Lightning Protection International GUARDIAN PLUS Installation Manual

GUARDIAN PLUS Installation Manual

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

Comprehensive Lightning, Surge Protection & Earthing Solutions www.lpi.com.au

Placement

method in

compliance with

IEEE STD. 998

(Substations)

Lightning Protection International Pty Ltd

ABN 11 099 190 897

PO Box 379 Kingston, Tasmania, Australia 7051

Phone: +61 3 62271955

Fax: +61 3 62291900

Email: info@lpi.com.au

Web: www.lpi.com.au

GUARDIAN PLUS

System Owner:

Date Installed:

Installation Contractor:

Supplied by:

Location of Installation

:

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

1

Guardian Plus Installation Manual

Lightning Protection International Pty Ltd

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

2

Contents

Placement Methodology (Software) 3

Substation Placement Methodology 4

Air Terminal (Hardware) 5

Warranty and Disclaimer 6

Safety Guidelines for Installatiion 7

Checking Lightning Protection

Components Supplied 8

LPI Guardian Plus Installation 8

Recommended Installation Method 9

Installation of the Lightning Earth 13

Earth Enhancing Compounds 14

Bonding the Lightning Earth 15

Labelling 15

Installation of the HVSC Plus

Downconductor 15

Hauling the HVSC Plus

Downconductor 15

HVSC Plus Downconductor

Clearance Holes 16

Routing 17

Fixing the HVSC Plus Downconductor 19

Installation of Conventional

Downconductor 19

Equipotential Bonding 21

Installation of Guardian Plus GI

Terminal to Threaded Pipe 21

Termination of the HVSC Plus Lower End

23

Lower Termination of Conventional

Downconductor to the Lightning Earth 26

Upper Termination Instructions

UTERMKIT-MK3 (Heatshrink) for HVSC Plus

27

Termination of the HVSC Plus Upper End

27

Upper Termination Instructions for

UTERMKIT-MK3 (Heatshrink) 28

Termination of the HVSC Plus Lower End 32

Connection of Factory Pre-Terminated

HVSC Plus (Upper End) to Guardian Plus

32

Labelling 33

Masts 33

Guying 35

Preparation for Raising the Mast

into Position 36

Raising of the Mast 37

Lightning Strike Recorder (LSR1) 39

Certification 41

Operation and Maintenance 41

Testing the Guardian Plus Terminal 42

Testing the HVSC Plus Downconductor 42

Testing the Lightning Earth 43

Installation Notes 45

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

3

Placement Methodology (Software)

The placement of the G+ air terminal range on structures and within facilities is achieved

via the Standards-compliant “leader inception theory” published in IEEE Std. 998 and other

international codes. In brief, the steps required to obtain capture areas and volumes according

to this method involve the computation of:

(a) Geometric factor R (induced voltage component due to the physical geometry of the

problem being solved);

(b) Leader inception proximity factor (which quantifies the “suppressing influence” of the

structure on which a protective air termination is installed);

(c) Space potential proximity factor (ratio of space potential at the air terminal tip position to

that which would have existed in the absence of the structure); and

(d) Critical ambient electric field required to initiate and sustain the continuous upward leader.

LPI’s in-house software (LITCALC) has been developed using a world-first three-stage approach

to identifying areas around the structure or facility where the strike probability exceeds a

minimum level and treating those areas appropriately. The computational stages implemented

are:

(a) Identification of likely strike points on a structure using the rolling sphere method per IEC

62305-3 for a range of stroke currents per lightning statistics as published in IEC 62305-1;

(b) Computation of the capture areas and volumes of those likely strike points on a structure

in accordance with the leader inception theory published in IEEE Std. 998; and

(c) Placement of air terminals on the structure at those locations and computations of the

capture areas and volumes of the air terminals in accordance with the leader inception

theory published in IEEE Std. 998.

(Refer to diagrams on Page 4.)

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

4

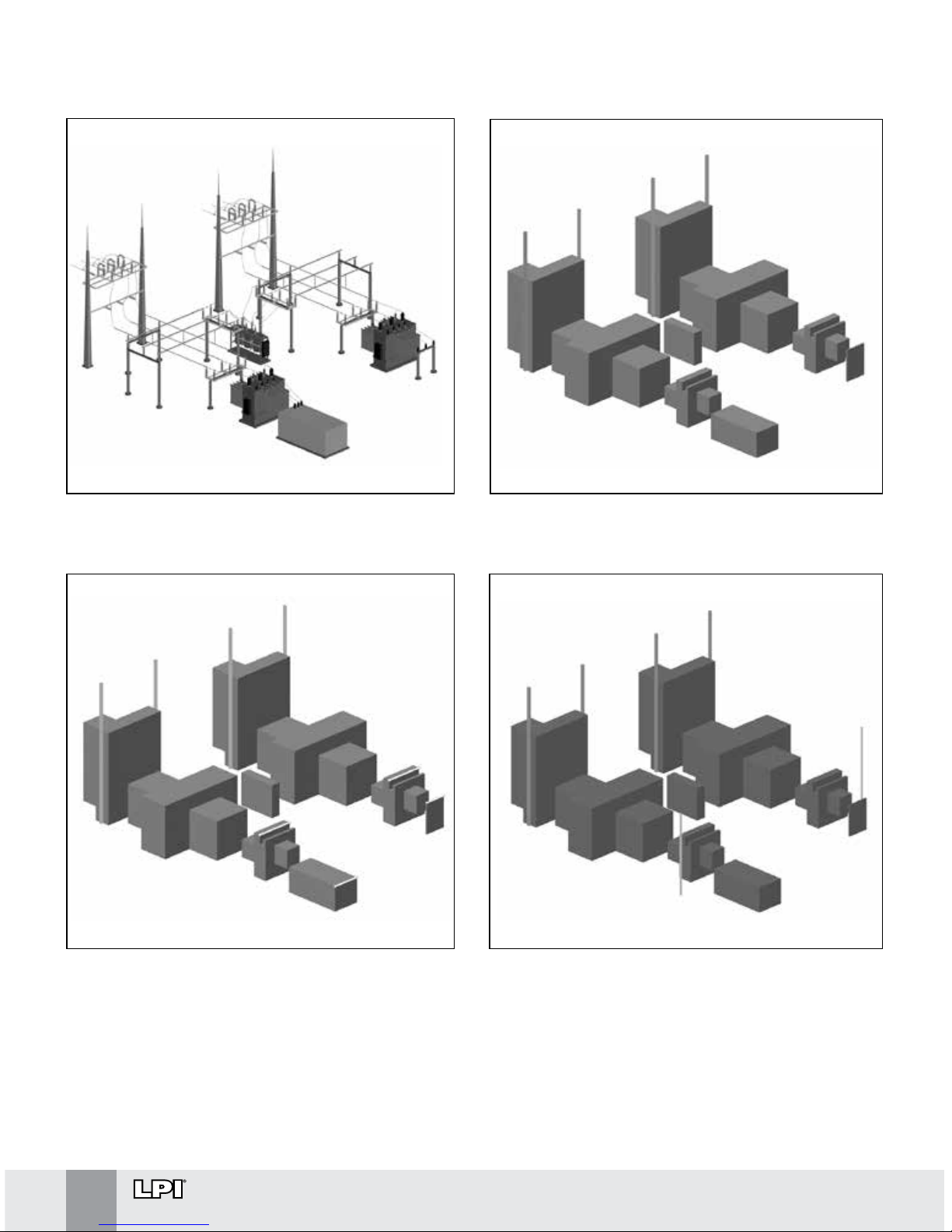

Substation Placement Methodology

Case Study: 69 kV substation in IEEE Std. 998.

Step 1: Simplify the equipment and buses.

Step 2: Perform strike probability analysis

(SPA) utilising a dynamic EGM and published

lightning stroke statistics.

Step 3: Position air terminals in optimum

locations based on the SPA and attractive

radius calculations in accordance with LIT.

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

5

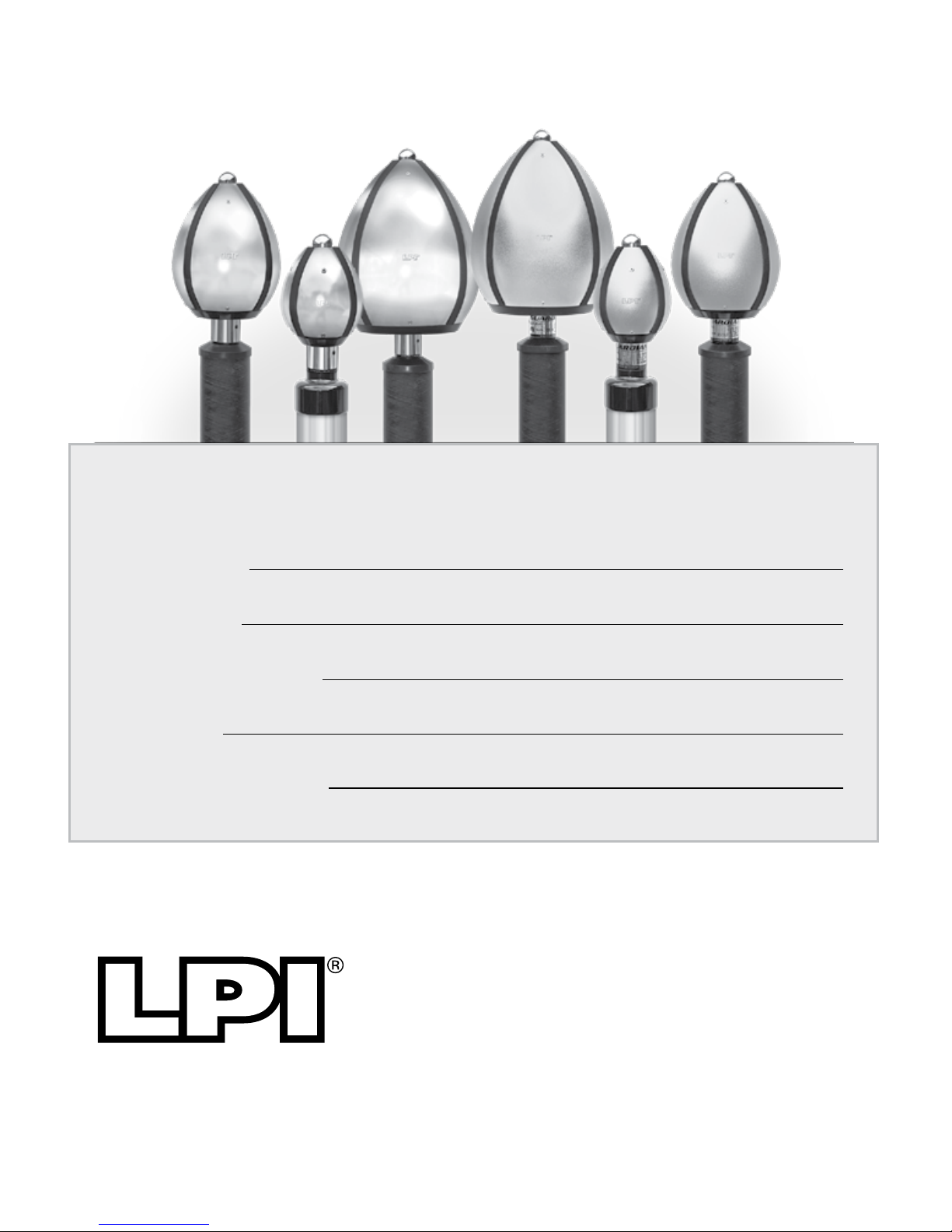

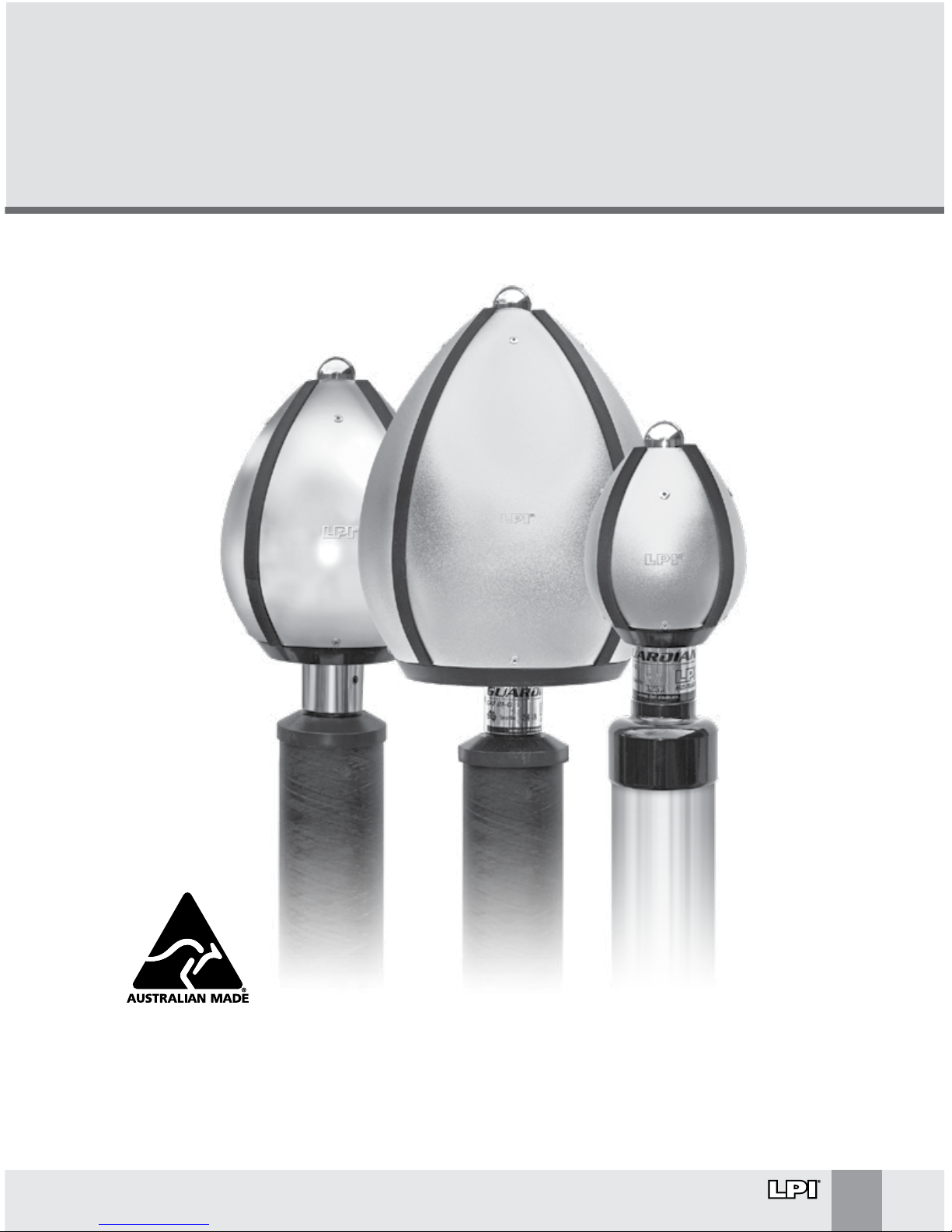

Air Terminal (Hardware)

The new Guardian Plus™ (G+) air terminal range has been developed after taking into account

the latest international research into the effect of space charge and air terminal geometry,

characteristics of long sparks, lightning characteristics and statistics, and the lightning

attachment process itself.

The design of the G+ air terminals was based on detailed modelling and calculations geared

towards achieving optimum corona performance in the quasi-static phase of a thunderstorm.

Some of the key technical factors considered in the optimised design included the:

∆ Dome size (there are three sizes to cater for all practical installation scenarios);

∆ Tip radius of curvature and tip protrusion (optimised to minimise corona discharge);

∆ Materials (robust, long-lasting yet cost-effective options).

Furthermore, under the dynamic phase of lightning, i.e., during the descent of the downward

leader, the response of the air terminal to the rapidly-escalating electric field is achieved via

capacitive coupling to four independent panels on the air terminal, leading to a triggering spark

that changes the spatial electric field as part of the leader initiation process.

Final optimisation of the G+ corona performance and upward leader initiation under dynamic

electric fields was achieved via extensive testing at a state-of-the-art high-voltage test

laboratory, namely the National Engineering Laboratory for Ultra High Voltage Technology

(NELUHVT) located near Kunming in China. The NELUHVT is an outdoor facility and hence the

air terminals were not only tested under different electrical conditions but also a range of

environmental effects.

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

6

WARRANTY

LPI’s Guardian Plus terminals (including all accessories) are guaranteed against

defects in materials or workmanship for a period of 5 years from the original sales

date when it was purchased from LPI or one of its authorised distributors.

The warranty is limited to the ex-factory cost of replacement of equipment providing

it has been installed and/or certified by LPI or its distributor. All other costs such as

freight, re-installation, loss of profit, or insurance premiums are not included.

Responsibility for other direct or indirect damages or death is also specifically

excluded from the warranty.

DISCLAIMER

The LPI Guardian Plus design software LITCalc provides the end-user with a

customised lightning protection design in compliance with the Leader Inception

Theory included in IEEE Std. 998 and other standards.

LPI has a policy of continuing research and product improvement and hence

retains the right without notice to alter future design methods or specifications

in accordance with revisions of applicable standards or other validated research

programs.

The range of Guardian Plus air terminals or, to our knowledge, any other lightning

protection system cannot provide 100% protection and it is not inferred.

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

7

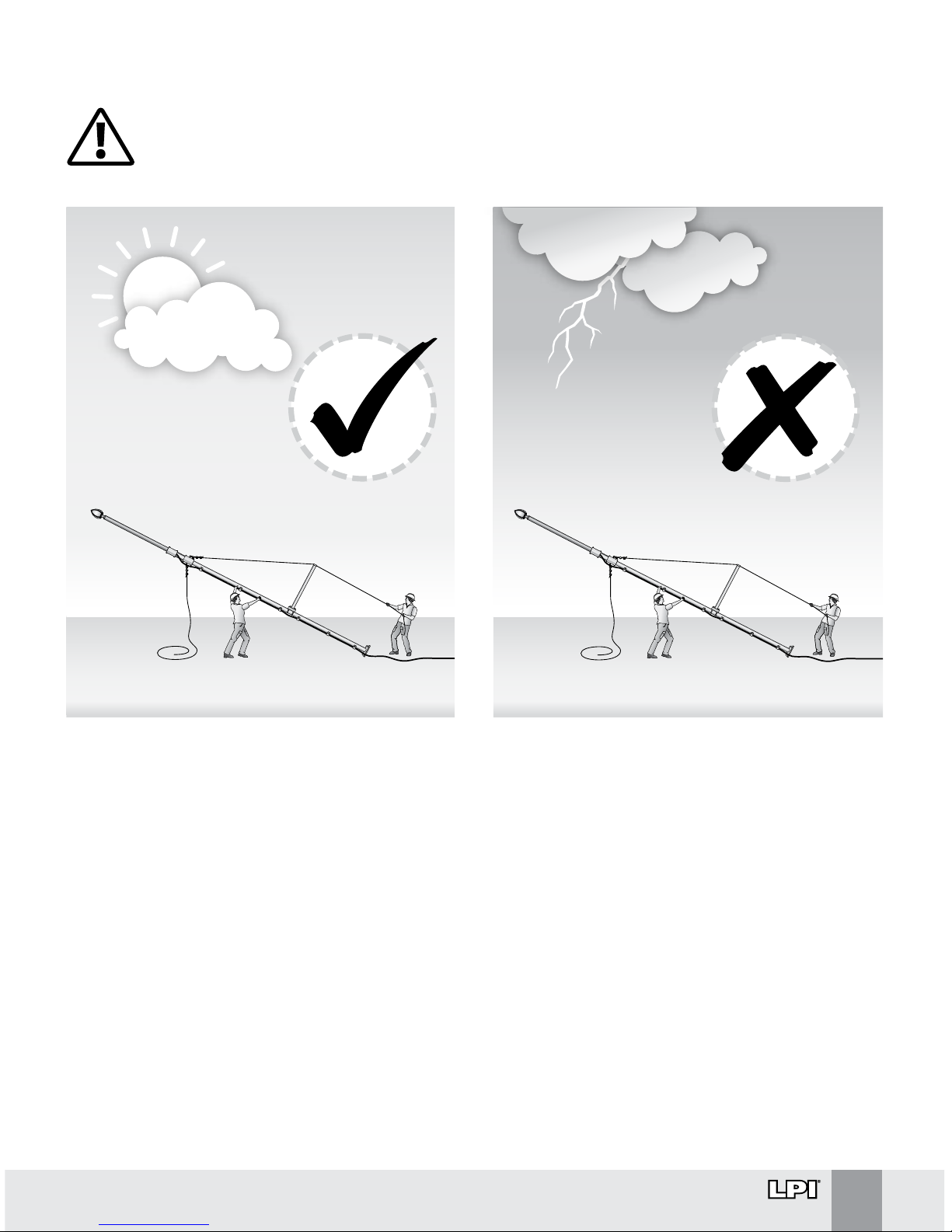

Figure 1.

Safety Guidelines for Installation

The LPI Guardian Plus terminals should only be installed when there is no threat of a

thunderstorm and lightning.

Other Recommendations:

∆ Ensure safe working environments and practices to local codes

∆ Use personal protective equipment during installation

∆ Use mechanical methods of raising and installing masts over 6 m

∆ Cordon off the area below the installation point

∆ Check for overhead powerlines, live conductors and any other obstructions before lifting or

raising

∆ Ensure enough personnel are used to safely conduct all aspects of the installation

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

8

Checking Lightning Protection Components Supplied

The LPI Guardian Plus components received should be checked against the “bill of materials” for

loss during shipping and for damage.

Check the following:

∆ Air terminals have not been dented or damaged in any way during transit

∆ Instructions, warning labels, warranty, test certificate and relevant mast base

components are supplied

∆ HVSC Plus cable drum (if supplied) is not damaged

∆ Correct HVSC Plus length(s) have been supplied

∆ There is no obvious damage to the HVSC Plus cable

∆ If a factory completed upper termination is supplied, check to see that it is not damaged

and confirm inside or outside termination(s)

∆ Order of lengths and quantities of HVSC Plus (if multiple lengths on one drum), will be

shown on the side of the cable drum(s)

LPI Guardian Plus Installation

All site and safety requirements must be followed during the installation of the LPI Guardian

Plus System. The correct order of installation is as follows:

1. Installation of the lightning earth.

2. Installation of the HVSC Plus downconductor.

3. Preparation of the lower termination of the HVSC Plus downconductor and connection

to the lightning earth.

4. Preparation of the upper termination of the HVSC Plus downconductor and connection

to the Guardian Plus terminal.

5. Preparation and raising of the mast into position.

Notes:

∆ The installation must comply with all of the relevant local standards and regulations

∆ If the Guardian Plus terminal needs to be raised prior to connection to the lightning

earth or immediate connection is not possible, then connect the lower end of the

downconductor to structural steel reinforcing or another suitable earth point

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

9

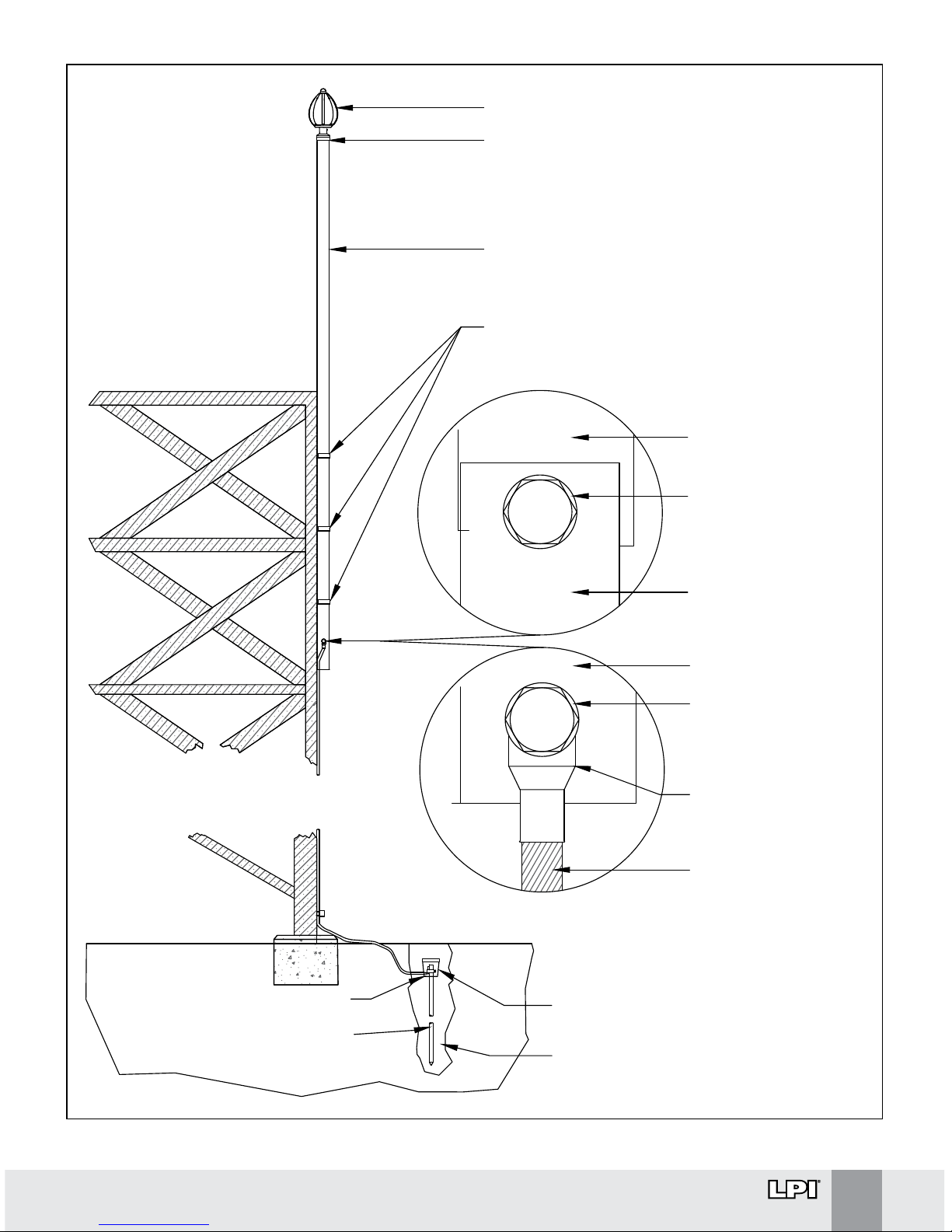

BASE OF MAST

PIPE

MOUNTING BOLT &

STAINLESS STEEL

WASHER

COPPER TAPE

BASE OF MAST PIPE

MOUNTING BOLT &

STAINLESS STEEL

WASHER

COMPRESSION

LUG

COPPER CABLE

LPI SADDLES FOR CANTILEVER MAST

LPI GUARDIAN PLUS GI TERMINAL

THREADED GI ADAPTOR (FEMALE THREAD

2 INCH BSP)

MAST ASSEMBLY WITH GI ADAPTOR

LPI LOWER TERMINATION KIT

LPI EARTHING SYSTEM

LPI EARTH ENHANCING MATERIAL

LPI INSPECTION PIT

®

®

®

®

®

®

IMPORTANT:

One Third of the mast

height must be securely

fixed to the structure.

Guardian Plus Terminal

to be a minimum of 2

metres above the

highest point of the

building or rooftop

objects.

Recommended

clearance height = 5

metres.

Figure 2.

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

10

Figure 3.

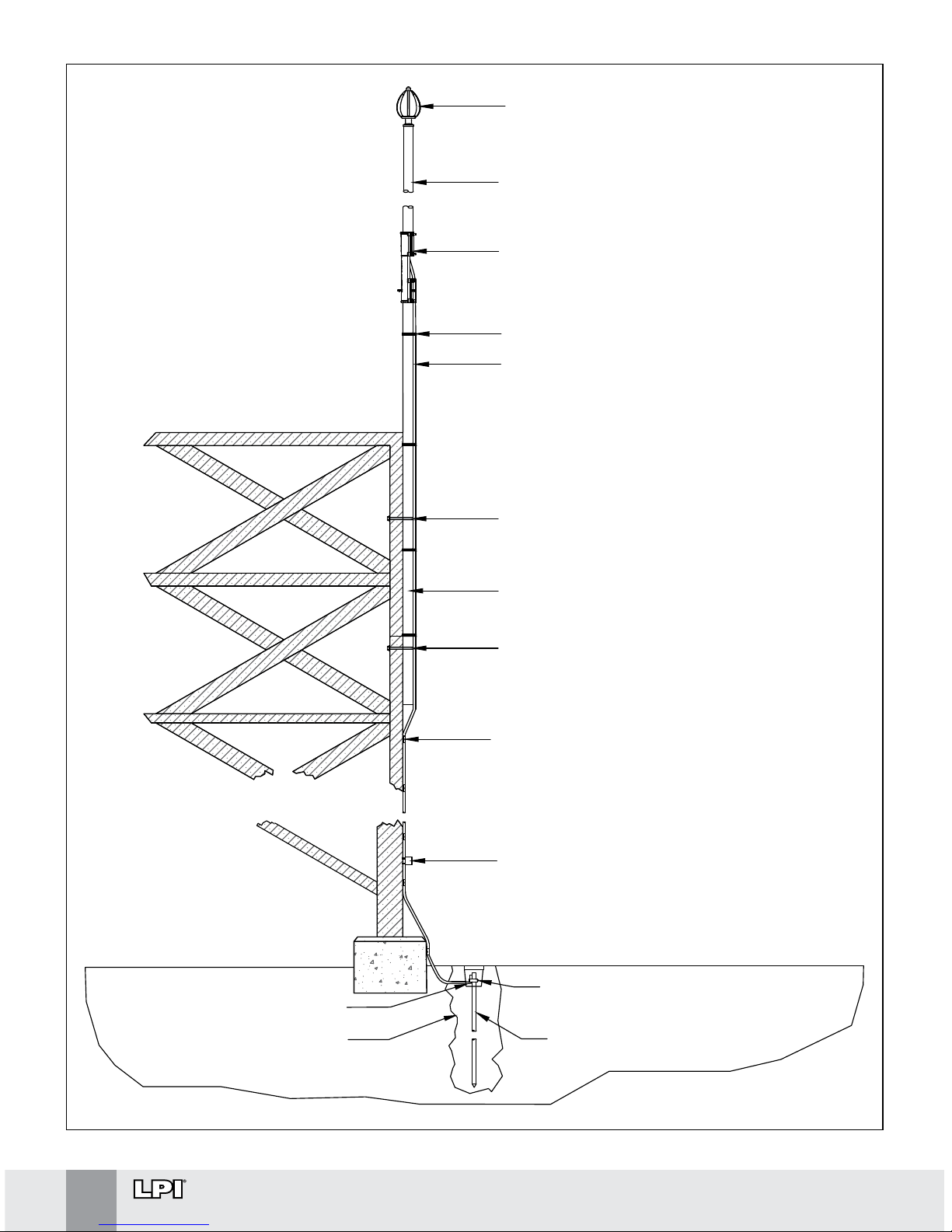

LPI GUARDIAN PLUS TERMINAL

LPI FRP SUPPORT MAST

LPI INLINE COUPLING

LPI CABLE TIES

LPI HVSC PLUS DOWNCONDUCTOR

LPI U-BOLT

LPI BEAM CLAMP AND CABLE

SUPPORT

LPI LIGHTNING STRIKE RECORDER

LPI LOWER TERMINATION KIT

LPI EARTHING SYSTEM

LPI EARTH ENHANCING

MATERIAL

LPI INSPECTION PIT

LPI LOWER MAST ASSEMBLY

LPI U-BOLT

IMPORTANT:

One Third of the mast

height must be securely

fixed to the structure.

Guardian Plus Terminal

to be a minimum of 2

metres above the

highest point of the

building or attached

objects.

Recommended

clearance height = 5

metres.

®

®

®

®

®

®

®

®

®

®

®

®

®

®

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

11

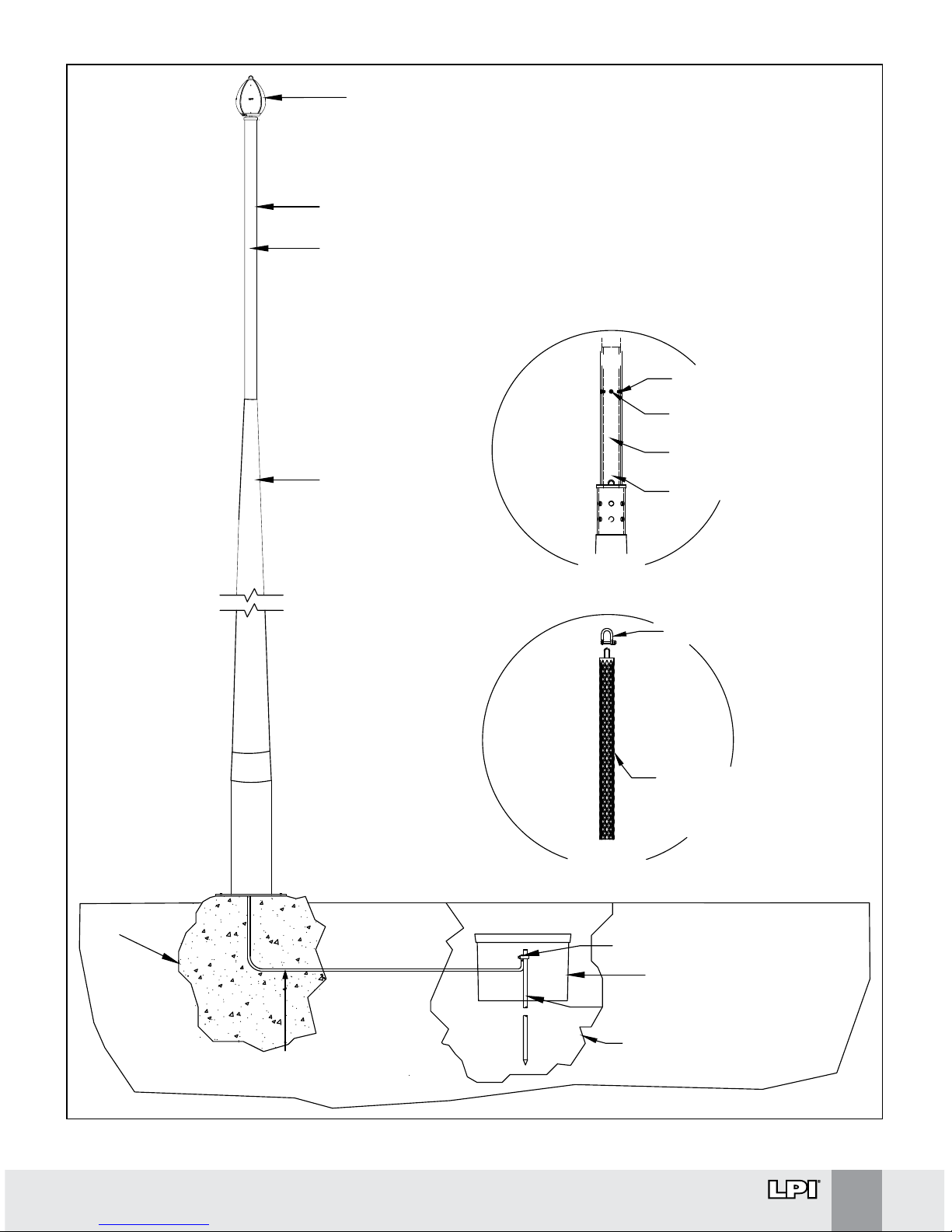

FOOTING

LPI LOWER TERMINATION KIT

LPI EARTHING SYSTEM

®

®

LPI EARTH ENHANCING

MATERIAL

®

LPI INSPECTION PIT

®

TERMINATION OF DOWNCONDUCTOR

TO EARTH

LPI GUARDIAN PLUS TERMINAL

LPI FRP SUPPORT MAST

LPI HVSC PLUS DOWNCONDUCTOR

OR LPI COPPER TAPE

(DOWNCONDUCTOR TO BE

RUN INTERNALLY)

®

®

®

®

FREESTANDING

MAST

CABLE SOCK LOCATED INSIDE

FREESTANDING MAST,

ATTACHED TO WELDED

LUG AT TOP VIA SHACKLE

SHACKLE

INTERNAL SPIGOT 59mm

OD FOR SLIDING FIT

M6 x 10 PAN HEAD SCREWS

3 PLACES AT 120°

CABLE SOCK

DETAIL

SPIGOT

DETAIL

3 HOLES DRILLED ON SITE,

Ø 6.5 SPACED AT 120°

WELDED LUG

Figure 4.

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

www.lpi.com.au

12

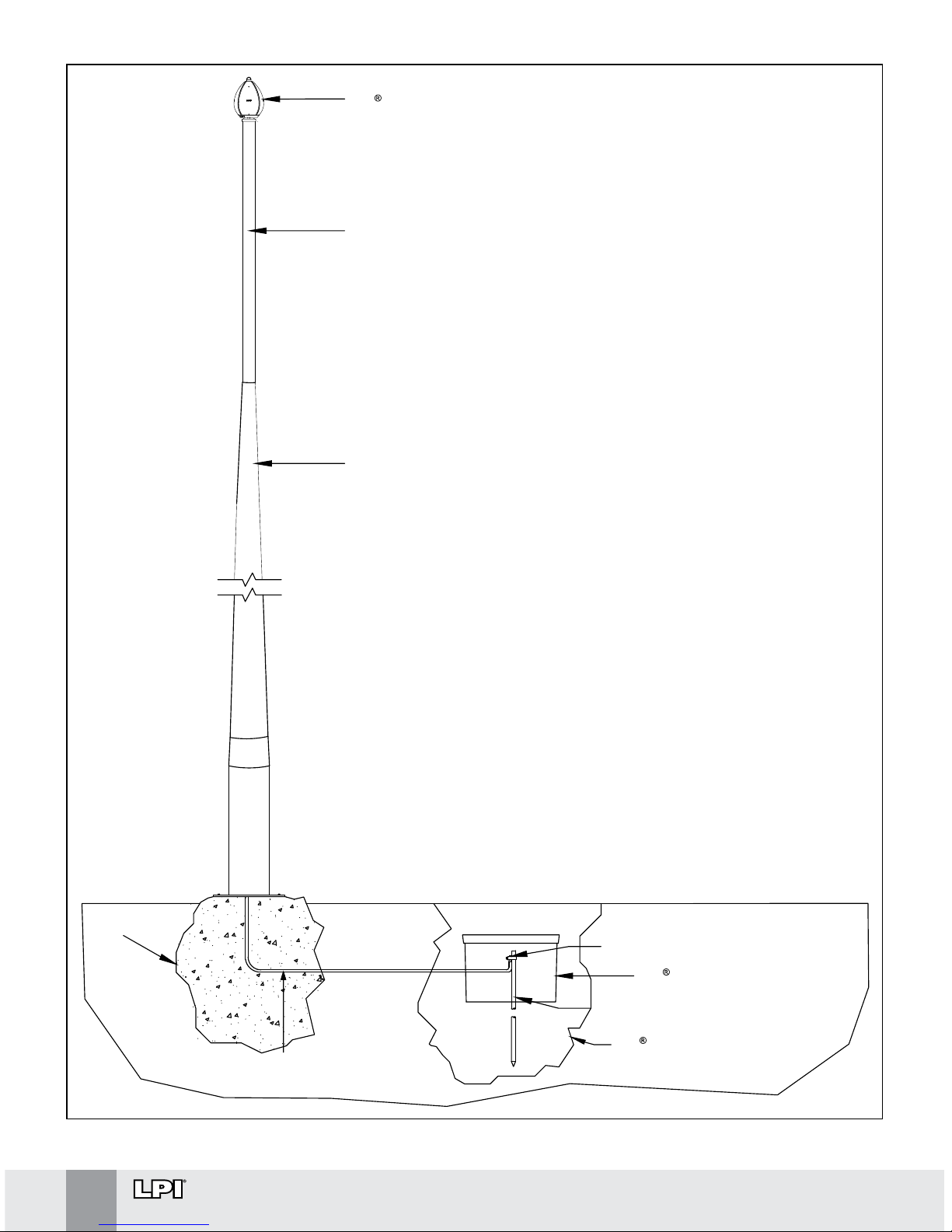

Figure 5.

LPI INSPECTION KIT

LPI GUARDIAN PLUS GI TERMINAL

FOOTING

LPI LOWER TERMINATION KIT

LPI EARTHING SYSTEM

®

®

LPI EARTH ENHANCING

MATERIAL

BONDING OF METALLIC

MAST TO EARTH

MAST CONVEYS LIGHTNING

ENERGY TO EARTH

FREESTANDING

MAST

www.lpi.com.au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

13

Installation of the Lightning Earth

Before installation of the lightning protection earth, consult site drawings of underground

services so that these are not damaged during installation of the earthing system.

An earth of ≤ 10 W is generally required for the successful operation of LPI Guardian Plus terminal.

For standalone Guardian Plus installations, LPI recommends the installation of a radial lightning

earth, as shown in Figure 6.

∆ The minimum earthing system comprises 3 x 10 metre radials, typically utilising 25 x 3 mm

copper tape

∆ Each radial must be installed in a trench with approximate dimensions 500 mm (depth) x

200 mm (width)

∆ An earth rod should be driven at the end of each radial. The depth of the earth rod length

should be tailored to the soil resistivity profile of the installation location

∆ The earth rod material should also be matched with the local conditions, i.e., typically

copper-bonded steel, but stainless steel may be required in more aggressive soils

∆ The use of earth rod clamps to fix the tape to rods is recommended

Note: If space constraints do not permit the installation of a radial earth system per above,

consult with LPI or an authorised distributor for further advice.

If the Guardian Plus is installed within an earth grid, e.g., in a substation, then the earth grid can

substitute the radials. However, an earth rod of suitable depth must be installed at the base of

the mast supporting the Guardian Plus air terminal.

Some of the practical aspects of the lightning earth installation are as follows:

∆ Waterproofing mastic tape should be used on all mechanical connections

∆ The use of earth enhancing compounds is recommended around all earth electrodes

installed, e.g., LPI RESLO, LPI SRIM or LPI GRIP, especially in areas where soil resistivity is

moderate to high

∆ An earth pit should be installed where the end of the downconductor terminates to the

lightning earth (see Figure 6). The earth pit provides an access point for disconnection and

future testing of the earthing system

∆ When installing the earth rods, use driving heads to prevent mushrooming of the top of the

rod and when using coupled rods. Use a post or picket driver

Note: do not connect the lower termination of the downconductor to the earthing system at

this point in time.

Loading...

Loading...