Page 1

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING TRACK

This fixture is intended for installation in accordance with the National Electrical Code and local or Federal code

specifications. To assure full compliance with codes and regulations, check with your local electrical inspector

before installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

and refer to them when additions to or changes in the track configuration are made.

Save these instructions for maintenance reference

Installation Instructions for ProSpec™ Track Lighting--

Recessed Feed Track and Plain Track Units.

ProSpec™ track lighting is designed to support and energize ProSpec™ Lytespots® which can be

attached anywhere along the track. It is a four conductor system, continuously grounded throughout, to be supplied by two single 120V, 20 amp, 60Hz branch circuits. It is not intended for use with

a power cord or convenience receptacles. ProSpec™ is listed by Underwriters Laboratories, Inc. It

may only be used with electrical fittings identified for use with ProSpec™ track.

IMPORTANT SAFETY INSTRUCTIONS

Read all Track, Connector, Feed-in Kits, and Accessory Instruction Sheets before

installing any ProSpec

safety precautions should be followed:

™ Track item. When installing or using this track system, basic

INSTRUCTION SHEET NO.

IS:26600

A0397 Page 1 of 4

Read all instructions before installing the track system.

• Do not install in wet media (concrete, plaster, etc.).

• This track system is intended for installation in accordance with the National

Electrical Code and Local or Federal Codes.

• Do not install this track in wet or damp locations.

• Do not install any part of this track system less than 5 feet above floor.

• Do not install any fixture assembly closer than 6 inches from any curtain, or similar

combustible material.

• To prevent electrical shock, turn off electricity at fuse box before installing the track

or adding to or changing the configuration of the track.

• Instructions for grounding per instruction sheet of the feed-in kit used must be

followed. Failure to do so may result in a hazardous condition.

• Use #12 ga. AWG solid wire only (not stranded wire) for supply to track.

• Observe polarity, white supply lead (neutral) to contact marked “NEUT” on screw

terminal connectors.

• Do not exceed 4 feet between mounting points.

• Do not attempt to energize anything other than track lighting fixtures on the track.

To reduce the risk of fire and electrical shock, do not attempt to connect power tools,

extension cords, appliances and the like to the track.

SAVE THESE INSTRUCTIONS

FALL RIVER, MASSACHUSETTS 02720

MONTREAL, QUEBEC, CANADA

Page 2

INSTRUCTION SHEET NO.

IS:26600

A0397 Page 2 of 4

Recessed ProSpec™ Track Mounting Methods

MOUNTING PROSPEC™ TRACK

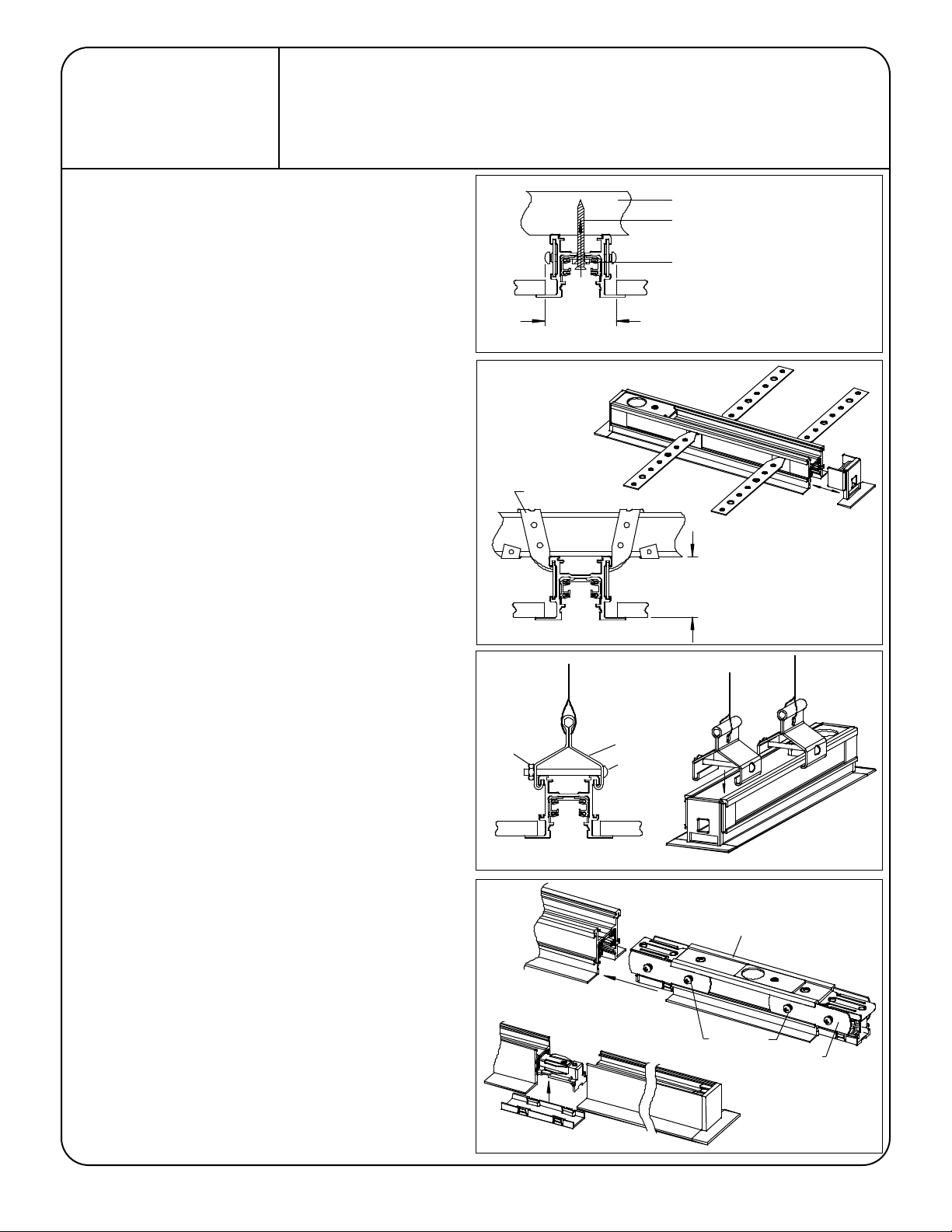

There are three methods of mounting the track to a surface (Fig A, B & C).

1. Direct mounting (Fig A):

•Mark centerline for track location.

•Add mounting holes to the track.

In the center of the track drill the appropriate number of mounting

holes. The holes should be 3/16" in diameter. Recommended: two

holes per 4' track, three holes per 8' track, and four per 12' track.

Never use one mounting hole per track length. Additional holes may

be added for more support. The holes should be evenly spaced along

the track length.

CLEAN ALL METAL AND PLASTIC CHIPS FROM THE TRACK.

•Mount the track to the structure using #6 flat or round head screws,

and plastic washers. Use a screw appropriate for the material. For

example, use a #6 flat head wood screw if you are mounting into a

wood beam. Plastic washers are included; screws are not included.

2. Mounting Straps (Fig. B):

•Mark centerline for track location.

•Remove the Dead End from one end of the track and save.

•Slide the mounting straps into the groove in the side of the track. An

equal number of straps should be on each side of the track. Always

use more then one strap per side.

•Wrap the straps around the building structure or nail the straps to the

structure.

•Push Dead End into the track at the end of the track run.

3. Hanger Clips (sold separately Cat. 26090 set of 4) (Fig. C):

•Slide or snap the hanger clips onto the track.

•Assemble the screws and nuts onto the mounting clips.

•Recommended: two clips per 4' track, three clips per 8' track, and four

per 12' track. Always use more then one clip per track length.

Additional clips may be added for more support. The clips should be

evenly spaced along the track length.

•Tighten the clip on the track by tightening the screw and nut. Pass

cable through hole in hanger clip. Level track and tie cable to support

the track.

FIG. A

FIG. B

Nut

Structural Mounting Material

#6 Screw appropriate to Mounting Material

Plastic Washer

1-7/8"

Ceiling Opening

Mounting Straps

Feed Track

Mounting Straps

Dead End (Remove)

1-1/2"

Hanger Clip

Screw

STRAIGHT CONTINUOUS RUN OF TRACK

•Remove the Dead End from one end of the track that will be joined.

•Slide the spline (1/2 its total length) into the side channels of the track

unit.

•Install the spline screws into the spline and tighten.

•Use an Invisible Coupler (26049WH) to join two tracks together

mechanically and electrically (Fig. D). Power cannot be fed into the

coupler. See the instructions provided with the coupler prior to

installation.

•Use an In-Line connector (26654WH) to feed power between two track

units. Additional splines are not required when using the In-line

Connector. The connector comes with the splines attached (Fig. D).

See instruction sheet provided with the In-line connector prior to

installation.

•Tighten all spline screws.

•Push Dead End into the track at the end of the track run.

FIG. C

FIG. D

Mini Coupler

Track Unit

In-Line Connector

Spline Screws

Spline

Track Unit

Page 3

Instructions for Recessed ProSpec™ Track

Power Feed to Track

DIRECT POWER FEED TO "FEED" TRACK

Use solid 12 ga. copper wire when feeding the track. The feed track accepts

two separate 120 V, 60 Hz branch circuits. Each circuit must not exceed the

20 amp capacity of the track system.

FEED FROM ABOVE TRACK (Fig E):

•Remove Bottom cover and save.

•Remove Knockout in Top Plate.

•Remove Top Plate from Track

•Secure electrical connector (by others;

Plate using the Nut provided. Position connector locking screws such

that the screws will be hidden behind the track width.

•Attach Top Plate to track.

•Pass wires through connector and secure the cable or conduit to the

connector.

The track must not support the cable

for securing the cable to the building structure.

•Secure the track to the ceiling (

•Form the wires in the Feed track to the connector terminals

(see FIG. F). Cut and strip each wire. Attach wires to the screw

terminals. Wires must be tightly held in the screw terminals. Neutral

wires must be attached to screw terminals marked "NEUT”. Ground

wire must be attached to the green ground screw.

•Snap Bottom Cover into the track.

3

/8 size recommended) to Top

. Use separate support

see mounting on previous page

).

Electrical

Connector

Knock out

FIG. E

Circuit 2

Neutral 2

INSTRUCTION SHEET NO.

IS:26600

A0397 Page 3 of 4

Top Plate

Feed Track

Bottom Cover

Use 12 ga. solid copper wire for feed

connections including ground.

Circuit 1

Neutral 1

FEEDING ALONG THE TRACK LENGTH (Fig. G)

A floating splice box may be used to feed the "Feed Track" from along the

tracks length. The floating splice box can be mounted anywhere on the track

up to 4' from the end of the track. The wires are passed along the top of the

track and into the feed end of the track. The floating splice box may

only be used when there is accessibility to the splice box after the

installation is complete.

Floating Splice Box (Cat. no. 26660) sold separately. See instructions

supplied with 26660 for complete installation details.

FIG. F

Feed End

Power

Terminals

Wire Cover

Neutral

Terminals

Floating Splice Box

Ground Terminal

.50

Two wires may be

attached to one

screw terminal.

Dead End

FIG. G

Feed Track Unit

Page 4

INSTRUCTION SHEET NO.

Power

Feed

P

o

w

e

r

O

u

t

Plain Track

Feed Track

or Power Extension

Connector

Power

Extension

Connector

Power

Feed

Power

Feed

P

o

w

e

r

O

u

t

Feed Track

Feed Track

or Power Extension

Connector

Mini Coupler or

In-Line Connector

Feed Track

Power

Feed

Power

Feed

P

o

w

e

r

O

u

t

Feed Track

Feed Track

or Power Extension

Connector

Power

Extension

Connector

Power

Extension

Connector

Power

Feed

Structural

Impediment

IS:26600

A0397 Page 4 of 4

POWER CONTINUITY FROM

A STRAIGHT RUN OF TRACK

This can be accomplished by using Feed Tracks coupler together, by using

Feed Track with a power extension connector, or by using Plain Track with

multiple Power Extensions. The Power Extension Connector is sold

separately (CAT, NO. 26646WH). See instructions with the power extension

for installation details.

NOTE: THIS TRACK SYSTEM IS NOT POLARIZED. Connectors can be

installed into both sides of the Plain Track and in any orientation. There is

no key that will prevent insertion of the connectors. Connectors cannot be

attached to the feed side of the Feed Track. Electrical polarity is maintained

by proper wiring of the circuits. (See Fig F.)

Recessed ProSpec™ Track

FIELD CUTTING TRACK

•Remove and save the Dead End Cover.

•Cut the track using a metal cutting blade (preferably in a miter box to

obtain a square cut)

•Remove ALL burrs and sharp edges from the cut surface of the track

being careful not to destroy the integrity of the track geometry. There

should be no burrs between the copper wire(s) and the aluminum track

housing.

•If an electrical connector is being installed into the cut section, open

the GAP of all copper wires using a wedging tool (such as a flat blade

screwdriver). CAUTION; DO NOT OPEN THE GAP MORE

THAN 3/16" FROM THE EDGE OF THE TRACK EXTRUSION.

•Insert the Dead End Cover into the end of the track run.

FIG. H

FIG. I

Power Extension

Connector

Aluminum Track Housing

Open copper conductor

gap after cutting

Open gap 3/16" max.

from track edge. Typical

for all copper wires.

Dead End

Loading...

Loading...