Page 1

User’s Guide

Temperature Controller

LDT-5525

ILX Lightwave Corporation · P. O. Box 6310 · Bozeman, MT, U.S.A. 59771 · U.S. & Canada: 1-800-459-9459 · International Inquiries: 406-556-2481 · Fax 406-586-9405

ilx.custhelp.com · www.ilxlightwave.com

70019904_07_01

Page 2

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Safety Information and the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Safety Marking Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Comments, Suggestions, and Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Chapter 1 Introduction and Specifications

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Available Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Operation

AC Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power-Up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Introduction to the LDT-5525 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parameter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SENSOR CAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Back Panel Controls and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

06_07 LDT-5525 i

Page 4

TABLE OF CONTENTS

SENSOR SELECT Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TEC Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TEC Grounding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Warm-Up and Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . 15

Temperature Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Resistance Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

External Safety Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Booster Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Maintenance and Troubleshooting

Calibration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Calibration Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Thermistor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AD590 Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LM335 Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ITE Current Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Appendix A Steinhart-Hart Equation

Computer Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Appendix B Sensing Current and Thermistor Selection

Thermistor Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Temperature Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Selecting the Sensing Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ii LDT-5525

Selecting and Using Thermistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 5

TABLE OF CONTENTS

Appendix C AD590 and LM335 Sensor Calibration

AD590 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

LM335 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

One Point Calibration Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Two Point Calibration Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

06_07 LDT-5525 iii

Page 6

TABLE OF CONTENTS

iv LDT-5525

Page 7

LIST OF FIGURES

LIST OF FIGURES

Figure 2.1 LDT-5525 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 2.2 LDT-5525 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 2.3 Back Panel TEC Connector . . . . . . . . . . . . . . . . . . . . . .13

Figure A.1 Thermistor Resistance vs. Temperature . . . . . . . . . . . . .28

Figure B.1 Thermistor Temperature Range . . . . . . . . . . . . . . . . . . .34

Figure C.1 AD590 Nonlinearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

06_07 LDT-5525 v

Page 8

LIST OF FIGURES

vi LDT-5525

Page 9

SAFETY AND WARRANTY INFORMATION

The Safety and Warranty Information section provides details about cautionary

symbols used in the manual, safety markings used on the instrument, and

information about the Warranty including Customer Service contact information.

Safety Information and the Manual

Throughout this manual, you will see the words Caution and Warning indicating

potentially dangerous or hazardous situations which, if not avoided, could result in

death, serious or minor injury, or damage to the product. Specifically:

Caution indicates a potentially hazardous situation which can result in minor or

moderate injury or damage to the product or equipment.

Warning indicates a potentially dangerous situation which can result in serious injury or

death.

WARNING

Visible and/or invisible laser radiation. Avoid direct exposure to the beam.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the

instrument until safe operation can be verified by trained service personnel:

• Visible damage

• Severe transport stress

• Prolonged storage under adverse conditions

• Failure to perform intended measurements or functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX

Lightwave distributor, for service or repair to ensure that safety features are

maintained (see the contact information on

All instruments returned to ILX Lightwave are required to have a Return

Authorization Number assigned by an official representative of ILX Lightwave

Corporation.

See Returning an Instrument on page ix for more information.

page xi).

LDT-5525 vii

Page 10

SAFETY SYMBOLS

SAFETY SYMBOLS

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within

the manual. See the Table of Contents to locate the specifications and other

product information. The following classifications are standard across all ILX

Lightwave products:

• Indoor use only

• Ordinary Protection: This product is NOT protected against the harmful ingress of moisture.

• Class I Equipment (grounded type)

• Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

• Pollution Degree II

• Installation (overvoltage) Category II for transient overvoltages

• Maximum Relative Humidity: <80% RH, non-condensing

• Operating temperature range of 0 °C to 40 °C

• Storage and transportation temperature of –40 °C to 70 °C

• Maximum altitude: 3000 m (9843 ft.)

• This equipment is suitable for continuous operation.

Safety Marking Symbols

This section provides a description of the safety marking symbols that appear on

the instrument. These symbols provide information about potentially dangerous

situations which can result in death, injury, or damage to the instrument and other

components.

Caution,

refer to

manual

Caution, risk

of electric

shock

On: In position of a bistable push control.

The slash (I) only denotes that mains are on.

or

(I)

Earth

ground

Te r mi n a l

Protective

Conductor

Te r mi n a l

Alternating

current

Caution, hot

surface

Off: Out position of a bistable push control.

The circle (O) only denotes that mains are off.

or

(O)

Visible and/or

invisible laser

radiation

Frame or

chassis

Te r mi n a l

viii LDT-5525

Page 11

WARRANTY

ILX LIGHTWAVE CORPORATION warrants this instrument to be free from

defects in material and workmanship for a period of one year from date of

shipment. During the warranty period, ILX will repair or replace the unit, at our

option, without charge.

Limitations

This warranty does not apply to fuses, lamps, defects caused by abuse,

modifications, or to use of the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any

implied warranty of merchantability or fitness for any particular purpose. ILX

Lightwave Corporation shall not be liable for any incidental, special, or

consequential damages.

WAR RA NT Y

If a problem occurs, please contact ILX Lightwave Corporation with the

instrument's serial number, and thoroughly describe the nature of the problem.

Returning an Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

1 Obtain a Return Authorization number (RA) from ILX Customer Service.

2 Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

3 Attach the anti-static protective caps that were shipped with the instrument and place the

instrument in a protective anti-static bag.

4 Place the instrument in the original packing container with at least 3 inches (7.5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

5 Secure the packing box with fiber reinforced strapping tape or metal bands.

6 Send the instrument, transportation pre-paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a

container with at least 3 inches (7.5 cm) of compressible packaging material on all

sides.

Repairs are made and the instrument returned transportation pre-paid. Repairs

are warranted for the remainder of the original warranty or for 90 days, whichever

is greater.

06_07 LDT-5525 ix

Page 12

WAR RA NT Y

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or

shortages on the packing list. If the instrument is damaged, file a claim with the

carrier. The factory will supply you with a quotation for estimated costs of repair.

You must negotiate and settle with the carrier for the amount of damage.

x LDT-5525

Page 13

WAR RA NT Y

Comments, Suggestions, and Problems

To ensure that you get the most out of your ILX Lightwave product, we ask that

you direct any product operation or service related questions or comments to ILX

Lightwave Customer Support. You may contact us in whatever way is most

convenient:

Phone . . . . . . . . . . . . . . . . . . . . . . . . . . . (800) 459-9459 or (406) 586-1244

Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (406) 586-9405

On the web at: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ilx.custhelp.com

Or mail to:

ILX Lightwave Corporation

P. O. Box 6310

Bozeman, Montana, U.S.A 59771

www.ilxlightwave.com

When you contact us, please have the following information:

Model Number:

Serial Number:

End-user Name:

Company:

Phone:

Fax:

Description of what is

connected to the ILX

Lightwave instrument:

Description of the problem:

If ILX Lightwave determines that a return to the factory is necessary, you are

issued a Return Authorization (RA) number. Please mark this number on the

outside of the shipping box.

You or your shipping service are responsible for any shipping damage when

returning the instrument to ILX Lightwave; ILX recommends you insure the

shipment. If the original shipping container is not available, place your instrument

06_07 LDT-5525 xi

Page 14

WAR RA NT Y

in a container with at least 3 inches (7.5 cm) of compressible packaging material

on all sides.

We look forward to serving you even better in the future!

xii LDT-5525

Page 15

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

This manual contains operation and maintenance information for the LDT 5525

Temperature Controller. If you want to get started right away, read Chapter 2,

which covers Operation, first.

Product Overview

The LDT-5525 Temperature Controller is a microprocessor-based, precision

thermoelectric temperature controller designed for temperature control of laser

diodes, detectors and other temperature sensitive devices. The LDT 5525 ca n be

used for laser diode testing, laser diode frequency stabilization, IR detector

cooling, and to determine the characteristics of electronic devices. The LDT-5525

combines high analog stability with the versatility of a microprocessor-based

instrument. The internal microprocessor controls the operation of the LDT-5525

and performs the non-linear conversion of thermistor resistance to temperature

based on two user-defined constants.

You can configure the LDT-5525 to operate with a wide variety of thermistor

temperature sensors and TE modules, as well as AD590 series and LM335 series

temperature sensors.

Features of the LDT-5525 include:

• Intuitive front panel layout

• Large and easy-to-read green LED display

• Display resolution of 0.1 degree Centigrade

• Output current limit control to safely operate al l TE coolers

• Configurable for a variety of thermal sensors

• Output will supply 4 amps, 24 Watts

• Closed-case calibration

LDT-5525 1

Page 16

CHAPTER 1

Available Options and Accessories

INTRODUCTION AND SPECIFICATIONS

Product Overview

Options and accessories available for the LDT-5525 Temperature Controller

include the following:

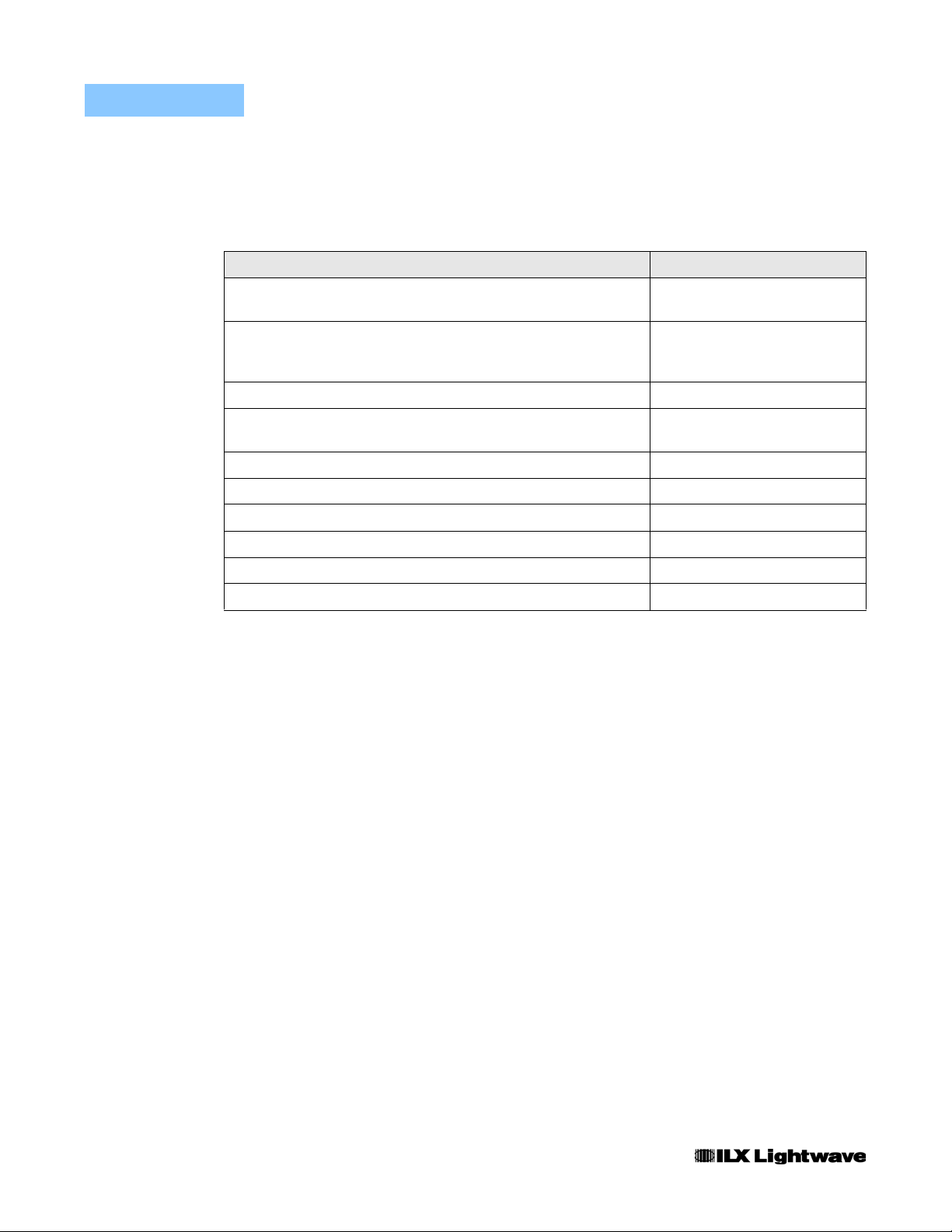

DESCRIPTION MODEL NUMBER

Single Rack mount kit

(enables installation into a standard 19” rack)

134

Dual Rack mount kit

(enables installation of two LDT-5525 instruments into a standard

19” rack)

Temperature Controlled Laser Diode Mount 4407

Temperature Controlled Laser Diode Mount

(available with collimating assembly)

High Power Laser Diode Mount 4442

Temperature Controller Interconnect Cable (unterminated) 501

Calibrated 10 Kohm Thermistor 510

Uncalibrated 10 Kohm Thermistor 520

Uncalibrated AD590LH IC Temperature Sensor 530

Uncalibrated LM335 IC Temperature Sensor 540

135

4412

Other Laser Diode Mounts are available. Please contact ILX Lightwave for

information on additional options for your applications.

2 LDT-5525

Page 17

Specifications

1

Output

Output Type Bipolar constant current source

Control Algorithm Smart Integrator, Hybrid PI

Compliance Voltage 6 Volts at 4 Amps

Maximum Current Output 4 Amps

Maximum Output Power

Current Limit Control Range

Current Limit Accuracy

Ripple / Noise

Temperature Control

Temperature Range

Sensor Type 2-wire thermistor, LM335 voltage type or AD590

3

INTRODUCTION AND SPECIFICATIONS

Specifications

2

24 Watts, typical

CHAPTER 1

0 to 4.4 Amps

+50 mA

<1 mA

4

-99 to 199.9oC

-20 to +70oC with typical (NTC) 10K thermistor

currenty type

Thermistor Sensing Current 10 µA or 100 µA

Temperature Set Point Resolution 0.1oC

Short Therm Stability

Long Term Stability +0.01oC

1 Output current and power are rated into a 1 ohm load

2 Higher output powers can be accommodated by using an external booster. Contact ILX Lightwave for further

information

3 Broadband noise (10 Hz to 10 MHz) is measured at 1 Amp output current

4 Temperature control range depends primarily on the type of thermistor and TE module used. The range can be

extended higher or lower by selecting appropriate components; see Appendix B for more details

5 Short term temperature stability is a strong function of the thermal environment of the thermistor and TE module;

room air currents in particular can easily cause fluctuations of 0.1

5

+0.005oC

o

C in an exposed mounting configuration

06_07 LDT-5525 3

Page 18

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

Specifications

Thermistor Range (10 µA) 0.0 to 450.0 KΩ

Thermistor Range (100 µA) 0.0 to 45.0 KΩ

Usable Thermistor Range 25 to 450,000 Ω, typical

Thermistor Resistance Resolution

(10 µA)

Thermistor Resistance Resolution

(100 µA)

Thermistor Resistance Accuracy +0.05% of FS

AD590 Reverse Bias 8 Volts

LM335 Bias 0.6 mA

User Calibration

Thermistor Steinhart-Hart equation (2 constants)

IC Sensor 2-point

Measurement (Display

Display Type 4-digit LED

TE Current Range -4.00 to 4.00 Amps

TE Current Resolution 0.01 Amps

TE Current Accuracy +0.03 Amps

Temperature Range -99.9 to 999.9oC

Temperature Resolution 0.1oC

Temperature Accuracy

6 Accuracy figures quoted are typical for a calibrated 10K thermistor; accuracy figures are relative to calibration

standard and are dependent on the user-defined configuration of the instrument; variation from typical value is

largely due to uncertainty in thermistor calibration

6

0.1 kΩ

0.01 kΩ

0oC: 0+0.6oC, typical

20oC: +0.3oC, typical

30oC: +0.4oC, typical

50oC: +0.6oC, typical

4 LDT-5525

Page 19

INTRODUCTION AND SPECIFICATIONS

Specifications

General

Output Connectors TEC I/O: 15-pin, D-sub

Analog Output: BNC

Size 3.5” x 7.3” x 12”

Weight 8.0 pounds

Power Requirements 90 - 125 VAC, 105 - 250 VAC (jumper selectable)

at 50-60 Hz

Ambient Temperature Range 0 to +40 oC operating

-40 to +70 oC storage

Humidity < 85% relative humidity, non-condensing

Warm-Up 1 hour to rated accuracy

CHAPTER 1

Our goal is to make the best laser diode instrumentation available anywhere. To

achieve this, we need your ideas and comments on ways we can improve out

products. We invite you to contact us at any time with your suggestions.

06_07 LDT-5525 5

Page 20

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

Specifications

6 LDT-5525

Page 21

CHAPTER 2

OPERATION

This chapter describes how to install, adjust, and operate the LDT-5525

Temperature Controller. It is divided into sections covering installation,

familiarization and adjustment, and normal operating procedures.

This chapter also gives an overview of the LDT-5525's front panel fe atures, an d it

presents a guide to quickly familiarize the user with the front panel operations.

Installation procedures and considerations are also covered in this chapter.

AC Power Considerations

The LDT-5525 Series Controllers can be configured to operate at nominal line

voltages of 100, 120 220, 230-240 VAC (all ±10%). This is done at the factory and

need not be changed before operating the instrument. However, check to be sure

that the voltage printed on the back panel of the instrument matches the powerline voltage in your area.

T o avoid electrical shock hazard, connect the instrument to properly earth-grounded, 3prong receptacles only. Failure to observe this precaution can result in severe injury or

death.

Rack Mounting

The LDT 5525 Series Precision Temperature Controller may be rack mounted by

installing a rack mount flange on either side of the enclosure. All rack mount

accessory kits contain detailed mounting instructions. Refer to Chapter 1 for

applicable rack mount accessory part numbers.

LDT-5525 7

Page 22

CHAPTER 2

L

R

T

Ω

A

R

T

I

E

T

T

Y

R

I

OPERATION

Power-Up Sequence

Power-Up Sequence

With the LDT-5525 Series Precision Temperature Controller connected to an AC

power source, pressing the POWER switch will supply power to the instrument

and start the power up sequence.

During the power-up sequence, the following takes place. For about two seconds

all indicators light up, and all of the 7-segment displays indicate "8". Then all

lamps are turned off for two seconds. Then, the sensor switch position is

displayed for two seconds. After this, the unit is configured to the state it was in

when the power was last shut off (except for the display mode which defaults to I

TE measurement). The adjust knob is always disabled at power up.

Introduction to the LDT-5525 Front Panel

The LDT-5525 Temperature Controller's front panel contains displays and controls

for the Temperature Controller hardware. Each of the labeled areas on the front

panel (i.e. DISPLAY or MODE) is described in this chapter.

Refer to Figure 2.1 for the following discussions of the LDT-5525 Temperature

Controller front panel sections. The key words are in capital letters for quick

identification.

Error Parameter Display Adjust Adjust

Indicators Switch Switch Enable Knob

Switch

LDT -5525

TE O PENSENS OR OPEN

POWE

ANALO G O U

100 C/V

10 k

100 k

/V

Ω

/V

Ω

AC POWER Analog CAL Mode Output

ON/Off Output Select Select On/Off

Switch Connector Switch Switch Switch

T EMPERA TURE CONT ROLL ER

k

C

SENS OR CA

C1

C2

TE

SENS OR

VI EW SET

PARA MET E

I LI MIT

T LI MIT

GAIN

DISPL A

ADJUS

ENBL

MOD

TE

OUT PU

ON

Figure 2.1 LDT-5525 Front Panel

8 LDT-5525

Page 23

OPERATION

Introduction to the LDT-5525 Front Panel

CHAPTER 2

Adjustments

The ADJUST section contains the Adjust knob for entering values, and it co nta ins

the ENBL (adjust enable) switch and indicator. In order to make any adjustment,

the ENBL indicator must be lit. Pressing the ENBL switch toggles the ENBL

indicator on or off.

Display

The display is used to show measurements, output set point, and parameter set

points. Whenever a set point is being displayed, the VIEW SET indicator will be lit.

The DISPLAY switch is used to select the measured current (I TE), temperature,

resistance, or the set point value. The set point type is determined by the MODE

selection. Repeatedly pressing the DISPLA Y switch will cycle the display from ITE

to temperature to resistance (with thermistor sensors only) to set point and back to

ITE, and so on.

When in I TE mode, the set point will be TE current.

When in R mode, the set point will be thermistor resistance in KΩ. R mode is not

available if the back panel SENSOR SELECT switch is set to LM335 or AD590.

R mode operation may offer improved set point resolution (over T mode),

depending on the desired temperature set point.

Note: The resistance set point is NOT maintained if the control mode is changed

(e. g. from R mode to T mode). Also, if the SENSOR SELECT switch is moved from 10 µA

to 100 µA while in R mode, the resistance set point will be rounded to match the display

resolution.

When in T mode the set point will be temperature in oC.

When the output is off and a measurement is displayed, if the adjust knob is

turned the control mode set point will be displayed for three seconds. If the set

point is adjusted (by turning the adjust knob) the set point timer will be restarted.

Therefore, three seconds after the set point is adjusted the display will return to

the last measurement.

Parameters

The LDT-5525 Temperature Controller allows adjustment of the following

parameters, I LIMIT (TE current limit), T LIMIT (temperature limit) and GAIN

(sensor feedback amplifier gain). In addition, the sensor calibration values may be

entered.

The LDT-5525 will limit the I TE output to the I LIMIT value, regardless of the set

point or control mode.

06_07 LDT-5525 9

Page 24

CHAPTER 2

OPERATION

Introduction to the LDT-5525 Front Panel

The temperature is limited (via the sensor feedback) to the T LIMIT value. If the

sensor reads a temperature which is greater than T LIMIT, the I TE output will be

shut off.

The GAIN value is used to control the sensor feedback gain, and thus the

temperature settling time and overshoot. If the GAIN is set too low (1 is the lowest

setting) the TE cooler will take longer to reach the temperature set point. If the

GAIN is set too high (300 is the highest setting) the actual temperature may

oscillate around the set temperature.

The optimum GAIN setting depends on the type of TE cooler and temperature that

you are setting . Set the GAIN to its lowest value and th en try increasing it until the

temperature oscillates around the set temperature. Then, reduce the GAIN one

step.

Parameter Setup

The PARAMETER switch is used to view and edit the parameters. Repeatedly

pressing the PARAMETER switch will cycle through the parameters.

When a parameter is selected for viewing, its value will remain on the display for

three seconds. If an adjustment is made to the parameter (by turning the adjust

knob) the three second timer will be restarted. Three seconds af te r the p ar ameter

adjustment is done, the display will revert to the last measurement mode.

SENSOR CAL

These are the constants of the Steinhart-Hart equation that the user enters to

calibrate the TEC for different thermistors' temperature conversions. The

Steinhart-Hart equation is used to derive temperature from the non-linear

resistance of an NTC (Negative Temperature Coefficient) thermistor. For

information on setting C1 and C2 for thermistors, see Appendix A. For information

on thermistor selection and sensor current selection, see Appendix B.

When a linear sensor device (such as an AD590 or LM335) is used, a linear

equation is used. If a linear sensor's calibration is not known, set C1 = 0.00, C2 =

1.00. For more information on linear sensor calibration, see Appendix C.

The range of values for C1 and C2 are -9.99 to +9.99.

To read C1 or C2, press the CAL button until it sequences to the desired constant.

The C1 or C2 indicator will become lit to indicate which constant is selected. To

change the value, turn the ADJUST knob until the correct value is displayed.

10 LDT-5525

Appendix A contains an explanation of the Steinhart-Hart equation and a

computer program to determine these values for any thermistor.

Page 25

OPERATION

Introduction to the LDT-5525 Front Panel

Appendix C contains information on sensor calibration constants for AD590 and

LM335 sensors. Since these devices are used over their linear range, the

constants C1 and C2 are used in this case to determine a linear approximation of

the temperature, rather than the Steinhart-Hart non-linear approximation which

applies for thermistors. The appropriate algorithms are automatically implemented

whenever the sensor type is selected via the back panel SENSOR SELECT

switch. However, C1 and C2 must be changed by the user.

CHAPTER 2

Output

The OUTPUT section contains the ON switch and indicator. The ON indicator is lit

whenever the output is on. Pressing the ON switch will toggle the TEC current

output on or off.

Conditions Which Will Automatically Shut Off the OUTPUT

1 Temperature Limit

2 External (Temp Limit) Safety Switch is closed (see Section 2.6.3)

3 Booster Changed (While Output On), (see Section 2.6.4)

4 Sensor Open (While Output On)

5 TEC Module Open (While Output On)

6 SENSOR SELECT Switch Moved (While Output On)

Control Mode

The MODE switch is used to select the control mode. Repeatedly pressing the

MODE switch cycles through the current (I TE), sensor reference (R), or

temperature (T) control modes. The LED indicators show the selected mode.

Changing the control mode forces the output off.

Error Indicators

The ERROR indicators become lit when the corresponding conditions occur. The

SENSOR OPEN light comes on whenever the sensor connections are open. The

TE OPEN indicator becomes lit whenever an open circuit (or a high impedance

condition) occurs on the TE module output when the output is on. When a TE

OPEN condition occurs, the output will be shut off and the indicator will remain on

until the problem is resolved and the output is turned on again.

The T LIMIT light will blink at 1 Hz whenever the temperature limit is reached. The

I LIMIT light will blink at 1 Hz whenever the I TE current limit is reached.

06_07 LDT-5525 11

Page 26

CHAPTER 2

OPERATION

Back Panel Controls and Connections

Analog Output

An analog output signal is available at the ANALOG OUTPUT connector (BNC)

on the front panel. This signal is a voltage between 0 - 5.0 volts which is

proportional to the measurement signal. For example, an analog output signal of

2.5 volts (

+0.5 volts) would represent a measurement of 50% of full scale.

Sensor Select Chassis

Switch Ground

Post

15-pin Connector Fan AC Power

(Current Output Entry

Sensor Input) Module

Figure 2.2 LDT-5525 Back Panel

Back Panel Controls and Connections

Refer to Figure 2.2 for the following discussions of back panel controls and

connectors. There are no user serviceable parts in the instrument, including the

external fuses in the AC power entry module.

SENSOR SELECT Switch

The SENSOR SELECT switch is used to select sensor type and, in the case of

thermistor sensor, the source current level. Table 2.4 shows the SENSOR

SELECT positions and corresponding position code. When the sensor switch is

changed during TEC mode operation, the new sensor position code will be

indicated on the TEC display for three seconds.

12 LDT-5525

Page 27

Back Panel Controls and Connections

Table 2.1 SENSOR SELECT Switch Positions

SWITCH POSITION CODE

100 µA -01-

10 µA -02-

LM335 -03AD590 -04-

OPERATION

CHAPTER 2

The 10 µA and 100 µA designations are for the current source level; thermistor

sensor type is implied. When using a thermistor, the supply current depends on

the thermistor operating temperature range and the required temperature

resolution. Guidelines for setting this switch are contained in Appendix B.

The AD590 sensor operates as a current source which is proportional to the

sensed temperature. The LM335 sensor operates as a voltage source which is

proportional to the sensed temperature. Both of these sensors are approximately

linear over their operating ranges. When they are used, the constants C1 and C2

are used for a two-point conversion. For more information on setting the const ants

for use with these sensors, see Appendix C.

TEC Connector

At the right of center, when facing the back panel, you will find the 15-pin

D-connector for the TEC MODULE. This connector is used for the input and

output connections, as shown by the pin-out diagram of Figure 2.12.

1, 2 TE Module (+)

3, 4 TE Module (-)

5 TE Module Shield

6 Sensor Shield

7 Sensor (+)

8 Sensor (-)

9 Analog Ground

10 Control Signal

11 Voltage Limit

12 Current Limit

13 Temp. Limit

14 Booster Present

15 Digital Ground

5

7

6

8

15

11

121314

1

234

9

10

Figure 2.3 Back Panel TEC Connector

06_07 LDT-5525 13

Page 28

CHAPTER 2

TEC Grounding Considerations

OPERATION

Back Panel Controls and Connections

The TEC outputs of the LDT-5525 are isolated from chassis ground, allowing

either output terminal to be grounded at the user's option.

Note: For the TEC connector, if any one terminal pin is grounded, then no other terminal

pin should be grounded. Damage to external unit or temperature controller will occur.

14 LDT-5525

Page 29

OPERATION

General Operating Procedures

General Operating Procedures

The following sections present some guidelines for operation, as well as some

common operating procedures.

Warm-Up and Environmental Considerations

Operate the LDT-5525 Temperature Controller at an ambient temperature in the

range of 0 to +40°C. S torage temperatures should be in the range of -40 to +70°C.

To achieve rated accuracy, let the LDT-5525 Temperature Controller warm up for

about 1 hour before use.

Temperature Mode Operation

Y ou can operate the LDT-5525 T emperature Controller in several modes, consta nt

current (I TE), constant thermistor resistance (R), or constant temperature (T).

This example is for constant temperature (T) mode.

a Plug the LDT-5525 Temperature Controller into an AC power source supplying the

correct voltage and frequency for your unit (refer to the back panel for the correct

ratings).

CHAPTER 2

b Turn on the LDT-5525 Temperature Controller. The OUTPUT stage will be off at

power up and the unit will automatically configure its parameters to the state which

existed when the power was last shut off.

c Press the ENBL switch in the ADJUST section of the front panel so that the indicator

is lit (adjustment enabled). Press the MODE switch until the T mode is selected.

d Check the setting of the SENSOR SELECT switch for the desired operation. The

sensor code will be displayed for two seconds during the power-up sequence.

e Press the PARAMETER switch and check the setting of I LIMIT, T LIMIT, and GAIN.

Press the CAL switch and check the setting of C1 and C2 to insure that they are

compatible with the equipment you are using. Refer to Section 2.4.5 if you need to

change them.

f Press the DISPLAY switch until the VIEW SET indicator is lit and check the set point

temperature. If it requires changing, turn the knob until the desired value is displayed.

Note: In some cases, a greater than 0.1oC temperature set point resolution may be

attained by using R mode with the appropriate resistance value.

g Turn the TEC output on by pressing the OUTPUT ON switch. The unit will

automatically control the temperature to the set point.

h When the unit is powered off, the state of the unit at power-down is saved in non-

volatile memory.

06_07 LDT-5525 15

Page 30

CHAPTER 2

Resistance Mode Operation

OPERATION

General Operating Procedures

Y ou can operate the LDT-5525 T emperature Controller in several modes, consta nt

current (I TE), constant thermistor resistance (R), or constant temperature (T).

This example is for constant resistance (R) mode.

a Plug the LDT-5525 Temperature Controller into an AC power source supplying the

correct voltage and frequency for your unit (refer to the back panel for the correct

ratings).

b Turn on the LDT-5525 Temperature Controller. The OUTPUT stage will be off at

power up and the unit will automatically configure its parameters to the state which

existed when the power was last shut off.

c Press the ENBL switch in the ADJUST section of the front panel so that the indicator

is lit (adjustment enabled). Press the MODE switch until the R mode is selected.

d Check the setting of the SENSOR SELECT switch for the desired operation (10 µA or

100 µA). The sensor code will be displayed for two seconds during the power-up

sequence.

e Press the PARAMETER switch and check the setting of I LIMIT, T LIMIT, and GAIN.

Press the CAL switch and check the setting of C1 and C2 to insure that they are

compatible with the equipment you are using.

f Press the DISPLAY switch until the VIEW SET indicator is lit and check the set point

resistance. If it requires changing, turn the knob until the desired value is displayed.

g Turn the TEC output on by pressing the OUTPUT ON switch. The unit will

automatically control the thermistor to the set point resistance.

If the exact resistance is unknown (to control to a desired temperature), press the

DISPLAY switch to view the measured temperature. Readjust the resistance set

point and recheck the temperature until the desired result is attained.

Note: In some cases, a greater than 0.1 oC temperature set point resolution may be

attained by using R mode with the appropriate resistance value.

If the mode is switched from R mode to T mode, the resistance set point will be lost. This is

becaused in T mode, the temperature set point is converted and also stored as a

resistance set point automatically.

h When the unit is powered off, the state of the unit at power-down is saved in non-

volatile memory.

16 LDT-5525

External Safety Switch Operation

On the TEC connector , pins 13 (TEMP LIMIT) and 15 (DIGITAL GND) form a type

of external safety switch (see Figure 2.3). These two pins are normally not

connected (open circuit), and must remain open for the TEC output to be on. If

there is a short circuit between these pins the TEC output will be disabled.

This circuit is useful for remote monitoring of temperature limit, and therefore is

labeled TEMP LIMIT on the back panel connector. This switch may be used with

Page 31

OPERATION

General Operating Procedures

an external current booster. A switch or control circuit of the user's own design is

required. It is left as an option which the user may or may not employ.

CHAPTER 2

Booster Operation

The LDT-5525 Temperature Controller may be used to control a booster current

source which accepts a control signal of up to

may be required if the LDT-5525 Temperature Controller's

not adequate to control a thermal load.

+5.0 volts. A booster current source

+4 A, 24 W output is

Whenever a connection is present between the BOOSTER PRESENT (pin 14)

and DIGIT AL GROUND (pin 15) of the back panel TEC connector (Figure 2.3) the

TEC OUTPUT will be disabled. In this case, the BOOST CONTROL signal voltage

will be available for controlling a booster current source.

The booster current source should use the control voltage which is available

between the BOOST CONTROL (pin 10) and AGND (pin 9) of the back panel

TEC connector.

During Booster operation, the normal ITE output is disabled, and the ITE display

will measure about 0.0 Amps (

linearly proportional to the control current (1 V/A), which is limited by the LIM I

parameter . If LIM I is set to 4 Amps, the maximum CONTROL SIGNAL voltage will

be approximately 4 volts. If a booster signal greater than

user-supplied control signal amplifier is required. For example, if the user's control

signal amplifier has a gain of 2, an I LIMIT of 3 Amps would allow a control volt age

of

+6 volts.

Whether or not a booster current source is used, the LDT-5525 Temperature

Controller uses a sensor for controlling the temperature.

The feedback loop GAIN may require adjustment when a booster current source

is used. This is because a booster current source may be used with different

thermal loads than those found with normal LDT-5525 Temperature Controller

operation, and those loads may require larger or smaller GAIN values in order to

settle to the set temperatures in a desirable fashion.

+0.05 Amps). The CONTROL SIGNAL voltage is

+4.0 volts is required, a

Contact ILX Lightwave for more information on using the LDT -55 25 with a booster

current source.

06_07 LDT-5525 17

Page 32

CHAPTER 2

OPERATION

General Operating Procedures

18 LDT-5525

Page 33

CHAPTER 3

MAINTENANCE AND TROUBLESHOOTING

This chapter describes how to maintain and troubleshoot the LDT-5525

Temperature Controller. Included are sections covering calibration, disassembly,

and troubleshooting.

THE SERVICE PROCEDURES DESCRIBED IN THIS CHAPTER ARE FOR USE BY

QUALIFIED PERSONNEL. POTENTIALLY LETHAL VOLTAGES EXIST WITHIN THE LDT

5525 TEMPERATURE CONTROLLER. TO AVOID ELECTRIC SHOCK, DO NOT PERFORM

ANY OF THE PROCEDURES DESCRIBED IN THIS CHAPTER UNLESS YOU ARE

QUALIFIED TO DO SO.

QUALIFIED SERVICE PERSONNEL ARE REQUIRED TO WEAR PROTECTIVE

EYEGLASSES AND ANTI-STATIC WRIST BANDS WHILE WORKING ON THE LDT-5525

TEMPERATURE CONTROLLER CIRCUIT BOARDS.

HIGH VOLTAGES ARE PRESENT ON AND AROUND THE PRINTED CIRCUIT BOARDS OF

THE LDT-5525 TEMPERATURE CONTROLLER.

Calibration Overview

The LDT-5525 Temperature Controller should be calibrated every 12 months or

whenever performance verification indicates that calibration is necessary.

All calibrations can be done with the case closed. The instrument is calibrated by

changing the internally stored digital calibration constants.

LDT-5525 19

Page 34

CHAPTER 3

Recommended Equipment

MAINTENANCE AND TROUBLESHOOTING

Calibration Overview

Recommended test equipment for calibrating the LDT-5525 Temperature

Controller is listed in Table 3.1. Equipment other than that shown in the table may

be used if the specifications meet or exceed those listed.

Table 3.1

DESCRIPTION MFG / MODEL SPECIFICATION

DMM HP 3457A DC Amps (@ 1.0A): +0.02%

Resistance (@ 10Ω): 0.02%

0.1 µA or 0.1 mW resolution

Resistors Metal Film 15 KΩ (for ITE calibration)

4 KΩ and 40 KΩ (for 100 mA calibration)

4 KΩ and 400 KΩ (for 10 mA calibration)

4 KΩ and 10 KΩ (for LM335 calibration)

10 KΩ and 20 KΩ (for AD590 calibration)

High Power 1 Ω, 20W, low TCR (for ITE calibration)

Environmental Conditions

Calibrate this instrument under laboratory conditions. We recommend calibration

o

C ± 1.0oC. When necessary, however, the LDT-5525 Temperature

at 23

Controller may be calibrated at its intended use temperature if this is within the

specified operating temperature range of 0 to 40

o

C.

Warm Up

The LDT-5 525 Temperature Controller should be allowed to warm up for at least 1

hour before calibration.

20 LDT-5525

Page 35

MAINTENANCE AND TROUBLESHOOTING

Calibration Adjustments

Calibration Adjustments

There are two calibration adjustments that need to be made for the LDT-5525

Temperature Controller. They are calibration of sensor measurement, and

calibration of the ITE current measurement and limit circuits.

If a problem arises during calibration which prevents its normal completion, the

calibration may be aborted with no ill effects by simply pressing the OUTPUT

switch. This is possible because the calibration values are not saved to

non-volatile memory until the last step of each calibration procedure.

Thermistor Calibration

The following procedure is for calibrating the 100 µA and 10 µA constant current

sources so that the thermistor resistance measurements for these ranges will be

as accurate as possible. This procedure calibrates the resistance measurements

of the thermistor. This procedure does not calculate C1 and C2. For information

on calibrating the thermistor sensor, see Appendix A.

CHAPTER 3

Calibration may be aborted by pressing the OUTPUT switch.

a Set the SENSOR SELECT switch (back panel) to the 100 µA position. Set C1 to

0.99, C2 to 2.57.

b Measure and record the exact resistance of your 4 KΩ, 40 KΩ, and 400 KΩ metal

film resistors. A 4-point probe resistance measurement is recommended.

c Connect the 4 KΩ metal film resistor to the sensor input of the LDT-5525

Temperature Controller (pins 7 and 8).

d Enter the sensor calibration mode by pushing the MODE and SENSOR CAL

switches at the same time. After this, the display will indicate the sensor resistance in

KΩ. Allow the measurement to settle for about three seconds.

e Press and hold in the ENBL switch and turn the ADJUST knob until the display

indicates the same resistance you recorded for the 4 KΩ metal film resistor.

f Release the ENBL switch and wait for the VIEW SET indicator (LED) to be unlit.

Replace the 4 KΩ resistor with the 40 KΩ metal film resistor (for 100 µA) or 400 KΩ

metal film resistor (for 10

Ten seconds after the ENBL switch is released, the LDT-5525 Temperature

Controller will store the calibration data in non-volatile memory.

Press the DISPLAY switch three times to rotate the display back to the SENSOR

mode.

g Switch the SENSOR SELECT switch to the 10 µA position and repeat Steps c - f.

h After calibration, the I LIMIT will be automatically set to 4.00 Amp s. Reset the I LIMIT

to the desired value.

µA). After three seconds, repeat Step e with this resistor.

06_07 LDT-5525 21

Page 36

CHAPTER 3

AD590 Sensor Calibration

MAINTENANCE AND TROUBLESHOOTING

Calibration Adjustments

The following procedure is for calibrating the AD590 sensor measurement so that

the temperature measurement will be as accurate as possible. This procedure

calibrates the current measurement of the AD590. This procedure does not

calibrate C1 and C2. For information on calibrating the AD590 sensor, see

Appendix C.

Calibration may be aborted by pressing the OUTPUT switch.

a Set the SENSOR SELECT switch (back panel) to the AD590 position. Set C1 to 0.00,

C2 to 1.00.

b Connect a precision 20 KΩ metal film resistor and a precision ammeter in series at

the sensor input of the LDT-5525 Temperature Controller.

c Enter the sensor calibration mode by pushing the MODE and SENSOR CAL

switches at the same time. After this, the TEC display will indicate sensor reference

current in µA. Wait for three seconds for the measurement to settle.

d Press and hold in the ENBL switch and turn the ADJUST knob until the display

indicates the same current as shown on the precision ammeter.

e Release the ENBL and wait for the VIEW SET indicator (LED) to be unlit. Replace

the 20 KΩ resistor with a 10 KΩ metal film resistor. Wait for three seconds, then

repeat Step d using the 10 KΩ resistor.

Ten seconds after the ENBL switch is released, the LDT-5525 Temperature

Controller will store the calibration data in non-volatile memory.

f Press the DISPLAY switch three times to rotate the display back to the SENSOR

mode. After calibration, I LIMIT will be automatically set to 4.00 Amps. Reset the I

LIMIT to the desired value.

22 LDT-5525

Page 37

MAINTENANCE AND TROUBLESHOOTING

Calibration Adjustments

CHAPTER 3

LM335 Sensor Calibration

The following procedure is for calibrating the LM335 sensor measurement so that

the temperature measurement will be as accurate as possible. This procedure

calibrates the voltage measurement of the LM335. This procedure does not

calibrate C1 and C2. For information on calibrating the LM335 sensor, see

Appendix C.

Calibration may be aborted by pressing the OUTPUT switch.

a Set the SENSOR SELECT switch (back panel) to the LM335 position. Set C1 to 0.00,

C2 to 1.00.

b Connect a precision 4 KΩ metal film resistor and a precision voltmeter in parallel at

the sensor input of the LDT-5525 Temperature Controller (pins 7 and 8).

c Enter the sensor calibration mode by pushing the MODE and SENSOR CAL

switches at the same time. After this, the display will indicate sensor reference

voltage in mV. Wait for three seconds for the measurement to settle.

d Press and hold in the ENBL switch and turn the ADJUST knob until the display

indicates the same voltage as shown on the precision voltmeter multiplied by 10. For

example, if the voltage across the resistor is 1.9871 Volts, turn the ADJUST knob

until the display reads 19.87.

e Release the ENBL switch and wait for the VIEW SET indicator (LED) to be unlit.

Replace the 4 KΩ resistor with a 10 KΩmetal film resistor. After three seconds,

repeat Step d with the 10 K* resistor. Ten seconds after the ENBL switch is released,

the LDT-5525 Temperature Controller will store the calibration data in non-volatile

memory.

f Press the DISPLAY switch three times to rotate the display back to the SENSOR

mode. After calibration, I LIMIT will be automatically set to 4.00 Amps. Reset the I

LIMIT to the desired value.

06_07 LDT-5525 23

Page 38

CHAPTER 3

ITE Current Calibration

MAINTENANCE AND TROUBLESHOOTING

Calibration Adjustments

The following procedure is for calibrating the ITE constant current source for both

polarities of current. During this procedure the ITE current is driven to a series of

pre-determined values. When each of these values is reached and is stable, the

user enters the actual value of the current, as measured by an externa l DMM. The

LDT-5525 Temperature Controller then automatically calibrates the TEC current

source and limits.

Calibration may be aborted by pressing the OUTPUT switch.

a Set the sensor select (back panel) switch to "100 uA." Set C1 to 0.99, C2 to 2.57.

Connect an (approximat el y) 15 k Ω resistor to the sensor pins (7 and 8). Connect a

1Ω, 20 W, resistor across the TEC output terminals (pins 1 and 3) and use a

calibrated DMM to measure the voltage across the resistor. Calculate the current in

the following steps by using Ohm's Law:

I = E / R

-where E is the accurately measured voltage across the resistor, and R is the

accurately measured load resistance. A 4-point probe resistance measurement is

recommended.

b Press and breifly hold in both the MODE and DISPLAY switches. This will put the

LDT-5525 into ITE calibration mode. Wait for three seconds for the output to settle to

about 3 Amps.

c Press and hold in the ENBL switch and turn the ADJUST knob until the display

shows the correct value (absolute value of the ITE measurement), as calculated from

Step a.

d Release the ENBL switch. Wait three seconds to allow the ITE current to settle at the

new set point.

24 LDT-5525

e Repeat Steps c and d four more times, once for each of the (automatically set) set

points -3 Amps, +3 Amps, +1 Amp, and -1 Amp. After the value for the -1 Amp (last)

set point is entered, the LDT-5525 Temperature Controller will automatically calibrate

its ITE current limits.

After about 10 seconds, the LDT-5525 Temperature Controller will store the new

calibration data in non-volatile memory.

f After calibration, the I LIMIT will be automatically set to 0.00 Amps. Reset the I LIMIT

to the desired value.

Page 39

MAINTENANCE AND TROUBLESHOOTING

Troubleshooting

Troubleshooting

This section is a guide to troubleshooting the LDT-5525 Temperature Controller.

Some of the more common symptoms are listed here, and the appropriate

troubleshooting actions are given. We recommend that the user start at the

beginning of this guide. Read the symptom descriptions, and follow the steps for

the corrective actions which apply. If you encounter problems which are beyond

the scope of this guide, contact your ILX Lightwave representative.

Symptom Causes and Corrective Actions

LDT-5525 Series unit will not

power up

Power on, but display is frozen,

switches don’t work

Check AC power line voltage and power cord connection

This may occur if the unit loses power (AC line) briefly. Turn the

power switch off and on again to restart

CHAPTER 3

Power on, but no TE current

output

Power on, but measured ITE

current is always about 0.0 A

Power on, but temperature is

not controlled

If TE OPEN indicator is lit, check the load connections and then

try again

Check that pins 14 and 15 of the output connector are not

connected (see Chapter 2: Booster Operation)

Check that pins 14 and 15 of the output connector are not

connected (see Chapter 2: Booster Operation)

If SENSOR OPEN indicator is lit, check the sensor connections

and then try again

Check that the back panel SENSOR SWITCH position is set to the

proper sensor type

Check that C1 and C2 are correct values for your sensor

Check that the GAIN setting is not too low and that the I LIMIT

value is not too low for your thermal load

06_07 LDT-5525 25

Page 40

CHAPTER 3

MAINTENANCE AND TROUBLESHOOTING

Troubleshooting

Unable to adjust output or

parameter

Unable to switch DISPLAY,

MODE, SENSOR CAL or

PARAMETER modes

Output goes off intermittently Check that th e AC power cord conne ction is secure; power line

R Mode set point is not saved The R mode set point value is not independent from the T mode

Check the ADJUST ENBL switch; the indicator must be lit for any

adjustments to be made

Check the MODE or DISPLAY switch; if they do not respond, the

unit may be in measurement calibration mode (see Chapter 3);

press the OUTPUT switch to abort this mode.

The unit may be in measurement calibration mode (see Chapter

3); press the OUTPUT switch to abort this mode

drop outs may reset the unit and when the power is restored, the

output will be off

Check the TE module connections; a high impendance on the TE

load may cause the output to exceed the compliance voltage

momentarily, thus shutting the output off

set point value; if the control mode is changed from R mode to T

mode, the R set value will change to a value which corresponds to

the temperature, based on C1 and C2

26 LDT-5525

Page 41

APPENDIX A

STEINHART-HART EQUATION

Two-terminal thermistors have a nonlinear relationship between temperature and

resistance. The resistance verses temperature characteristics for a family of

similar thermistors is shown in Figure A.1. It has been found empirically that the

resistance versus temperature relationship for most common negative

temperature coefficient (NTC) thermistors can be accurately modeled by a

polynomial expansion relating the logarithm of resistance to inverse temperature.

The Steinhart Hart equation is one such expression and is given as follows:

1/T = A + B(Ln R) + C(Ln R)3 Equation 1

- where T is expressed in KELVIN.

Once the three constants A, B, and C are accurately determined, Equation 1

introduces small errors in the calculation of temperature over wide temperature

ranges. Table A.1 shows the results of using equation 1 to fit the resistance verses

temperature characteristic of a common 10K ohm (at room temperature)

thermistor. Equation 1 will produce temperature calculation errors of less than

o

C over the range -20 oC to 50 oC.

0.01

Table A.1 Comparison of Curve Fitting Equations

Error T (°C)

R1 T

Actual

32128 0.00 -0.0000 -0.23

19549 10.00 0.0005 -0.11

12262 20.00 -0.0001 -0.06

9814 25.00 -0.0002 -0.06

7908 30.00 0.0009 -0.07

5331 40.00 0.0003 -0.15

3542 50.00 -0.0030 -0.30

Third Order Fit Eq 1 First Order Fit Eq 2

Error T (°C)

LDT-5525 27

Page 42

CHAPTER A

For the LDT-5525, the Steinhart Hart equation has been simplified to a first order

polynomial:

1/T = A' + B' * ln R Equation 2

This equation is easier to solve and provides adequate results. Table A.1 also

shows that the use of Equation 2 introduces temperature errors of less than 0.3

over the range -20

temperature ranges near room temperature

1 Resistance of a 10 kW, Dale 1T1002-5 thermistor

2 Constants A' = 0.99 * 10-3, B' = 2.57 * 10-4 (C1 = 0.99, C2 = 2.57).

50.00

40.00

30.00

kΩ

20.00

10.00

o

C to 50oC, with accuracies of up to 0.06oC over smaller

THERMISTOR R/T CURVES

FOR VARYING ROOM TEMP. RESISTANCES

1 k

2.5 k 5 k

10 k

25 k

50 k

2

.

100 k

o

C

28 LDT-5525

0.00

-40

-60

Figure A.1 Thermistor Resistance vs. Temperature

0

20

-20

TEMPERATURE (DEGREES C)

40

60

80

100 120

140

160

Once the constants A' and B' are determined, the LDT 5525 Temperature

Controller is programmed with the following values of C1, and C2:

C1 = A' * 10+3

C2 = B' * 10+4

Page 43

CHAPTER A

Computer Program

We have included a computer program called STEIN1 that uses a least squares

curve fitting routine to determine the values of C1 and C2. The program is written

in IBM's advanced BASICA.

You must create a data file for your thermistor that describes the resistance at

various temperatures. The temperature verses resistance calibration data can be

obtained from the thermistor manufacturer. Enter the resistance at various

temperatures as data points into an ASCII file. You can write the data file on a

word processor, but you must use non document mode so special word

processing characters are not inserted into the data file. Format the data with one

temperature resistance pair per line and at least one space separating the two

numbers. Temperatures should be in centigrade and resistances in ohms. For an

accurate determination of the coefficients, we recommend that you use at least

twenty data points uniformly spread over the intended range of use. Enter a -1 to

signify the end of the resistance data and temperature data.

A small sample data file is included below as an example of the data format and

end of data marker (R = 1).

Temperature Resistance

-20 97072

-10 55326

0 32650

10 19899

20 12492

25 10000

30 8056.8

40 5326.4

50 3602.3

-1 -1

Run the STEIN1 program. The best curve fitting values for C1, and C2 will be

displayed. Enter these numbers into the LDT-5525 Temperature Controller.

06_07 LDT-5525 29

Page 44

CHAPTER A

80 REM * * * * * * * * * * * * * * STEIN1 * * * * * * * * * * * * * * *

90 REM

92 REM Rev: 3 11 87

94 REM T is expressed in Kelvins.

100 REM Least squares fit program to find the thermistor coefficients

110 REM C1 and C2 in the following equation:

120 REM

130 REM 1/T = C1 + C2 * (ln R)

140 REM

200 REM

210 REM Variables:

220 REM

230 REM T[i], R[i] temperature and resistance data values.

240 REM

250 REM Y[i] = 1/T[i] the dependent variable (depends on R[i])

260 REM in the Steinhart Hart equation (above).

270 REM

280 REM X[i] = ln(R[I]) the value of the ith function of the independent

290 REM variable ln(R) (natural log of resistance)

330 REM

1000 DEFDBL A Z

1010 DEFINT I, J, K, L

1020 DIM R[400], T[400], Y[400], X[400]

1030 PRINT "What is the data file name"; : INPUT D$

1040 OPEN "i", 1, D$

1050 REM **** read and echo T(i), R(i) from the data file ****

1060 REM (terminate read on R= 1)

1070 I=0

1080 PRINT "Data:"

1090 G$="Point Temperature (Celsius) Resistance (ohms)"

1100 H$=" ### #####.## ########.##"

1110 PRINT G$

1120 PRINT

1130 I=I+1

1140 INPUT #1, T(I), R(I)

1150 IF R(I)<0 THEN GOTO 1180

30 LDT-5525

Page 45

1155 X(I)=LOG(R(I)) : Y(I)=1/(T(I)+273.15)

1160 PRINT USING H$; I, T(I), R(I)

1170 GOTO 1130

1180 N=I 1

1190 CLOSE

1200 REM **** accumulate sums ****

1205 SX=0 : SY=0 : SXY=0 : SXX=0

1210 FOR I = 1 TO N

1220 SX=SX+X(I)

1230 SY=SY+Y(I)

1240 SXY=SXY+X(I)*Y(I)

1250 SXX=SXX+X(I)*X(I)

1260 NEXT I

1300 REM **** print out results ****

1310 C[2]=(N*SXY SX*SY)/(N*SXX SX*SX)

1320 C[1] = (SY C[2]*SX)/N

1620 PRINT

1630 G$="Key in: C1 C2"

1640 P$=" #.## #.##"

1650 PRINT G$

1660 PRINT USING P$; C[1]*1000!, C[2]*10000!

1700 '

1702 C1=INT(C[1]*1000000!)/1000000!

1704 C2=INT(C[2]*1E+07)/1E+07

1710 PRINT

1712 PRINT " T T T"

1714 PRINT " R ACTUAL CALC ERROR"

1716 PRINT " ======== ========= ========== ========="

1718 P$= " ####### ####.## ####.## ####.##"

1720 FOR L=1 TO N

1730 X=LOG(R(L))

1740 TCALC=1/(C1+C2*X) 273.15

1760 PRINT USING P$;R(L),T(L),TCALC,T(L) TCALC

1780 NEXT L

CHAPTER A

06_07 LDT-5525 31

Page 46

CHAPTER A

32 LDT-5525

Page 47

APPENDIX B

SENSING CURRENT AND

THERMISTOR SELECTION

Choosing the right sensing current depends on the range of te mperature you want

to measure and the resolution you require at the highest measured temperature.

To correctly set the SENSOR SELECT switch you must understand how the

thermistor and the LDT-5525 Temperature Controller interact, and how

temperature range and resolution values are inherent in the nature of thermistors.

Thermistor Range

Thermistors can span a wide temperature range, but their practical range is

limited by their non-linear resistance properties. At high temperatures, the

thermistor resistance changes less for an equivalent temperature change at lower

temperatures (the thermistor becomes less sensitive). Consider the temperature

and sensitivity figures in Table B.1 below for a 10 K thermistor.

Table B.1 Thermistor Sensitivity

TEMPERATURE SENSITIVITY

-20oC 5600 ohms / oC

25oC 439 ohms / oC

50oC 137 ohms / oC

In the LDT-5525 Temperature Controller, the practical upper temperature limit is

the temperature at which the thermistor becomes insensitive to temperature

changes. The lower end of the temperature range is limited by the maximum input

voltage of the LDT-5525 Temperature Controller. Thermistor resistance and

voltage are related through Ohms Law (V = I x R). The LDT-5525 Temperature

Controller supplies current to the thermistor, either 10 µA or 100 µA. As the

thermistor resistance changes, a changing voltage signal is available to the

LDT-5525 33

Page 48

CHAPTER B

Thermistor Range

thermistor inputs of the LDT-5525. The LDT-5525's measurement system will

over-range when the input voltage exceeds about 4.5 volts. Figure B.1

graphically shows the lower temperature and upper voltage limits for a typical 10

K thermistor. (A 10 K thermistor has a resist ance of 10 kΩ at 25

o

C). The practical

temperature ranges for a typical 10 K thermistor with the LDT-5525 are given in

Table B.2, below. These temperature ranges may vary from thermistor to

thermistor, even though both thermistors are nominally 10 K. This is due to

manufacturing tolerances in the thermistor, and is compensated for by

determining C1, and C2 (calibrating the thermistor). The practical temperature

ranges for a 10 K thermistor are also shown as solid bars at the bottom of Figure

B.1.

Table B.2 10K Thermistor Temperature Range

SENSING CURRENT TEMPERATURE RANGE

10 µA -30 to 30 oC

100 µA 10 to 70 oC

5.00

4.50

4.00

3.00

THERMISTOR

VOLTAGE

2.00

1.00

0.00

* ILX default values for C1 and C2

(USING TYPICAL* 10 k @ 25 C THERMISTOR)Ω

-60

-20

-40

02040

DEGREES C

o

60

10 Aµ

- Denotes practical range with typical 10K thermistor

- Denotes measurable range with typical 10K thermistor

Figure B.1 Thermistor Temperature Range

80

100

100 Aµ

34 LDT-5525

Page 49

Thermistor Range

CHAPTER B

Temperature Resolution

You must also consider measurement resolution since the measurement

resolution decreases as the thermistor temperature increases. A temperature

controller (such as the LDT-5525) has a limited measurement resolution. A

temperature change of one degree centigrade will be represented by a greater

resistance increase at a lower temperature than at a higher temperature because

of the non-linear resistance of the thermistor. Resolution figures for a typical 10 K

thermistor are given in Table B.3, below.

Table B.3 10K Thermistor Voltage vs. Resolution

TEMPERATURE VOLTAGE AT 10 µA RESOLUTION

-20oC 56 mV / oC 0.018 oC / mV

25oC 4.4 mV / oC 0.23 oC / mV

50oC 1.4 mV / oC 0.70 oC / mV

For a typical 10 K thermistor, a temperature change from -20 oC to -19oC will be

represented by a measurement change of about 56 mV (if supplied with 10 µA).

The same thermistor measurement will only change about 1.4 mV from 49 to

o

50

C! For that case, with the LDT -55 25, the tempera ture measurement resolution

would be reduced to about 0.2

thermistor measurement would change by 14 mV from 49 to 50*C, providing the

maximum resolution of 0.1

Therefore, the sensor current you choose may impact the temperature

measurement resolution as well as the set point control accuracy.

o

C. If the 100 µA setting were used instead, the

o

C (with the LDT-5525).

Selecting the Sensing Current

To select the current setting for a typical 10K thermistor, determine the lowest

temperature you will need to sample and set the SENSOR SELECT switch

according to the range limits in Table B.2. If the temperature you want to sample

is below 10

o

C you will probably need to set the switch to the 10 µA setting.

If you require temperatures of 10 oC to 30 oC, either SENSOR SELECT setting

(100 µA or 10 µA) will work with a 10K thermistor. However, the 100 µA setting

provides greater measurement resolution, and therefore better control.

Note: Generally, it is best to use the 100 µA SENSOR SELECT setting for all

measurements of 10

o

C or greater with a typical 10 K thermistor.

Selecting and Using Thermistors

The type of thermistor you choose will depend primarily on the operating

temperature range. These guidelines for selecting the range and resolution will

apply to any thermistor. From Figure B.1 you can see that 10 K thermistors are

06_07 LDT-5525 35

Page 50

CHAPTER B

Thermistor Range

generally a good choice for most laser diode applications where high stability is

required near room temperatures. Similarly, 10 K thermistors are often a good

choice for detector cooling applications where you want to operate at

temperatures from -30

If you require a different temperature range or the accuracy you need can't be

achieved with either switch setting, select another thermistor. Thermistor

temperature curves, supplied by the manufacture, show the resistance verses

temperature range for many other thermistors. ILX Lightwave Corporation will also

offer help for your specific application.

o

C to room temperature.

36 LDT-5525

Page 51

APPENDIX C

AD590 AND LM335 SENSOR CALIBRATION

The LDT-5525 Temperature Controller uses two constants (C1 and C2) for

calibrating linear thermal sensing devices, such as the AD590, and the LM335.

C1 is used as the linear or zero offset value, and C2 is used as the slope or gain

adjustment. Therefore, C1 should be set to a nominal value of 0, and C2 should

be set to a nominal value of 1, when the SENSOR SELECT switch is in the

AD590, or LM335 positions.

In order to calibrate a linear sensor device, the sensor must be operated at an

accurately known, stable temperature. For example, the sensor may be calibrated

o

C if the sensor is placed in ice water until its temperature is stable. A highly

at 0

accurate temperature probe, thermometer , environment al chamber , etc., may also

be used to determine the known temperature for calibration. This appendix

contains one and two point calibration methods for linear sensor devices. These

methods will work for either type of device.

AD590 Sensor

The AD590 is a linear thermal sensor which acts as a constant current source. It

produces a current, i, which is directly proportional to absolute temperature, over

its useful range (-50

i = 1µA / K

o

C to +150oC). This nominal value can be expressed as:

- where i is the nominal current produced by the AD590, and K is in Kelvin.

The LDT-5525 Temperature Controller uses i to determine the nominal

temperature, T

T

= ( i / ( 1µA / K ) ) - 273.15

n

- where Tn is in oC.

The temperature, Td, which is displayed by the LDT-5525 Temperature Controller

is first calibrated as follows:

, by the formula:

n

LDT-5525 37

Page 52

CHAPTER C

Td = C1 + ( C2 * Tn )

- where C1 and C2 are the constants stored by the user in the LDT-5525

Temperature Controller for the AD590.

The AD590 measurement is calibrated, at the factory, with C2 = 1 and C1 = 0

(nominal values). The AD590 grades of tolerance vary, but typically this means

that without adjusting C1 or C2, the temperature accuracy is

+1 oC over its rated

operating range. If C1 and C2 are also calibrated, the temperature accuracy is

+0.2 oC over its rated operating range. However, the AD590 is not perfectly linear,

and even with C1 accurately known there is a non-linear absolute temperature

error associated with the device. This non-linearity is shown in Figure C.1,

reprinted from Analog Devices specifications, where the error associated with C1

is assumed to be zero.

1.6

0.8

ABSOLUTE

ERROR

(DEGREES C)

0

-0.8

-1.6

-55 150

Figure C.1 AD590 Nonlinearity

DEGREES C

If a maximum absolute error of 0.8 oC is tolerable (over the entire temperature

range), the one point calibration of C1 should be used (see page C-5). If C1 is

o

calibrated at 25

error of about

C, and the intended operating range is 0 to 50 oC, a maximum

+0.2 oC may be expected over that operating range. If a greater

accuracy is desired, the two point method of determining C1 and C2 should used

(see page C-6). Note however , the absolu te error curve is non-linear , therefore the

constant C2 will vary over different temperature ranges.

LM335 Sensor

The LM335 is a linear thermal sensor which acts as a constant voltage source. It

produces a voltage, v, which is directly proportional to absolute temperature, over

its useful range (-40

v = 10mV / K

- where v is the nominal voltage produced by the LM335 and K is in Kelvin.

o

C to +100oC). This nominal value can be expressed as:

38 LDT-5525

Page 53

CHAPTER C

The LDT-5525 Temperature Controller uses v to determine the nominal

temperature, T

Tn = ( v / ( 10mV / K ) ) - 273.15

- where Tn is in oC.

The temperature, Td, which is displayed by the LDT -5525 Temperature Controller,

is first calibrated as follows:

, by the formula:

n

Td = C1 + ( C2 * Tn )

- where C1 and C2 are the constants stored by the user in the LDT-5525

Temperature Controller for the LM335.

When the LDT-5525 is ship ped from the factory, the LM335 measurement system

is calibrated, but the sensor (C1 and C2) is not. Nominally, C1 = 0, and C2 = 1. In

that case, the temperature accuracy is typically

range. With C1 and C2 calibrated also, the temperature accuracy is typically

o

C over the rated operating range. The temperature accuracy may be improved

over a narrow temperature range by a two-point calibration of C1 and C2.

However, the LM335 is not perfectly linear, and even with C1 accurately known

(and C2 uncalibrated) there is a non-linear absolute temperature error associated

with the device. This non-linearity caused error is typically

associated with C1 assumed to be zero.

If a maximum absolute error of +1oC is tolerable, no calibration of C1 or C2 is

required, just set C1 = 0, C2 = 1. If a maximum absolute error of

tolerable, the one point calibration of C1 may be used (see page C-5). If a greater

accuracy is desired, the two point method of determining C1 and C2 should used

(see page C-6). Note however , the absolute error associated with the const ant C2

may vary over different temperature ranges.

+1oC over the rated operating

+0.3

+0.3 oC, with the error

+0.5 oC is

06_07 LDT-5525 39

Page 54

CHAPTER C

One Point Calibration Method

This procedure will work for any linear temperature sensor. The accuracy of this

procedure depends on the accuracy of the known temperature, externally

measured. It is used to determine the zero offset of the device, and it assumes

that the gain offset (slope) is known and is correct.

1 Allow the LDT-5525 Temperature Controller to warm up for at least one hour. Set the

SENSOR SELECT switch for the desired sensor type, and RECALL the constants for the

particular device to be calibrated.

2 Select the C1 parameter. Read and record the value of C1.

3 Place the sensor at an accurately known and stable temperature, Ta. Connect the sensor

to pins 7 and 8 of the LDT-5525's 15-pin connector. Set the LDT-5525 for normal constant

temperature (T mode) operation. Allow the LDT-5525 Temperature Controller to stabilize