Page 1

Instruction Sheet Number 1101FIC

Page 1 of 2 Installation Procedure for High Wattage Insulated Ceiling

Frame-In Kits 100IFIC, 1101FIC, 2001FIC

Read and understand these instructions before installing fixture.

This fixture is intended for installation in accordance with the National Electrical Code and local regulations. To assure full compliance with local codes and

regulations, check with your local electrical inspector before installation. To prevent electrical shock, turn off electricity at fuse box before proceeding.

Retain these instructions for maintenance reference.

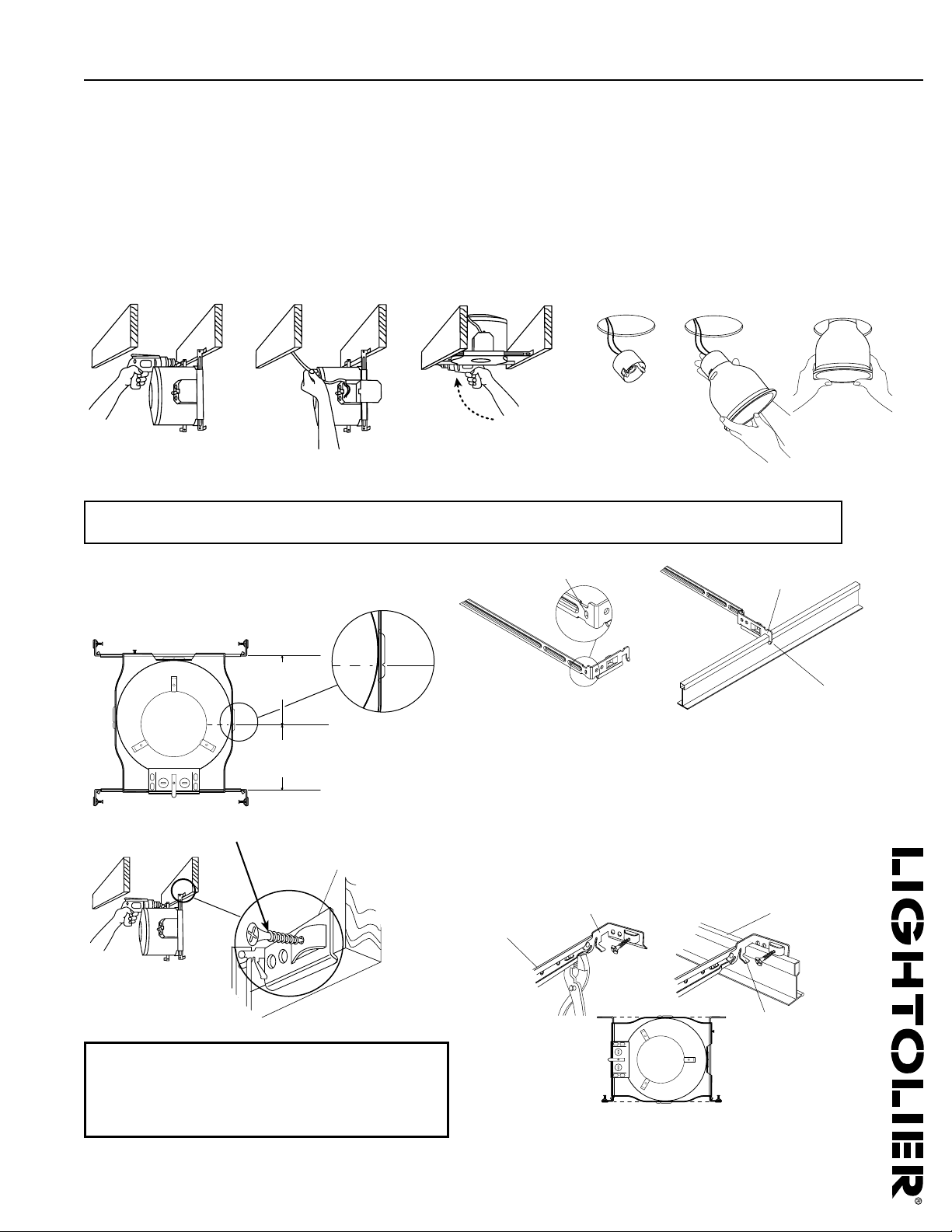

New Construction

NOTE: I.C. Frame-In Kit may be used in direct contact with insulation.

Fig. A

Frame-In

Fig. B

Wire-In

Fig. C

Swing-Up

Fig. D

Close-In

Fig. E

Snap-On

Warning: Use Only With Lightolier Reflector Trims Marked With I.C. Lamping Information.

Use of Other Manufacturers’ Trims Voids the Underwriters Laboratories Listing and Could Constitute A Fire Hazard

1. FRAME-IN (Fig. A)

Locate fixture along joist and line up bottom edge of HINGED MOUNTING BAR

with the bottom of joist and fasten in place.

5 3/4" 2001FR

5 1/4" 1004ICX

5 5/8" 1101FIC

CENTER LINE OF

5 7/8" 2001FIC

6 3/8" 1001FIC

6" 1101FIC

APERTURE OPENING

Note: Integral nail version available

HINGED MOUNTING BAR

BEND AT HOLE

For suspended ceilings:

• Rotate HINGED BAR ENDS to position shown and fully extend bars.

• Crimp bottom of edge of CHANNEL to prevent rotation of

HINGED BAR ENDS.

• Bend NON-HINGED end of mounting bar at featured hole location and

extend out.

• Position notched area of MOUNTING BARS onto T-BAR and lock by

bending TAB underneath T-BAR BEAD as shown.

• For suspended ceiling, make cer tain that bottom of Mounting Frame is no

higher than 1" above ceiling line.

Fig. F

Push-Up

TAB

BEND AT TAB

For Joist Spacing Less Than 16" On Center (To 12 " On Center):

• MOUNTING BAR CHANNELS can be shor tened and used as nailing

legs in tight spaces. Simply remove INNER BAR from holed CHANNEL,

bend CHANNEL at appropriate point and use extra screw to secure it

to the joist. (Fig. G)

HINGED BAR ENDS

CHANNEL

T-BAR

TAB

Fig. G

Lightolier a Genlyte company www.lightolier.com

631 Airport Road, Fall River, MA 02720 • (508) 679-8131 • Fax (508) 674-4710

We reserve the right to change details of design, materials and finish.

© 2007 Genlyte Group LLC • B0607

Page 2

Instruction Sheet Number 1101FIC

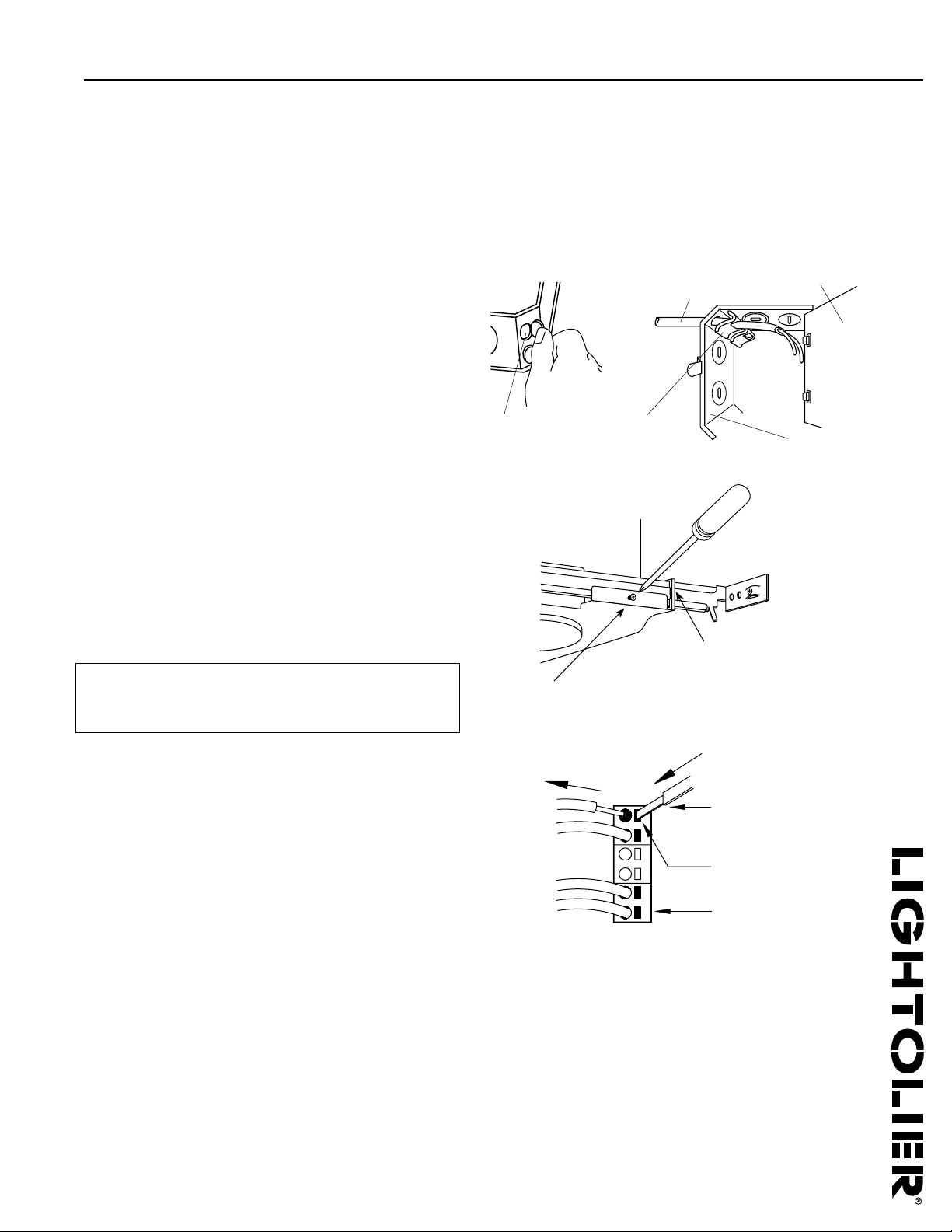

REMOVE

INSE

RT

BALLAST WIRE

CONNECTORS

WIRE RELEASE

BLADE

(BY OTHERS)

WIRE RELEASE

SLOTS

Page 2 of 2 Installation Procedure for High Wattage Insulated Ceiling

Frame-In Kits 100IFIC, 1101FIC, 2001FIC

2. WIRE-IN (Fig. B)

Open hinged J-BOX COVER fully to its locked position (lift slightly to unlock).

Open hinged KNOCK OUT to allow NON-METALLIC CABLE to enter JUNCTION

BOX. Push CABLE through CLAMP.

Note: Wiring and connections must not be placed in JUNCTION BOX in a

manner which will interfere with the CLAMPS action to provide strain relief.

Wire to SUPPLY LEADS. WHITE FIXTURE LEAD to NEUTRAL SUPPLY LEAD.

BLACK FIXTURE LE AD to HOT (120V) SUPPLY LEAD. BARE FIXTURE WIRE to

SUPPLY GROUND. Use wirenuts (local hardware item). Place all electrical connections in the J-BOX and close the J-BOX COVER.

3. SWING-UP (Fig. C)

Extend MOUNTING BAR to reach opposite joist and fasten in place.

Adjust to desired position along MOUNTING BAR and lock in place using

LOCKING SCREW.

4. CLOSE-IN (Fig. D)

Install plasterboard or other dry type ceiling. Hole in board can be cut either

on the floor or after the board is secured to the ceiling using MOUNTING

FRAME opening as cut ting guide. Make sure spring clips are rotated out of

hole area to be cut, also making sure that socket and wiring are positioned

away from hole area. Spring clips can only be rotated counterclock wise. This

detail allows easy removal of reflector trim by rotating TRIM counterclockwise and permits installing Reflector Trim tightly against the ceiling surface

by rotating trim clockwise af ter pushing Trim into ceiling.

5. AIRSEAL

Install a bead of silicone caulking compound between the ceiling opening and

edge of HOUSING. Housings are tested in accordance with ASTM E 283 (max

2 cfm @ 75 pa) and comply with WSEC & IECC when installed as instructed.

6. SNAP-ON (Fig. E)

Important - Insert SOCKET CUP in

neck of REFLECTOR making sure

SPRING TABS fully engage into SLOTS

in REFLECTOR.

7. PUSH-UP (Fig. F)

Push REFLECTOR TRIM straight up

until it is tight against ceiling.

8. BALLAST REPL ACEMENT

A qualified electrician must perform ballast replacement. Turn off power.

Remove reflector trim from luminaire. Remove fasteners that secure the ballast to the housing. Remove ballast assembly through ceiling hole. Disconnect

all input wiring to the ballast. Release all wires from ballast wire connectors

by inserting small blade tool with insulated handle into wire release slots

(Figure H). Remove ballast and replace with new ballast. Rewire, see label on

ballast for wiring diagram then reassemble.

®

INSTALLATION (optional)

}

See Separate

Reflector Trim

Instruction

Sheets

HINGED KNOCK OUT

LOCKING SCREW

NON-METALLIC

SHEATHED CABLE

(12 OR 14 GAUGE ONLY)

CABLE CLAMP

DEFORM MATERIAL AT ANY

CORNER OF FRAME FOR ADDITIONAL LOCK IF NEEDED

Figure H

J-BOX COVER

JUNCTION BOX

U.S. and Foreign Patents Pending

Lightolier a Genlyte company www.lightolier.com

631 Airport Road, Fall River, MA 02720 • (508) 679-8131 • Fax (508) 674-4710

We reserve the right to change details of design, materials and finish.

© 2007 Genlyte Group LLC • B0607

Loading...

Loading...