Lighthouse Remote 3014PN, Remote-4 PN, Remote 3104PN, Remote 5014PN, Remote 5104PN Operating Manual

00

Lighthouse Worldwide Solutions

REMOTE-4 PN Series Airborne Particle Counter

Operating Manual

Copyright © 2007-2014 by Lighthouse Worldwide Solutions. All rights reserved. No part of this

document may be reproduced by any means except as permitted in writing by Lighthouse

Worldwide Solutions.

The information contained herein constitutes valuable trade secrets of Lighthouse Worldwide

Solutions. You are not permitted to disclose or allow to be disclosed such information except as

permitted in writing by Lighthouse Worldwide Solutions.

The information contained herein is subject to change without notice. Lighthouse Worldwide

Solutions is not responsible for any damages arising out of your use of the LMS program.

REMOTE 3014PN™, REMOTE 5014PN™, REMOTE 3104PN™, REMOTE 5104PN™ and

LMS™ are trademarks of Lighthouse Worldwide Solutions.

Microsoft

®

, Microsoft Windows™ and Excel™ are trademarks of Microsoft Corporation.

LWS Part Number 2489083317-1 Rev 4

EU DECLARATION OF CONFORMITY

Manufacturer’s Name: Lighthouse Worldwide Solutions, Inc.

Manufacturer’s Address: Lighthouse Worldwide Solutions, Inc.

1221 Disk Drive

Medford, OR 97501 USA

Declares that the product:

Product Name: REMOTE Airborne Particle Counter

Model Number(s): REMOTE 3014PN, 3104PN, 5014PN, 5104PN

Conforms to the following Product Specifications:

SAFETY

LASER SAFETY

EMC

UL 61010A-1 - UL Standard for Safety Electrical Equipment for Laboratory Use; Part 1: General Requirements

Replaces UL 3101-1

Supplementary information

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC amended by

Directive 93/68/EEC and the EMC Directive 89/336/EEC amended by Directive 93/68/EEC and carries the

CE marking accordingly.

EN61010-1:2001 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use Part 1:

General Requirements IEC 61010-1:2000

CAN/CSA C22.2

No. 1010.1-1992

IEC 60825-1 Am. 2

IEC 60601-2-22

(Laser Notice 50)

EN61326 Electrical Equipment for Measurement, Control and

Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use, Part 1:

General Requirements

Guidance on Laser Products: Conforms to FDA 21 CFR

Chapter 1 Subchapter 1

Laboratory Use EMC Requirements Part 1: General

Requirements Includes Amendment A1:1998; IEC

61326:1997 + A1:1998

Fremont, CA. May 15, 2007

William Shade - V.P. Engineering

00

Table of Contents

About This Manual

Text Conventions............................................................................................................................ i

Additional Help............................................................................................................................... i

Chapter 1 General Safety

Safety Considerations .................................................................................................... 1-1

Laser Safety Information ............................................................................................... 1-1

Electrostatic Safety Information .................................................................................... 1-2

LAN-connect Warning .................................................................................................. 1-2

Chapter 2 Introduction

Overview ........................................................................................................................ 2-1

Description ..................................................................................................................... 2-1

Accessories .................................................................................................................... 2-2

REMOTE 3014PN Specifications ................................................................................. 2-3

REMOTE 3104PN Specifications ................................................................................. 2-4

REMOTE 5014PN Specifications ................................................................................. 2-5

REMOTE 5104PN Specifications ................................................................................. 2-6

Interface Pin Assignments ............................................................................................. 2-7

Data Port ............................................................................................................ 2-7

Annual Calibration ............................................................................................. 2-8

Chapter 3 Getting Started

Unpacking and Initial Inspection ................................................................................... 3-1

Shipping Instructions ..................................................................................................... 3-1

Data Cable Build ............................................................................................................ 3-2

Requirements ..................................................................................................... 3-2

Site Preparation .................................................................................................. 3-2

Procedure ........................................................................................................... 3-3

Mount the REMOTE-4PN ............................................................................................. 3-9

Connect Interface and Power Cables ........................................................................... 3-10

Connections ..................................................................................................... 3-10

Communication Port (Data Port) ..................................................................... 3-11

248083317-1 Rev 4 t-i

Lighthouse REMOTE-4PN Series Operating Manual

Data Cable Install ................................................................................. 3-12

Pump Remote Cable Install ................................................................. 3-14

Energize Connections .......................................................................... 3-14

Understanding the LEDs .................................................................................. 3-15

Chapter 4 Communication Set Up

Definitions of Terms Used ............................................................................................. 4-1

REMOTE-4PN Communication Modes ........................................................................ 4-2

Communicating with the Instrument .................................................... 4-2

Data Port ............................................................................................................ 4-2

RS232 Communications .................................................................................... 4-4

RS485 Communications .................................................................................... 4-4

Connecting to a PC ............................................................................................ 4-5

Ethernet Configuration .................................................................................................. 4-6

Lantronix Software Use ................................................................................................. 4-7

Preparing for Network Installation .............................................................................. 4-12

Equipment Required: ....................................................................................... 4-12

Software Required: .......................................................................................... 4-12

Additional Requirements: ................................................................................ 4-12

Configure Device ......................................................................................................... 4-12

Ethernet REMOTE-4PN Configuration ........................................................... 4-12

Straight-through Cat5/Cat6 Setup: ....................................................... 4-13

Cross-over Cat5/Cat6 Setup: ............................................................... 4-14

Program the Interface ................................................................................................... 4-14

Windows Telnet Programming: ....................................................................... 4-14

TIA568A and TIA568B wire Examples ...................................................................... 4-19

Connect REMOTE-4PN to Ethernet LAN .................................................................. 4-19

Connect Ethernet Cable to Instrument ............................................................. 4-19

Chapter 5 Programming with MODBUS Protocol

DIP Switches .................................................................................................................. 5-1

Protocol Settings ............................................................................................................ 5-1

Power On/Auto Start ...................................................................................................... 5-1

Running the Instrument Using MODBUS ..................................................................... 5-2

AUTOMATIC Counting Mode ......................................................................... 5-2

MANUAL Counting Mode ................................................................................ 5-3

Configuring with the MODBUS Protocol ..................................................................... 5-4

Setting the Real Time Clock .............................................................................. 5-4

Changing the Default Instrument Parameters .................................................... 5-5

Using Sensor Setting Registers .............................................................. 5-5

Location (Register 40026) ..................................................................... 5-6

Hold Time (Registers 40031, 40032) .................................................... 5-6

Sample Time (Registers 40033, 40034) ................................................ 5-6

t-ii 248083317-1 Rev 4

Appendix A Limited Warranty

Limitation Of Warranties: ............................................................................................. A-1

Warranty Of Repairs After Initial Two (2) Year Warranty: ......................................... A-1

Appendix B MODBUS Register Map v1.44

COMM Settings ............................................................................................................. B-1

Supported MODBUS Commands .................................................................................. B-1

Sensor Settings Registers ................................................................................... B-2

Device Status ......................................................................................... B-4

Data Registers ................................................................................................................ B-6

Device Status Word ........................................................................................... B-8

Data Enable Registers ........................................................................................ B-9

Data Type Registers ........................................................................................... B-9

Data Units Registers ........................................................................................ B-10

Index

Table of Contents

248083317-1 Rev 4 t-iii

Lighthouse REMOTE-4PN Series Operating Manual

t-iv 248083317-1 Rev 4

00

About This Manual

This manual describes the detailed operation and use of the Lighthouse

REMOTE-4PN Series Airborne Particle Counters.

Text

Conventions

Note:

the sidebar to give extra

information regarding a

feature or suggestion

WARNING:

warning appears in a

paragraph like this and

warns that doing

something incorrectly

could result in personal

injury, damage to the

instrument or loss and/or

improper storage of data.

A note appears in

A

The following typefaces have the following meanings:

italics Represents information not to be typed

or interpreted literally. For example, file

represents a file name. Manual titles are

also displayed in italics.

boldface Introduces or emphasizes a term.

Courier font Indicates command syntax or text

displayed by the diagnostic terminal.

Bold Courier Indicates commands and information that

you type. You can use uppercase or

lowercase letters; in this manual,

commands are shown in uppercase.

Helvetica Italics Indicates a comment on a command or

text output.

Additional

Help

For more information about Lighthouse REMOTE-4PN Series

Airborne Particle Counters, contact Lighthouse Worldwide Solutions.

Service and Support

Tel: 800-945-5905 (USA Toll Free)

Tel: 510-438-0500 (Outside of USA)

techsupport@golighthouse.com

248083317-1 Rev 4 i

Lighthouse REMOTE-4PN Series Operating Manual

ii 248083317-1 Rev 4

00

1 General Safety

Safety

Considerations

Laser Safety

Information

Warnings and cautions are used throughout this manual. It is the

responsibility of the user to familiarize themselves with the meaning of

a warning before operating the particle counter. All warnings will

appear in the left margin of the page next to the subject or step to which

it applies. Take extreme care when doing any procedures preceded by

or containing a warning.

There are several classifications of Warnings defined as follows:

• Laser - pertaining to exposure to visible or invisible laser radiation

• Electrostatic - pertaining to electrostatic discharge

• LAN-Connect - pertaining to Ethernet LAN and instrument damage

This product contains a laser-based sensor that is a Class 1 product (as

defined by 21 CFR, Subchapter J of the Health and Safety Act of 1968)

when used under normal operation and maintenance. Service

procedures on the sensor can result in exposure to invisible radiation.

Service should be performed only by factory-authorized personnel.

The particle counter has been evaluated and tested in accordance with

EN 610109-1:1993, "Safety Requirements For Electrical Equipment

for Measurement, Control, and Laboratory Use" and IEC 825-1:1993,

"Safety of Laser Products". See Figure 1-1.

WARNING:

of controls, adjustments

or performance of

procedures other than

those specified within

this manual may result in

exposure to invisible

(infrared) radiation that

can quickly cause

blindness.

248083317-1 Rev 4 1-1

The use

Figure 1-1 Laser Warning Label Inside Unit

For further technical assistance, contact our Technical Support Team at

800-945-5905 (USA Toll Free) or 541-770-5905 (Outside of USA).

Lighthouse REMOTE-4PN Series Operating Manual

Electrostatic

Safety

Information

WARNING: Using a

wrist-strap without an

isolation resistor will

increase the severity of

an electrical shock.

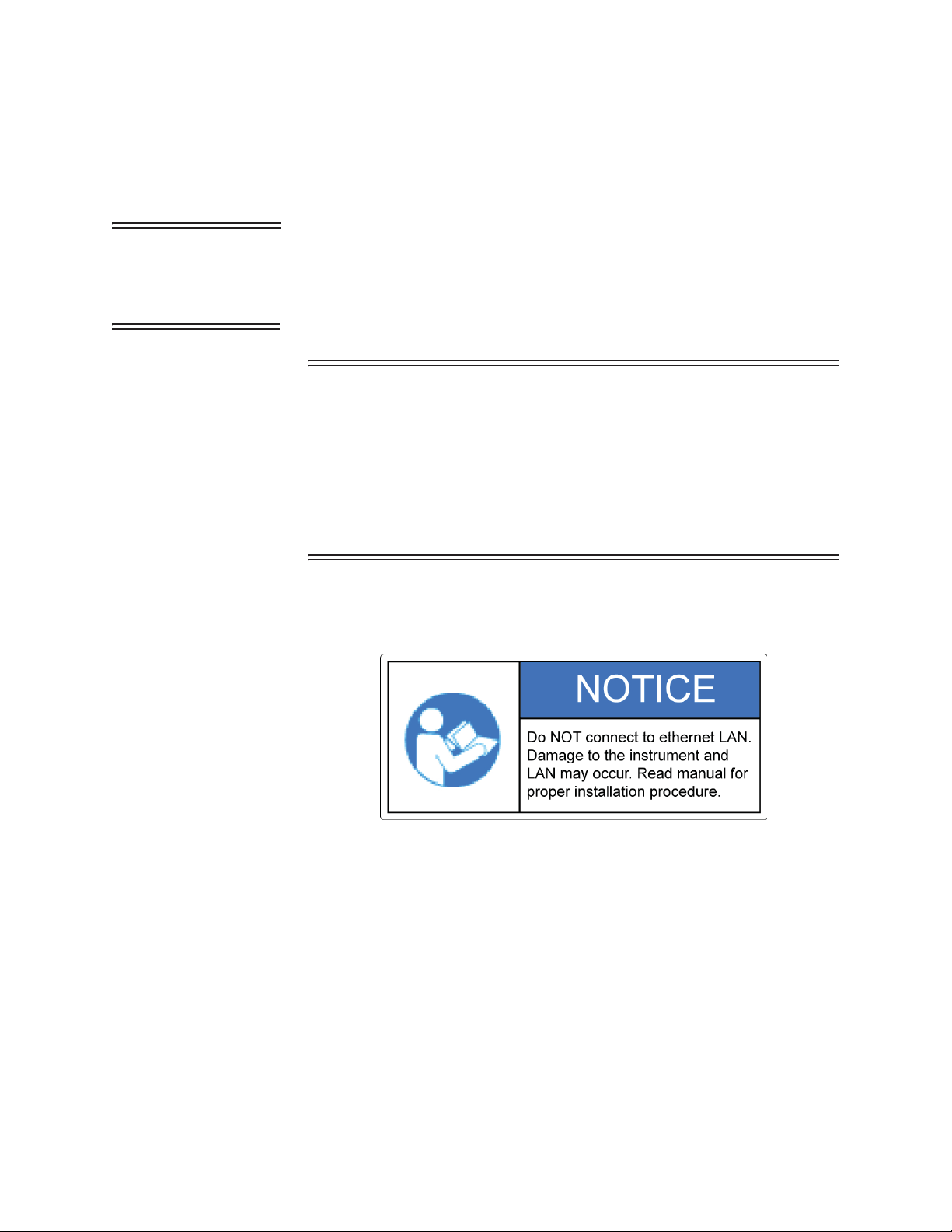

LAN-connect

Warning

Electrostatic discharge (ESD) can damage or destroy electronic

components. Therefore, all service or maintenance work should be

done at a static-safe work station. A static-safe work station can be

created by doing the following:

• Use a grounded conductive table mat and resistor-isolated wriststrap combination.

Earth-ground all test instruments to prevent a buildup of static charge.

WARNING: Connect only Ethernet REMOTE-4PN Series

instruments to a standard Ethernet LAN (Local Area Network). An

RS485 MODBUS REMOTE-4PN may damage the instrument, LAN

hardware or both if its RJ45 port is connected to an Ethernet

network.

Failure to heed this warning will void the instrument warranty and

may void the associated warranties of any affected LAN

equipment.

Figure 1-2 is the warning label attached to the face of the REMOTE4PN Series:

Figure 1-2 Ethernet LAN Connect Notice

1-2 248083317-1 Rev 4

00

2 Introduction

Overview This operating manual introduces the reader to the Lighthouse

REMOTE-4PN Series of four-channel Airborne Particle Counters.

Also included in this manual are instructions for inspecting, using and

maintaining the instrument. Any instrument design changes that may

affect its operation are covered at the back of this manual.

Description

Note: References in this

manual to the different

models of instruments may

be stated as REMOTE4PN Series or REMOTE4PN - they mean the same

and are specific to the

entire unit. References to

Rxxx4 are specific to the

counter within the NEMA

enclosure.

The REMOTE 3014PN (R3014PN) instrument incorporates up to four

particle-size channels starting at 0.3 microns; the REMOTE 5014PN

(R5014PN) shown in Figure 2-1 incorporates up to four particle-size

channels starting at 0.5 micron at 0.1 CFM. The REMOTE 3104PN

(R3104PN) incorporates up to four particle-size channels starting at 0.3

micron and the 5104PN (R5104PN) incorporates up to four particlesize channels starting at 0.5 micron at 1.0 CFM.

Figure 2-1 REMOTE 5104PN Particle Counter

248083317-1 Rev 4 2-1

Lighthouse REMOTE-4PN Series Operating Manual

REMOTE-4PN instruments use a laser diode light source and

collection optics for particle detection. The collection optics collect and

focus light scattered by the particles onto a photo diode that converts

the bursts of light into electrical pulses. The pulse height is a measure

of particle size. Pulses are counted and their amplitude is measured for

particle sizing.

The REMOTE-4PN Series of particle counters were designed for

continuous trouble-free operation using an internal flow-controlled

vacuum pump and a standard NEMA style 316L stainless steel

enclosure. This design provides an industry standard mounting

configuration and can be installed where space is limited. REMOTE4PN Series instruments integrate seamlessly with large facility

monitoring and management systems and transfer up to 4 channels of

simultaneous particle count data using RS485 output.

Accessories The REMOTE-4PN Series instrument supports remote monitoring

when equipped with a tubing kit of 3 meters.

Several accessories can be ordered to tailor the instrument to specific

needs. Please contact a Sales Engineer for these options.

2-2 248083317-1 Rev 4

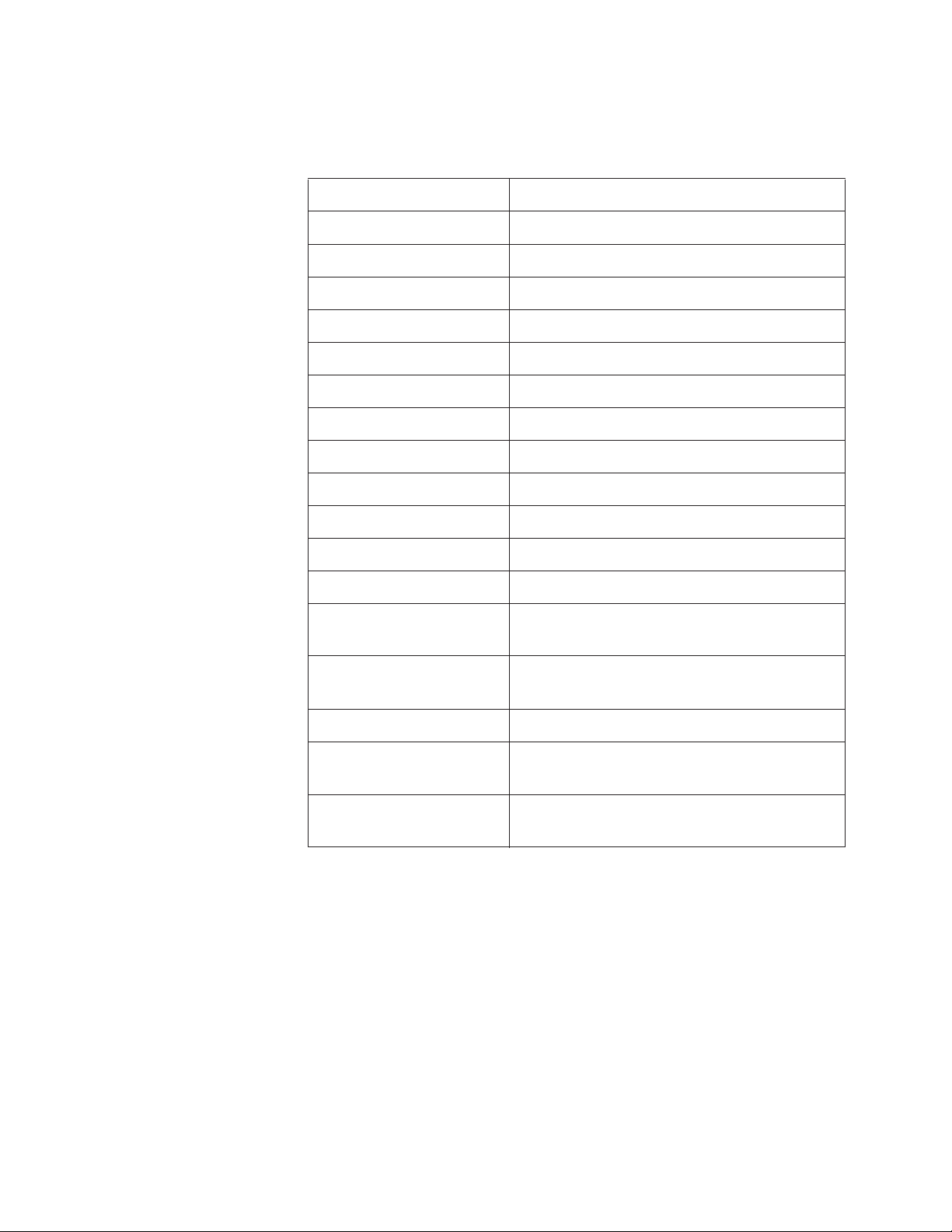

REMOTE

3014PN

Specifications

Introduction

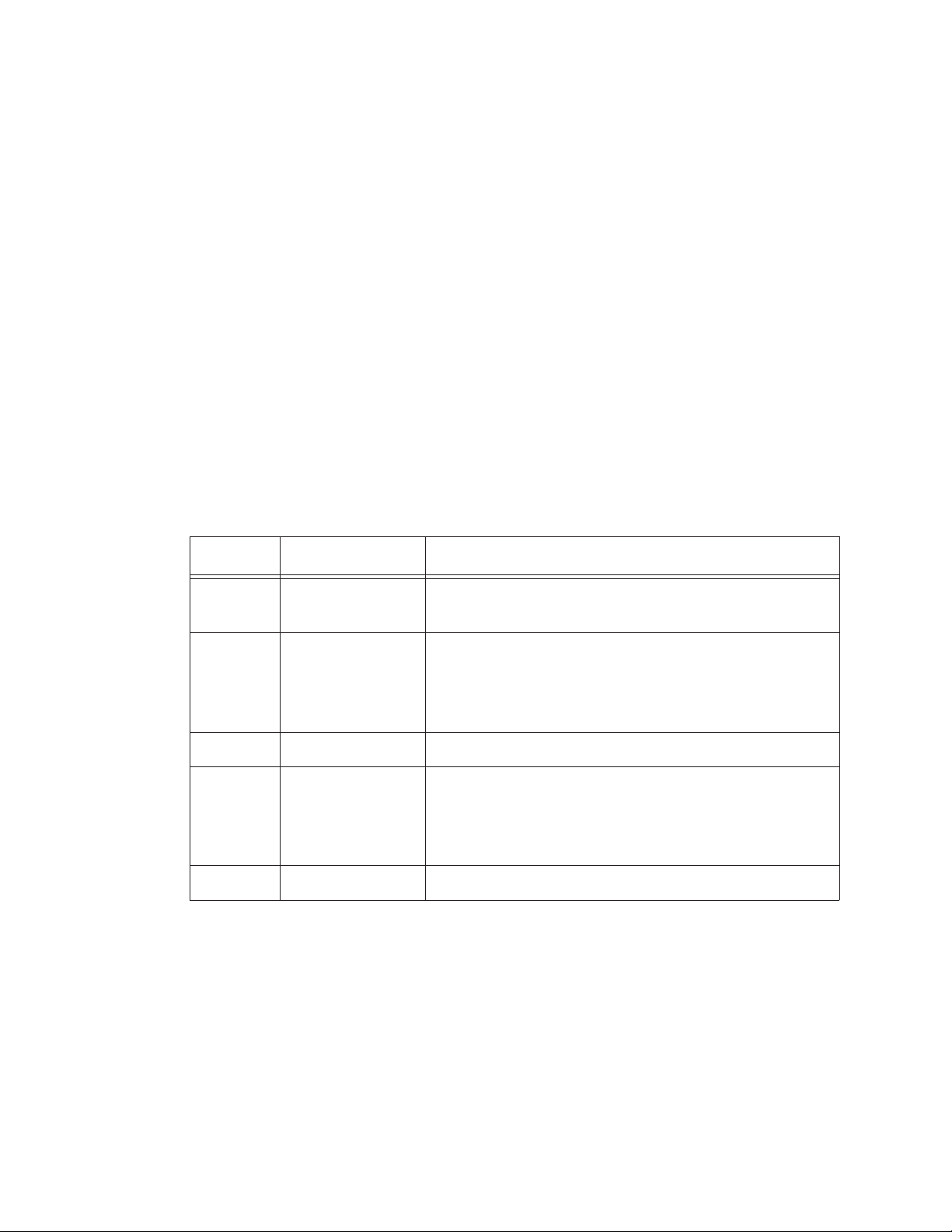

Table 2-1 REMOTE 3014PN Specifications

Size Ranges 0.3 - 25.0m

Channel Thresholds Standard: 0.3, 0.5m

Other sizes specified at time of order

Flow Rate 0.1 CFM (2.83 LPM)

Counting Efficiency 50% (per ISO 21501-4)

Laser Source Laser Diode

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Data Storage Rotating buffer, 2000 Records

Vacuum Internal flow-controlled pump

Calibration NIST Traceable

Communication Modes RS232/RS485 MODBUS

Alerts Calibration Due; Service Alert; Flow Alert

Enclosure 316L Stainless Steel, NEMA

Power Instrument Power: +6V to +30VDC

Chassis Power: 100-220VAC

Dimensions 10" (W) x 12" (H) x 6.9" (D) [25.4 x 30.4 x.

14.9 cm]

Weight 20 lbs (9.6 kg)

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

non-condensing

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

non-condensing

The manufacturer recommends that the Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to

ensure that it continues to perform within specification.

When Calibration comes due, the Service LED will illuminate and stay ON

during sampling mode until the instrument has been calibrated.

248083317-1 Rev 4 2-3

Lighthouse REMOTE-4PN Series Operating Manual

REMOTE

3104PN

Table 2-2 REMOTE 3104PN Specifications

Specifications

Size Ranges 0.3 - 25.0m

Channel Thresholds Standard: 0.3, 0.5m

Flow Rate 1.0 CFM (28.3 LPM)

Counting Efficiency 50% (per ISO 21501-4)

Laser Source Laser Diode

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Data Storage Rotating buffer, 2000 Records

Vacuum Internal flow-controlled pump

Calibration NIST Traceable

Communication Modes RS232/RS485 MODBUS

Other sizes specified at time of order

Alerts Calibration Due; Service Alert; Flow Alert

Enclosure 316L Stainless Steel, NEMA

Power Instrument Power: +6V to +30VDC

Chassis Power: 100-220VAC

Dimensions 10" (W) x 12" (H) x 6.9" (D) [25.4 x 30.4 x.

14.9 cm]

Weight 20 lbs (9.6 kg)

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

non-condensing

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

non-condensing

The manufacturer recommends that the Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to

ensure that it continues to perform within specification.

When Calibration comes due, the Service LED will illuminate and stay ON

during sampling mode until the instrument has been calibrated.

2-4 248083317-1 Rev 4

REMOTE

5014PN

Specifications

Introduction

Table 2-3 REMOTE 5014PN Specifications

Size Ranges 0.5 - 25.0m

Channel Thresholds Standard: 0.5, 5.0 or 0.5, 10.0m

Other sizes specified at time of order

Flow Rate 0.1 CFM (2.83 LPM)

Counting Efficiency 50% (per ISO 21501-4)

Laser Source Laser Diode

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Data Storage Rotating buffer, 2000 Records

Vacuum Internal flow-controlled pump

Calibration NIST Traceable

Communication Modes RS232/RS485 MODBUS

Alerts Calibration Due; Service Alert; Flow Alert

Enclosure 316L Stainless Steel, NEMA

Power Instrument Power: +6V to +30VDC

Chassis Power: 100-220VAC

Dimensions 10" (W) x 12" (H) x 6.9" (D) [25.4 x 30.4 x.

14.9 cm]

Weight 20 lbs (9.6 kg)

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

non-condensing

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

non-condensing

The manufacturer recommends that the Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to

ensure that it continues to perform within specification.

When Calibration comes due, the Service LED will illuminate and stay ON

during sampling mode until the instrument has been calibrated.

248083317-1 Rev 4 2-5

Lighthouse REMOTE-4PN Series Operating Manual

REMOTE

5104PN

Table 2-4 REMOTE 5104PN Specifications

Specifications

Size Ranges 0.5 - 25.0m

Channel Thresholds Standard: 0.5, 5.0 or 0.5, 10.0m

Flow Rate 1.0 CFM (28.3 LPM)

Counting Efficiency 50% (per ISO 21501-4)

Laser Source Laser Diode

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Data Storage Rotating buffer, 2000 Records

Vacuum Internal flow-controlled pump

Calibration NIST Traceable

Communication Modes RS232/RS485 MODBUS

Other sizes specified at time of order

Alerts Calibration Due; Service Alert; Flow Alert

Enclosure 316L Stainless Steel, NEMA

Power Instrument Power: +6V to +30VDC

Chassis Power: 100-220VAC

Dimensions 10" (W) x 12" (H) x 6.9" (D) [25.4 x 30.4 x.

14.9 cm]

Weight 20 lbs (9.6 kg)

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

non-condensing

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

non-condensing

The manufacturer recommends that the Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to

ensure that it continues to perform within specification.

When Calibration comes due, the Service LED will illuminate and stay ON

during sampling mode until the instrument has been calibrated.

2-6 248083317-1 Rev 4

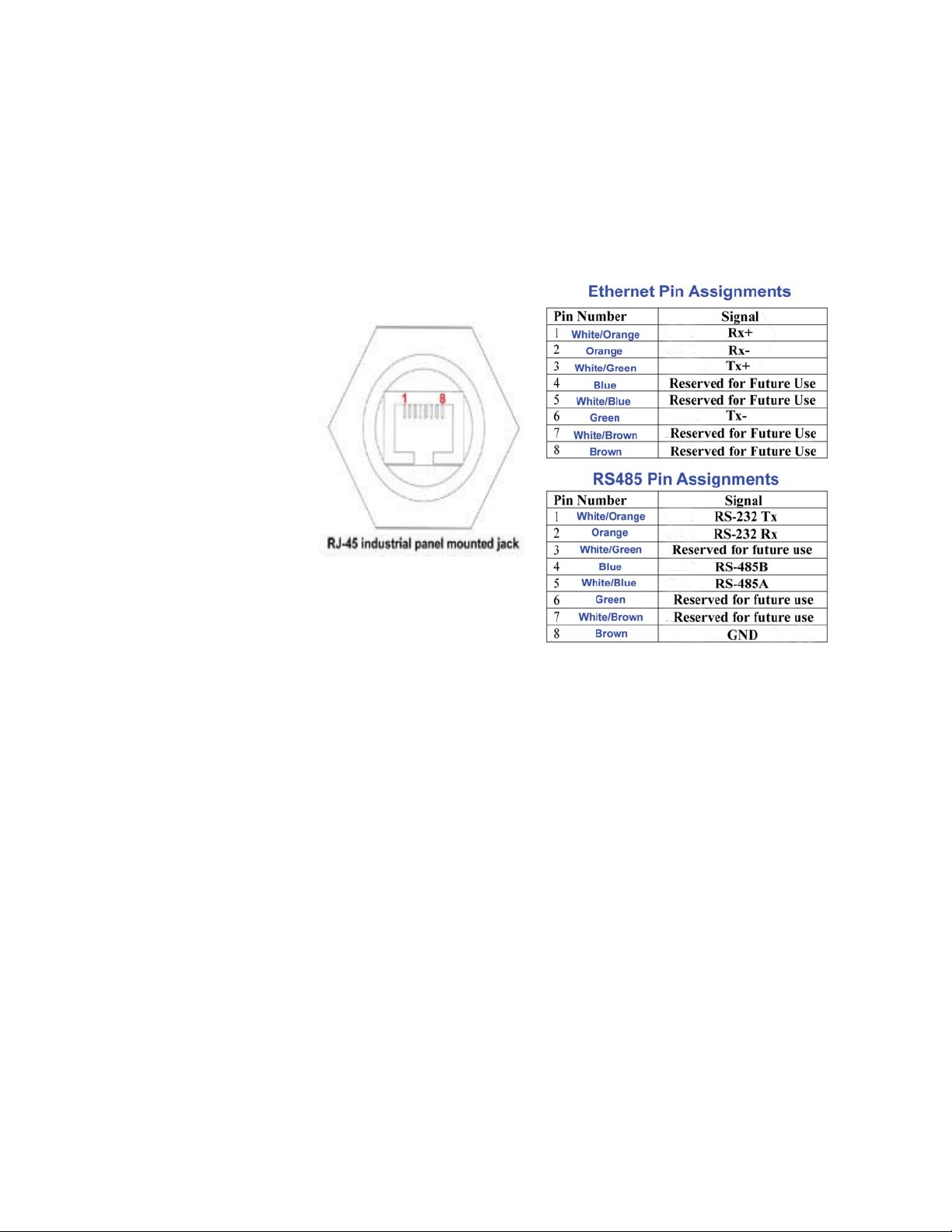

Introduction

Interface Pin

Assignments

Data Port

Figure 2-2 displays the REMOTE-4PN Series industrial RJ45

connector and tables 2-5 and 2-6 show pin assignments.

Figure 2-2 RJ45 Pin Assignments

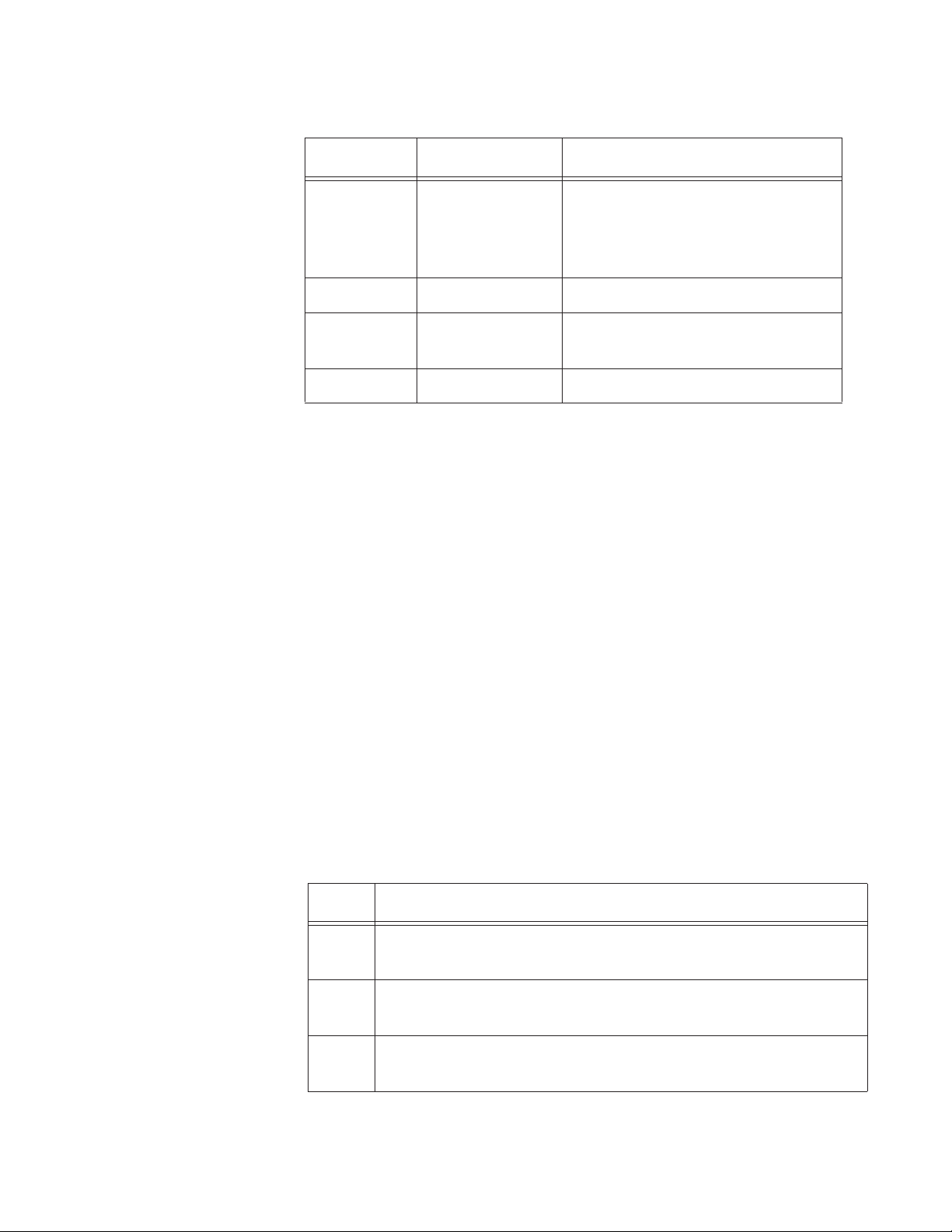

Table 2-5 MODBUS RJ-45 Pinouts

RS485 RJ-45 Pin Description Signal Name

1 White/Orange RS232 Tx

2 Orange RS232 Rx

3 White/Green Reserved for Future Use

4 Blue RS485B

5 White/Blue RS485A

6 Green Reserved for Future Use

7 White/Brown Reserved for Future Use

8 Brown Ground

248083317-1 Rev 4 2-7

Lighthouse REMOTE-4PN Series Operating Manual

Table 2-6 Ethernet RJ-45 Pinouts

Ethernet RJ-45 Pin Description Signal Name

1 White/Orange Rx+

2 Orange Rx-

3 White/Green Tx+

4 Blue Reserved for Future Use

5 White/Blue Reserved for Future Use

6 Green Tx-

7 White/Brown Reserved for Future Use

8 Brown Reserved for Future Use

Please refer to the “Data Cable Build” on page 2 of “Getting Started”

(Chapter 3) for detailed instructions for terminating Cat5, Cat5e or

Cat6 cabling for use with this connector. Parts for completing this task

are available from Lighthouse if they were not provided with the order

or have been damaged and need to be replaced.

Annual Calibration

The manufacturer recommends that the Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to

ensure that it continues to perform within specification.

When Calibration comes due, the Service LED will illuminate and stay ON

during sampling mode until the instrument has been calibrated.

2-8 248083317-1 Rev 4

00

3 Getting Started

Unpacking

and Initial

Inspection

Shipping

Instructions

WARNING:

If the instrument is

damaged during a

return shipment due

to inadequate user

packing, the warranty

may be voided and all

repairs required will

be at cost.

The instrument is thoroughly inspected and tested at the factory and is

ready for use upon receipt.

When received, inspect the shipping carton for damage. If the carton is

damaged, notify the carrier and save the carton for carrier inspection.

Inspect the unit for broken parts, scratches, dents, or other damage.

If the carton is not damaged, keep it for reshipment when returning the

instrument for the annual factory calibration or a Return Merchandise

Authorization for repair. Replacements are available for purchase.

Should it become necessary to return the unit to the factory for any

reason, contact Lighthouse Customer Service or visit our website,

www.golighthouse.com/rma, and obtain a Return Merchandise

Authorization (RMA) number. Reference this number on all shipping

documentation and purchase orders. After receipt of the RMA number,

follow the shipping instructions below:

1. Use the original container, nozzle caps and packing materials

whenever possible. If the instrument contains a battery, remove it

before packing the instrument. If the battery needs to be shipped,

package it separately and refer to www.golighthouse.com/rma for

detailed instructions.

2. If the original container and packing materials are not available,

wrap the unit in "bubble pack", surround with shock-absorbent

material and place in a double-wall carton - the instrument should

not rattle around when the carton is vigorously shaken. If the

instrument is damaged during shipment due to inadequate user

packing, the warranty may be voided and all repairs required will

be at cost. Contact Lighthouse to purchase a replacement shipping

container and nozzle caps.

3. Seal container or carton securely. Mark "FRAGILE" and write the

Return Merchandise Authorization (RMA) number on any

unmarked corner.

4. Return the instrument to the address provided by a Lighthouse

representative or the RMA website.

248083317-1 Rev 4 3-1

Lighthouse REMOTE-4PN Series Operating Manual

Data Cable

Build

Note: The term, "hub", is

used frequently in this

manual to indicate an

RS485 connection point hub, computer, PLC, etc.

An industrial RJ45 connector is required to attach the instrument to an

RS485 or Ethernet network (model dependant) and may be supplied in

kit form with the instrument. A replacement adapter kit is available

from Lighthouse. This section of the manual will show construction of

this special cable and connector.

Requirements

The following tools and materials are required to build / attach the

sealed industrial RJ45 connection used on the REMOTE-4PN Series.

• Solid core Category 5e Unshielded Twisted-Pair 24AWG wire

(CAT5e UTP), minimum

• CAT5e UTP plenum wire may be required for installation in ceiling

plenum area

• Industrial RJ45 kit

• Wire strippers

• RJ45 crimp tool

Site Preparation

WARNING: Both ends of the cable must be wired the same.

References are made throughout this section to the EIA/TIA-568B

standard for ethernet/RJ45 wiring that must be followed.

Failure to wire both ends to this standard will cause failure of the

instrument and may damage the instrument, the hub or both and

void the respective warranties.

When all needed tools and materials are ready, proceed through the

following steps:

1. Check with local regulatory agencies to determine installation

restrictions and cable requirements for the application before

starting cable runs.

2. Make the necessary cable "runs" and leave about two to three feet

at each end as a "service loop". When pulling CAT5, CAT5e or

CAT6 cable, prevent cable kinking and knotting or the cable may

break internally and cause failures. Typical installations use

Unshielded Twisted Pair (UTP) but Shielded Twisted Pair (STP)

may be required in areas of high electrical noise equipment, such as

3-2 248083317-1 Rev 4

Getting Started

Wire

Loom

RJ45

Lock

RJ45

Connector

Seal

CAT5e Cable

Lock

Ring

RJ45 Housing

Clamping

Nut

around generators, fans and fluorescent lights. When cable has to

be installed in the false ceilings or air space above a work area

(plenum), plenum cable may be required.

3. Even though the RJ45 connectors used to build ethernet cables are

typically the same on both ends, the connector supplied in the kit

MUST be used on the instrument end.

4. If STP wire is needed, the RJ45 required for wire termination is

metal-jacketed and provides a grounding point for the cable’s

shield. Only one end of the cable should be grounded. This

provides a shield to block electrical noise from entering the wire. If

both ends of the cable are grounded, a ground loop may be created

and cause failures of the attached equipment. Because hubs or

data-gathering devices typically use grounded connector housings,

the hub end is usually best for the ground connection. Check with

the local IT (Information Technology) personnel for specific wire

termination and installation details.

Procedure

1. Remove 1-1/2-inch to two-inches of insulation from the instrument

end of the cable, taking extreme care to not nick or cut the

individual wires. Do NOT strip the individual wires.

2. Remove the contents of the Industrial RJ45 connector from the

package - do NOT dispose of or lose any pieces. Compare the

contents with Figure 3-1. Contact Lighthouse Support if it appears

that something is missing from the package.

Figure 3-1 REMOTE-4PN Series RJ45 Cable Parts

3. Remove the large lock ring from the RJ45 Housing.

248083317-1 Rev 4 3-3

Lighthouse REMOTE-4PN Series Operating Manual

4. Loosen the RJ45 Housing Clamping Nut to allow the CAT5e cable

to pass through the housing.

5. Insert the stripped end of the cable through the large Lock Ring and

RJ45 Housing as illustrated in Figure 3-2. Make sure the ring is

oriented as shown. If it is reversed, the cable will have to be cut,

the RJ45 connector discarded and a new connector installed.

Figure 3-2 Housing with Cable Inserted

6. Separate the pairs of wires down to about 1-inch from where the

insulation starts. There will be an orange, a green, a blue and a

brown pair of wires. Each pair will have a solid color wire and a

wire striped with the color of that pair. Do not get them confused the orange and brown pair may look alike in plenum cable and

"swapping" these two pairs will cause failure of the instrument.

7. Carefully untwist each pair about 1/2-inch and straighten the wire.

The individual wires will be inserted into the Wire Loom shown in

Figure 3-1 and Figure 3-3.

Note straightened portion

Note the twisted portion

Figure 3-3 Close-up of Wire Loom

Note the shape of the Loom - inserting the wire into the larger opening

is the correct method as shown in Figure 3-3.

3-4 248083317-1 Rev 4

Getting Started

View is tab facing reader

View is from RJ45

opening

1/4-inch maximum

1/2-inch maximum

8. Separate the wires and insert them into the loom based on the EIA/

TIA-568B standard. When all of the wires are in the correct holes,

push the loom onto the wires as far as it will go and verify that at

least one-half-inch of each wire extends beyond the edge of the

loom. This will allow for trimming the wires in a straight line

parallel to the loom edge. One-quarter-inch is required for

crimping into the RJ45 connector. Review the photos in Figure 3-4

to ensure accuracy.

Note:

wires in the loom changes

at positions 4 through 6.

The "pairing" of

9. Trim the ends of the wires in a straight line to one-quarter-inch as

illustrated in the center panel of Figure 3-4.

Figure 3-4 EIA/TIA-568B Color Code Example

10. Insert the wires and loom into the RJ45 connector (lock tab facing

down) and push inward until they fully butt against the end of the

wire channels as shown in Figure 3-5. The loom helps to keep the

wires positioned so they will go into the correct channel for

crimping.

248083317-1 Rev 4 3-5

Figure 3-5 Loomed Wires Being Inserted into RJ45

Lighthouse REMOTE-4PN Series Operating Manual

Insert the RJ45 connector into a crimp tool similar to that shown in

Figure 3-6. Maintain inward pressure while crimping the wires into

their channels.

Figure 3-6 Typical RJ45 Crimp Tool

11. Check the cable wire ends in the RJ45 to make sure they have been

crimped properly. If the crimp was not successful, removing the

connector at this point is a lot easier than after everything is

installed and communications with the instrument are failing.

12. Review Figure 3-7 for an illustration of how tightly each wire end

should fit against the end of each channel. If removal of the RJ45

connector is required because of a poor crimp, contact Lighthouse

to order replacement connectors. The connectors supplied are

designed specifically for this application and using the wrong

connector may result in failure, even if the crimp operation appears

to have been successful.

Figure 3-7 Close-up - Wire Ends Butted to Channel Ends

It may be difficult to get a straight line across the ends of the wires but

gaps or differences in length of 1/8-inch between wires may cause

failures.

3-6 248083317-1 Rev 4

Getting Started

13. Squeeze the latch tab to allow it to enter the slot in the housing as

shown in Figure 3-8 and pull the cable through the connector

housing, bringing the RJ45 into the housing.

Figure 3-8 Close-up of RJ45 Latch

14. Push the RJ45 connector fully into the housing and insert the Lock

Clip, round edge out as illustrated in Figure 3-9, until it is flush.

Figure 3-9 Lock Clip Installation

15. Hand tighten the Clamping Nut until snug. See Figure 3-10.

Figure 3-10 Tighten Cable Clamp Nut

248083317-1 Rev 4 3-7

Lighthouse REMOTE-4PN Series Operating Manual

16. Install the sealing ring onto the front of the connector housing. This

seal is held in place when the connector is locked onto the

instrument. See Figure 3-11.

Figure 3-11 Install Connector Seal

17. Slide the large lock ring down the cable and over the cable housing

body. It may need a twisting action to fully position it against its

retainer ring. Verify that its larger opening is facing outward, away

from the cable. See Figure 3-12.

Figure 3-12 Cable Connector Completed

Note: It is presumed that the REMOTE-4PN Series will be used in a

network of RS485/MODBUS instruments. Therefore, references are

made to a "hub" or the "hub end" of the ethernet cable.

The "hub" may be a computer equipped with an RS232 adapter, an

RS485 hub or one of many RS485 data gathering equipment.

3-8 248083317-1 Rev 4

Getting Started

18. The hub end of the cable run can now be terminated. After both

ends are terminated, the wire should be checked using an ethernet

100baseT cable tester (not just a continuity tester) to ensure that the

signals and ground will be reliable. Steps 6 through 12 can be used

as a reference for termination of the hub end. Figure 3-13 illustrates

how the wires should be connected.

Mount the

REMOTE-4PN

Figure 3-13 RJ45 to Cat5 Pinout

19. Make sure the hub power is OFF or the hub end of the cable is

disconnected from the equipment before connecting the cable to the

instrument, but do NOT connect it, yet. Connecting cables is

discussed later in this chapter.

The REMOTE-4PN Series uses a NEMA style enclosure and mounting

to a flat vertical surface is required for proper operation. Pump flow

control is managed by the REMOTE-4PN Series pump controller.

Power to the REMOTE-4PN Series is managed by a power switch on

the NEMA enclosure bottom plate. The cover lock uses a flat blade or

coin to turn the latch to the open or closed position. Do NOT apply

power to the REMOTE-4PN Series until cables are attached properly at

both ends.

Sample tubing runs should terminate at the instrument location and

should use Bevaline tubing to prevent static and particle dropout. The

REMOTE-4PN Series instrument supports remote monitoring when

equipped with a tubing kit of 3 meters.

248083317-1 Rev 4 3-9

Lighthouse REMOTE-4PN Series Operating Manual

If the Inlet tubing is run over walls or around corners, keep the bend

radius greater than ninety degrees and three feet.

Do not patch sections together and keep the tubing supported to prevent

sagging and kinking over time.

Typical installations use a short length of tubing and a barbed ISO

probe that is either handheld or supported on a tripod.

Connecting the tubing to the instrument Inlet requires removing the cap

from the Inlet connector and installing the ferrule and nut assemblies

on the tubing as shown in Figure 3-14. This may be done with the

Outlet connector, as well, if the pump output requires that it be

exhausted to another area. The procedure is the same for the Outlet.

Connect

Interface and

Power Cables

Figure 3-14 Nut and Ferrule Installed on Tubing

After the ethernet and AC Power cables have been completed, they are

ready for connecting the REMOTE-4PN Series to AC power and datagathering equipment. Proceed as follows:

Connections

The top of the instrument has the inlet line, which supplies sample air

to the sensor. Using the compression fittings is required to allow wipedown of the instrument. See Figure 3-15.

Inlet

Figure 3-15 Instrument Top Connections

3-10 248083317-1 Rev 4

Getting Started

HEPA

RS232/RS485

Filter

Data Port

Power Switch

Outlet

fitting

Pump Remote

AC IN

Figure 3-16 shows the bottom connectors for the REMOTE-4PN

Series.

Figure 3-16 Instrument Bottom Connections

Communication Port (Data Port)

The Data Port uses either RS232/RS485 MODBUS or MODBUS TCP/

IP (for Ethernet) protocols (see Figure 3-13 on page 9 for pinout

differences). To connect the RS485 MODBUS counter to a PC requires

an adapter cable. Please contact a Lighthouse Sales Representative for

this cable.

1. Make sure that any RS485/MODBUS

cable will NOT

be connected to an Ethernet TCP/IP LAN.

Connecting to these networks may result in damage to the

instrument or the LAN and will void their respective warranties.

The Ethernet

version REMOTE-4PN can, of course, be conncted

to an Ethernet LAN.

2. For information on how to use the Data Port to change the

instrument settings, please refer to “Programming with MODBUS

Protocol” on page 5-1.

instrument’s communication

248083317-1 Rev 4 3-11

Lighthouse REMOTE-4PN Series Operating Manual

Data Cable Install

WARNING: Make

sure the data cable is

NOT attached to the hub

before it is connected to

the REMOTE-4PN.

Power to the REMOTE4PN should be OFF when

connecting to the hub.

Best practices dictate that power to equipment on both ends of the data

cable should be OFF before a cable is attached. That is not always

practical, especially if the instrument will be attached to a network with

actively-monitored devices and service cannot be interrupted.

If the REMOTE-4PN is involved in a new installation, power should be

OFF at both ends, cables installed and power applied to the REMOTE4PN then hub. If power cannot be removed from the hub end, make

sure the REMOTE-4PN is powered OFF before connecting the data

cable.

The required data cable incorporates an O-ring and provides a positive

seal through its twist-lock design. The AC Power cable incorporates

the same twist-lock action. Figures in this section illustrate how both

of these cables are "mated" to the REMOTE-4PN Series.

Note that Figure 3-17 shows the orientation of the key. Make sure the

cable is positioned as shown before connecting. Do NOT force the

connector or it will be damaged.

Figure 3-17 Cable Attachment Step 2

1. Insert the male cable connector into the sensor receptacle, key in

the down position. Make sure the cable fully seats into the

receptacle.

3-12 248083317-1 Rev 4

Getting Started

Twist clockwise

to lock cable

onto instrument

Lock groove

2. Figure 3-18 shows the twist motion required to lock cable into

place - make sure the lock groove and lock sleeve mate.

Figure 3-18 Cable Receptacle Lock Groove

3. Figure 3-19 shows the final "seating" of the twist lock. The free

end of the cable may now be connected to the RS485 hub, power

applied to the hub and the sensor powered up.

248083317-1 Rev 4 3-13

Figure 3-19 Cable Fully Attached

Lighthouse REMOTE-4PN Series Operating Manual

Mounting

Screws

Block

Pump Remote Cable Install

1. Figure 3-20 shows the Pump Remote cable connector. The

connector block must be removed before attaching 22-16 AWG

stranded wires.

Figure 3-20 Pump Remote Cable Connector

Note: If the remote

switch is no longer needed,

reinstall the jumper or the

pump will not run when

power is applied to the

REMOTE-4PN.

2. Loosen the two mounting screws using a small slotted screw driver.

Pull out to remove the connector block, then loosen the two screws

holding the wire jumper and replace it with 22-16 AWG twistedpair wire of sufficient length to reach the remote switch location.

3. Tighten the screws to hold the wire in place and reattach the

connector block by pushing in on the block. Make sure it is

properly positioned as it is keyed to fit only one way.

4. Tighten the two mounting screws to lock the block in place.

Energize Connections

1. Connect the signal cable to the hub or data-gathering equipment.

2. Connect the AC Power cord to the AC source.

3. Apply AC power by turning the power switch ON.

4. Power should be applied to the instrument, indicated by the

REMOTE-4PN Power LED illuminating; the pump should start

running if the jumper is in place or the Pump Remote switch is ON.

After approximately twenty seconds, data will be supplied by the

REMOTE-4PN Series to data-gathering equipment or network.

Best practices dictate that power to equipment on both ends of the data cable

should be OFF before a cable is attached. That is not always practical,

especially if a Lighthouse LMS Server or other equipment is monitoring

devices around the clock and service cannot be interrupted.

3-14 248083317-1 Rev 4

If the REMOTE-4PN is involved in a new installation, power should be OFF at

both ends, cables installed and power applied to the REMOTE-4PN then hub.

If power cannot be removed from the hub end, make sure the REMOTE-4PN

is powered OFF before

connecting the data cable.

Operation Understanding the LEDs

Getting Started

Note: The REMOTE-

4PN incorporates a pump

protection circuit that turns

the pump OFF if the Inlet

air supply is blocked. To

restore the instrument to

normal operation, clear the

obstruction, open the

cover, turn the switch OFF,

wait a few seconds and

turn the switch ON. The

pump should start.

The front-panel LEDs have specific meanings when illuminated.

Figure 3-21 shows location of the LEDs and gives a brief description of

their meaning.

Power

Flow

Sampling

Service

Figure 3-21 Front Panel LEDs

• The green POWER LED turns on when the instrument is powered

on.

• The green FLOW LED turns on when the flow is within

specification (programmed parameters) and will blink when flow is

out of specification.

• The orange SERVICE LED will turn on and remain steady if Laser

power is out of range, the sensor optics are dirty, the view volume

contains foreign objects or the Calibration has come due on the

instrument. If calibration is due, the LED illuminates during

sampling mode until the instrument has been calibrated.

• The blue SAMPLING LED indicates the Sample mode is active.

248083317-1 Rev 4 3-15

Lighthouse REMOTE-4PN Series Operating Manual

• If the internal pump stops running, the Inlet air supply may be

obstructed and the pump protection circuit has turned the pump

OFF. The FLOW LED will also blink. To restore normal pump

operation, find and clear the obstruction and open the instrument

cover. Turn the switch OFF, wait a few seconds and turn the switch

ON. The pump should start and remain running. Contact

Lighthouse Technical Support if this fails to restore normal pump

operation.

3-16 248083317-1 Rev 4

00

4 Communication Set Up

This chapter contains information on how to set up the REMOTE-4PN

in order to program and communicate with it.

Definitions of

Terms Used

This list is provided for the convenience of the user or technician.

• ARP - Address Resolution Protocol, a program that can change

the ARP Cache of a host by adding or removing IP addresses.

Each IP address is associated to a MAC address.

• ARP Cache - List of IP addresses and their associated MAC

addresses for hosts whose addresses cannot be resolved normally.

• DHCP - Dynamic Host Configuration Protocol, a program

running on a server that issues IP addresses to computers or

devices (Hosts) on its LAN.

• Gateway - a network device that controls traffic between two or

more networks.

• Hardware address - a unique identifying code programmed by the

factory into a network device, such as a network PCB, comprised

of six two-digit groups of letters A-F and numbers 0-9.

• Host - a computer or device that allows access to itself via a LAN.

• IP (Internet Protocol) Address - a unique logical address used to

identify a host on a TCP/IP network.

• LAN - Local Area Network, a group of computers or hosts

connected together in a relatively small geographical area, such

as a building or floor of a building.

• MAC address - the same as hardware address.

• Netmask - a logical hexadecimal number that prevents accessing

hosts outside of its range. A bit value of zero allows access and a

non-zero blocks access.

• Subnet - a logical grouping of hosts based on their IP addresses.

• TCP/IP - a communication protocol suite that is used for the

Internet and a large number of LANs that allows hosts to share

data.

• Telnet - a communication program used primarily to issue

commands directly to a TCP/IP-based host.

248083317-1 Rev 4 4-1

Lighthouse REMOTE-4PN Series Operating Manual

REMOTE-4PN

Communication

Modes

The default communication mode for the REMOTE-4PN series is

MODBUS TCP over Ethernet. An alternative is MODBUS ASCII

over Ethernet.

Communicating with the Instrument

The RJ-45 connector marked "Data Port" shown in Figure 4-1 is used

to connect the unit to a port of a desktop or laptop PC or to an RS485

MODBUS or Ethernet network with the appropriate cabling or adapter.

Data Port

Figure 4-1 REMOTE-4PN Series Bottom Connectors

Data Port

The Data Port RJ-45 connector provides RS485 signals. Changing the

instrument communication mode requires changing its physical

configuration. If the LWS Network Adapter will be used to attach the

REMOTE4-PN to an Ethernet network or the instrument must operate

in a mode other than RS485 MODBUS, contact Lighthouse Technical

Support for more information. Table 4-1 and Table 4-2 illustrate RJ45

pins and the signals assigned.

4-2 248083317-1 Rev 4

Communication Set Up

The pinouts are defined as follows:

Table 4-1 MODBUS RJ-45 Pinouts

RS485 RJ-45 Pin Description Signal Name

1 White/Orange RS232 Tx

2 Orange RS232 Rx

3 White/Green Reserved for Future Use

4 Blue RS485B

5 White/Blue RS485A

6 Green Reserved for Future Use

7 White/Brown Reserved for Future Use

8 Brown Ground

Table 4-2 Ethernet RJ-45 Pinouts

Ethernet RJ-45 Pin Description Signal Name

1 White/Orange Rx+

2 Orange Rx-

3 White/Green Tx+

4 Blue Reserved for Future Use

5 White/Blue Reserved for Future Use

6 Green Tx-

7 White/Brown Reserved for Future Use

8 Brown Reserved for Future Use

An RJ-45 to DB-9 modular adapter to connect the REMOTE-4PN to a

computer DB9 COM port is available from Lighthouse. The pinouts of

the RJ-45 to DB9 adapter are shown in Table 4-3.

248083317-1 Rev 4 4-3

Lighthouse REMOTE-4PN Series Operating Manual

Table 4-3 RJ-45 to DB-9 Connections

RJ-45 Pin Signal Name DB-9 Pin

1TX2

2RX3

8 Ground 5

3DTE7

RS232 Communications

WARNING: Contact

Lighthouse Technical

Support for the correct

instrument configuration

BEFORE attempting to

use RS232 COM mode.

Failure to heed this

warning can result in

damage to PC,

instrument or both.

WARNING: Contact

Lighthouse Technical

Support for the correct

instrument configuration

BEFORE attempting to

use RS485 COM mode

with a PC. Failure to

heed this warning can

result in damage to PC,

instrument or both.

RS232 is used for point-to-point communication and may be used to

program the instrument via a stand-alone PC.

To connect the instrument to a computer using RS232 Protocol:

1. Remove power from the instrument.

2. Connect the RJ45 end of the LWS RS232 Converter Cable to the

Data Port on the instrument.

3. Attach the USB connector of the RS232 Converter Cable to any

available USB Port on a computer.

4. Apply power to the instrument.

RS485 Communications

The instrument uses RS485 as its default communication mode.

To use the RS485 protocol with a computer USB port, an RS485 / USB

converter must be used. Please contact a Lighthouse Sales

Representative for an RS485 converter kit that includes the cable and

driver software needed to set this up.

4-4 248083317-1 Rev 4

Communication Set Up

Connecting to a PC

To connect the instrument to a computer using RS485 Protocol:

1. Remove power from the instrument.

2. Connect the RJ45 end of the LWS RS485 converter cable to the

REMOTE-4PN Data Port.

3. Connect the USB end of the RS485 converter to any available USB

port on the computer and wait for computer to install drivers.

4. Make sure each REMOTE-4PN has a unique non-zero address or

data will be lost then power on the instrument.

The REMOTE-4PN complies with EIA’s RS485 standards in Table 4-4.

Table 4-4 EIA Industry Standards for RS485 Communications

SPECIFICATIONS RS485

Mode of Operation Differential

Total Number of Drivers and Receivers on

One Line (One driver active at a time for

32 Drivers

32 Receivers

RS485 networks)

Maximum Cable Length 4000 ft. (1,219.2 m)

Maximum Data Rate (40 ft. - 4000 ft. for

10Mb/s - 100Kb/s

RS422/RS485)

Maximum Driver Output Voltage -7V to +12V

Driver Output Signal Level (Loaded

+/-1.5V

Min.): LOADED

Driver Output Signal Level (Loaded

+/-6V

Max.): UNLOADED

Driver Load Impedance (Ohms) 54

Max Driver Current in High Z State

+/-100μA

(POWER ON)

Max Driver Current in High Z State

+/-100μA

(POWER OFF)

Receiver Input Voltage Range -7V to +12V

Receiver Input Sensitivity +/-200mV

Receiver Input Resistance (Ohms), (1

>

12k

Standard Load for RS485)

248083317-1 Rev 4 4-5

Lighthouse REMOTE-4PN Series Operating Manual

Ethernet

Configuration

The Ethernet REMOTE-4PN comes preconfigured to use DHCP and receive an IP

address automatically. If this is not a

desired configuration, use this section to

change these settings.

If the user does not understand the terms

used or the possible impact of changing

the REMOTE-4PN’s settings, do NOT

proceed without contacting the facility’s IT

personnel.

The following procedure requires a preapproval and planning by the IT

department and a joint setup effort.

Please Note: The Ethernet version of Lighthouse Worldwide Solutions REMOTE-4PN

instrument uses MODBUS ASCII over Ethernet. Connecting a REMOTE-4PN particle

counter directly to an Ethernet network should only be done with the permission and

guidance of the network administrator.

4-6 248083317-1 Rev 4

Communication Set Up

The primary advantage of using the REMOTE-4PN on an Ethernet

network is that a separate network does not have to be installed just for

the instruments. Using the REMOTE-4PN Data Port allows the

instruments to co-exist with computers, printers and servers on a LAN

that is already in place, thereby reducing installation costs.

This document will explain how to program the instruments Ethernet

chipset through its TCP/IP interface. It will also list typical equipment

required and provide some troubleshooting information. The end of this

chapter includes examples of T568A and T568B wiring diagrams for

straight-through and cross-over cables.

Lantronix

Software Use

Use Lantronix DeviceInstaller to make configuration changes to IP

Address and subnet.

1. Start the Lantronix DeviceInstaller program. DeviceInstaller will

automatically begin searching for attached devices. The Hardware

Address (MAC Address) for the REMOTE-4PN will be displayed

as shown in Figure 4-2.

• Confirm the device by verifying that the Hardware address

displayed in DeviceInstaller matches the address on the back of the

instrument.

Ethernet Chipset

MAC Address

Figure 4-2 Detecting Attached Devices

248083317-1 Rev 4 4-7

Lighthouse REMOTE-4PN Series Operating Manual

Web Configuration Tab

Green Arrow

OK

2. Select and double-click the XPort for the REMOTE-4PN to open

the Device Details tab.

• Select the Web Configuration tab and then press the green arrow.

The Windows Security Login window will open.

• Select OK without entering a username or password. See

Figure 4-3.

Figure 4-3 Web Configuration Tab

3. The Device Server Configuration Manager will open as shown in

Figure 4-4.

Figure 4-4 Device Server Configuration Manager

4-8 248083317-1 Rev 4

Communication Set Up

4. Select Network Settings and choose the Use the following IP

configuration: radio button.

• Enter the IP Address: “XXX.XX.X.XX” and the Subnet Mask:

“255.255.255.0”.

• Leave the Default Gateway: blank unless the IT department

indicates one is needed. If a gateway is needed, the IT department

will provide one.

• Press the OK button to save the settings. Network Settings will

display Done! See Figure 4-5.

Figure 4-5 Network Settings

Note: These settings

should be the default

settings and may not need

to be changed.

5. Select Serial Settings under Channel 1.Verify that the Port

Settings are set to the following:

• Protocol: RS485 - 2 wire

• Flow Control: None

• BaudRate: 19200

• Data Bits: 8

248083317-1 Rev 4 4-9

Lighthouse REMOTE-4PN Series Operating Manual

• Parity: None

• Stop Bits: 1.

• Press the OK button to save the settings. Serial Settings will display

Done! See Figure 4-6.

Figure 4-6 Serial Settings

6. As shown in Figure 4-7, select Connections and verify that

Connect Protocol and Connection settings are set to the following:

• Protocol: Modbus

• Local Port: 502

• Accept Incoming: Yes.

• Under Modbus Mode, set the Message Timeout to “1000ms” if

not already set.

• Press the OK button. Connections Settings will display Done! as

4-10 248083317-1 Rev 4

shown in Figure 4-7.

Communication Set Up

Search Icon

Figure 4-7 Connection Settings

7. Select Apply Settings link to save the setting to the REMOTE-4PN

as shown in Figure 4-8.

Apply Settings

Figure 4-8 Apply Settings

248083317-1 Rev 4 4-11

Lighthouse REMOTE-4PN Series Operating Manual

8. Select the Search icon to refresh the attached devices and verify

that the IP Address for the REMOTE-4PN has been changed.

Preparing for

Network

Installation

Note:

network where these

instruments will operate

must have an available IP

address for each

instrument. The IP

scheme, or subnet, must

match that of the PC that

will be used to retrieve the

data from the instruments.

Contact Lighthouse

Technical Support at 800945-5905 (USA Toll Free)

or 541-770-5905 (Outside

of USA) for additional

information.

Note:

screen shots are examples

only. Use only the values

provided by the Network

Administrator.

The production

All values in

Equipment Required:

• Network enabled Personal Computer (IBM-compatible)

• REMOTE-4PN

• Small 5-port hub or switch and two 3-foot long straight-through

Cat5 Ethernet cables (For connection to network)

• Or one 3-foot cross-over Cat5 Ethernet cable (For connection to a

PC)

Software Required:

Contact the network administrator if any of the following are not

installed or not functional:

• Windows 2000, XP Professional, or Windows 7

• Telnet

Additional Requirements:

1. Contact the network administrator and obtain administrator rights

on the PC to be used for this procedure.

2. For each unit to be attached, obtain an unused static IP address,

Gateway IP address and the appropriate Netmask for the LAN

into which they will be installed.

3. Create a list and record the MAC address(es) for all REMOTE-

4PNs to be configured. It is suggested that the IP address that will

be used for each REMOTE-4PN be written next to its MAC

address. This list can be provided to the network administrator for

future reference.

4. The PC being used to program the REMOTE-4PN must be using

the same subnet that the adapter will use. See the network

administrator for assistance with this.

5. The PC that will monitor or retrieve data from the instrument(s)

must be using the same subnet and gateway programmed on the

REMOTE-4PN(s) network interface.

Configure

Ethernet REMOTE-4PN Configuration

Device

This section is organized based on the cable used to perform the

4-12 248083317-1 Rev 4

Communication Set Up

Ethernet REMOTE-4PN programming.

Straight-through Cat5 or Cat6 cables require a hub or switch and two

straight-through cables.

Using a cross-over Cat5/Cat6 cable connects the PC directly to the

REMOTE-4PN with no hub.

Each of these configuration modes will be explained separately. If

troubleshooting is required, the cross-over cable technique is easier to

use in the field because it requires fewer devices.

It cannot be stressed enough, however, that the instrument and PC be

configured using the same IP scheme (IP range, Default Gateway and

Netmask).

For troubleshooting outside of the LAN, it is suggested that the PC’s IP

address be used as the Default Gateway for both the PC and the

REMOTE-4PN.

Note:

are examples only. Data

displayed and command

responses may differ.

Screens shown

Frequently, it is necessary to change the REMOTE-4PN Ethernet

parameters to allow for easier troubleshooting. When this is needed,

make sure the instrument is reprogrammed to its previous network

settings before reattaching to the LAN. Contact Lighthouse Technical

Support at 800-945-5905 (USA Toll Free) or 541-770-5905 (Outside of

USA) or the network administrator for additional information.

Straight-through Cat5/Cat6 Setup:

This section requires the PC, two straight-through Cat5 cables and the

hub or switch.

1. Connect one end of a straight-through Cat5 cable to the Ethernet

REMOTE-4PN’s Data Port.

2. The other end of the cable should plug into one port on the hub or

switch.

3. Attach another straight-through cable to the PC’s RJ45 receptacle

and an open port on the hub or switch.

4. Proceed to “Windows Telnet Programming:” on page 4-14.

248083317-1 Rev 4 4-13

Lighthouse REMOTE-4PN Series Operating Manual

Cross-over Cat5/Cat6 Setup:

1. Attach one end of the cross-over cable to the RJ45 receptacle on

the PC.

2. Attach the other end of the cable to the REMOTE-4PN Data Port.

3. Apply power to the REMOTE-4PN. Apply power to the PC if it is

not already running. Observe the LEDs on the PC’s RJ45

connector - blinking indicates network/instrument activity.

Program the

Interface

WARNING:

only the steps or

commands as provided

in this guide. Failure to

heed this warning can

result in damage to

equipment, personal

injury or data loss and

may void the equipment

warranties.

Perform

Windows Telnet Programming:

This section is included just in case some of the automated programs

are not working and programming the instrument is not, yet, successful.

1. Start Windows.

2. On the Taskbar, click on Start.

3. Select Run as shown in Figure 4-9.

Figure 4-9 RUN Screen

4. In the Run window, type CMD and click OK. See Figure 4-10.

Note: Typing commands

in the command console

requires a space between

the instruction and the

command variables. For

example, arp is followed by

a space, then -d and

another space then the *.

Figure 4-10 Starting the Command Console

4-14 248083317-1 Rev 4

Communication Set Up

5. A command prompt window will open. Clear the ARP Cache by

typing arp -d * at the command line and press Enter. Ignore any

error messages that indicate the address table doesn’t exist or has

no entries. See Figure 4-11.

Figure 4-11 Clear Address Table Command

6. The next step requires the unit’s assigned IP and its MAC

address. The MAC address is a group of six two-digit characters

(0-9 and A-F) found on the back of the REMOTE-4PN that may

be referred to as the HW address.

7. The next step adds the IP and MAC addresses to the ARP Cache

which allows direct communications with the instrument before

an IP is programmed into its Ethernet interface.

8. Type arp –s xxx.xxx.xxx.xxx nn-nn-nn-nn-nn-nn and press Enter.

Replace the x’s with the desired IP address, such as 192.168.0.10

or 10.10.0.15, and the n’s with the desired MAC address, such as

00-20-4a-8a-26-31. The IP address will be four segments total

with up to 3 digits per segment, each segment separated by a

period. Note that the MAC address segments are separated by

dashes (-), not periods. See Figure 4-12.

Figure 4-12 ARP Command to Add New IP

9. Activate the REMOTE-4PN Ethernet interface by typing, telnet

xx.xx.xx.xx 1 (replace x’s with the IP address to be used for the

instrument) and press Enter. This command will cause a connect

error but is required to establish communications. See

Figure 4-13.

Figure 4-13 Telnet 1

248083317-1 Rev 4 4-15

Lighthouse REMOTE-4PN Series Operating Manual

10. Type telnet xx.xx.xx.xx 9999 and press Enter. This command

accesses the telnet port of the instrument. The expected error

message from Step 9. is shown in Figure 4-14.

The user will have 4 seconds to respond in the next step. If the user

responds too slowly, they will have to repeat step 10.

11. Press Enter to start the REMOTE-4PN Ethernet interface setup

program. Figure 4-15 displays some of the default settings - make

no changes to these settings except as instructed.

Figure 4-14 Telnet 9999

Figure 4-15 Starting the Set Up Program

12. Type 1 to set the IP address. Type the desired IP address and press

Enter. See Figure 4-16.

4-16 248083317-1 Rev 4

Communication Set Up

Figure 4-16 Assigning IP Address

13. Type Y to set the Gateway IP address. Type the Gateway IP

address and press Enter. See Figure 4-17.

Figure 4-17 Assigning Gateway IP Address

14. Type Y to set the Netmask. type the desired Netmask value and

press Enter. See Figure 4-18.

Figure 4-18 Assigning Netmask

248083317-1 Rev 4 4-17

Lighthouse REMOTE-4PN Series Operating Manual

15. Type N in response to “Change telnet config password” as shown

in Figure 4-19. The instrument is shipped without a password.

Changing the telnet password or providing one is discouraged,

except for absolute security requirements. If a password is

applied and forgotten, the instrument will have to be returned to

Lighthouse to get the password cleared.

Figure 4-19 Telnet Config Password Screen

Note:

Ethernet restarts, it will

lose connection to the PC,

reported as, “Connection

to host lost”.

When the

16. Type S to Save and restart and press Enter to save the changes.

See Figure 4-20.

Figure 4-20 Saving the Settings

17. Perform Step 7. though Step 16. for each REMOTE-4PN.

4-18 248083317-1 Rev 4

Communication Set Up

WARNING: Step 18 is

very important to prevent

network address errors

on the PC when the

process is complete.

TIA568A and

TIA568B wire

Examples

18. Clear the ARP Cache by type arp –d * and press Enter. If this is

not done before quitting this process, the PC may create “ghost

IPs” on the LAN and cause serious problems with the network.

19. Type Exit to quit the command console.

The TIA568A and TIA568B standards are used for creating Ethernet

cables. Either standard can be used to create a straight through cable

but both ends must be wired the same (TIA568A to TIA568A or

TIA568B to TIA568B).

Even though the TIA568A is considered the desired wiring standard for

either Cat5, Cat5e or Cat6, most cables built today are built using the

TIA568B standard. To avoid confusion or possible miswiring errors, it

advised to use whichever standard is the defacto standard used in the

facility.

Figure 4-21 TIA568A, TIA568B Comparison

Connect

REMOTE-4PN

to Ethernet

LAN

248083317-1 Rev 4 4-19

Connect Ethernet Cable to Instrument

Power OFF the Ethernet REMOTE-4PN before connecting the

instrument to a network then attach the network cable to the REMOTE4PN and the other end to the network receptacle. Apply power to the

instrument and check the port LEDs to make sure the connection is

working.

When all steps are completed, the REMOTE-4PN will supply data to

the LAN connection. After approximately 60 seconds, monitoring

equipment and software should “see” the instrument and be able to

retrieve data from it.

Contact Lighthouse Worldwide Solutions Technical Support at 800945-5905 (USA Toll Free) or 541-770-5905 (Outside of USA) for

additional information or further assistance.

Lighthouse REMOTE-4PN Series Operating Manual

4-20 248083317-1 Rev 4

00

5 Programming with

MODBUS Protocol

The REMOTE-4PN can be programmed using the MODBUS Protocol.

The full protocol is detailed in Appendix B: “MODBUS Register Map

v1.44” on page B-1.

This chapter contains the information needed to program the basic

configuration for the instrument using the MODBUS protocol.

DIP Switches During power-up and reset, the counter reads its DIP switches to

determine its operating mode. The REMOTE-4PN is shipped

configured to use the MODBUS protocol.

Protocol

Settings

WARNING: ALWAYS

use the RS485 to RS232

adapter combination

whenever connecting the

REMOTE-4PN to a PC

COM port. Failure to do

so will damage the

instrument, PC COM port

or both.

Power On/

Auto Start

The MODBUS Protocol is used through an RS232 or RS485 interface

with all necessary adapters and the following COM port settings:

• Baud Rate: 19200

•Data Bits: 8

• Stop Bits: 1

• Parity: None

• Flow Control: None

When powering up the instrument, it will begin sampling using the

default configuration:

• Location = 0

• Sample Time = 60 seconds

• Hold Time = 0 seconds

248083317-1 Rev 4 5-1

Lighthouse REMOTE-4PN Series Operating Manual

Note: The automatic

starting of the sampling

accommodates systems

that do not send a START

command but just polls the

instrument for its data.

Running the

Instrument

Using

MODBUS

To stop the sampling, send the command 10 or 12 to command register

40002.

Stopping the sampling will set the Device Status bit in Register 40003

to 0.

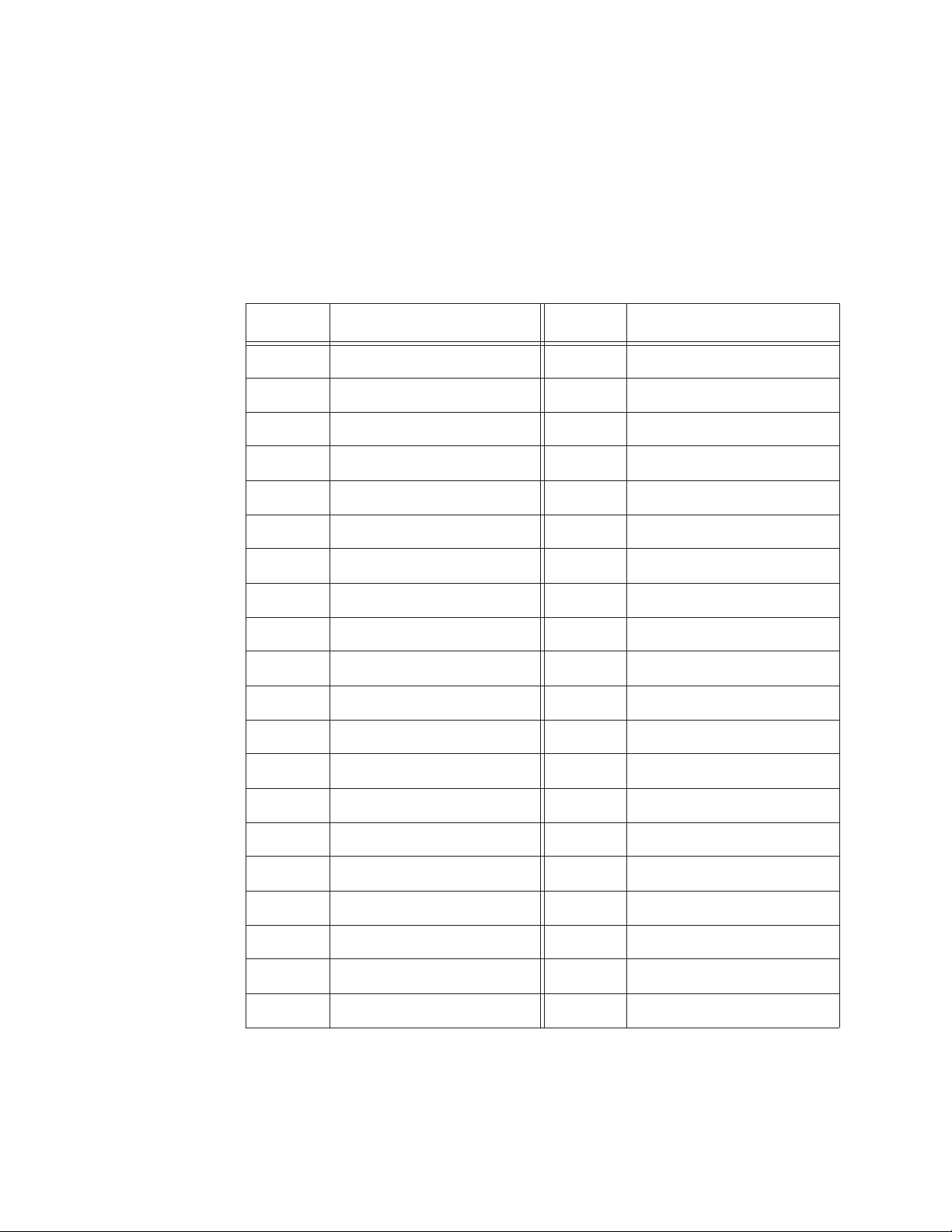

The applicable action commands are shown here in Table 5-1

Table 5-1 Action Commands

Value Actio n

1 Saves all writable 4xxxx register values to the EEPROM.

3 Clears the Data Buffer. Record count is set to zero.

4 Saves the instrument parameters in the 40xxx registers to

the EEPROM. Parameters include Sample Time, Hold

Time, and Location.

7 Start Pump (flow regulated by internal setpoint).

8 Stop Pump.

9 Manual Start.

The instrument samples continuously until it receives a

Manual Stop command. Ignores local timing parameters.

Sets Sample Time for data record to equal the time

interval between the Manual Start and Manual Stop

command. Should be preceded by Start Pump command.

10 Manual Stop.

Stops sampling. Records counts since Manual Start.

Should be followed by Pump Stop command.

11 Instrument Start (Automatic Counting).

Uses defined Hold Time and Sample Time. Instrument

starts pump, executes samples and holds until an

Instrument Stop command is issued.

12 Instrument Stop.

Aborts current sample. Stops pump and data collection.

Each of the described action commands above are written to the

command register (40002).

AUTOMATIC Counting Mode

In Automatic counting mode, the instrument uses the configured

sample time and hold time to record samples.

5-2 248083317-1 Rev 4

Programming with MODBUS Protocol

The instrument will continue running samples at the configured sample

time until it receives a stop command. When the stop command is

given, the most current data will not record to the buffer.

After setting all the instrument parameters as described in “Changing

the Default Instrument Parameters” on page 5-5, write these commands

to the Command register (40002):

11 Start Instrument; to start pump and recording

12 Stop Instrument; to stop pump and recording

MANUAL Counting Mode

In Manual counting mode, the computer starts the sample and the

instrument continues counting until a stop command is given. At that

point, the sample time is listed at whatever the time interval was

between the start command and the stop command.

Write these commands to the Command register (40002):

7 Start Pump - must be sent before ’9’, below

8 Stop Pump - must be sent after ’10’ below

9 Start Instrument; to start recording (does not start pump - see ’7’).

10 Stop Instrument; to stop recording after desired sample time (does

not stop pump - see ’8’).

248083317-1 Rev 4 5-3

Lighthouse REMOTE-4PN Series Operating Manual

Configuring

with the

MODBUS

Protocol

Register Data Type Description

Setting the Real Time Clock

The Real Time Clock (RTC) can be read in registers 40027 and 40028

as shown in Table 5-2.

Register 40027 is the high word for the real time clock; 40028 is the

low word. The date/time is calculated as the number of seconds since

midnight of 1/1/1970.

The date & time is stored in a 4-byte unsigned integer or as a 32-bit

unsigned integer.:

Table 5-2 Real Time Clock Registers

40027 unsigned integer Real Time Clock (RTC) [high]. Works in

conjunction with 40028. Displays date and

time, in number of seconds since

midnight, 1/1/1970.

40028 unsigned integer Real Time Clock [low]

In order to change the RTC to the current local date/time, enter the high

and low values as unsigned integers to registers 40035 and 40036

respectively, the Data Set registers.See Table 5-3.

Table 5-3 Data Set Registers

Register Data Type Description

40035 unsigned integer Data Set [high]. Works in conjunction

with 40036. Data entered here is applied

to the device through the command

register.

40036 unsigned integer Data Set [low]

Then write the command 13 to the command register 40002. This will

write the values in the Data Set registers (40035 and 40036) to the RTC