Page 1

READ AND UNDERSTAND ALL TRACK, CONNECTOR, FEED-IN-KITS, AND ACCESSORY

INSTRUCTION SHEETS BEFORE INSTALLING ANY PROSPEC™ TRACK ITEM.

This fixture is intended for installation in accordance with the National Electrical Code and local or Federal

code specifications. To assure full compliance with codes and regulations, check with your local electrical

inspector before installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

Retain these instructions for maintenance reference.

Power Extention Connector for use with ProSpec™ Track System Only.

INSTRUCTION SHEET NO.

IS:26046

A0197 Page 1 of 2

The Power Extension Connector allows power to be jumped from one

track, around or through structural obstacles, to another track unit. It

replaces the Dead End Cover at the end of a Feed Track unit or a run

of track units. Power can be fed into or removed from the Power

Extension Connector by using any of the power feed-in kits available

for ProSpec Track. A few examples are shown on the reverse side.

Caution:

• Turn off power at fuse box before installing the Power

Extension Connector and track.

• Instructions for grounding must be followed. Failure to do

so may result in a hazardous condition.

• Use only #12 ga. solid copper wire in connectors to

maintain proper track rating.

• Observe polarity, white (neutral) wire must be connected

to terminal marked "NEUT". Failure to observe Polarity may

result in an electrical hazard.

• Do not use Track as a conduit support. Independent conduit

supports (such as suitable conduit straps) must be used to

attach the conduit installation to the building structure.

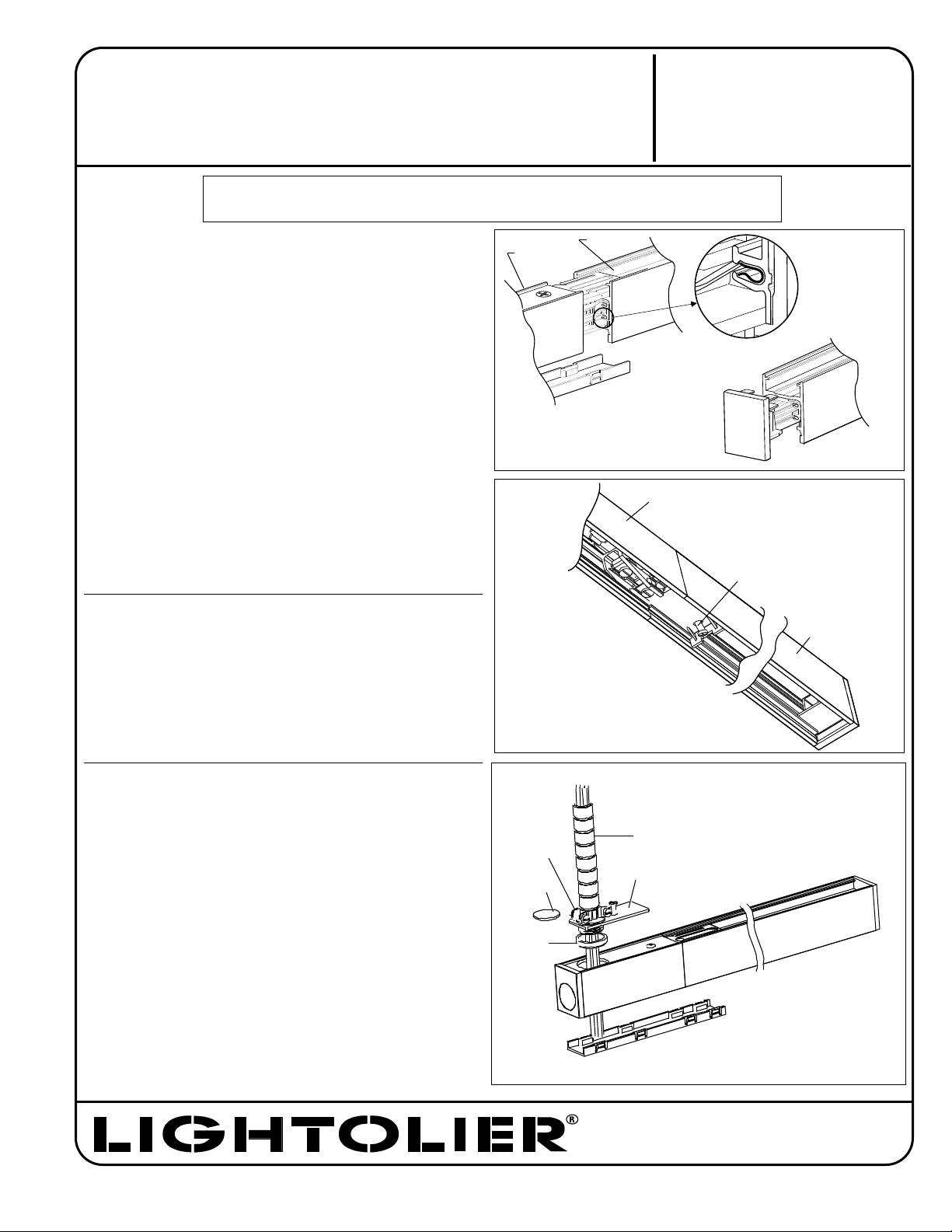

INSTALLING CONNECTOR INTO TRACK SECTION--Fig.1 & Fig. 2

1. Remove Dead End Cover if necessary by pulling it out of the track

(save Dead End cover).

2. Push connector into the track until there is no gap between the

track unit and connector. Ensure that the contact blades are

aligning with the copper wirers in the track during assembly.

3. Tighten the locking screw.

Fig. 1

Fig. 2

Connector

Track Unit

Bottom Cover

Dead End

Connector

Track Unit

Locking Screw

Track Unit

POWER FEED TO THE CONNECTOR(S)

DIRECT FEED FROM ABOVE CEILING--Fig.3

1. Remove the bottom cover (if required) by snapping it out of the

connector. Save cover.

2. Remove K.O. plate from the connector.

3. Remove the K.O..

4. Attach the electrical connector onto the K.O. plate using the nut

provided. Align the electrical connector such that the connector is

hidden by the track width.

5. Attach the K.O. plate onto the connector using the screw that was

previously removed.

6. Pass cable or conduit through electrical connector and clamp cable

or conduit to electrical connector.

7. Form the wires to the appropriate screw terminals. Cut and strip

wires and attach to the screw terminals. (See wiring section of

instruction sheet).

8. Snap the bottom cover onto the connector.

Electrical

Connector

(by Others)

Knock Out

Fig. 3

Nut

Conduit or Cable

(by Others)

K.O. Plate

Track Unit

Bottom Cover

FALL RIVER, MASSACHUSETTS 02720

MONTREAL, QUEBEC, CANADA

Dead End

© 1997

Page 2

INSTRUCTION SHEET NO.

IS:26046

A0197 Page 2 of 2

Power Extention Connector for use with ProSpec

Track System Only.

™

POWER FEED TO THE CONNECTOR(S) (continued)

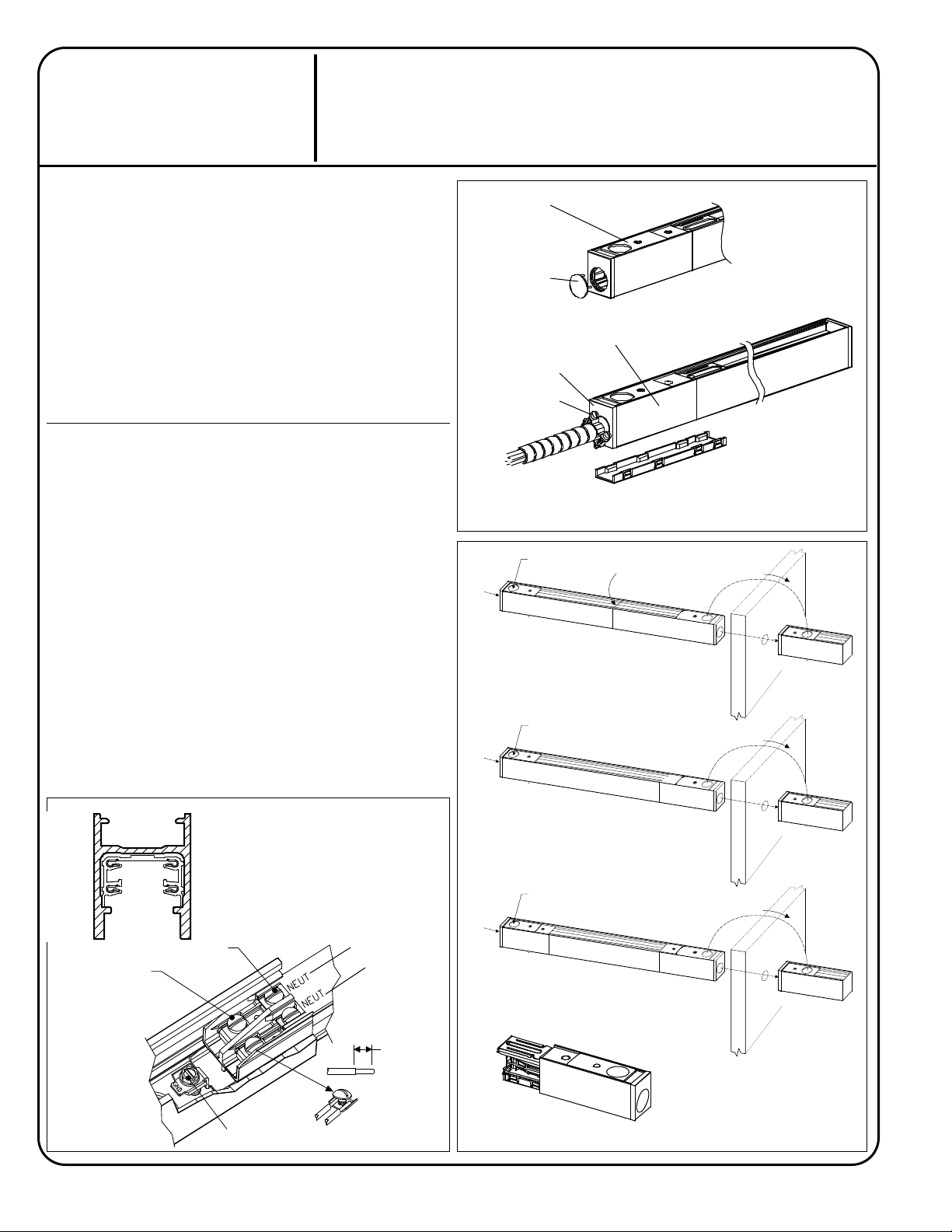

DIRECT POWER FEED FROM A STRUCTURAL SURFACE--Fig 4 & Fig. 5

1. Remove the bottom cover (if required) by snapping it out of the

connector. Save cover.

2. Push out hole plug.

3. Thread electrical connector into the end cap.

4. Pass conduit or cable through electrical connector and secure

conduit or cable to electrical connector.

5. Form the wires to the appropriate screw terminals. Cut and strip

wires and attach to the screw terminals. (See wiring section of

instruction sheet).

6. Snap the bottom cover onto the connector.

WIRING THE CONNECTOR--Fig. 6 & Fig. 7

Note: Multiple circuits can be fed into the Power Extension Connector.

The Connector is not polarized and can be inserted into the track in

any orientation. Therefore identification of the circuits during wiring

needs to be controlled by the installer or electrician. The brass screw

terminals are for the hot leads, the silver screw terminals are for

neutral leads, and terminals marked "GND" are for the ground. The

individual circuits are arranged vertically (see diagrams).

1. Form the wires to the screw terminals, strip the insulation

back 1/2".

2. Slip the wire under the terminal screw head. Tighten all screw

terminals when wiring is completed.

3. Make sure stripped portion of wires are not touching each other.

4. Snap bottom cover onto the connector to cover the wires.

There are additional feed in kits (Floating Canopy, End Feed Canopy,

Floating Invisible Feed, Grid Ceiling Canopy Kit, Stem Kits....) that can

be used with these connectors. See the Instruction Sheet supplied

with the Feed-in Kit for detailed instructions on mounting the kit to the

connector.

Fig. 4

Conduit or Cable

Fig. 5

Power

Feed

Power

Feed

Power

Extention

Connector

Hole Plug

End Cap

Electrical

Connector

(by Others)

(by Others)

Power

Feed

Feed Track

Power

Feed

Power

Extention

Connector

Mini Coupler or

In-Line Connector

Feed Track

Track Unit

Bottom Cover

P

P

Dead End

Track Unit

Structural

t

u

O

r

e

w

o

t

u

O

r

e

w

o

Impediment

Feed Track

or Power Extension

Connector

Circuit 2

Fig. 6

Feed Track

Use 12 ga. solid copper wire for

feed connections including

Circuit 1

N

Power

Terminals

N

Neutral

Terminals

ground.

Circuit 1

Circuit 2

Power

Power

Feed

.50

Feed

Power

Extension

Connector

Plain Track

Power

Extension

Connector

Power

Extension

Connector

Feed Track

or Power Extension

Connector

t

u

O

r

e

w

o

P

Feed Track

or Power Extension

Connector

Fig. 5

Power Extension

Connector

Fig. 7

© 1997

Ground Terminal

Two wires may be

attached to one

screw terminal.

Loading...

Loading...