Page 1

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING FIXTURE

This fixture is intended for installation in accordance with the National Electrical Code and local regulations. To

assure full compliance with local codes and regulations, check with your local electrical inspector before

installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

INSTRUCTION SHEET NO.

IS:CACS

A0604

Page 1 of 2

INSTALLATION PROCEDURE FOR: CEILING MOUNT STEM KIT CACS AND C4CS SERIES

WARNING: USE ONLY FIXTURE PROVIDED BY LIGHTOLIER. USE OF OTHER MANUFACTURES’ FIXTURES MAY VOID

USED WITH CEILING MOUNT CYLINDERS (ORDER SEPARATELY)

THE UNDERWRITERS LABRATORIES LISTING AND COULD CONSTITUTE A FIRE HAZARD.

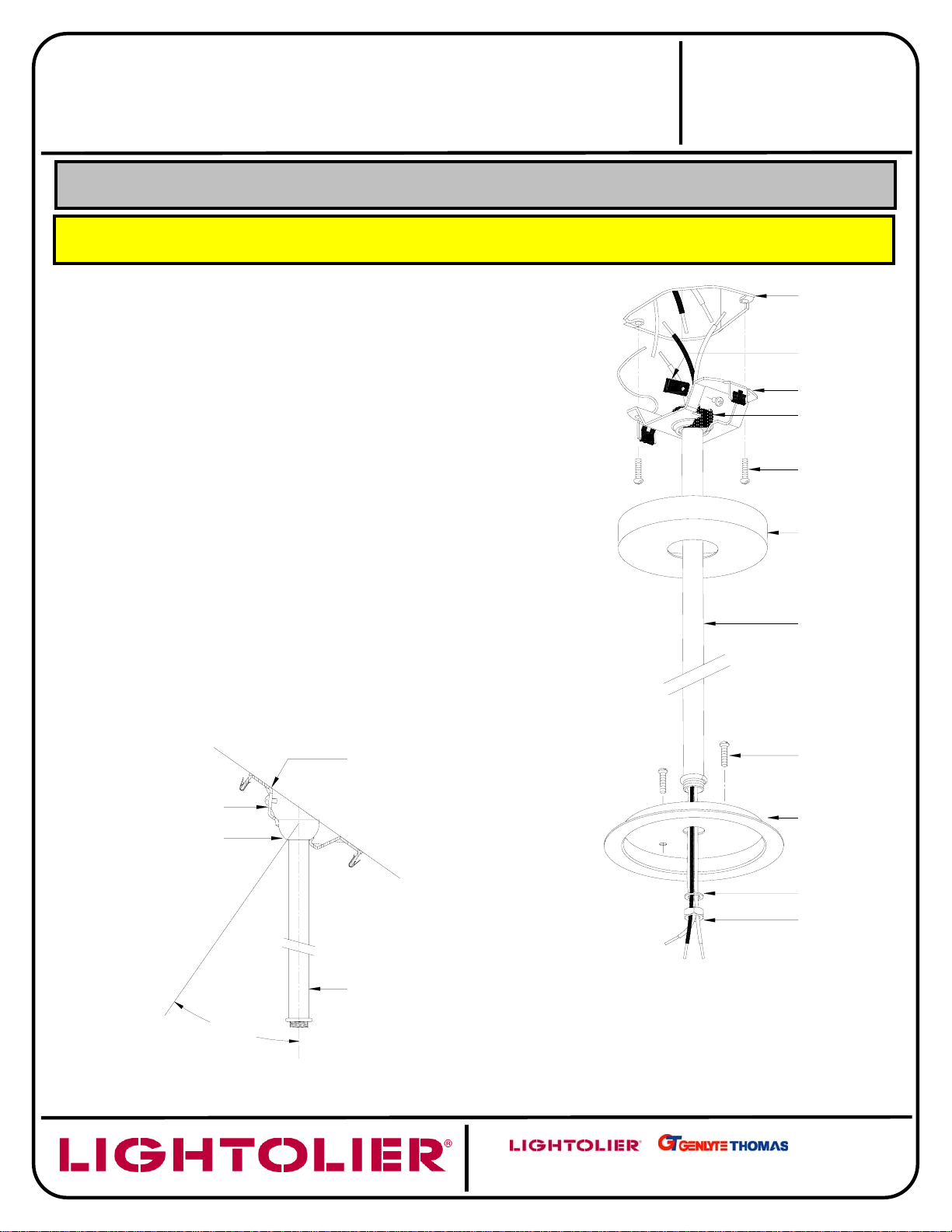

INSTALLATION OF STEM KIT ONTO CEILING

(Fig. 1 & 2)

(NOTE: If custom length is required see page 2.)

1. Assemble STEM to BALL ALIGNER using set screws. Pull wires

through BALL ALIGNER leaving no less than 6" exposed.

2. For sloped ceilings, position opening in CROSSBAR facing

upward. (Fig. 2) Install CROSSBAR using OUTLET BOX SCREWS.

3. Place BALL ALIGNER of STEM into CROSSBAR through side

access hole. When seated the BALL ALLIGNER keyway will line up

with TAB on CROSSBAR.

4. Slide SAFETY STRAP into position and secure in position with

screw.

5. Make Connections. Bare Copper and/or green insulation wire(s)

must be connected to SUPPLY GROUND. Connect WHITE

LEAD to NEUTRAL (WHITE) SUPPLY LEAD. Connect BLACK

LEAD to HOT SUPPLY LEAD. Use wire nuts (local hardware

items). Push spliced leads into outlet box.

6. Slide CANOPY over CROSSBAR and push up against ceiling.

7. Insert SUPPORT COVER onto stem, secure with LOCK WASHER

and LOCK NUT.

OCTAGON

OUTLET BOX

(BY OTHERS)

SAFETY STRAP

CROSSBAR

BALL ALIGNER

OUTLET BOX

SCREWS

CANOPY

STEM

CROSSBAR

SCREWS

SAFETY STRAP

BALL ALIGNER

SUPPORT

COVER

LOCK WASHER

LOCK NUT

STEM

FIG. 1

45° MAX.

FIG. 2

631 Airport Road, Fall River, MA 02720

A COMPANY

Page 2

A

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING FIXTURE

This fixture is intended for installation in accordance with the National Electrical Code and local regulations. To

assure full compliance with local codes and regulations, check with your local electrical inspector before

installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

INSTRUCTION SHEET NO.

IS:CACS

A0604

Page 2 of 2

INSTALLATION PROCEDURE FOR: CEILING MOUNT STEM KIT CACS AND C4CS SERIES

USED WITH CEILING MOUNT CYLINDERS (ORDER SEPARATELY)

WARNING: USE ONLY FIXTURE PROVIDED BY LIGHTOLIER. USE OF OTHER MANUFACTURES’ FIXTURES MAY VOID

THE UNDERWRITERS LABRATORIES LISTING AND COULD CONSTITUTE A FIRE HAZARD.

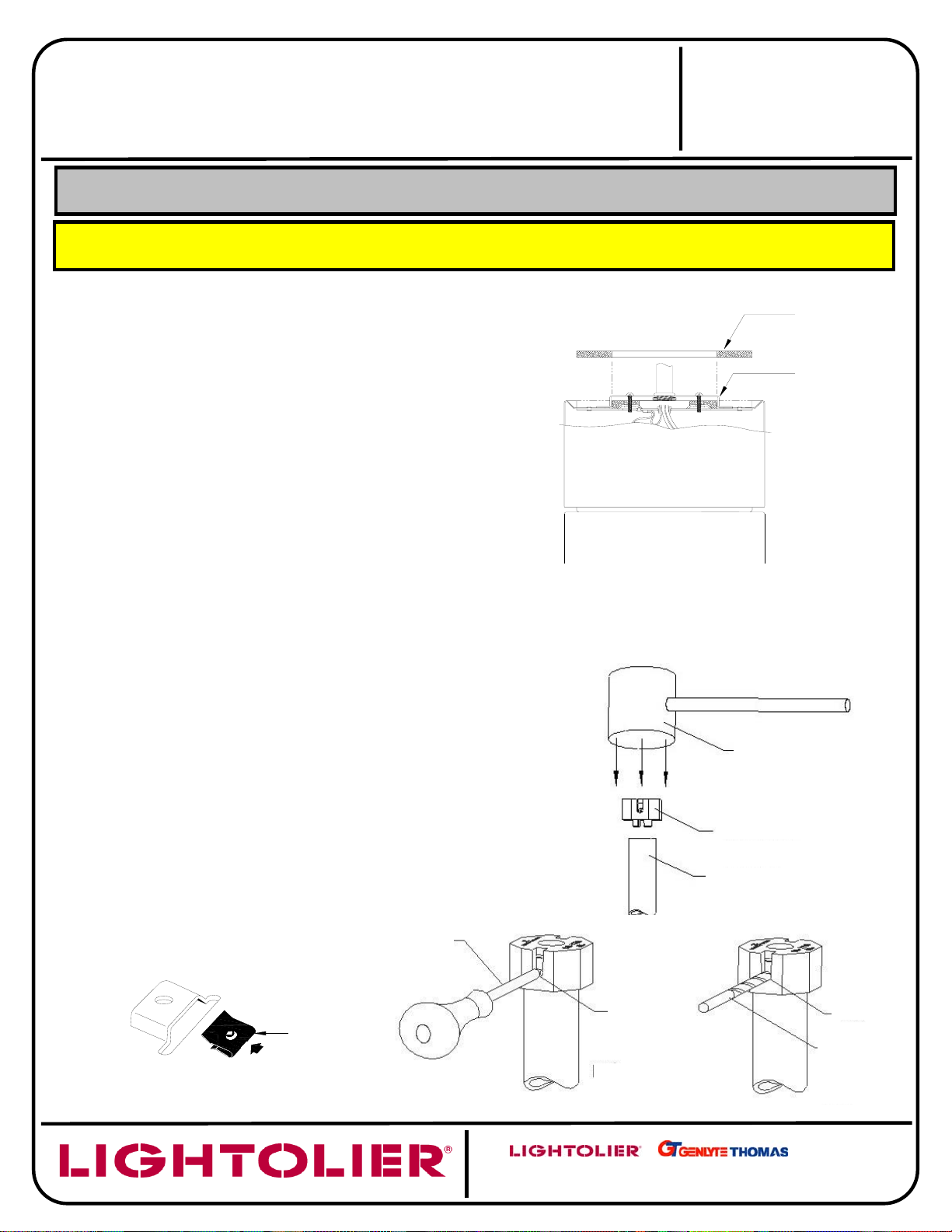

INSTALLATION OF CEILING MOUNT CYLINDER TO

STEM (Fig. 1 & 3)

FIBERGLASS

PAD (DISCARDED)

1. Attach (2) SPRING CLIPS to CYLINDER HOUSING by sliding

SPRING CLIPS onto (2) raised pockets on top of CYLINDER

HOUSING. NOTE: Discard SPRING CLIPS for Cylinders which

do not have the raised pockets; these cylinders have integral tap

holes. (Fig. 3)

2. For C7CS series cylinders, tear off the fiberglass pad from top

of cylinder. The remaining fiberglass pad can be left inside of

SUPPORT COVER or removed. (Fig. 4)

3. Make Connections. Bare Copper a nd/or green insulation wire(s)

must be connected to SUPPLY GROUND. Connect WHITE

BALLAST LEAD to NUETRAL (WHITE) SUPPLY LEAD. Connect

BLACK BALLAST LEAD to HOT SUPPLY LEAD. Use wire nuts

(provided). Place spliced leads into SUPPORT COVER.

4. Align (2) holes in SUPPORT COVER with (2) SPRING CLIPS or

Tap holes, then tighten with (2) SCREWS (provided). (Fig. 1 & 3)

INSTRUCTIONS FOR SHORTENING STEM

TTENTION: Cut end with smaller diameter holes only. (Fig.1)

CAUTION: Eye protection should always be worn when using ha nd

and power tools during the cutting procedure outlined below.

1. Using pipe cutting tool, shorten STEM to appropriate length. Clean

all burrs and sharp edges from cut end of Stem.

2. Position DRILL LOCATOR over cut end of STEM (Fig. 5). Gently

tap down on DRILL LOCATOR until fully seated on end of STEM.

3. Position CENTER PUNCH into bottom SLOT in DRILL LOCATOR

and mark a small dimple in STEM (Fig. 6).

4. Align 1/8" DRILL BIT (local hardware item) into bottom slot of

DRILL LOCATOR so tip of DRILL BIT rests in dimple (Fig. 7).

5. Drill hole completely through STEM allowing DRILL LOCATOR

to guide DRILL BIT. Do not force DRILL BIT. It is recommended to

hold DRILL LOCATOR securely in a

vise or other device prior to drilling hole.

CENTER

PUNCH

FIBERGLASS

PAD (DISCARDED)

SUPPORT

COVER

FIG. 4

HAMMER

DRILL LOCATOR

STEM (CUT)

FIG. 5

SLOT SLOT

SPRING

CLIPS

FIG.6

FIG. 3

DRILL BIT

FIG. 7

A COMPANY

631 Airport Road, Fall River, MA 02720

Loading...

Loading...