Page 1

EPP 35” Magnum

EPP 35” Rebel Z

Instruction Manual

Page 2

Hardware

Carbon

6mm x 1mm x 1000mm strip

(3)

3mm x 1mm x 500mm strip (1)

2mm x 1000mm rod (1)

1mm x 1000mm rod (2)

Poly Fiber Control Horn Card

Motor Mount Screws

Motor Mount Tubing

Adhesive Lined Heat Shrink

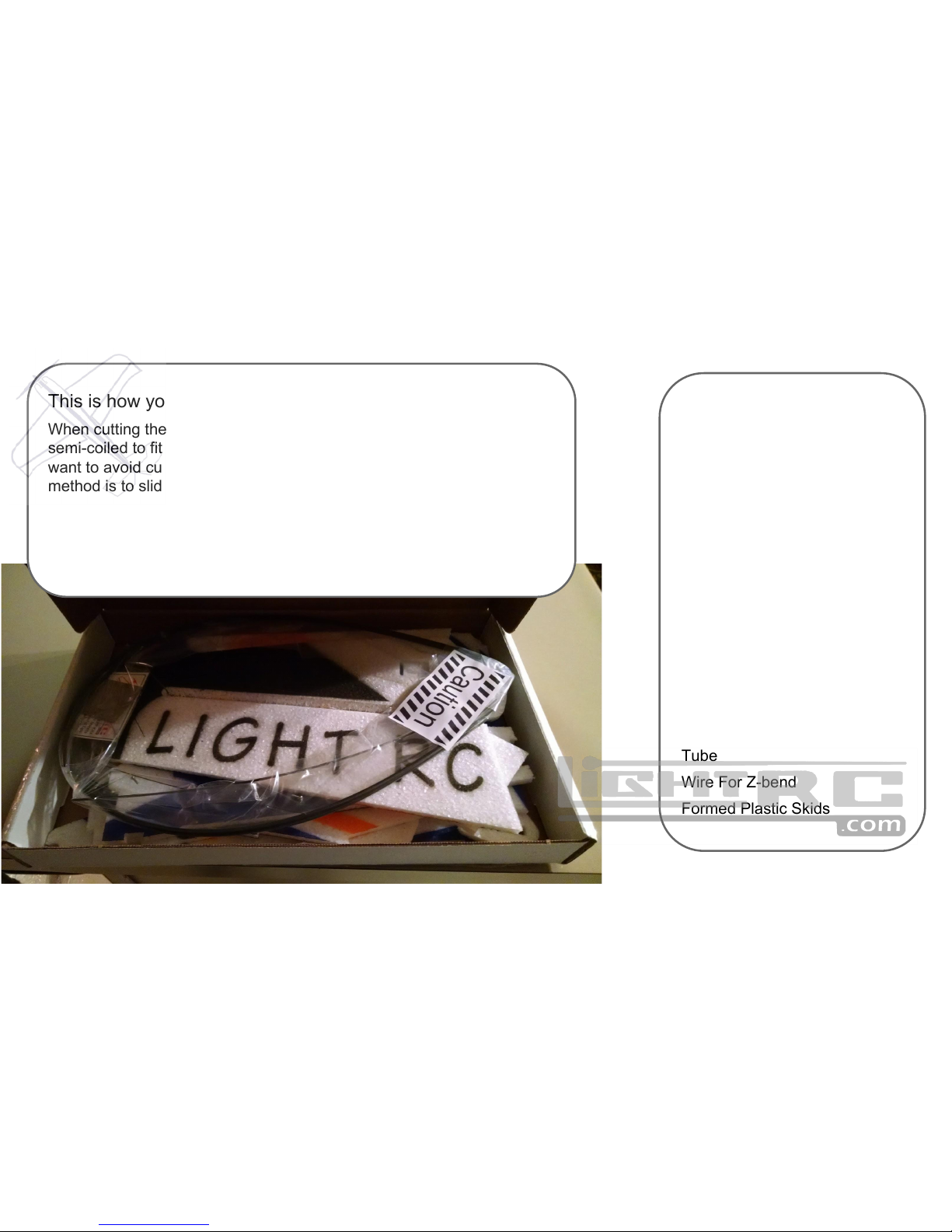

Tube

Wire For Z-bend

Formed Plastic Skids

This is how your kit will arrive

When cutting the hardware package open use caution. The contents are

semi-coiled to fit in the box. They will spring open very quickly. You also

want to avoid cutting or losing any of the parts in the bag. Safest

method is to slide the carbon out one at a time, leaving the bag coiled.

All kits come with motor mount tube and screws. A poly-card with the

needed control horns (and other poly parts if needed) Heat shrink tube

(self adhering) for control horns (do not use CA with this). Wire for zbends is also included. Ohh, and lots of carbon fiber.

Page 3

Carbon Lengths

1mm rod lengths

(see pics later in manual)

(x4) 5.5"

4.75"

4.5"

4.0"

3.0"

Wing Main spar 6mm flat, 30.5"

Sub spar 3mm flat, 29.25"

Gear legs 9.0"

Tail skid 6mm flat, 6.5"

Aileron braces 2mm rod 3.5"

Build Order

(if you don’t want to follow the manual)

Wing -> Nose -> Wing

Main Spar 6mm

Sub Spar 3mm

Elevator Spar 3mm

Aileron Spars 2mm

Reinforce Hinges

Horizontal Mid -> Wings

Horizontal Tail -> Wings

Vertical top nose -> Vertical Tail

Test fit elevator servo ( then glue)

Vertical lower -> Wings

Gear Legs 6mm

Truss Work 1mm

Tail Skid 3mm

Wheel Pants

Skids

Vertical Upper

Vertical Support Truss 1mm

Page 4

Suggested Setup

Electronics

Motor

Cobra 2208-34

Esc

Castle Creations Talon 15a

Servos

(4) Futaba s3114

Battery

500-800mAh 3s

Throw

Ailerons ±40°

Elevator ±50°

Rudder ±40°

Expo

Ailerons 30%

Elevator 35%

Rudder 35%

CG

8” From Nose of Plane (Foam)

Page 5

Hardware

Carbon

6mm x 1mm x 1000mm strip

(2)

3mm x 1mm x 1000mm strip

(1)

2mm x 1000mm rod (1)

1mm x 1000mm rod (2)

Poly Fiber Control Horn Card

Motor Mount Screws

Motor Mount Tubing

Adhesive Lined Heat Shrink

Tube

Wire For Z-bend

Formed Plastic Skids

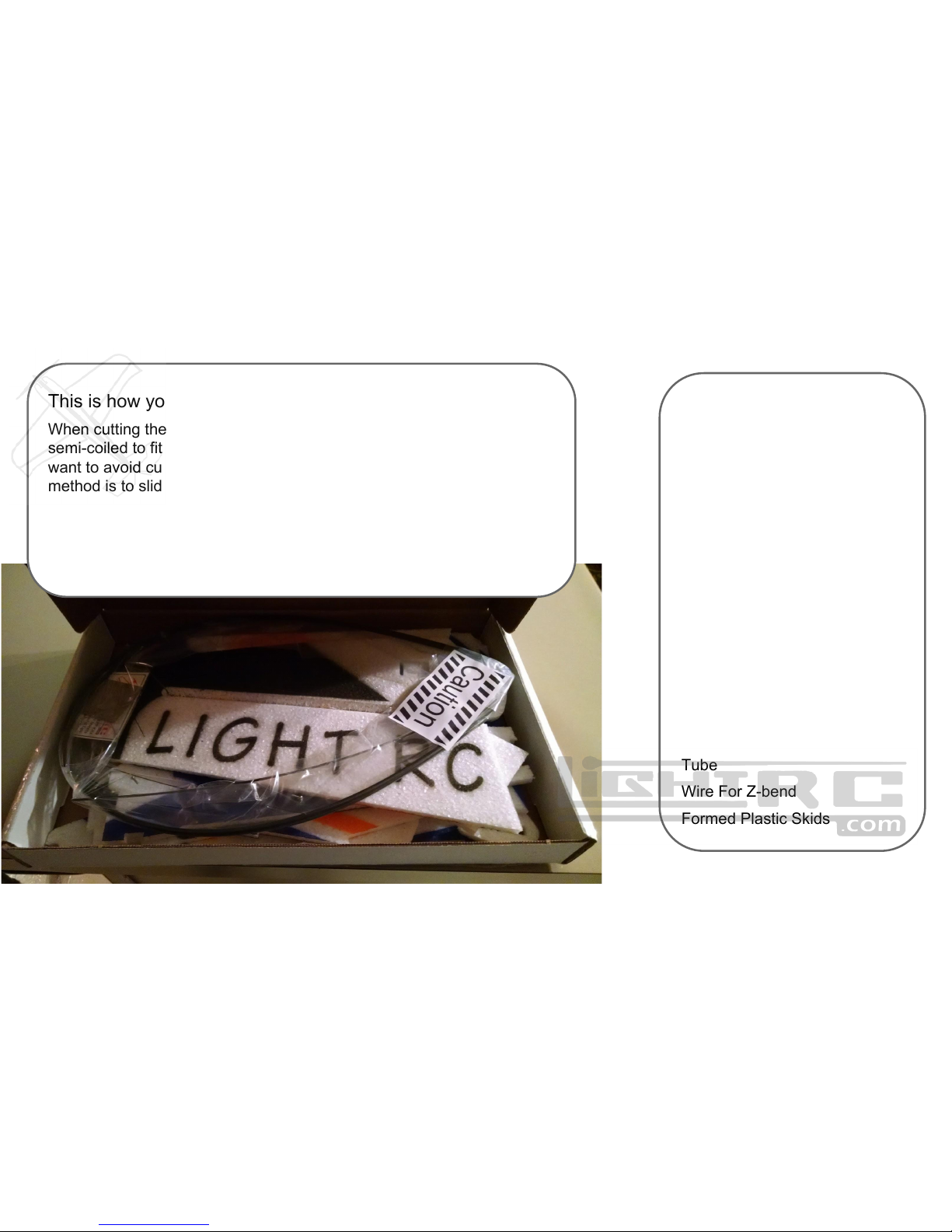

This is how your kit will arrive

When cutting the hardware package open use caution. The contents are

semi-coiled to fit in the box. They will spring open very quickly. You also

want to avoid cutting or losing any of the parts in the bag. Safest

method is to slide the carbon out one at a time, leaving the bag coiled.

All kits come with motor mount tube and screws. A poly-card with the

needed control horns (and other poly parts if needed) Heat shrink tube

(self adhering) for control horns (do not use CA with this). Wire for zbends is also included. Ohh, and lots of carbon fiber.

Page 6

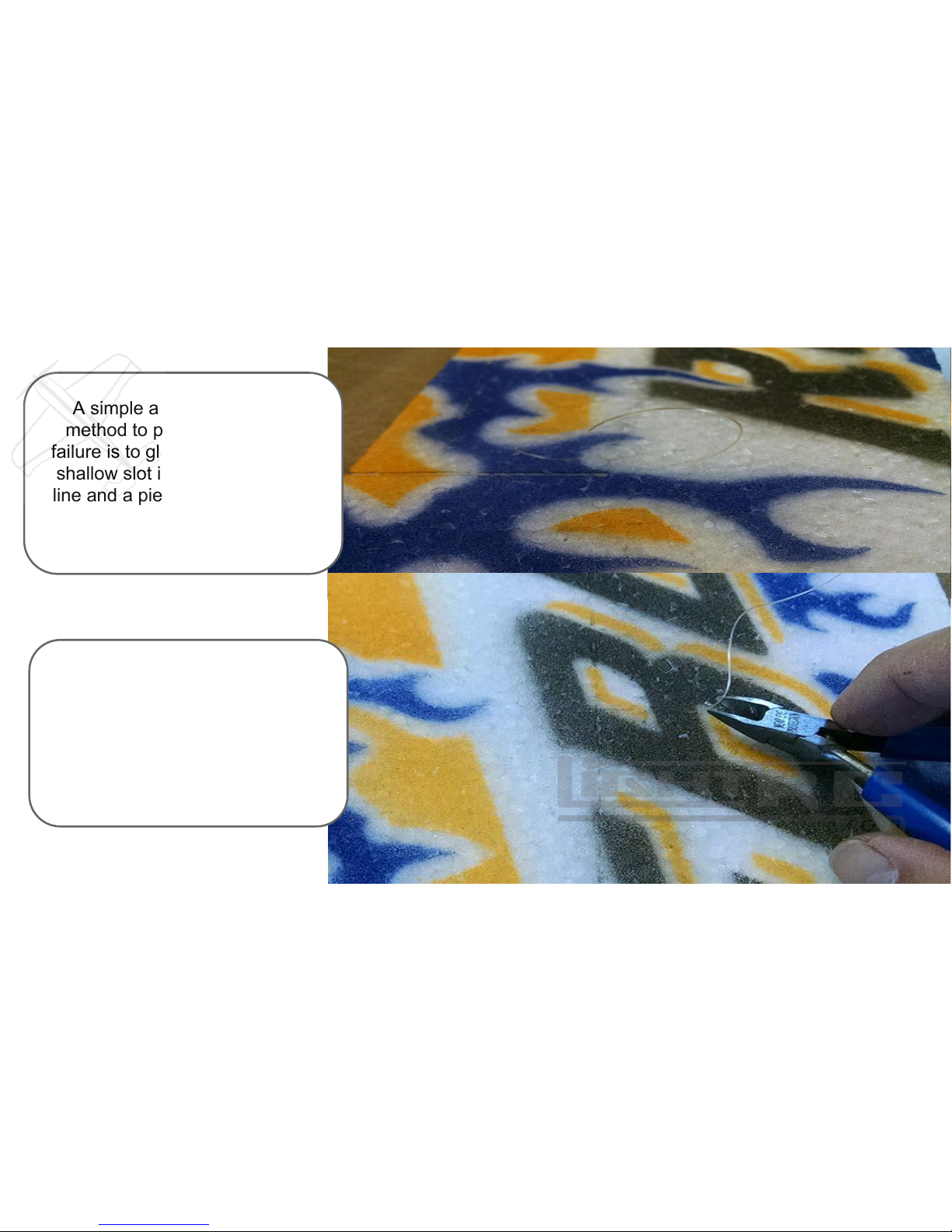

A simple and very effective

method to prevent epp hinge

failure is to glue in fishing line. A

shallow slot is cut across hinge

line and a piece of fishing line is

inserted. Do this at both ends of

the hinge and at control horn.

It is possible to use many other

filaments. Various threads work

well, nylon, kevlar, etc. If using CA

be careful to avoid the glue

wicking into the pivot. Filament

packing tape also works very well

Page 7

The rectangular recess pockets are for

mounting servos. The servo arm should

pass through the corresponding slots.

This arrangement is to provide better

linkage geometry than previous designs.

Notches will help line up parts. Most

builders have a glue preference. Many

glues will work well for this.

Horizontal nose, midsection, wing panels

and elevator assemblies can all be glued

up with parts laying flat on build table.

Only thing to watch for is to not fill carbon

slots with glue.

Page 8

Glue the Vertical Fuselage parts

together as shown.

Glue the Elevator

Carbon Strip 3mm

11⅝” into place

Glue the Aileron

counterbalance

braces (3½) in each

wingtip

Page 9

Carbon can now be added

to horizontal assembly.

Wing carbons are 6mm x

1mm. Front wing carbon is

35 5/16”. Rear wing carbon

is 31 ½”. Test fit the carbon

after cutting to length, then

glue.

Aileron counterbalance

carbons are 2mm rod x 3 ½”

long. Elevator carbon is

3mm x 1mm x 15”.

Weighting the assembly to

hold assembly flat while all

glue dries can help insure a

flat build.

Page 10

Glue lower side of vertical fuselage to bottom. Foam can be slightly stretched and

compressed to fit into notches. Glue a small area at a time while checking for square with

square scrap foam supplied with kit.

Be sure the assembly lies flat and does not lift off the table anywhere. If it does not lay flat,

move the lower until it will lay flat before gluing.

Page 11

Carbon can now be added for landing gear legs, (2) 6mm x 1 mm x 9” long. A notch is

provided in front of wing and a slot is precut for intersecting point in vertical fuselage. These

are glued into place at notches and intersecting point being sure to pull carbon up away

from table to top of slot.

9

Page 12

5 ½

4 ¾

5½

5½

Start by threading carbon through center of vertical fuselage and

then into wing. After getting location established, pull out and add

drop of hot glue to each end of carbon. Reinsert while twisting the

carbon truss. This will drag glue down into hole with carbon and

makes for a strong and clean install.

5½

4

Page 13

Install the formed

plastic parts. Cut

the formed plastic

into sections that

fit onto the bottom

of the wheel

section of the

wheel pant foam.

Cut a slit into the

gear leg support.

Glue a length of

1mm rod into the

slit.

The 1mm rods that

meet at the gear

leg intersection

should touch the

gear legs. This will

help strengthen by

reducing the force

the foam absorbs.

Glue the reinforced

gear leg supports

into the plane.

Create a little

preload by holding

the foam into the

carbon enough to

slightly flex it.

Page 14

Top side of fuselage can now be installed. Same way as bottom being careful to fit snug

into slots and squaring with horizontal while gluing. Back will wrap around elevator and

meet up with underside.

Page 15

6½4½

The back of the upper fuselage will

wrap around elevator and meet up

with underside. This intersection is

where to install the tail skid, 3mm x

1mm x 7”.

Carbon braces can now be added to top side of plane to

support and hold rudder square to the elevator. Run

1mm carbon rod from top of rudder assembly to where

bottom carbon meets the elevator. It is acceptable to use

carbon on only one side of the vertical stab.

3

Page 16

Prepare for electronics by cutting the z-

bend wire into (8) equal lengths. Also

cut the poly mount tubing into (4) equal

lengths.

Now plane can be turned over on the

workbench to check for level. Gear legs

can be shortened until the wing is

parallel with work surface.

Page 17

After the gluing on

the mount tubes,

trim the tubes.

Clipping the tubes

about 1/16th

behind the motor

mount foam. This

will allow for thrust

angle changes.

To mount the motor, start by mounting the poly tubing to the motor, or to

the X-mount without the motor.

Before gluing the tubing to the plane, spread a thin layer of glue around

that area that the tubes will glue to. Tubing should be glued to sides of

plane as shown. This arrangement puts the torque of motor pushing

against surface and not pulling away from the foam. While the glue is

setting twist the motor against the plane. This will self center the motor

on the nose of the plane.

Page 18

The supplied heat

shrink is adhesive

lined. Do NOT use

CA with this heat

shrink. Simply

position and heat.

If needed the tube

can be reheated to

reposition.

To create linkages

with minimal slop,

rotate the z-bend

around the control

rod. The intent is

to put the heat

shrink against the

control horn.

Control horns are included on

the polyfiber hardware card.

Be sure to use the horn with

notch for the elevator. The

notch fits over the carbon

stiffener. 2mm Carbon can be

cut to length for push rods.

Reheat the heat shrink as

needed to center surfaces.

Page 19

Suggested Setup

Electronics

Motor

Cobra 2208-34

Esc

Castle Creations Talon 15a

Servos

(4) Futaba s3114

Battery

500-800mAh 3s

Throw

Ailerons ±40°

Elevator ±50°

Rudder ±40°

Expo

Ailerons 30%

Elevator 35%

Rudder 35%

CG

8” From Nose of Plane (Foam)

Loading...

Loading...