Lightmed LightLas 532 Operator's Manual

Operator’s Manual

Green Laser Photocoagulator With LCD

LightLas532 – Operators Manual Rev. No 01 Page 1of 115

LightLas 532

Control Panel

Operator’s Manual

for the

LightLas 532

Green Laser Photocoagulator With LCD

Control Panel

Directive 93/42/EEC

as amended by 2007/47/EC

LightLas 532 – Operator's Manual Rev. No 01 Page 2 of 115

Doc. No. : DC1001

Rev. No. : 01

Operator’s Manual for the LightLas 532 Green Laser

Operators Manual for the LightLas 532 Ophthalmic Laser

DC1001

March 2014

Draft prepared

01

August

Release 01 version

Photocoagulator

Clinicians or Doctors should ensure that they are adequately knowledge of the

operation procedures prior to using the LightLas 532 Laser system.

This Operators Manual should be studied and understood before proceeding to

operate the equipment on patients.

CAUTIONS - Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposure.

CAUTIONS - Any modification to the Ophthalmic Laser will result in the necessity for

it to be reclassified

CAUTIONS - U.S. law restricts this device to sell by or on the order of a physician

This Operators Manual contains confidential and proprietary information of the

Manufacturer.

Manufactured by: LightMed Corporation, No.1-1, Ln. 1, Pao-An St. Sec. 3,Shulin Dist.,

New Taipei City 23861, Taiwan

USA Address: 1030 Calle Cordillera, Suite 101, San Clemente, CA 92673

Tel No.: 949-218-9555 Fax No.: 949-218-9556

Copyright © LightMed Corporation

EU Representative: Medical Device Safety Service GmbH

Schiffgraben 41, 30175 Hannover, Germany

LightLas 532 – Operator's Manual Rev. No 01 Page 3 of 115

Table of Contents

Section 1 INTRODUCTION .................................................................................. 9

Section 2 SAFETY ............................................................................................. 10

2.1 Product Classifications ............................................................... 10

2.2 Warnings and Precautions ......................................................... 11

2.3 Optical Hazards ......................................................................... 12

2.3.1 Nominal Ocular Hazard Distance (NOHD) ........................... 12

2.3.2 Avoid Exposure to Laser beams .......................................... 13

2.4 Electrical Hazards ...................................................................... 13

2.5 Safety Controls and Features ..................................................... 14

2.6 Product Labeling ........................................................................ 14

2.6.1 Console system .................................................................. 14

2.6.2 Integrated Slitlamp LDU .................................................... 16

2.6.3 Laser Indirect Ophthalmoscope LDU ................................... 18

2.6.4 Attachment LDU ................................................................ 19

2.6.5 Safety Filter (Manually) ..................................................... 20

Section 3 PRODUCT SPECIFICATIONS............................................................... 21

3.1 LightLas 532 System Specification ............................................. 21

3.2 CSO SL980 and SL990 Slitlamp Specifications ............................. 24

Section 4 PRINCIPLES OF OPERATION .............................................................. 25

4.1 General Description ................................................................... 25

4.2 LightLas 532 Laser Controls and Displays ................................... 33

4.2.1 Laser Console .................................................................... 33

4.2.2 Slitlamp Delivery Unit ....................................................... 40

4.2.3 Laser Indirect Ophthalmoscope (LIO) ................................. 44

4.2.4 Two types of Integrated CSO SL980 and SL990

Slitlamp Controls Breakdown ............................................ 47

Section 5 INSTALLATION .................................................................................. 51

5.1 Introduction and Requirements ................................................. 51

5.2 Unpacking and Receiving Inspection .......................................... 52

5.3 Tools and Equipment ................................................................. 54

5.4 Setting Up the Laser System Parts .............................................. 55

5.4.1 Slitlamp Integrated LDU .................................................... 56

5.4.2 Laser Indirect Ophthalmoscope LDU (LIO) .......................... 68

5.4.3 Endoprobes LDU ............................................................... 69

5.5 Pre-check / Alignment Procedures ............................................. 72

5.5.1 Pre-check Laser console operation .................................... 72

5.5.2 Pre-check / Alignment LDU ............................................... 74

LightLas 532 – Operator's Manual Rev. No 01 Page 4 of 115

Section 6 CLINICAL USE .................................................................................... 87

6.1 Different types of LDUs Indication / Contraindication Use....88

6.1.1 Slitlamp Delivery Unit ........................................................ 88

6.1.2 Laser Indirect Ophthalmoscope (LIO) .................................. 88

6.1.3 Endoprobe devices ............................................................. 89

6.2 General Warnings ...................................................................... 90

6.3 Possible side-effect or adverse reactions .................................... 92

Section 7 MAINTENANCE ................................................................................. 93

7.1 Operator / User Maintenance ..................................................... 93

7.2 Laser Beam Alignment Check ...................................................... 94

7.3 System Output Power Checking Procedure ................................. 95

Section 8 TROUBLESHOOTING .......................................................................... 97

8.1 Symptom / Warning ................................................................... 97

8.2 Warning ..................................................................................... 99

8.3 Error Codes ............................................................................... 102

Section 9 European Community Issues ............................................................. 106

Section 10 EMC Test Tables ............................................................................... 108

LightLas 532 – Operator's Manual Rev. No 01 Page 5 of 115

LIST OF DRAWINGS / FIGURES

Figure

Description

Page

2.1

Laser Console Safety and Controls Labels

14

2.2

Laser Console Safety labels

15

2.3(a)

Integrated Slitlamp LDU with Labels (RH side)

16

2.3(b)

Integrated Slitlamp LDU with Labels (LH side)

17

2.4

LIO LDU with Labels

18

2.5

Attachment LDU with Labels

19

2.6

Microscope Doctor Safety Filter with Labels

19

2.7

Microscope Safety Filter with labels

20

4.1

System software start up screen shot

29

4.2

System software boot up ok and system is "Standby" mode

29

4.3

System software is ready to shutdown

32

4.4

Laser Console Controls and LCD Displays

33

4.5

LCD Panel Displays and Control

34

4.6

Integrated Slitlamp LDU Controls

40

4.7(a)

Attachment Slitlamp LDU Controls

41

4.7(b)

Truspot Attachment Slitlamp LDU Controls (New version)

41

4.8(a)

Front View of LIO LDU Controls

44

4.8(b)

Top View of LIO LDU Controls

44

4.9

SL980 Slitlamp Parts List and Controls

47/48

4.10

SL990 Slitlamp Parts List and Controls

49/50

5.1

Packing Carton for Integrated LDU and Slitlamp

52

5.2

Portable Carry Cases for Console and LDU’s

53

5.3

Laser System Parts

55

5.4

Slitlamp table top ass'y

57

5.5(a)

Rear view box connection

57

5.5(b)

Removal fuse socket

58

5.5(c)

Removal fuses

58

5.5(d)

Removal voltage setting block and reinsert it back upon completion

59

5.6

Slitlamp Ass’y

59

5.7

Assembled Upper and Lower Housing Screw

60

5.8

Slitlamp mounted onto Table Top ready for Integrated LDU

60

5.9

Slitlamp arm ready for Delivery housing

61

5.10

Fit Delivery unit housing to the Slitlamp

62

5.11

Lock the housing securely to the Slitlamp when it is pushed against

Chrome Stop screw

62

LightLas 532 – Operator's Manual Rev. No 01 Page 6 of 115

Figure

Description

Page

5.12

Align the keyways then fit the Zoom unit to the Delivery housing

63

5.13

Rotate the Zoom housing to the end stop

63

5.14(a)

Original Illumination Tower

64

5.14(b)

New modified Illumination Tower fitted

64

5.15(a)

Haag Streit Attaching Tonometer mount ready for Attachment LDU

65

5.15(b)

Zeiss 30SL Attaching the Tonometer mount and Attachment LDU

Mounting Arm

65

5.15(c1)

Lightmed SYL9000 Attaching Tonometer mount ready for Attachment

LDU

66

5.15(c2)

Lightmed SYL9000 Attaching the Tonometer mount and Attachment

LDU Mounting Arm

66

5.16(a)

Haag Streit Mounting the whole attachment LDU to Tonometer mount

& micromanipulator

67

5.16(b)

Zeiss Style 30SL Mounting the whole attachment LDU to Tonometer

mount & micromanipulator

67

5.16(c)

Lightmed SYL9000 Mounting the whole attachment LDU to Tonometer

mount & micromanipulator

67

5.17

Fiber tips cleaning

68

5.18

LIO connections in console

68

5.19

LIO LDU fiber connection

68

5.20

Endoprobe plug installation

69

5.21(a)

Standard System connection set-up

71

5.21(b)

Combo System Y-Joint connection set-up

71

5.21(c)

Sample of Delivery Fiber and Delivery Key Connection

71

5.22(a)

System boot up sequential display #1

72

5.22(b)

System boot up sequential display #2

72

5.22(c)

Initial Power on displays and outputs

72

5.22(d)

Sample of Delivery Fiber and Delivery Key Connection

72

5.23

Safety filter checks

73

5.24

Attach the Delivery fiber to the Zoom unit

73

5.25

Upper / Lower Slit Alignment Aiming Integrity and Focus Checkout

75

5.26

Realignment set screw location (X-Y axis)

76

LightLas 532 – Operator's Manual Rev. No 01 Page 7 of 115

Figure

Description

Page

5.27(a)

Checking Field of View set-up

76

5.27(b)

Checking manipulator operation on the target

76

5.28(a)

New Type Version Check Slitlamp focus on Target Rod and Laser focus

of aiming beam

79

5.28(b)

Old type Version Adjust the Attachment LDU Spot Size Focus using the

knob on the mounting arm

80

5.29

Old type version Adjusting Micromanipulator Arm to verify Laser Spot is

in the Aperture Center

80

5.30

Old / New type version Adjusting sideways movement of Attachment

LDU during alignment

81

5.31(a)

Fiber and Delivery Key fitted to Console Front Panel

82

5.31(b)

LIO Intensity Control Knob

83

8.1

Sample of Error code display

102

Installation Record Sheet

84/85/86

Power Meter Calibration Record Sheet

96

All the Accessories Listing Detailed

113/114

Record Sheet

Appendix I

LightLas 532 – Operator's Manual Rev. No 01 Page 8 of 115

Section 1 INTRODUCTION

This manual is intended to provide the operator with an overview of the operation

and safety requirements for the LightLas 532 Ophthalmic Laser. This manual is not

intended to provide instructions on actual treatment procedures and it is expected

that users will have undertaken training prior to using the equipment.

The Manufacturer and Distribution organization assume no liability through the use

of this Laser system.

All care has been taken in the preparation and checking of this manual however there

is no guarantee provided that all information is correct. The information provided in

this manual is subject to change without notice.

Only approved or authorized accessories may be used in the LightLas 532. The

Manufacturer and Distribution organization shall not be held liable or responsible for

damages or injury caused as a result of using non-approved accessories. This includes

all Optical Fiber systems, Laser Delivery Units, Safety Filters, Safety Glasses and Table

units.

All maintenance and service work must be carried out by authorized and trained

service agents and only those procedures outlined in the operator and service

manual are allowed. Any service work carried out by unauthorized persons will void

all warranties.

No circuit diagrams or component part lists are to be supplied for the LightLas 532. If

you require technical documentation that is not provided in this manual then please

contact the manufacturer or your local distributor in writing with your reasons for

wanting them and then a copy of the service manual may be provided.

Before using the LightLas 532 Photocoagulator Laser system the operator should

read this manual carefully and pay particular attention to the sections of Safety,

Operation and Maintenance.

LightLas 532 – Operator's Manual Rev. No 01 Page 9 of 115

Section 2 SAFETY

This Laser system has been designed and tested to function in a safe and correct

when used as indicated in this manual.

Do not use this laser before reading and understanding completely this Operators

Manual.

It is important to remember that this laser emits high levels of visible laser radiation

which can cause permanent and irreparable eye and tissue damage. Always observe

precautions for laser safety including using warning signs, safety glasses and only

operating the laser in a treatment room that provides protection to casual observers.

2.1 Product Classifications

The LightLas 532 Photocoagulator Laser is a Class IV laser product as specified in the

standard IEC60825-1 (2007) and the USA 21 CFR’s 1040.10, 1040.11.

The LightLas 532 Photocoagulator Laser is classified as Class I Type B Electromedical

equipment as specified in the IEC60601-1 standard.

The LightLas 532 Photocoagulator Laser is classified as a Class II device according to

the FDA CFR21 regulations.

The LightLas 532 Photocoagulator Laser is classified as a Class II Type B Medical

Device according to the MDD 93/42/EEC (as amended by 2007/47/EC).

The LightLas 532 has been designed to comply with the following standards:

Laser standards

IEC 60825-1 (2007)

USA 21 CFR 1040.10, 1040.11 (1997)

IEC60601-2-22 (1995)

Electrical standards

IEC 60601-1:2005

EN 60601-1:2006

EN 60601-1-2:2007

IEC60601-1-2 :2007

USA UL 2601

JIS T1001 (1992) and T1002 (1992)

Others

MDD 93/42/EEC (as amended by 2007/47/EC)

EN 60601-1-6:2010

IEC 60601-1-6 :2010

LightLas 532 – Operator's Manual Rev. No 01 Page 10 of 115

EN62366 :2008

IEC62366 :2007

EN 980:2008

ISO14971 (2012)

2.2 Warnings and Precautions

The following warnings and precautions apply to the LightLas 532 Laser System and

should be observed by all users at all time:

DO NOT look directly into the laser beam or at laser reflections since direct

and reflected laser light from the laser aperture can cause permanent eye

injury.

DO NOT operate the laser unless observers are using the correct protective

eyewear. The protective eyewear must have an optical density of OD4 or

more at 532 nanometers wavelength. This information must be present on

the eyewear.

DO NOT use objects that can readily reflect light in the vicinity of the laser

beam to avoid reflecting the beam in a hazardous manner.

DO NOT fire the Laser directly onto flammable agents or gasses as the

focused laser beam may cause ignition. There is no AP/ APG protection.

DO NOT try to service or repair the laser other than what is included in this

manual. Service should only be performed by an authorized and trained

agent of the manufacturer.

DO NOT fire the laser on a patient without first checking the operation of the

laser and verifying the optical alignment of the treatment Laser beam.

ALWAYS use the lowest power settings possible when treating a patient

with the laser and start the treatment with minimum level of power.

ALWAYS set the correct spot size and/or use the most appropriate one for

the power setting and type of procedure that is to be performed.

DO NOT put the laser into ‘TREAT’ mode until ready to operate on the

patient.

DO NOT inhale any laser plume generated by the Laser during surgery.

Personnel should take an extreme measured precaution, such as wearing

surgical masks or use plume evacuation systems when a treatment is

undergoing. Caution - Laser plume may contain viable tissue particulates.

ALWAYS take particular care of the optical fibers that connect the Laser

Delivery Units to the Console to make sure they do not get damaged.

LightLas 532 – Operator's Manual Rev. No 01 Page 11 of 115

Additional clinical warnings may be found in Section 6.1.4 of this Manual.

ALWAYS try to let the laser have its own or dedicated power outlet.

Additional items may be plugged in a Multiple Portable Socket Outlet, which

may be plugged into an additional outlet.

DO NOT use the Laser Console if the ambient temperature is outside the

range of 20 to 35°C. This temperature range is the rated operating

temperature limits where the Laser system can be guaranteed to operate

without any interruptions to normal use. Outside this range of temperature

it is possible that the Laser will generate an error condition where the word

“hold” is displayed and the system goes to Standby until the internal

temperature returns to within normal limits then the Laser can be used again

but the error condition may reoccur unless the rated temperature comes

within limits.

2.3 Optical Hazards

Guidance for the safe use of Lasers and Laser systems is found in the standard

IEC60825-1, the USA 21CFR 1040.10, 1040.11 and ANSI Z136.1 - 1986.

During normal operation of the LightLas 532 the operator is protected from Laser

hazards by built in optical absorption Safety Filters. All other personnel in the area

should wear protective eyewear to eliminate the risk of eye injury occurring.

The optical density (OD) of eye protection must be greater than or equal to 4 and the

wavelength 532nm range is also specified on it. It is shown in the following format:

OD4+ @ 532nm

Otherwise, the safety glasses are NOT suitable for this purpose of eye protection.

Safety Glasses are required to have the CE mark applied if used in the EU.

The LightLas 532 uses a Class II Laser Diode Aiming beam. Its wavelength range from

635 to 650 nanometers (nm) and the maximum power output is set at the factory to

be less than 1mW delivered to the patients cornea. However it is always

recommended to use the lowest aiming beam intensity during treatments.

The LightLas 532 Photocoagulator Laser has been classified as a Class 4 and its

classification specified accordingly to the above quoted standards. This classification

is also based on the Accessible Emission Limits (AEL) as calculated according to the

standards.

2.3.1 Nominal Ocular Hazard Distance (NOHD)

The Nominal Ocular Hazard Distance (NOHD) is the distance between the equipment

LightLas 532 – Operator's Manual Rev. No 01 Page 12 of 115

and a person’s eye for which the optical power, from the equipment, entering the

dilated pupil of the person will be less than or equal to the Maximum Permissible

Exposure (MPE) as specified in the standards (i.e. less than a Class 1 Laser Output).

The calculated NOHD for the LightLas 532 with different Laser Delivery Units is:

5 meters at maximum power settings for the Endoprobes

18 meters at maximum power settings and 1000m spot size for Slitlamp Delivery

Units

20 meters at maximum power settings for LIO

Therefore when the laser is in operation, all persons that are closer than these

distances to the equipment should be wearing eye protection.

Patients, where possible, should have the untreated eye covered or protected from

laser reflections.

2.3.2 Avoid Exposure to Laser beams

Reassembly or maintenance of the laser system should only be performed by

authorized and trained personnel. The external housing of the laser system should

never be removed otherwise you or standby observers could be exposed to

dangerous levels of laser radiation and potentially lethal electrical voltages.

Eye safety filters are designed to protect physician’s eyes from back scattered laser

beams must always be used. They are integrated into the Slitlamp and LIO Delivery

Units. When using the endoprobes a separate filter that attaches to the operating

microscope must be used.

For other personnel that may be exposed to reflections or backscatter they must

wear safety glasses or goggles. In any case NEVER look directly at the treatment

laser beam as severe eye injury is likely. This means avoid looking into the aperture of

any of the laser delivery units or the console.

2.4 Electrical Hazards

The Lightlas 532 Photocoagulator laser has been designed to apply the International

Standards for Medical Equipment. The laser system is designed to operate with three

terminal prongs AC voltage where the third prong pin is the earth-grounded prong.

Warning: It is not safe to operate the Lightlas 532 photocoagulator laser without an

earth-grounded receptacle. There is possible risk of electric shock.

No cover or housing need to be removed by the operator or user. Only the

authorized and trained service or agent can remove the cover or housing assembly

LightLas 532 – Operator's Manual Rev. No 01 Page 13 of 115

since there is possible of exposing laser radiation and high current or voltages.

EXPLOSIONSGEFAHR

Dieses Gerat ist nicht fur den Betrieb in

explosiongefahrdeten bereichen bestimmt

exposition dangereuse au rayonnement

Complies to the requirements of

21CFR, Chapter 1, Subchapter J

connect only to with a "Hospital

d'anesthesiques inflammables

Risques d'explosion si utilise en presence

Ne pas ouvrir L'appareil risque de chocs electriques

Laser direct ou diffuse reparations par service

For grounding reliability

Gefahr eines elektrischen Schlages

GEHAUSETEILE NICHT ENTFERNEN

Wartungsarbeiten nur durch qualifizierten

accessible laser radiation. Refer servicing to

Risk of explosion if used in the presence of

Do not remove covers. Shock hazard and

qualified service personnel.

Laserstrahlung zuganglich.

flammable anesthetics.

Kundendienst.

ACHTUNG!

DANGER!

technique qualifie.

Grade receptacle".

DANGER!

FOOTSWITCH

INTERLOCK

DOOR

fuse as marked above

WARNING

Risk of fire

Replace only with

AC MAINS INPUT

50/60Hz, 400VA

100-230V ~ (Fuse:T3.15AH250V)INPUT:

Danger/Caution

DIRECT OR SCATTERED RADIATION

AVOID EYE OR SKIN EXPOSURE TO

Visible and Invisible laser radiation when open

LIO

LIO

LIGHTMED

STOP

Delivery

Key

STOP

DIRECT OR SCATTERED RADIATION

AVOID EYE OR SKIN EXPOSURE TO

Diode Aiming Laser 635-650nm 1mW CW Max

Green Laser 532nm 2.0W CW Max

CLASS 4 LASER PRODUCT

LASER RADIATION

DIRECT OR SCATTERED RADIATION

AVOID EYE OR SKIN EXPOSURE TO

Diode Aiming Laser 635-650nm 1mW CW Max

Green Laser 532nm 2.0W CW Max

CLASS 4 LASER PRODUCT

LASER RADIATION

2.5 Product Labeling

All the labels on the LightLas 532 comply with the requirements of the various

regulatory standards referred to previously.

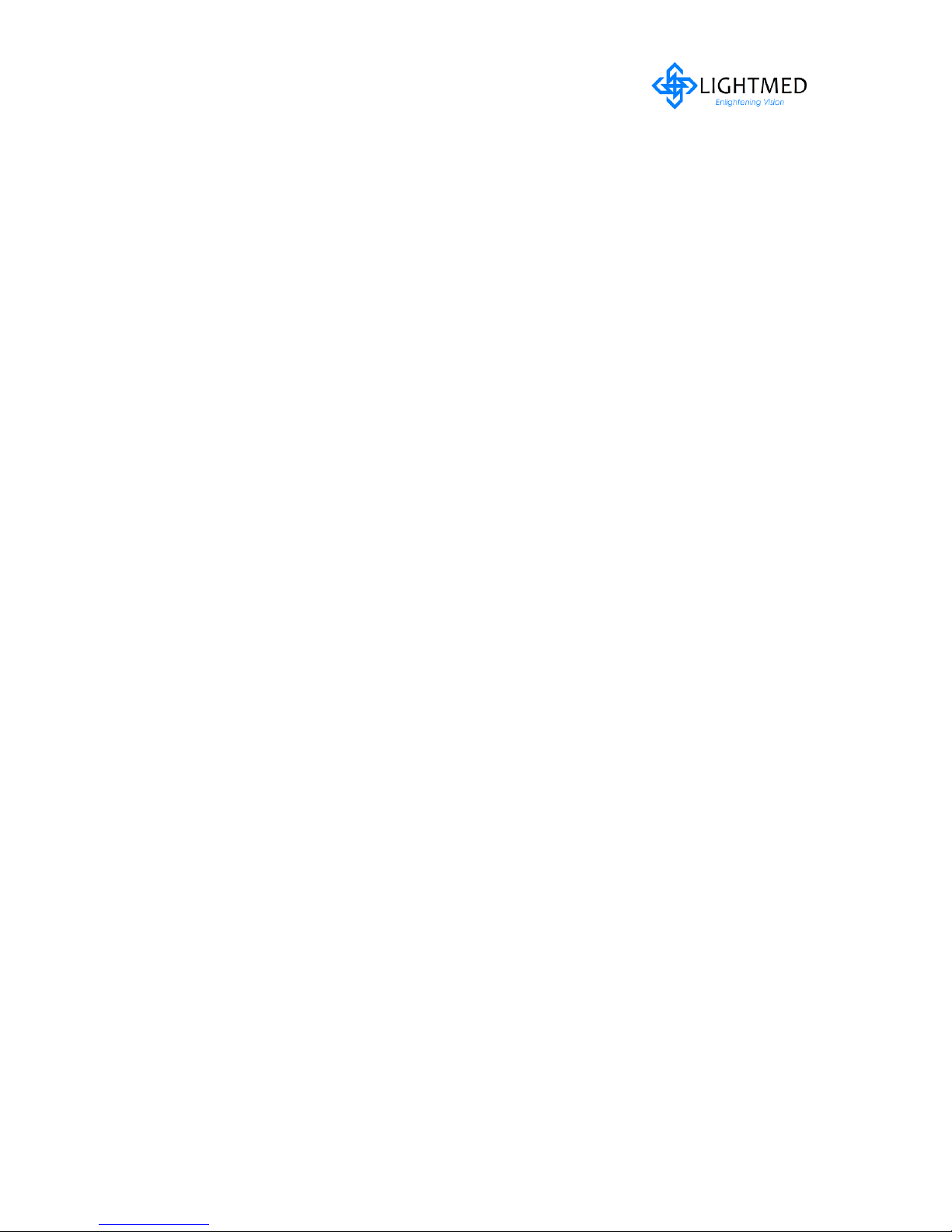

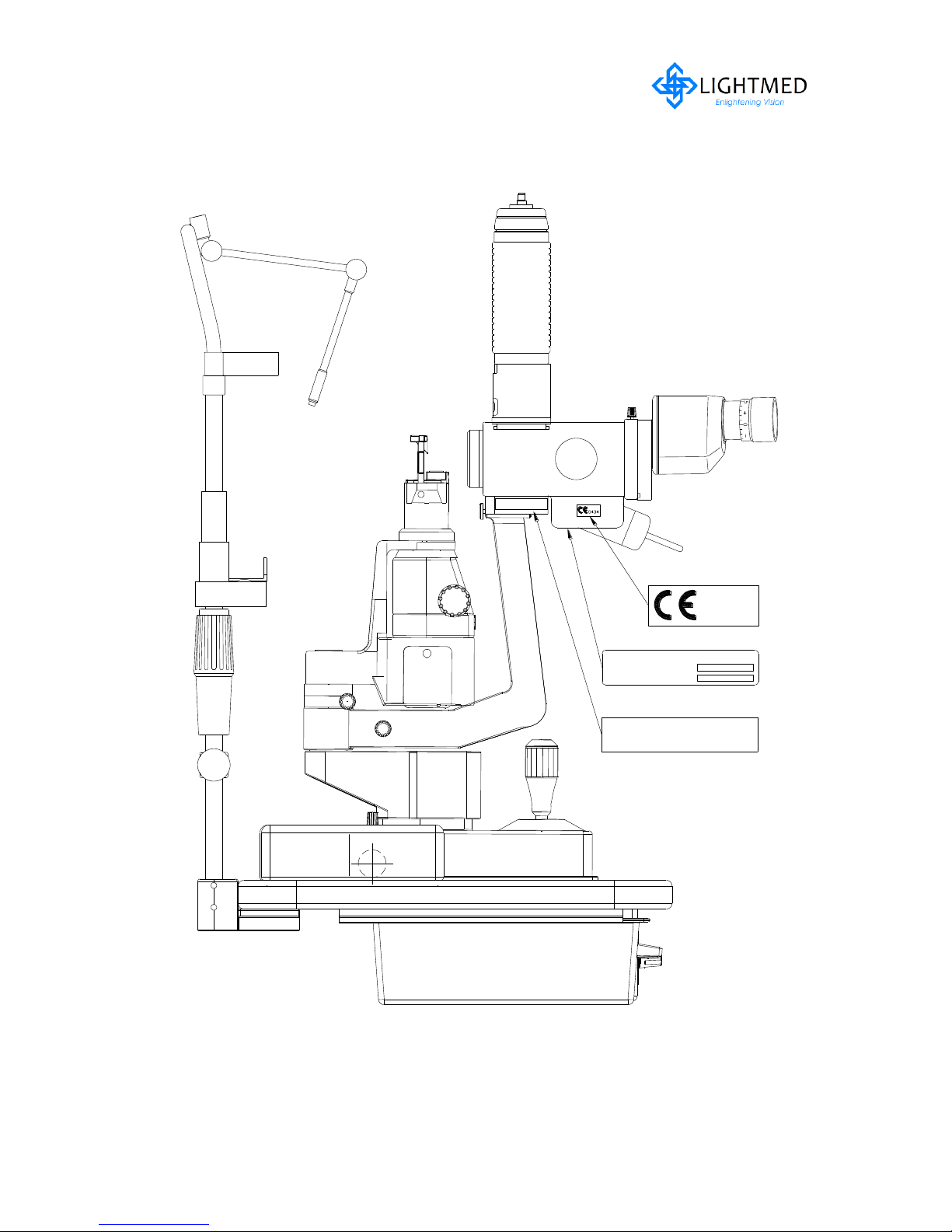

2.5.1 Console system

A full facsimile of all the safety and control labels is shown in the figures 2.1 and 2.2.

Figure 2.1

Laser Console Safety and Control Labels

LightLas 532 – Operator's Manual Rev. No 01 Page 14 of 115

2.5.1 Console system continues...

Lightmed Corporation

SERIAL NO:

MODEL NO:

Lightmed Corporation

SERIAL NO:

MODEL NO:

MANUFACTURED:

Manufactured by LightMed Corporation

No1-1, Lane 1, Pao-An Street, Section 3

Shulin City, Taipei 238, TAIWAN

Schiffgraben 41, 30175 Hannover, Germany

Medical Device Safety Service GmbH

(MDD 93/42/EEC as amended by 2007/47/EC)

EU Authorized Representative

EC REP

"Instructions Under Lid"

Lightmed Corporation

MODEL NO:

SERIAL NO:

Coiling

EXPLOSIONSGEFAHR

Dieses Gerat ist nicht fur den Betrieb in

explosiongefahrdeten bereichen bestimmt

exposition dangereuse au rayonnement

Complies to the requirements of

21CFR, Chapter 1, Subchapter J

connect only to with a "Hospital

d'anesthesiques inflammables

Risques d'explosion si utilise en presence

Ne pas ouvrir L'appareil risque de chocs electriques

Laser direct ou diffuse reparations par service

For grounding reliability

Gefahr eines elektrischen Schlages

GEHAUSETEILE NICHT ENTFERNEN

Wartungsarbeiten nur durch qualifizierten

accessible laser radiation. Refer servicing to

Risk of explosion if used in the presence of

Do not remove covers. Shock hazard and

qualified service personnel.

Laserstrahlung zuganglich.

flammable anesthetics.

Kundendienst.

ACHTUNG!

DANGER!

technique qualifie.

Grade receptacle".

DANGER!

FOOTSWITCH

INTERLOCK

DOOR

fuse as marked above

WARNING

Risk of fire

Replace only with

AC MAINS INPUT

50/60Hz, 400VA

100-230V ~ (Fuse:T3.15AH250V)INPUT:

Danger/Caution

DIRECT OR SCATTERED RADIATION

AVOID EYE OR SKIN EXPOSURE TO

Visible and Invisible laser radiation when open

Figure 2.2

Laser Console Safety Labels

LightLas 532 – Operator's Manual Rev. No 01 Page 15 of 115

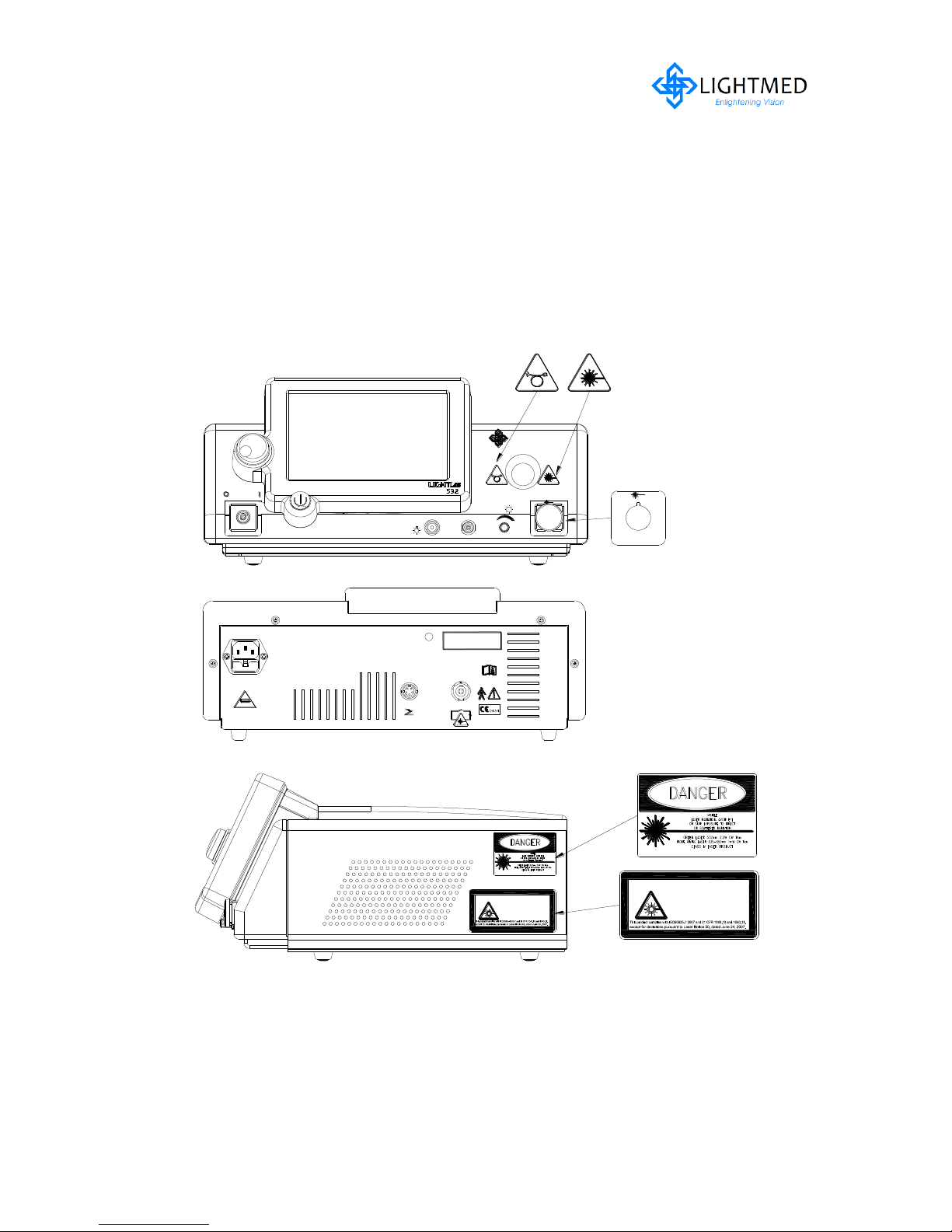

2.5.2 Integrated Slitlamp LDU

VISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE

TO DIRECT OR SCATTERED

RADIATION

CLASS 4 LASER PRODUCT IEC/EN 60825-1:2007

CAUTION/DANGER

VISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE

TO DIRECT OR SCATTERED

RADIATION

CLASS 4 LASER PRODUCT IEC/EN60825-1: 2007

Figure 2.3(a)

Integrated Slitlamp LDU with labels (RH side)

LightLas 532 – Operator's Manual Rev. No 01 Page 16 of 115

2.5.2 Integrated Slitlamp LDU continues...

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION

0434

Lightmed Corporation

OD4@532nm

Safety Filter

Serial No:

Model No:

Visible laser radiation when open

DANGER / CAUTION

DIRECT OR SCATTERED RADIATION

AVOID EYE OR SKIN EXPOSURE TO

Visible laser radiation when open

DANGER / CAUTION

Figure 2.3(b)

Integrated Slitlamp LDU with labels (LH side)

LightLas 532 – Operator's Manual Rev. No 01 Page 17 of 115

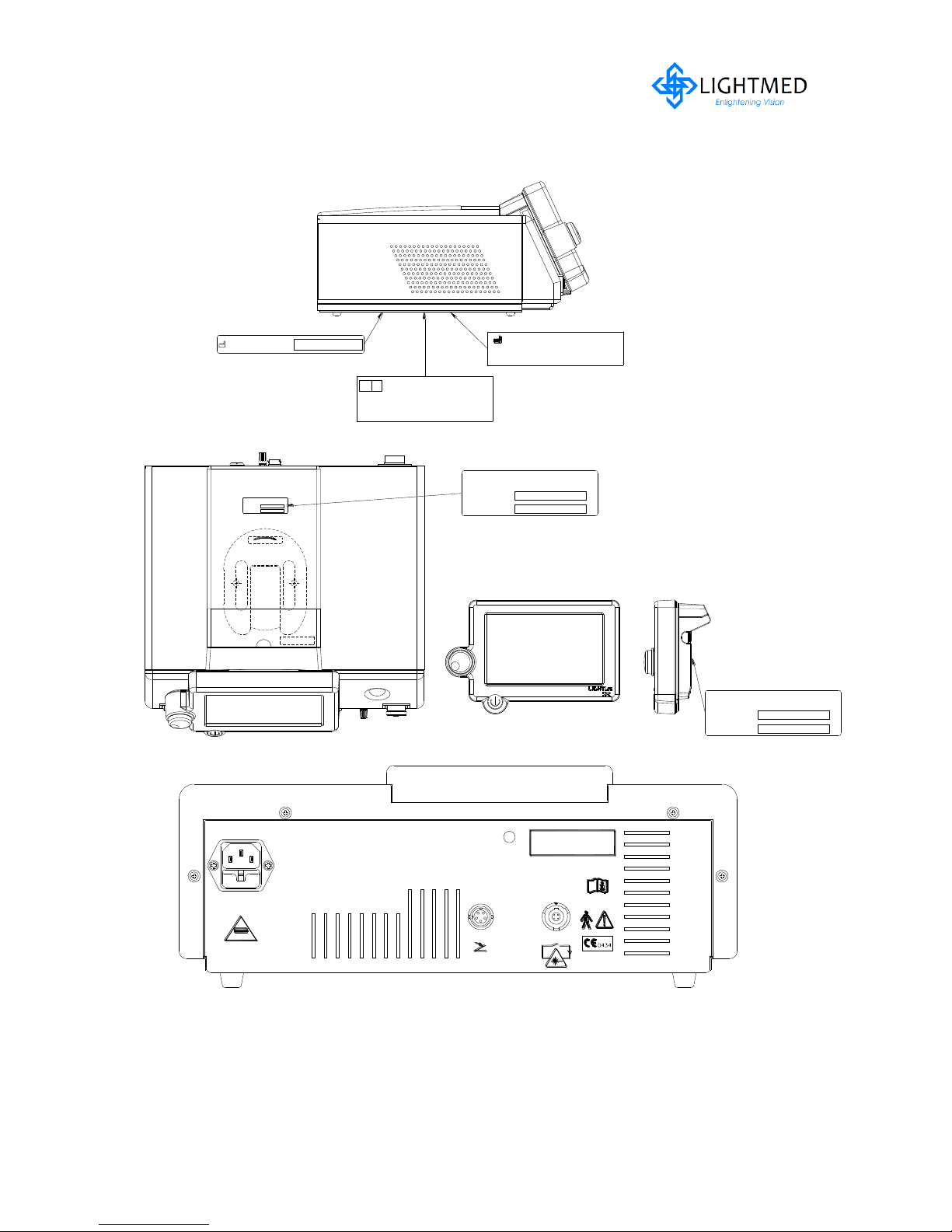

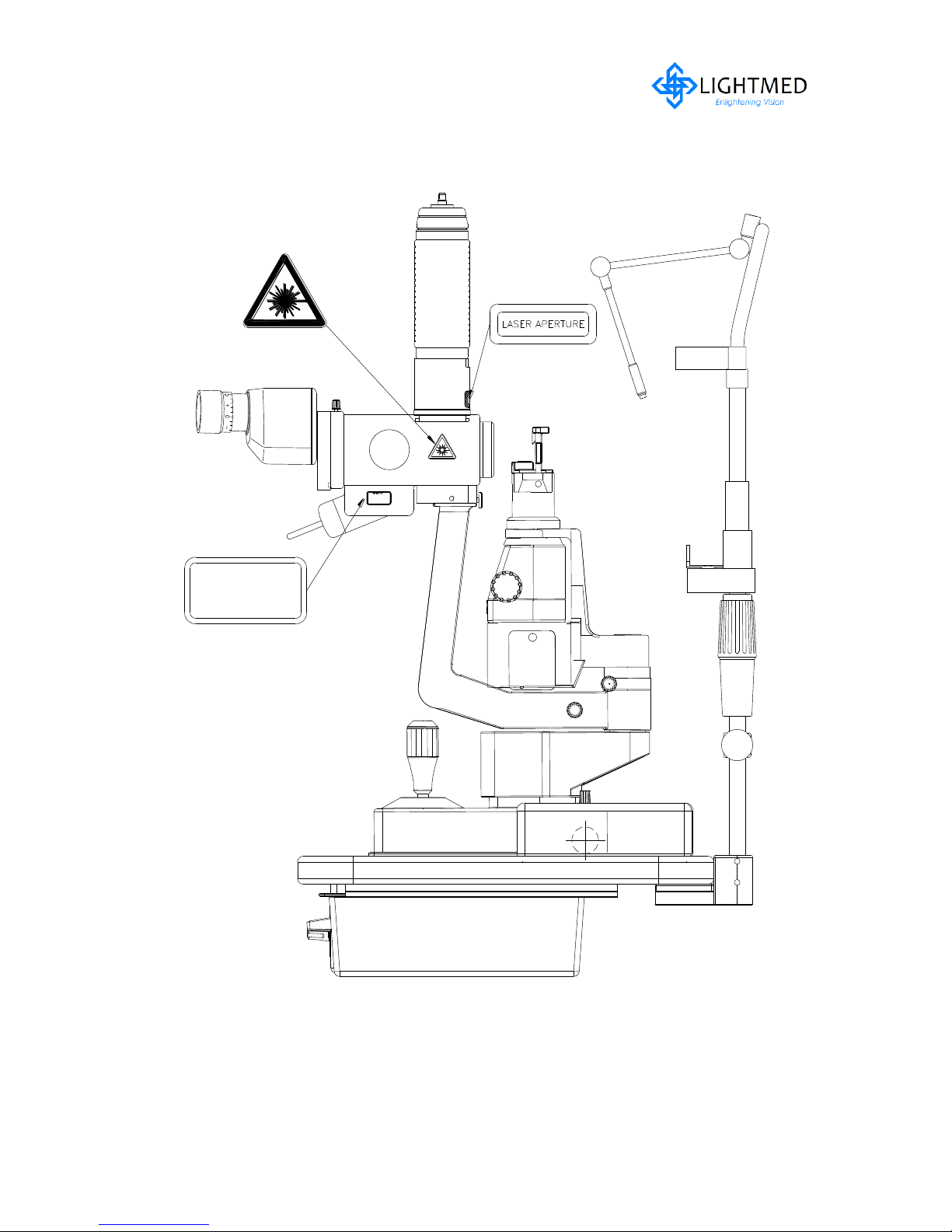

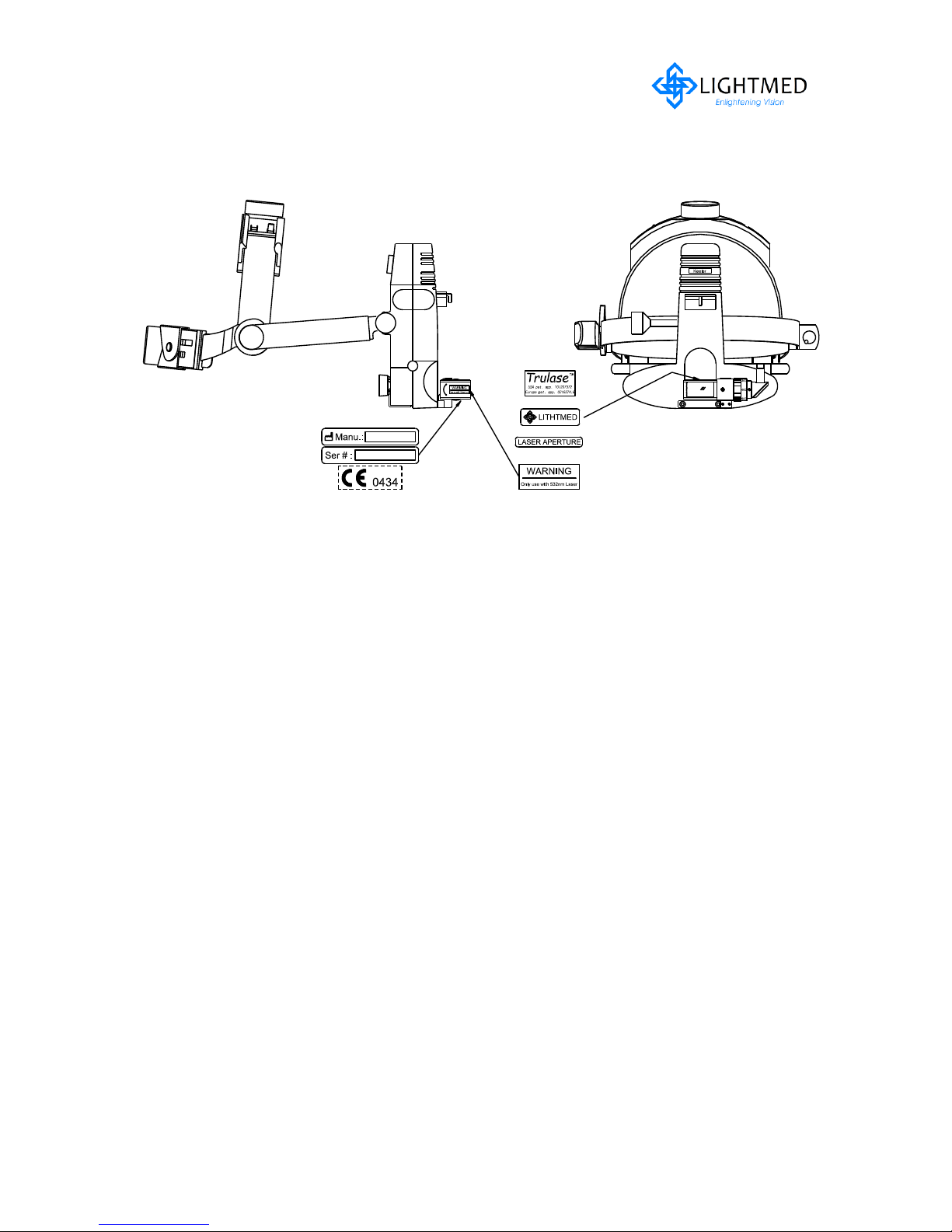

2.5.3 Laser Indirect Ophthalmoscope LDU

Figure 2.4 LIO LDU with labels

LightLas 532 – Operator's Manual Rev. No 01 Page 18 of 115

2.5.4 Attachment LDU

Manufactured:

DANGER / CAUTION

Visible laser radiation when open

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION

CAUTION/DANGER

VISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE

TO DIRECT OR SCATTERED

RADIATION

CLASS 4 LASER PRODUCT IEC/EN 60825-1:2007

Manufactured:

Lightmed Corporation

Safety Filter OD4@532nm

Model No:

Serial No:

Lightmed Corporation

Serial No:

Safety Filter OD4@532nm

Model No:

400300 500

500

VISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE

TO DIRECT OR SCATTERED

RADIATION

CLASS 4 LASER PRODUCT IEC825-1(1993)

CAUTION/DANGER

CAUTION/DANGER

VISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE

TO DIRECT OR SCATTERED

RADIATION

CLASS 4 LASER PRODUCT IEC60825-1 2007

Manufactured:

Serial No:

Model No:

Lightmed Corporation

Safety Filter OD4@532nm

Safety Filter OD4@577nm

Lightmed Corporation

Manufactured:

Serial No:

Model No:

Attachment LDU with labels

Figure 2.6

TruSpot Attachment LDU Labeling

Figure 2.5

LightLas 532 – Operator's Manual Rev. No 01 Page 19 of 115

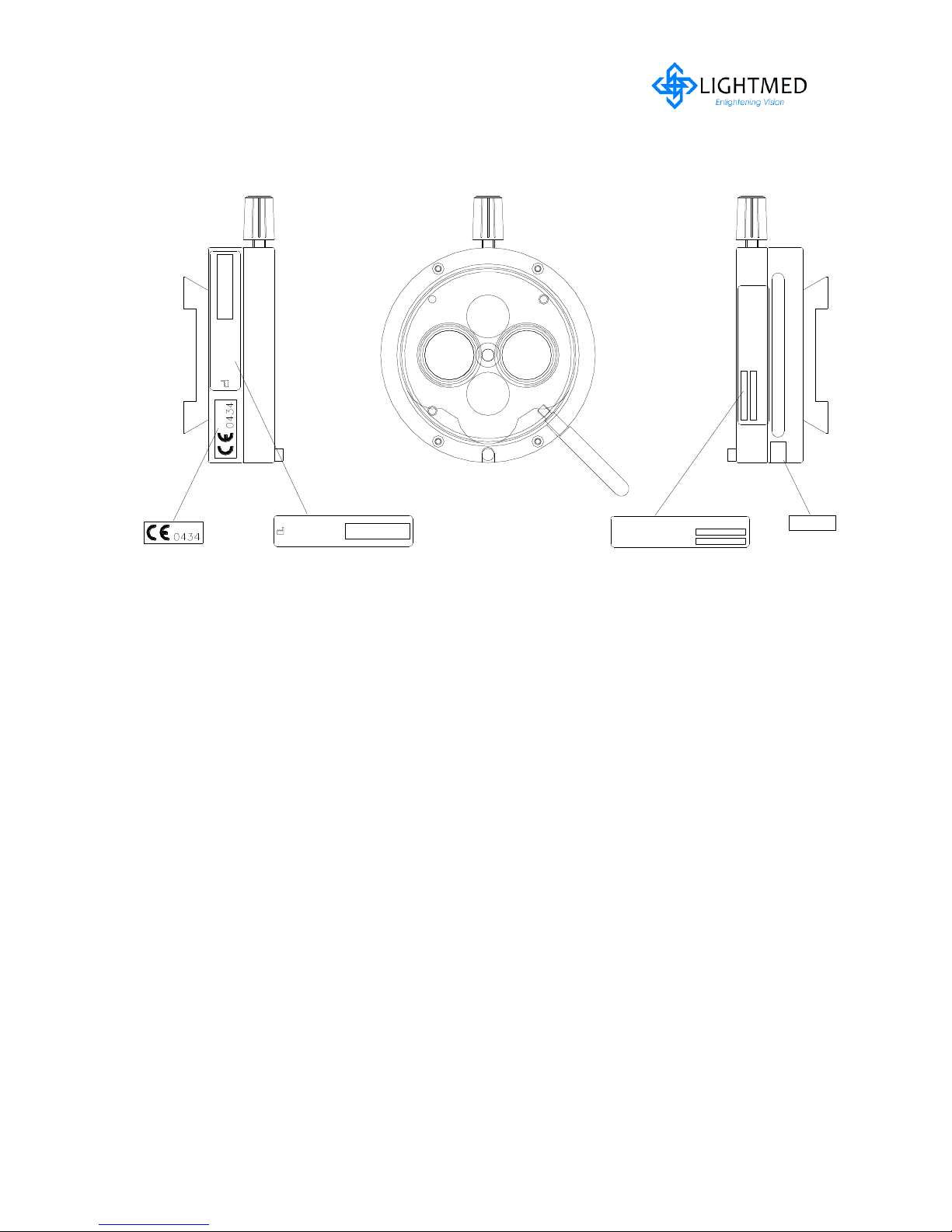

2.5.5 Safety Filter (Manually)

Manufactured:

Manufactured:

OD4@532nm

Safety Filter

Lightmed Corporation

Serial No:

Model No:

FILTER

Lightmed Corporation

Serial No:

Model No:

FIL

OD4@532nm

Safety Filter

Figure 2.7

Microscope Safety Filter with labels

LightLas 532 – Operator's Manual Rev. No 01 Page 20 of 115

Section 3 PRODUCT SPECIFICATIONS

3.1 LightLas 532 System Specification

The following are the System Specifications for the LightLas 532 Ophthalmic Laser.

_____________________________________________________________________

Console Laser System

General Specification

Electrical Input : 100 to 230 Vac. 50/60 Hz Single phase

Power : 400W

Fuse rating : T3.15AH250V @ 100-230Vac (Time Lag)

Temperature Range : Transport: -10 to 70°C

Operating: 15 to 30°C

Storage: -10 to 55°C

Relative Humidity Range : Operating: 30% - 85% non-condensing

Storage and Transport: up to 95% non-condensing

Atmospheric pressure : Operating: 800-1060 mbar

Storage and Transport: 500-1060 mbar

Cooling System : Fan cooled and TEC’s for Laser Diode and Crystal

Dimensions (Total) : 130mm(H) x 370mm(W) x 330mm(D)

Weight : 13 Kg (System) 20 Kg (Packed)

Treatment Laser

Laser Type : Diode Pumped Frequency Doubled YAG

Wavelength : 532 nm

Mode of Operation : CW

Power Output : 2 W Maximum

Power Adjustment : Variable from 0.05 to 2.0 W

Exposure Duration : 0.01, 0.02, 0.03, 0.04, 0.05, 0.06, 0.08, 0.1, 0.15 and

0.2 to 3.0s is 0.1s increment

Repeat Interval : Selectable from 0.01 to 3.0 secs and equal to or greater

than exposure duration in same discrete steps as

duration

SP Mode : Duty cycle selections - 7.5%, 150µs ‘On’ time

- 10%, 200µs ‘On’ time

- 12.5%, 250µs ‘On’ time

- 15%, 300µs ‘On’ time

- 17.5% ,350µs ‘On’ time

- 20%, 400µs ‘On’ time

LightLas 532 – Operator's Manual Rev. No 01 Page 21 of 115

Doctor Safety Filter : OD4 at 532 nm

Safety Class : Class 4

Power Display accuracy: Better than +/-20% of actual

Beam Divergence : < 0.2 NA

____________________________________________________________________

Aiming Laser

Laser Type : Red Laser Diode

Wavelength : 635–650 nm (Red)

Mode of operation : Continuous Wave (CW)

Output power : Maximum of 1.0mW

Power adjustment : Continuously variable

Safety Class : Class 2

___________________________________________________________________

Laser Delivery Units (LDU)

Integrated Slitlamp LDU

Slitlamp model : CSO Model SL980 (Detailed refer to p.32)

Spot Sizes : 50, 100, 200, 300, 400, 500, 1000 m selectable

on Zoom assembly of Delivery unit

Focus plane : All spot sizes Parfocal to Slitlamp focus plane

Fiber Length : 2 m

Mounting : Direct to Slitlamp housing

Safety Filter : Fixed filter OD 4 @ 532nm

Beam Divergence : Cone angle of 20°

Attachment Slitlamp LDU

Slitlamp model : To attach on CSO Model SL990 (Detailed refer to p.32),

Haag Streit models BM or BQ, most Haag Streit Clone

Slitlamps and Zeiss SL30

Spot Sizes : 50, 125, 200, 300, 500m selectable on housing of

Delivery unit

Focus plane : All spot sizes Parfocal to Slitlamp focus plane

Fiber Length : 2 m

Mounting : On adapters fitted to Slitlamp Tonometer Mounts

Safety Filter : Fixed filter OD 4 @ 532nm

Beam Divergence : Cone angle of 20°

___________________________________________________________________

Laser Indirect Ophthalmoscope

Indirect model : Keeler All Pupil II

Retinal Spot size : 300µm nominal at focus with 20D Laser Lens

Illumination power : From Laser Console or stand alone power source

Fiber Length : 3 m

LightLas 532 – Operator's Manual Rev. No 01 Page 22 of 115

Weight : Less than 500g without laser attachment

Safety Filter : Fixed filter OD 4 @ 532nm

Beam Divergence : Cone angle 20°

___________________________________________________________________

Endo-ocular Probes

Probe Types : Straight, Curved and Aspirating

Fiber Length : 3 m

Safety Filters : OD 4 @ 532nm in housing for installation to Operating

Microscope before Laser can be fired

Sterile : Sterilized by Ethylene Oxide and a single use

device only

Beam Divergence : 0.2 NA

___________________________________________________________________

Accessories

Safety Filters

Types : To suit Zeiss, Moeller, Leica and Topcon Operating

Microscopes

Safety Filter : OD4@532nm

LightLas 532 – Operator's Manual Rev. No 01 Page 23 of 115

3.2 CSO SL980 and SL990 Slitlamp Specifications

The following are the Slitlamp Specifications for the CSO SL980 and SL990 Slitlamps

that are used in the LightLas 532 Photocoagulator Laser System. The SL980 is a Zeiss

clone and the SL990 is a Haag Streit clone. Both Slitlamps have very similar

specifications however the SL980 uses an illumination source below the viewing path

and the SL990 uses illumination from above the viewing path.

Microscope : Galilean

Magnification Set : 5 Step Drum Rotation

Eyepiece : 12.5X

Magnification Ratio : 6X, 10X, 16X, 25X, 40X

PD Range : 48.5-80mm

Diopter Adjustment : +/-8

Slit Illumination : 6V 20W Halogen Lamp

Slit Width : 0-14mm (SL980) and 0-12mm (SL990)

Slit Length : 1.8 – 12mm

Slit Apertures : 0.3, 5.5, 9, 14mm(SL980) and 0.2, 1, 3, 5, 9, 12mm(SL990)

Slit Angles : 0°- 180°

Filters : Red Free, Heat Absorbing, Cobalt Blue

Movement Ranges

Longitudinal (In/Out) : 113mm

Lateral (Left/Right) : 108mm

Vertical (Up/Down) : 35mm

Fine movement range : 10mm

Chin Rest Range : 70mm

LightLas 532 – Operator's Manual Rev. No 01 Page 24 of 115

Section 4 PRINCIPLES OF OPERATION

4.1 General Description

The LightLas 532 Green Laser is an Ophthalmic Laser suitable for performing the

following clinical procedures:

Retinal Photocoagulation

Pan Retinal Photocoagulation

Endo photocoagulation

Macular Treatments

Laser Trabeculoplasty

The LightLas 532 Laser system has a wavelength of 532nm, which is in the visible

spectrum and is a green light. A red aiming beam is used to position the treatment

green light beam prior to delivery.

The word LASER is an acronym for “Light Amplification by Stimulated Emission of

Radiation”. The light from a laser has particular characteristics, which makes it a

valuable tool for medical applications.

The beam from a laser is collimated which means that the beam does not

diverge and can maintain a constant diameter over a long distance. This

means that the Laser beam can be focused to a very small spot with high

energy and power densities.

The beam is Monochromatic, which means that it is a single wavelength

beam and therefore the effects of the beam on tissue are very predictable

and reproducible.

The light waves are coherent which means they are in phase with each

other and do not interfere and generate losses in energy.

The LightLas 532 system consists of a laser console where the green laser is housed

along with the electronic control system and power supplies and accompanies along

with various Laser Delivery Units (LDU’s). These LDU’s include:

Slitlamp Integrated into CSO model SL980

Slitlamp Attachment for CSO model SL990 and other Haag Streit clones.

Slitlamp Attachment for Zeiss model SL30 Slitlamp

Laser Indirect Ophthalmoscope (LIO) using a Keeler II

Endo photocoagulation hand pieces (Endoprobes)

When using these LDU’s a microscope Doctor Safety Filter (DSF) is required to

protect the doctor from unexpected reflections causing eye injury during the

treatments. The DSF is mounted in the beam path of the microscope.

LightLas 532 – Operator's Manual Rev. No 01 Page 25 of 115

All the normal functions of a Slitlamp are available to the operator when using the

LightLas 532 on a Slitlamp unit and when the doctor is using the LIO they will use a

Contact Lens of either 20D or 28D.

On the laser console there is a remote control module that the doctor can remove

from the top of the console and position it close to the treatment location so as to

have easy access to the laser displays and controls. This remote control module is

connected to the laser console by a flexible cable that is coiled up and sits in the

recess area on the top of the laser console.

The doctor must first confirm the patient meets the treatment requirements of the

indications and contraindications before proceeding with any treatment. Typically

the doctors or their assistant will verify that the laser and delivery unit are operating

correctly before positioning the patient in the Chinrest are for avoiding any patient

inconvenience. This checking includes the laser output and alignment.

The doctor must set the laser power and pulse interval whenever the System is

turned on. It is the responsibility of the doctor to set acceptable power levels and

pulse intervals. It is recommended that always start with a lower power and shorter

pulse interval to reduce any risk of unintended injury to the patient. By default

setting the laser system, the power is set to 0mW, the pulse duration is set to 0.02

seconds and the pulse interval is set to “One” which means one shot per requested

only. These settings can be altered and saved by the operators or doctors

preference.

Conversely, the doctor can select a repeat pulse mode where the laser is pulsed

repetitively according to the doctor’s requirements. However, even in this mode, the

laser is always under the control of the doctor’s the footswitch, which means that

whenever the footswitch is released, there will be no laser output.

The following paragraphs give a general description of the operation of the Laser

System

The laser system console generates a controlled beam of the 532nm wavelength light

that is focused to a small spot so that it can be delivered into an optical fiber that

then connects to one of the Delivery units. The Slitlamp LDU’s optical fiber has a

diameter of 200µm and is 2 meters long and 3 meters long for the LIO. Special care

must be taken with the fibers not to damage the jacket as this may create extra

losses and may allow the laser beam to be transmitted at the damaged place along

the fiber. Therefore the fiber should be kept off the floor and away from sharp edges.

The 532nm wavelength green laser light is primarily used as a source of energy to

heat the tissue and thereby cause photocoagulation. The laser beam is directly

applied to the treated tissue and absorbed by the melanin pigment within the retinal

pigment epithelium and the choroid. This absorption converts the light energy into

LightLas 532 – Operator's Manual Rev. No 01 Page 26 of 115

heat energy which raises the temperature of the tissue being treated producing

thermal coagulation of the protein. The green laser beam is readily transmitted

through the cornea, lens, and vitreous regions of the eye. If the patient’s eye does

not allow for good transmission or introduces some dispersion of the beam then the

patient is not suitable for this type of laser treatment. Increasing the laser power and

pulse duration will generate more heat and therefore the coagulative effect will be

greater.

If the power or duration of exposure is too high then the surrounding tissue may

sustain some damage. Therefore, a careful selection of the power and pulse

duration is essential to a successful treatment.

Different Types of LDU

For the Slitlamp Delivery Units and LIO, the laser beam is delivered into the patient’s

eye as a focused spot that can be positioned accurately by the doctor to the

treatment site. When using the LIO the laser beam is delivered through a Contact

Lens that is held by the doctor and assists in positioning the laser beam on the site

and setting the desired spot size. For the Slitlamp delivery unit the spot size at the

treatment site is adjustable and set by the doctor according to the type of treatment

to be used. The spot size selector is located on the delivery unit attached to the

Slitlamp and can be set from 50µm to 1000µm in a continuous adjustment for the

Integrated SL980 design. As for Attachment LDU, it can be selected from 50m to

500m.

When using the Endoprobes, the doctor will use an Operating Microscope to view

the patient’s eye. These probes are inserted into the eye and used in very close

proximity to the treatment site (almost in contact). The Endoprobes are sterile

devices intended for direct patient contact and are a purchased item with a sterility

guarantee.

For each LDU, a “Delivery Key” is used by the laser console as a means of

determining which type of LDU is connected. The Delivery Key is required because

each type of LDU has a different amount of loss through the optical elements and

therefore the output power factor calibration will be different for each. The

Endoprobes have the least loss of all the LDU’s because the only losses are through

the fiber itself and in the coupling of the laser beam into the fiber. The LIO has more

loss than the Endoprobes as it has a collimating system, mirror, and focusing lens for

the laser beam to be transmitted through and all of these have some contributing

losses. The least efficient of the LDU’s is the Slitlamp delivery unit. There are many

optics in this unit due to the spot size adjustment zoom system so the losses are the

greatest. Also when the small spot sizes are selected there may be some aperture of

the beam that contributes to the losses.

LightLas 532 – Operator's Manual Rev. No 01 Page 27 of 115

When setting up the laser unit for the operation, the correct type of Laser Delivery

Unit must be connected along with the Delivery Key that accompanies it. If no

Delivery Key is inserted then the warning message “Delivery Key Not Found” on the

LCD screen panel and system will wait for correction or reinserted before normal

console operation resume.

The Delivery Key is also an additional safety feature that prevents unauthorized use

of the laser unit. It is attached to the fiber for each of the LDU’s to eliminate any risk

of inserting the wrong Delivery Key. It is an essential requirement in order to ensure

that the correct calibrated power level is delivered to the patient.

The following paragraphs describe the actual operation of the system

The system consists of two major parts: the console and the LCD touch control panel

integrated with computer platform

Inside the Laser Console there are several operating components that put together

to provide the output Laser beam such as:

Laser Diode (808nm)

Laser Cavity and optics system

Thermal Electric Coolers and Driver units

Electronic Microprocessor control system

Power supply

First of all, main source power must be connected to the laser console system before

the system is enabled to function accordingly. Secondly, a blue LED backlight power

switch, located at the bottom of the screen (refer to fig. 4.3), on the LCD control

panel display needed to be enabled and wait for system software to boot up before

proceed to the next procedure (refer to fig. 4.1 - 4.2). Once the software is properly

boot up, then the key-switch is inserted and turned to the ON position (with the

Emergency switch in the out or OFF position). And then the console system

microprocessor controller will perform some internal checks to verify that the

machine is functioning as it should be. Few warning messages such as, "BBF

Temperature Not Ready", "LBO Temperature Not Ready" ...etc. will display on the

LCD when the console power is ‘ON’. This process usually takes less than few

seconds. If the temperature setting up process time is out of specification (> 5mins),

there will be an error code shown on the LCD display (for more detailed refer to

troubleshooting section of this manual).

LightLas 532 – Operator's Manual Rev. No 01 Page 28 of 115

Figure 4.1 System software start up screen shot

Figure 4.2 System software boot up ok and system is "Standby" mode

LightLas 532 – Operator's Manual Rev. No 01 Page 29 of 115

All operating conditions and switches are shown on the LCD control panel. The LCD

control panel display consists of:

Laser Power

Laser Power Pulse Duration

Pulse Interval

Accumulated number of pulses

The type of LDU connected

Aiming intensity

Mode of operation

SP Mode Selection

Customized treatment configuration

Query or Help functionality

The mode of operation is an important function display because when the laser is

turned ON STANDBY mode is automatically selected, which prevents any accidental

firing of the LightLas 532 Laser System with LCD panel. In STANDBY mode, the

footswitch is disabled and the shutter module blocker will obstruct the beam path is

closed.

Only ‘Standby’ button switch is toggled, the system will be in treat mode. Then the

footswitch and shutter are now enabled and the aiming beam is turned on. If the

footswitch is pressed, the Green laser beam will be delivered into the fiber. The

system will turn back to STANDBY mode in the following situations:

No controls are operated for 10 minutes

Any warning or error condition occurs

Prior to activate the ‘Treat’ mode, it is recommended that all operating conditions are

to be set correctly such as patient positioning, power selection, pulses duration,

interval duration, aiming beam intensity, spot size and illumination intensity. This will

prevent the likelihood of accidental firing of the Green laser or unintentional delivery

during the set up stages.

Output power distribution can fine tune through an up/down arrow switch button on

the LCD touch control panel. The power setting will remain the same whenever the

power is on which means the default setting screen will be primary unless it is

replaced by another setting. The power can be adjusted from 50 to 2000 mWatts.

The pulse duration can be adjusted from 0.01 secs to 3.0 secs. by pressing the action

key switch buttons on the LCD touch control panel. Similarly, the Repeat Interval

LightLas 532 – Operator's Manual Rev. No 01 Page 30 of 115

Loading...

Loading...