Lighthouse REMOTE 2, REMOTE 3102, REMOTE 2012, REMOTE 3012, REMOTE 5102 Operating Instructions Manual

...

00

Lighthouse Worldwide Solutions

REMOTE 2012, 3012, 5012, 3102, 5102 Airborne Particle Counter

Operating Manual

Copyright © 2004-2008 by Lighthouse Worldwide Solutions. All rights reserved. No part of this

document may be reproduced by any means except as permitted in writing by Lighthouse

Worldwide Solutions.

The information contained herein constitutes valuable trade secrets of Lighthouse Worldwide

Solutions. You are not permitted to disclose or allow to be disclosed such information except as

permitted in writing by Lighthouse Worldwide Solutions.

The information contained herein is subject to change without notice. Lighthouse Worldwide

Solutions is not responsible for any damages arising out of your use of the LMS program.

REMOTE 2012, 3012, 5012, 3102, 5102™ are trademarks of Lighthouse Worldwide Solutions.

Microsoft®, Microsoft Windows©, and Excel© are trademarks of Microsoft Corporation.

LWS Part Number 248083201-1 Rev 6

EU DECLARATION OF CONFORMITY

Manufacturer’s Name Lighthouse Worldwide Solutions, Inc.

Manufacturer’s Address: Lighthouse Worldwide Solutions, Inc.

1221 Disk Drive

Medford, OR 97501

Declares that the product:

Product Name: Remote Airborne Particle Counter

Model Number(s): REMOTE 2012, 3012, 5012, 3102, 5102

Conforms to the following Product Specifications:

SAFETY

LASER SAFETY

EMC

UL 61010A-1 – UL Standard for Safety Electrical Equipment for Laboratory Use; Part 1: General Requirements.

Replaces UL 3101-1

Supplementary information: The product herewith complies with the requirements of the Low Voltage

Directive 73/23/EEC amended by Directive 93/68/EEC and the EMC Directive 89/336/EEC amended by Directive

93/68/EEC, and carries the CE marking accordingly.

EN61010-1:2001 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use Part I:

General Requirements IEC 61010-1:2000

CAN/CSA C22.2 Safety Requirements for Electrical

No. 1010.1-1992 Equipment for Measurement, Control, and Laboratory

Use, Part1: General Requirements

IEC 60825-1 Am. 2 Guidance on Laser Products: Conforms to

IEC 60601-2-22 FDA 21 CFR Chapter 1 Subchapter J

(Laser Notice 50)

EN61326 Electrical Equipment for Measurement, Control and

Laboratory Use EMC Requirements Part 1: General

Requirements Includes Amendment A1:1998;IEC

61326:1997 + A1:1998

Fremont, CA, May 15, 2007 William L. Shade – V.P. Engineering

00

Table of Contents

About This Manual

Text Conventions ................................................................................................................ i

Additional Help ................................................................................................................... i

Chapter 1 General Safety

Safety Considerations .................................................................................................... 1-1

Laser Safety Information ............................................................................................... 1-1

Electrostatic Safety Information .................................................................................... 1-2

Chapter 2 Introduction

Overview ........................................................................................................................ 2-1

Description ..................................................................................................................... 2-1

Accessories .................................................................................................................... 2-2

REMOTE Specifications ............................................................................................... 2-3

Chapter 3 Getting Started

Unpacking and Initial Inspection ................................................................................... 3-1

Shipping Instructions ..................................................................................................... 3-1

Interpreting the Indicators .................................................................................. 3-2

Connections ................................................................................................................... 3-3

Installation ..................................................................................................................... 3-4

Installing an Isokinetic Probe ........................................................................................ 3-5

Data Port ........................................................................................................................ 3-5

Applications ................................................................................................................... 3-7

Chapter 4 Programming

General ........................................................................................................................... 4-1

DIP Switches .................................................................................................................. 4-1

DIP Switch Settings ....................................................................................................... 4-2

GENERAL DEFINITIONS ............................................................................... 4-2

Time:Range ........................................................................................................ 4-2

248083201-1 Rev 6 t-i

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

DIP Switch Settings and Meanings ................................................................... 4-3

Procedure to Set DIP Switches .......................................................................... 4-3

Example Startup Echo, Reading DIP Switches: .................................... 4-3

Connecting the Instrument to a Terminal ...................................................................... 4-4

Power Up ....................................................................................................................... 4-6

Session Example ............................................................................................................ 4-6

ASCII Programming Syntax .......................................................................................... 4-7

Command Structure ........................................................................................... 4-7

Handshake .......................................................................................................... 4-8

Protocol .............................................................................................................. 4-8

Command Set ..................................................................................................... 4-9

VERBOSE MODE ................................................................................ 4-9

GET CURRENT SETTINGS ................................................................ 4-9

DISPLAY MENU OF COMMANDS ................................................... 4-9

START/STOP COUNTING MODE ................................................... 4-10

START Counting ..................................................................... 4-10

STOP Counting ........................................................................ 4-10

GET CURRENT VERSION NUMBER .............................................. 4-11

SET CHANNEL RANGES ................................................................. 4-11

SET SAMPLE TIME (seconds) .......................................................... 4-12

SET ALARM CHANNEL ................................................................... 4-12

SET ALARM THRESHOLD .............................................................. 4-12

Hyperterminal Alarm Alert without Alarm Suppression: .................... 4-13

SET ALARM SUPPRESSION ............................................................ 4-13

Hyperterminal Alarm Alert with Alarm Suppression: ......................... 4-13

Service High and Service Low .................................................................................... 4-14

Hyperterminal Service Alert Example: ................................................ 4-14

Service Menu ............................................................................................................... 4-15

DON’T SHOW 1 SEC DATA ............................................................. 4-15

SHOW 1 SEC DATA .......................................................................... 4-15

GET BACKGROUND LIGHT VALUE ............................................. 4-16

Chapter 5 Technical Data

Introduction .................................................................................................................... 5-1

Control Design ............................................................................................................... 5-1

START .............................................................................................................. 5-1

SETUP .............................................................................................................. 5-1

Startup Example: .................................................................................... 5-2

COUNT .............................................................................................................. 5-2

TIMER ............................................................................................................... 5-2

OUTPUT ............................................................................................................ 5-3

ALARM ............................................................................................................. 5-3

SERVICE ALERT ............................................................................................. 5-3

EXTERNAL ALARM ....................................................................................... 5-3

t-ii 248083201-1 Rev 6

Chapter 6 Maintenance Procedures

Introduction .................................................................................................................... 6-1

Safety ............................................................................................................................. 6-1

Calibration ..................................................................................................................... 6-1

Purge Count Test ........................................................................................................... 6-1

Fault Isolation ................................................................................................................ 6-2

Appendix A Limited Warranty

Limitation Of Warranties: ............................................................................................. A-1

Warranty Of Repairs After Initial Two (2) Year Warranty: ......................................... A-1

Index

Table of Contents

248083201-1 Rev 6 t-iii

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

t-iv 248083201-1 Rev 6

00

About This Manual

This manual describes the detailed operation and use of the Lighthouse

REMOTE 2 Series Airborne Particle Counters.

Text

Conventions

Note: A note appears in

the sidebar to give extra

information regarding a

feature or suggestion

WARNING: A

warning appears in a

paragraph like this and

warns that doing

something incorrectly

could result in personal

injury, damage to the

instrument or loss and/or

improper storage of data.

The following typefaces have the following meanings:

italics Represents information not to be typed

or interpreted literally. For example, file

represents a file name. Manual titles are

also displayed in italics.

boldface Introduces or emphasizes a term.

Courier font Indicates command syntax or text

displayed by the diagnostic terminal.

Bold Courier Indicates commands and information that

you type. You can use uppercase or

lowercase letters; in this manual,

commands are shown in uppercase.

Helvetica Italics Indicates a comment on a command or

text output.

Additional

Help

For more information about Lighthouse REMOTE 2 Series Airborne

Particle Counters, contact Lighthouse Worldwide Solutions.

(800) 945-5905 Sales & Support

(510) 438-0500 Outside of USA

www.golighthouse.com

techsupport@golighthouse.com

248083201-1 Rev 6 i

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

ii 248083201-1 Rev 6

00

1 General Safety

Safety

Considerations

Laser Safety

Information

Warnings and cautions are used throughout this manual. Familiarize

yourself with the meaning of a warning before operating the particle

counter. All warnings will appear in the left margin of the page next to

the subject or step to which it applies. Take extreme care when doing

any procedures preceded by or containing a warning.

There are several classifications of Warnings defined as follows:

• Laser - pertaining to exposure to visible or invisible laser radiation

• Electrostatic - pertaining to electrostatic discharge

This product contains a laser-based sensor that is a Class 1 product (as

defined by 21 CFR, Subchapter J of the Health and Safety Act of 1968)

when used under normal operation and maintenance. Service

procedures on the sensor can result in exposure to invisible radiation.

Service should be performed only by factory-authorized personnel.

The particle counter has been evaluated and tested in accordance with

EN 610109-1:1993, "Safety Requirements For Electrical Equipment

for Measurement, Control, and Laboratory Use" and IEC 825-1:1993,

"Safety of Laser Products".

WARNING: The use

of controls, adjustments

or performance of

procedures other than

those specified within

this manual may result in

exposure to invisible

(infrared) radiation that

can quickly cause

blindness.

248083201-1 Rev 6 1-1

Figure 1-1 Warning label on unit

For further technical assistance, contact our Technical Support Team at

(800) 945-5905.

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Electrostatic

Safety

Information

WARNING: Using a

wrist-strap without an

isolation resistor will

increase the severity of

an electrical shock.

Electrostatic discharge (ESD) can damage or destroy electronic

components. Therefore, all service or maintenance work should be

done at a static-safe work station. A static-safe work station can be

created by doing the following:

• Use a grounded conductive table mat and resistor-isolated wriststrap combination

• Earth-ground all test instruments to prevent a buildup of static

charge

1-2 248083201-1 Rev 6

00

2 Introduction

Overview This operating manual introduces you to the Lighthouse REMOTE

2012, 3012, 5012, 3102, 5102 (REMOTE 2 Series) family of twochannel Airborne Particle Counters. Also included in this manual are

instructions for inspecting, using, and maintaining the instrument. Any

changes of instrument operation due to design changes are covered at

the back of this manual.

Description The 2012 instrument is manufactured to count particles at 0.2 and 0.3

micron, the 3012 counts particles at 0.3 and 0.5 micron and the 5012

model counts particles at 0.5 and 5.0 microns at 0.1 CFM. The 3102

model counts at 0.3 and 0.5 micron and the 5102 model counts particles

at 0.5 and 5.0 microns at 1.0 CFM.

The instruments are effective in both ultra-clean areas (such as Class 1

or Class 10) and in more traditional cleanzones rated as Class 100 or

higher. Refer to Specifications in this manual for additional instrument

information.

Figure 2-1 REMOTE 3012 Airborne Particle Counter

248083201-1 Rev 6 2-1

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

The particle counter uses laser diode light source and collection optics

for particle detection. The collection optics collect and focus light

scattered by the particles onto a photo diode that converts the bursts of

light into electrical pulses. The pulse height is a measure of particle

size. Pulses are counted and their amplitude is measured for particle

sizing.

The REMOTE 2 Series line of Airborne Particle counters was created

for continuous operation 24 hours per day, 7 days per week.

Using an external vacuum source, the instrument provides versatile

mounting options and can be installed where space is at a premium.

The REMOTE 2 Series instrument integrates seamlessly with large

facility monitoring/management systems and transfers 2 channels of

simultaneous particle count data using 4-20mA output.

Accessories You can order several accessories to tailor the instrument to your

needs. These accessories are listed below.

• Isokinetic Sampling Probe 0.1 or 1.0 CFM

• Sample Tubing

• Instrument to PC Cabling, RJ-45 to DB-9

• 0.1Pm Purge Filter Assembly 0.1 or 1.0 CFM Flow Rate with

Tubing

• Vacuum tubing per foot

• Cable per foot

2-2 248083201-1 Rev 6

REMOTE

Specifications

Introduction

Size Ranges, 2012 0.2 - 2.0

Size Ranges, 3012/3102 0.3 - 10.0Pm

Size Ranges, 5012/5102 0.5 - 10.0μm

Channel Thresholds, 2012 0.2, 0.3μm

Ch. Thresholds, 3012/3102 0.3, 0.5μm

Ch. Thresholds, 5012/5102 0.5, 5.0μm

Flow Rate, 2012/3012/5012 0.1 CFM (2.83 LPM)

Flow Rate, 3102/5102 1.0 CFM (28.3 LPM)

Counting Efficiency 50% (per JIS)

Laser Source Laser Diode

Zero Count Level <1 count/5 minutes (per JIS)

Vacuum Requirements External Vacuum >18" (45.7 cm) of Hg

Calibration NIST Traceable

Communication Modes 4-20mA: Ch1, Ch2

Alarms Ch1, Ch2 Count Overflow Alarm

Alerts Service Alert

Enclosure Stainless steel

Power Instrument Power: +6V to +30VDC

Loop Power: +15V to +30VDC

Dimensions 1.7" (L) x 4.2" (W) x 2.5" (H) [4.3 x 10.7 x.

6.3 cm]

Wei ght 12.5 oz (0.35 kg)

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

non-condensing

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

non-condensing

Table 2-1 Specifications

The manufacturer recommends that your Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to

ensure that it continues to perform within specification.

248083201-1 Rev 6 2-3

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

2-4 248083201-1 Rev 6

00

3 Getting Started

Unpacking

and Initial

Inspection

Shipping

Instructions

The instrument is thoroughly inspected and tested at the factory and is

ready for use upon receipt.

When received, inspect the shipping carton for damage. If the carton is

damaged, notify the carrier and save the carton for carrier inspection.

Inspect the unit for broken parts, scratches, dents, or other damage.

Verify the contents of the package against the packing list.

If the carton is not damaged, keep it for reshipment when you return the

instrument for the annual factory calibration.

Should it become necessary to return the unit to the factory for any

reason, be sure to contact Customer Service and obtain a Return

Merchandise Authorization (RMA) number. Reference this number on

all shipping documentation and purchase orders. After receipt of the

return number, follow the shipping instructions provided below:

1. Use the original container or carton and packing materials

whenever possible.

2. If the original container and packing materials are not available,

wrap the unit in "bubble pack" plastic; surround with shockabsorbent material and place in a double-wall carton.

3. Seal container or carton securely. Mark "FRAGILE" and enter

Return Merchandise Authorization (RMA) number in any

unmarked corner.

4. Return to the address instructed by your Lighthouse representative.

248083201-1 Rev 6 3-1

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Operation Interpreting the Indicators

Both front-panel indicators have a specific meaning when illuminated.

The figure below shows location of the indicators and gives a brief

description of their meaning.

POWER LIGHT (GREEN)

SERVICE LIGHT (RED)

Figure 3-1 Front Panel LEDs

• The green POWER indicator lights when power is received through

the DATA connector.

• The red SERVICE indicator blinks if either of the Channels

overflows its programmed threshold.

• The red SERVICE indicator is ON if Laser power is low, sensor

optics are dirty or the view volume contains foreign objects.

3-2 248083201-1 Rev 6

Connections

Inlet fitting

Figure 3-2 Connections on Top of Instrument

for external

vacuum

Getting Started

Programming

Port

Figure 3-3 Connections on Bottom Right of Instrument

Figure 3-4 J10 Labeling (with Status feature on pin 5)

248083201-1 Rev 6 3-3

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Figure 3-5 J10 Labeling (without Status feature on pin 5)

Installation Your instrument(s) can be easily prepared for use by performing the

steps below. Depending on the unit’s output, each instrument can be

located up to 1000 feet (330 meters) from the counting device.

1. Locate instrument(s) in areas to be sampled.

2. Attach barbed fitting to top inlet.

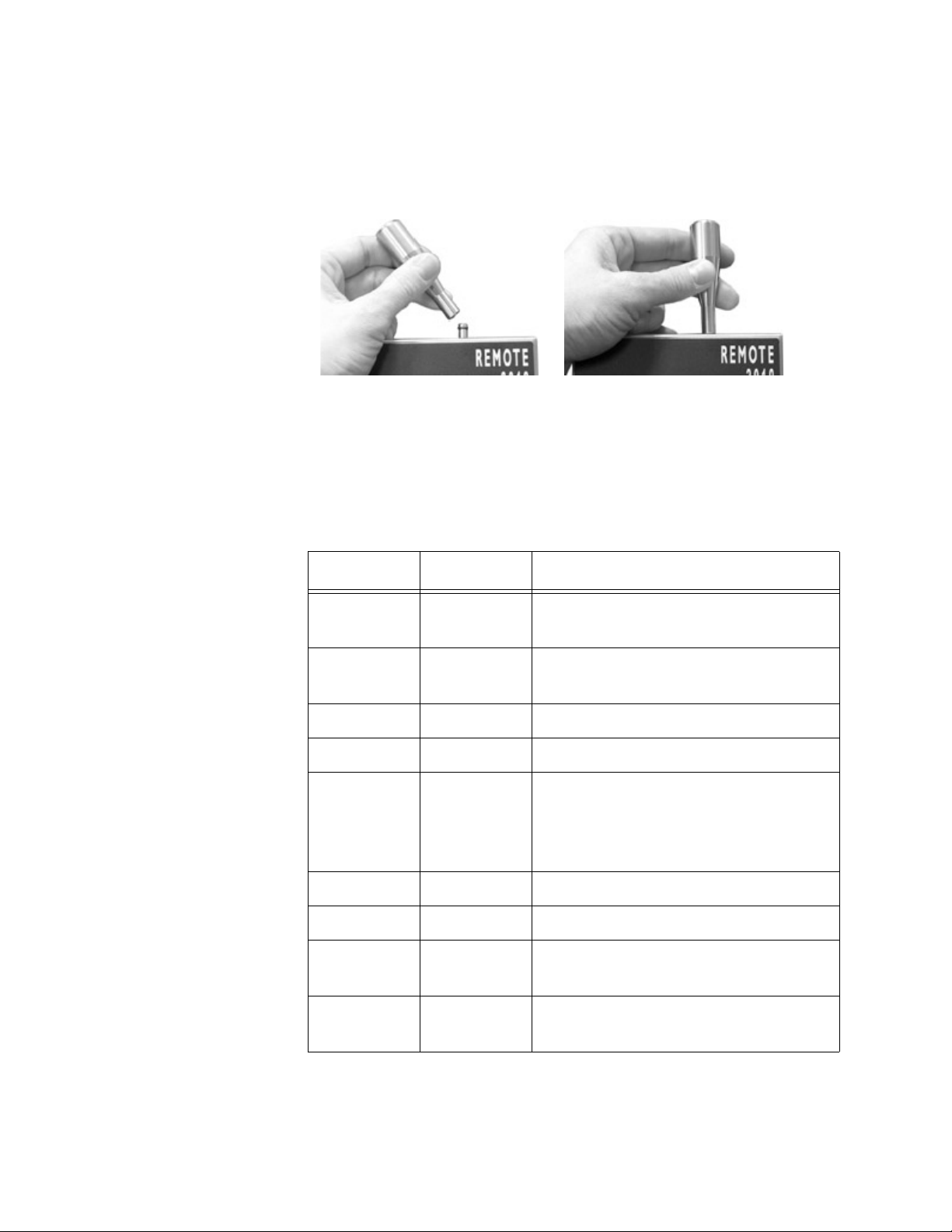

Figure 3-6 Attaching the Fitting

3. Attach sample tubing to barbed (top) fitting.

Figure 3-7 Attach sample tubing to inlet

3-4 248083201-1 Rev 6

Getting Started

4. Attach tubing from external vacuum source to the barbed fitting on

the bottom of the unit.

Installing an

Isokinetic

An Isokinetic probe can be attached directly to the unit. Screw the

probe directly onto the inlet.

Probe

Figure 3-8 Installing Probe Directly on Barb

Data Port Connector J10 on the bottom of the instrument is used to communicate

with your Facility Management System. Signals at this port include two

4-20mA data channels, an external alarm channel, power and ground.

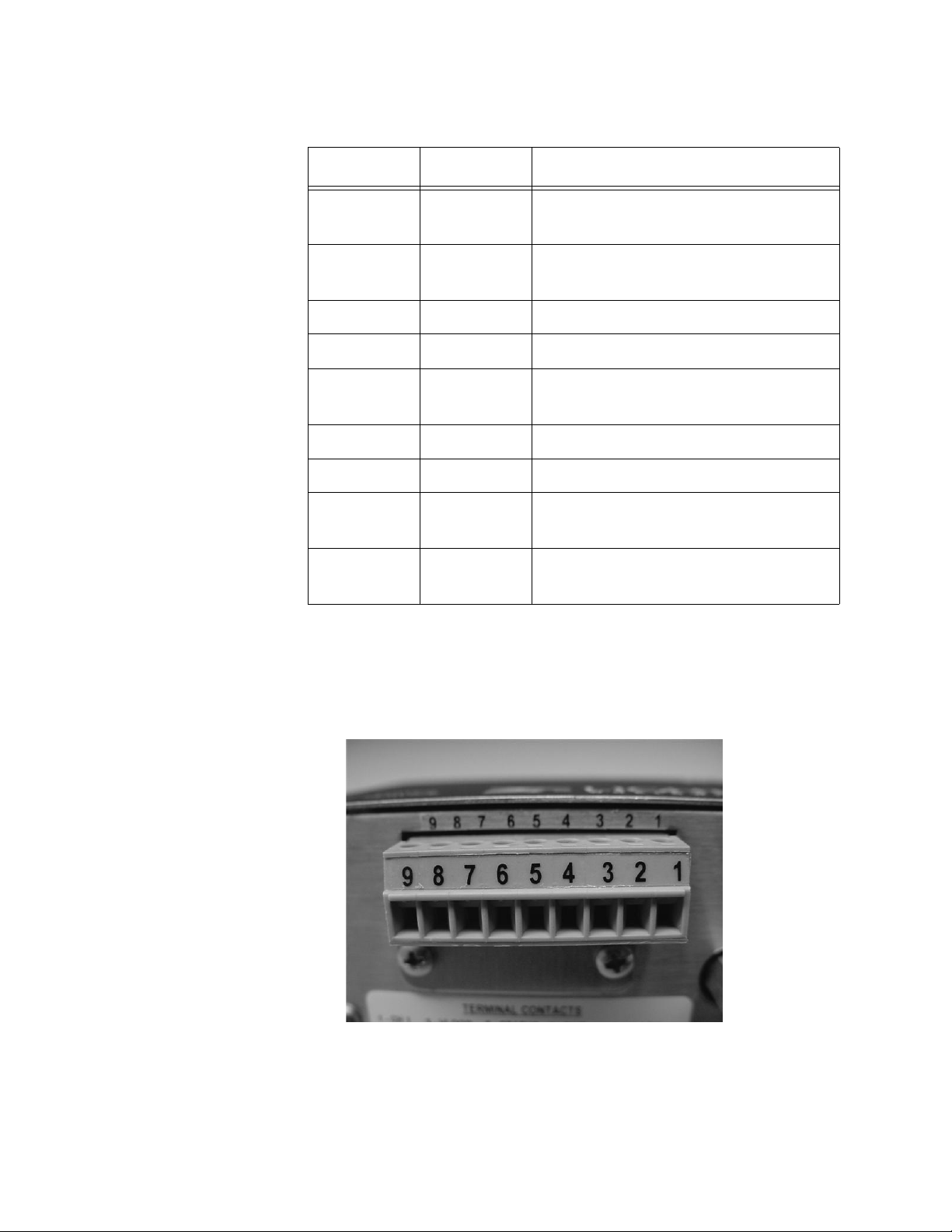

Table 3-1 J10 with Status Data Connector Pinouts

Pin Number Signal Range

1 Chan 1 1) 4-20mA particle count levels

2) 2mA Service Alert level

2 Chan 2 1) 4-20mA particle count levels

2) 2mA Service Alert level

3 * VLOOP +15VDC to +30VDC

4 Ground

5 Status (if

signal is

available Figure 3-4)

6 Ground

7 * VPWR +6VDC to +30VDC

8 External

Alarm (-)

9 External

Alarm (+)

* If the application allows, VLOOP and VPWR may be connected to

the same source. In that case, the VPWR is +15VDC to +30VDC.

1) 4mA: no Alarm, no Service Alert

2) 12mA: Channel overflow Alarm

3) 20mA: SERVICE Alert

Continuity with Pin 9 if ALARM.

+40VDC at 1A maximum

248083201-1 Rev 6 3-5

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Table 3-2 J10 without Status Data Connector Pinouts

Pin Number Signal Range

1 Chan 1 1) 4-20mA particle count levels

2) 2mA Service Alert level

2 Chan 2 1) 4-20mA particle count levels

2) 2mA Service Alert level

3 * VLOOP +15VDC to +30VDC

4 Ground

5N/A -

(Figure 3-5)

6 Ground

7 * VPWR +6VDC to +30VDC

8 External

Continuity with Pin 9 if ALARM.

Alarm (-)

9 External

+40VDC at 1A maximum

Alarm (+)

* If the application allows, VLOOP and VPWR may be connected to

the same source. In that case, the VPWR is +15VDC to +30VDC.

Included with the instrument is a plug to connect the J10 connector to

your Facilities Monitoring System.

Figure 3-9 J10 Connector With Plug Attached

3-6 248083201-1 Rev 6

Getting Started

Applications Figure 3-10 and Figure 3-11 illustrate how to wire J10 for a two-wire or

a three-wire system.

When feature is

available, pin 5

is STATUS

Figure 3-10 Application for a Two Wire System

248083201-1 Rev 6 3-7

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

When feature is

available, pin 5

is STATUS

Figure 3-11 Application for a Three Wire System

3-8 248083201-1 Rev 6

00

4 Programming

General The REMOTE 2 Series family of instruments can be programmed in

either of two ways. The DIP switches can be used to set the Sampling

Time and Range values. If an ASCII terminal is connected to the

instrument, it can program the unit’s Sample Time, Range, Service

High, Service Low, Alarm Threshold and Suppress Alarm Count.

This chapter contains the information needed to program the

instrument to meet your needs.

DIP Switches The DIP switches are behind a panel under the Data connector J10.

Figure 4-1 Panel Covering the DIP Switches

Remove the two Phillips head screws to expose the DIP switches.

248083201-1 Rev 6 4-1

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

1 2 3 4 5 6 7 8

Switch

Numbers

DIP Switch

Settings

Note: The DIP Switches

must be set before the unit

is powered ON.

Figure 4-2 Panel Removed, Switches Exposed

GENERAL DEFINITIONS

OFF (DOWN) = 0, ON (UP) = 1

Switch Number1234 5678

Data 0000:0000

At Startup:

0000:0000==> Program Mode (ASCII terminal)

0000:0001==> Immediate Startup using last stored parameters

Anything Else==> DIP Switch Mode

Time:Range

When a DIP switch is set to any of the pre-programmed values listed

below and power applied to the instrument, information is echoed back

to the terminal, if connected.

These settings affect time and range only. All other parameters, such

as Alarm Value and Suppress Alarms, are left at their previous settings.

Time is the sampling time in seconds. The Range setting is applied to

both channels.

4-2 248083201-1 Rev 6

DIP Switch Settings and Meanings

1000:1000 ==> 6 seconds, 1000 counts

1000:0100 ==> 6 seconds, 10,000 counts

1000:0010 ==> 6 seconds, 100,000 counts

0100:1000 ==> 60 seconds, 1000 counts

0100:0100 ==> 60 seconds, 10,000 counts

0100:0010 ==> 60 seconds, 100,000 counts

0010:1000 ==> 600 seconds, 1000 counts

Programming

0010:0100 ==> 600 seconds, 10,000 counts

0010:0010 ==> 600 seconds, 100,000 counts

If the user chooses DIP switch combinations other than the ones

specified above, the unit will default to a sample time of 300 seconds,

Range1 and Range2 to 100,000 counts.

Procedure to Set DIP Switches

1. Remove power from the instrument.

2. Set the DIP Switches to the desired Time and Range, using the

information above.

3. Apply power to the instrument.

Example Startup Echo, Reading DIP Switches:

Lighthouse Remote Instrument (4-20mA):

- reading dip switch:

Sample Time = 60 secs

Range1= 10000.

Range2= 1000.

Alarm Threshold = 750 counts

Suppress Alarms = 2

Service High = 3500 mV

Service Low = 125 mV

248083201-1 Rev 6 4-3

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Connecting

the

Instrument to

a Terminal

The RJ-45 connector on the instrument (marked "Programming Port" in

Figure 4-3) is used to interconnect the unit with a COM port on a

desktop or laptop PC. Once connected and set up as an ASCII

terminal, the PC can be used to program and/or monitor the instrument

settings.

Programming

Port

8 1

Figure 4-3 The Programming Port, Showing Pin Numbers

A modular adapter, RJ-45 to DB-9, is available from Lighthouse. The

pinouts of the adapter are shown in the table below:

Table 4-1 RJ-45 to DB-9 Connections

RJ-45 Pin Signal Name DB-9 Pin

1TX2

2RX3

8 Ground 5

To connect the instrument to a computer:

1. Remove power from the instrument.

2. Connect the RJ-45 end of the adapter cable to the Programming

Port on the instrument.

3. Connect the DB-9 end of the cable to a COM (Serial) Port on your

computer.

4. Open Hyperterminal on your computer.

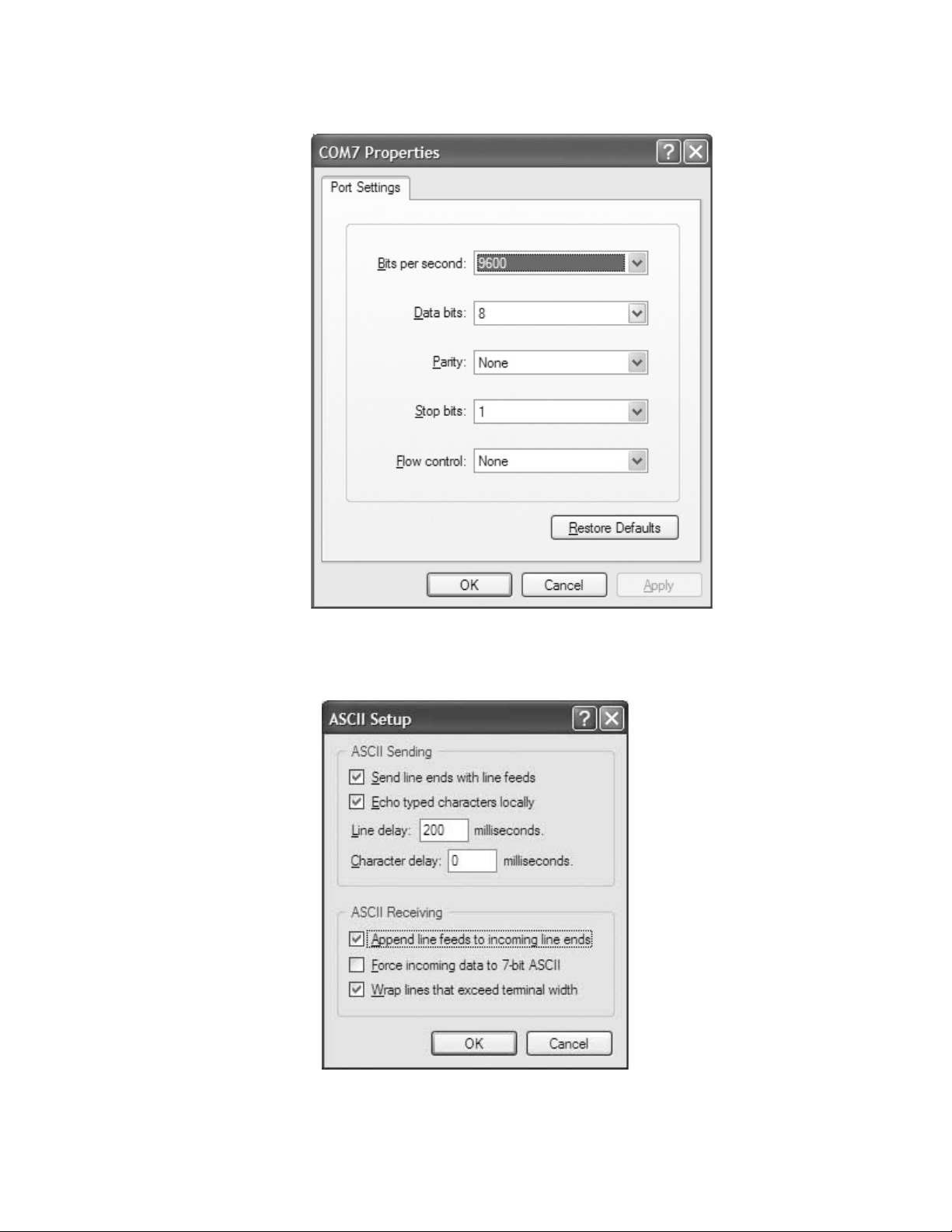

5. Configure the COM Port settings as follows. Any available COM

Port may be used:

4-4 248083201-1 Rev 6

Programming

Figure 4-4 COM Port Properties

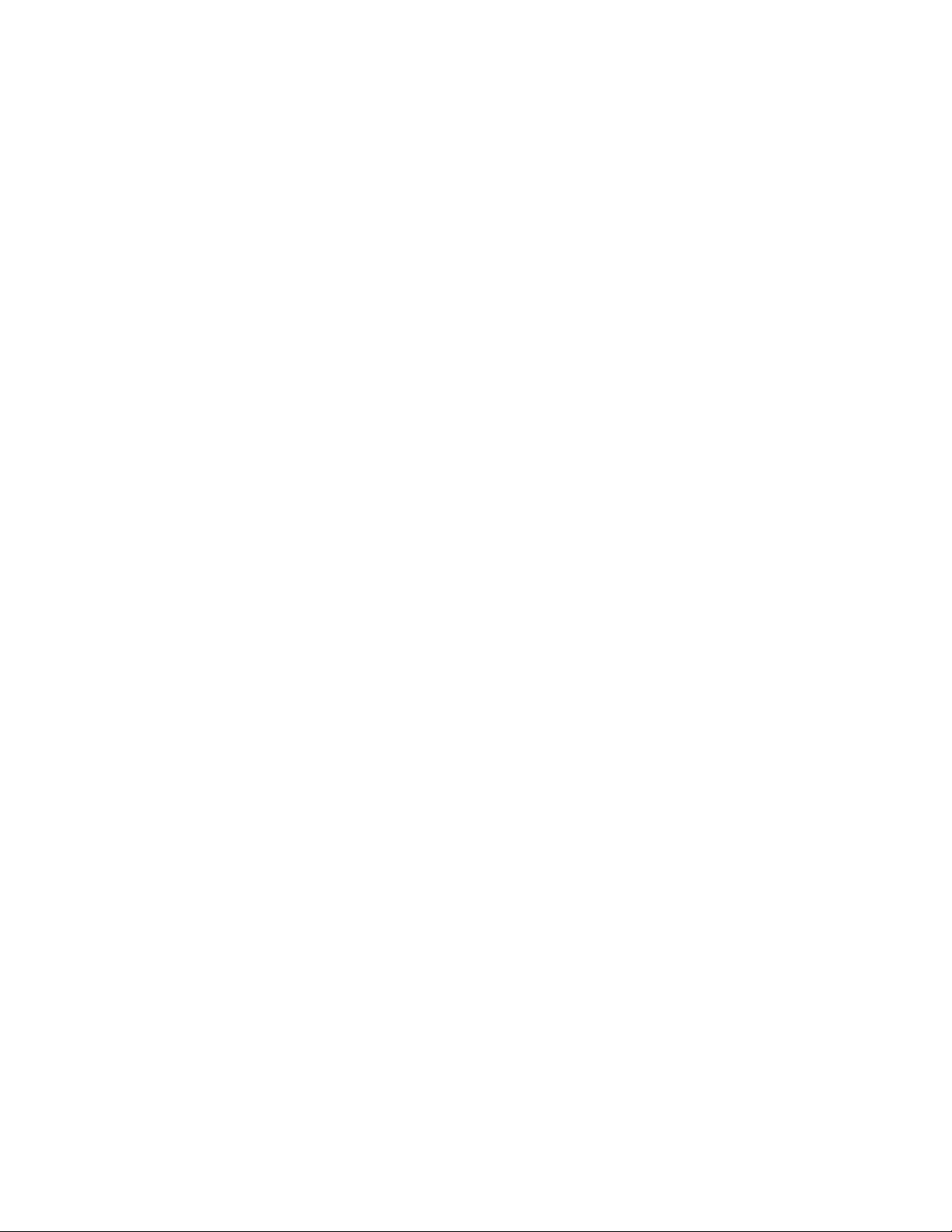

6. Configure the ASCII settings as follows:

Figure 4-5 ASCII Settings

248083201-1 Rev 6 4-5

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

7. Ensure that all DIP Switches are set to 0 (OFF/DOWN).

Power Up If DIP Switches all = 0 ==> Program Mode:

During the first 20 seconds after power is applied, the unit waits for

programming commands. If no commands are received within that

time, the instrument recalls its last stored parameters (or default

settings) and continues to use them.

If a programming command is received within the first 20 seconds, the

command is examined and, if valid, the parameters are set and stored in

non-volatile memory, overwriting the previous parameters for that

command.

The instrument waits another 20 seconds for the next command and the

process repeats for each command that is sent. After the last command,

the timer times out and the instrument is loaded with the commands

that were issued. Old parameters are used if they were not modified

during this session.

Session

Example

Note: Upper case V.

The < and > characters are

needed; they mark the

beginning and end of the

command.

Once programmed, the instrument retains its settings until they are

modified. The user can set DIP Switch 8 to ON (UP, 1) to eliminate the

20 second timer when the unit is next powered up.

Lighthouse recommends that, before powering up the instrument, you

make a list of the commands and parameters you want to use, thus

avoiding an unwanted timeout.

The following steps should be performed whenever you want to

program the instrument or check its settings using the ASCII terminal.

1. Set all DIP Switches to OFF (DOWN, 0) to program the instrument

and connect it to the ASCII terminal.

2. Apply power to the instrument. The Hyperterminal programming

prompt is sent from the unit.

3. Type: <V> -- this is Verbose mode. This must be the first

command sent if you wish to see responses from the

instrument

4. Type: <?> -- the unit’s current settings are displayed.

<?>

Flow Rate = 0.1 cfm

Sample Time = 5 secs

Range1= 10000.

4-6 248083201-1 Rev 6

Programming

Range2= 1000.

Service High = 3000 mV

Service Low = 145 mV

Alarm Channel = 1

Alarm Threshold = 1000 counts

Suppress Alarms = 2

Channel 1 = 0.3

Channel 2 = 0.5

5. Type: <m1> -- the unit’s menu is displayed to show commands to

use to change parameters.

<m1>

*** User Menu ***

<?> Display Parameters

<V> Verbose Mode

<sa> Start Counting

<sb> Stop Counting

<gv> Get Version Number

<ra#> Set Range 1 (counts)

<rb#> Set Range 2 (counts)

<ta#> Set Sample Seconds

<aa#> Set Alarm Channel #

<ab#> Set Alarm Threshold (# of counts)

<ae#> Set Alarm Suppression #

ASCII

Programming

Syntax

6. The instrument will wait 20 seconds after the last command is sent,

then begin sampling

Using a simple ASCII protocol, the REMOTE 3012 family of

instruments can be programmed from an ASCII terminal (i.e. Hyper

Terminal). The protocol format is based on a start character, followed

by a command, which is then followed by a terminating character. Any

characters before the start character, or after the terminating character

are ignored. White spaces between command character and command

parameter are ignored.

Command Structure

The commands are defined as single case-sensitive ASCII characters.

Format is defined as shown on page 8.

248083201-1 Rev 6 4-7

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Note: The < and >

characters are part of the

command and must be

typed. The brackets [ and ]

are field delimiters and are

not typed.

Note:

characters are lower case,

except for the V (verbose).

All command

<x[yyyy]>

where:

< = Start Character

x = Command Character

yyyy = Optional Command Parameter

> = Terminating Character

Handshake

Upon execution of the command, and assuming you have typed <V>

for Verbose, the REMOTE instrument will send a response based on

the value of the counts, suppress alarms, and alarm status. Examples of

responses are listed below:

<ERR> = Error in Command String.

-or-

Sample: ch1-2: 0, 0 Range1= 5000, Range2= 2500.

When the unit is powered up, it sets up the counters and timers, and

starts reporting data. The data will be similar to this example:

Sample: ch1-2: 0, 0 Range1= 5000, Range2= 2500.

Sample: ch1-2: 0, 0 Range1= 5000, Range2= 2500.

Protocol

Protocol is defined through an RS-232 interface. The hardware

protocol is defined as:

Baud Rate: 9600

Data Bits: 8

Stop Bits: 1

Parity: None

Flow Control: None

4-8 248083201-1 Rev 6

Command Set

VERBOSE MODE

Note: Upper case V <V>

Normally, VERBOSE MODE is off and the computer responds with

<OK> after each command is received and correctly implemented.

Turning on VERBOSE MODE tells the computer to echo back the

information to the screen.

VERBOSE MODE is required in order to program the device. It is not

required to run the counter.

GET CURRENT SETTINGS

<?>

Shows current parameter settings.

Programming

Type:

<?>

Response:

<?>

Flow Rate = 0.1 cfm

Sample Time = 5 secs

Range1= 10000.

Range2= 1000.

Service High = 3000 mV

Service Low = 145 mV

Alarm Channel = 1

Alarm Threshold = 1000 counts

Suppress Alarms = 2

Channel 1 = 0.3

Channel 2 = 0.5

DISPLAY MENU OF COMMANDS

<m1>

Shows menu of commands.

248083201-1 Rev 6 4-9

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Type:

<m1>

Response:

<m1>

*** User Menu ***

<?> Display Parameters

<V> Verbose Mode

<sa> Start Counting

<sb> Stop Counting

<gv> Get Version Number

<ra#> Set Range 1 (counts)

<rb#> Set Range 2 (counts)

<ta#> Set Sample Seconds

<aa#> Set Alarm Channel #

<ab#> Set Alarm Threshold (# of counts)

<ae#> Set Alarm Suppression #

START/STOP COUNTING MODE

START Counting

<sa>

This will start the device’s counting mode. When implemented, the

unit will wait until the sample time passes before displaying the sample

data.

Type:

<sa>

Response:

<sa>START

Sample: ch1-2: 0, 0 Range1= 10000, Range2= 5000.

Sample: ch1-2: 0, 0 Range1= 10000, Range2= 5000.

STOP Counting

<sb>

This will stop the device’s counting mode.

4-10 248083201-1 Rev 6

Type:

<sb>

Response:

<sb>STOP

GET CURRENT VERSION NUMBER

<gv>

Shows current version number of the device firmware.

Type:

<gv>

Response:

<gv> Version: 010

Programming

Note: Range 1 should

always be greater than or

equal to Range 2; Range 2

should never be greater

than Range 1.

When using the DIP switch

programming, both

channels are set to the

same range value.

SET CHANNEL RANGES

<ra#> -- sets upper range of channel 1 where # is the range value

<rb#> -- sets upper range of channel 2 where # is the range value

Sets upper limit to counting range. The upper limit will be equal to

20mA, and the lower range will always be 0 counts = 4 mA. If the

counts exceed range limit, the counts will be set to the range limit. The

maximum range is 10,000,000.

Type:

<ra10000>

Response:

<ra10000>Range1= 10000.

Type:

<rb7500>

Response:

<rb7500>Range2= 7500.

248083201-1 Rev 6 4-11

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

SET SAMPLE TIME (seconds)

Note: Sample times <5

seconds are not

recommended.

<ta#>

Sets sample time in # seconds, where # >1 and nnnn < 3600.

Type:

<ta30>

Response:

<ta30>Sample Time = 30 secs

SET ALARM CHANNEL

<aa#>

Sets the alarm channel to channel 1 or 2.

Type:

<aa1>

Response:

<aa1>Alarm Channel= 1

SET ALARM THRESHOLD

<ab#>

Sets Alarm High count threshold for the configured alarm channel.

Value # must be less than range in order to set the threshold. Set the

value to 0 (zero) to disable alarm.

If the count for the configured alarm channel exceeds the threshold

then:

• The red SERVICE indicator on the instrument blinks.

• The EXTERNAL ALARM relay, described below, is set.

• The alarm alert will be seen on the ASCII terminal as illustrated

next:

Type:

<ab1000>

4-12 248083201-1 Rev 6

Programming

Response:

<ab1000>Alarm Threshold= 1000 counts

Hyperterminal Alarm Alert without Alarm Suppression:

Note: The field bk= 429

in this example is the

"backlight" function which

is a measurement of

scattered light in the

instrument. See

SET_SERVICE_HIGH and

SET_SERVICE_LOW

In this example, the Alarm Suppress is disabled (0).

secs=1: ch1-2: 285, 48 , bk= 429

secs=2: ch1-2: 487, 89 , bk= 429

secs=3: ch1-2: 1699, 1033 , bk= 1049

secs=4: ch1-2: 2572, 1320 , bk= 434

secs=5: ch1-2: 3337, 1575 , bk= 429

Sample: ch1-2: 3337, 1575 Range1= 10000, Range2= 5000.

Alarms: Threshold= 1000, Channel= 1, # in a row=1

secs=1: ch1-2: 615, 228 , bk= 434, alarm alert.

secs=2: ch1-2: 1115, 382 , bk= 429, alarm alert.

secs=3: ch1-2: 1595, 502 , bk= 429, alarm alert.

secs=4: ch1-2: 2029, 637 , bk= 429, alarm alert.

secs=5: ch1-2: 2381, 738 , bk= 429, alarm alert.

Sample: ch1-2: 2381, 738 Range1= 10000, Range2= 5000.

Alarms: Threshold= 1000, Channel= 1, # in a row=2

SET ALARM SUPPRESSION

<ae#>

Sets the alarm suppression for the configured alarm channel. The

number of alarm conditions have to be greater than # in order to turn on

the Alarm Relay.

For example, if Alarm Suppress is set to 2, then the device won’t report

an alarm condition via the external alarm output or the flashing service

light until the 3rd consecutive alarm condition.

Type:

<ae2>

Response:

<ae2>Suppress Alarms = 2

Hyperterminal Alarm Alert with Alarm Suppression:

In this example, the Alarm Suppress is set to 2.

248083201-1 Rev 6 4-13

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

<ae2>Suppress Alarms = 2

secs=1: ch1-2: 0, 0 , bk= 429

secs=2: ch1-2: 681, 430 , bk= 2558

secs=3: ch1-2: 1629, 886 , bk= 444

Sample: ch1-2: 1629, 886 Range1= 10000, Range2= 5000.

Note: The first line

starting with "Alarms" (in

boldface) shows what the

current alarm threshold is,

which channel is set for

alarming and how many

alarm conditions in a row

have occurred.

Alarms: Threshold= 1000, Channel= 1, # in a row=1

secs=1: ch1-2: 828, 517 , bk= 1640

secs=2: ch1-2: 1861, 1230 , bk= 434

secs=3: ch1-2: 3149, 2177 , bk= 449

Sample: ch1-2: 3149, 2177 Range1= 10000, Range2= 5000.

Alarms: Threshold= 1000, Channel= 1, # in a row=2

secs=1: ch1-2: 450, 126 , bk= 434

secs=2: ch1-2: 1279, 530 , bk= 444

secs=3: ch1-2: 1875, 678 , bk= 439

Sample: ch1-2: 1875, 678 Range1= 10000, Range2= 5000.

Alarms: Threshold= 1000, Channel= 1, # in a row=3

Note: The "alarm alert"

(in boldface) doesn’t

display until after the 3rd

consecutive alarm

condition; the external

alarm light goes on at this

point as well.

Service High

and Service

Low

Note: The "normal"

levels seen in these "bk"

fields are examples only

and are not necessarily

what you will see with your

instrument.

secs=1: ch1-2: 697, 131 , bk= 439, alarm alert.

secs=2: ch1-2: 1215, 227 , bk= 434, alarm alert.

secs=3: ch1-2: 1505, 302 , bk= 439, alarm alert.

Sample: ch1-2: 1505, 302 Range1= 10000, Range2= 5000.

Alarms: Threshold= 1000, Channel= 1, # in a row=4

Service High and Service Low are the voltage levels at which the

Service Light will go on. Those levels are compared to the "Backlight"

measurement (seen as the bk= 1455 field) in every sample period. If

the Backlight measurement is greater than Service High or less than

Service Low, then:

• the service alert appears as seen in the following Hyperterminal

Service Alert example:

• J10 pins 1 and 2 (Chans 1 and 2) = 2mA

• the Service Light is turned on

The default Service High threshold is 3500.

Hyperterminal Service Alert Example:

secs=1: ch1-2: 667, 214 , bk= 463

secs=2: ch1-2: 2262, 1395 , bk= 449

secs=3: ch1-2: 2890, 1608 , bk= 434

secs=4: ch1-2: 4719, 2983 , bk= 4995, service alert.

4-14 248083201-1 Rev 6

secs=5: ch1-2: 4719, 2983 , bk= 4995, service alert.

Sample: ch1-2: 4719, 2983 Range1= 10000, Range2= 5000.

Alarms: Threshold= 1000, Channel= 1, # in a row=1

Service Menu The Service Menu is available by typing <ms>.

Type:

<ms>

Response:

<ms>

*** Service Menu ***

<ia> Don't show 1 sec data

<ib> Show 1 sec data

<gb> Get Bkgnd

DON’T SHOW 1 SEC DATA

Programming

<ia>

Turns OFF 1 second data display.

Type:

<ia>

Response:

<ia>Don't show 1 sec data.

After starting the counter with <sa>, the device will wait until the

sample time interval passes before displaying the first sample.

SHOW 1 SEC DATA

<ib>

Turns ON 1 second data display.

Type:

<ib>

Response:

<ib>Show 1 sec data.

248083201-1 Rev 6 4-15

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

After starting the counter with <sa>, the device will show the samples

collecting every second.

secs=1: ch1-2: 0, 0. , bk= 424

secs=2: ch1-2: 0, 0. , bk= 424

secs=3: ch1-2: 0, 0. , bk= 424

secs=4: ch1-2: 0, 0. , bk= 424

secs=5: ch1-2: 1, 0. , bk= 424

This mode can be used to view the data on a second-by-second basis

for troubleshooting.

GET BACKGROUND LIGHT VALUE

<gb>

Displays the current background value in milli-volts (mV).

4-16 248083201-1 Rev 6

00

5 Technical Data

Introduction This chapter describes the operation and programming of the

instrument.

Control

Design

Setup

Start

Figure 5-1 States for the 3012, 5012, 3102, 5102 Particle Counter

START

• Starts microprocessor, and initializes hardware.

SETUP

Count Timer

Output

Alarm

Counts

• If DIP Switches all = 0 ==> Program Mode:

During the first 20 seconds, the unit waits for programming

commands. If any programming commands are received within the

first 20 seconds, those commands will be examined and executed.

If the commands are valid, the parameters will be set. If no

248083201-1 Rev 6 5-1

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

commands are received (all DIP switches = 0) or if an invalid

command is received, the instrument will recall its last stored

parameters (or default settings) and continue to use them.

• If DIP Switches = 0000 0001 ==> Use last stored parameters

With the DIP switches set with this value, the instrument will start

up immediately using the last stored parameters.

Startup Example:

Lighthouse Remote Instrument (4-20mA):

- reading dip switch:

Sample Time = 60 secs

Range1= 10000.

Range2= 1000.

Alarm Threshold = 750 counts

Suppress Alarms = 2

Service High = 3500 mV

Service Low = 125 mV

• DIP Switches = Anything other than (0000 0000 or 0000 0001)

The DIP switch settings will be read and interpreted. If the

combination is valid, those parameters will be chosen. Otherwise,

sample time of 300 seconds and 100,000 counts will be used.

COUNT

The instrument uses setup parameters to run, collect data, and output

count and alarm data. 0 counts will be represented by 4mA, and counts

equal to upper range will equal 20mA. The current output will have a

direct linear relationship to the range.

• Iout= 16mA(counts/ range) + 4mA

• Vout= Iout(R-load)

• If a Service Alert occurs, both channels are set to 2mA.

TIMER

Keeps track of time relative to sample seconds, and outputs sample data

every SampleSecs.

5-2 248083201-1 Rev 6

Technical Data

OUTPUT

• Counts are output on CH1 and CH2 lines in 4-20 mA current.

• If STATUS feature is available and counts become greater than the

alarm threshold, after a "suppress" of # of consecutive alarm

conditions, STATUS (pin 5) is set to 12mA and the ALARM relay

is turned ON.

• If STATUS feature is not available and counts become greater than

the alarm threshold, after a "suppress" # of consecutive alarm

conditions, the ALARM relay is turned ON.

• If STATUS feature is available and Background Light laser voltage

exceeds the ServiceHigh or ServiceLow limit or when the laser

optics are dirty, STATUS (pin 5) is set to 20mA.

ALARM

If the CH1 or CH2 count exceeds the programmed ALARM threshold,

• The red SERVICE indicator on the instrument blinks.

• The EXTERNAL ALARM relay, described below, is set.

• If STATUS feature is available, STATUS (pin 5) is set to 12mA.

SERVICE ALERT

If the service/background light voltage is greater than the Service High,

or less than Service Low limits, then:

• CH1 and CH2 outputs are set to 2mA.

• The red SERVICE indicator on the instrument is turned on steady.

• If STATUS feature is available and pin 5 = 4 mA ==> No Alarms

and No Service Alerts.

EXTERNAL ALARM

An ALARM condition, as described above, also closes a relay inside

the instrument. Contacts of that relay are connected to the DATA

connector, pins 8 (-) and 9 (+). The user may use an external power

supply and a buzzer or light stick to provide local indication of an

alarm condition. The contacts are rated at 40VDC, 1A maximum.

248083201-1 Rev 6 5-3

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

5-4 248083201-1 Rev 6

00

6 Maintenance

Procedures

Introduction This chapter provides instructions for routine maintenance that may be

required for your REMOTE 2012, 3012, 5012, 3102 or 5102

instrument.

The maintenance procedures described in this chapter are not required

on regular or prescribed intervals and should be performed only if you

have reason to question the data you are receiving from the instrument.

Safety Before performing any of the maintenance tasks described in this

chapter, read Chapter 1 of this manual and become familiar with the

warnings and caution labels.

Calibration To maintain optimum performance of this instrument, it should be re-

calibrated annually by a Lighthouse Authorized Service Provider.

Purge Count

Test

This section will provide you with the procedure to check the counter

for zero counts. A purge filter must be attached to the instrument and

six (6) five (5) minute samples must be taken. There should be no more

than 1 count on average per five-minute sample.

1. Disconnect power from the instrument.

2. Connect the Purge filter to the sample inlet.

3. Apply power to the instrument.

4. Configure the unit to run one 30-minute sample.

5. Run the 30-minute sample. This time allows the unit to warm up

and purge any residual particles that might be inside the

instrument.

6. Stop sampling.

248083201-1 Rev 6 6-1

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

7. Program the unit for 5-minute sample time and 10-second hold.

8. Run six 5-minute samples.

9. If an average of more than one count per five-minute period is

reported, run another 30-minute sample to purge it and repeat

Step 8.

10. If the instrument has met the requirement of the Purge Count test,

return the instrument to its normal location and operating status.

Fault Isolation If the instrument does not pass the Purge Count test, please perform the

following procedure:

1. Check the data over the last 6 five-minute sample times.

2. If sporadic counts over all channels are occurring, the unit may

still have particles inside it. Allow the unit to sample overnight

with the purge filter attached before retesting it. If the counts are

still high after the overnight purge, call Lighthouse Technical

Support for assistance.

3. If the data shows consistent counts in the smallest channel only,

the instrument may have electrical problems. Call your

Lighthouse Service Representative for assistance.

6-2 248083201-1 Rev 6

00

A Limited Warranty

Limitation Of Warranties:

A. Lighthouse Worldwide Solutions (LWS) warrants that all

equipment shall be free from defects in material and

workmanship under normal use for a period of two years from

date of shipment to Buyer except that LWS does not warrant that

operation of the software will be completely uninterrupted or

error free or that all program errors will be corrected. Buyer shall

be responsible for determining that the equipment is suitable for

Buyer’s use and that such use complies with any applicable

local, state, or federal law. Provided that Buyer notifies LWS in

writing of any claimed defect in the equipment immediately

upon discovery and any such equipment is returned to the

original shipping point, transportation charges prepaid, within

two years from date of shipment to Buyer and upon examination

LWS determines to its satisfaction that such equipment is

defective in material or workmanship, i.e. contains a defect

arising out of the manufacture of the equipment and not a defect

caused by other circumstances, including, but not limited to

accident, misuse, unforeseeable use, neglect, alteration,

improper installation, improper adjustment, improper repair, or

improper testing, LWS shall, at its option, repair or replace the

equipment, shipment to Buyer prepaid. LWS shall have

reasonable time to make such repairs or to replace such

equipment. Any repair or replacement of equipment shall not

extend the period of warranty. If the Instrument is modified or in

any way altered without the explicit written consent of LWS then

the warranty is null and void. This warranty is limited to a period

of two years, except as noted below, without regard to whether

any claimed defects were discoverable or latent on the date of

shipment. The length of warranty for pumps in hand held particle

counters is one (1) year. Batteries and accessories with all

products are warranted for one (1) year. Fuses and purge filters

carry no warranty. If a third party battery is used in the product,

the product warranty is null and void. If the battery is charged by

a third party battery charger the battery warranty is null and void.

B. If Buyer shall fail to pay when due any portion of the purchase

price or any other payment required from Buyer to LWS under

this contract or otherwise, all warranties and remedies granted

under this Section may, at LWS’s option, be terminated.

C. THE FOREGOING WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER REPRESENTATIONS, WARRANTIES

AND COVENANTS, EXPRESS OR IMPLIED WITH

RESPECT TO THE EQUIPMENT AND ANY DEFECTS

THEREIN OF ANY NATURE WHATEVER, INCLUDING

AND WITHOUT LIMITATION WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. LWS SHALL NOT BE LIABLE FOR, AND

BUYER ASSUMES ALL RISK OF, ANY ADVICE OR

FAILURE TO PROVIDE ADVICE BY LWS TO BUYER

REGARDING THE EQUIPMENT OR BUYERS USE OF THE

SAME. UNDER NO CIRCUMSTANCES SHALL LWS BE

LIABLE TO BUYER UNDER ANY TORT, NEGLIGENCE,

STRICT LIABILITY, OR PRODUCT LIABILITY CLAIM

AND BUYER AGREES TO WAIVE SUCH CLAIMS. LWS’s

SOLE AND EXCLUSIVE LIABILITY AND BUYERS SOLE

AND EXCLUSIVE REMEDY, FOR ANY

NONCONFORMITY OR DEFECT IN THE PRODUCTS OR

ANYTHING DONE IN CONNECTION WITH THIS

CONTRACT, IN TORT, (INCLUDING NEGLIGENCE),

CONTRACT, OR OTHERWISE, SHALL BE AS SET FORTH

IN THE SUBSECTION A HEREOF AS LIMITED BY

SUBSECTION B HEREOF. THIS EXCLUSIVE REMEDY

SHALL NOT HAVE FAILED OF ITS ESSENTIAL PURPOSE

(AS THAT TERM IS USED IN THE UNIFORM

COMMERCIAL CODE) PROVIDED THAT THE SELLER

REMAINS WILLING TO REPAIR OR REPLACE

DEFECTIVE EQUIPMENT (AS DEFINED IN SUBSECTION

A) WITH A COMMERCIALLY REASONABLE TIME

AFTER RECEIVING SUCH EQUIPMENT. BUYER

SPECIFICALLY ACKNOWLEDGES THAT SELLER’S

PRICE FOR THE EQUIPMENT IS BASED UPON THE

LIMITATIONS OF LWS’S LIABILITY AS SET FORTH IN

THIS CONTRACT.

Warranty Of Repairs After

Initial Two (2) Year Warranty:

A. Upon expiration of the initial two-year warranty, all parts and

repairs completed by an authorized Lighthouse repair technician

are subject to a six (6) month warranty.

B. Other than the above, LWS makes no warranty of any kind,

expressed or implied, except that the products manufactured and

sold by LWS shall be free from defects in materials and

workmanship and shall conform to LWS’s specifications; Buyer

assumes all risk and liability resulting from use of the products

whether used singly or in combination with other products. If

instrument is modified or in any way altered without the explicit

written consent of LWS, then the warranty is null and void.

C. WARRANTY REPAIRS SHALL BE COMPLETED AT THE

FACTORY, BY AN AUTHORIZED SERVICE LOCATION,

BY AN AUTHORIZED SERVICE TECHNICIAN, OR ON

SITE AT BUYER’S FACILITY BY A LIGHTHOUSE

AUTHORIZED EMPLOYEE. BUYER PAYS FREIGHT TO

FACTORY; SELLER WILL PAY STANDARD RETURN

FREIGHT DURING THE WARRANTY PERIOD. BUYER

MAY SELECT A FASTER METHOD OF SHIPMENT AT ITS

OWN EXPENSE.

248083201-1 Rev 6 A-1

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

A-2 248083201-1 Rev 6

00

Index

A

Accessories 2-2

Alarm 5-3

Alarm Channel 4-12

Alarm Suppression 4-13

Alarm Threshold 4-12

Applications, two and three wire 3-7

ASCII Programming

Command Set 4-9

Command Structure 4-7

Display Menu of Commands 4-9

Don’t Show 1 Second Data 4-15

Get Background Light Value 4-16

Get Current Setings 4-9

Get Current Version Number 4-11

Handshake 4-8

Protocol 4-8

Service Menu 4-15

Set alarm Channel 4-12

Set Alarm Suppression 4-13

Set Alarm Threshold 4-12

Set Channel Ranges 4-11

Set Sample Time 4-12

Show 1 Sec Data 4-15

Start/Stop Counting Mode 4-10

Syntax 4-7

Verbose Mode 4-9

B

COM Port connection 4-4

Command Structure 4-7

Communication Modes 2-3

Connecting the Instrument to a Terminal 4-4

Connections 3-3

Control Design 5-1

Alarm 5-3

Count 5-2

External Alarm 5-3

Output 5-3

Service Alert 5-3

Setup 5-1

Start 5-1

Timer 5-2

Counting Efficiency 2-3

Current Settings 4-9

Current Version Number 4-11

D

Data Port 3-5

Description, general 2-1

Dimensions 2-3

DIP Switches 4-1

=0 at Power Up 4-6

Meanings 4-3

procedure 4-3

Settings 4-2

Don’t Show 1 Second Data 4-15

Background Light Value 4-16

E

External Alarm 5-3

C

Calibration 2-3

Channel Threshold 2-3

Collection Optics 2-2

248083201-1 Rev 6 I-1

External vacuum source 3-5

F

Flow Rate 2-3

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

Front panel lights 3-2

I

Initial Inspection 3-1

Installation 3-4

Installing an Isokinetic Probe 3-5

Interpreting indicators 3-2

Introduction

Description, general 2-1

Overview 2-1

isokinetic probe 3-5

L

Laser Diode 2-2

Laser Source 2-3

M

Menu of Commands 4-9

O

Operating Temp/RH 2-3

Operation 3-2

Interpreting indicators 3-2

Overview 2-1

Sample Time 4-12

Service

High and Low 4-14

Service Alert 5-3

Service Menu 4-15

Set Channel Ranges 4-11

Setting DIP Switches 4-2

Shipping instructions 3-1

Show 1 Sec Data 4-15

Size Ranges 2-3

Specifications 2-3

Start Counting 4-10

Startup using defaults 5-2

Startup using last stored paramaters 5-2

Stop Counting 4-10

Storage Temp/RH 2-3

T

Terminal

ASCII Settings 4-5

COM Port Properties 4-5

Command Structure 4-7

Programming Syntax 4-7

Session Example 4-6

Terminal, Connecting To 4-4

Three wire systems 3-7

Troubleshooting, Zero Count 6-2

Two Wire Systems 3-7

P

Particle Detection 2-2

Particles, sizes 2-1

Power 2-3

Power Up, DIP Switches = 0 4-6

Programming

DIP Switches 4-2

S

Safety 1-1, 6-1

Electrostatic safety information 1-2

Laser safety information 1-1

I-2 248083201-1 Rev 6

U

Unpacking 3-1

V

Vacuum Requirements 2-3

Verbose Mode 4-9

W

Warning

Electrostatic Discharge 1-2

Infrared Radiation 1-1

Weight 2-3

Z

Zero Count Check

Troubleshooting 6-2

Zero Count Level 2-3

Index

248083201-1 Rev 6 I-3

Lighthouse REMOTE 2012, 3012, 5012, 3102, 5102 Operating Manual

I-4 248083201-1 Rev 6

00

Loading...

Loading...