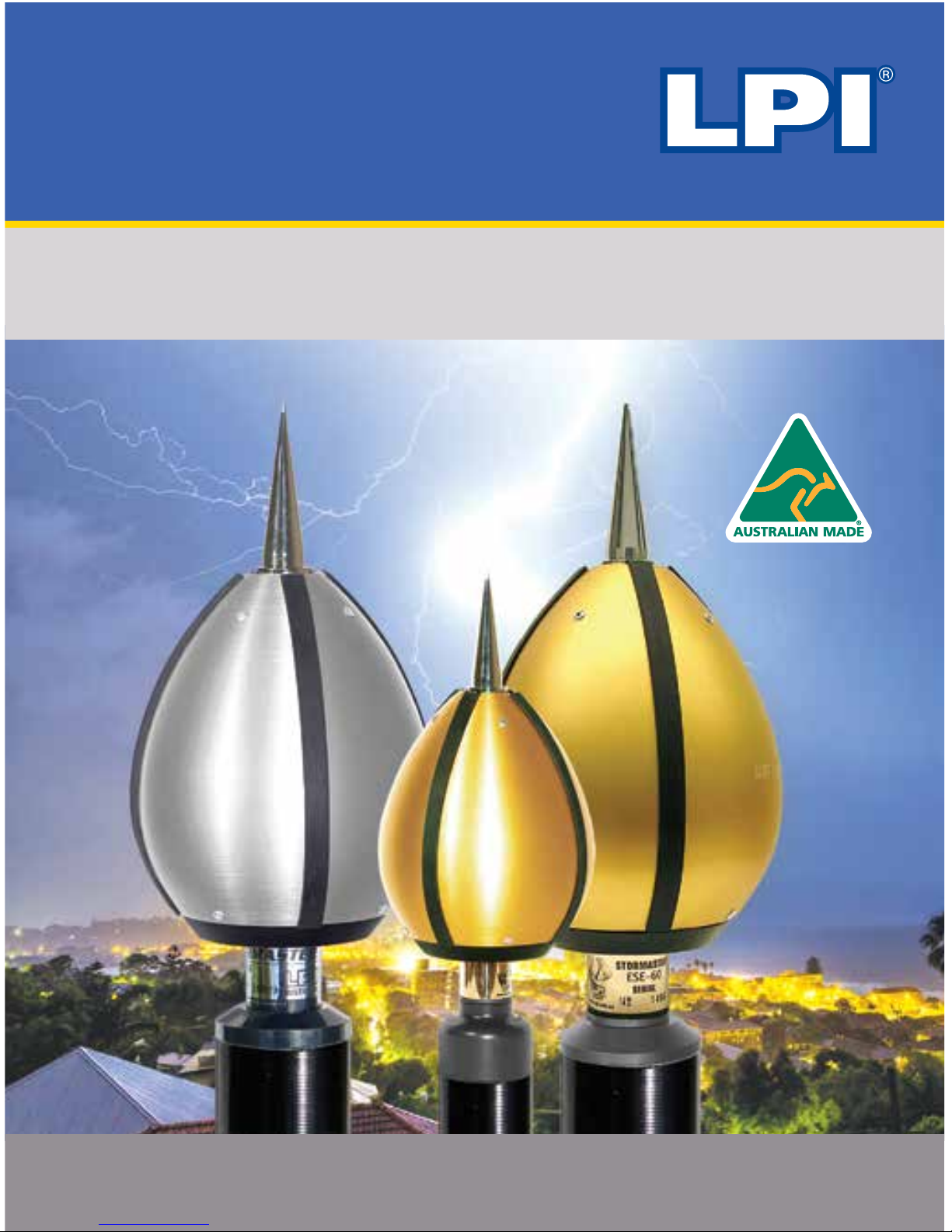

Lightning Protection International Stormaster ESE 15, Stormaster ESE 30, Stormaster ESE 50, Stormaster ESE 60 Installation Manual

Page 1

Stormaster ESE Installation Manual

Comprehensive Lightning, Surge Protection & Earthing Solutions

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

Page 2

Lightning Protection International Pty Ltd

ABN 11 099 190 897

PO Box 379 Kingston, Tasmania, Australia 7051

Phone: +61 3 62271955

Fax: +61 3 62291900

Email: info@lpi.com.au

Web: www.lpi.com.au

STORMASTER ESE INSTALLATION MANUAL

As a result of continuing research and product development in the area of lightning and

lightning protection, LPI reserves the right to alter any detail contained within at any

time without notice.

Prior to installation of the Stormaster ESE system, installers should check with LPI or an

authorised distributor to confirm they have the most recent version of the Stormaster

ESE Installation manual.

It should be noted that 100% (100 percent) protection for direct lightning strikes is not

possible and cannot be provided due to the lightning discharge process being a natural

atmospheric event.

Stormaster ESE Lightning Protection System

System Owner:

Date Installed:

Installation Contractor:

Supplied by:

Location of Installation

:

Page 3

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

1

Stormaster ESE Installation Manual

Lightning Protection International Pty Ltd

Page 4

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

2

Contents

Protection Performance 3

Warranty 5

Lightning Protection 6

General Safety Guidelines 7

Recommended Installation Method 7

Checking Lightning Protection

Components Supplied 16

LPI Stormaster ESE Installation 16

Installation of the Lightning Earth 17

Earth Enhancing Compounds 18

Bonding the Lightning Earth 18

Labelling 19

Installation of the HVSC Plus

Downconductor 19

Hauling the HVSC Plus

Downconductor 19

HVSC Plus Downconductor Clearance

Holes 21

Routing 21

Fixing the HVSC Plus Downconductor 22

Installation of Conventional

Downconductors 23

Installation of Stormaster GI Terminal

to Threaded Pipe 25

Termination of the HVSC Plus

Lower End 26

Lower Termination of Conventional

Downconductor to the Lightning

Earth 30

Upper Termination Instructions for

UTERMKIT-Mk3 (Heatshrink) 30

Termination of the HVSC Plus Upper

End 30

Upper Termination Instructions for

UTERMKIT-Mk3 (Heatshrink) 31

Connection of Factory Pre-Terminated

HVSC Plus (Upper End) to Stormaster

ESE Terminal 36

Labelling 36

Masts 36

Types of Mast Configurations 37

Cantilevered 37

Guyed 37

Freestanding 37

Mast Bases 38

Mast Couplings and Guying Points 38

Guying 39

Preparation for Raising the Mast into

Position 40

Raising of the Mast 40

Lightning Strike Recorder (LSR1) 42

Certification 44

Operation and Maintenance 44

Testing the Stormaster Terminal 45

Testing the HVSC Plus Downconductor 45

Testing the Lightning Earth 46

Record of Earth Resistance Readings

Table 48

Installation Notes 48

Page 5

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

3

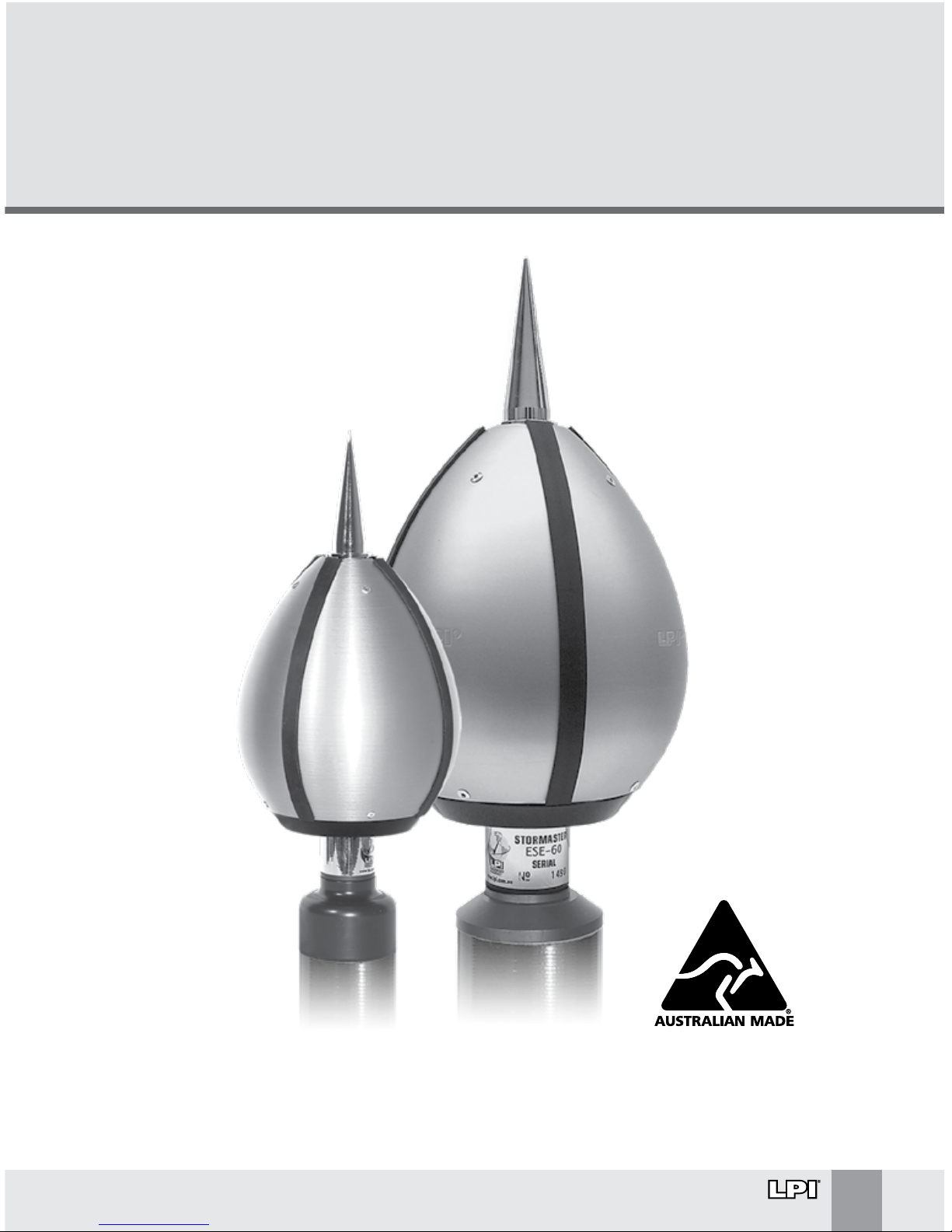

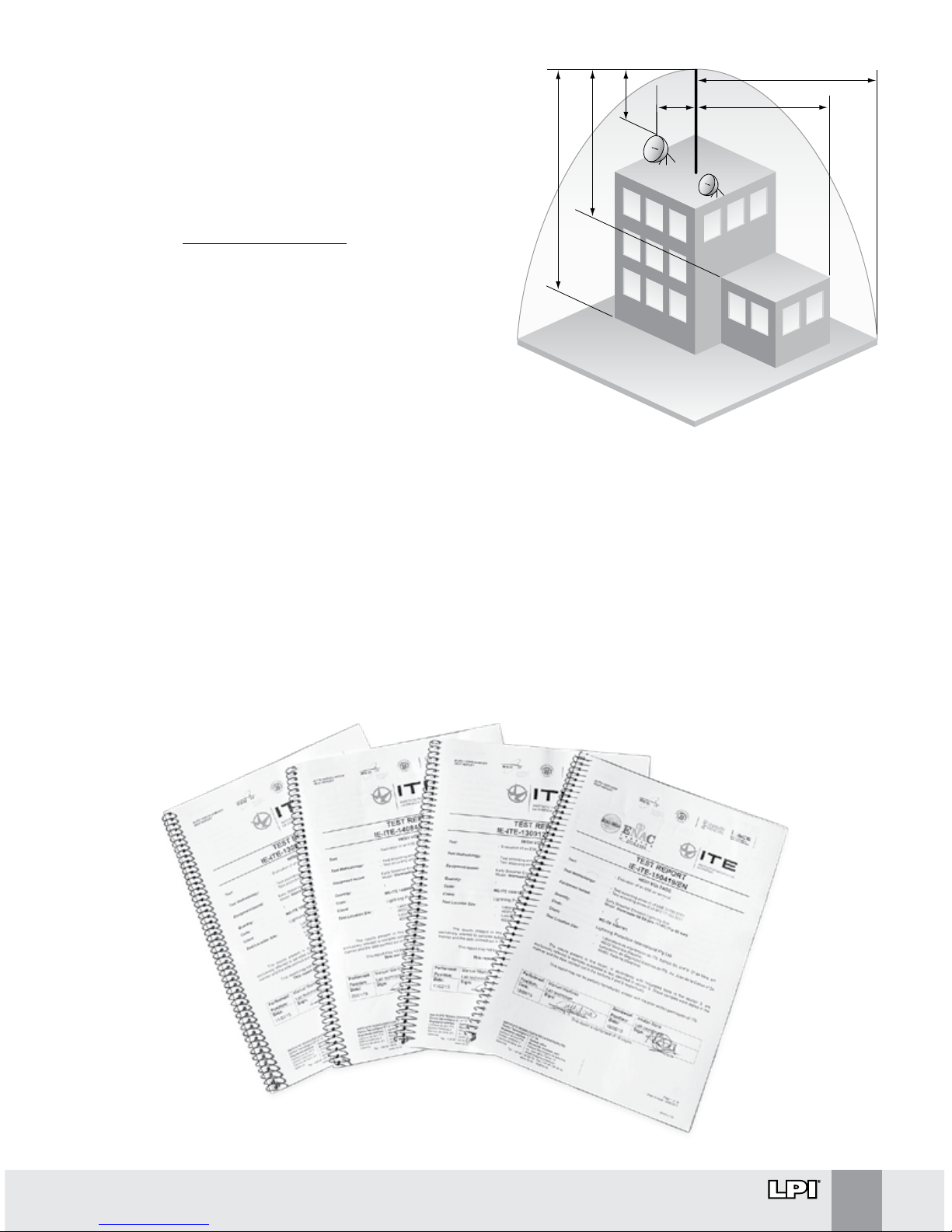

(1) Rp(h) = √2rh − h2 + Δ(2r + Δ) for h ≥ 5 m

and

(2)

Rp = h x Rp5 / 5 for 2 ≤ h < 5 m

where h = Stormaster height relative

to the area being protected (m)

Rp

5

= value of Rp from Eqn. (2) when h = 5 m

r = 20 m for protection level I (Very High protection)

30 m for protection level II (High protection)

45 m for protection level III (Medium protection)

60 m for protection level IV (Standard protection)

and Δ = Stormaster time and height advantage according to the

Stormaster model installed:

Choices: Stormaster ESE 15: Δ = 15 µs

Stormaster ESE 30: Δ = 30 µs

Stormaster ESE 50: Δ = 50 µs

Stormaster ESE 60: Δ = 60 µs

Rp3

Rp2

Rp1

h3 h2

h1

Protection Performance

The protection radius (Rp) of a Stormaster

ESE terminal is calculated using the formula

as defined in NF C 17-102 (September 2011),

namely:

Page 6

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

4

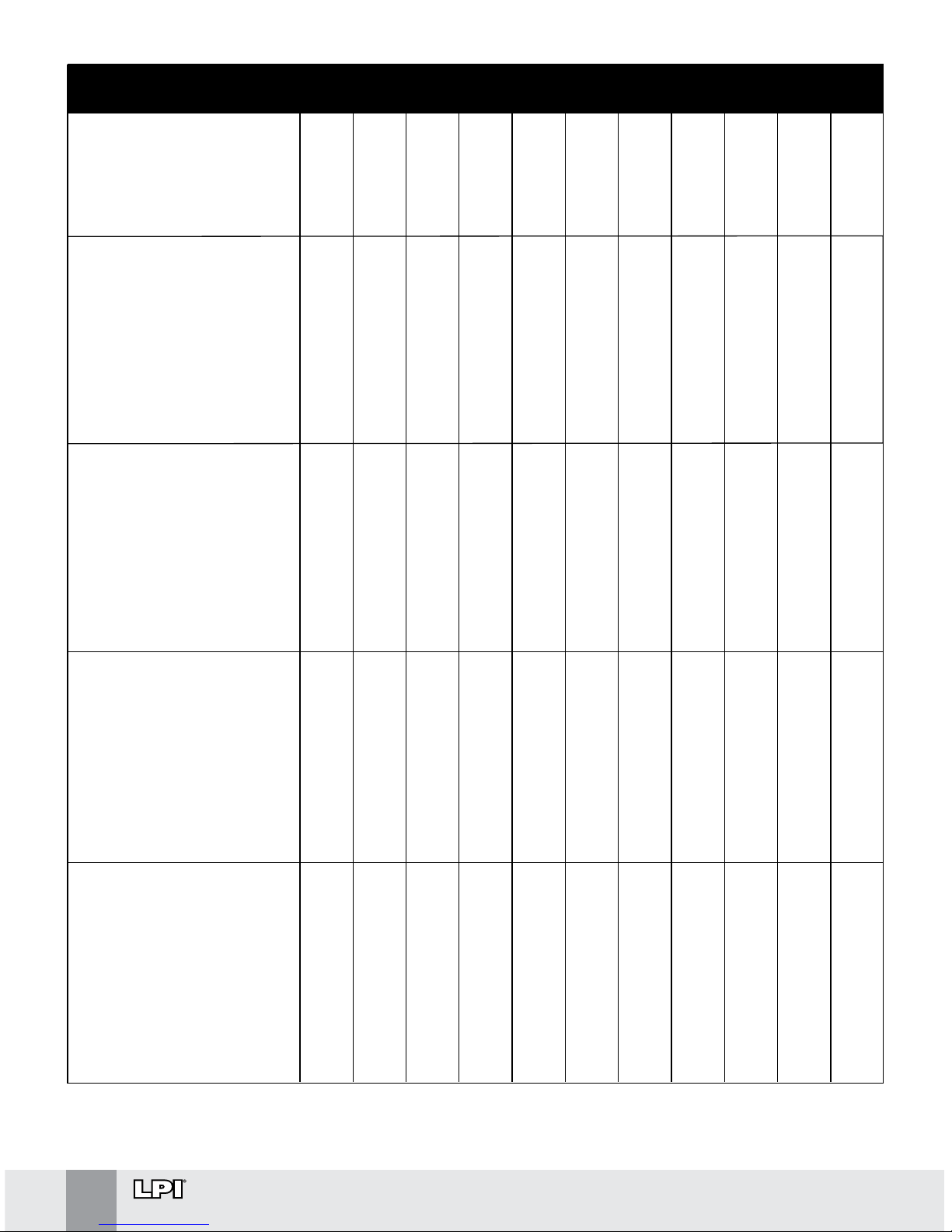

Contact LPI for Protection Radius for Level I+ and Level I++

PROTECTION RADIUS, Rp (m)

h = height of Stormaster

ESE terminal above the 2 4 5 6 10 15 20 45 60 80 100

area to be protected (m)

Protection Level I

(Very High)

Stormaster ESE 15 13 25 32 32 34 35 35 35 35 35 35

Stormaster ESE 30 19 38 48 48 49 50 50 50 50 50 50

Stormaster ESE 50 27 55 68 69 69 70 70 70 70 70 70

Stormaster ESE 60 31 63 79 79 79 80 80 80 80 80 80

Protection Level II

(High)

Stormaster ESE 15 15 30 37 38 40 42 44 44 44 44 44

Stormaster ESE 30 22 44 55 55 57 58 59 59 59 59 59

Stormaster ESE 50 30 61 76 76 77 79 79 79 79 79 79

Stormaster ESE 60 35 69 86 87 88 89 89 89 89 89 89

Protection Level III

(Medium)

Stormaster ESE 15 18 36 45 46 49 52 55 60 60 60 60

Stormaster ESE 30 25 51 63 64 66 69 71 75 75 75 75

Stormaster ESE 50 35 69 86 87 88 90 92 95 95 95 95

Stormaster ESE 60 39 78 97 97 99 101 102 105 105 105 105

Protection Level IV

(Standard)

Stormaster ESE 15 20 41 51 52 56 60 63 73 75 75 75

Stormaster ESE 30 29 57 71 72 75 78 81 89 90 90 90

Stormaster ESE 50 38 76 95 96 98 100 102 109 110 110 110

Stormaster ESE 60 43 85 107 107 109 111 113 119 120 120 120

Page 7

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

5

WARRANTY

This product has a limited manufacturer’s warranty given by Lightning Protection

International Pty Ltd (LPI) to the original purchaser. The warranty covers any

manufacturing defects, material defects and workmanship for a period of five (5)

years from the date of dispatch from the manufacturer. This warranty is only valid if

the purchaser sends a copy of the dulyfilled warranty card back to LPI within 30 days

of purchase.

The purchaser acknowledges 100% protection for direct strike lightning is not

possible and cannot be provided due to the lightning discharge process being a

natural atmospheric event with statistical variation in behaviour and energy levels,

which may exceed product ratings. Hence, the manufacturer’s liability is limited to

repair or replacement of the faulty product with an equivalent product. The option

to repair or replace the product will be at manufacturer’s sole decision. The repaired

or replacement product will be warranted under the terms of this warranty for the

remainder of the warranty period for the product originally supplied. This warranty

does not indemnify the purchaser of the product for any consequential claim for

damages or loss of operations or service or profits.

This warranty only covers products supplied by LPI or its authorized distributor.

The manufacturer also confirms that the warranty will not be applicable (in its

judgement) under the following conditions:

(a) The product being connected to equipment and accessories not authorised by

LPI.

(b) Improper handling, misuse, abuse, neglect, accident, improper installation or

non-compliance with the direction of use.

(c) Any alteration or modification which in the opinion of LPI will affect the

performance of the product.

(d) The product not earthed (where ever applicable) according to LPI’s

recommendations.

Page 8

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

6

Lightning Protection

Comments on the French Standard NF C 17-102 (2011).

Refer to the section in the standard titled “foreward” which states the following:

Installations for protection against lightning designed and made according to this document,

may not, like everything about the natural elements, ensure the absolute protection of structures,

people or objects; however, the application of this document must reduce significantly the risk

of damage due to lightning on protected structures.

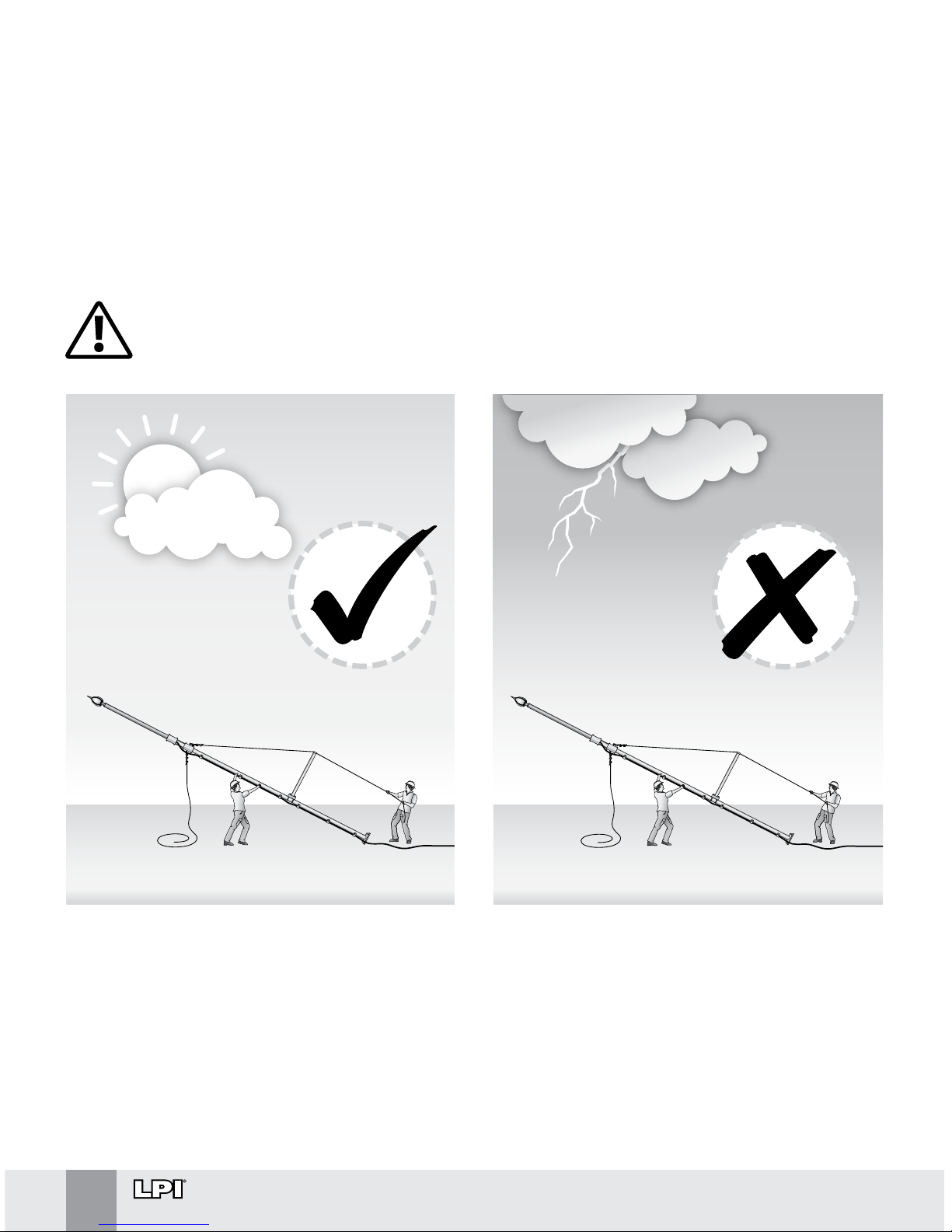

The LPI Stormaster ESE terminal should only be installed during storm free periods.

Figure 1.

Page 9

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

7

General Safety Guidelines

Recommended Installation Method

∆ Ensure safe working environments and practices to local codes

∆ Use personal protective equipment during installation

∆ Use mechanical methods of raising and installing masts over 6 m

∆ Cordon off area below installation point

∆ Check for overhead powerlines or any other obstructions before lifting or raising

∆ Ensure enough man power to safely conduct all aspects of installation

∆ The installation must conform to all relevant local standards and regulations.

To assist in the installation of the Stormaster ESE terminal and accessories, refer to drawings

as illustrated on pages 8 to 15.

1. Installation of the lightning earth.

2. Installation of the HVSC Plus downconductor.

3. Lower termination of the HVSC Plus downconductor and connection to the lightning earth.

4. Upper termination of the HVSC Plus downconductor and connection to the Stormaster ESE

terminal.

5. Preparation and raising of the mast into position.

Page 10

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

8

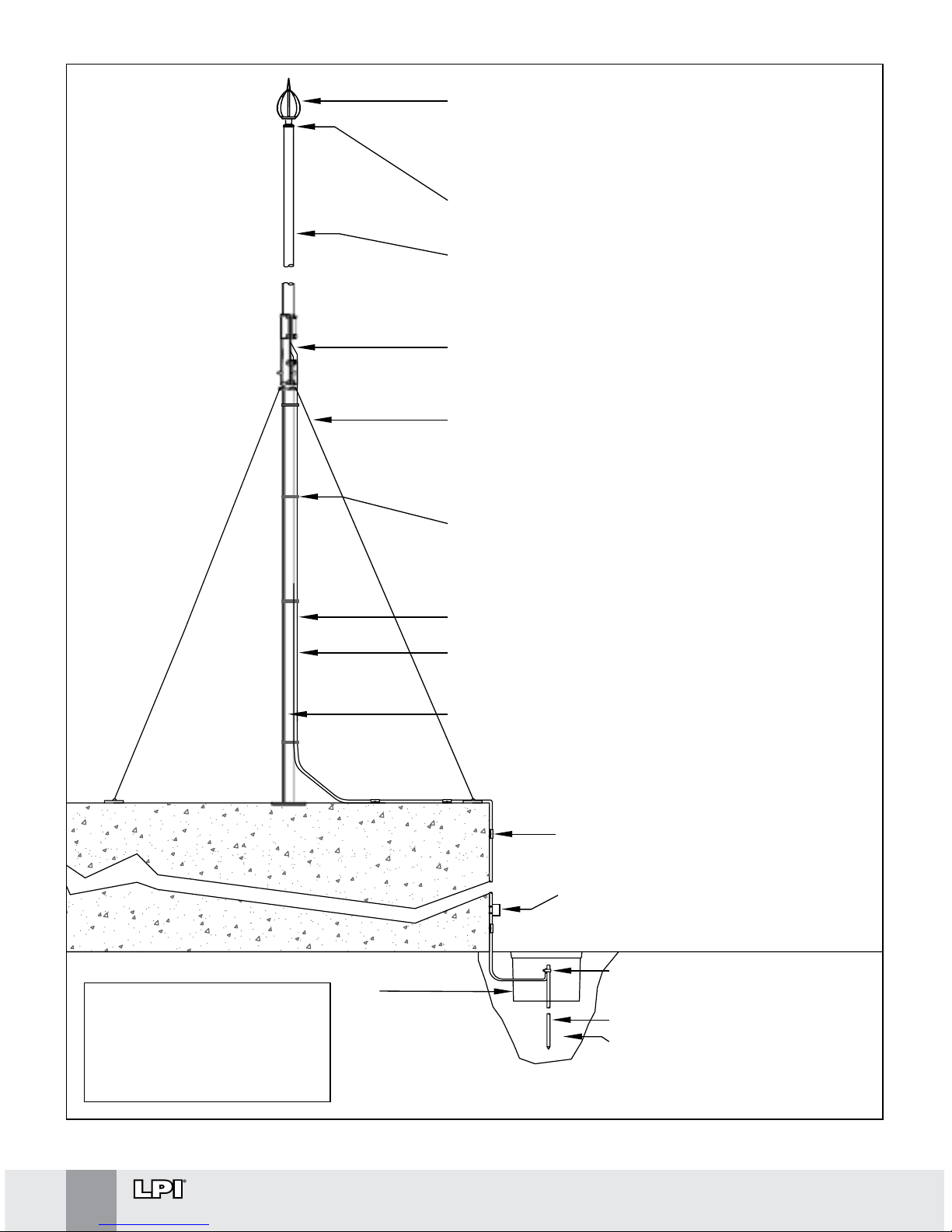

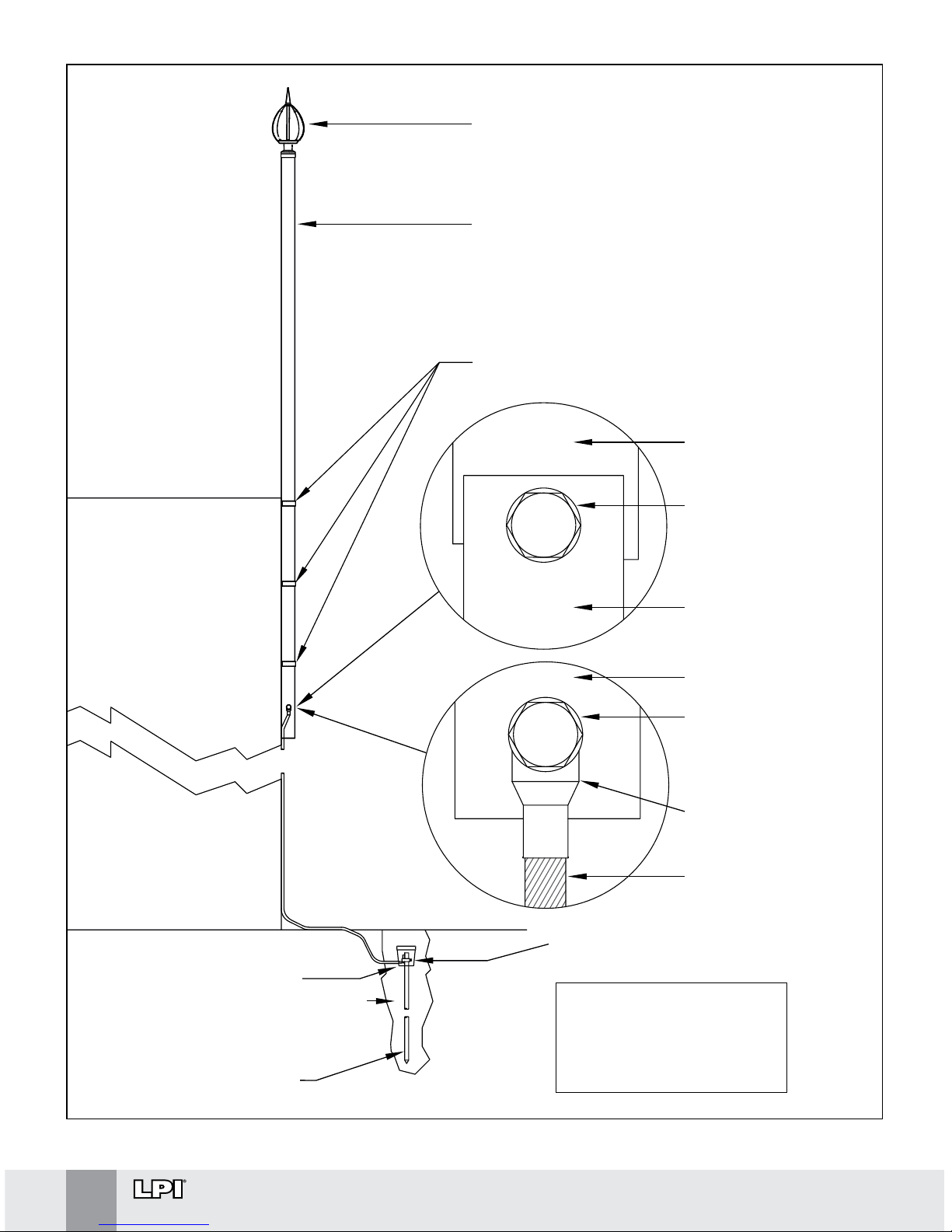

Figure 2.

LPI® SADDLES AND FIXINGS

ORDERING CODE: SAD FIX

LPI

®

LIGHTNING STRIKE RECORDER

ORDERING CODE: LSR1

LPI

®

STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15

STORMASTER-ESE-30

STORMASTER-ESE-50

STORMASTER-ESE-60

LPI

®

UPPER TERMINATION KIT

ORDERING CODE: UTERMKIT-Mk3

LPI

®

FRP SUPPORT MAST

ORDERING CODE: FRP-2M

FRP-3M

FRP-4M

LPI

®

INLINE COUPLING

ORDERING CODE: ILCOUPLING

LPI

®

GUY KIT

ORDERING CODE: GUYKIT-4M

GUYKIT-4M-SS

GUYKIT-7M

GUYKIT-7M-SS

LPI

®

CABLE TIES

ORDERING CODE: S/S-CABTIES-STD

S/S-CABTIES-L

LPI

®

HVSC PLUS DOWNCONDUCTOR

ORDERING CODE: HVSCPLUS-PM

OR LPI COPPER TAPE

ORDERING CODE: FL6T253C

LPI

®

LOWER MAST ASSEMBLY

ORDERING CODE: ALUMB-3M

ALUMB-4M

ALUMB-5M

ALUMB-6M

LPI

®

LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT-MK3

LPI® EARTHING SYSTEM

LPI® EARTH ENHANCING MATERIAL

ORDERING CODE: GRIP-10

SRIM-20

RESLO-20

LPI®

INSPECTION PIT

ORDERING CODE:

EPIT-P

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10

SRIM-20

RESLO-20

30 x FL6T253C

TYPICAL PRODUCTS

REQUIRED FOR

RADIAL LP EARTH:

Page 11

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

9

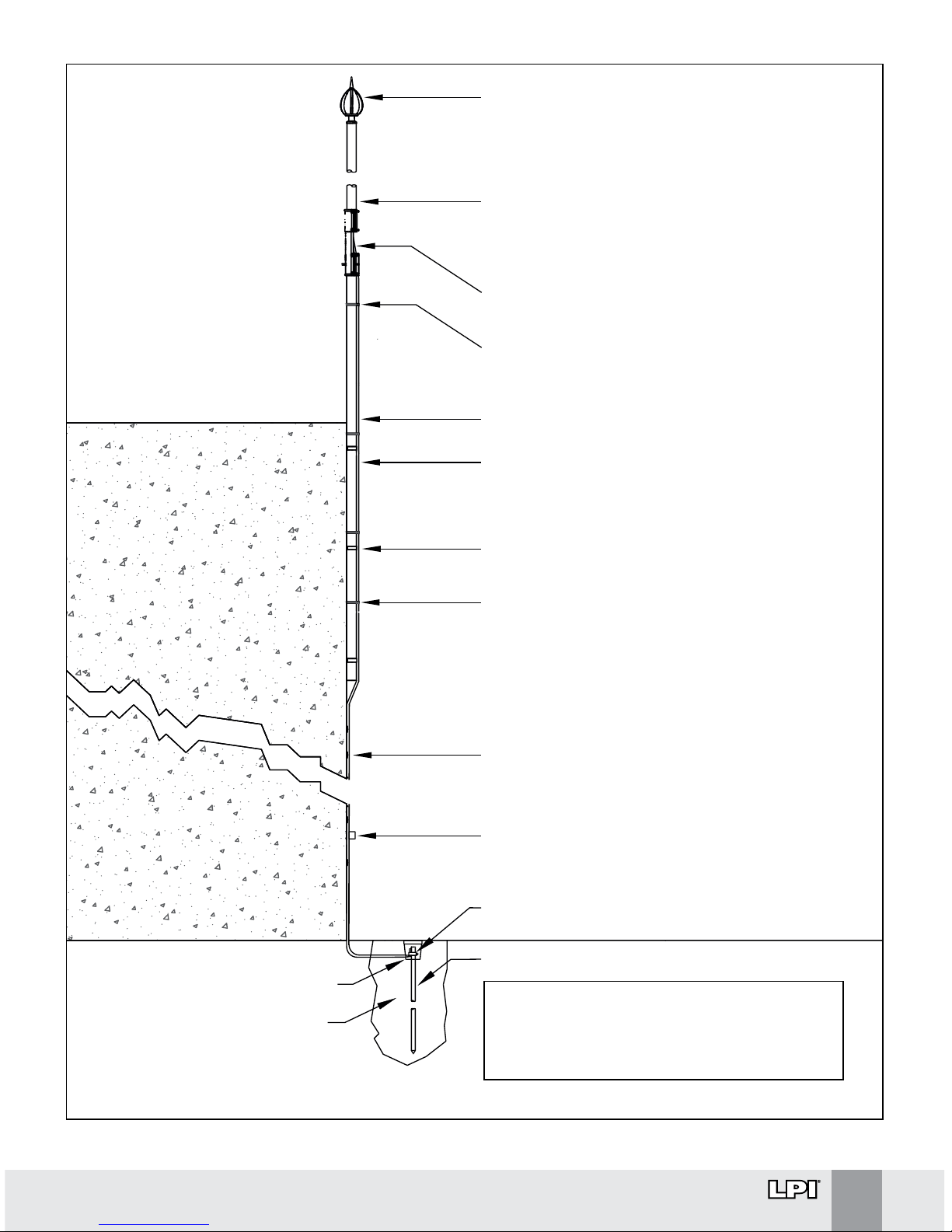

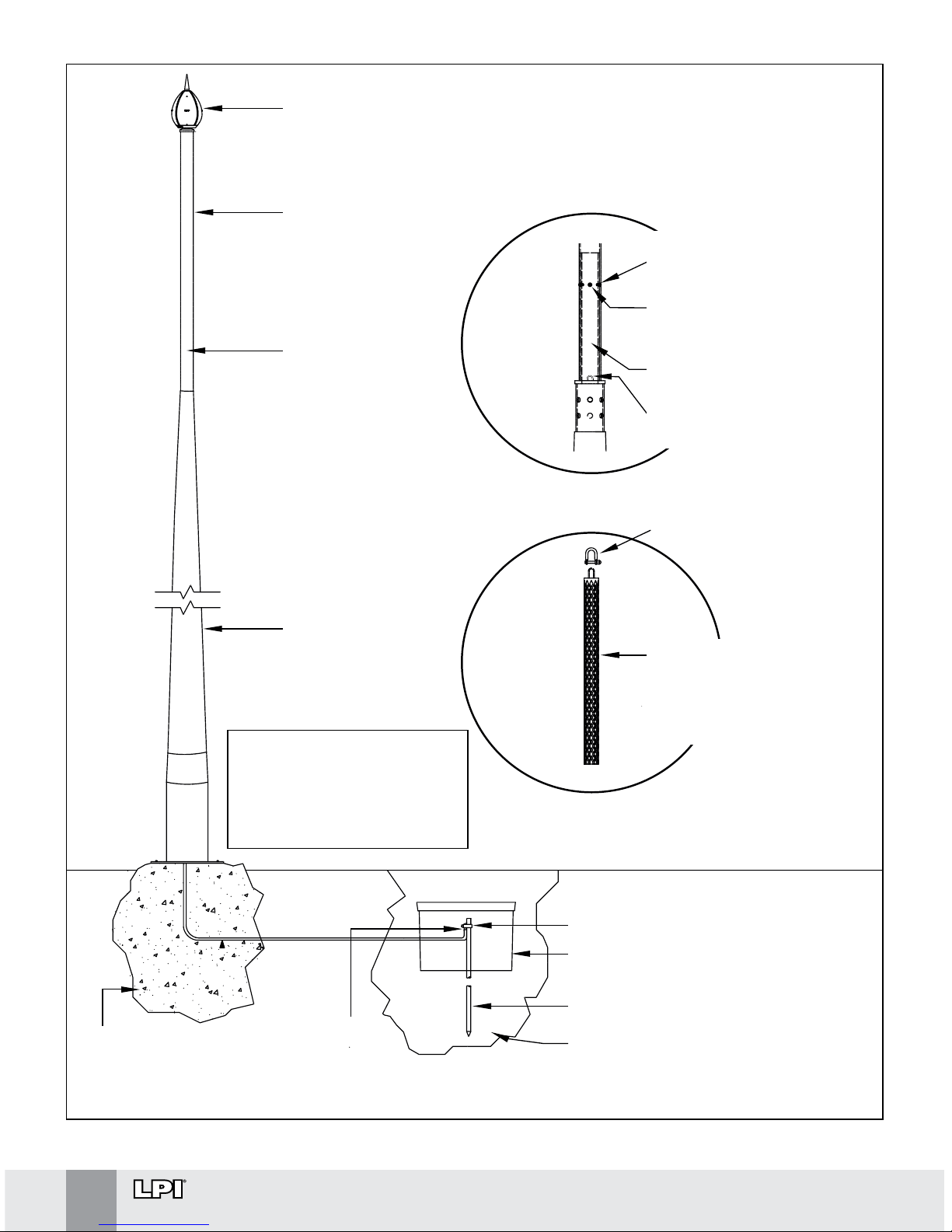

Figure 3.

LPI® STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15

STORMASTER-ESE-30

STORMASTER-ESE-50

STORMASTER-ESE-60

LPI

®

FRP SUPPORT MAST

ORDERING CODE: FRP-2M

FRP-3M

FRP-4M

LPI

®

INLINE COUPLING

ORDERING CODE: ILCOUPLING

LPI

®

CABLE TIES

ORDERING CODE: SS-CABTIES-STD

SS-CABTIES-L

LPI

®

HVSC PLUS DOWNCONDUCTOR

ORDERING CODE: HVSCPLUS-PM

OR LPI

®

COPPER TAPE

ORDERING CODE: FL6T253C

LPI

®

SADDLES FOR CANTILEVERING MAST

ORDERING CODE: CANTSAD

LPI

®

LOWER MAST ASSEMBLY

ORDERING CODE: ALUM-3M

ALUM-4M

ALUM-5M

ALUM-6M

LPI

®

SADDLES AND FIXINGS

ORDERING CODE: SAD FIX

LPI

®

EARTH ENHANCING

MATERIAL

ORDERING CODE: GRIP-10

SRIM-20

RESLO-20

LPI

®

INSPECTION PIT

ORDERING CODE: EPIT-P

IMPORTANT:

One third of the mast

height must be securely

fixed to the structure.

Stormaster ESE

terminal to be a

minimum of 2 metres

above the highest point

of the building or

rooftop objects.

Recommended

clearance height = 5

metres.

LPI

®

LIGHTNING STRIKE RECORDER

ORDERING CODE: LSR1

LPI

®

EARTHING SYSTEM

TYPICAL PRODUCTS REQUIRED FOR RADIAL LP EARTH:

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10 / SRIM-20 / RESLO-20

30 x FL6T253C

LPI® LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT-MK3

Page 12

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

10

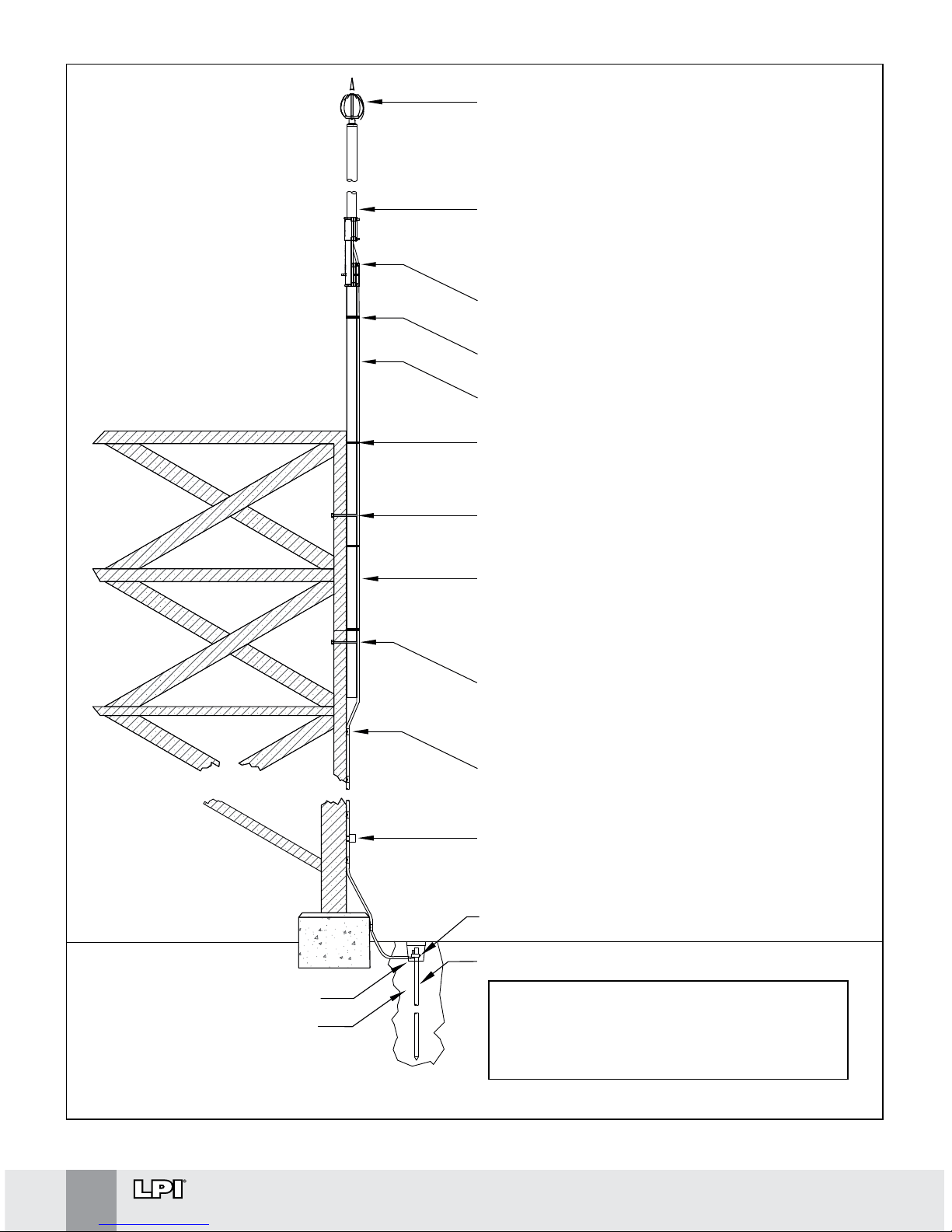

IMPORTANT:

One third of the mast

height must be securely

fixed to the structure.

Stormaster ESE

terminal to be a

minimum of 2 metres

above the highest point

of the building or

rooftop objects.

Recommended

clearance height = 5

metres.

LPI® HVSC PLUS DOWNCONDUCTOR

ORDERING CODE: HVSCPLUS-PM

OR LPI

®

COPPER TAPE

ORDERING CODE: FL6T253C

LPI

®

STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15

STORMASTER-ESE-30

STORMASTER-ESE-50

STORMASTER-ESE-60

LPI

®

FRP SUPPORT MAST

ORDERING CODE: FRP-2M

FRP-3M

FRP-4M

LPI

®

INLINE COUPLING

ORDERING CODE: ILCOUPLING

LPI

®

CABLE TIES

ORDERING CODE: SS-CABTIES-STD

SS-CABTIES-L

LPI

®

U-BOLT

ORDERING CODE: U-BOLT (2 PER SET)

LPI

®

BEAM CLAMP AND CABLE SUPPORT

ORDERING CODE: BEAM CLAMP /

CABLE SUPPORT - HVSC

LPI

®

LIGHTNING STRIKE RECORDER

ORDERING CODE: LSR1

LPI

®

LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT-MK3

LPI

®

EARTHING SYSTEM

LPI

®

EARTH ENHANCING

MATERIAL

ORDERING CODE: GRIP-10

RESLO-20

SRIM-20

LPI

®

INSPECTION PIT

ORDERING CODE: EPIT-P

LPI

®

LOWER MAST ASSEMBLY

ORDERING CODE: ALUM-3M

ALUM-4M

ALUM-5M

ALUM-6M

LPI

®

U-BOLT

ORDERING CODE: U-BOLT (2 PER SET)

TYPICAL PRODUCTS REQUIRED FOR RADIAL LP EARTH:

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10 / RESLO-20 / SRIM-20

30 x FL6T253C

Figure 4.

Page 13

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

11

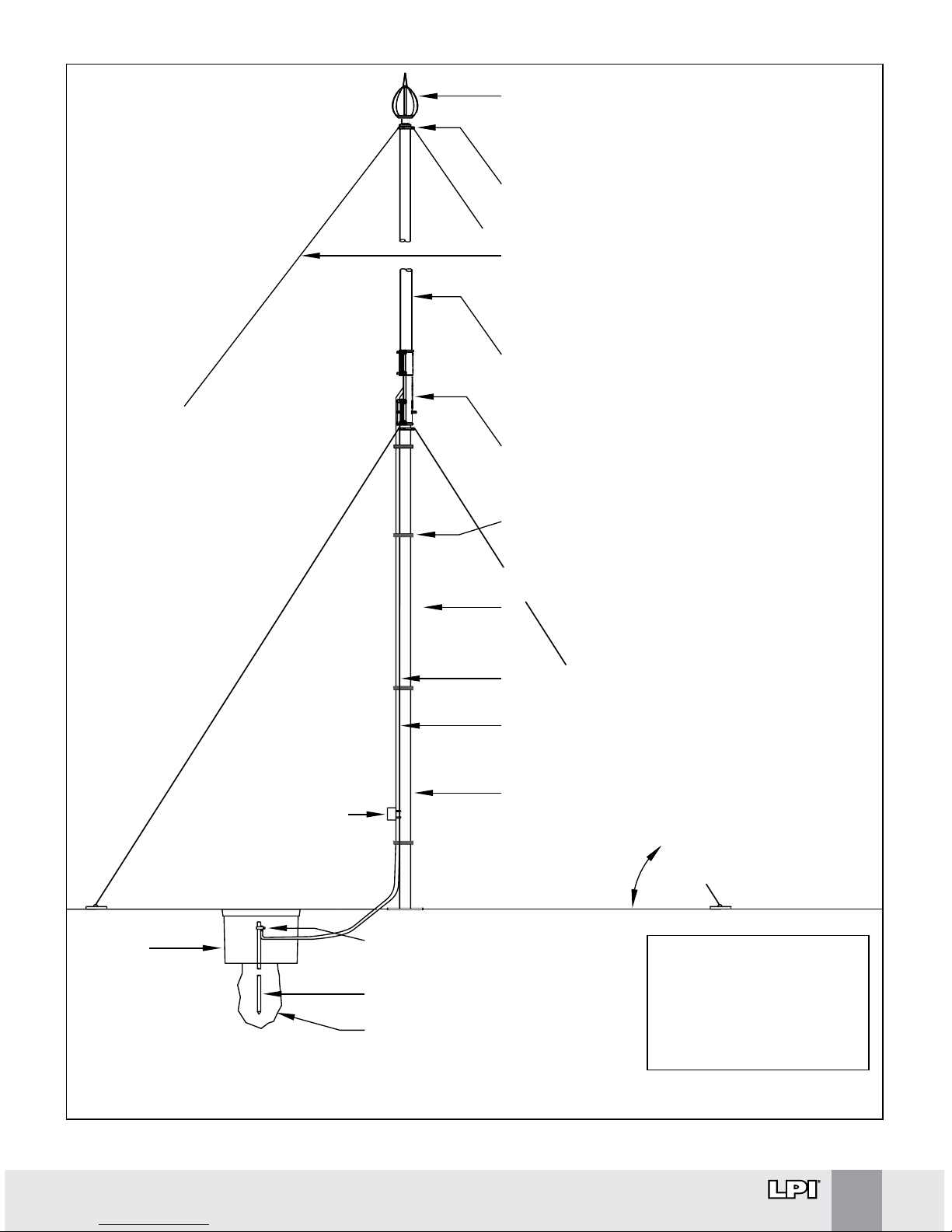

Figure 5.

Preferred Angle

60 - 45 Degrees

GUY WHERE

NECESSARY

LPI

®

STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15

STORMASTER-ESE-30

STORMASTER-ESE-50

STORMASTER-ESE-60

LPI

®

GUY KIT

ORDERING CODE: GUYKIT-4M

GUYKIT-4M-SS

GUYKIT-7M

GUYKIT-7M-SS

LPI

®

FRP SUPPORT MAST

ORDERING CODE: FRP-2M

FRP-3M

FRP-4M

LPI

®

INLINE COUPLING

ORDERING CODE: ILCOUPLING

LPI

®

CABLE TIES

ORDERING CODE: SS-CABTIES-STD

SS-CABTIES-L

LPI

®

GUY KIT

ORDERING CODE: GUYKIT-4M

GUYKIT-4M-SS

GUYKIT-7M

GUYKIT-7M-SS

LPI

®

HVSC PLUS DOWNCONDUCTOR

ORDERING CODE: HVSCPLUS-PM

OR LPI

®

COPPER TAPE

ORDERING CODE: FL6T253C

LPI

®

LIGHTNING

STRIKE RECORDER

ORDERING CODE: LSR1

LPI® LOWER MAST ASSEMBLY

ORDERING CODE: ALUMB-3M

ALUMB-4M

ALUMB-5M

ALUMB-6M

DO NOT OVERTENSION

GUY WIRES (SLIGHTLY

SAGGING)

LPI

®

LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT-MK3

LPI® EARTHING SYSTEM

LPI

®

EARTH ENHANCING

MATERIAL

ORDERING CODE: GRIP-10

SRIM-20

RESLO-20

LPI®

INSPECTION

PIT

ORDERING

CODE: EPIT-P

IMPORTANT:

Stormaster ESE Terminal to

be a minimum of 2 metres

above the highest point

of the building or rooftop

objects. Recommended

clearance height = 5

metres.

TYPICAL PRODUCTS

REQUIRED FOR RADIAL

LP EARTH:

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10 / SRIM-20 / RESLO-20

30 x FL6T253C

LPI® GUY RING

ORDERING CODE: GUY RING

Page 14

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

12

Figure 6.

LPI® INSPECTION PIT

ORDERING CODE: EPIT-P

IMPORTANT:

One third of the

mast height must be

securely fixed to the

structure. Stormaster

ESE terminal to be a

minimum of 2 metres

above the highest

point of the building

or rooftop objects.

Recommended

clearance height = 5

metres.

TYPICAL PRODUCTS REQUIRED

FOR RADIAL LP EARTH:

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10 / SRIM-20 / RESLO-20

30 x FL6T253C

BASE OF MAST PIPE

MOUNTING BOLT &

STAINLESS STEEL

WASHER

COPPER TAPE

BASE OF MAST PIPE

MOUNTING BOLT &

STAINLESS STEEL

WASHER

COMPRESSION LUG

COPPER CABLE

LPI

®

SADDLES FOR CANTILEVER MAST

ORDERING CODE: CANTSAD

LPI STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15-GI

STORMASTER-ESE-30-GI

STORMASTER-ESE-50-GI

STORMASTER-ESE-60-GI

MAST ASSEMBLY WITH GI ADAPTOR

ORDERING CODE: ALUM3M-MGI

ALUM4M-MGI

ALUM5M-MGI

ALUM6M-MGI

LPI

®

LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT-MK3

LPI

®

EARTHING SYSTEM

LPI® EARTH ENHANCING MATERIAL

ORDERING CODE: GRIP-10

SRIM-20

RESLO-20

Page 15

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

13

BASE OF MAST PIPE

MOUNTING BOLT &

STAINLESS STEEL

WASHER

MOUNTING BOLT &

STAINLESS STEEL

WASHER

COPPER TAPE

BASE OF MAST PIPE

COMPRESSION LUG

COPPER CABLE

LPI

®

STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15-GI

STORMASTER-ESE-30-GI

STORMASTER-ESE-50-GI

STORMASTER-ESE-60-GI

MAST ASSEMBLY WITH GI ADAPTOR

ORDERING CODE: ALUMB-3M-MGI

ALUMB-4M-MGI

ALUMB-5M-MGI

ALUMB-6M-MGI

IMPORTANT:

Stormaster ESE

terminal to be a

minimum of 2

metres above the

highest point of

the building or

rooftop objects.

Recommended

clearance

height = 5

metres.

LPI

®

SADDLES AND FIXINGS FOR

COPPER TAPE

ORDERING CODE: FL3DCTC253C

LPI

®

LIGHTNING STRIKE RECORDER

ORDERING CODE: LSR1

LPI

®

LOWER TERMINATION KIT

ORDERING CODE:

LTERMKIT-MK3

LPI

®

EARTHING SYSTEM

LPI

®

EARTH ENHANCING

MATERIAL

ORDERING CODE: GRIP-10

SRIM-20

RESLO-20

LPI

®

INSPECTION PIT

ORDERING CODE: EPIT-P

LPI

®

GUY RING

ORDERING CODE: GUY RING

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10

/ SRIM-20

/ RESLO-20

30 x FL6T253C

TYPICAL PRODUCTS

REQUIRED FOR

RADIAL LP EARTH:

Figure 7.

Page 16

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

14

Figure 8.

SHACKLE

FOOTING

LPI

®

LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT-MK3

LPI

®

EARTHING SYSTEM

LPI

®

EARTH ENHANCING MATERIAL

ORDERING CODE: GRIP-10

SRIM-20

RESLO-20

LPI

®

INSPECTION PIT

ORDERING CODE: EPIT-P

TERMINATION OF

DOWNCONDUCTOR

TO EARTH

LPI

®

STORMASTER ESE TERMINAL

ORDERING CODE: STORMASTER-ESE-15

STORMASTER-ESE-30

STORMASTER-ESE-50

STORMASTER-ESE-60

LPI

®

FRP SUPPORT

MAST

ORDERING CODE:

FRP-2M

FRP-3M

FRP-4M

LPI

®

HVSC PLUS

DOWNCONDUCTOR

OR LPI COPPER

TAPE

(DOWNCONDUCTOR

TO BE RUN

INTERNALLY)

ORDERING CODE:

HVSCPLUS-PM OR

FL6T253C

FREESTANDING

MAST

CABLE SOCK

DETAIL

SPIGOT

DETAIL

CABLE SOCK LOCATED

INSIDE FREESTANDING

MAST, ATTACHED TO

WELDED LUG AT TOP

VIA SHACKLE

M6 x 10 PAN HEAD

SCREWS 3 PLACES

AT 120°

3 HOLES DRILLED

ON SITE, Ø 6.5 SPACED

AT 120°

INTERNAL SPIGOT

59 mm OD FOR SLIDING

FIT

WELDED LUG

4 x CBER1214

4 x RTC253

1 x EPIT-P

1 x GRIP-10

/ SRIM-20

/ RESLO-20

30 x FL6T253C

TYPICAL PRODUCTS

REQUIRED FOR

RADIAL LP EARTH:

Page 17

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

15

Figure 9.

NOTE: IF SUPPORT MAST ASSEMBLY IS

INSTALLED CLOSER TO EDGE OF STRUCTURE,

MINIMUM BENDING OF 0.43 m SHOULD BE

MAINTAINED

STAINLESS STEEL

CABLE TIES

STAINLESS STEEL

SADDLES

FIX EVERY 1-2 METRES

THIS TYPE OF ROUTING

TO BE AVOIDED. SHARP

BENDING RADIUS MAY

DAMAGE HVSC PLUS

REQUIRED “ANGULAR”

ROUTING OF THE HVSC.

NOTE: MINIMUM BEND

RADIUS 0.43 m

3 METRES MINIMUM

Page 18

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

16

Checking Lightning Protection Components Supplied

The LPI Stormaster ESE components received should be checked against the “bill of materials”

for loss during shipping and for damage.

Check the following:

Terminal(s)

∆ Terminals have not been dented or damaged in any way during transit

∆ Instructions, warning labels, warranty, test certificate and relevant mast base components

are supplied

Downconductor(s)

∆ The HVSC Plus cable drum (if supplied) is not damaged

∆ The correct HVSC Plus length(s) have been supplied

∆ There is no obvious damage to the HVSC Plus cable

∆ If a factory completed upper termination is supplied, check to see that the termination is

not damaged and confirm inside or outside termination(s)

∆ Order of lengths and quantities of HVSC Plus (if multiple lengths on one drum), will be

shown on the side of the cable drum(s)

LPI Stormaster ESE Installation

All site and safety requirements must be followed during the installation of the LPI Stormaster ESE.

The correct order of installation is as follows:

1. Installation of the lightning earth.

2. Installation of the HVSC Plus downconductor.

3. Lower termination of the HVSC Plus downconductor and connection to the lightning earth.

4. Upper termination of the HVSC Plus downconductor and connection to the Stormaster ESE

terminal.

5. Preparation and raising of the mast into position.

LPI Stormaster ESE should only be installed during storm free periods.

If the Stormaster ESE terminal needs to be raised prior to connection to the lightning earth or

immediate connection is not possible, then connect the lower end of the downconductor to

structural steel reinforcing or other suitable earth point.

Page 19

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

17

Earth Pit (Polymer)

Ordering Code: EPIT-P

Lower Termination

Ordering Code: LTERMKIT - MK3

Each radial trench is treated

with earth enhancing compounds

Ordering Code: GRIP-10

RESLO-10

SRIM-20

Earth Rods

Ordering Code: CBER1214

25 x 3 mm typically

3 radial lengths of 10 m,

with 500 mm depth.

Ordering Code: FL6T253C

Earth Rod Clamp

Ordering Code: RTC253

Installation of the Lightning Earth

Before installation of the lightning protection earth, consult site drawings of underground

services so that these are not damaged during installation of the earthing system.

Earth DC resistance (typically ‹10 ohms) and impedance (typically ‹30 ohms) is required for

successful operation of LPI Stormaster ESE.

LPI recommends the installation of a radial lightning earth as shown in figure 10.

∆ It is recommended to install a 3 x 10 metre length radial trench

∆ Each radial should consist of a trench (Approx: 500 mm Deep x 200 mm wide x 10 m length)

∆ An earth rod should be driven at the end of each trench

∆ All rods should be interconnected through the use of 25 x 3 mm copper tape. The use

of earth rod clamps to fix the tape to rods is recommended

Figure 10.

Page 20

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

18

∆ Waterproofing mastic tape should be used on all mechanical connections

∆

It is recommended to apply earth enhancing compound such as LPI RESLO-20, GRIP-10

or

SRIM-20 to reduce soil resistivity to less than 10 ohms

∆ An earth pit should be installed where the end of the downconductor terminates to the

lightning earth as shown in figure 10. This gives an access point for disconnection

and future testing

∆ Do not lower terminate (connect) the downconductor to the earthing system at this point

in time

Note: If due to space constraints it is not possible to install a radial earth as recommended,

consult with LPI or an authorised distributor for further advice

When using earth rods:

∆ Use driving heads to prevent mushrooming on top of rod

∆ Use driving heads when using coupled rods

∆ Use a post or picket driver

Earth Enhancing Compounds

∆ Earth Enhancing Compounds (such as LPI RESLO-20, GRIP-10 or SRIM-20) are supplied

when the existing soil mass has a high resistivity

∆ Using the compounds can lower earth resistance/impedance

∆ Compounds will require water and a mixing container

∆ Follow all installation and safety instructions as supplied with products when applying

the compounds

Bonding the Lightning Earth

Where separate earths exist e.g. structure, power, communications and lightning protection,

they need to be bonded to form an equipotential ground plane. This will stop ground loops and

potential differences arising under transient conditions.

Before bonding of these earths takes place, make sure proper authorisation is gained.

Bonding cable must be 70 mm

2

(2/0 AWG) minimum depending on local standards. It may be

necessary to use a transient earth clamp (TEC100-2L) which bonds all earths to the same

potential under transient conditions.

For further information, it is advisable that local applicable standards are used, i.e. IEC 62305,

AS1768, NFPA 780, C22.1-98 and NEC.

Page 21

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

19

Pre-terminated end of HVSC Plus

hauled from the ground

to the top of the structure

Pre-terminated end

of HVSC Plus on the

inside end when

wound on the drum

Pre-terminated end of

HVSC Plus wound on to

the outside of the drum

Cable pre-termination and drum locations

Lower un-terminated

end to the ground

Labelling

It is the responsibility of the customer/installer to label earth pits or earthing systems to local

requirements.

Installation of the HVSC Plus Downconductor

If installing LPI HVSC Plus, the HVSC Plus downconductors(s) may have had the upper

terminations completed at a pre-specified end of the cable by the LPI factory before being

shipped.

When removing HVSC Plus downconductor packaging, do not use a knife or cut in any way as

this can damage the outer layer of termination.

LPI’s HVSC Plus has an outer layer which is approximately 2 mm (1/16 in.) thick. Be careful not

to damage this layer.

Hauling the HVSC Plus Downconductor

Place the HVSC Plus downconductor cable drum close to where it is to be installed.

Figure 11.

Page 22

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

20

Incorrect method of hoisting

HVSC Plus

Correct method of hoisting

HVSC Plus

Figure 12.

∆ Make sure that the cable drum is in a serviceable condition

∆ Check that the correct length of HVSC Plus downconductor has been supplied. The length

of HVSC Plus will be marked on the drum

∆ If the HVSC Plus downconductor has been upper terminated on the outside of the drum,

then the HVSC Plus downconductor will need to be hauled up the structure with the drum

staying on the ground

∆ If the HVSC Plus downconductor has been upper terminated on the inside of the drum,

then the drum has to be taken to the top or near the top of the structure. Then the HVSC

Plus downconductor can be hauled downwards from the drum to the ground

∆ Any lifting slings or ropes must be securely attached

∆ DO NOT haul the HVSC Plus downconductor from the termination. See Figure 12

∆ Protect the HVSC Plus downconductor at all times when it is being moved

Page 23

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

21

HVSC Plus Downconductor Clearance Holes

Before running the HVSC Plus downconductor through any clearance holes, ensure that:

∆ A minimum hole diameter of 60 mm (2 3/8”) is used

∆ Enough protection is provided so that the HVSC Plus downconductor is not damaged

during or after installation

∆ A waterproofing sealant or sealing gland should be used if the hole needs to be

weatherproof

Routing

The routing of the HVSC Plus downconductor needs to follow these guidelines:

∆ The route of the HVSC Plus downconductor should be as set out in the original

design. Ensure no structural changes such as new antenna or mast installations, air

conditioning towers or ducting has been installed

∆ DO NOT double the HVSC Plus downconductor back against itself after changes of

direction, i.e. 180°

∆ The HVSC Plus downconductor may be installed internally or externally on the structure

∆ The HVSC Plus downconductor should be installed as close (flush) as possible to the

structure

∆ Minimise the number of bends and use the most direct route to ground

∆ Minimise strain on the HVSC Plus downconductor

∆ Ensure minimum bend radius maintained ›430 mm (20in.)

∆ Parallel routing with other services – Minimum separation = 2 m. See Figure 13 on

page 22

∆ If the HVSC Plus downconductor has to cross other services make sure it crosses at right

angles using a conduit that extends at least 1 m past either side of the existing service

∆ The lower end of the HVSC Plus downconductor must terminate close to the initial injection

point of the lightning earth

∆ Be sure to allow for enough slack in the HVSC Plus at the top end for connection to the

Stormaster ESE terminal and the raising of the mast

∆ If it is necessary to isolate the HVSC Plus downconductor from the structure, run the cable

in an insulating conduit with a minimum wall thickness of 3 mm (1/8 in.). The maximum

length isolated from the structure should be 2.5 m (9 ft). The entire length of the HVSC

Plus downconductor cannot be run in insulated conduit

Page 24

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

22

INCORRECT

CORRECT

Power and Communication Lines

Power and Communication Lines

Radius <430 mm

Radius

>

430 mm

<

2 m

2 m

2 m Max.

Figure 13.

∆ HVSC Plus downconductor should be protected from damage at the lower end by installing

a “Top Hat” surface mount cover of no more than 2 m from ground level

The HVSC Plus downconductor must be checked by an LPI representative if it is damaged during

installation to see if the damage will affect performance

Fixing the HVSC Plus Downconductor

Using non LPI saddles can damage the downconductor outer sheath.

∆ The HVSC Plus downconductor should be fixed to the structure every 2 m for the entire

length of the run. (Use LPI supplied or recommended saddles, fixing and cable ties)

∆ For masonry walls or roofs, use the LPI saddles provided. These can be used with

masonry anchors, suitable fastenings for wood, fibreglass and metallic surfaces or self tapping screws

∆ The most direct path to ground is recommended. Avoid sharp bends (refer to Figure 9 on

page 15)

Page 25

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

23

∆ Use cable ties when fixing to round sections, such as pipes, tower legs, masts, etc.

∆ If the HVSC Plus downconductor is to be routed above a false ceiling, ensure that it is fixed

to the underside of the concrete floor slab.

∆ Do not use explosive fastening methods on LPI saddles or HVSC Plus downconductors.

Installation of Conventional Downconductors

In some installations, the use of copper tape or insulated stranded copper cable may be installed

as the downconductor. In such cases, it may be necessary to install multiple downconductors

in compliance with local and/or international standards such as NFC 17-102, AS1768, and

IEC 62305. See the following dot points for further information.

The Stormaster ESE terminal provides a bolt for the lug connection to the lower finial connector

of the mast butt adaptor. All conventional downconductors should be lugged and fixed to the

terminal per Figure 14 on page 24.

The following are recommendations and points that should be considered when installing

conventional downconductors.

∆ For structures made of combustible materials, downconductors must be separated from

the structure by a distance of at least 0.1 m and they must have a cross-sectional area of

100 mm

2

Installation on structures:

∆ Minimum of two downconductors are required, preferably on opposite sides of the

structure

∆ At least one of these downconductors must be a dedicated downconductor per

EN 50164-2 and the other can be the natural components of the structure (i.e., both

downconductors cannot be natural components)

∆ For installations where multiple Stormaster terminals are installed, the requirement for

two downconductors per terminal is waived

Standalone / isolated installation:

∆ Only one downconductor is required

∆ The “structure” may be used if metallic and complies with the requirements for

downconductors

Note: EN 50164-2 has a requirement for copper and aluminium downconductors to have a

cross-sectional area of at least 50 mm

2

Routing and installation:

∆ Install externally wherever possible. Internal installation requires routing inside a non-

flammable insulating pipe

Page 26

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

24

MAST BUTT ADAPTOR MAST BUTT ADAPTOR

Figure 14.

∆ As direct and straight as possible

∆ Avoid sharp bends. Bend radius must not be smaller than 20 cm

∆ Avoid routing along or across electrical conduits

∆ Use three fasteners per metre

∆ Protect against the risk of mechanical impact damage with guard tubes up to a height

of at least 2 m above the ground level

Natural components:

∆ External interconnected steel frames (metal structures) may be used in place of

dedicated downconductors if it is shown that the electrical continuity / resistance is

≤ 0.1 W

Page 27

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

25

∆ Internal metallic structures, concrete reinforcements, metal structures inside walls,

metal sheets and pipes at least 2 mm thick may be used to supplement dedicated

downconductors(s)

Equipotential bonding:

Dangerous sparking may occur between the external Stormaster system and the following

components:

∆ Metal installations

∆ Internal systems

∆ External conductive parts and lines connected to the structure

The dangerous sparking can be avoided by means of:

∆ Equipotential bonding, using conductors and/or SPDs or

∆ Electrical insulation between the parts (must comply with separation distance

requirements)

Installation of Stormaster GI Terminal to Threaded Pipe

LPI offers within its range of Stormaster terminals a GI version which is designed for a threaded

connection to a 2 inch BSP GI pipe. Please refer to drawings on pages 12 and 13 along with

Figure 15 for further details.

The Stormaster GI terminal is supplied with a threaded coupler (female thread) fixed to the

terminal and designed for connection to a 2 inch pipe (male thread).

∆ Following installation of the Stormaster GI terminal to the threaded pipe as per Figure 15

it will be necessary to connect the metallic pipe to a conventional downconductor in order

to convey the lightning energy to the earthing system

∆ Ideally the connection between the metallic pipe and the conventional downconductor

should be completed by lugging the downconductor at a practical point somewhere along

the length of the pipe

∆ Particular care should be taken to ensure that compatible metals are used when

connecting the downconductor to the metallic pipe

∆ For installation details of the conventional downconductor please review instructions

and comments as detailed per “Installation of Conventional Downconductors” on page 23

Page 28

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

26

Note: This Document is to be used in conjunction with the LTERMKIT-MK3 on HVSC

Plus cable only. Using the following guide, check the cable first prior to performing the

termination to ensure the use of the correct lower termination kit.

Termination of the HVSC Plus Lower End

Figure 15.

Page 29

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

27

HVSC Plus cable has an outer diameter of approximately 35 mm and has an aluminium

stranded centre conductor and copper tape screen (which can be easily seen from the

end of the cable).

This termination kit will not work with any other cable.

Black

Outer Sheath

Outer Copper

Screen Tape

Black Insulation

with Semiconductive Outer

Inner Aluminium

Conductors

Black Inner

Filler

Tools and parts required for the completion of HVSC Plus lower termination include:

∆ Compression or mechanical crimping tool (for 70 mm² crimp lug)

∆ Sharp knife

∆ Shifting spanner (or 17 mm A.F. spanner/socket)

∆ Rubber gloves

∆ Tape measure (metric)

Lower Termination Kit consists of:

∆ Instructions

∆ 1 x Roll of waterproofing mastic tape

∆ 1 x 70 mm² crimp lug

∆ 2 x Warning labels

∆ U-Bolt earth clamp

∆ 1 x Tube of conductive paste

The following steps outline the termination of the lower end of the HVSC Plus to the

lightning earth.

Figure 16.

The diagram below shows the different layers of the HVSC Plus cable and indicates

their names as referred to in the following instructions:

Page 30

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

28

5 cm

15 cm

Figure 17.

1. First, remove the black outer sheath for a length of 15 cm by cutting radially round the

HVSC Plus cable with a sharp knife. The lengthwise cut can also be completed with a knife,

but take great care not to score or damage the copper tape. Cut and remove the material

lining over the copper tape (Figure 17).

Figure 19.

2. Carefully unwind the copper tape to expose about 7 cm of the sheath underneath. Again,

be careful not to damage the copper tape during this process. Measure 5 cm from the

end of the cable and remove the black insulation section of the sheath over the aluminium

conductors (Figure 18). Note: There are many valid ways of removing this layer, but it is

very important that the aluminium conductor strands are not scored or damaged in any

way as this will decrease their strength and may lead to breakage when bending them for

insertion into the crimp lug.

Figure 18.

3. Cut and remove the black binding tape from over the aluminium strands. Remove at least

3 cm of the black lnner filler core under the inner aluminium conductors by carefully

bending back the conductor strands to expose the filler core then cut and remove the

core with a knife. Carefully bend the conductors back to allow them to be fed into the lug.

Page 31

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

29

4. Using a rubber glove, apply all conductive paste evenly over the 5 cm length of aluminium

strands prior to re-wrapping the copper tape.

5. Re-wrap the copper tape back into its original position neatly over the aluminium

conductors. Wrap the tape as tight as possible over the aluminium strands and place

both the tape and strands into the supplied 70 mm² crimp lug and crimp securely using

a suitable compression or mechanical crimping tool (Figure 19). Note, this will require

crimping at 70 mm² to obtain a secure compression.

6. If terminating the lower end of the HVSC Plus to a bus bar, connect to the bus bar as per

Figure 20.

7. Connect the crimp lug to the earthing system using the supplied U-Bolt earth clamp if

necessary (Figure 21). Ensure the connection is aligned correctly and tightly secured

using a 17 mm spanner, socket or shifting spanner.

8. Use the waterproofing mastic tape to completely cover all exposed conductive areas of the

lower termination and to seal the termination from moisture ingress where it connects to

the earthing system (Figure 21).

9. Place the warning labels on or next to the HVSC Plus cable where they can be easily seen

and read by anyone with access to that area.

Figure 20.

Page 32

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

30

Figure 21.

Termination of the HVSC Plus Upper End

Note: This Document is to be used in conjunction with the UTERMKIT-MK3 on HVSC

Plus cable only. Using the following guide, check the cable first prior to performing the

termination to ensure the use of the correct upper termination kit.

Lower Termination of Conventional Downconductor to the

Lightning Earth

∆ If installing stranded copper cable as a downconductor then the lower end should be

connected to the lightning earth through the use of an earth rod clamp and then wrapped

with waterproofing tape to avoid oxidisation

∆ If installing copper tape (25 x 3 mm) as a downconductor then the lower end should

be directly connected to the lightning earth through the use of a suitable earth rod clamp

and then wrapped with waterproofing tape to avoid oxidisation

Upper Termination Instructions for UTERMKIT-Mk3

(Heatshrink) for HVSC Plus

Page 33

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

31

Black

Outer Sheath

Outer Copper

Screen Tape

Black Insulation

with Semiconductive Outer

Inner Aluminium

Conductors

Black Inner

Filler

Figure 22.

HVSC Plus cable has an outer diameter of approximately 35 mm and has an aluminium

stranded centre conductor and copper tape screen (which can be easily seen from the

end of the cable).

This Termination Kit will not work with any other cable.

Tools and parts required for the completion of the HVSC Plus Upper Termination include:

∆ Compression or mechanical crimping tool (for 50 mm² crimp lug)

∆ Sharp knife

∆ Scissors

∆ #2 Phillips head screwdriver

∆ Shifting spanner (or 17 mm spanner/socket)

∆ Heat gun or gas torch (LPG)

∆ Tape measure (metric)

∆ Combination pliers/cutters

∆ Mast base assembly (supplied with the Stormaster Terminal)

Upper Termination Kit consists of:

∆ Instructions

∆ 1 x Roll of semi-conductive tape

∆ 1 x 50 mm² crimp lug

∆ 2 Heatshrink tubes (1 x 1200 mm & 1 x 600 mm length)

Upper Termination Instructions for UTERMKIT-Mk3 (Heatshrink)

The diagram below (Figure 22) shows the different layers of the HVSC Plus cable and

indicates their names as referred to in the following instructions:

Page 34

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

32

1. First, remove the black outer sheath for a length of 160 cm by cutting radially round the

HVSC Plus cable with a sharp knife. The lengthwise cut is also performed with a knife, but

take great care not to score the black insulation under the copper tape as well as the 1

st

3 cm of copper tape against the outer sheath. Cut and remove the material lining over the

copper tape (Figure 23).

2. With a knife, cut and remove the fabric tape material over the copper tape up to the outer

sheath. Measure and mark with a pen the outer copper screen tape at 3 cm along from

the end of the outer sheath (Figure 23). With a knife or scissors, carefully cut and remove

the copper tape, again without damaging the black insulation below. If using a knife,

carefully score the tape without cutting through it and use this score line to tear the tape

along the line.

3. Using a sharp knife, remove the black insulation to expose the inner aluminium

conductors for a length of 5 cm from the top end of the HVSC Plus (Figure 24). Also

remove the black fabric material lining over the aluminium conductors. Be careful not

to damage the conductor strands during this process. Note: There are many valid ways

of removing this layer, but it is very important that the aluminium conductor strands are

not scored or damaged in any way as this will decrease their strength and may lead to

breakage when bending them for insertion into the crimp lug.

4. Remove at least 3 cm of the black inner filler core under the inner aluminium conductors

by carefully bending back the conductors to expose the filler core then cut and remove the

core with a knife. Carefully bend the conductors back to allow them to be fed into the lug.

3 cm

160 cm

Figure 23.

Figure 24.

5 cm

Page 35

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

33

5. Straighten the cable back to the black outer sheath as much as possible then crimp

the inner aluminium conductors into the supplied 50 mm² crimp lug using a suitable

compression or mechanical crimping tool (Figure 25).

Figure 25.

6. Connect the crimp lug to the Stormaster mast base assembly using the bolt and washers

as supplied with the assembly. Ensure the connection is aligned correctly and tightly

secured using a 17 mm spanner, socket or shifting spanner. Note orientation of lug

on lower finial connector (Figure 26).

Figure 26.

7. Using the semi-conductive tape provided, starting 2 cm in front of the end of the outer

copper screen tape (or 5 cm in front of the black outer sheath), stretch and wrap the tape

back over the tape and 3 cm over the black with 50 % overlap, securing the outer copper

screen tape in place. This should use approximately 50 cm of the tape (Figure 27).

Note: DO NOT cut the tape at this stage.

3 cm2 cm

Start winding

Semi-conducting

tape here

3 cm

Figure 27.

Page 36

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

34

8. Over wrap back towards the crimp end of the cable, again stretching the tape and

with 50 % overlap, leaving 5 cm covering the outer copper screen tape and black insulation

and 3 cm covering the black outer sheath. This should use approximately another 50 cm of

the tape. Wrap another 2 layers, again stretched with 50 % overlap back up to where the

black outer sheath ends, to build up the cable diameter and to smooth out transitions in

diameter Figure 28. Cut the tape and press down firmly to ensure it amalgamates with the

tape below it.

9. Again using the semi-conductive tape, start stretching and wrapping over the aluminium

conductor strands and connection to the lower finial connector to start building up in

multiple layers. Continue wrapping the tape over the area shown to cover the last 3 cm of

the black insulation, over the lower finial connector and up to the black plastic section of

the mast base assembly in multiple layers, completely covering the crimp and achieving as

smooth and level a surface as possible, removing all sharp edges (Figure 29).

3 cm5 cm

10. Remove the plastic mast butt adaptor section of the mast base assembly (if fitted) by

unscrewing the M6 Phillips head screw on the side. Straighten the cable as much as

possible then carefully slip the first 1.2 m length of heatshrink over the cable until the end

of the heatshrink tube covers and overlaps the semi-conductive tape (over the black

outer sheath) by at least 3 cm (Figure 30). Ensure that the semi-conducting tape is not

damaged or lifted during this process. Using a gas torch or heat gun, carefully shrink the

lower end of the heatshrink into the correct position and gradually work up towards the top

of the heatshrink ensuring there are no pockets of air trapped under the heatshrink.

Figure 28.

3 cm

Figure 29.

Page 37

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

35

3 cm

1st Heatshrink length

Note: Ensure that the heat gun or gas torch is not pointed in the same area for too long as this

will burn the heatshrink. Also be careful around the ends of the tube as too much heat will

damage the black outer sheath, semi-conductive tape and black insulation.

Figure 30.

11. Place the 2nd 600 mm heatshrink tube into place over the cable, again ensuring that the

semi-conductive tape is not damaged, overlapping the previous heatshrink tube by

approximately 6 cm. Shrink about 7 cm of the upper end of the heatshrink into place so

that it will sit flush with the base of the plastic mast butt adaptor when fitted back into

place. Note: That there is a mark on the lower finial connector indicating where the heat-

shrink needs to be fitted to. Shrink the rest of the heatshrink from the top down, ensuring

that it overlaps the previous piece of heatshrink by at least 6 cm Figure 31. Ensure the rest

of the heatshrink has a smooth overall finish. Note: Do not bend the cable while the heat

shrink is still hot.

Note: If required, feed the cable through the mast sections & guying ring prior to refitting the

mast butt adaptor. Replace the plastic mast butt adaptor section of the mast base assembly

back onto the lower finial connector and ensure that the M6 Phillips head screw is tight and

secure.

12. The lugged HVSC Plus is now ready to be connected to the base of the Stormaster

terminal. Screw the terminal onto the completed terminal base assembly and secure with

the supplied M6 locking grub screw.

Figure 31.

2nd Heatshrink length

1st Heatshrink length

6 cm

Page 38

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

36

Connection of Factory Pre-Terminated HVSC Plus (Upper End) to

Stormaster ESE Terminal

Tools required for the installation of the factory completed upper termination include:

∆ Sharp knife

∆ PH2 Phillips head screw driver

∆ 3 mm Hex/Allen Key

1. Firstly remove the protective packaging from the cable and upper terminated end section

taking care not to cut cable or associated upper termination parts in the process.

2. Using a Phillips Head screwdriver, remove the M6 Phillips Head screw holding the mast butt

adaptor (if fitted) to the lower connector and retain both screw and mast butt adaptor.

3. Feed the HVSC Plus cable through the FRP support mast.

4. Slide the black plastic mast butt adaptor back onto the lower finial connector, line up

holes and screw the Phillips Head screw into position tightly. Now screw the mast butt

adaptor into the Stormaster ESE terminal and tighten the M6 Grub screw at the base of the

terminal to lock the assembly.

Labelling

Warning labels are supplied with all Stormaster ESE terminals and should be installed as per

the following.

∆ In locations where personnel may be in close proximity to the HVSC Plus downconductor

∆ Where the HVSC Plus downconductor connects to the earthing system

∆ At the base of the support mast

There are 2 warning labels supplied in the front cover of this manual and also 2 supplied in the

lower termination kit. If more labels are required, contact your nearest LPI supplier or distributor.

Masts

The mast chosen for the application must:

∆ Raise the terminal to a height of at least 2 metres higher than the structure

Figure 32.

Page 39

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

37

∆ Have an FRP mast section of at least 2 metres below the air terminal if

using LPI HVSC Plus

∆ Be suitable for local weather conditions. Seek guidance from a local civil

engineer

∆ Be guyed and securely attached to the dedicated mounting points (if

required)

Types of Mast Configurations

When mounting a Stormaster ESE terminal, there are generally three

types of mast configurations that can be used.

Cantilevered

Typically used for mounting to a tower or the side wall of a

plant room when a mast and base are not suitable. See

drawings on pages 9, 10 and 12 Figure 33.

∆ 1/3 of the overall mast height must be fixed to the structure

for adequate mechanical strength

∆ Cantilevered masts can be guyed for additional strength. If

guying, the use of a guy ring and/or the eyelets provided on

the inline coupling can be utilized

Guyed

When mounting a Stormaster ESE terminal, a typical guyed configuration

would involve the following. See drawing on pages 8 and 11 Figure 34.

∆ Two sections of mast (aluminium mast & FRP mast coupled together

with an inline coupling. Securing of guy wires is completed at the

eyelets as provided on the inline coupling

∆ Alternatively or in addition, a guy ring can be supplied which is installed

at the neck of the mast in between the Stormaster terminal and the

top section of the FRP. The guy ring provides eyelets for connection of

the guy wires

Freestanding

A freestanding mast configuration is typically used in situations where

protection by isolation is required. For example a Stormaster ESE

terminal is installed 5 metres or more away from a fuel storage tank.

Prior to installing the freestanding mast, ensure that:

∆ A spigot has been supplied with the freestanding mast which

allows for external or internal mounting of the FRP mast

Figure 33.

Cantilevered Mast

Figure 34. Guyed Mast

Page 40

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

38

Stormaster ESE Terminal

2.0 m (6.7 ft) FRP

3.0 m (10 ft)

Aluminium

Mast

U Bolts

Figure 36.

Figure 35.

Freestanding Mast

∆ The downconductor can exit through the base of the freestanding mast

if run internally

∆ Adequate information is provided for mast foundation requirements.

Contact LPI or an authorised dealer for further detail if required

Mast Bases

LPI supplies a mast base welded directly onto the required length of aluminium

mast.

Mast Couplings and Guying Points

There are two methods of coupling two sections of mast:

1. The U-Bolt set uses two stainless steel U-Bolts to clamp the two masts

together Figure 36

2. The inline coupling fixes the upper and lower mast sections together and

provides guying points and an exit point for the HVSC Plus downconductor

U-Bolts and inline couplings nuts must be tightened to no more than

55 kg/cm (45 in/lb).

A guying ring is supplied for guy points for any two piece masts that require double

guying. This fits on the terminals mast butt adaptor between the Stormaster ESE

terminal and the top of the mast. See Figure 37.

Page 41

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

39

Stormaster

ESE terminal

Guy ring fitted

between Stormaster

ESE terminal

and FRP mast

Insulated

guying

FRP

mast

Figure 37.

Guying

LPI offers a standard 4 m and 7 m guy kit made up of light weight synthetic, non-conductive

cable. The LPI GUYKIT-4M and GUYKIT-7M are both non-conductive guying kits. They are

designed to be installed with the use of a guy ring at the top section of the FRP mast as

illustrated in figure 37. When guying from the LPI inline coupling, the use of stainless steel guy

wire kits (GUYKIT-4M-SS, GUYKIT-7M-SS) is recommended.

Important Recommendations:

∆ The guying angle must be no greater than 60° from horizontal

∆ The inline coupling couples the upper and lower mast

sections and provides guying points and an exit

point for the HVSC Plus downconductor

∆ Minimum of 3 guying grips per guy end

∆ Guying grips spaced at a minimum of 25 mm

∆ Grips are correctly orientated. Saddle on the

longer length side of the guy and U-bolt over

the tail side of the guy

∆ Tighten grips to no more than 60 cN.m

(5 Ibf.in) of torque

∆ Protect guying from

abrasion

∆ Customised guy kits

can be supplied

upon request

Page 42

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

40

Preparation for Raising the Mast into Position

With the upper termination of the HVSC Plus completed and the FRP mast in position it is now

time to finalise the mounting arrangement so that the mast can be raised and secured into

position.

∆ If using the recommended installation methods as per drawings (on pages 8-11) fit the

inline coupling to the lower mast material

∆ If required, fit the HVSC Plus downconductor through the side entry of the inline coupling

and through the FRP mast. Refer to Figure 39 on page 42

∆ Feed the upper termination through the guying ring if required

∆ Carefully fit the mast adaptor of the Stormaster terminal into the top of the FRP

∆ It may be necessary to pull back any slack of HVSC Plus downconductor through the FRP

support mast to achieve a tight fit for the Stormaster terminal. This should be completed

carefully so as to not damage the upper termination

∆ Fix the FRP support mast firmly into the inline coupling and tighten the coupling so that

the FRP mast and lower mast material are secured firmly into position with no more than

55 kg/cm (45 in/lb)

∆ If a guy kit is to be installed, the guys should be securely fixed to the eyelets as provided on

the inline coupling and or the guy ring. See text and graphics as detailed under the heading

Guying for more information

Raising of the Mast

When raising the mast, ensure:

∆ Guys to inline coupling and/or guy ring are properly secured

∆ Guys are not twisted, kinked or damaged

∆ Guys are able to be easily secured at the lower guy anchoring points when the mast has

been raised

Turnbuckles or rigging screws are recommended at the base anchor points of the guys.

Other guying methods such as conductive stainless steel can be used only on aluminium masts

or inline couplings below an FRP section.

Using a crane is recommended (or other suitable equipment) for anything over 6 metres in

height, or for hazardous areas or high areas.

∆ It is very important to keep the mast straight during the lift to avoid damaging the mast

Page 43

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

41

Do not lift with more

than 5 m (17 ft) of

downconductor

hanging from mast

without tying off

to mast

Max 5 m

(17 ft)

Do not sling at base

Sling in at

least two places

Stress removed from upper

termination by securing

downconductor to lower mast

with flat webbing or other

appropriate sling

∆ The Stormaster ESE terminal must NOT be used as a slinging point

∆ When lifting the mast, ensure that the slings or ropes cannot damage the Stormaster ESE

terminal. See Figure 38

Figure 38.

∆ When lifting the mast, the HVSC Plus downconductor must be tied off to the mast to

remove any strain on the HVSC Plus downconductor termination to the Stormaster ESE

terminal

∆ Protect the HVSC Plus downconductor at the base of the mast when lifting, maintain

a minimum bending radius of 430 mm and ensure it does not drag over rough or sharp

surfaces

Page 44

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

42

Lightning Strike Recorder (LSR1)

The Lightning Strike Recorder (LSR1) should be installed at a position along the downconductor

length where it can be accessed easily for inspection. Typically the LSR1 should be installed

approximately 1.5 m from ground level or alternatively within the earth pit at the lower

termination point of the HVSC Plus.

When installing the LSR1 the following should be considered:

∆ The LSR1 should be mounted away from areas where damage may occur due to theft,

vandalism or nearby operations

∆ The LSR1 can be enclosed in a security enclosure but the display should be kept visible to

allow for the checking of recorded strikes

Inline coupling

Make sure the base will not slip during the lift

Secure

guying

Removable gin pole

and associated

rigging

Protect the

HVSC Plus

from abrasion

during the lift

Figure 39.

Page 45

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

43

Downconductor

lower termination

bound in

waterproofing tape

Lightning Strike

Recorder (LSR1)

Lightning Strike

Recorder

(LSR1)

Earth Rod

Counter

Downconductor

(HVSC Plus)

Saddle

Earth Pit

(EPIT-P)

Figure 40.

Lightning Strike Recorder

installed on HVSC Plus

Downconductor

Figure 41.

Lightning Strike Recorder

installed on Rod.

Page 46

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

44

Certification

The certification of the LPI Stormaster ESE installation should be performed by an authorised

LPI representative.

A certificate of compliance and warranty registration is provided with the installation manual.

This certificate should be completed in full following the successful inspection and certification

of the installation.

The following should be checked for quality of workmanship and compliance to recommended

installation instructions.

Certification checklist:

∆ Correct mast and any associated brackets and fastenings have been used for installation

∆ Guying, anchor points and fastenings

∆ HVSC Plus downconductor routing, fixing and weatherproofing

∆ Lower termination of HVSC Plus downconductor

∆ Earthing system

∆ Labelling

Operation and Maintenance

The LPI Stormaster ESE lightning protection system is designed to react to the rise in electric

field which is present in approaching thunder storms. The Stormaster ESE terminal becomes

active only during storm activity.

∆ The system operates without the need for external power supply or spare parts for

standard operation

∆ To keep the LPI Stormaster ESE lightning protection system operating at optimum

levels it needs to be regularly checked

Maintenance checks must be done:

∆ After each known lightning strike to the terminal

∆ Once every twelve months

∆ If changes have been made to the structure

Checks to be conducted in standard maintenance inspection:

∆ Is there any damage to Stormaster ESE system?

∆ Has the structure to be protected been modified since the last maintenance check?

Page 47

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

45

∆ Check finial tip for excessive pitting

∆ Check all rigging, mast mounts, saddles and conductor fixings are secure and tight

∆ Ensure that no dirt or other matter is sitting in the air gap between the finial tip and the

surrounding panel edges

∆ If conventional downconductors are used, check that all conductors are securely fixed

and not damaged

∆ Check for damage to the LPI HVSC Plus. The downconductor should not be able to be

accessed by non authorised people or machinery

∆ All warning labels must still be in place

∆ Check LSR1 for secure installation and record number of strikes

Testing the Stormaster Terminal

LPI manufactures and supplies a terminal spark-over tester suitable for testing the Stormaster

ESE range of terminals. Contact your local distributor for further details.

Testing the HVSC Plus Downconductor

The HVSC Plus downconductor can be tested at various stages of its preparation for service.

These stages and the tests that can be performed are summarised below.

1. Before upper or lower terminations are made (raw cable):

∆ Use a digital multimeter or, preferably, a Megger to measure the continuity between the

inner and outer conductors of the HVSC Plus downconductor. The measurement should be

“open circuit” (exceeding 1 M

W

)

2. After the upper termination is made but before the lower termination is made:

∆ Use a digital multimeter or, preferably, a Megger to measure the continuity between the

inner conductor at the top (upper termination) and the shield (outer copper tape conductor)

at the bottom of the cable. The measurement should give a resistance greater than about 3

k

W

and no more than about 15 k

W

3. After the upper termination and lower termination are first made:

∆ Use a digital multimeter or, preferably, a Megger to measure the continuity between the

inner conductor at the top (upper termination) and the shield (outer copper tape conductor)

at the bottom of the cable. The measurement should be a “short circuit” (less than 1

W

,

excluding the resistance of the leads, the exact value depending on the length of HVSC Plus)

Page 48

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

46

4. After installation of the HVSC Plus downconductor:

∆ Remove the waterproofing tape from the lower termination

∆ Disconnect the HVSC Plus downconductor from the lightning earth

∆ Use a digital multimeter or, preferably, a Megger to measure the continuity between the

inner conductor at the top (upper termination) and the shield (outer copper tape conductor)

at the bottom of the cable. The measurement should be a “short circuit” (less than 1

W

,

excluding the resistance of the leads, the exact value depending on the length of HVSC Plus)

∆ Reconnect the HVSC Plus lower termination to the lightning earth and re-seal the termination

using waterproofing tape to ensure that it is waterproof

5. Report any problems arising from the above tests to your local LPI distributor for further advice

Testing the Lightning Earth

The procedure for obtaining the resistance of the lightning earth is described below. The method

that is used is called the “fall-of-potential” (FOP) or “three-point” method. It relies on the use

of a suitable 3-point or 4-point earth tester. As testing is carried out, please record all values

per the table on page 48.

1. Disconnect the bonding cable from the structure to the lightning earth, as shown in Figure 42.

2. A “standard” LPI lightning earth will comprise radials of length 10 m. Assuming a 10 x 10 m

earthing system, the current injection point for the FOP test should be at least 50 m, but

preferably 100 m away from the lightning earth, with no intervening buried conductors.

For a larger earthing system, this distance should be increased. Install a remote current

injection electrode (RCIE) at a suitable location at about the above distance. This

electrode may be a simple driven rod of sufficient depth to get a low resistance. (Note:

if the resistance of this rod is too high, the instrument may be incapable of injecting a

current to make the test).

3. Now install a rod at about 62 % of the distance between the RCIE and the lightning earth. The

depth of this “potential rod” is not important (it can be less than 100 mm). Make a 3-point

resistance measurement and note the value.

4. Shift the potential rod 1 m closer to the lightning earth, measure and note the value.

5. Shift the potential rod 1 m further away from the original test point, measure and note

the value.

6. If the RCIE is sufficiently far away and there are no buried conductors affecting the results,

the three values recorded should all be within 5 % of each other. If this is the case, then

the resistance value measured is a true indication of the resistance of the lightning earth.

Page 49

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

47

Record the value in the table on page 48 (lightning earth resistance).

7. The same procedure can be used to measure the resistance of the structure earth, bearing

in mind that the RCIE distance needs to be 5-10 times the size of the earth grid. Record the

resistance in the table on page 48 (structure earth resistance).

8. Reconnect the structure earth bonding cable to the lightning earth and measure and record

resistance in the table on page 48 (overall earth resistance).

9. Record the lightning strike recorder (LSR) reading in the table on page 48.

10. Report any problems arising from the above tests to your local LPI distributor for further advice.

LP Earthing System

Ground Resistance

Meter

Structure Earth Cable

(Disconnected from LP Earth)

HVSC Plus Downconductor

(Disconnected from LP Earth)

Figure 42.

Page 50

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

48

Record of Earth Resistance Readings Table

Date

Inspected byLightning earth

resistance (

W

)

Structure earth

resistance (W)

Overall earth

resistance (W)

LSR

reading

Note

(see below)

Notes:

Page 51

Page 52

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

ABN 11 099 190 897

∆

PO Box 379 Kingston, Tasmania, Australia 7051

∆

49 Patriarch Drive, Huntingfield, Tasmania, Australia 7055

∆

Phone: Australia: 03 6281 2477

International: +61 3 6281 2480

∆

Email: info@lpi.com.au

∆

Web: www.lpi.com.au

© Copyright 2018 Lightning Protection International Pty Ltd

LPI proudly services customers from the following countries:

¬ Afghanistan

¬ Australia

¬ Bahrain

¬ Bangladesh

¬ Bhutan

¬ Brunei

¬ Burundi

¬ Cambodia

¬ Chile

¬ China (PRC)

¬ Colombia

¬ Dominican

Republic

¬ Ecuador

¬ El Salvador

¬ Fiji

¬ Gabon

¬ Guatemala

¬ Haiti

¬ Hong Kong

¬ India

¬ Indonesia

¬ Iran

¬ Iraq

¬ Japan

¬ Jordan

¬ Kenya

¬ Kuwait

¬ Laos

¬ Macau

¬ Madagascar

¬ Malaysia

¬ Maldives

¬ Mauritius

¬ Mexico

¬ Myanmar

¬ Nepal

¬ New Zealand

¬ Nicaragua

¬ Nigeria

¬ Oman

¬ Papua New Guinea

¬ Peru

¬ Philippines

¬ Qatar

¬ Rwanda

¬ Samoa

¬ Saudi Arabia

¬ Seychelles

¬ Singapore

¬ South Africa

¬ South Korea

¬ Spain

¬ Sri Lanka

¬ Sudan

CustomersHead Office

¬ Taiwan

¬ Thailand

¬ Tonga

¬ UAE

¬ United

Kingdom

¬ USA

¬ Vanuatu

¬ Venezuela

¬ Vietnam

¬ Yemen

IM-STORM-V5

LPI0216 04/18

Loading...

Loading...