Page 1

■ Meets requirements for Federal Standard

209E Class 10,000 & 100,000 Clean Room

tested by Independent Lab.

■ UL and ULc Listed for wet or damp

locations for covered ceiling use.

■ Fits 15/16" to 1" wide face grid ceiling systems or flanged for drywall type ceilings.

Contractor responsible for sealing fixture to

ceiling.

■ Full perimeter gasketing (closed cell

Neoprene) between door frame and lens,

between housing and door frame.

■ Ends sealed to body.

■ .125 pattern 12 lens installed smooth side

down.

■ Door frame is post painted, baked

acrylic enamel.

■ Hemmed over side rails for maximum safety.

■ Spring loaded rooster head latches.

■ 18 gauge steel hinges.

■ Flat and regressed aluminum doors available.

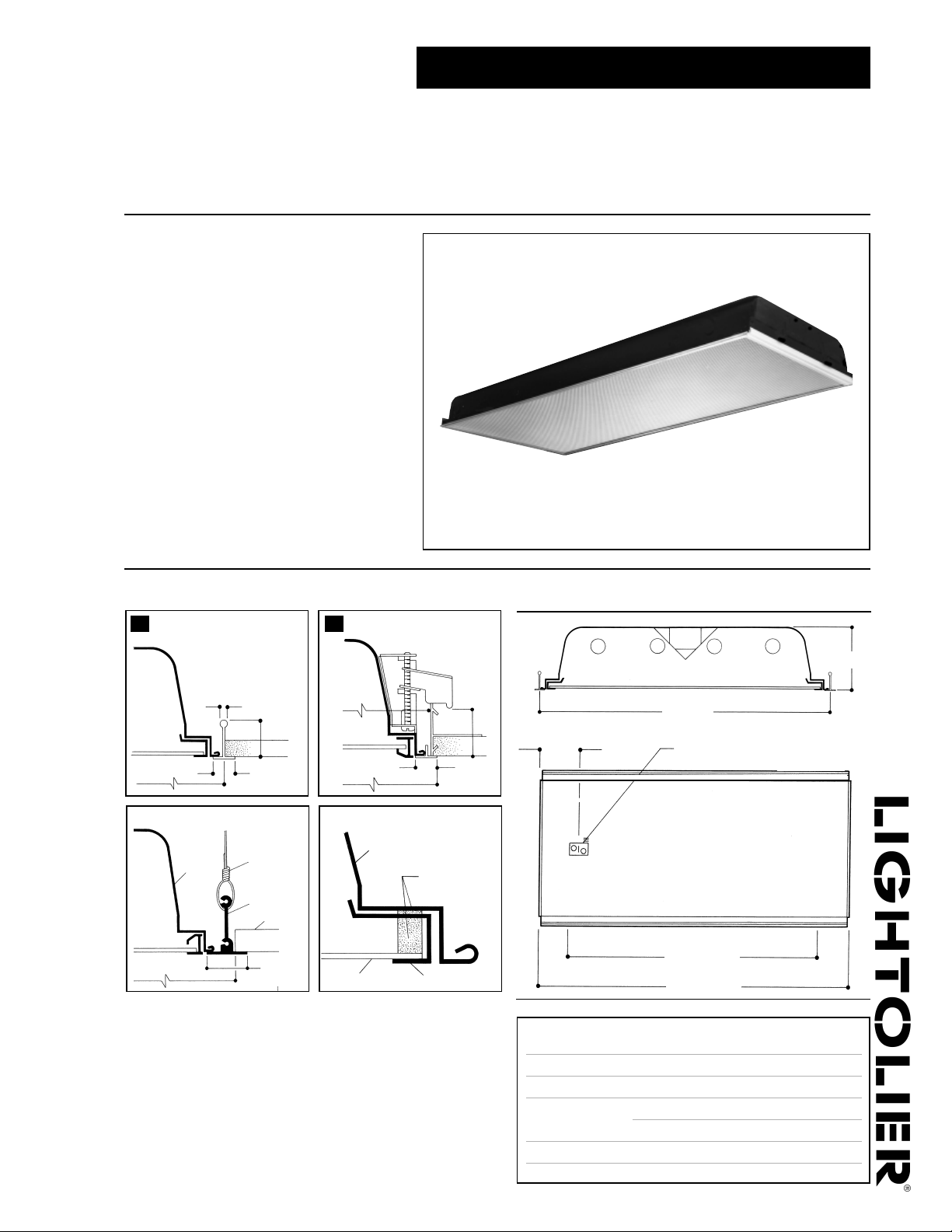

CXS SERIES 2x4

CLEANGUARD CLASS 10,000 CLEAN ROOM

RECESSED FLUORESCENT

2, 3 OR 4 LAMP, T8

MOUNTING METHODS DIMENSIONS

exposed T-grid ceiling.

G

(with flat aluminum frame)

24"

drywall kit (see options)

Type “G”

FIxture

Ceiling Opening

24-5/16" x 48-5/16"

1/4" max.

1-1/2" max.

15/16" or 1"

Support

(by others)

Drywall Kit

(See Options)

Drywall

(by others)

15/16"

plaster ceiling/flanged.

F

Plaster

Opening

24-1/8"

24-11/16"

gasketing detail

Fixture

Lens

1-1/8" min.

3-3/4" max.

13/16"

Gasketing

(Close Cell Neoprene)

Door Frame

6" (152mm)

FIXTURE TYPE VOLTS

24" (610mm)

2" x 2-1/2" access plate

with two K.O.s

(7/8" dia.)

39-1/4" (997mm)

47-31/32" (1218mm)

5" (127mm)

JOB INFORMATION:

SECTION 6/Folio N40-12

Page 2

CXS SERIES 2X4

CLEANGUARD CLASS 10,000 CLEAN ROOM

RECESSED FLUORESCENT

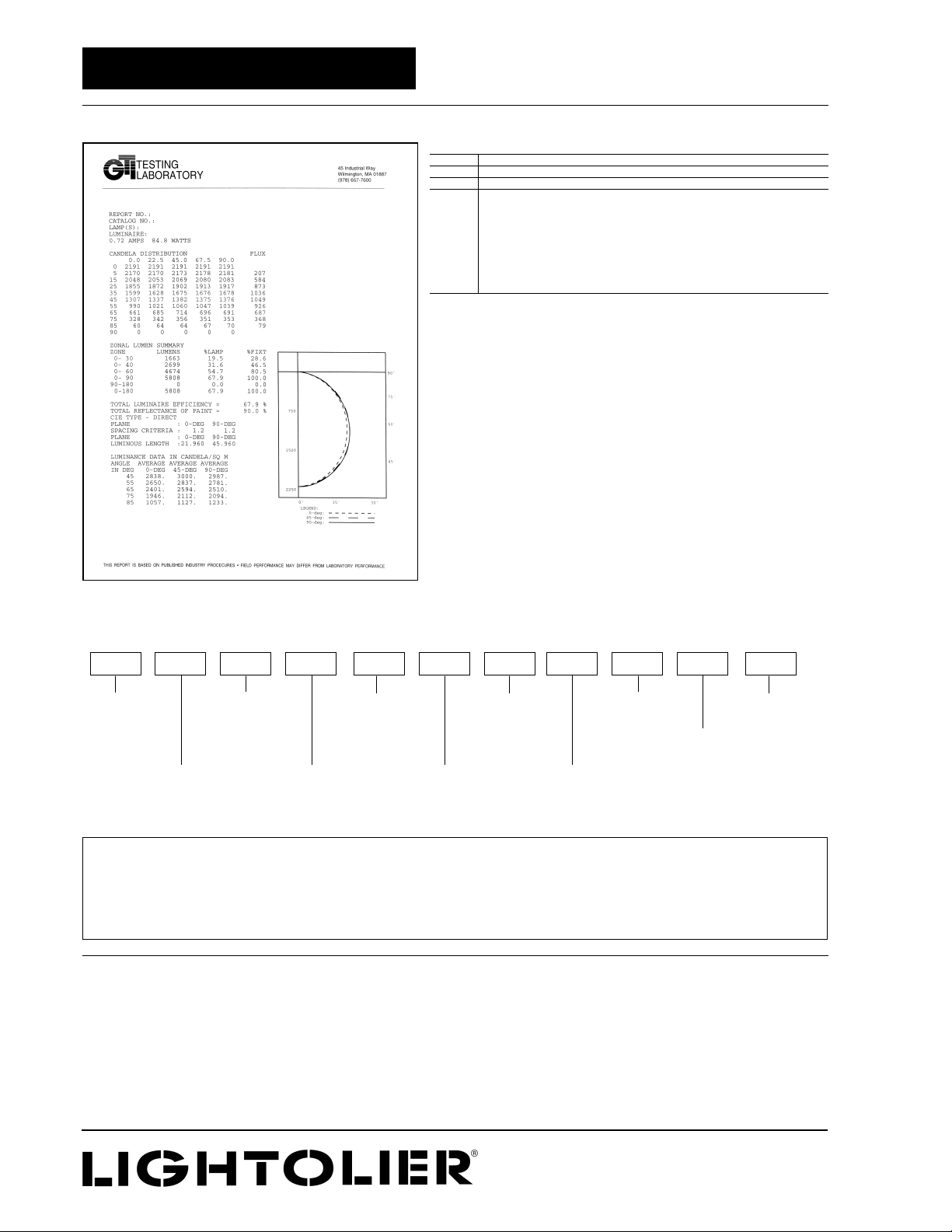

PHOTOMETRY MODEL NO. CXS2GFSVI332120O3

G02021 DATE: 01-30-02

CXS2GFSVI332120O3

3 F32/T8 TL841, EACH RATED 2850 LUMENS

STANDARD CXS FIXTURE WITH INVERTED VI LENS IN FS F

LER = FL - 73.2 IW - 108.7 BF - 0.86

Comparative yearly lighting energy cost per 1000 lumens = $3.28

coefficients of utilization — zonal cavity method (effective floor cavity reflectance 0.20)

RF 20 20 20

RC 80 50 30

RW 70 50 30 50 30 10 50 30 10

1747168 676462 646261

2686257 585552 565351

3625549 514744 504643

4564843 464137 444037

5524337 413632 403532

6483933 373228 363128

7453530 342925 332825

8413227 312622 302622

room cavity ratio

9393024 292420 282320

10 36 27 22 26 22 18 26 21 18

ORDERING INFORMATION

Explanation of Catalog Number. Example: CXS2GFSVI332120O3GLR

CX

CLEANGUARD

WET

LOCATION

Class 10,000

or

100,000

Clean Room

OPTIONS/ACCESSORIES

PLASTER FRAME: Catalog Number PF24.

CONTINUOUS ROW INSTALLATION: For F

type fixtures, half width flanges are required

between fixtures. Order Catalog Number:

S2FCTRIM (each joint).

S 2 VI 4

STATIC

FIXTURE

WIDTH

CEILING TYPE:

G= Grid (lay-in T bar)

F=Flanged (overlap) Z spline

and plaster frame

LENS FRAME:

FS= Flat steel frame

RA=Regressed

aluminum frame

FA=Flat aluminum

frame

LENS/SHIELDING TYPE:

VI (virgin acrylic) .125

standard. For options

consult factory.

Smooth side of

lens towards room.

FUSING: Internal fast-blow fusing.

SUFFIX: GLR.

Internal slow-blow fusing.

SUFFIX: GMF.

ELECTRICAL/WIRING OPTIONS:

Consult factory.

SPECIFICATIONS:

MATERIALS: Chassis parts are die-formed code gauge cold rolled steel.

Housing with side rails hemmed over and housing ends turned-in for safe

handling.

FINISH: Chassis exterior–black baked polyester enamel. Cavity–white

baked polyester enamel minimum 86% reflectance. Phosphate undercoating.

LENSES: VI (standard) extruded virgin acrylic, 3/16" square based female

cones, running 45° to the panel edge, .125" nominal thickness (similar to

pattern 12).

ELECTRICAL: Thermally protected class “P” ballast C.B.M. approved, non

PCB. If K.O. is within 3" of ballast, use wire suitable for at least 90°.

LABELS: I.B.E.W./UL and ULc Listed.

LAMP

QUANTITY:

2=2 Lamp

3=3 Lamp

4=4 Lamp

LAMP/

FIXTURE LENGTH:

32=T8

(Nominal 48")

VOLTAGE:

120 or 277

BALLAST TYPE:

1 & 2 Lamp Elec. T8 SO* H

2-2 Lamp Elec. T8 SO* HI*

1-3 Lamp Elec. T8 O3* H3*

1-4 Lamp Elec. T8 O4* H4*

LOL T8 Dimming PS

*Instant Start Standard

Other dimming options. Consult factory.

Add appropriate suffix

to catalog no., ie: (GLR)

20THD <10THD

<

OPTIONS:

I*

We reserve the right to change design, materials and finish in any way that will not alter installed appearance or reduce function and performance.

TECHNICAL INFORMATION • (978) 657-7600

631 AIRPORT ROAD, FALL RIVER, MA 02720 • (508) 679-8131

C.F.I. DIVISION OF CANLYTE, INC.

A Genlyte Thomas Company

525 EDUCATION ROAD, CORNWALL, ONTARIO

CANADA K6H 6C7 • (613) 938-6221

PRINTED IN USA 3/02

Loading...

Loading...