Lightspeed Rocket

Hardware Installation Guide

1800 19th Street / Bakersfield, CA 93301 / Tel: 661.716.7600 / Toll Free: 877.447.6244 / www.lightspeedsystems.com

Table of Contents

Section 1 Safety Notice and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 3 Electrical and General Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 4 Unpacking the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 5 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 6A 4-Post Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 6B 2-Post Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 7A Lightspeed Rocket Email Manager-R Rear Panel Connections . . . . . . . . . . . . . . . . . . . . . 10

Section 7B Lightspeed Rocket Web Access Manager-R Rear Panel Connections . . . . . . . . . . . . . . . 11

Section 7C Lightspeed Rocket Web Access Manager-RQ Rear Panel Connections . . . . . . . . . . . . . 12

Section 7D Lightspeed Rocket Web Access Manager-1Gb Rear Panel Connections . . . . . . . . . . . . 13

Section 7E Lightspeed Rocket Web Access Manager-10Gb Rear Panel Connections . . . . . . . . . . . 14

Section 7F Lightspeed Total Traffic Control Rocket-R Rear Panel Connections . . . . . . . . . . . . . . . . . 15

Section 8 End User License Agreement (EULA) and Front Panel Operation . . . . . . . . . . . . . . . . . . 16

Section 9 Ship Carton Packing/Repacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Lightspeed Hardware Installation Guide 2

1. Safety Notice and Warnings

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause

undesired operation.

No Telecommunications Network Voltage (TNV)-connected PCBs shall be installed.

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference,

in which case the user may be required to take adequate measures.

VCCI Warning

This is a product of VCCI Class A Compliance.

Environmental Warning

Perchlorate Material - special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate.

This notice is required by California Code of Regulations, Title 22, Division 4.5, Chapter 33: Best Management

Practices for Perchlorate Materials. This product/part includes a battery that contains Perchlorate material.

2. Ratings

AC input voltage: 100 - 240 VAC (auto-range)

Rated input current: 8.0 / 4.0

Hz: 50 / 60

Lightspeed Hardware Installation Guide 3

3. Electrical and General Safety Guidelines

CAUTION

This appliance is intended for installation in restricted areas only. Initial setup and maintenance

should be performed by qualified personnel.

CAUTION

Power down the appliance following the operating system’s proper power down procedure

from the front panel. Unplug all AC power cord(s) before servicing.

CAUTION

To avoid electrical shock, check the power cords as follows.

• This product is to be installed in Restricted Access Location only.

• Use the exact type of power cords required.

• Use power cord(s) that came with safety certifications.

• Power cord(s) must comply with AC voltage requirements in your region.

• The power cord plug cap must have an electrical current rating that is at least 125% of

the electrical current rating of this product.

• The power cord plug cap that plugs into the AC receptacle on the power supply must be

an IEC 320, sheet C13, type female connector.

• Plug the power cord(s) into a socket that is properly grounded before turning on the power.

CAUTION

Required operating conditions for the appliance are -

• Temperature: 10 to 35oC.

• Humidity, non-condensing: 8 to 90%.

CAUTION

Risk of explosion if the battery is installed upside down or is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

DISPOSING OF BATTERY BACKUP UNITS - IF APPLICABLE

WARNING

If the BBU is damaged in any way, toxic chemicals may be released.

The material in the battery pack contains heavy metals that can contaminate the environment.

Federal, state, and local regulations prohibit the disposal of rechargeable batteries in public landfills.

Be sure to recycle the old battery packs properly. Comply with all applicable battery disposal and

hazardous material handling laws and regulations in the country or other jurisdiction where you are

using the BBU.

WARNING

There is danger of an explosion if the battery is incorrectly replaced. Replace it only with the same

or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Lightspeed Hardware Installation Guide 4

3. Electrical and General Safety Guidelines (continued)

WARNING

Disconnect the power supply at the circuit breaker before accessing any components.

Turning off the system power supply switch does not reduce the risk of electrical shock

from the power supply terminal block.

CAUTION

• To prevent the unit from overheating, never install the appliance in an enclosed area that is

not properly ventilated or cooled. For proper airflow, keep the front and back sides of the

appliance clear of obstructions and away from the exhaust of other equipment.

• Be aware of the locations of the power switches on the chassis and in the room, so you

can disconnect the power supply if an accident occurs.

• Take extra precautionary measures when working with high voltage components.

Do not work alone.

• Before removing or installing main system components, be sure to disconnect the

power first. Turn off the system before you disconnect the power supply.

• Use only one hand when working with powered-on electrical equipment to avoid possible

electrical shock.

• Use rubber mats specifically designed as electrical insulators when working with

computer systems.

• The power supply or power cord must include a grounding plug and must be plugged

into grounded outlets.

CAUTION

Electric Static Discharge (ESD) can damage electronic components. To prevent damage to your

system board, it is important to handle it very carefully. The following measures can prevent

ESD damage to critical components.

• Use a grounded wrist strap designed to prevent static discharge.

• Keep all components and printed circuit boards (PCBs) in their antistatic bags until ready

for use.

• Touch a grounded metal object before removing the board from the antistatic bag.

• Do not let components or PCBs come into contact with your clothing, which may retain a

charge even if you are wearing a wrist strap.

• Handle a board by its edges only; do not touch its components, peripheral chips, memory

modules or contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard and peripherals back into their antistatic bags when not in use.

• For grounding purposes, make sure your computer chassis provides excellent conductivity

between the power supply, the case, the mounting fasteners and the motherboard.

Lightspeed Hardware Installation Guide 5

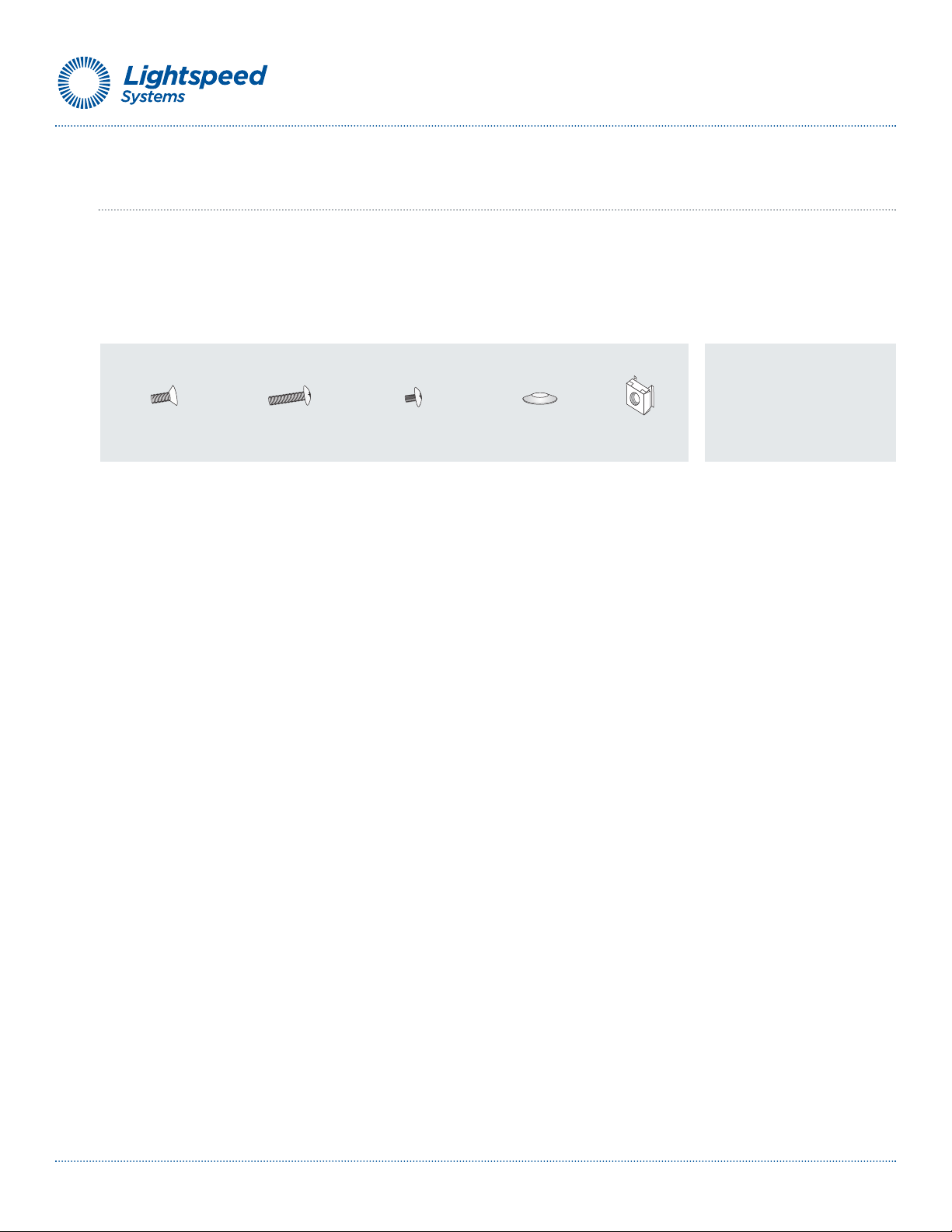

4. Unpacking the Appliance

Before you begin:

Verify that the ship kit includes two power cords, the screws, cone washers and cage

nuts (shown below) that you will need to install the appliance in your rack, the 4-post and/or

2-post rack rail bracket assemblies.

Hardware Kit: screws, cone washers and cage nuts

(Eight) M5 x 12

flat head screws

(Two) 10-32 x 3/4"

pan head screws

(Twenty-two) M4 x 4

truss head screws

(Eight) M5 x 12

cone washers

The 4-post rack assembly consists of:

• A set of long, fixed rack brackets that attach directly to the rack itself.

• A set of medium-sized adjustable rack brackets that attach to the long,

fixed rack brackets.

NOTE: See Section 6A on the page 8 of this document for the 4-post rack rail assemblies.

The 2-post rack assembly consists of:

• A set of long, fixed rack brackets.

• Three sets of short rack brackets that attach to the long fixed rack brackets.

One of these sets has threaded holes (for placement in the front) to allow the

appliance to be secured in the rack.

NOTE: See Section 6B on page 9 of this document for the 2-post rack rail assemblies.

(Ten) M5

Cage nuts

NOTE: Use the hardware

supplied with your specific

rack if different from the

hardware supplied in this kit.

Lightspeed Hardware Installation Guide 6

5. Site Preparation

Setup location, rack and appliance precautions

• Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than room ambient. Therefore,

consideration should be given to installing the equipment in an environment compatible with the

maximum ambient temperature (Tma) specified by the manufacturer.

Always keep the rack’s front door and all panels and components on the appliances closed when

not servicing to maintain proper cooling.

• Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow

required for safe operation of the equipment is not compromised. Leave enough clearance,

approximately 25 inches in the front, and 30 inches in the back of the rack to enable you to access

appliance components and allow for sufficient air flow.

• Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous

condition is not achieved due to uneven mechanical loading.

ALL RACKS MUST BE MOUNTED SECURELY.

properly attached to the rack. If installing multiple appliances in a rack, make sure the overall loading

for each branch circuit does not exceed the rated capacity.

Do not slide more than one appliance out from the rack at a time. Extending more than one appliance

at a time may result in the rack becoming unstable. Install your appliance in the lower part of the rack

because of its weight and also for ease in accessing appliance components.

Ensure that all leveling jacks or stabilizers are

• Circuit Overloading - Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing

this concern.

• Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch circuit

(e.g. use of power strips).

Install near appropriate AC outlets, and Ethernet hubs or individual jacks. Be sure to install an AC

Power Disconnect for the entire rack assembly. The Power Disconnect must be clearly marked.

Ground the rack assembly properly to avoid electrical shock.

Lightspeed Hardware Installation Guide 7

Fixed chassis rail

(attached prior to shipment)

Two 10-32 x 3/4"

truss head screws

Locking tab

*

Release mechanism for the bezel

is located on this side.

Two M5 x 12

flat head screws

and two cone washers

(rear)

Two cage nuts

(rear)

Outer fixed

chassis rails

4-post rack

Three cage nuts

(front)

Two M5 x 12

flat head screws

and two cone

washers

6A. 4-Post Rack Installation

Unpack the appliance and locate the mounting hardware

Step 1

• Locate the two rack rail brackets that came in your ship kit.

• Attach the medium-sized adjustable rack bracket to the

longer fixed rack bracket as shown.

• Insert the tab on the rear of the medium adjustable rack

bracket through the larger round opening on the back end

of the long fixed rack bracket and slide the long bracket

forward to keep the two brackets from coming apart. These

rail brackets slide to accommodate different rack depths.

Step 2

• Insert a cage nut into each of the square holes in the rack

you will be using as shown (three in the front and two in

the rear). They click into place.

• Attach the rack /rail assemblies to the rack using two

M5 x 12 flat head screws and cone washers in the front

and back.

the rack.

• Make sure the rack / rail assemblies and screws are

aligned in the rack not only in the front and back, but

are level in height on the left and right sides for proper

alignment for appliance installation.

The convex side of the cone washers face toward

NOTE: The following installation procedures for 6a, 4-post rack

and

6b, 2-post rack are for use with the rails and hardware provided

in your ship kit. If different style rails are being used, or if your rack

requires different hardware, refer to the instructions provided with

your rail’s or rack’s ship kit.

Rack bracket tab

Rear medium-sized

adjustable bracket

Step 3

• Align the fixed chassis rails on the appliance with the

fixed rack rail brackets installed in the rack.

• Carefully slide the appliance into the rack until you

hear the locking tabs on each side of the fixed front

rails click into place.

• Push the appliance all the way into the rack

until it stops.

• Secure the unit in the rack using a 10-32 x 3/4”*

truss head screw (and a cage nut if not already

installed) in the center hole on each rail.

*NOTE: Refer to your rack’s mounting hardware for the proper

size and type of screws to secure the appliance in the rack.

Lightspeed Hardware Installation Guide 8

Small fixed

rack bracket

Small fixed

rack brackets with

threaded holes

Small fixed

rack brackets

Long bracket

A

B

C

B

C

A

Two M4 truss

head screws

One M4 truss

head screw

Fixed chassis rail

(attached prior to shipment)

Two 10-32 x 3/4"

truss head screws

Locking tab

*

Release mechanism for the bezel

is located on this side.

M5 x 12

flat head screws*

(two front and rear)

A

A

A

A

B

B

6B. 2-Post Rack Installation

Unpack the appliance and locate the mounting hardware

Step 1

Locate the two long and six short rack brackets that came in your

ship kit.

A. Securely attach the set of short brackets with the threaded

screw holes to the long bracket in the front as shown.

Use two M4 truss head screws for each bracket.

B. Loosely attach one set of the other short brackets to the

long fixed bracket as shown using one M4 truss head screw

on each bracket. The three holes on the flap will face toward

the back for later attachment to the 2-post rack.

C. Loosely attach the remaining set of short brackets to the

long fixed bracket as shown using one M4 truss head screw

on each bracket. The three holes on the flap will face toward

the front for later attachment to the 2-post rack.

Step 2

Attach the assembled brackets to the 2-post rack.

A. Insert two M5 x 12 flat head screws through the short

brackets into the 2-post rack (in the front and back of the

rack as shown) and tighten. Make sure the brackets are

aligned and level in height, not only in the front and back

but also on the left and right sides.

B. Tighten each of the the single screws on the small fixed

brackets (located on either side of the rack) to secure the

brackets in the rack and ensure appliance stability.

NOTE 1: The following installation procedures for 6B, are for use

with the rails and hardware provided in your ship kit. If different

style rails are being used, or if your rack requires different hardware,

refer to the instructions provided with your rail’s or rack’s ship kit.

NOTE 2: When removing the appliance from the 2-post rack (Step

3 below), you will need to press down on the right locking tab and

lift up on the left locking tab in order to release it from the rack.

Carefully slide it out supporting the unit on both sides at all times.

NOTE: Once the assembled rails are attached to the rack, securely

tighten the single screws on steps

B and C.

Lightspeed Hardware Installation Guide 9

Step 3

• Align the fixed chassis rails on the appliance with the fixed

rack rail brackets installed in the rack.

• Carefully slide the appliance into the rack until

you hear the locking tabs on each side of the

fixed front rails click into place.

• Push the appliance all the way back into the

rack until it stops. Secure the unit in the rack

using a 10-32 x 3/4”

center hole on each rail.

Refer to your rack's mounting hardware for the proper size

*

and type of screws to secure the appliance in the rack.

* truss head screw in the

7A. Lightspeed Rocket Email Manager-R Rear Panel Connections

Power Good LEDs

AC Power Inlets

Power Supply Locks

Mouse Port

COM Port

VGA Port

Network Interface Connectors

USB Ports

Keyboard Port

Ethernet

Cable

Management

Port

Local

Area

Network

1

2

Power Cords

4

4

Step 1 Connect one end of the yellow Ethernet cable into the Ethernet port labeled MANAGEMENT.

Step 2 Connect the other end of the yellow Ethernet cable into an available switch port on your

Local Area Network. This port will require Internet access.

Step 3 Please review the latest Lightspeed Rocket Email Manager Product Manual on the Lightspeed Wiki

at (http://wiki.lightspeedsystems.com/LSREM).

Step 4 Connect the power cords.

Step 5 Proceed to Front Panel Operation on page 16.

NOTE: The Power Good LED on the rear panel will illuminate

green during normal operation. During standby or when it is

powered down, the Power Good LED will be yellow.

Lightspeed Hardware Installation Guide 10

7B. Lightspeed Rocket Web Access Manager-R Rear Panel Connections

Mouse Port

Network Interface

Connectors

Internal

External

Power Cords

Power Good LEDs

AC Power Inlets

Power Supply Locks

Keyboard Port

VGA Port

COM Port

USB Ports

Ethernet

Cable

Management

Port

Local

Area

Network

2

4

4

1

Step 1 Connect one end of the yellow Ethernet cable into the Ethernet port labeled MANAGEMENT.

Step 2 Connect the other end of the yellow Ethernet cable into an available switch port on your

Local Area Network. This port will require Internet access.

It is very important that ONLY the Management NIC is connected at this time. DO NOT connect

the External or Internal NIC car ds until instructed to do so by a Lightspeed Support Engineer.

Step 3 Please review the latest Lightspeed Rocket Web Access Manager Product Manual on the

Lightspeed Wiki at (http://wiki.lightspeedsystems.com/LSRWAM).

Step 4 Connect the power cords.

Step 5 Proceed to Front Panel Operation on page 16.

NOTE: The Power Good LED on the rear panel will illuminate

green during normal operation. During standby or when it is

powered down, the Power Good LED will be yellow.

Lightspeed Hardware Installation Guide 11

7C. Lightspeed Rocket Web Access Manager-RQ Rear Panel Connections

Mouse Port

Network Interface

Connectors

Internal 0

External 0

Power Cords

Power Good LEDs

AC Power Inlets

Power Supply Locks

Keyboard Port

VGA Port

COM Port

USB Ports

Ethernet

Cable

Management

Port

Local

Area

Network

2

4

4

1

Internal 1

External 1

Step 1 Connect one end of the yellow Ethernet cable into the Ethernet port labeled MANAGEMENT.

Step 2 Connect the other end of the yellow Ethernet cable into an available switch port on your

Local Area Network. This port will require Internet access.

It is very important that ONLY the Management NIC is connected at this time. DO NOT connect

the External or Internal NIC car ds until instructed to do so by a Lightspeed Support Engineer.

Step 3 Please review the latest Lightspeed Rocket Web Access Manager Product Manual on the

Step 4 Connect the power cords.

Lightspeed Wiki at (http://wiki.lightspeedsystems.com/LSRWAM).

Step 5 Proceed to Front Panel Operation on page 16.

NOTE: The Power Good LED on the rear panel will illuminate

green during normal operation. During standby or when it is

powered down, the Power Good LED will be yellow.

Lightspeed Hardware Installation Guide 12

7D. Lightspeed Rocket Web Access Manager-1Gb Rear Panel Connections

Mouse Port

Network Interface

Connectors

Power Cords

Power Good LEDs

AC Power Inlets

Power Supply Locks

Keyboard Port

VGA Port

COM Port

USB Ports

Ethernet

Cable

Management

Port

Local

Area

Network

2

4

4

1

Internal

External

Step 1 Connect one end of the yellow Ethernet cable into the Ethernet port labeled MANAGEMENT.

Step 2 Connect the other end of the yellow Ethernet cable into an available switch port on your

Local Area Network. This port will require Internet access.

It is very important that ONLY the Management NIC is connected at this time. DO NOT connect

the External or Internal NIC car ds until instructed to do so by a Lightspeed Support Engineer.

Step 3 Please review the latest Lightspeed Rocket Web Access Manager Product Manual on the

Lightspeed Wiki at (http://wiki.lightspeedsystems.com/LSRWAM).

Step 4 Connect the power cords.

Step 5 Proceed to Front Panel Operation on page 16.

NOTE: The Power Good LED on the rear panel will illuminate

green during normal operation. During standby or when it is

powered down, the Power Good LED will be yellow.

Lightspeed Hardware Installation Guide 13

7E. Lightspeed Rocket Web Access Manager-10Gb Rear Panel Connections

Mouse Port

Network Interface

Connectors

Power Cords

Power Good LEDs

AC Power Inlets

Power Supply Locks

Keyboard Port

VGA Port

COM Port

USB Ports

Ethernet

Cable

Management

Port

Local

Area

Network

2

4

4

1

Internal

External

Step 1 Connect one end of the yellow Ethernet cable into the Ethernet port labeled MANAGEMENT.

Step 2 Connect the other end of the yellow Ethernet cable into an available switch port on your

Local Area Network. This port will require Internet access.

It is very important that ONLY the Management NIC is connected at this time. DO NOT connect

the External or Internal NIC car ds until instructed to do so by a Lightspeed Support Engineer.

Step 3 Please review the latest Lightspeed Rocket Web Access Manager Product Manual on the

Lightspeed Wiki at (http://wiki.lightspeedsystems.com/LSRWAM).

Step 4 Connect the power cords.

Step 5 Proceed to Front Panel Operation on page 16.

NOTE: The Power Good LED on the rear panel will illuminate

green during normal operation. During standby or when it is

powered down, the Power Good LED will be yellow.

Lightspeed Hardware Installation Guide 14

7E. Lightspeed Total Traffic Control Rocket-R Rear Panel Connections

Mouse Port

Network Interface

Connectors

Internal

External

Power Cords

Power Good LEDs

AC Power Inlets

Power Supply Locks

Keyboard Port

VGA Port

COM Port

USB Ports

Ethernet

Cable

Management

Port

Local

Area

Network

2

4

4

1

Step 1 Connect one end of the yellow Ethernet cable into the Ethernet port labeled MANAGEMENT.

Step 2 Connect the other end of the yellow Ethernet cable into an available switch port on your

Local Area Network. This port will require Internet access.

It is very important that ONLY the Management NIC is connected at this time. DO NOT connect

the External or Internal NIC car ds until instructed to do so by a Lightspeed Support Engineer.

Step 3 Please review the latest Lightspeed Total Traffic Control Rocket Product Manual on the

Lightspeed Wiki at (http://wiki.lightspeedsystems.com/TTC).

Step 4 Connect the power cords.

Step 5 Proceed to Front Panel Operation on page 16.

NOTE: The Power Good LED on the rear panel will illuminate

green during normal operation. During standby or when it is

powered down, the Power Good LED will be yellow.

Lightspeed Hardware Installation Guide 15

8. Front Panel Operation

By powering on the appliance you agree to all terms and conditions included in the

End User License Agreement (EULA) located at eula.lightspeedsystems.com

Power on the appliance

• Remove the front bezel by pressing in on the right side of the bezel to release it

(see the diagram in Step 3 on page 8 or 9 for the location of the release tab).

• Press the power button located on the far right on the front side of the appliance.

• Once the system has been powered on, replace the bezel.

Power Button

Lightspeed Hardware Installation Guide 16

9. Ship Carton Packing/Repacking Instructions

PLEASE HOLD ON TO THESE INSTRUCTIONS AND THE BOX

To ensure the Lightspeed Systems server a safe return, please follow these steps.

Step 1

Open up the original shipping box.

•

• Remove packing material leaving the large gray section

of foam located in the bottom of the carton and the two

side sections of white foam in position as shown.

Step 2

• Remove the front bezel if it is still installed on the server,

re-wrap in plastic bubble wrap and put it aside for later

packing.

• Put the server back in its plastic bag and fit it in between

the two side sections of white foam pieces as shown.

• Place the rack kit along one edge of the box.

Step 3

• Place the second large section of gray foam with the

opening for the smaller parts carton facing up on top of

the previously packed server and rail kit carton.

• Put the bezel, all of the Ethernet cables and power cords in

the smaller parts carton. Place this carton in the opening

in the top gray foam.

Bottom foam

Small parts carton Top foam section

Side foam sections

Rack kit cartonServer

Step 4

• Close the flaps and securely tape the carton closed.

You’ve prepared the server for a safe return!

• Contact Lightspeed Systems at 877-447-6244 or

shipping@lightspeedsystems.com so we can issue an

RMA and send out UPS to pick it up.

Lightspeed Hardware Installation Guide 17

Lightspeed Systems

1800 19th Street

Bakersfield, CA 93301

Corporate Tel: Voice: 661.716.7600

Fax: 661.716.8600

Toll Free: 877.447.6244

Support Phone: 800.444.9267

www.lightspeedsystems.com

Lightspeed Systems Europe:

Whitegates

Alexander Lane

Shenfield

Essex

CM15 8QF

Tel: 01277.240.630

Fax: 01277.240.641

www.lseurope.com

Copyright ©2010-2011 Lightspeed Systems, Inc. All rights reserved.

Loading...

Loading...