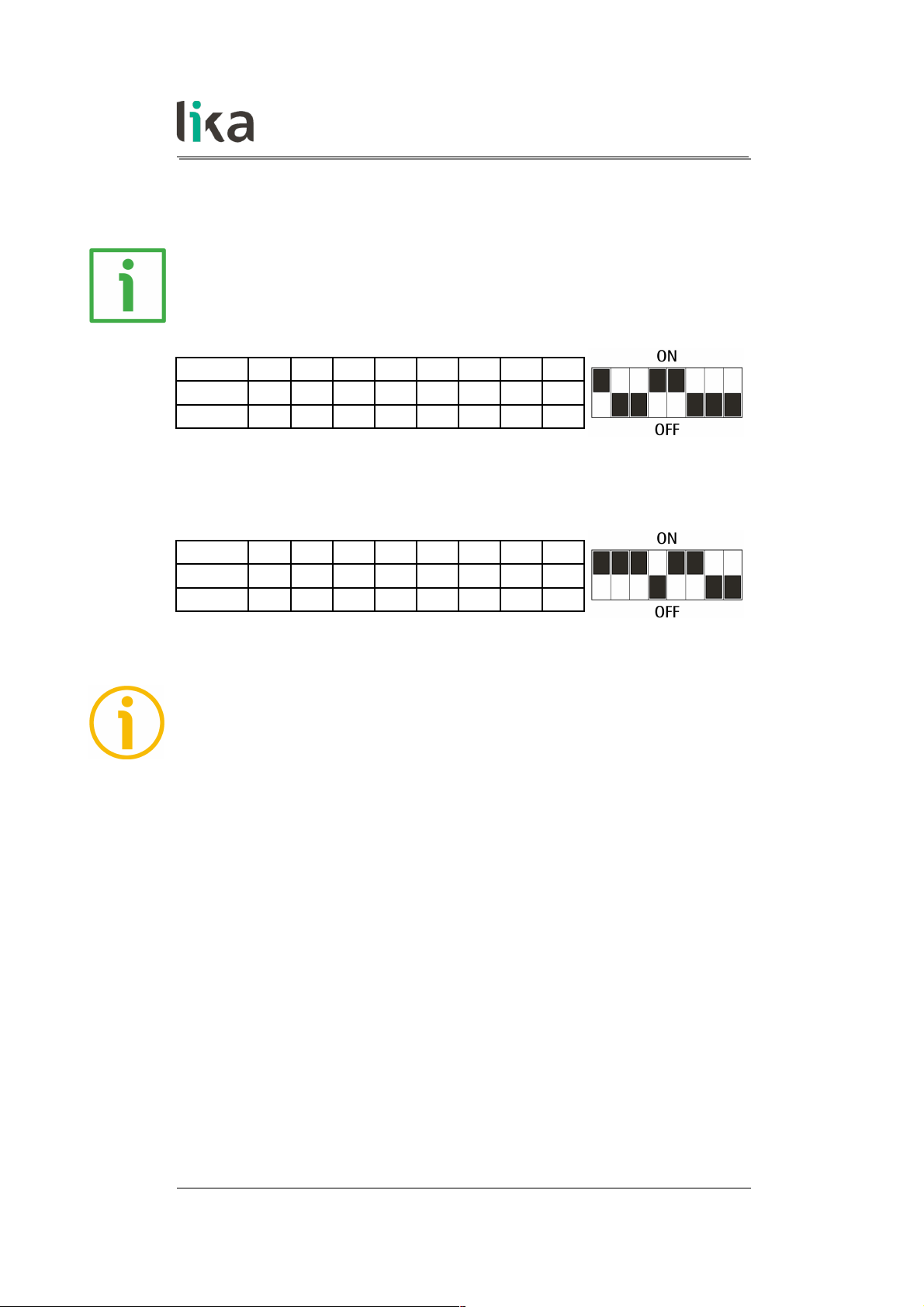

4.5.1 Setting data transmission rate: Baud rate and Parity bit (Figure 3)

WARNING

Power supply must be turned off before performing this operation!

Use the DIP switch A to set the data transmission rate (baud rate and parity bit).

Set the binary value of the baud rate and the parity bit according to the

following table, considering that: ON = 1; OFF = 0.

Switch Baud rate Parity bit

0000 9600 bit/s No parity

1000 9600 bit/s Even

0100 9600 bit/s Odd

1100 19200 bit/s No parity

0010 (default) 19200 bit/s Even

1010 19200 bit/s Odd

0110 115200 bit/s No parity

1110 115200 bit/s Even

0001 115200 bit/s Odd

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 26 of 92

Page 27

ES58 • EM58 MODBUS®

EXAMPLE

Set the baud rate to 9600 bits per second and Odd parity bit:

Switches 1 2 3 4

Position OFF ON OFF OFF

Value 0 1 0 0

Set the baud rate to 115200 bits per second and Even parity bit:

Switches 1 2 3 4

Position ON ON ON OFF

Value 1 1 1 0

The data transmission rate which is currently set in the unit can be read next to

the DIP switch baud rate [0006 hex] register, see on page 78.

4.5.2 Setting the node address (Figure 3)

WARNING

Power supply must be turned off before performing this operation!

Use the DIP switch B to set the node address.

Set the binary value of the node address, considering that: ON = 1; OFF = 0.

bit

1

LSB

2 3 4 5 6 7

8

MSB

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 27 of 92

Page 28

ES58 • EM58 MODBUS®

The range of node addresses is between 1 and 247. The default address is 1.

EXAMPLE

Set the node address to 25:

2510 = 0001 10012 (binary value)

Switches 1 2 3 4 5 6 7 8

Position

ON OFF OFF ON ON OFF OFF OFF

Value

1 0 0 1 1 0 0 0

Set the node address to 55:

5510 = 0011 01112 (binary value)

Switches 1 2 3 4 5 6 7 8

Position

ON ON ON OFF ON ON OFF OFF

Value

1 1 1 0 1 1 0 0

NOTE

The default address is 1.

The address 0 is reserved to identify a “broadcast” exchange (Master sends a

request to all Slaves connected to the Modbus network). See the “6.1 MODBUS

Master / Slaves protocol principle” section on page 50.

The Modbus Master node has no specific address, only the Slave nodes must

have an address. Each Slave must have a unique address.

Addresses from 248 to 255 are reserved.

If you set the address 0, device will be set to 1 automatically.

If you set an address that is greater than 247, the device will be set to 247

automatically.

The node address which is currently set in the unit can be read next to the DIP

switch node ID [0007 hex] register, see on page 79.

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 28 of 92

Page 29

ES58 • EM58 MODBUS®

4.5.3 Termination resistor (Figure 3)

WARNING

Power supply must be turned off before performing this operation!

Use the RT DIP switch to activate or deactivate the bus termination. The bus

termination resistor must be activated as line termination in the first or the last

device of the transmission line (both at the beginning and the end of the

communication bus).

RT Description

1 = 2 = ON

Activated: when the device is either the first

or the last of the transmission line

1 = 2 = OFF

Deactivated: when the device is neither the

first nor the last of the transmission line

MAN ESx58x_EMx58x MB E 1.2 Electrical connections 29 of 92

Page 30

ES58 • EM58 MODBUS®

5 Quick reference

5.1 Getting started

The following instructions are given to allow the operator to set up the device

for standard operation in a quick and safe mode.

• Mechanically install the device, see on page 15 ff;

• execute electrical connections, see on page 20 ff;

• set the data transmission rate (baud rate and parity bit; see the “4.5.1

Setting data transmission rate: Baud rate and Parity bit (Figure 3)” section

on page 26); the default value set by Lika Electronic at factory set-up is

“baud rate = 19200 bit/s, parity = Even”;

• set the node address (node ID; see the “4.5.2 Setting the node address

(Figure 3)” section on page 27); the default value set by Lika Electronic at

factory set-up is “1”;

• switch +10Vdc ÷ +30Vdc power supply on;

• if you want to use the physical resolution of the device (ES58: singleturn

physical resolution = 4,096 cpr; number of physical revolutions = 1

revolution; total physical resolution = 4,096 counts; 12 bits; EM58:

singleturn physical resolution = 4,096 cpr; number of physical revolutions

= 16,384 revolutions; total physical resolution = 67,108,864 counts; 26

bits), please check that the Scaling function item is disabled (bit 0 in the

Operating parameters [0008 hex] register = 0; see on page 72);

• otherwise if you need a specific resolution, please enable the Scaling

function item (bit 0 in the Operating parameters [0008 hex] register =

1; see on page 72);

• then set the value you need for the singleturn resolution next to the

Custom counts per revolution [0000-0001 hex] item (registers 1 and

2; see on page 65);

• set the value you need for the overall resolution next to the Custom total

resolution [0002-0003 hex] item (registers 3 and 4; see on page 67);

• now, if you need you can set the Preset next to the Preset value [0004-

0005 hex] register and then execute the Perform counting preset

command bit 11 in the Control Word [0009 hex] register; see on page

70);

• finally save the new setting values (Save parameters command bit 9 in

the Control Word [0009 hex] register; see on page 74).

MAN ESx58x_EMx58x MB E 1.2 Quick reference 30 of 92

Page 31

ES58 • EM58 MODBUS®

5.2 Configuring the encoder using the software tool by Lika Electronic

ES58 / EM58 series rotary encoders with MODBUS interface are supplied with a

software expressly developed by Lika Electronic in order to easily programme

and configure the devices. It allows the operator to set the working parameters

of the device and monitor whether the devices are running properly. The

program is supplied for free and can be installed in any PC fitted with a

Windows operating system (Windows XP or later). The name of the program

executable file is MODBUS-RTU.EXE, it is available for download through the

SOFTWARE link in the page of the website dedicated to the devices. The program

is designed to be installed simply by copying the executable file to the desired

location and no installation process is required. To launch the program just

double-click the file icon. To close the program press the CLOSE button at the

top right of the window.

NOTE

Please note that the program is designed to interface several encoder models

equipped with MODBUS interface. When you open the page of the interface,

before trying to establish the serial connection, it is necessary to select the

model of the connected encoder among the ones in the list.

NOTE

Before starting the program and establishing a communication with the device,

it is necessary to connect it to the personal computer. The interface of the

ES58 / EM58 series encoders is a serial RS-485 type, the standard of the serial

port in the personal computer (when the port is available) is the RS-232 type.

Therefore you must install an RS-232 to RS-485 converter, easily available in the

market. Should the personal computer not be equipped with a serial port (RS232 or RS-485), you must install a USB to RS-485 converter, easily available in

the market too. For complete information on the connection scheme and the

cable pinout refer to the instruction sheet provided with the converter.

On the ENCODER side the cable must be connected as described in the

“Electrical connections” section on page 20. Always be sure that RX wire in the

MODBUS ENCODER is connected up to TX wire in the PC and RX wire in the PC

is connected up to TX wire in the MODBUS ENCODER.

An optional kit fitted with RS-485/USB adapter for the communication between

the encoder and the PC is available for M12 output.

The order code is as follows:

• KIT EM58 MB M12 / USB adapter cable.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 31 of 92

Page 32

ES58 • EM58 MODBUS®

5.3 Main page of the interface

To launch the program and configure the MODBUS encoder double-click the

MODBUS-RTU.EXE executable file.

The interface consists of a main page and two subpages.

When the program starts, the main page will appear on the screen.

The main page of the interface can be divided into seven parts.

1. In the first SERIAL LINE group box on the top left of the page the items

necessary to select the serial port and connect to the device are

available.

2. In the DEVICE group box on the top centre of the page the items

necessary to select the node address and the commands needful for

starting the connection process and, once the connection is established,

for reading and writing the parameters are available.

3. In the group box on the further right some information on the

connected encoder are displayed (after the connection is established).

4. In the FUNCTIONS group box on the top right of the page you can find

the commands to enter the main page, the page for firmware upgrade

and the page that allows to send Request PDUs manually.

5. In the INPUT REGISTERS group box on the bottom left of the page the

Input registers are available, they provide result values and status /

alarm information on the device. These items are described in the “7.1.2

Input Register parameters” section on page 76.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 32 of 92

Page 33

ES58 • EM58 MODBUS®

6. In the EXCEPTION ERROR group box just beneath, the exception

response messages are shown, the Server transmits exception responses

to the Client when an error occurs because the Server is not able to

handle the request from the Client. For more information on the

exception responses and the MODBUS exception codes please refer to

the “7.2 Exception response and codes“ section on page 82.

7. In the HOLDING REGISTERS group box on the bottom right of the page

the Holding Registers are available; the items in this area allow to read

in or write into the working parameters of the connected device.

The main page allows the operator to choose the language used to display texts

and items in the user interface. Click the Italian flag icon at the top

right of the page to choose the Italian language; click the UK flag icon

to choose the English language.

On the top right of the page over the FUNCTIONS group box the MESSAGES >

button is available. By pressing the button the main page widens and a window

appears on the right: it shows the frames that are exchanged between the

software tool and the device. To close the messages window and display back

the main page only, press the < CLOSE button.

5.3.1 Configuring the serial port – Connection to the encoder

The first four group boxes at the top of the main page are used to connect to

the device via serial port. In particular they allow (in order):

• to select the serial port of the pc the encoder is connected to (SERIAL

LINE group box);

• to set the node address of the connected device and start the scanning

operation for finding the connected device (DEVICE group box);

• to show information about the connected device, once the connection is

carried out properly (group box between DEVICE and FUNCTIONS);

• to choose the page to be displayed (FUNCTIONS group box).

MAN ESx58x_EMx58x MB E 1.2 Quick reference 33 of 92

Page 34

ES58 • EM58 MODBUS®

When the page of the interface opens, by means of the drop-down box in the

Select serial com drop-down box of the SERIAL LINE group box you can

choose the serial port the device is connected to. The port that is currently

selected is indicated in the drop-down box. If you do not know the number of

the COM port the device is connected to, select the All coms check box.

In the Address item of the DEVICE group box the MODBUS address of the

connected device must be entered. By default the address of all Lika devices is

“1”. If you do not know the MODBUS address of the networked device select the

All addresses check box.

If you select the All coms check box and the All addresses check box the tool

will scan all the available serial ports (COM1 first, then COM2, COM3, etc., if

installed) and will test for each one all the baud rate and parity bit options

(9600 No parity, 9600 Even, 9600 Odd, etc.) and all the possible addresses (from

1 to 247, according to the MODBUS protocol).

It is clear that this searching operation may take a while.

To start searching and connect to the device press the CONNECT button in the

DEVICE group box. While the program is attempting to connect to the device, a

green progress bar and the Busy label over the Select serial com drop-down

box indicate that the port is currently open and being checked. As long as the

communication is active the bar indicates that the port is open. When there is

no communication the port becomes available for other applications after a

timeout of about 1 second.

If problems occur while trying to establish the connection (you have selected a

wrong or not available serial port, or the port is currently busy; or you have set a

wrong node address, etc.), the interface will go on trying to establish the

connection uninterruptedly, until the CONNECT button is pressed once again.

The message No com and the name of the last address and serial port that have

been checked will appear next to the button.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 34 of 92

Page 35

ES58 • EM58 MODBUS®

If the connection succeeds, the Device connected message as well as the model

of the connected device are displayed in the group box between the DEVICE and

the FUNCTIONS group boxes. Actually the software is able to recognize

automatically the model of the connected device and changes the lay-out of

the software tool's pages consequently.

The values of the registers that are currently set in the device are shown in the

INPUT REGISTERS and HOLDING REGISTERS group boxes.

Furthermore the Read Params and Write Holding buttons appears in the

DEVICE group box.

Read Params

When you press the Read Params button you send a single command to read

the Input Registers and the Holding Registers. The Input Registers and the

Holding Registers listed in the page are updated according to the values of the

device in the moment when the request is transmitted (instantaneous reading).

To read the registers uninterruptedly you must press the Continuous reading

button, see on page 37.

Write Holding

When you press the Write Holding button you send a command to write all

Holding Registers at the same time. It is also possible to press the ENTER key in

the keyboard of your personal computer: it sends a command to write the only

MAN ESx58x_EMx58x MB E 1.2 Quick reference 35 of 92

Page 36

ES58 • EM58 MODBUS®

register where the cursor is placed. After having set a new value next to any

Holding Register, press the Write Holding button to transmit to the encoder all

Holding Registers data; or just press the ENTER key to send only the datum of

the Holding Register where the cursor is placed.

Inside the FUNCTIONS group box two further buttons are available: Update FW

and Manual frame. The first button allows the operator to enter the page for

the firmware upgrade; the second button allows to enter the page where PDUs

can be transmitted manually. For complete information on the firmware

upgrade procedure please refer to the “5.4 Update FW page - Firmware upgrade”

section on page 45; for complete information on the manual transmission of

the PDUs please refer to the “5.5 Manual frame page – Transmitting PDUs

manually” section on page 48. If you press the NORMAL button you go back to

the main page.

5.3.2 Reading the Input Registers

In the largest group box on the left of the programming interface the Input

Registers are available, they provide result values and status / alarm information

on the device. These items are described in the “7.1.2 Input Register parameters”

section on page 76 of this manual.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 36 of 92

Page 37

ES58 • EM58 MODBUS®

In this group box the items listed hereafter are available.

Continuous reading

When you press the Continuous reading button you enable the transmission of

continuous commands to read the Input Registers uninterruptedly. After

pressing the button, its background is coloured orange and a green progress bar

appears beneath the field to indicate that a reading operation is being

executing. A further green progress bar and the Busy label over the Select

serial com drop-down box indicate that the serial port is open. The items in the

FUNCTIONS and HOLDING REGISTERS group boxes are made nonavailable. The

values of the Input Registers listed in the page are updated without cease. To

stop the continuous reading press the Continuous reading button once again.

To send a single command to read the registers (instantaneous reading) press

the Read Params button in the DEVICE group box, see on page 35.

Current position

It shows the current position of the device expressed in counts. The value does

not appear if an error is active in the device. See the Current position [0001-

0002 hex] register on page 77.

Angle

It shows the angular position of the encoder shaft expressed in degrees. The

value does not appear if an error is active in the device.

Counts

It shows the angular position of the encoder shaft expressed in counts per

revolution. The value does not appear if an error is active in the device.

Turns It shows the number of measured revolutions (Current position / Counts per rev). The value does not appear if an error is active in the device.

Baud rate dip switch

It shows the data transmission rate (baud rate and parity bit) that is currently

set through the DIP switch A (it is expressed in decimal notation -4 in the

Figure-, in a string format -19200 Even in the Figure- and by means of a

picture). See the DIP switch baud rate [0006 hex] register on page 78. To set

the baud rate refer to the “4.5.1 Setting data transmission rate: Baud rate and

Parity bit (Figure 3)“ section on page 26.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 37 of 92

Page 38

ES58 • EM58 MODBUS®

Address dip switch

It shows the node address that is currently set through the DIP switch B (it is

expressed both in decimal notation -1 in the Figure- and by means of a picture).

See the DIP switch node ID [0007 hex] register on page 79. To set the node

address refer to the “4.5.2 Setting the node address (Figure 3)“ section on page

27.

SW version

It shows the version of the software that is installed currently (both as a decimal

value -512 in the Figure- and as a string -V2.0 in the Figure). See the SW

Version [0008 hex] register on page 79.

HW version

It shows the version of the hardware (PCB version) that is installed currently

(both as a decimal value -256 in the Figure- and as a string -V1.0 in the Figure).

See the HW Version [0009 hex] register on page 79.

Status word

It shows the value expressed in decimal notation (257 in the Figure) that can be

read currently next to the Status word [000A hex] register, refer to page 80. If

there are active alarms, the Alarm message appears on the right while the

position and number of revolutions values above disappear. A further yellow

message shows whether the scaling function and the counting direction

function are enabled.

Alarm register

It shows the value expressed in decimal notation (1 in the Figure) that can be

read currently next to the Alarms register [0000 hex] register, refer to page

76. If there are active alarms, the specific alarm message appears on the right

(e.g. DM error in the Figure) while the position and number of revolutions

values above disappear.

Machine data not valid

It shows the value expressed in decimal notation (2 in the Figure) that can be

read currently next to the Wrong parameters list [0004-0005 hex] register,

refer to page 77. If a wrong parameter has been set, it is stated on the right

(Counts per rev in the Figure) while the position and number of revolutions

values above disappear. Status word and Alarm register registers activate too.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 38 of 92

Page 39

ES58 • EM58 MODBUS®

The input field of the specific wrong parameter in the HOLDING REGISTERS

group box of the interface is highlighted in red.

5.3.3 Reading the exception responses – Exception error

In the EXCEPTION ERROR group box just beneath the INPUT REGISTERS group

box, the exception response messages that the Server transmits to the Client

when an error occurs are shown.

Exception error

It shows the exception response messages that the Server transmits to the

Client when an error occurs because the Server is not able to handle the request

from the Client (for example, if you confirm values that are not allowed or

because of a request to read a non-existent output or register). For more

information on the exception responses and the MODBUS exception codes

please refer to the “7.2 Exception response and codes“ section on page 82.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 39 of 92

Page 40

ES58 • EM58 MODBUS®

5.3.4 Reading / writing the Holding Registers

In the largest group box on the right of the programming interface, the Holding

Registers are available. The items in this group box allow to read in or write into

the working parameters of the device, by pressing the Read Params and Write

Holding buttons respectively, they are available in the DEVICE group box. The

Holding Registers are fully described in the “7.1.1 Machine data parameters

(Holding registers)” section on page 65 in this manual.

WARNING

If the Auto save check box at the bottom of the page is selected (see on page

44), all the parameters of the Holding registers are stored automatically and

instantaneously as soon as they are set: check box settings are saved as soon as

the check box is selected / deselected; the write registers are saved as soon as

you press the ENTER key in the keyboard or place the cursor anywhere outside

the field after setting the value.

MAN ESx58x_EMx58x MB E 1.2 Quick reference 40 of 92

Page 41

ES58 • EM58 MODBUS®

If the Auto save check box is not selected instead, you must press the Save

parameters button to store the parameters permanently on the EEPROM after

setting (see on page 44).

In this section the items listed hereafter are available.

Counts per rev

It allows both to set a custom singleturn resolution of the device and to show

the value that is set currently. The value is expressed in counts. See the Custom

counts per revolution [0000-0001 hex] register on page 65. This register can

be modified only if the Enable scaling function option next to the Operating