2-Way Communicating Thermostat

Hardware Installation and Operation Manual

Intended for connection to

Class 2 Circuit(s) Only (24 VAC)

Common Wire is Required

Manufactured by:

Lightstat Inc.

Barkhamsted, CT

www.lightstat.com

.....INSTALLERS....

CONTACT LIGHTSTAT FOR ACTIVATION

1-800-292-2444

For e-Stat™ Model Thermostat

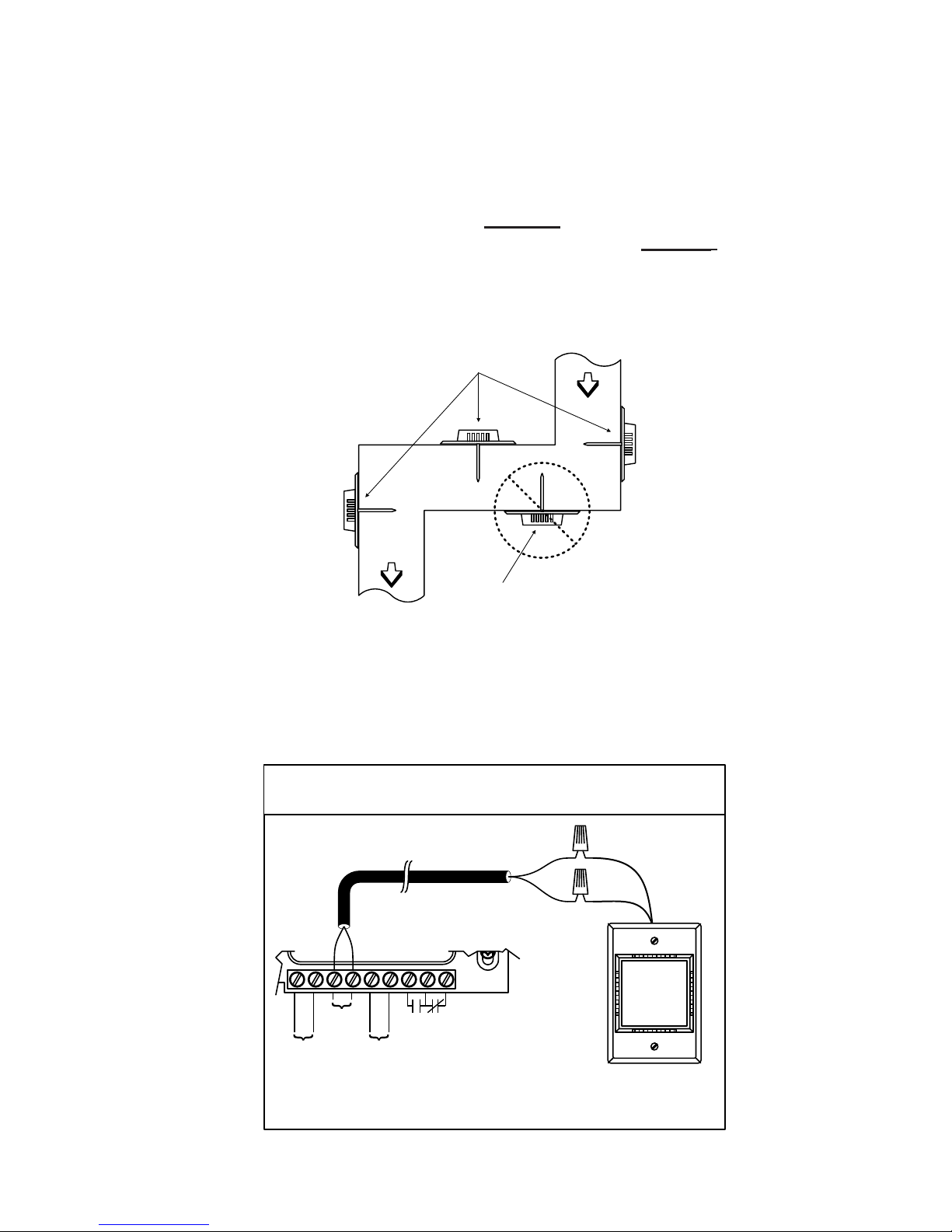

1

Supply

Ductwork

Return

Ductwork

Roof Top Unit #1

Retail or restaurant

interior area

Your existing POS

computer and/or

network connection

e-Stat

Remote Room Sensor

Hub

Remote supply sensor is

located in supply ductwork

2-conductor

#18 low voltage

cable

2-conductor

#18 low voltage

cable

Existing

8-conductor

#18 low voltage

cable

Cat 6

cable

e-Stat Typical Wiring Configuration

1. Typically, the e-Stat™ should be located within

a few feet of the network equipment such as the

network switch. It may be located farther. The

maximum Cat 6 cable run is 328 ft

(100 meters).

2. Mount the Remote Room Sensor on a wall or

column in the conditioned space, away from

windows, doors and supply air ducts. (Refer to

page 9 for more instructions.)

3. Mount the Supply Air Sensor in the supply air

duct as close to the HVAC unit as possible.

(Refer to page 10 for more instructions.)

Note: You must use the remote temperature

sensor supplied. The e-Stat™ does NOT contain

an onboard temperature sensor.

2

Description:

The e-Stat

™

is a low voltage, solid state, automatic

changeover, heating/cooling thermostat with digital

display showing setpoints and room temperature.

The

e-Stat

™

is a 2-Way Communicating, remotely

programmable thermostat.

Standard Features:

• Control of up to two stages of heating

and cooling.

• Proportional plus Integral (P+I) control for

accurate, even temperature control.

• Automatic changeover from heating to

cooling with deadband to prevent short

cycling of HVAC equipment.

• Remotely programmable, adjustable deadband.

(5°F is default)

• Remotely congurable Y1, Y2 interstage

differential. (1.5°F is default)

• Intelligent pre-conditioning of the controlled

space prior to the start of the workday.

• Automatic randomized delay to prevent power

surges at power up. (4 to 12 minutes)

• Backlit display for easy viewing in low light

conditions.

• Support for optional humidity sensing.

• Contact Closure terminal input to monitor switch

closure.

• Limited Lifetime Warranty.

General:

Voltage Rating (min, max).........................20 to 30 VAC

Current Draw (typ).............................285 mA @ 24VAC

A1-A2-A3 Relay Load (max)................1 Amp @ 24VAC

G, Y1, Y2, W1, W2, O/B Load (max)...1 Amp @24VAC

Network:

Cabling........................Cat6 (UTP) with RJ45 connector

Ethernet....................................10/100BT Auto-Sensing

Wiring Cable Distance (Max).................................328 ft

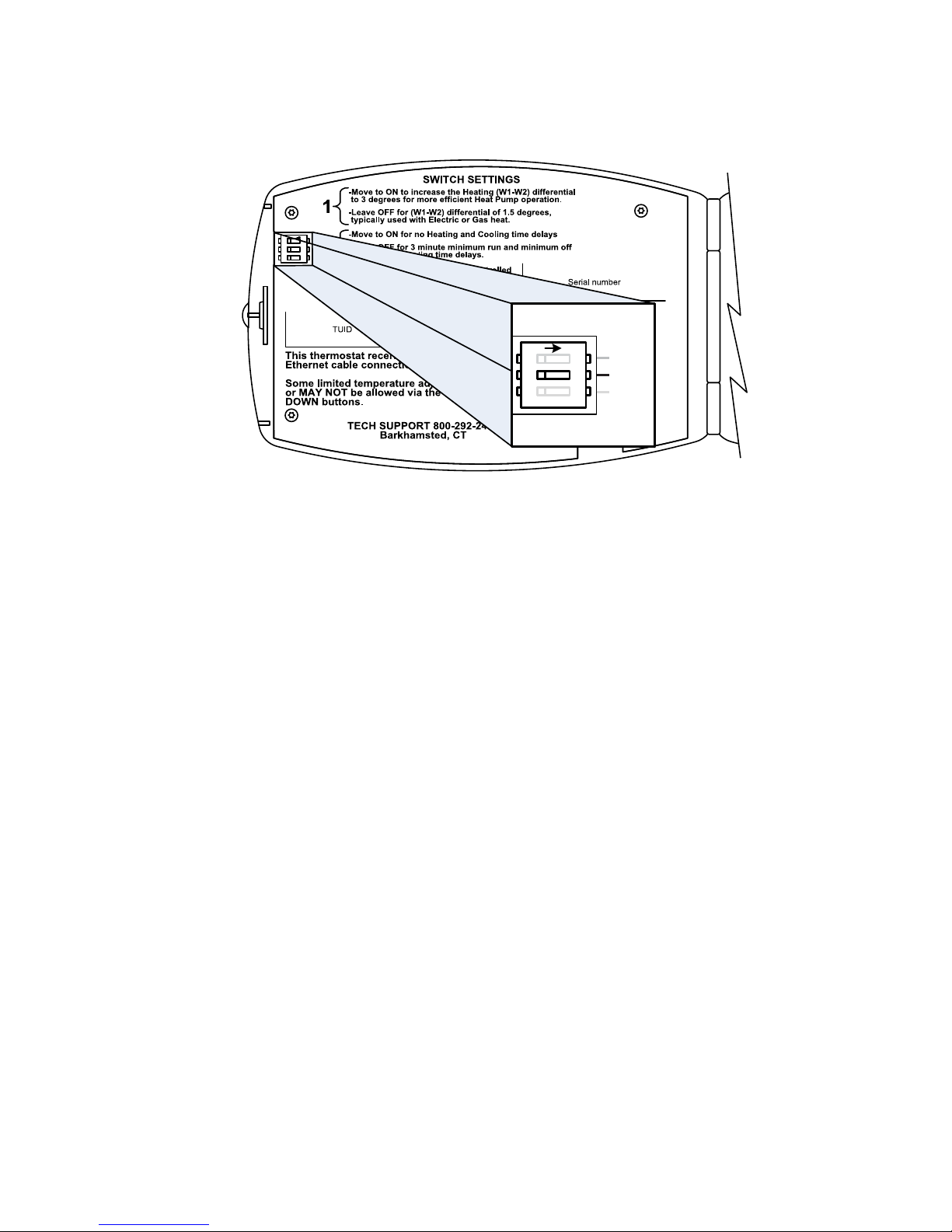

Inside View - Door (Left)

Inside View - Base (Right)

ON

1 2 3

This th ermost at rec eive s programm ing vi a

E thernet cable connec tion .

S ome li mited te mperature adjust ment MAY

or MAY NO T be allow ed via the UP and

DOW N buttons .

TEC H SUPPOR T 800-292-2444

P leasant Valley , C T

OFF ON

1

2

3

1

2

3

-Mov e to ON fo r gas heat . Fan contr olled

by limit switch .

-L eave O FF for fan contr olled by Light stat

in heat c ycle ( typical f or electric heat ).

-Mov e to ON for no compres sor time del ays .

-L eave O FF for 3 minute compress or minimum r un

a nd minim um o

tim e delays .

-Mov e to ON to increase the Heatin g ( W1-W 2) di erential

to 3 d egrees f or m ore e

cien t Heat Pump opera tion .

-L eave O FF for (W 1-W 2) d i

erent ial of 1 .5 d egrees ,

typ ically used wi th Ele ctri c or Gas h eat .

WRA P 00003 R EV . ?

S WITCH SE TTINGS

3

Connecting the Outputs

Caution: Risk of Electrical Shock - More than one

disconnect switch may be provided. Disconnect

all power to device before servicing.

Remove the old thermostat from the wall taking note of

the wire colors on the back of the mounting kit

provided. Thread the thermostat cable through the

hole in the back of the

e-Stat

™

. Mount the e-Stat™

securely to the wall using the hardware provided.

The

e-Stat

™

should be leveled for cosmetic reasons.

GENERAL HVAC WIRING DIAGRAM

e-Stat

G

R

Y1

W1

W2

C

O

Y2

B

CLASS 2 XFMR

SYSTEM

TRANSFORMER

HVAC

EQUIPMENT

TERMINAL

STRIP

20-30 VAC

ONLY

A2

A1

A3

G

R

Y1

W1

W2

C

O

Y2

B

MAY BE USED

FOR NIGHT

SHUTDOWN

OF DAMPERS

OR OTHER

EQUIPMENT.

RELAY LOAD:

1 AMP (MAX)

@ 24VAC

CONNECT

AS REQUIRED

BY HVAC

EQUIPMENT

A1-A2-A3

C ONTACT

TERMINALS

ON e-Stat

FAN

HEAT 1

20-30 VAC ONLY

(C OMMON

)

(COMMON)

HEAT PUMPS

MAY REQUIRE

JUMPER

BETWEEN Y1

AND W1 TO

BRING ON

COMPRESSOR IN

BOTH HEATING

AND COOLING.

(SEE NOTES ON

PAGE 5)

HEAT 2

COOL 1

COOL 2

4

R - Hot Wire; one side of the control (20 - 30 VAC)

transformer. If two hot wires are present (as with RC and RH)

determine if they come from separate transformers. The e-Stat

™

must be installed on a single transformer

system.

G - Fan Wire.

W1 - First stage of heating.

Y1 - First stage of cooling.

When conventional rooftop equipment is selected, the interstage

differential is always 1.5°F. With heat pump switch #1 set to “ON”,

the interstage differential is 3.0°F for heating stages and 1.5°F for

cooling stages. (If using a humidity sensor, interstage differential

will increase during cooling to compensate for high humidity

conditions.)

C - Common or Neutral side of transformer. This must be

connected for the e-Stat

™

to operate.

W2 - Second stage of Heat or Auxiliary heat with heat pumps.

Y2 - Second stage of cooling.

O - This output will be active with a call for cooling.

Often used for heat pump reversing valve.

B - This output will be active with a call for heating.

(Connect O & B outputs as required by the HVAC equipment.)

Note: When connecting to a heat pump with Thermostat

Reversing Valve Control you will need to install a jumper

wire between W1 and Y1 at the e-Stat™. There should be no

connection between W1 on the e-Stat™ and the RTU terminal

strip. Aux heat is connected to W2.

Note: When connecting to a heat pump with Unit Reversing

Valve Control no jumper wire is required as the reversing valve is

positioned by the unit internal controls based on whether cooling

or heating is being called by Y1, Y2 or W1, W2.

A1, A2, A3 are dry contact relay terminals that may be used for

night shutdown of dampers or control of other equipment. This is a

separate relay with isolated contacts.

Relay load: 1 AMP (MAX) @ 24VAC.

Connecting the Outputs

5

A - Indicates day of the week.

B - Signal/Status L.E.D. Indicators.

C - Output designators.

D - Press once to see supply air temp and

“last program” information, 2nd press displays %

relative humidity (if a humidity sensor is in use).

E - Check button. Use to cancel time delays.

F - Temperature up/down buttons.

G - Fan On/Auto button.

H - System power button.

Front View - Front Door Open

Temp

ONFANAUTO

HEATSET

COOLS ET

OVERRIDE

NEW PROGRAM

SYSTEM OFF

REL

HUMIDITY

ERROR

REMOTE TEMP

MONTUEWEDTHUFRISATSUN

ON

ON

ON

ON

ON

ON

A

P

Cool 1

Cool 2

Fan

O

Heat 1

Heat 2

System

On/Off

Check

Fan

On/Auto

Read

Sensor

Yellow -

Website

program

active

Red -

Utility Program

active

Press to cancel

Time delays

On – Constant Fan

Auto – Fan only with

Heat / Cool cycle

Press to read

Supply Air Sensor

& Humidity (Optional)

Web controlled thermostat.

Buttons may be disabled.

Tech Support 800-292-2444

Turns entire system off

F

B

H

D

E

G

C

A

6

7

A - Output indicators. Illuminated “ON” and arrow indicates

output is active. Flashing arrow and steady “ON” indicates

output is being held on by time delay. Flashing arrow alone

indicates output is being held off by time delay.

B - Cooling temperature setpoint.

C - Indicates day of the week.

D - Current remote room temperature, supply air temp, or

ambient humidity.

E - REL HUMIDITY will ash to indicate setpoint reduction is

active.

F - Antenna icon indicates that an ethernet carrier is sensed.

G - Remote temperature sensor indicator.

H - Indicates status of hosting server communications.

I - If arrow and “ON” are not illuminated, the output is off.

J - Heating temperature set point.

K - Fan On/Auto indicator.

L - Indicates system is off.

M - Ramp symbol will be illuminated if space is actively being

preheated or precooled.

N - Solid “OVERRIDE” indicates the program has been over-

ridden with the Up/Down buttons if allowed locally. Flashing

“OVERRIDE” indicates remote override.

O - “New Program” will illuminate when “Read Sensor”

button is pressed once (provided thermostat has been

programmed).

P - Indicates AM or PM Local time.

Display Designators

COO LSET

AUTO FAN ON

ON

ON

ON

ON

ON

ON

MONTUEWEDTHUFRISATSUN

HEA TSET

SYS TEM OFF

OVERRIDE

NEW PROGRAM

ERROR

REMOTE T EMP

REL

HUMIDITY

P

A

Cool 1

Cool 2

Fan

O

Heat 1

Heat 2

H

P

M

CB

J

K

A

O

N

GF

E

L

D

I

The e-Stat

™

is used as a stand-alone thermostat to

control a single HVAC system. Do not attempt to control more than one HVAC unit with an

e-Stat

™

A Remote Temperature Sensor MUST BE installed for

the e-Stat™ to function properly. A Supply Air Sensor is

optional.

All wiring should be a minimum of #18AWG. Shielding

is not required.

Wiring Layout

8

TYPICAL

ROOFTOP

UNIT

SUPPLY AIR DUCT

S UPPLY AIR SENS OR

MOUNT O N DISCHARGE AIR DUCT W IT H

P RO BE I N DISCHARGE AIR ST REAM

REMOTE TEMPERATURE AND

HUMIDITY SENSOR

MOUNT IN SP ACE TO B E CONTRO LLED

10 WIRE #18A WG

2 WIRE #18A WG

2 WIRE #18A WG

NETWORK

CABLE

DO NOT INSTALL ON THE BOTTOM OF THE DUCT

Cat-6/6e

Remote Sensor Installation

The e-Stat™ must have a Remote Temperature Sensor

installed. A Supply Air Sensor is optional. These sensors

are supplied for each thermostat.

Note: See Appendix B for Remote Temperature and

Humidity Sensor.

Use #18 gauge 2-conductor twisted pair cable between the

e-Stat™ and the remote sensors. Remote sensors are

unaffected by wire runs of up to 500 feet.

Remote sensors do not have polarity, either wire may be

connected to either terminal. Shielded cable is not required

for remote sensors.

Mount the remote temperature sensor in the area to be

heated and/or cooled. If the remote temperature sensor is

installed where the old thermostat was, use the supplied wall

plate for cosmetic reasons.

Connect the 2-conductor cable to the two terminals marked

Remote Temperature Sensor. These are located in the cen-

ter of the bottom terminal block as seen in the gure below.

Note that this sensor is not designed to be placed into a

moving air stream.

9

Wire Nuts

(supplied)

REMOTE ROOM SENSOR

WIRING DIAGRAM

RELAYS: G, W1, Y1, W2, Y2, O, B,

A1, A2, and A3 rated 24 V ac, 60 Hz,

Class 2, 1A, resistive / pilot duty.

A1-A2-A3 Relay: Normal

position indicated.

Contacts reverse during

Unoccupied (night) mode

or, via OFF signal from

website.

Dry contacts

are isolated.

C1 C2

Contact

Closure

Input

Supply

Air

Sensor

A1A2A

3

Remote

Room

Temperture

(& Humidity)

Sensor

Non-twisted Pair #18 AWG Wire

500 feet (maximum)

(not supplied)

Remote Room

Temperature

(& Humidity)

Sensor

Supply Air Sensor

Mount the Supply Air Sensor on the discharge air duct

with the probe in the discharge air stream making sure

the inner duct liner is penetrated, if present, so the

probe is in the air stream.The probe must be positioned

horizontally or downward. Do not place on the bottom of the duct with the probe sticking up. Do not use

probe as a tool to puncture ductwork.

10

Connect the 2-conductor cable to the two terminals

marked Supply Air Sensor. These are located on the

bottom terminal block as seen in gure below.

Discharge

From RTU

To

Supply Air

Diffuser

Acceptable

Supply Air

Sensor

Locations

Unacceptable

Supply Air

Sensor

Location

Wir e Nuts

(supplied)

(REMOTE) SUPPLY AIR SENSOR

WIRING DIAGRAM

RELAYS: G, W1, Y1, W2, Y2, O, B,

A1, A2, and A3 rated 24 V ac, 60 Hz,

Class 2, 1A, resistive / pilot duty.

A1-A2-A3 Relay: Normal

position indicated.

Contacts reverse during

Unoccupied (night) mode

or, via OFF signal from

website.

Dry contacts

are isolated.

C1 C2

Contact

Closure

Input

Supply

Air

Sensor

A1A2A

3

Remote

Room

Temperture

(& Humidity)

Sensor

Non-twisted Pair #18 AWG Wire

500 feet (maximum)

(not supplied)

Supply

Air

Sensor

11

When using the e-Stat

™

on a heat pump, move this

switch to the ON position. This will increase the

interstage differential between W1 and W2 from 1.5°F

to 3°F in the heating mode to allow the HVAC to

operate the compressor longer before turning on the

backup heat.

Moving this switch to ON also tells the

e-Stat

™

to use

a different intelligent recovery warm up from the

unoccupied to the occupied mode, to minimize the use

of backup heat.

The recovery period is a maximum of 128 minutes.

The

e-Stat

™

will automatically determine the amount of

time required to bring the space up to the

desired temperature setpoint.

During this recovery period, the

e-Stat

™

will display the

“ramp” symbol in the digital display and the

temperature setpoints will ramp automatically.

Setting the Heat Pump Switch (#1)

ON

1 2 3

This th ermostat recei ves pr ogramming via

E thernet cable connection .

S ome li mited te mperature adjustment MAY

or MAY NOT be allow ed via the UP and

DOW N butt ons .

TECH SU PPOR T 800 -292-2444

P leasant Valley , C T

OFF ON

1

2

3

1

2

3

-Move to ON fo r gas heat . F an con trol led

by limit switch .

-L eave O FF for fan contr olled by Light stat

in heat c ycle (typ ical f or elect ric heat ).

-Mov e to ON fo r no c ompres sor time delay s .

-L eave O FF for 3 minut e compress or m inimum r un

a nd minim um o

time delays .

-Move to ON to incre ase the Heatin g (W1 -W2) di e rential

to 3 d egrees f or m ore e

cien t H eat Pump o peration .

-L eave O FF for ( W1-W 2) di

erent ial of 1. 5 deg rees ,

typ ically used wi th Ele ctri c or Gas h eat .

WRAP 00003 R EV . ?

S WITCH SE TTINGS

ON

1 2 3

.

OFF ON

1

2

3

-L eave O FF for f an c ontrolle d by Lig htstat

in he at cyc le (typic al for electri c heat ).

WRAP00003 REV. ?

1 2 3

ON

OFF ON

1

2

3

12

When this switch is set to OFF, the minimum On and

Off time for any stage of Heating or Cooling will be 3

minutes.

When set to ON, no delays are used when heating or

cooling stages change state.

In either position, the Fan will continue to run for 45

seconds after the Heating or Cooling stops;

unless the Fan switch is set to ON in which case the

fan runs continuously.

During night setback the Fan will revert to the Auto

Mode.

Setting the Compressor Time Delay Switch (#2)

ON

1 2 3

This th ermostat recei ves pr ogramming via

E thernet cable connection .

S ome li mited te mperature adjustment MAY

or MAY NOT be allow ed via the UP and

DOW N butt ons .

TECH SU PPOR T 800 -292-2444

P leasant Valley , C T

OFF ON

1

2

3

1

2

3

-Move to ON fo r gas heat . F an con trol led

by limit switch .

-L eave O FF for fan contr olled by Light stat

in heat c ycle (typ ical f or elect ric heat ).

-Mov e to ON fo r no c ompres sor time delay s .

-L eave O FF for 3 minut e compress or m inimum r un

a nd minim um o

time delays .

-Move to ON to incre ase the Heatin g (W1 -W2) di e rential

to 3 d egrees f or m ore e

cien t H eat Pump o peration .

-L eave O FF for ( W1-W 2) di

erent ial of 1. 5 deg rees ,

typ ically used wi th Ele ctri c or Gas h eat .

WRAP 00003 R EV . ?

S WITCH SE TTINGS

ON

1 2 3

.

OFF ON

1

2

3

-L eave O FF for f an c ontrolle d by Lig htstat

in he at cyc le (typic al for electri c heat ).

WRAP00003 REV. ?

1 2 3

ON

OFF ON

1

2

3

13

Setting the Heat Fan switch to Gas/Electric (#3)

This is often called the “Gas/Electric” switch.

Consult the HVAC equipment manufacturers’

instructions for details on how to set this switch.

When controlling fossil fueled equipment with a fan

limit control, you may want to set this switch to the ON

position.

Note: The e-Stat

™

will not bring on the fan in this

setting during the heat cycle.

Leave this switch set to OFF for all other

equipment, such as electric heat or heat pumps.

ON

1 2 3

This th ermostat recei ves pr ogramming via

E thernet cable connection .

S ome li mited te mperature adjustment MAY

or MAY NOT be allow ed via the UP and

DOW N butt ons .

TECH SU PPOR T 800 -292-2444

P leasant Valley , C T

OFF ON

1

2

3

1

2

3

-Move to ON fo r gas heat . F an con trol led

by limit switch .

-L eave O FF for fan contr olled by Light stat

in heat c ycle (typ ical f or elect ric heat ).

-Mov e to ON fo r no c ompres sor time delay s .

-L eave O FF for 3 minut e compress or m inimum r un

a nd minim um o

time delays .

-Move to ON to incre ase the Heatin g (W1 -W2) di e rential

to 3 d egrees f or m ore e

cien t H eat Pump o peration .

-L eave O FF for ( W1-W 2) di

erent ial of 1. 5 deg rees ,

typ ically used wi th Ele ctri c or Gas h eat .

WRAP 00003 R EV . ?

S WITCH SE TTINGS

ON

1 2 3

.

OFF ON

1

2

3

-L eave O FF for f an c ontrolle d by Lig htstat

in he at cyc le (typic al for electri c heat ).

WRAP00003 REV. ?

1 2 3

ON

OFF ON

1

2

3

Use #18 gauge cable between the e-Stat

™

and the

damper or equipment to be controlled. Cables do not

need to be shielded.

The A1-A2-A3 terminals are an isolated set of dry

contacts rated 1 Amp at 24 VAC.

Connect the cable to the appropriate terminals marked

A1-A2-A3. Connect the other end to the damper or

equipment to be controlled as needed.

The default operation for A1-A2 is open during “oc-

cupied” period and closed during “unoccupied” period.

A2-A3 is closed during “Occupied” period and open

d u r i n g “ u n oc cu pi e d ” p e r i o d .

Note: Alternatively, these contacts can be controlled

remotely via the Internet. See Appendix A.

14

A1-A2-A3 DRY CONTACT CLOSURE

WIRING DIAGRAM

RELAYS: G, W1, Y1, W2, Y2, O, B,

A1, A2, and A3 rated 24 V ac, 60 Hz,

Class 2, 1A, resistive / pilot duty.

A1-A2-A3 Relay: Normal

position indicated.

Contacts reverse during

Unoccupied (night) mode

or, via OFF signal from

website.

Dry contacts

are isolated.

C1 C2

Contact

Closure

Input

Supply

Air

Sensor

A1A2A

3

Remote

Room

Temperture

(& Humidity)

Sensor

Non-twisted Pair #18 AWG Wire

500 feet (maximum)

(not suppl ied)

May be used for

night shutdown of

dampers or other

equipment

A1-A2 = Normally

Open (N.O)

Contacts

A2-A3= Normally

Closed (N.C)

Contacts

1 Amp

(Max) @

24VAC

Powering up the e-Stat

™

First you must turn on the breaker or switch that feeds

power to your HVAC equipment.

Next, press the blue System On/Off button to turn on

the

e-Stat

™

.

The power-up sequence will give you information about

your

e-Stat

™

.

IMPORTANT: The

e-Stat

™

must be programmed

remotely. The thermostat will run the HVAC system on

default temperatures. After power up, this thermostat

must be activated in order for the customer to change

the programming. (see page 16 for activation

instructions).

You must connect the Cat 6 RJ45 jack in

order for the e-Stat

™

to communicate on the

network and be programmed.

15

ETHERNET CABLE (NETWORK)

WIRING DIAGRAM

Use supplied

Ethernet cable

If substituting Ethernet

cable length must not

exceed 328 feet

Connect to RJ -45 jack

positioned near eStat or to

a network hub, switch, or

router.

Networking equipment to

be supplied by others.

Temp

ONFANAUTO

HEATSET

COOLSE T

OVERRIDE

NEW PROGRAM

SYSTEM OFF

REL

HUMIDITY

ERROR

REMOTE TEMP

MONTUEWEDTHUFRISATSUN

ON

ON

ON

ON

ON

ON

A

P

Cool 1

Cool 2

Fan

O

Heat 1

Heat 2

System

On/Off

Check

Fan

On/Auto

Read

Sensor

Yellow -

Website

program

active

Red -

Utility Program

active

Press to cancel

Time delays

On – Constant Fan

Auto – Fan only with

Heat / Cool cycle

Press to read

Supply Air Sensor

& Humidity (Optional)

Web controlled thermostat.

Buttons may be disabled.

Tech Support 800-292-2444

Turns entire system off

System

On/Off

Press to read

Supply Air Sensor

& Humidity (Optional)

Turns entire system off

F

Thermostat Activation

The e-Stat

™

thermostat must be activated after

installation. Activation only takes a few

minutes.

Information you will need before calling to activate your

e-Stat

™

:

1. Location Name, such as restaurant

or store name.

2. Store Number.

3. Thermostat TUID number (yellow label

afxed on the inside wrap of the

thermostat).

During the activation, Lightstat Support will be able to

bring on the heating and/or cooling for you to verify

proper equipment operation.

Depending on the model

e-Stat

™

you have,

the temperature buttons may or may not work. If the

temperature up/down buttons function, do not use

these to test the HVAC operation prior to activation.

This will put the

e-Stat

™

in override mode. If the word

“override” is in the display, you must turn the power off

and then back on in order to clear the override.

PLEASE CALL TO ACTIVATE THE

THERMOSTAT

1-800-292-2444

YOUR CUSTOMER CANNOT COMMUNICATE

WITH THE THERMOSTAT UNLESS IT HAS

BEEN ACTIVATED.

16

Green Button Functions

Check - Cancels all time delays (primarily used for

troubleshooting purposes).

Fan On/Auto - Some model thermostats may not have

a selectable fan function. If selectable, choose be-

tween “ON” (Constant Fan) or “AUTO” (Fan only with

heat or cool cycle) during OCCUPIED period.

Read Sensor - Press the “Read Sensor” button once

to see when the last program was received. This will

also display the supply air sensor temperature. Press

a second time to see the relative humidity (if an RTH

sensor is in use).

17

Check

Fan

On/Auto

Read

Sensor

Press to cancel

Time delays

On – Constant Fan

Auto – Fan only with

Heat / Cool cycle

Press to read

Supply Air Sensor

& Humidity (Optional)

Use the UP and DOWN temperature buttons to change

the heating and cooling setpoints. To conserve energy

and make sure that the heating and cooling units do

not ght each other, the heating and cooling setpoints

typically cannot be set closer than 5°F. Other “ONOFF

differentials” may be used. 3, 4 or 6°F can be selected

via the web interface.

The range of local temperature adjustment may be

restricted to owner specications.

On some models the temperature buttons may not

function.

If the temperature buttons function and they are used,

the word “OVERRIDE” will appear in the display. The

override period is determined by the communications

interface. When the override period expires, the

e-Stat

™

will revert back to its program.

Note: Not all

e-Stat™s

allow button adjustment of

temperature settings during the OCCUPIED period.

During the UNOCCUPIED program period pressing

either up or down buttons will adjust the setpoints to

the settings dened for the previously occupied state.

The previously occupied state setpoints will remain

in effect for 2 hours (time frame is adjustable) before

reverting back to the setpoints dened in the current

program. If previously occupied state data is

unavailable for the current day, default temperature

settings are used.

18

Setting Temperature

Output Status

Your e-Stat

™

will show the status of the HVAC system

outputs. It will indicate when the Fan, Heating or Cooling should be running.

A solid arrow “◄” and the word “ON” in the display

indicates the output is on.

A ashing arrow “◄” and the word “ON” in the display

indicates the output has recently turned on and is being

held on by a time delay.

A ashing arrow “◄” by itself in the display indicates

the output has recently turned off and is being held off

by a time delay.

Note: Use the CHECK button to cancel equipment

time delays for faster checkout.

You can use the output indicators to help

troubleshoot your HVAC system. If the Cool 1 and

Cool 2 output indicators are displayed, you should feel

cool air coming from the HVAC system. This tells you

the HVAC system is working properly. Press “Read

Sensor” to see supply air temperature.

19

ON

ON

ON

ON

ON

ON

Cool 1

Cool 2

Fan

O

Heat 1

Heat 2

Check

Press to cancel

Time delays

Indicator Lights

The e-Stat

™

contains (4) indicating lights:

Yellow Green Blue Red

Solid Yellow Time and setpoint program

are in effect.

Flashing Yellow Program setpoints have been

overriden at thermostat.

Flashing Green No valid program or time;

Default setpoints overriden at

thermostat.

Solid Green Operating on default

setpoints.

Flashing Blue Combined with Green or Yellow:

connected to a network device.

Flashing Red Information being sent or

received over Internet.

All colors ash Duplicate IP address on

network. Call tech support for

assistance.

20

Temp

ONFANAUTO

HEATSET

COOLS ET

OVERRIDE

NEW PROGRAM

SYSTEM OFF

REL

HUMIDITY

ERROR

REMOTE TEMP

MONTUEWEDTHUFRISATSUN

ON

ON

ON

ON

ON

ON

A

P

Cool 1

Cool 2

Fan

O

Heat 1

Heat 2

System

On/Off

Check

Fan

On/Auto

Read

Sensor

Yellow -

Website

program

active

Red -

Utility Program

active

Press to cancel

Time delays

On – Constant Fan

Auto – Fan only with

Heat / Cool cycle

Press to read

Supply Air Sensor

& Humidity (Optional)

Web controlled thermostat.

Buttons may be disabled.

Tech Support 800-292-2444

Turns entire system off

ï

Symptom

No Operation of

Heating or Cooling.

1. e-Stat

™

Power

Off.

2. No Power to

equipment or

eStat

™

3. e-Stat

™

at limit

temperature

1. Press system On/Off

button

2. Check switches,

circuit breakers, fuses,

gas valve and pilot.

3. Check display to

verify the e-stat temperature is above the heat

setpoint and below the

cool setpoint.

Display does not

come on during

power up.

1.No Power to the

e-Stat

™

1. Verify 24 VAC is

present at terminal

block by measuring

from R to C. If no

voltage present, check

breakers and fuses.

Fan blows cold

air in heating

season.

1. Fan ON/AUTO

is in wrong position.

2. Heat Fan DIP

switch in wrong

position.

3.O/B terminals

miswired for heat

pump.

1. Move Fan to Auto

position by pressing

FAN ON/AUTO button.

2. See setting the Heat

Fan switch on Page 13.

3. See the O/B direc-

tions on Page 5.

Basic Troubleshooting

Questions...Call Tech Support at 800-292-2444

Possible Cause

Solution

Heating or

Cooling will not

come on.

1. O/B terminals

miswired for heat

pump.

2. Time delay

holding the Cool

or Heat OFF.

1. See the O/B direc-

tions on Page 5.

2. Press the check

button to cancel time

delays.

21

Symptom

Possible Cause Solution

Display shows

“REMOTE

TEMP” and “--”

for the

temperature.

1. There is a

wiring issue.

1. Check remote

sensor and wiring.

The eStat

®

powers up

correctly, but

the display

goes blank.

1. Transformer is

too small for the

installation.

1. The eStat™

needs a minimum

of 20 VAC to

operate. You may

have to install a

larger transformer

to provide adequate power to

keep the voltage

at 24 VAC.

2. The e-Stat

™

resets when

outputs come on.

2. Remove all output wires except

“R” & “C”. Then

reconnect the

wires one by one.

Check eld wiring

connections and

equipment for

short or overload.

Basic Troubleshooting Continued

Questions...Call Tech Support at 800-292-2444

2. Humidity

sensor saturated

or defective.

2. If problem

persists, contact

Lightstat support.

22

Symptom

Display shows

“00” for the

Supply Air

Temperature

1. There is no

Supply Air Sensor

connected or there

is a broken wire.

1. Check Supply

Air Sensor wiring.

Display shows

“99” for the

Supply Air

Temperature

1.The Supply Air

Sensor wires are

shorted.

1. Check Supply

Air Sensor wiring.

Display shows

”REMOTE

TEMP” and “--”

for the temperature AND the display shows low

temperature “55”

for the Supply

Air Temperature

1. The Remote

Temperature Sensor and Supply Air

Sensor wires are

swapped .

1. Check the wiring.

Basic Troubleshooting

Questions...Call Tech Support at 800-292-2444

Possible Cause

Solution

23

Appendix A

Using the A1-A2-A3 relay to remotely control

an auxiliary load.

The “A” Relay can be programmed via the internet to

remotely switch a load such as lighting.

Wire the load such that the A relay is in the “normal”

position. This will keep the load ON when the e-Stat™

A relay is powered off. The web program logic will assume it is wired this way.

To ensure the stat is wired correctly, the state of the

relay can be toggled using the following steps:

Press and hold the “READ SENSOR” then “DOWN”

button uninterrupted for 10 seconds. Press the up or

down button until you reach screen #7, which is indi-

cated by the ashing number. Press the check button

to momentarily change the state of the relay. When

nished testing, press “READ SENSOR” to exit this

mode.

WARNING! FOR CONNECTION TO CLASS 2

CIRCUIT ONLY. DO NOT EXCEED 1 AMP (MAX)

@ 24VAC.

24

A1-A2-A3 DRY CONTACT CLOSURE

WIRING DIAGRAM

RELAYS: G, W1, Y1, W2, Y2, O, B,

A1, A2, and A3 rated 24 V ac, 60 Hz,

Class 2, 1A, resistive / pilot duty.

A1-A2-A3 Relay: Normal

position indicated.

Contacts reverse during

Unoccupied (night) mode

or, via OFF signal from

website.

Dry contacts

are isolated.

C1 C2

Contact

Closure

Input

Supply

Air

Sensor

A1A2A

3

Remote

Room

Temperture

(& Humidity)

Sensor

Non-twisted Pair #18 AWG Wire

500 feet (maximum)

(not suppl ied)

May be used for

night shutdown of

dampers or other

equipment

A1-A2 = Normally

Open (N.O)

Contacts

A2-A3= Normally

Closed (N.C)

Contacts

1 Amp

(Max) @

24VAC

Appendix B

Connecting the RTH or DTHS sensor allows the

e-Stat™ to read and display relative humidity (%) as

well as temperature.

The yellow or blue LED, depending on your model will

turn on for 3 minutes when the e-Stat™ is turned on.

This helps identify which sensor goes with which

e-Stat™

.

The #18-2 conductor wires which attach the sensor do

not require shielding and are not polarized.

Press the “READ SENSOR” Button twice to read % RH

from the sensor.

Using the Temperature Sensor with (optional)

Humidity.

Yellow LED

“Temperature + Humidity”

Digital Temperature

& Humidity Sensor

25

Blue LED

(inside)

Remote Temperature

& Humidity Sensor

Using the (optional) Humidity Temperature

Adjustment

Occupant comfort is determined by both temperature

and humidity. There are times of the year (especially

Spring and Fall) when temperatures may be at the

proper setting, but high humidity can cause

discomfort.

The

e-Stat

™

can automatically lower the programmed

cooling setting by 2°F when a pre-selected Relative

Humidity (RH) setting is exceeded.

It lowers the cooling setpoint only when the

e-Stat

™

is

satised at the programmed cooling setpoint.

You can choose a relative humidity “trigger point”

remotely via the web based interface. (from 45% RH

to 70% RH) Let’s choose 55% RH. In this example

let’s assume that the e-Stat™ has been remotely programmed for a 74° F cooling setting.

If the

e-Stat

™

is holding the temperature in the space

at 74° F and the RH is below 55%, then the cooling

would turn off normally. However, if the space tem-

perature is at 74°F and the RH goes above 55%,

then the “Cool Set” would automatically drop to 72°F.

The words “REL HUMIDITY” will appear (ashing) in

the display for as long as the cooling is operating in

this high humidity mode.

Two conditions will stop the extra cooling. First, if the

room temperature drops below 72°F, or second, if

the relative humidity drops 5% below the “RH trigger

point”. In this example, the humidity would have to

drop to 50% R.H. in order for the cooling setpoint to

revert back to 74°F.

26

Appendix B continued

27

The e-Stat™ can be used to monitor a Contact Closure

such as a switch.

Use #18 gauge 2-conductor twisted pair cable between

the e-Stat™ and the switch or other open/closed contact type device. Contact Closure is unaffected by wire

runs of up to 500 feet.

Contact closure terminals do not have polarity, either

wire may be connected to either terminal. Shielded

cable is not required.

Connect the 2-conductor cable to the two terminals

marked C1 C2 Contact Closure Input. These are

located at the far left of the bottom terminal block as

seen in the gure below.

Contact Closure Connection

CONTACT CLOSURE

WIRING DIAGRAM

RELAYS: G, W1, Y1, W2, Y2, O, B,

A1, A2, and A3 rated 24 V ac, 60 Hz,

Class 2, 1A, resistive / pilot duty.

A1-A2-A3 Relay: Normal

position indicated.

Contacts reverse during

Unoccupied (night) mode

or, via OFF signal from

website.

Dry contacts

are isolated.

C1 C2

Contact

Closure

Input

Supply

Air

Sensor

A1A2A

3

Remote

Room

Temperture

(& Humidity)

Sensor

Non-twisted Pair #18 AWG Wire

500 feet (maximum)

(not suppl ied)

Contact Closure

terminal input to

monitor switch

closure.

1 Amp

(Max) @

24VAC

28

This device complies with Part 15 of the FCC

rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful

interference and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

29

Notes

30

Notes

Lightstat Limited Lifetime Warranty

Lightstat Inc. warrants that all Hardware Products (Products) sold by it after October 1, 2015 are free

of defects in material and workmanship, under normal use and service for as long as the Products are

installed in their original installation for the original End User and operator of the Products with the following limitations:

1. In the event of Product discontinuance, warranty support is limited to ve (5) years from the

announcement of discontinuance.

2. The duration of the warranty period for Products not designed or manufactured by Lightstat

(e.g. power supplies, Ethernet cables, motion sensors, etc) and mechanical assemblies that are

subject to normal wear and tear (e.g. timers, electrical contractors, relays) shall be two (2) years

from the time of purchase.

3. This warranty does not apply to any Product which was not operated in accordance with the

printed instructions, has been damaged by accident or acts of God or which has been misused,

abused or neglected or has been damaged by other cause. This warranty also does not apply

to any Product, which was maintained, altered or repaired by anyone other than Lightstat or its

authorized representatives.

4. This warranty is conditioned upon (a) proper storage, installation, use and maintenance and

conformance with any applicable recommendations of Lightstat and (b) Customer promptly notifying Lightstat of any defects and, if required, promptly making the Product available for correction.

All claims for nonconforming or defective Products must be made within the warranty period. Any claim

not made within that period shall be deemed waived and released. Lightstat’s sole responsibility with

respect to such claims shall be, at its option, to repair or replace any Product or component that it determines to be defective. Replaced Products may be refurbished or new equipment at the option of Light-

stat. Such Product must be removed by the installer and returned to the factory within the applicable

warranty period with transportation charges, if any, prepaid, after rst obtaining proper authorization and

shipping instructions by contacting Lightstat. Any repaired or replacement Product shall be warranted

for the remaining period of the original Warranty Period. Repair or replacement as provided under this

warranty shall be the exclusive remedy of the Customer.

In no event, shall Lightstat be responsible for any monetary damage or be liable for any incidental or

consequential damages due to any cause whatsoever, including, without limitation, commercial loss or

damage resulting from an alleged defect in the Product.

Lightstat does not authorize any other person or organization to assume for it any liability in connection with this Product and any statements or representations made by any other person or organization

are void.

EXCEPT FOR THOSE WARRANTIES EXPRESSLY SET FORTH IN THIS AGREEMENT, LIGHTSTAT INC. DISCLAIMS ANY AND ALL OTHER WARRANTIES, EXPRESS IMPLIED, STATUTORY,

OR OTHERWISE INCLUDING, BUT NOT LIMITED TO, ALL WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY. LIGHTSTAT INC. MAKES NO ADDITIONAL EXPRESS OR IMPLIED WARRANTIES EXCEPT TO THE EXTENT, IF ANY, THEY ARE SPECIFICALLY

REQUIRED BY LAW.

Some states do not allow the exclusion or limitation of implied warranties or consequential damages, so

the above limitations or exclusions may not apply to the purchase of this Product. This warranty gives

each original purchaser specic legal rights, and such purchaser may have other rights that vary from

state to state.

Lightstat Inc. ٠ 22 W. West Hill Road ٠ Barkhamsted, CT 06063 ٠ USA ٠ 800.292.2444

sales@lightstat.com ٠ www.lightstat.com ٠ © 2016 Lightstat Inc. All Rights Reserved. Made in USA.

WARRANTY 10115v1.1

I-12 Rev 51818 Rev. B.

Loading...

Loading...