Lighting Controls Blue Box LT Maintenance Manual

®

™

THE BLUE BOX

LT

OPERATION

& MAINTENANCE

MANUAL

LCDBBO&M03Sept08

®

Lighting Control & Design

905 Allen Ave, Glendale CA 91201

Tel: 800-345-4448 • www.lightingcontrols.com

THE BLUE BOX LT OPERATION & MAINTENANCE MANUAL 3

TABLE OF CONTENTS

OVERVIEW..........................................................................5

GR1404LT / GR1408LT Drawings & Details......................................................7

Relay Overview ..........................................................................10

GR1416 LT Drawings & Details.................................................................11

Introduction to The Blue Box LT™ Series......................................................15

The Blue Box LT™ vs. Lighting Contactors .....................................................16

Build Your System in 3 Steps ................................................................17

Most Popular Accessories ..................................................................20

Applications...........................................................................22-23

MAINTENANCE & TROUBLESHOOTING ..............................................25

Making Up Cat. 5 Cable With RJ45 Connectors ................................................27

How To Make Proper Crimps...............................................................35

Adding a New Device ..........................................................................39

Parts Replacement & Installation Guide...............................................47

Hardware Troubleshooting .........................................................59

Troubleshooting with An Oscilloscope................................................63

Programming ....................................................................67

DTC Clock Navigation Basics ...............................................................69

Manual Control of Relays ..................................................................70

Programming Switches or DI Inputs..........................................................71

Time Schedules...........................................................................73

Programming a Blue Box LT Photocell........................................................76

To Add a Holiday List to a Schedule .........................................................77

More Data on Scheduled Events ............................................................78

Group Types .............................................................................80

Programming Groups......................................................................81

Additional Groups Parameters ..............................................................82

Group FAQs .............................................................................83

Other System / Set up Programming.........................................................86

LCDBBO&M04Sept08

Daylight Saving Time .......................................................................86

Keyboard Lock Code ......................................................................87

4 THE BLUE BOX LT OPERATION & MAINTENANCE MANUAL

TABLE OF CONTENTS (Continued)

Time Schedule Programming Examples...........................................................88

Exercise #1- Contact Closure Device Controlling 4 Relays ......................................88

Exercise #2 - Contact Closure Device Controlling 10 Relays ....................................88

Exercise #3 - Time Schedules with Override Switches ..........................................88

Exercise #4 - Retail Store ..................................................................89

System Diagnostics Tools...........................................................91

System Start Up & Cabling Guide ...................................................95

Frequently Asked Questions .......................................................103

APPENDIX ........................................................................111

Installation Guide GR1404 LT & GR1408 LT ..........................................113

Installation Guide GR1416 ........................................................117

Chelsea Installation Guide ........................................................121

PCO Installation (Out Door Photocell) Installation Guide ..............................123

Digital Input Card Installation Guide (For Contact Closures)............................125

Occupant Sensors (Hook-Up and Programming)......................................129

Novitas® Brand Occupant Sensors .............................................................131

Sensor Switch® Brand Occupant Sensors ........................................................132

Wattstopper® Brand Occupant Sensors .........................................................133

Hubbell® Brand Occupant Sensors .............................................................134

LC&D® Brand Occupant Sensors...............................................................135

Clock /Programming Navigation Tree ...........................................137-139

Technical Glossary ...........................................................141-143

LCDBBO&M04Sept08

®

™

THE BLUE BOX

OVERVIEW

LT

LCDBBO03Sept08

®

Lighting Control & Design

905 Allen Ave, Glendale CA 91201

Tel: 800-345-4448 • www.lightingcontrols.com

6 THE BLUE BOX LT OVERVIEW

TABLE OF CONTENTS

GR1404LT / GR1408LT Drawings & Details..........................................................7

Relay Overview ..................................................................................10

GR1416LT Drawings & Details .....................................................................11

Introduction to The Blue Box™ LT Series ...........................................................15

The Blue Box™ LT VS. Lighting Contactors .........................................................16

Build Your System In 3 Steps .......................................................................17

3 Enclosure Sizes ..................................................................................18

2 Panel Configurations.............................................................................19

Master Relay Panel ................................................................................19

Slave Relay Panel..................................................................................19

Most Popular Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Applications .......................................................................................22

Small Parking Lot (Single Control Panel) ..............................................................22

Retail Stores (With 6 Override Zones)...............................................................22

Warehouse (Multiple Control Panels)................................................................23

Blue Box Technical Support ........................................................................24

LCDBBO03Sept08

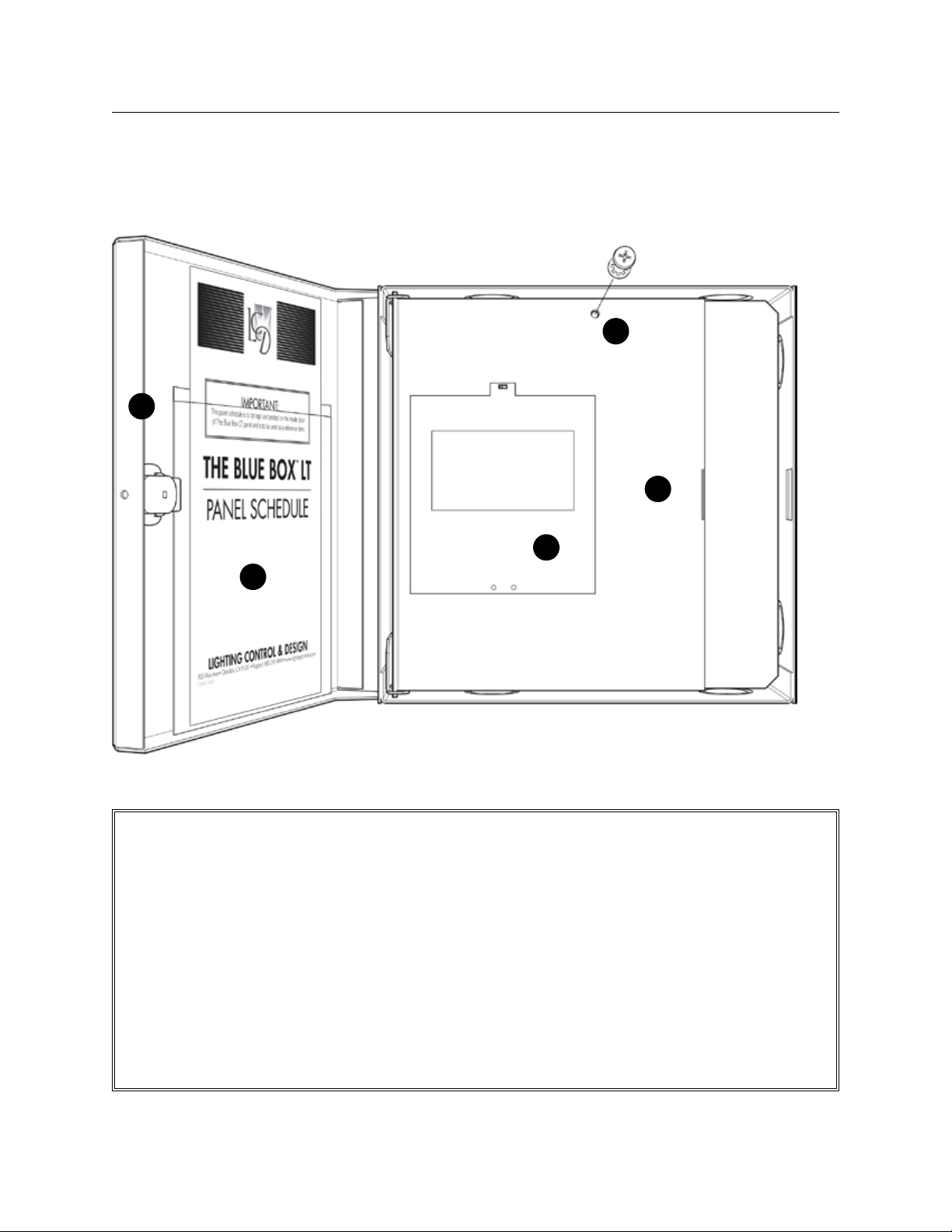

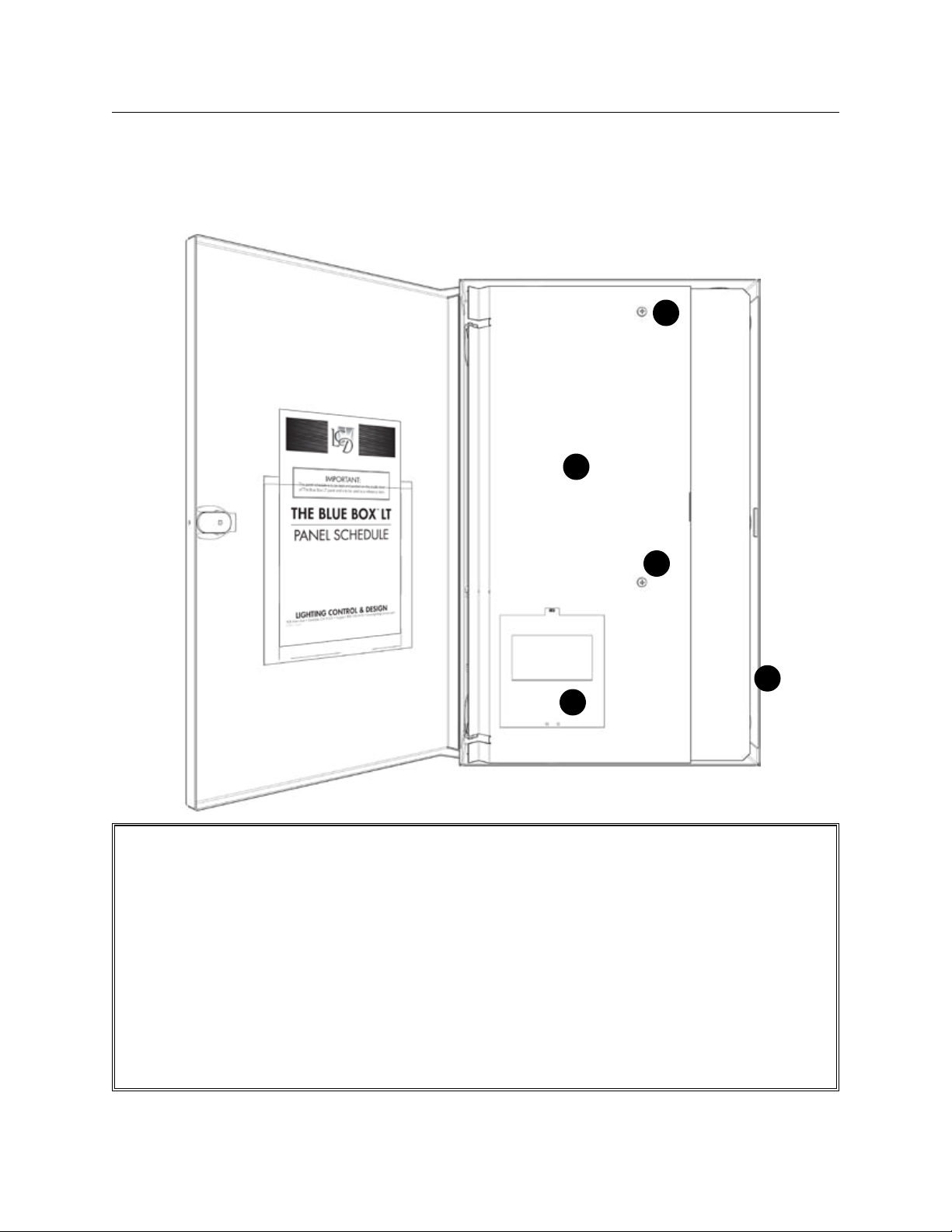

THE BLUE BOX LT OVERVIEW 7

GR1404LT / GR1408LT DRAWINGS & DETAILS

1

3

2

4

LCDBBO03Sept08

5

NEMA 1 surface mount enclosure with hinged door and key lock;

8.375” h x 8.375” w x 3.125” d (GR1404 LT)•

13.5” h x 8.5” w x 3.125” d (GR1408 LT)•

GR1404/08 LT (FRONT DOOR OPEN)

Screw fastener secures white door (Master only).1.

White door provides a barrier between Control 2.

Interface and High Voltage connections beneath

(Master only).

Hinged locking blue door.3.

DTC Clock / Display & Programming Interface: 4.

32-channel, 365-day astronomical clock with

Scroll and Tab to access control features for entire system (Master only).

Door pocket contains the following documenta-5.

tion: Refer to the Blue Box LT Installation Guide

for more information on these documents.

Panel Schedulea)

(optional) DI Card schedule.b)

If this is a Master panel, the System Device c)

Schedule on the back of the Panel Schedule

should also be filled-out.. It lists out all of the

digital lighting controls devices, where they are

and what they do. (see System Star t-Up Guide

for more information.

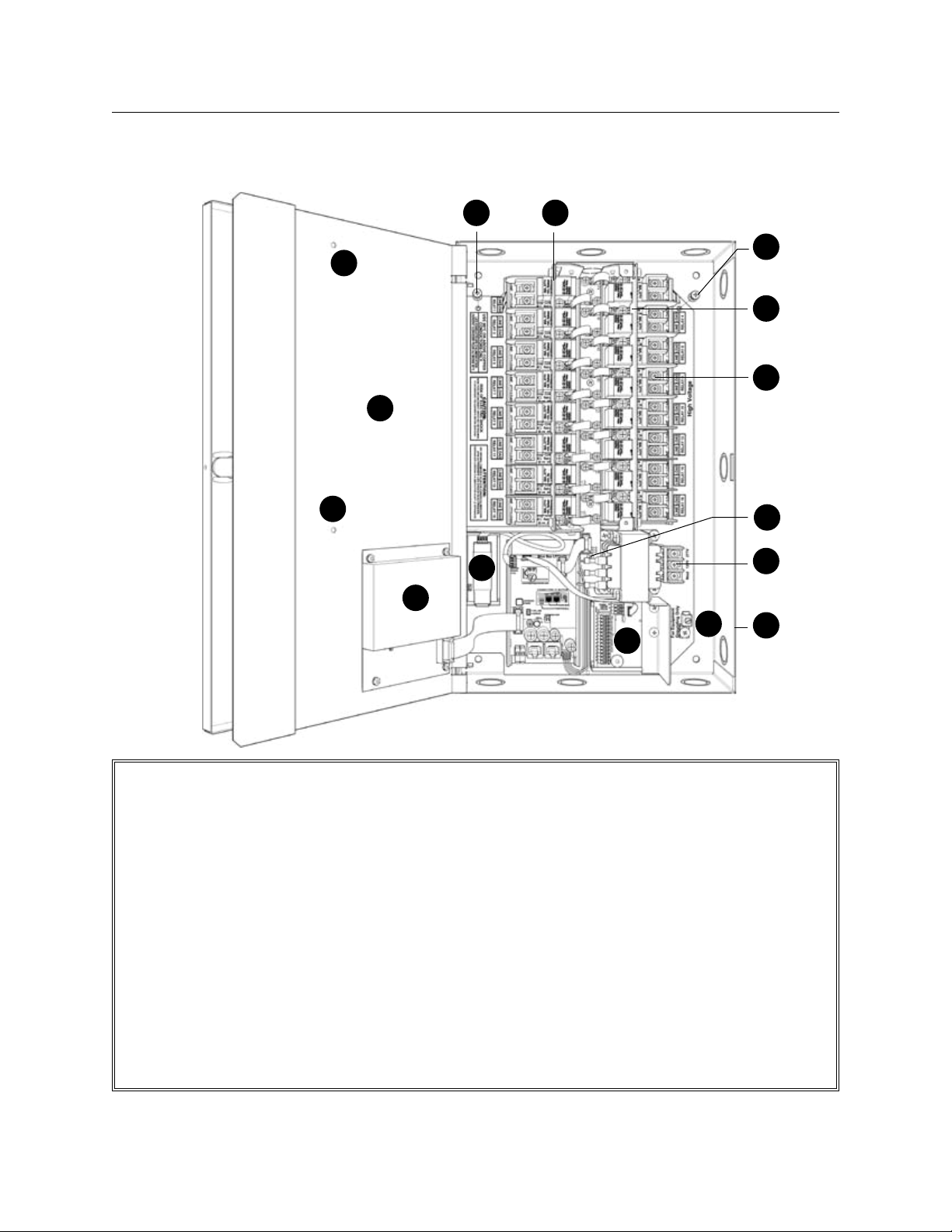

8 THE BLUE BOX LT OVERVIEW

low voltage only line voltage only

2

1

8

3

4

12

6

9

7

10

5

11

55

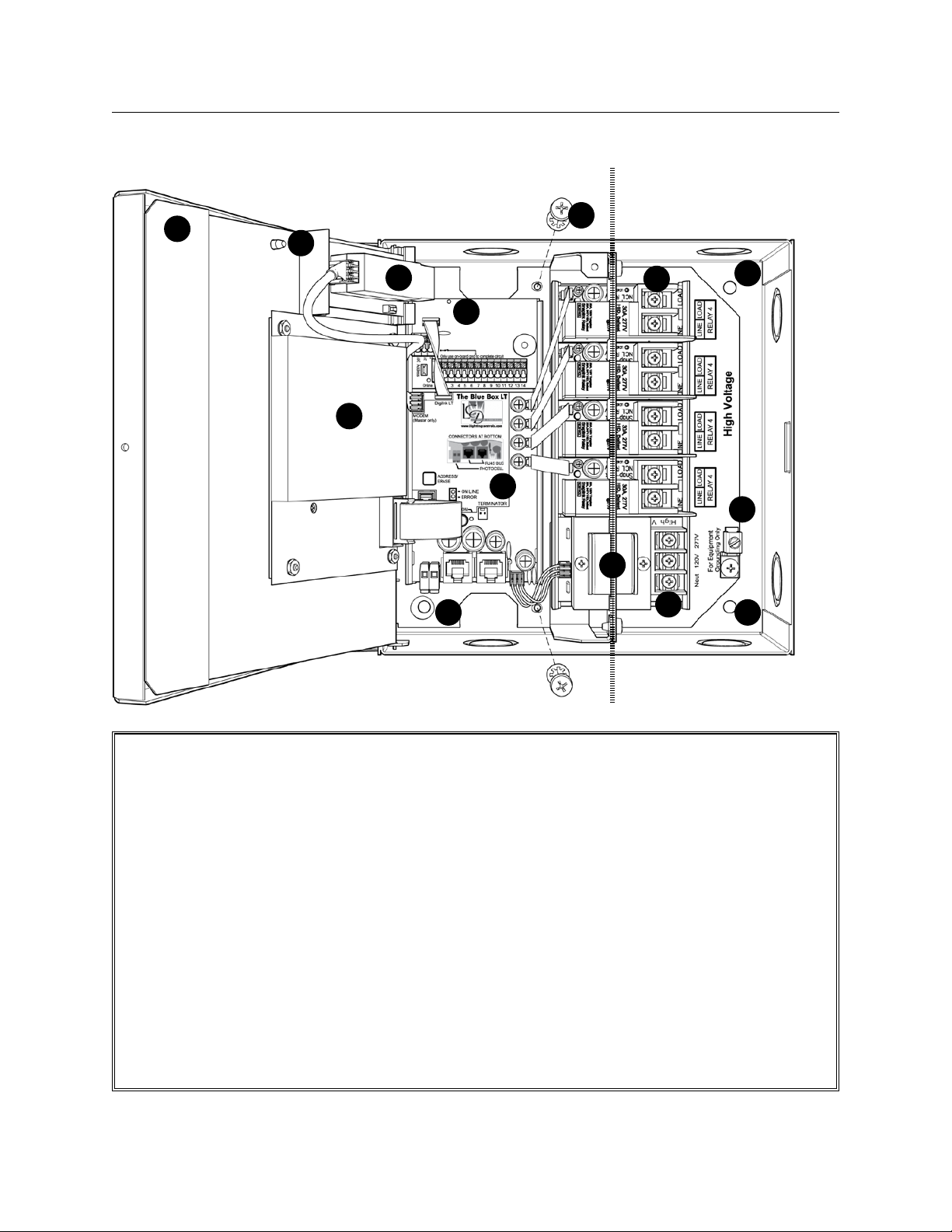

GR1404/08 LT (WHITE DOOR OPEN)

Screw fastener secures hinged Control Panel 1.

Door (Master only).

White door provides barrier between human 2.

interface and line voltage connections beneath

(Master only).

Optional Modem. Free factory dial-up programming.3.

Optional DI contact closure interface card.4.

Ø1/4" mounting holes at 4 places.5.

Optional: Unfasten two screws to remove chassis 6.

assembly from enclosure providing full access to

mounting holes if required.

SnapLink7.

LED is ON when relay is OFF.

DTC Clock / Display & Programming Interface: 8.

™

relays, Normally-Closed (NC). Status

32-channel, 365-day astronomical clock with

Scroll and Tab to access control features for entire system (Master only).

Voltage barrier separates line voltage (class 1) & 9.

low (class 2) connections.

Dual Voltage Power Supply Input: Blue Box LT10.

operates on either 120V or 277V.

Ground Lug for equipment grounding.11.

Relay Control Card provides interface between 12.

control network and relays. The Relay Control

Card in the Master panel also holds time schedules and system mapping.

™

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 9

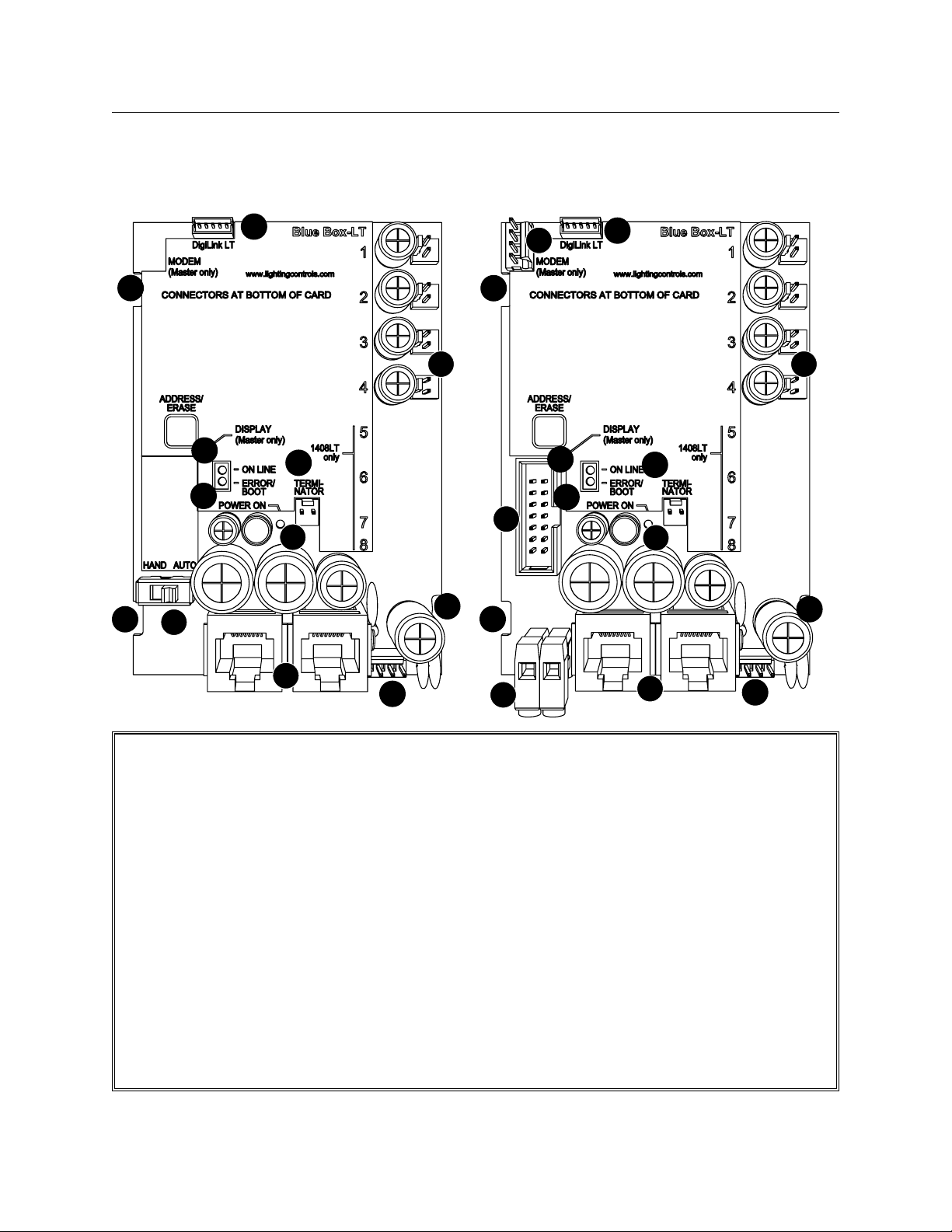

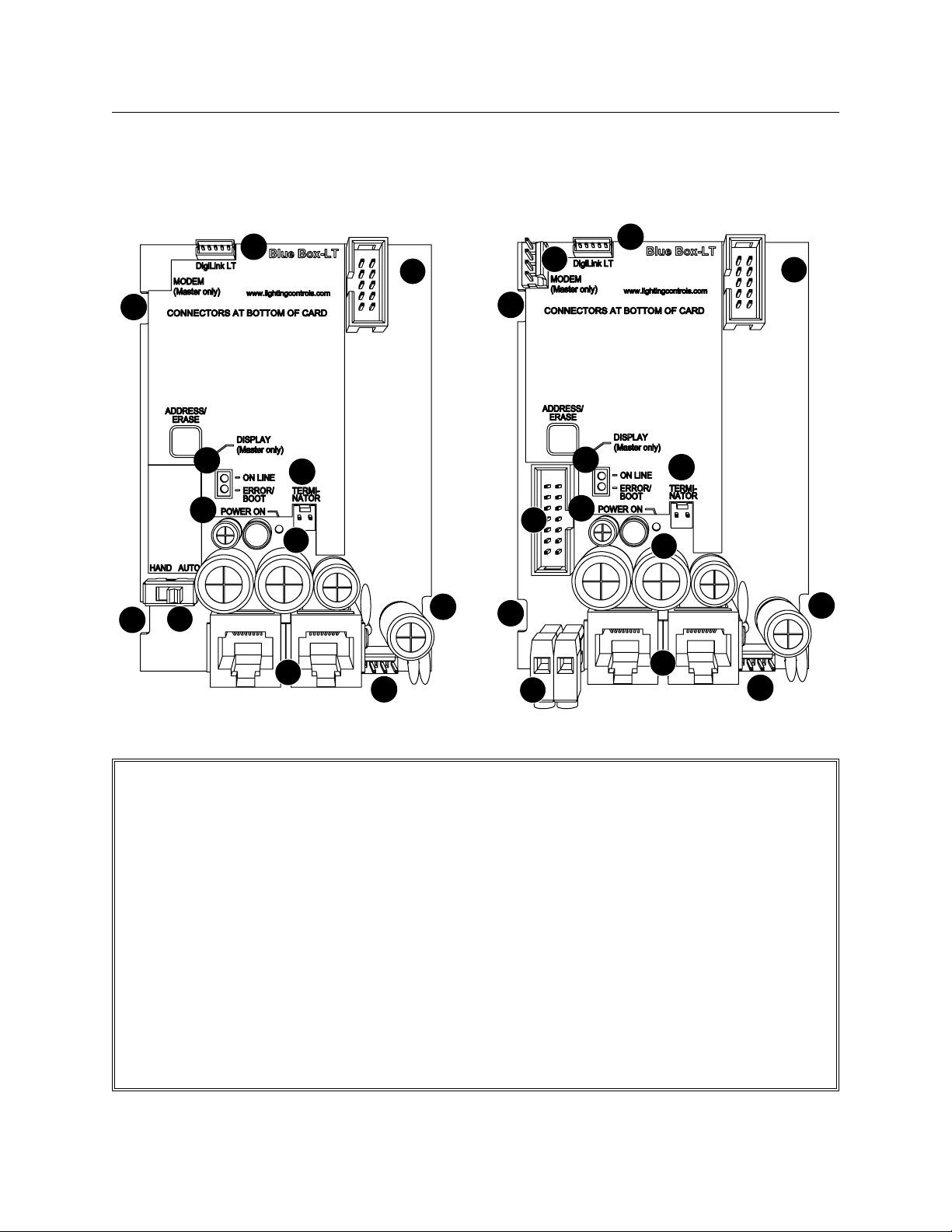

GR1404/08 SLAvE PANEL RELAY CONTROL CARD

4

7

1

9

11

8

10

7

7

12

GR1404/08 MASTER PANEL RELAY CONTROL CARD

5

4

7

1

9

11

8

6

10

7

7

LCDBBO03Sept08

2

13

Relay Drivers. Opto-isolated to prevent line volt-1.

age back-feed and to help prevent RF and EMF

noise interference. Relay drivers will close latching

relays upon loss of power to the Control Card.

RJ45 sockets for digital bus. Digital devices (relay 2.

panels, digital switches, etc) connect to this panel

using a bus (daisy-chain) topology.

Photocell port (master panel only). +V output 3.

with a photocell input. Photocells are polarized follow color code.

Power/data connector for DI Card.4.

Power/data connector for modem (master panel).5.

Power/data connector for DTC clock/display 6.

(master panel only).

Removal slots for control card. Used with a flat 7.

blade screw driver to remove the Control Card.

3

Terminator pins. Add terminator here if this is the 8.

first or last item on a bus (follow the “System

Start-Up & Cabling Guide”).

Online LED indicates the communications mi-9.

cro-processor is functioning, not that the panel

can see the digital bus.

Power ON LED indicates the control card is re-10.

ceiving power from the transformer and has successfully converted it to DC.

Error/Boot LED. Flashes continuously if system 11.

failed to boot.

Hand/Auto Switch (slave panel only). In Auto 12.

mode, relays will react to schedules and switches.

In Hand mode, relays will remain closed.

Power input from transformer.13.

2

13

10 THE BLUE BOX LT OVERVIEW

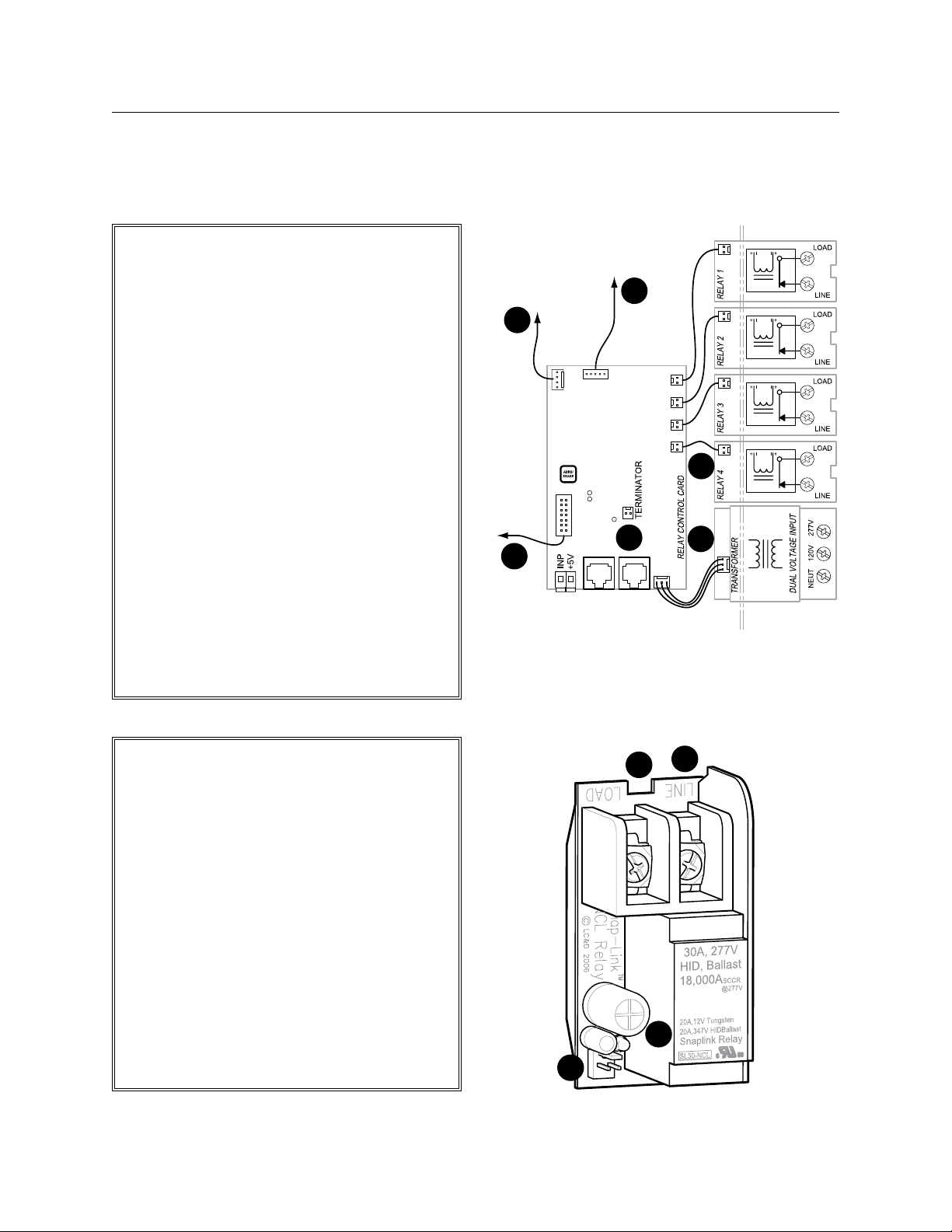

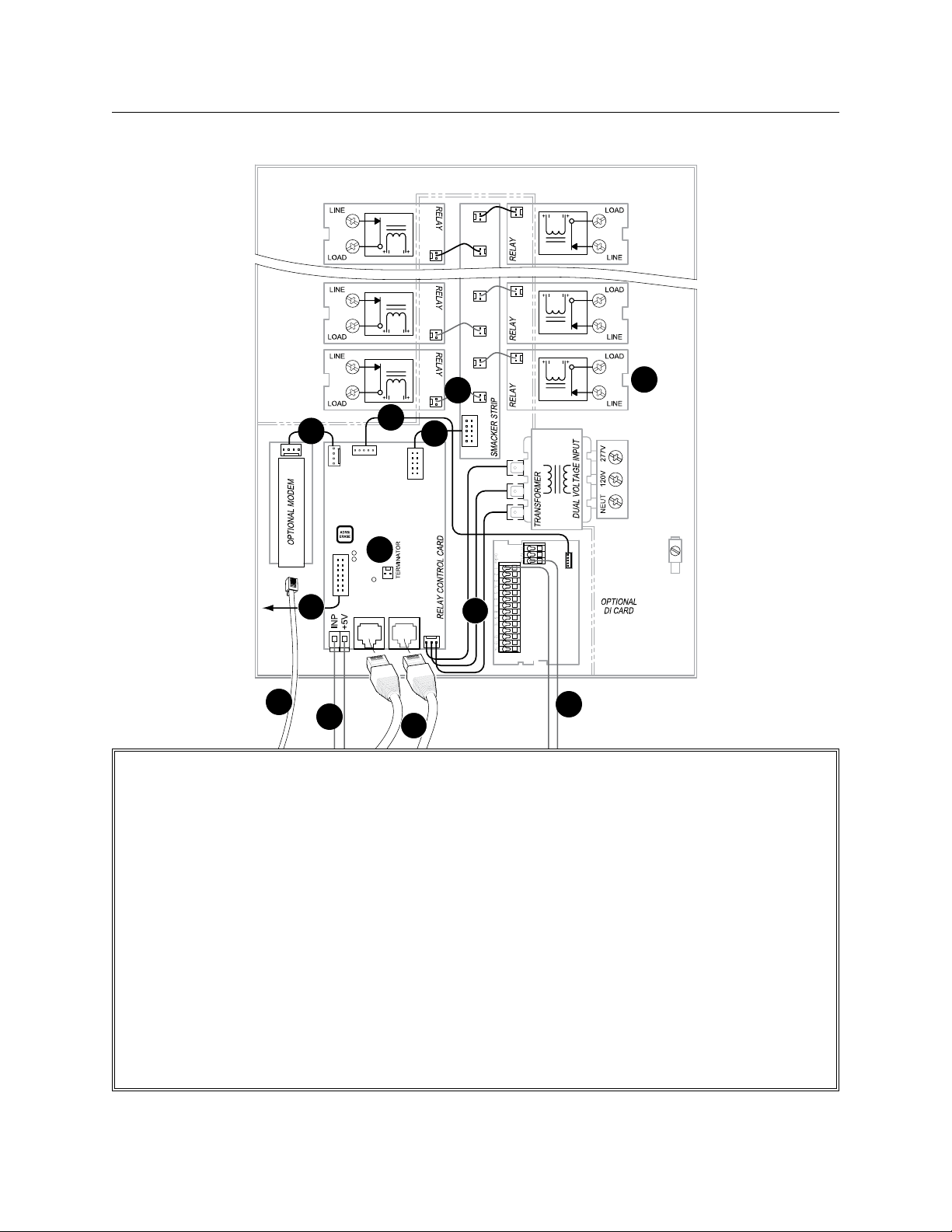

BLUE BOX LT 1404/1408

INTERNAL SCHEMATIC

3#18 AWG. Supplies power from trans-1.

former to relay control card.

14 conductor ribbon cable: carries control 2.

signal between DTC and relay control card

(master panel only).

2 conductor ribbon cable: carries control 3.

signal from smacker strip to relays - one

per relay.

5 conductor ribbon cable: carries digital 4.

signal from relay control card to (optional)

digital input card.

4#22AWG carries RS-232 signal from 5.

(optional) modem to relay control card

(master panel only).

Terminator pins. Add terminator here if this 6.

is the first or last item on a bus (follow the

“System Start-Up & Cabling Guide”).

For more information about external hook-ups,

refer to GR 1404 LT Installation Guide.

To optional

Modem

master panels

only

5

To DTC

2

To optional

DI Card

4

6

3

1

RELAY OvERvIEW

Low voltage connector.1.

Status indicator LED.2.

Quick removal slot.3.

High conductivity terminal block.4.

SnapLink

ing (NCL), UL listed for 30 amps lighting (ballast,

HID) at 277v, 20 amps at 347v and 20 amps

Tungsten at 120v, 18,000 amp SCCR at 277v,

rated 250,000 on/off cycles, 3 yr. warranty.

™

Latching Relay: Normally closed latch-

1

3

4

2

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 11

GR1416LT DRAWINGS & DETAILS

1

2

LCDBBO03Sept08

1

3

4

GR1416 LT (FRONT DOOR OPEN)

Screw fastener secures hinged Control Panel Door (Master only).1.

Hinged Door Panel provides a barrier between Control Interface and High Voltage connections beneath 2.

(Master only).

NEMA 1 surface mount enclosure with hinged door and key lock; Ø1/4" mounting holes at 4 places 3.

(hardware not included).

DTC Clock / Display & Programming Interface: 32-channel, 365-day astronomical clock with Scroll and Tab 4.

to access control features for entire system (Master only).

12 THE BLUE BOX LT OVERVIEW

1

1

2

8

6

3

9

4

11

6

9

7

6

10

5

GR1416 LT (WHITE DOOR OPEN)

Screw fastener secures hinged Control Panel 1.

Door (Master only).

Hinged Door Panel provides a barrier between 2.

Control Interface and High Voltage connections

beneath (Master only).

Optional Modem. Free factory dial-up programming3.

Optional DI contact closure interface card.4.

NEMA 1 surface mount enclosure with hinged 5.

door and key lock; Ø1/4" mounting holes at 4

places (hardware not included).

Optional: Unfasten three screws to remove chas-6.

sis assembly from enclosure providing full access

to mounting holes if required.

SnapLink7.

LED: ON when relay is OFF (NC).

DTC Clock / Display & Programming Interface: 8.

32-channel, 365-day astronomical clock with

Scroll and Tab to access control features for en-

.

tire system (Master only).

Voltage barrier separates low & line voltage con-9.

nections.

Dual Voltage Input: Blue Box LT10.

ther 120V or 277V.

Ground Lug for equipment grounding.11.

™

relays, Normally-Closed (NC). Status

™

operates on ei-

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 13

GR1416 LT SLAvE PANEL RELAY CONTROL CARD GR1416 LT MASTER PANEL RELAY CONTROL CARD

7

7

12

11

9

4

2

10

8

13

1

7

7

7

3

6

5

11

9

4

1

8

10

7

2

13

LCDBBO03Sept08

Relay Drivers connect to Smacker Strip. Relay 1.

drivers will close latching relays upon loss of

power to the Control Card.

RJ45 sockets for digital bus. Digital devices (re-2.

lay panels, digital switches, etc) connect to this

panel using a bus (daisy-chain) topology.

Photocell por t (master panel only). +V output 3.

with a photocell input. Photocells are polarized

- follow color code.

Power/data connector for DI Card.4.

Power/data connector for modem (master panel).5 .

Power/data connector for DTC clock/display 6.

(master panel only).

Removal slots for control card. Used with a flat 7 .

blade screw driver to remove the Control Card.

Terminator pins. Add terminator here if this is 8.

an end-of-bus panel (per “System Star t-Up &

Cabling Guide”).

Online LED indicates the communications mi-9.

cro-processor is functioning, not that the panel

can see the digital bus.

Power ON LED indicates the control card is 10.

receiving power from the transformer and has

successfully converted it to DC.

Error/Boot LED. Flashing constantly if card can-11.

not boot on start up.

Hand/Auto Switch. (slave panel only) In Auto 12.

mode, relays will react to schedules and switches. In Hand mode, relays will remain closed.

Power input from transformer.13.

14 THE BLUE BOX LT OVERVIEW

3

5

6

4

7

2

8

9

GR1416 LT (DOOR OPEN) INTERNAL SCHEMATIC

3#18 AWG. Supplies power from transformer 1.

to relay control card.

14 conductor ribbon cable: carries control signal 2.

between DTC and relay control card (master

panel only).

2 conductor ribbon cable: carries control signal 3.

from smacker strip to relays - one per relay.

10 conductor ribbon cable: carries digital signal 4.

from relay control card to smacker strip.

5 conductor ribbon cable: carries digital signal 5.

from relay control card to (optional) digital input

card.

4#22 AWG carries RS-232 signal from (optional) 6 .

modem to relay control card (master panel only).

10

12

1

11

Terminator/terminator pins to terminate bus line.7.

External Connections

4#24 flat cable from modem to analog phone 8.

jack. Always note phone number of modem.

2#18 AWG to Blue Box photocell. Up to 300 feet.9.

Cat. 5 cable with RJ45 connectors links Blue Box 10.

to other digital devices (other blue box panels or

digital switches).

Contact closure inputs & DI card common 11.

“GND” + 1 #18 per input.

Line and load relay lugs.12.

For information about cabling for contact closure

switches or occupant sensors. Refer to DI Card

Installation Guide for options and details.

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 15

INTRODUCTION TO THE BLUE BOX™ LT SERIES

The only panel you will ever need for small to medium projects - quicker to install than traditional lighting contactors and

much easier to configure. The Blue Box™ LT Series is UL Listed and complies with every energy code in the USA.

LCDBBO03Sept08

16 THE BLUE BOX LT OVERVIEW

THE BLUE BOX™ LT vS. LIGHTING CONTACTORS

SMART RELAY PANEL

The Blue Box™ LT Series is the only panel you will ever

need for small to medium projects.

It is quicker to install than traditional lighting contactors as

well as more flexible.

With purchase of the optional modem you receive free

lifetime dial-up programming support from the factory.

Or you can connect remotely using our free software.

The Blue Box™ LT is part of the GR 2400 lighting control

system, from LC&D.

Control up to 16 devices.

DITCH THE OLD WAY OF DOING THINGS

Traditional lighting contactor panels require an electrical-mechanical assembly specific to the job at hand. This

means parts and pieces must be field-assembled and

field-programmed.

Any programming or hard-wire changes made to lighting

contactor panels require you to go back to the site.

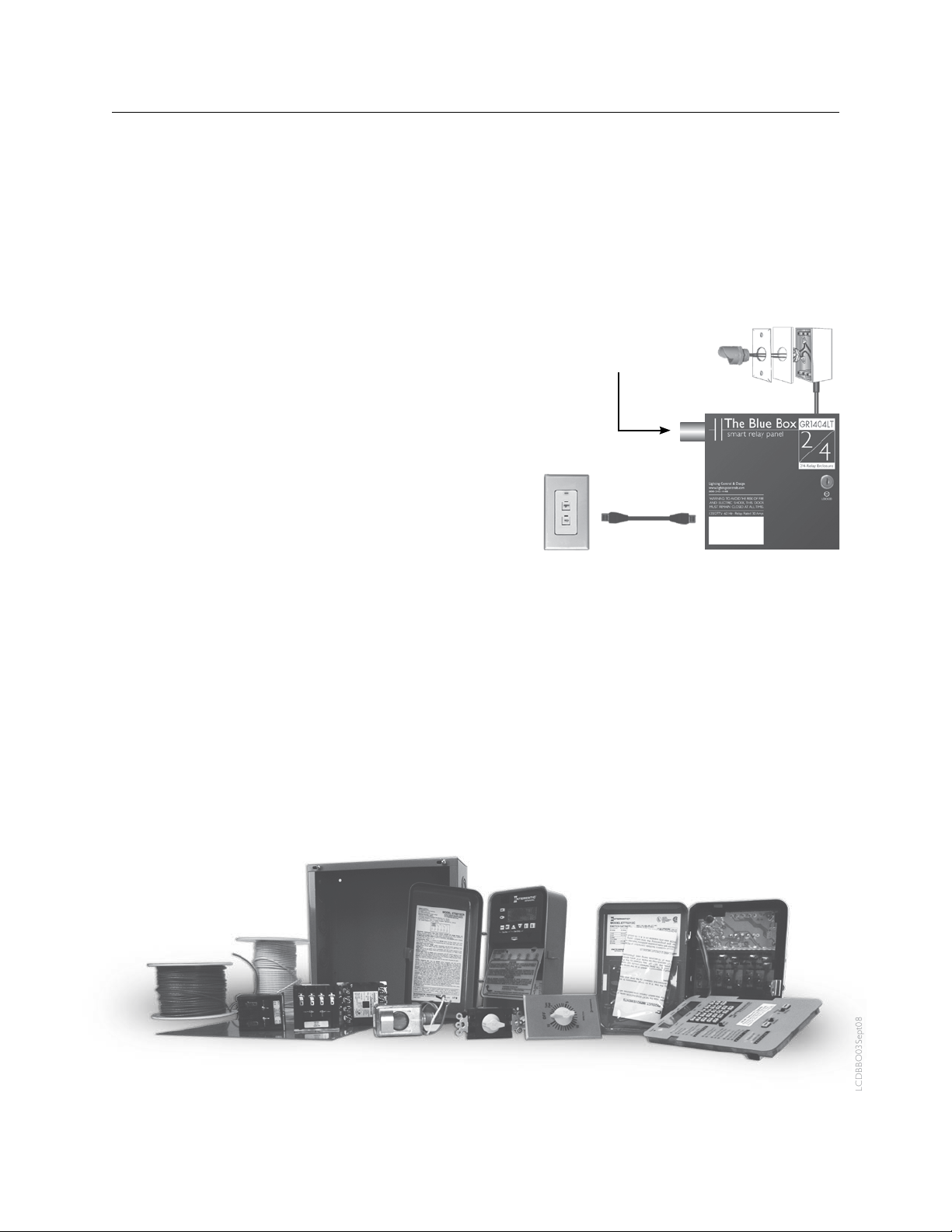

Outdoor Photocell

Breaker Panel

Digital Override Switch

Master Relay Panel

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 17

BUILD YOUR SYSTEM IN 3 STEPS

Every system must have a Master Panel which contains

the clock and photocell inputs and connections for the

optional modem.

STEP 1: MASTER PANEL

How many circuits (relays) do you need to control? (See

pgs. 6-7 for enclosure sizes).

Do you need a modem for remote dial-up programming?

(See pg. 10, “Modem”).

Do you need inputs for occupant sensors, or contact closure switches? (See pg. 10, “Digital Input Card”)

Each system needs one master panel. Use one Blue Box

for each electric room you are controlling lighting circuits in.

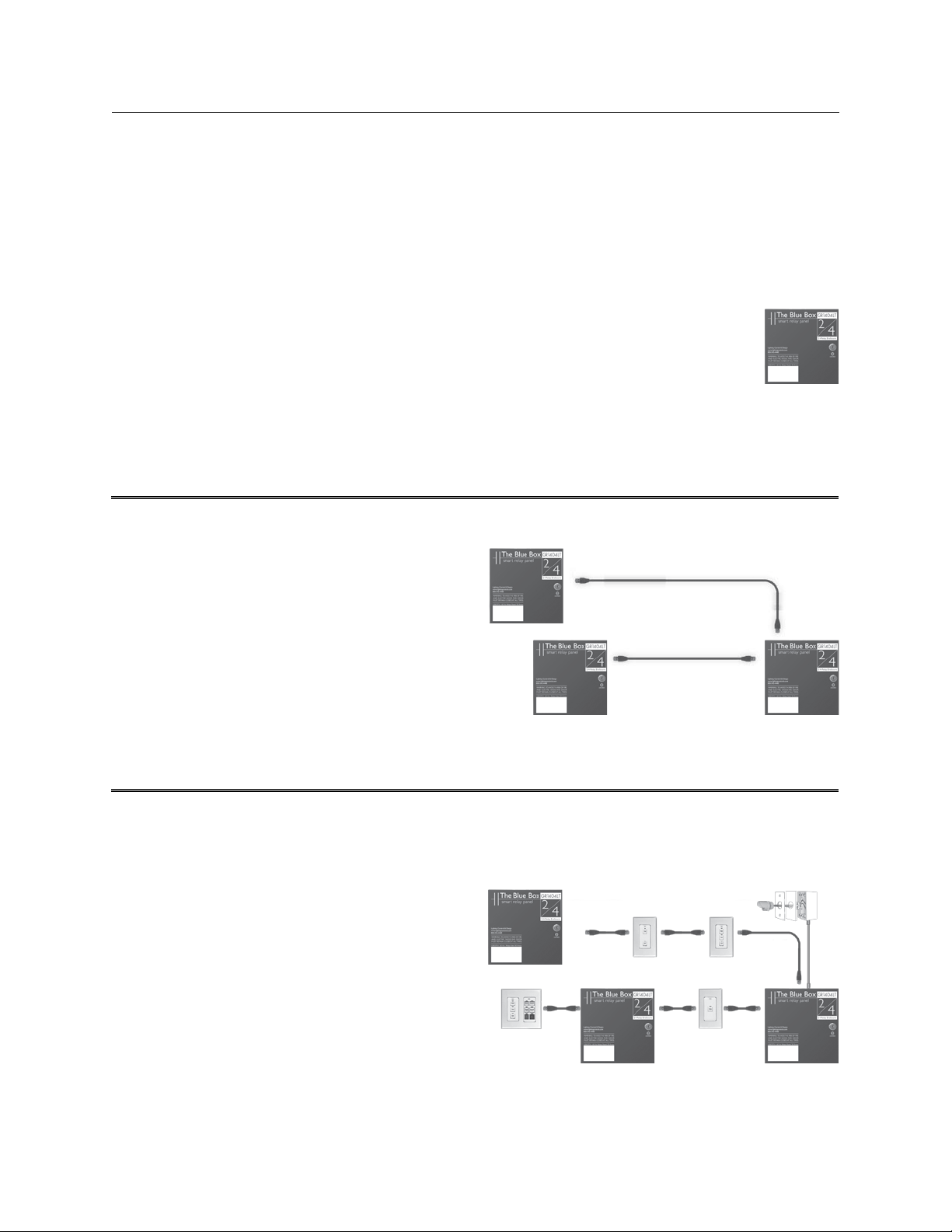

Slave Relay Panel

Master Relay Panel

™

STEP 2: SLAvE PANELS

For each additional Blue Box™ LT, how many circuits (relays) do you need to control? (See pgs. 6-7).

™

For each additional Blue Box

puts for occupant sensors, or contact closure switches?

(See pg. 10, “Digital Input Card”)

Up to 16 panels and switches may be controlled on the bus.

LT Series, do you need in-

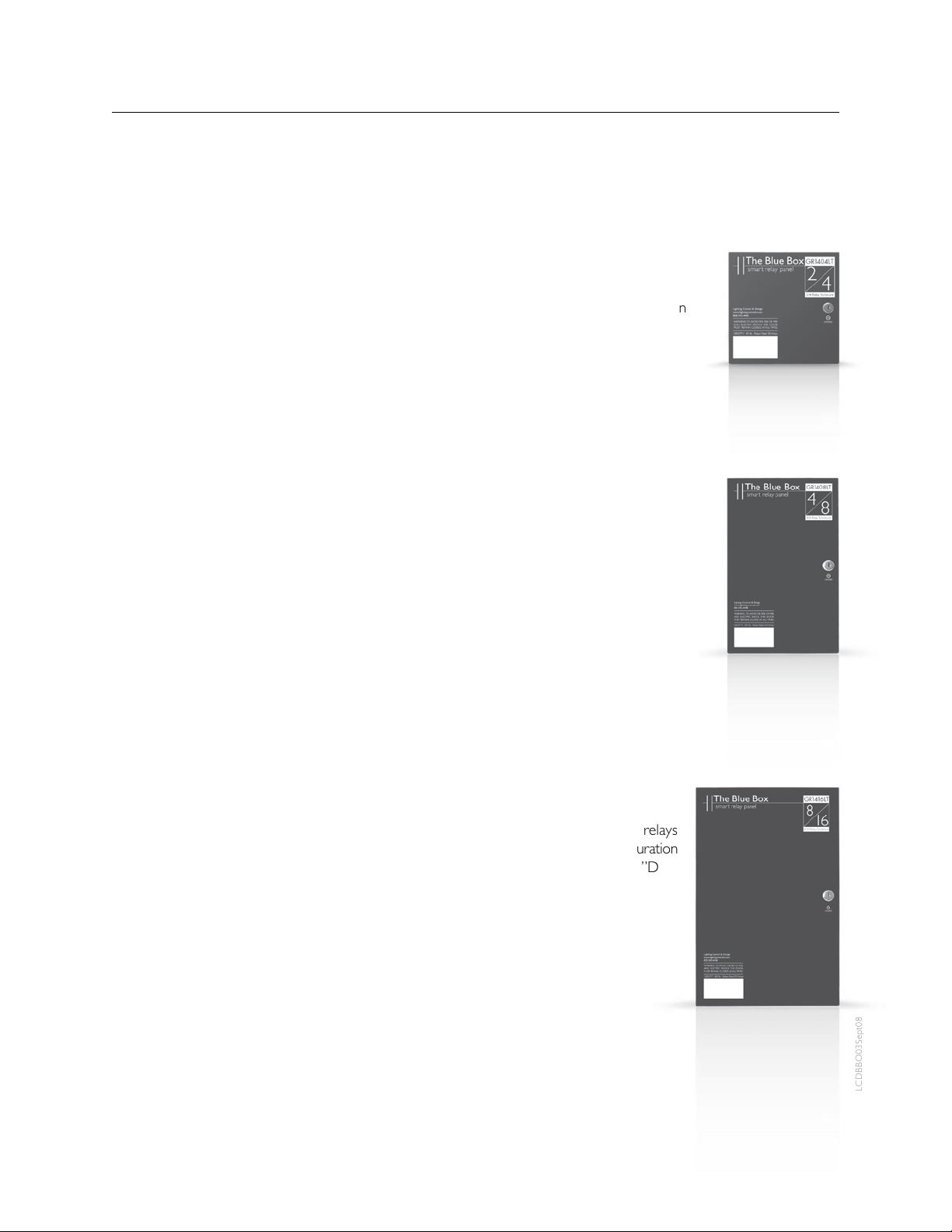

STEP 3: SWITCHES, OUTDOOR PHOTOCELLS &

ACCESSORIES

How many override switches do you need?

How many buttons on each switch? (1 to 6 buttons cost

the same).

Will you need a photocell to supplement the DTC astro-

LCDBBO03Sept08

nomical clock? (See pg. 10, “Digital Photocell”).

Add other accessories as shown on pages 10-11.

Control up to 16 devices.

Slave Relay Panel

Slave Relay Panel

Chelsea

Digital Switch

Master Relay Panel

Outdoor Photocell

Slave Relay Panel

Master

Relay Panel

18 THE BLUE BOX LT OVERVIEW

3 ENCLOSURE SIzES

DESIGNING WITH LIMITED SPACE?

The Blue Box™ LT Series comes pre-assembled and ready

for installation in three compact enclosure sizes!

This 100% digital panel can be programmed to operate

any lighting scenario and is equipped with a number of

accessory devices:

Easy energy code compliance•

277V, 30a relays UL Listed for 18,000 SCCR•

Competitively priced against lighting contactors •

and astronomical or multi-channel clocks

Digital Switches can turn relays on or off or over-•

ride time schedules for energy code compliance

Our simple, intuitive network connects multiple •

panels and switches using Cat. 5 with RJ45s

Panels can share the same time schedules and •

photocell

Additional relays can be purchased for partially •

filled panels.

Hinged locking door•

GR1404LT

Shipped with 2 or 4 relays•

Master or slave configuration•

8.4”H x 8.4”W x 3”D•

GR1408LT

Shipped with 4 or 8 relays•

Master or slave configuration•

13.4”H x 8.4”W x 3”D•

GR1416LT

Shipped with 8 or 16 relays•

Master or slave configuration•

17.1”H x 10.6”W x 3”D•

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 19

2 PANEL CONFIGURATIONS

MASTER RELAY PANEL

Each system needs one master panel equipped with: DTC

clock/programmer. Program schedules, switches and photocells for multiple panels.

365-day/7-day/astronomical 32 channel clock•

Plain English command prompts•

Non-volatile memory for all programming, 10 year •

battery back-up for time of day

Photocell Input: One photocell can control any relay in

any panel.

Optional modem and Digital Input Card (See pgs. 10-11,

“Accessories”).

Control up to 16 devices.

SLAvE RELAY PANEL

The slave panel is a fully programmable panel that networks to the DTC, modem, and photocell from the master panel.

No DTC, photocell input, or modem is required in a slave

panel, as it uses the master panel.

Option: Digital Input Card allows dry-contact closure

switches to control any relay in any panel – wall switches,

momentary switches, occupant sensors or any other dry

contact switch

(See pgs. 10-11, “Accessories”).

Master Relay Panel

Modem for remote programming

Optional Hand/Auto Switch

DTC clock/programmer

• 32 channel 365 day, 7

day astronomical clock

• Programming access for

time schedules, switches,

photocell etc.

• Large format screen

Slave Relay Panel

Lighting relays:

• 30A @ 277V Ballast

• 20A @ 120V Tungsten

• 20A @ 347V Ballast

• SCCR 18,000 Amps

Power supply:

• 120V/277V

RJ45s inputs for digital bus

LCDBBO03Sept08

Chelsea Digital SwitchChelsea Digital Switch

Master Relay Panel Slave Relay Panel

20 THE BLUE BOX LT OVERVIEW

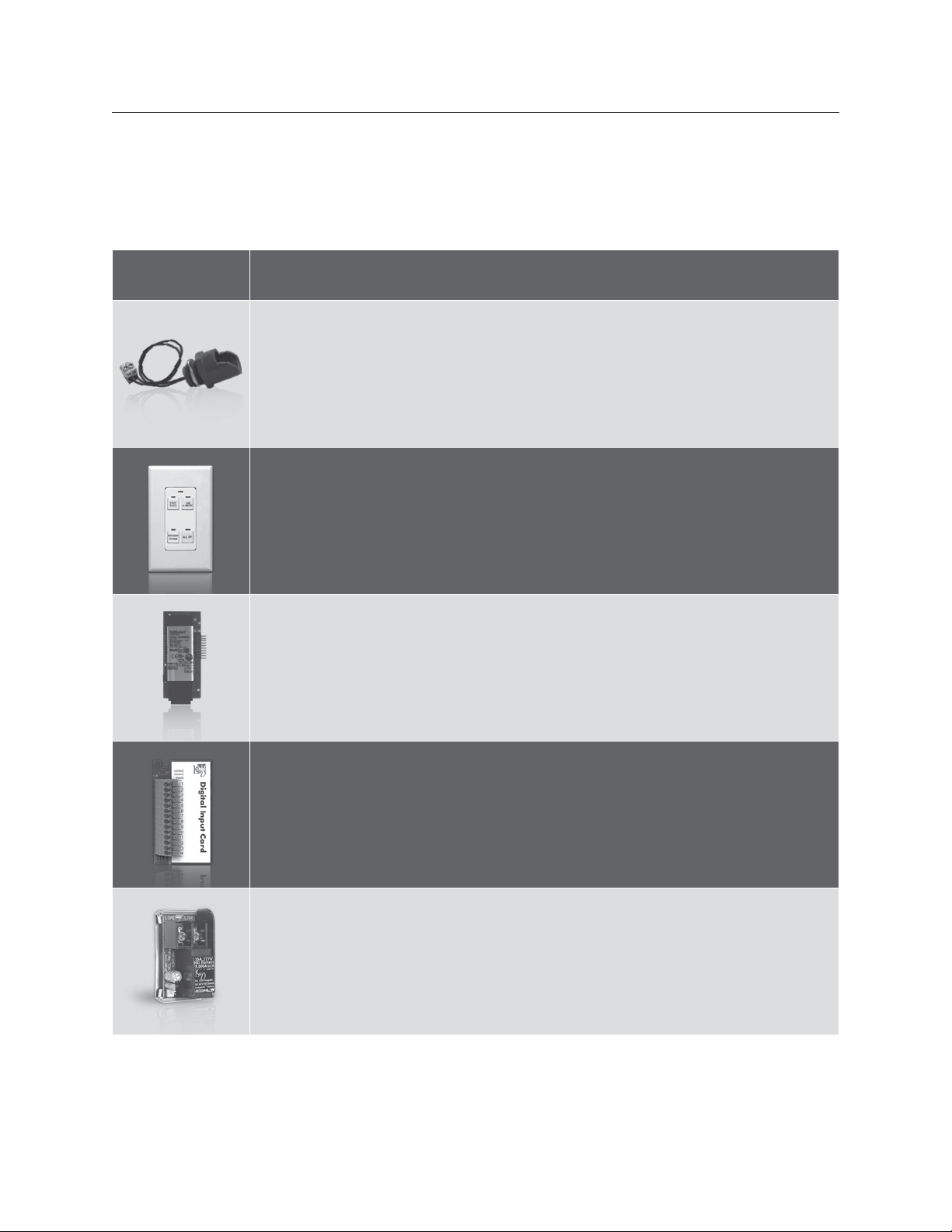

MOST POPULAR ACCESSORIES

These represent the most popular LC&D accessories. For a complete list of accessories refer to the LC&D Catalog.

Product: Description:

Digital Outdoor Photocell (PCO): Connects to the master panel. Recommended for stormy

regions (where it may darken early) to supplement the astronomical clock.

Product Code: PCO

Chelsea Digital Switch: With 1, 2, 3, 4 and 6 buttons and free factory engraving. Ideal for override of automatic controls and manual control of lighting. Link with Cat. 5 cable with RJ45s.

Product Code: CH-1, 2, 3, 4 and 6

Modem: Allows you to make changes to the Blue Box™ LT remotely over dial-up. Or call our

technical support line and have us do it for you (for free) for the life of the system.

Product Code: MOD

Digital Input Card: Plugs into master or slave panels. For projects that require non-digital

switches, including: standard wall switches, center-off momentary switches, occupant sensors,

or any dry-contact closure. DI 6 inputs may be enabled / disabled over the bus.

Product Code: DI 6 or DI 14

SnapLink™ Latching Relay: Normally closed latching (NCL), UL listed for 30 amps lighting

(ballast, HID) at 277v, 20 amps at 347v and 20 amps Tungsten at 120v, 18,000 amp SCCR at

277v, rated 250,000 on/off cycles, 3 yr. warranty.

Product Code: SLNC or SLNO

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 21

The accessories below may not be available as a stocking product, but can be ordered.

Product: Description:

SwitchBolt: One or two vandal resistance buttons per gang. Switches can be mounted outdoors or almost any location.

Product Code: SB-1 or 2

Link-To PC/Ethernet: Connect multiple computers to the GR 2400 system from any RS232,

USB port or an ethernet network connection.

Product Code: L2-PC

LCDBBO03Sept08

Occupant Sensors: A full line of sensors. One sensor can control any relay(s) in any panel(s).

Occupant sensors require a Digital Input Card.

Product Code: (Contact LC&D factory)

Digital Rocker Switch: Looks like a regular decora style switch; operates like a 2-button digital

switch.

Product Code: RS

Digital Thermostats/T-Link: A single T-Link card can control up to 32 digital thermostats (heatpump or multi-stage).

Product Code: T-LINK (Contact factory for T-STAT ordering.)

22 THE BLUE BOX LT OVERVIEW

APPLICATIONS

See how easy it is to design and install the Blue Box™ LT in

different applications. We stand behind each of our products with a 3 year warranty.

SMALL PARkING LOT (SINGLE CONTROL PANEL)

Select a master panel with the correct number of relays.

The DTC astronomical clock does the rest. Order an outdoor photocell (PCO) as a back up for stormy days (not

required for code compliance).

GR1408LT master was compared to a equivalent

assembly of lighting contactors and a multi-channel astronomical clock. The Blue Box

less expensive than the lighting contactors!

Outdoor Photocell

Master

Relay Panel

™

LT was 50%

RETAIL STORES (WITH 6 OvERRIDE zONES)

Separately zone lighting circuits to comply with local

codes, and use the DTC clock to schedule the off-sweeps.

A multi-button digital switch is the override and manual

control, and complies with energy codes.

Master Relay Panel

Digital Override Switches

The Blue Box™ LT was compared to similar package of (4) 2-pole lighting contactors, a multichannel clock and twist-timers: The Blue Box™ LT

Series was 60% less expensive than the lighting

contactors!

LCDBBO03Sept08

THE BLUE BOX LT OVERVIEW 23

APPLICATIONS (Continued)

How Does the Blue Box™ LT Series Stack-up? In a nationwide survey of Electrical Contractors, the cost to

purchase and field-assemble lighting contactor panels was

compared to the cost of the Blue Box™ LT Series.

WAREHOUSE (MULTIPLE CONTROL PANELS)

Locate multiple Blue Box™ LT panels and digital switches

where you need them and then link them with Cat. 5 cable.

One Blue Box™ LT master (with a Digital Time Clock

(DTC) can control relays in multiple slave panels and digital switches (up to 16 digital devices).

Digital switches are used for manual control and afterhours override.

A photocell can be used as back up for outdoor lighting, or

even as a simple daylight harvesting system for skylights.

Check your local codes for how large an area each switch

can override.

If you are unsure, visit www.lightingcontrols.com for a free

code excerpt for your state.

Slave Relay Panel

Slave Relay Panel

Chelsea

Digital Switch

The Blue Box™ LT Series system shown above was

compared to multiple lighting contactor panels

(each with a multi-channel clock), manual switches,

twist-timers, and photocells.

The Blue Box™ LT Series was 64% less expensive!

Outdoor Photocell

Master

Relay Panel

LCDBBO03Sept08

24 THE BLUE BOX LT OVERVIEW

BLUE BOX TECHNICAL SUPPORT

AFTER-MARkET SUPPORT

The Blue Box™ LT Series comes with LC&D’s top-notch

customer suppor t and, when connected to a phone line,

includes free lifetime dial-up programming.

Make changes to the Blue Box™ LT Series remotely (with

purchase of a modem) over dial-up. Or call our Technical

Support line and have us do it for you (for free) for the

life of the system.

DITCH THE OLD WAY OF DOING THINGS

Traditional lighting contactor panels require an electrical-mechanical assembly specific to the job at hand. This

means design, parts/pieces and assembly time. Any customer changes require re-wiring and re-assembly.

LIGHTING CONTROL & DESIGN

905AllenAve•Glendale,CA91201•Support800-345-4448•www.lightingcontrols.com

LCDBBO03Sept08

MAINTENANCE

& TROUBLESHOOTING

MAINTENANCE & TROUBLESHOOTING

Making Up Cat. 5 with RJ45 Connectorsa)

Adding a New Deviceb)

Parts Replacement Guidec)

Hardware Troubleshootingd)

LCDBBO&M03Sept08

LCDBBO&M03Sept08

®

™

THE BLUE BOX

LT

MAKING UP CAT.5

CABLE WITH RJ45

CONNECTORS

LCDBBMUCAT03Sept08

®

Lighting Control & Design

905 Allen Ave, Glendale CA 91201

•

Tel: 800-345-4448

www.lightingcontrols.com

28 THE BLUE BOX LT MAKING UP CAT. 5 CABLE WITH RJ45 CONNECTORS

TABLE OF CONTENTS

Introduction .......................................................................................29

Ethernet Network ................................................................................29

The GR 2400 Bus and RS485 Communications Protocol................................................30

Cable and Crimping Quality .......................................................................31

The Importance of a Proper Crimp..................................................................31

Type of Wire .....................................................................................31

The Ideal Scene: Professionally Made Commercial Cables ...............................................32

Reasons Why It’s Hard to Make Good Crimps on RJ45s ............................................33

Solid Wire is Ductile...............................................................................33

The Right Crimping Tool ...........................................................................33

The Right Modular Connector ......................................................................34

How to Make Proper Crimps ......................................................................35

Sequence of Actions ..............................................................................35

Miscellaneous Information .........................................................................37

Cable Kinks ......................................................................................37

Dirty RJ45 Sockets ................................................................................37

Summary ........................................................................................38

Stable Datums on Crimping Cat. 5...................................................................38

LCDBBMUCAT03Sept08

THE BLUE BOX LT MAKING UP CAT. 5 CABLE WITH RJ45 CONNECTORS 29

INTRODUCTION

All Lighting Control & Design systems use Cat. 5 cable with

RJ45 connectors to network devices. While both our system & Ethernet networks use Cat. 5 cabling, there are huge

differences between the two (Note: Cat. 6 is often substituted for Cat. 5. Our system accepts either type of cable.)

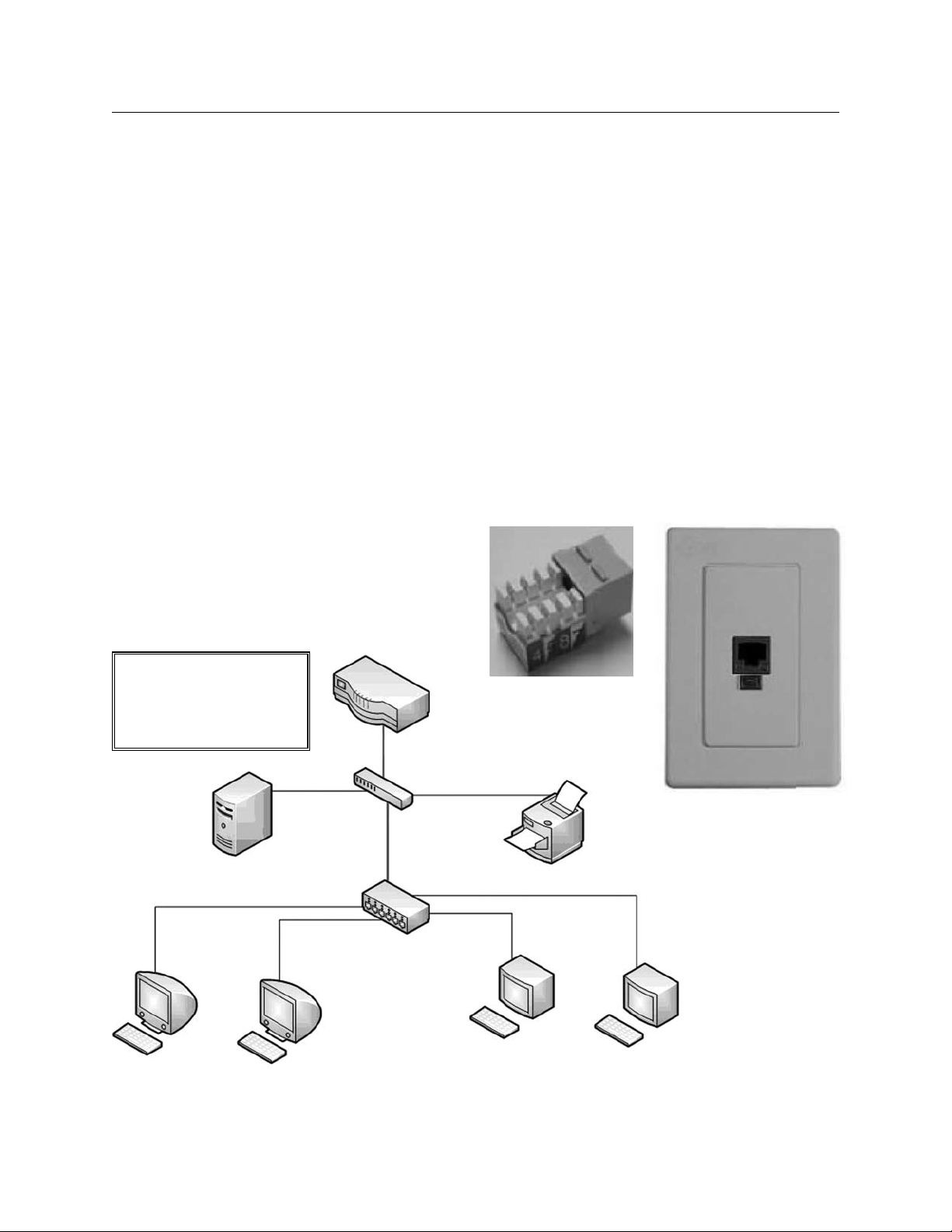

ETHERNET NETWORk

Typically Ethernet networks have multiple devices connected to a central point, this design scheme is called a

star topology (Figure 1.1 illustrates a multi-level star topology). In this example, the four workstations are connected directly to a switch/hub, which is connected to another

star to access either the file server, printer or router.

The hub/switch receives the data sent by the four workstations; upon receipt of the data, the hub/switch checks

the data for errors and re-transmits to another switch to

access the other devices on the network. The data travels

only one section of the cable before it gets cleaned up or

repeated and forwarded to another point. Thus any incon-

Figure 1.1 - Typical Ethernet Network Setup

Ethernet uses Cat. 5 cables,

each cable does not exceed

100 meters (330ft).

Router

sistent quality in the Cat. 5 cable or crimp will not severely

impact this network’s stability. It may slow the data transmission on one leg of the network, but not as to affect the

other nodes on the network.

In an Ethernet network, one cable is connected to the

switch, workstation, printer, etc. and terminated at a jack

socket in the wall (Figure 1.2a and 1.2b). This socket has

insulation displacement connections, which do not require

crimping. The cable from the wall socket to the device is

typically a factory-manufactured cable. These cables use

flexible stranded wires and crimps made on pneumatic

crimping machines, which exert several hundred pounds

of pressure to ensure an excellent crimp.

Figure 1.2a: Insulation

Displacement Socket

LCDBBMUCAT03Sept08

Switch

File Server

Switch/Hub

Workstation 1 Workstation 2 Workstation 3 Workstation 4

Printer

Figure 1.2b

30 THE BLUE BOX LT MAKING UP CAT. 5 CABLE WITH RJ45 CONNECTORS

INTRODUCTION (Continued)

THE GR 2400 BUS AND RS485

COMMUNICATIONS PROTOCOL

LC&D devices communicate using a method known simply as half duplex RS485. This data communication method uses one twisted pair of the stranded Cat. 5 cable to

transmit data; and the other three pairs to carry power to

the switches.

All devices are connected in a single line (or bus). This

RS485 network allows multiple items on a bus to be connected in parallel, also called “Daisy Chain” wiring.

Each item on our system has two RJ45 jacks that allow the

cabling to come in on one side and go out the other.

To illustrate the “daisy chain” method, Figure 1.3 shows a

diagram of an LC&D GR2400 lighting control system.

One can see how a bad connection, say at the digital

switch, can prevent communication from the Master Panel

/DTC from reaching the rest of the bus.

Small imperfections in the Cat. 5 cable crimps tend to be

the most common “bad connections.”

Though a single imperfection may only slow down the

communication by a small margin it gets multiplied up

over the length of the chain.

RJ45 connectors simplify the wiring and connections of

our system, but the impor tance of having a good crimp

is paramount.

Figure 1.3

Uplink

™

Card

GR 2400

™

Master Panel

Chelsea

DigitalSwitch

GR 2400™ Slave Panel

MicroPanel

™

SmartBreaker

™

GR 2400 Master Panel GR 2400 Slave Panel SmartBreaker Panel

™

Panel

LCDBBMUCAT03Sept08

Loading...

Loading...