Page 1

OPERATING MANUAL

Handheld

PARTICLE COUNTERS

Handheld 2016, 3016, 5016

Page 2

00

Page 3

Lighthouse Worldwide Solutions

HANDHELD 2016, 3016, 5016 Airborne Particle

Counter Gen F

Operating Manual

Page 4

Copyright © 2011-2017 by Lighthouse Worldwide Solutions. All rights reserved. No part of this

document may be reproduced by any means except as permitted in writing by Lig hthouse

Worldwide Solutions.

The information contained herein constitutes valuable trade secrets of Lighthouse Worldwide

Solutions. You are not permitted to disclose or allow to be disclosed such information except as

permitted in writing by Lig hthouse Worldwide Solutions.

The information contained herein is subject to change without notice. Lighthouse Worldwide

Solutions is not responsible for any damages arising out of your use of the LMS program.

HANDHELD 2016™, HANDHELD 3016™, HANDHELD 5016™ and LMS™ are

trademarks of Lighthouse Worldwide Solutions.

Microsoft®, Microsoft Windows© and Excel© are trademarks of Microsoft Corporation.

LWS Part Number: 248083400-1 Rev 7

Page 5

EU DECLARATION OF CONFORMITY

Manufacturer’s Name Lighthouse Worldwide Solutions, Inc.

Manufacturer’s Address: Lighthouse Worldwide Solutions, Inc.

1221 Disk Drive

Medford, OR 97501

Declares that the product:

Product Name: Handheld Airborne Particle Counter

Model Number(s): Handheld 2016, 3016, 5016

Conforms to the following Product Specifications:

SAFETY

LASER SAFETY

EMC

UL 61010A-1 – UL Standard for Safety Electrical Equipment for Laboratory Use; Part 1: General Requirements.

Replaces UL 3101-1

Supplementary information: The product herewith complies with the requirements of the Low Voltage

Directive 73/23/EEC amended by Directive 93/68/EEC and the EMC Directive 89/336/EEC amended by Directive

93/68/EEC, and carries the CE marking accordingly.

EN61010-1:2001 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use Part I:

General Requirements IEC 61010-1:2000

CAN/CSA C22.2 Safety Requirements for Electrical

No. 1010.1-1992 Equipment for Measurement, Control, and Laboratory

Use, Part1: General Requirements

IEC 60825-1 Am. 2 Guidance on Laser Products: Conforms to

IEC 60601-2-22 FDA 21 CFR Chapter 1 Subchapter J

(Laser Notice 50)

EN61326 Electrical Equipment for Measurement, Control and

Laboratory Use EMC Requirements Part 1: General

Requirements Includes Amendment A1:1998;IEC

61326:1997 + A1:1998

Fremont, CA, May 15, 2007 William L. Shade – V.P. Engineering

Page 6

Page 7

00

Table of Contents

About this Manual

Text Conventions ................................................................................................................ i

Additional Help ................................................................................................................... i

Chapter 1 General Safety

General Safety ............................................................................................................... 1-1

Laser Safety Information ............................................................................................... 1-1

Chapter 2 Introduction

Overview ........................................................................................................................ 2-1

Description ..................................................................................................................... 2-2

HANDHELD Specifications .......................................................................................... 2-3

Chapter 3 Unpacking, Inspecting and Installation

Initial Inspection ............................................................................................................ 3-1

Unpacking ...................................................................................................................... 3-1

Shipping Instructions ..................................................................................................... 3-2

Accessories .................................................................................................................... 3-2

Prepare Instrument for Use ............................................................................................ 3-3

Power Requirements ......................................................................................... 3-3

Install the Battery ................................................................................... 3-3

Connect Power ................................................................................................... 3-6

Battery Removal ............................................................................................... 3-7

Optional Printer Accessory ................................................................................ 3-9

Connecting to an External Computer or Facility Management System .......... 3-10

Chapter 4 Operation

Using the Instrument ...................................................................................................... 4-1

Touch Screen Overview ................................................................................................. 4-2

Menu Map ......................................................................................................... 4-2

MAIN Screen ................................................................................................................. 4-3

248083400-1 Rev 7

t-i

Page 8

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

LOCATION Selection ....................................................................................... 4-7

Changing Locations ............................................................................... 4-7

Locations in AUTO Mode ..................................................................... 4-7

Zoomed Data View ............................................................................................ 4-8

Viewing Two Columns of Data ........................................................... 4-10

CONFIGURATION Screen ......................................................................................... 4-13

DATA SETUP ............................................................................................................. 4-14

Particle Channels ............................................................................................. 4-14

Analog Channels .............................................................................................. 4-15

SAMPLE .......................................................................................................... 4-18

SETTINGS ....................................................................................................... 4-21

COUNT MODE ................................................................................... 4-21

Geiger Counter Mode .......................................................................... 4-22

PARTICLE Display ............................................................................. 4-23

ALARM ........................................................................................................... 4-23

Alarm Threshold .................................................................................. 4-24

Clear Buffer ..................................................................................................... 4-26

DEVICE SETUP .......................................................................................................... 4-26

CLOCK ............................................................................................................ 4-27

OPTIONS ......................................................................................................... 4-30

CONTRAST ADJUST ........................................................................ 4-30

AUDIBLE BEEP ADJUST ................................................................. 4-30

ALIGN TOUCH SCREEN .................................................................. 4-30

Autostart Mode .................................................................................... 4-33

DiffCuml on Zoom .............................................................................. 4-33

One Channel ........................................................................................ 4-33

ONE SECOND OUTPUT .................................................................. 4-34

Pump Startup ........................................................................................ 4-35

LANGUAGE ....................................................................................... 4-35

COMM ADDRESS .......................................................................................... 4-36

OUTPUT SETUP ............................................................................................ 4-37

SECURITY ...................................................................................................... 4-38

POWER ON PASSWORD .................................................................. 4-39

CONFIGURATION PASSWORD ...................................................... 4-39

SERVICE ......................................................................................................... 4-40

STATUS ...................................................................................................................... 4-40

RECIPE ........................................................................................................................ 4-41

LOCATION ................................................................................................................. 4-44

Data View Buffer Screen ............................................................................................. 4-47

Analog Data ......................................................................................... 4-49

Printing Data View Buffer Report ....................................................................................49

Printing Range ..................................................................................... 4-51

REPORTS .................................................................................................................... 4-53

Setting up Counter to Run Reports .................................................................. 4-62

Report Output Setup ........................................................................................ 4-63

Printing a Report .............................................................................................. 4-63

t-ii

248083400-1 Rev 7

Page 9

Report Requirements ....................................................................................... 4-64

Fed Std ft3 ............................................................................................ 4-64

ISO 14644-1 ......................................................................................... 4-64

EU GMP 2009 ..................................................................................... 4-64

Sample Printouts of Standard Reports ................................................. 4-65

Power Shutdown Levels .............................................................................................. 4-68

Chapter 5 Setting up the Counter

Using Report Parameters ............................................................................................... 5-1

Basic Requirements ....................................................................................................... 5-1

Fed Std 209E (feet) ............................................................................................ 5-1

ISO 14644-1 ....................................................................................................... 5-2

EU GMP 2009 ................................................................................................... 5-2

Chapter 6 Maintenance Procedures

Safety ............................................................................................................................. 6-1

Calibration ..................................................................................................................... 6-1

Cleaning ......................................................................................................................... 6-1

Purge Test ...................................................................................................................... 6-1

Table of Contents

Appendix A Limited Warranty

Limitation Of Warranties: ............................................................................................. A-1

Warranty Of Repairs After Initial Two (2) Year Warranty: ......................................... A-1

Appendix B HANDHELD Default Settings

Appendix C HANDHELD MODBUS Register Map v1.48

COMM Settings ............................................................................................................. C-1

Supported MODBUS Commands .................................................................................. C-1

Register Map .................................................................................................................. C-2

Sensor Settings Registers ................................................................................... C-2

Device Status ..................................................................................................... C-5

Command Register ........................................................................................................ C-6

Data and Alarm Registers .............................................................................................. C-8

Data and Alarm Enable Registers ...................................................................... C-8

Enable Alarming for a Channel ......................................................................... C-9

Threshold Setup Registers ............................................................................... C-10

Setting the Alarm Threshold Value ................................................................. C-11

Data Registers .............................................................................................................. C-12

Device Status Word (30007 - 30008) .............................................................. C-14

248083400-1 Rev 7

t-iii

Page 10

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Valid Data in Channels (30073 - 30076) ......................................................... C-15

Data Type Registers ......................................................................................... C-15

Data Units Registers ........................................................................................ C-17

Index

t-iv

248083400-1 Rev 7

Page 11

00

About this Manual

This manual describes the detailed operation and use of the Lighthouse

HANDHELD 2016, 3016 and 5016 Airborne Particle Counters.

Text

Conventions

Note:

the sidebar to give extra

information regarding a

feature or suggestion.

WARNING:

warning appears in a

paragraph like this and

warns that doing

something incorrectly

could result in personal

injury, damage to the

instrument or loss of

data.

A note appears in

A

The following typefaces have the following meanings:

italics Represents information not to be typed

or interpreted literally. For example, file

represents a file name. Manual titles are

also displayed in italics.

boldface Introduces or emphasizes a term.

Courier font Indicates command syntax or text

displayed by the diagnostic terminal.

Bold Courier Indicates commands and information that

you type. You can use uppercase or

lowercase letters; in this manual,

commands are shown in uppercase.

Helvetica Italics Indicates a comment on a command or

text output.

Hexadecimal numbers are shown with the word “hex” or with a small

“h” following the digits. For example:

hex 0D

0Dh

Additional

Help

248083400-1 Rev 7

For more information about the Lighthouse HANDHELD 2016, 3016,

5016 Airborne Particle Counter, contact Lighthouse Worldwide

Solutions:

Service and Support

Tel: 800-945-5905 (USA Toll Free)

Tel: 541-770-5905 (Outside of USA)

techsupport@golighthouse.com

i

Page 12

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

ii

248083400-1 Rev 7

Page 13

00

1 General Safety

General

Safety

Laser Safety

Information

WARNING:

of controls, adjustments,

or performance of

procedures other than

those specified within

this manual may result in

exposure to invisible

(infrared) radiation that

can quickly cause

blindness. As a general

precaution, avoid any

possible exposure to

laser radiation by

honoring manufacturer

seals and warranty

stickers .

The use

Warnings and cautions are used throughout this manual. Familiarize

yourself with the meaning of a warning before operating the particle

counter. All warnings will appear in the left margin of the page next to

the subject or step to which it applies. Pay close attention to each

warning message. Take extreme care when performing any procedure

preceded by or containing a warning.

There are several classifications of Warnings directed as follows:

• Laser - pertaining to exposure to visible or invisible laser radiation

• Electrostatic - pertaining to electrostatic discharge

This product contains a laser-based sensor that is a Class 1 product (as

defined by 21 CFR, Subchapter J of the Health and Safety Act of 1968)

when used under normal operation and maintenance. Service

procedures on the sensor can result in exposure to invisible radiation.

Service should be performed only by factory-authorized personnel.

The particle counter has been evaluated and tested in accordance with

EN 610109-1:1993, “Safety Requirements For Electrical Equipment

for Measurement, Control, and Laboratory Use” and IEC 825-1:1993,

“Safety of Laser Products”. See Figure 1-1.

Figure 1-1 Example of Laser Warning Label

For further technical assistance, contact Lighthouse at 800-945-5905

(USA Toll Free), 541-770-5905 (Outside of USA).

248083400-1 Rev 7

1-1

Page 14

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

1-2

248083400-1 Rev 7

Page 15

00

2 Introduction

Overview This operating guide describes how to use the Lighthouse

HANDHELD 2016, 3016 and 5016 Airborne Particle Counters.

The HANDHELD 2016 has up to six particle-size channels starting at

0.2 microns with a flow of 0.1 CFM and a touch screen interface. The

HANDHELD 3016 has up to six particle-size channels starting at 0.3

microns and the HANDHELD 5016 has up to six channels starting at

0.5 microns. They are otherwise identical to the 2016 model. A

microprocessor controls all instrument functions. Count data is

displayed as cumulative or differential count.

The model number signifies the minimum particle size measured by the

instrument. The number “2016” indicates a 0.2μm minimum channel

size at 0.1 CFM with up to 6 channels. The number “3016” indicates a

0.3 μm minimum channel size at 0.1 CFM with up to 6 channels. The

number “5016” represents a 0.5μm minimum channel size at 0.1 CFM

with up to six channels.

The instrument uses a laser-diode light source and collection optics for

particle detection. Particles scatter light from the laser diode. The

collection optics collect and focus the light onto a photo diode that

converts the bursts of light into electrical pulses. The pulse height is a

measure of particle size. Pulses are counted and their amplitude is

measured for particle sizing. Results are displayed as particle counts in

the specified size channel.

248083400-1 Rev 7

2-1

Page 16

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Description Ergonomically designed and lightweight, the Lighthouse HANDHELD

2016, 3016 and 5016 particle counters are the newest and most

advanced handheld particle counters on the market. See Figure 2-1.

Figure 2-1 Handheld 3016

The HANDHELD 2016/3016/5016 displays cumulative or differential

particle count data as well as Temperature/Relative Humidity data on

its easy to read 3.8" (9.25cm) touch screen. A rechargeable battery

maximizes the HANDHELD’s uptime. Data is easily downloaded

using the LMS XChange software.

The HANDHELD allows you to:

• Set the Sample Time

• Configure the number of samples taken in a given Location

• Sample many different locations

• Print reports (with optional, external printer) based on Federal

Standard 209E (ft

3

), ISO 146441-1, and EU GMP 2009 (if unit has

0.5 and 5.0 channels).

• Save your data for historical data review

• Print data tables using the data transfer software included with your

2-2

instrument. Additionally use LMS Express to print graphs, data

tables, and standards reports.

248083400-1 Rev 7

Page 17

HANDHELD

Specifications

Introduction

Size Range 0.2 - 10.0 μm

HANDHELD 2016

Channel Thresholds

HANDHELD 3016

Channel Thresholds

HANDHELD 5016

Channel Thresholds

Flow Rate 0.1 CFM (2.83 LPM)

Counting Efficiency 50% (per ISO 21501-4)

Laser Source Laser diode

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Calibration NIST Traceable

Count Modes Concentration, manual/automatic, beep,

Data Storage Up to 3000 sample records, includes particle

0.2, 0.3, 0.5, 0.7, 1.0, 2.0 μm

0.3, 0.5, 0.7, 1.0, 2.5, 5.0 μm

0.5, 0.7, 1.0, 3.0, 5.0, 10.0 μm

Other sizing available for each model; specify

at time of order

cumulative/differential

& environmental data, plus location and time

Communication Modes RS232 or RS485 via RJ-45 to PC or printer

Supporting Software LMS XChange Data Transfer Software, LMS

Express/RT/RT Plus; LMSNet

Environmental Sensors Temperature/Relative Humidity Probe:

0-150°F (-17.8 to 65.6°C) ±1.8°F @ 77°F, 0100% ± 5% @ 33%

Touch Screen Display 3.8" (9.25 cm), 320x240

Printer External thermal printer (optional)

Reports FS-209E (ft) , FS-209E (m), ISO 14644-1, EU

GMP (0.5 and 5.0μ channels must be active)

Key Software Features Historical data review, password protection

Enclosure High impact injection molded plastic

Sample Output Internally filtered to HEPA standards

(>99.97% @ 0.3μm)

Vacuum Source Internal pump, flow controlled

Table 2-1 Specifications

248083400-1 Rev 7

2-3

Page 18

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Power Unit: +12VDC; AC/DC Adapter: 100-240V,

50-60Hz

Battery Li-Ion, removable and rechargeable

Dimensions 8.75"(L) x 5.0"(W) x 2.5"(H) [22.23 x 12.7 x

6.35 cm]

Weight 2.2 lb (1kg)

Operating Temp/RH 50°F to 104°F (10°C to 40°C) / 20% to 95%

non-condensing

Storage Temp/RH 14°F to 122°F (-10°C to 50°C) / Up to 98%

non-condensing

Table 2-1 Specifications

The manufacturer recommends that your Lighthouse instrument be

calibrated annually by a Certified Lighthouse Service Provider to ensure

that it continues to perform within specification.

2-4

248083400-1 Rev 7

Page 19

00

3 Unpacking, Inspecting

and Installation

Initial

Inspection

The instrument is thoroughly inspected and tested at the factory and is

ready for use upon receipt.

Unpacking It is presumed that when the shipment was received, the following took

place:

1. The shipping container was inspected for damage.

2. If the container was damaged, the shipper was notified

immediately.

3. The instrument was carefully inspected for broken parts,

scratches, dents and other damage before use,

container appeared undamaged, and

4. Any damages were reported to Lighthouse Technical Support at

800-945-5905 (USA Toll Free) or 541-770-5905 (Outside of

USA) before proceeding.

Verify the contents of the package against the Shipping List. If anything

appears to be missing, please contact your sales representative at

Lighthouse Worldwide Solutions immediately at 510-438-0500 (Sales).

even if the

To maintain your warranty, keep the undamaged shipping

container and all packing material for reshipment of the

instrument for annual calibration. Order replacement

containers and packing materials from Lighthouse directly,

or from a Lighthouse-authorized distributor.

248083400-1 Rev 7

3-1

Page 20

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Shipping

Instructions

WARNING:

instrument is damaged

during a return shipment

due to inadequate user

packing, the warranty

may be voided and may

result in additional

repairs being billed to

the customer.

If the

Should it become necessary to return the unit to the factory for any

reason, contact Lighthouse Customer Service or visit our website,

www.golighthouse.com/rma, and obtain a Return Merchandise

Authorization (RMA) number. Reference this number on all shipping

documentation and purchase orders. After receipt of the RMA number,

follow the shipping instructions below:

1. Use the original container, nozzle caps and packing materials

whenever possible. Remove any instrument battery and package

it to ship separately - refer to www.golighthouse.com/rma for

detailed instructions. Remove attachments, such as TRH or Isokinetic probes, and package to prevent physical and ESD damage.

2. If the original container and packing materials are not available,

wrap the unit in “bubble pack”, surround with shock-absorbent

material and place in a double-wall carton - the instrument should

not rattle around when the carton is vigorously shaken. If the

instrument is damaged during shipment due to inadequate user

packing, the warranty may be voided and may result in additional

repairs being billed to customer. You may contact Lighthouse to

purchase a replacement shipping container and nozzle caps.

WARNING:

ship the instrument with

the battery installed.

Do not

3. Seal container or carton securely. Mark “FRAGILE” and write the

Return Merchandise Authorization (RMA) number on any

unmarked corner.

4. Return the instrument to the address provided by your Lighthouse

representative or the RMA website.

Accessories You may order several optional accessories to tailor the unit to your

needs.

• External Battery Charger with AC and car adapters

• Spare Li-Ion Battery (removable and rechargeable)

• Carrying Case

• Isokinetic Sample Probe

• 6 ft. Tubing (for extending Isokinetic sampling input)

• Thermal Printer with cable (AC or battery operated)

• Validation Documentation

3-2

248083400-1 Rev 7

Page 21

Unpacking, Inspecting and Installation

• LMS Express software (standard), an analysis tool that allows the

user to:

1. Manually download data from the instrument

2. Save data for historical review

3. Have advanced reporting with standard reports and much more.

• LMS Express RT software (optional), an analysis tool that allows

the user to perform the following:

1. Download data from the instrument

2. Collect data real time

3. Save data for historical review

4. Have advanced reporting with standard reports

...and much more.

Please contact Lighthouse Worldwide Solutions at 800-945-5905 (USA

Toll Free) or 541-770-5905 (Outside of USA) for details.

Prepare

Instrument for

Use

Power Requirements

The power adapter input requirement is 100-240VAC, 50-60Hz, 1.25

Amps. Its output is +12VDC, 3A. A power cord and power adapter are

included with your HANDHELD 2016, 3016 or 5016.

To protect the instrument from voltage spikes, Lighthouse recommends

using protected power . Using an uninterruptible power supply (UPS)

when the HANDHELD is kept in a stationary location will help prevent

damage to the instrument or loss of data in the event of a power outage.

Install the Battery

The HANDHELD comes with a standard rechargeable battery. An

optional external battery charger is available; otherwise, the battery

recharges in the unit when the unit is plugged into AC power.

Install the battery as illustrated in the following instructions.

1. Make sure that the power switch is in the OFF position and the

instrument’s power adapter is not connected.

248083400-1 Rev 7

3-3

Page 22

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

2. Open the battery compartment by sliding the battery compartment

door on the bottom of the unit to the left to unlock it. When the

door is unlocked, open the door. The hinge is on the right side of

the door. See Figure 3-1.

Figure 3-1 Open the Battery Compartment Door

3. Pull the battery release ribbon out of the battery compartment as

shown in Figure 3-2.

3-4

Figure 3-2 Pull Battery Release Ribbon Out

4. Hold the battery connector side toward the HANDHELD. Place

the battery into the compartment, on top of the release ribbon.

Push the battery fully into the compartment until it connects and

is entirely inside the battery compartment. See Figure 3-3.

248083400-1 Rev 7

Page 23

Unpacking, Inspecting and Installation

Figure 3-3 Insert Battery into Battery Compartment

5. Tuck the battery release ribbon over the battery. See Figure 3-4.

Figure 3-4 Tuck Battery Release Ribbon

6. Close the door so that it is flush with the bottom of the

HANDHELD as shown in Figure 3-5.

Figure 3-5 Close the Battery Compartment Door

7. Slide the battery compartment door to the right until it clicks and

latches. See Figure 3-6.

248083400-1 Rev 7

3-5

Page 24

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Figure 3-6 Secure the Battery Compartment Door

Connect Power

Connect the power adapter as illustrated in the following steps:

1. Insert the round DC power plug into its receptacle on the left side

of the HANDHELD. See Figure 3-7.

3-6

Figure 3-7 DC Power Plug

2. Push the connector in until fully seated as shown in Figure 3-8.

Figure 3-8 Inserting DC Power Plug.

248083400-1 Rev 7

Page 25

Unpacking, Inspecting and Installation

3. Plug the adapter’s AC power cord into the AC power source. The

battery will begin and continue to charge until it is fully charged

or DC power is removed.

WARNING:

ship the instrument with

the battery installed.

Do not

Battery Removal

1. To remove the battery, open the door to the battery compartment

by sliding the door to the left to unlatch it. See Figure 3-9.

Figure 3-9 Unlatch Battery Compartment Door

248083400-1 Rev 7

3-7

Page 26

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

2. Swing the battery compartment door open as shown in Figure 3-

10.

Figure 3-10 Open Battery Compartment Door

Note: Remove the

battery if the instrument will

be stored for a month or

longer. Leaving the battery

in during storage will drain

the battery to the point

where it will not recharge.

3. Hold the instrument securely then pull the battery release ribbon

outward to disconnect the battery and slide the battery out.

Remove the battery. See Figure 3-11.

Figure 3-11 Remove Battery

3-8

248083400-1 Rev 7

Page 27

Unpacking, Inspecting and Installation

Optional Printer Accessory

An optional external thermal printer can be used with the HANDHELD

to print reports directly from the instrument.

Connect the external printer as illustrated in the printer Read Me First,

document #248083378-1, which is included on the Operating Manual

CD.

Figure 3-12 HANDHELD External Printer

248083400-1 Rev 7

3-9

Page 28

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Connecting to an External Computer or Facility

Management System

The HANDHELD has the ability to be connected to the Lighthouse

Monitoring System (LMS), LMS Express or LMS XChange Data

Transfer Software to download its data.

By transferring the instrument’s data to the Lighthouse Monitoring

System (LMS) or a PC running LMS Express, historical data can be

stored externally for future reviewing and trending. LMS XChange

software can export data to a *.csv file for historical review.

Note:

can be used for the printer

or to connect HANDHELD

to an external computer. It

cannot be used to connect

to both at the same time.

The DATA port

Note: LMS Express

allows you to upload data

from your HANDHELD;

LMS Express RT allows

you to also collect data in

real time.

1. To connect to the HANDHELD, insert the RJ45 end of the

HANDHELD data communications cable to the DATA port as

shown in Figure 3-13.

Figure 3-13 Connecting RJ45 Data Communications Cable

2. Connect the other end of the data communication cable to your

Lighthouse Monitoring System or PC running LMS Express or

LMS XChange software.

Please refer to the LMS XChange, LMS Express or LMSNet manual

for additional information.

3-10

248083400-1 Rev 7

Page 29

00

4 Operation

This chapter describes how to use the HANDHELD 2016, 3016 and

5016 Airborne Particle Counters.

Using the

Instrument

WARNING:

attempt to sample

reactive gases (such as

hydrogen or oxygen)

with this instrument.

Reactive gases create an

explosion hazard in the

instrument.

Sampling any gas under

pressure can damage the

instrument and void the

warranty.

Sampling any gas that is

not the same density as

ambient air can result in

inaccurate data.

Contact Lighthouse for

more information.

Do not

The HANDHELD comes with a charged battery and is ready for use.

To start using the instrument, proceed as follows:

1. Insert the battery included with the shipment. (See Chapter 2 for

instructions.)

2. Position the instrument in the environment to be measured.

3. Remove the protective cap from the inlet tube. To use the

provided isokinetic probe, install it by connecting to inlet tube on

the top of the instrument. NOTE: Do not discard the protective

cap. It should be placed on the inlet tube any time the

instrument is moved outside the environment being

measured.

4. The included Temperature/Relative Humidity probe can be

attached to the provided receptacle to read environmental data.

5. Set on/off switch found on the left side of the unit to ON.

6. The Start Up screen displays on the LCD.

WARNING:

allow water, solvents, or

other liquids enter the

instrument via the inlet

tube - the instrument will

be damaged and void the

warranty.

Do NOT operate the

instrument with the inlet

tube capped or plugged the internal pump will be

damaged and void the

warranty.

248083400-1 Rev 7

Do NOT

7. The MAIN screen appears.

8. On the touch screen, press the START button to start the

9. “STARTING” will display when the pump is initially turned on.

instrument.

4-1

Page 30

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

10. When the HANDHELD starts counting, “COUNTING” appears

on the display. Particle counts are displayed according to the size

of each particle.

Note:

requires a minimum of 5

seconds to ramp up to full

flow. Refer to “Pump

Startup” on page 35.

The pump motor

Touch Screen

Overview

11. If the instrument is in AUTO mode with cycles and a hold time,

“HOLDING” will display after each cycle and “FINISHED” will

display when all the cycles are complete.

12. Press the “STOP” button to stop the instrument before the cycles

are complete.

The HANDHELD incorporates a unique touch screen interface to

control and configure the instrument.

This interface allows the user to easily view and configure the

instrument to specific needs and applications. See Figure 4-1.

Menu Map

4-2

Figure 4-1 Menu Map

248083400-1 Rev 7

Page 31

MAIN Screen

Operation

Note: The Screen Shots

shown in this chapter were

taken from the 3016

model. The 2016 and 5016

screens are identical

except for the channel

sizes.

The MAIN screen gives the user a single snapshot view of the status of

the instrument. The instrument can be powered by a power supply or

from a removable battery. When a battery is used, the battery indicator

will show the level of the battery charge remaining. See Figure 4-2 &

Figure 4-3.

Figure 4-2 MAIN Screen - Battery Operation

When the AC/DC indicator symbol is displayed, it indicates that the

instrument is getting its power from an AC source.

248083400-1 Rev 7

Figure 4-3 MAIN Screen - AC Operation

4-3

Page 32

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

The MAIN screen displays the following options and information.

• LOCATION: Displays the location that is currently being

measured. Up to 200 alphanumeric locations can be configured.

• LOCATION SELECT button: Allows user to change location

before sampling.

• RECIPE button: Allows the user to view, load and unload recipes

that have been configured and saved in the recipe data base.

• PRINT LAST RECORD: Prints the last recorded sample using

the current configuration to determine the type of data printed (i.e.

cumulative vs. differential, raw vs. normalized, ft

The print configuration is set through the PRINT SETUP button in

the Configuration screen. For more details about printing, see the

Configuration section later in this chapter.

3

vs. m3).

Note:

in the battery indicator

while the instrument is

counting, the pump will

stop automatically to

prevent the battery from

discharging completely.

If the “X” appears

• Date/Time: Displays the current date and time.

• Battery Indicator: Indicates that the instrument is being powered

by a rechargeable battery. The amount of battery life left is denoted

by the fill inside the battery icon. When the battery is low, the

words “BATT LOW!” will appear on the screen and the unit will

beep continually until it is plugged into its AC power cord for

recharging. See Figure 4-4.

Figure 4-4 Battery Indicator Levels

• AC Indicator: Indicates that the instrument is being powered with

its AC power cord. If the battery is installed, the HANDHELD will

charge the battery when the instrument is plugged in.

• Flow Status: When the instrument is sampling, the Flow Indicator

will display sufficient or insufficient flow.

WARNING: If the Air Flow is insufficient, turn the instrument off and

contact Lighthouse Worldwide Solutions tech support.

4-4

248083400-1 Rev 7

Page 33

Operation

• Service Indicator: Indicates that the instrument may be in need of

service. If wrench displays, please contact your authorized

Lighthouse Service Provider for assistance or send an e-mail to

techsupport@golighthouse.com.

• μ: The mu symbol indicates the particle sizes, in micrometers,

configured for the instrument. These sizes are pre-configured at the

factory. To order an instrument with different sizes, please contact

a sales representative at Lighthouse ((800) 945-5905 Toll Free).

• DATA DISPLAY: This indicates whether the counts are being

displayed in Differential (Diff) mode or in Cumulative (Cuml)

mode and when the counts are normalized to ft

3

or m3.

• Analog Data: Gives a snapshot view of the enabled analog

channels. (Analog channels are enabled by default.)

•MODE: Displays the current mode selected; possible modes are

AUTO, MANUAL, CONCEN (Concentration) and BEEP.

Note:

greater than 1 minute, the

pump will stop during that

time. At the end of the hold

time, the pump will restart.

If Hold time is

•CYCLES: Indicates the number of times that the count will be

taken at a given location in Auto mode. “1/ 3" indicates that the

count is the first of three samples to be recorded at this location.

The maximum number of cycles is 999. When set to 0, the unit will

run in Auto mode continuously until the STOP button is pressed.

• SAMPLE: The Sample Time (hh:mm:ss) is the duration of one

counting cycle. The Sample Time will count down on the MAIN

screen when the instrument is in AUTO or Manual mode so you can

see how much time is remaining in the sample period. In

Concentration mode, the Sample Time will count up to 6 seconds

per cycle.

•HOLD: Displays the hold time in between cycles. The maximum

hold time is 99 hours, 59 minutes, 59 seconds.

•RECS: This displays the current number of records stored in the

instrument and the total number of records that can be stored. The

data buffer is a circular buffer. The HANDHELD can store up to

3000 records. An asterisk (*) will appear in front of counts when

the buffer wraps.

248083400-1 Rev 7

4-5

Page 34

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Note: There is a one

second startup during

which the pump is

accelerating to full power.

During this time, the word

“STARTING” will display.

•START/STOP: Press START button on the screen to start

counting. When running, the instrument will display

“COUNTING” in the lower right portion of the screen as shown in

Figure 4-5.

Figure 4-5 Main Screen, Counting Mode

Press the STOP button to stop counting; the word “STOPPED” will

display.

4-6

248083400-1 Rev 7

Page 35

Operation

LOCATION Selection

Changing Locations

The location number for the environment to be measured can be

changed by pressing the LOCATION button at the top of the MAIN

screen. The Select Location screen opens as shown in Figure 4-6.

Figure 4-6 Location Select Screen

• The blue highlight indicates which location is currently selected.

• Use the UP and DOWN arrows to select a location. The single

arrows will move the cursor up and down by a single line.

Locations can also be selected by touching the location name on the

screen.

• Recipes associated with a specific location may also be loaded

when that location is selected.

• The AUTO INC button, when activated will allow the user to

advance to the next location once the current cycle is completed.

• Press the MAIN button to return to the MAIN screen. Whichever

location is currently selected will be the location displayed on the

MAIN screen.

Locations in AUTO Mode

• When the instrument is in Automatic Mode and the START button

is pressed, the instrument will start counting particles automatically

according to the SAMPLE time, HOLD time and number of cycles

that are configured.

248083400-1 Rev 7

4-7

Page 36

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Zoomed Data View

Press anywhere in the Particle Data area to display the Zoomed view.

See Figure 4-7.

4-8

Figure 4-7 Zoomed Data View

248083400-1 Rev 7

Page 37

Operation

In Figure 4-8, the following functions can be performed using the

toggle buttons on the right side bar:

START or STOP counting

Display Particle data or Analog data

Display Cumulative / Differential data

Display Raw / Normalized particle data

3

Display ft

/ m3 when configured

PRINT the last record

Figure 4-8 Zoomed Data View Buttons

When the instrument is STOPPED or HOLDING, press anywhere in

the white data area to return back to the MAIN screen.

248083400-1 Rev 7

4-9

Page 38

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

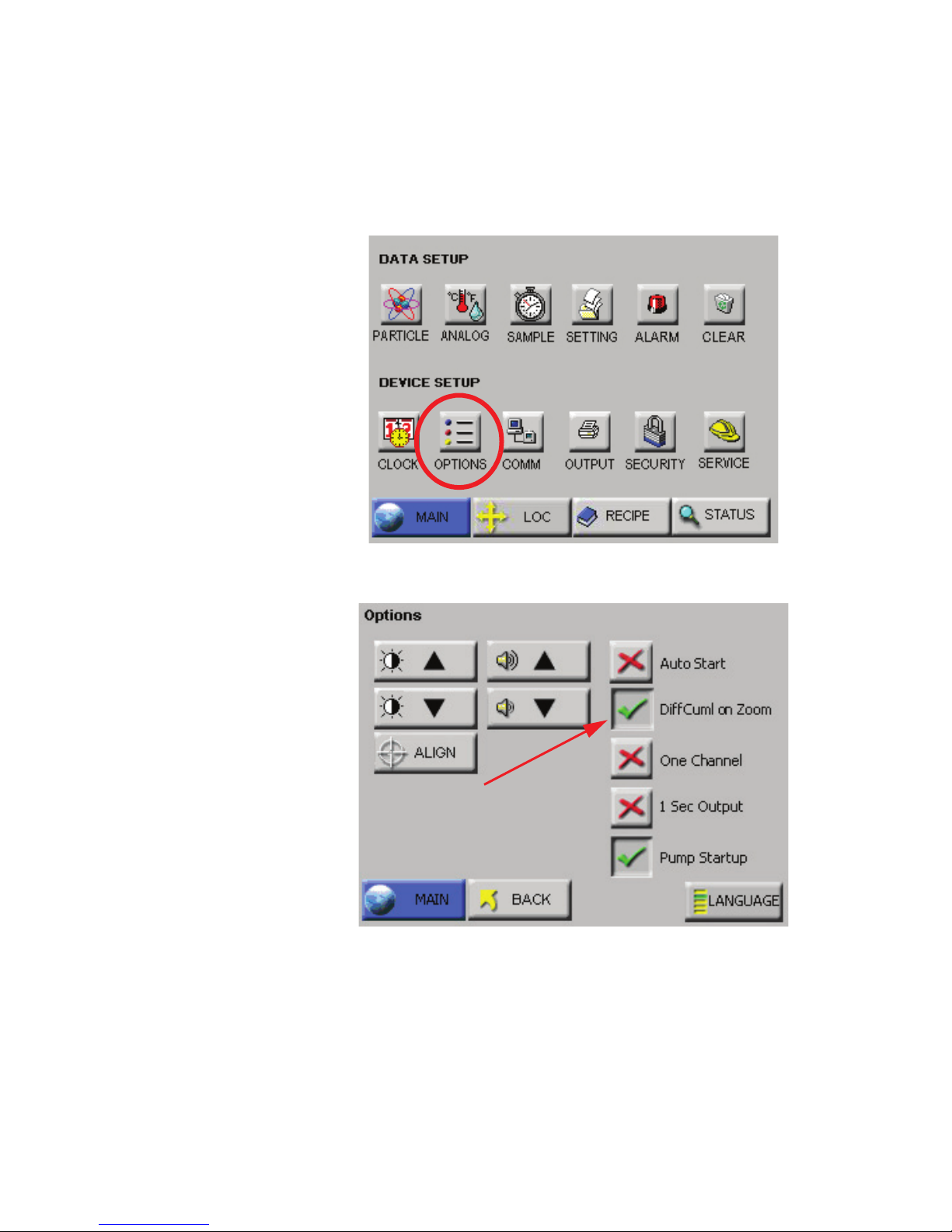

Viewing Two Columns of Data

The unit can display both Differential and Cumulative data at the same

time on the Zoomed View screen. To enable this feature, go to the

CONFIG: Options screen as shown in Figure 4-9.

Figure 4-9 CONFIG: Options Button

Figure 4-10 CONFIG: Options Screen

4-10

248083400-1 Rev 7

Page 39

Operation

START/STOP counting

Display Particle data or Analog data

PRINT the last record

Display Raw / Normalized particle data

Display ft

3

/ m3 when configured

Select the button “DiffCuml on Zoom” as shown in Figure 4-10; this

will display both differential and cumulative data on the Zoomed View

screen as shown in Figure 4-11.

Figure 4-11 Differential and Cumulative Data in Zoomed View

The buttons available when touching the data area of the screen after

selecting DiffCuml on Zoom are shown in Figure 4-12. Note the

selections are different but their functions are the same as on dual

display screen.

248083400-1 Rev 7

Figure 4-12 Diff / Cuml Screen Button Actions

4-11

Page 40

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

To return the instrument to the default single-column zoom view, return

to the MAIN Screen view, press CONFIG, Options and deselect the

button “DiffCuml on Zoom” button. See Figure 4-13.

Figure 4-13 DiffCuml on Zoom Disabled

Select the MAIN button to return to the MAIN Screen view or press

BACK to return to the previous level. Here, the user can choose what

data type is to be displayed in one column on the Zoomed View screen.

Go to the CONFIG: Settings screen and select Differential or

Cumulative for the data type. SeeFigure 4-14 .

4-12

Figure 4-14 Configuration: Setting Screen

248083400-1 Rev 7

Page 41

Operation

Press the MAIN button, then tap in the data area to go into the Zoomed

View. See Figure 4-15.

Figure 4-15 Zoomed View with Only Cumulative Data

Only one column of data is displayed.

CONFIGURATION

Screen

Press CONFIG on the MAIN screen to display the Configuration

screen as shown inFigure 4-16 .

Figure 4-16 Configuration Screen

Data Setup includes buttons to enable/disable particle channels,

configure analog temperature readings, set sample record parameters,

sample settings, thresholds, enable/disable alarms, and clear the data

buffer.

Device Setup includes buttons to configure the instrument’s date and

time, set the LCD contrast, adjust the instrument’s beep volume, enable

the instrument to AutoStart, set it to display only one channel of data,

enable 1 Second Output, set the instrument’s communication address,

enabling print functions, enable password restrictions, and/or (with

proper authorization) adjust service settings.

248083400-1 Rev 7

4-13

Page 42

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

DATA SETUP Figure 4-17 displays the Data Setup option buttons. These options

allow the user to configure the parameters for data collection during a

sample.

Figure 4-17 Data Setup Options

Particle Channels

The instrument’s particle channels can be enabled or disabled on the

Particle Channel. A checkmark is displayed next to each enabled

channel as shown in Figure 4-18.

Note: The data buffer is

cleared when channels are

enabled or disabled. This

ensures that all of the data

in the buffer will have the

same number of channels.

4-14

• The checkmark button next to each channel size is a toggle. Press it

Figure 4-18 Particle Channel Configuration

once to disable a channel and a red “X” will display, indicating that

the channel is disabled. Press the button again and it will change

back to the checkmark, enabling the channel.

248083400-1 Rev 7

Page 43

Operation

• Pressing MAIN or BACK will prompt to clear all collected data as

shown in Figure 4-19.

Figure 4-19 Clear Data Screen

• From this screen, press CANCEL to cancel changes and return to

the Configuration screen.

When channels are disabled, they are removed from the MAIN screen

display, from the reports, and from the printouts.

The channel size for disabled channel(s) remain in the Data screen,

however the instrument does not record data for disabled channels.

Analog Channels

A Temperature and Relative Humidity probe can be connected to the

HANDHELD via a connector on the top of the unit.

Users can select if the HANDHELD displays analog temperature data

as Fahrenheit or Celsius by pressing the ANALOG button on the

Configuration screen. The Select Temperature Units window displays.

There are two buttons on the Select Temperature Units window. The

button displayed shows the units that are currently selected: F for

Fahrenheit and C for Celsius.

248083400-1 Rev 7

4-15

Page 44

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

To change to Celsius, press the C button. To change to Fahrenheit,

press the F button. See Figure 4-20 & Figure 4-21.

Figure 4-20 Analog Channels - Select Celsius Units

4-16

Figure 4-21 Analog Channel - Select Fahrenheit Units

248083400-1 Rev 7

Page 45

Operation

Temperature and relative humidity values appear on the MAIN screen

with the units you selected as shown in Figure 4-22.

Figure 4-22 Analog Data on MAIN Screen

When the unit is not counting or when it is holding, you can display the

instrument’s current Analog data by pressing press anywhere in the

Particle Data area to bring up the Zoomed Data View, then press the

Analog toggle button to display Analog data. See Figure 4-23.

Figure 4-23 Zoomed Data View: Analog Data

248083400-1 Rev 7

4-17

Page 46

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

SAMPLE

Configure the Sample Time and the number of samples to be collected

on the Sample screen as shown in Figure 4-24.

Note:

immediately when START

is pressed. If a Start Delay

is required, the Delay

should not be set to less

than 5 seconds or readings

may be unreliable.

The pump starts

Figure 4-24 Sample Timing Configuration Screen

•CYCLES: The number cycles is set to determine how many times

the instrument samples the air in a single location. This is used only

in AUTO mode. The range is 0 - 999. When Cycles is set to 0, the

instrument will continue running samples indefinitely until the

STOP button is pressed.

Select the CYCLES button; enter the number of desired cycles

using the numeric keypad on the right. Press ERASE to erase a

number, if needed. Press ENTER to set the Cycles.

• DE LAY: The Initial Start Delay (hh:mm:ss) is the time between

pressing the START button and the unit actually starting counting.

The Initial Start Delay gives the operator time to exit the area under

test so that the measurement is taken under a controlled condition.

The maximum delay time is 99 hours, 59 minutes and 59 seconds.

Select the DELAY button; enter the initial delay time in hours,

minutes and seconds using the numeric keypad on the right.

4-18

After the value is entered, press ENTER.

248083400-1 Rev 7

Page 47

Operation

Note: If the Hold time is

set to 00:00:00 in Auto

Mode, the instrument will

run the samples according

to the sample time and the

# of cycles, but with no

hold time in between

cycles.

Note:

greater than one minute,

the pump will shut off

during the specified hold

time.

Note:

Sample Time is 23:59:59.

If the Hold time is

The maximum

The maximum hold time is 99 hours, 59 minutes and 59 seconds.

This field will count down to indicate how much time is left for the

Hold period.

Select the HOLD button; enter the time in hours, minutes and

seconds using the numeric keypad on the right. Press ERASE to

erase a number, if needed. Press ENTER to set the Hold Time.

• HOLD: The Hold Time (hh:mm:ss) is the time between count

cycles when the instrument is not counting particles.

• SAMPLE: The Sample Time (hh:mm:ss) is the duration of one

counting cycle. The Sample Time will count down on the MAIN

screen when the instrument is in Auto or Manual mode to indicate

how much time is remaining in the Sample.

Select the SAMPLE button; enter the time in hours, minutes and

seconds using the numeric keypad on the right. Press ERASE to

erase a number, if needed. Press ENTER to set the Sample time.

Note:

volume is ft

sample volume is 0.1 ft

When the particle

3

the minimum

• SAMPLE VOLUME: Instead of selecting a specific Sample Time,

3

.

the instrument can be set to measure a specific Sample Volume in

cubic feet (ft

3

), cubic meters (m3) or liters (l). When this is set, the

corresponding Sample Time will automatically be set. See Figure

4-25.

248083400-1 Rev 7

4-19

Page 48

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Note: If the particle

volume is liters or m

sample volume is

displayed in liters.

If the particle volume is

cubic feet (ft

volume is displayed in

cubic feet (ft

3

3

3

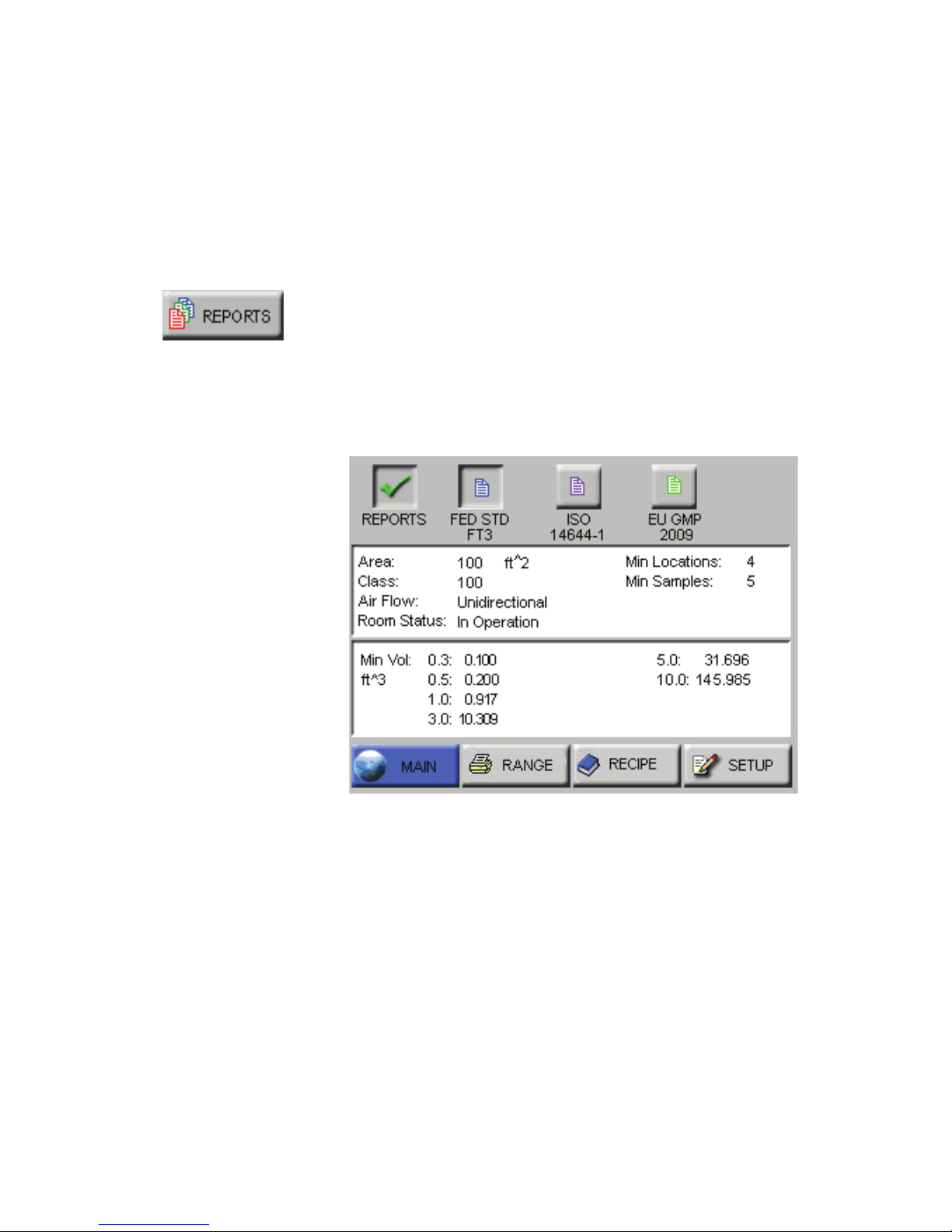

), the sample

).

,

4-20

Figure 4-25 Changing Sample Volume unit of measure

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

248083400-1 Rev 7

Page 49

Operation

SETTINGS

The instrument can be configured to count in different modes and

formats. See Figure 4-26.

Note:

for Auto, Manual, and

Beep modes count down

and the sample times for

Concentration mode count

up.

The sample time

Figure 4-26 Sample Settings Screen

COUNT MODE

The following modes are available: Auto, Manual, Beep and

Concentration.

• AUTO - When the instrument is in Automatic Mode and the

START button is pressed, the instrument will start counting

particles automatically according to the Sample Time, Hold Time

and the number of Cycles that are configured. If Cycles are set to 0,

the instrument will continue indefinitely in Auto Mode until the

STOP button is pressed.

• MANU (Manual Mode) - When the instrument is in Manual

Mode, it will start counting when START is pressed and stop at the

end of one programmed Sample Time.

• CONC (Concentration Mode) - When the instrument is in

Concentration mode, it gives a calculated value of the concentration

of particles in a volume of air, measured and displayed on the

MAIN screen in either counts per cubic foot or per cubic meter.

Counting starts when the START button is pressed and it will

continue until the STOP button is pressed. The sample time for

Concentration mode is six seconds. As the sample time on the

MAIN screen counts from one to six, the particle counts are

updated continuously.

248083400-1 Rev 7

Concentration data will be recorded and can be viewed in the Data

screen and on the printouts.

4-21

Page 50

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Note: BEEP mode only

works with CUMULATIVE

data and for Sample Times

greater or equal to 6

seconds.

Note:

works with CUMULATIVE

data.

Note:

set to one count, the beeps

may not be for every single

count.

BEEP mode only

If BEEP mode is

• BEEP - In this mode, the instrument is pre-configured to beep

according to the alarm threshold set in Alarm Configuration and the

instrument’s sample time if the instrument is set to collect

cumulative data. Counting starts one second after the START

button is pressed and will continue until the STOP button is

pressed.

If no channel is set for alarming and BEEP mode is selected, the

smallest channel size will be automatically selected and its alarm

threshold will be used to trigger the alarm.

If alarming is enabled on more than one channel size, only the

smallest channel size will be used to trigger the alarm in BEEP

mode. Larger channel sizes will be ignored.

The data will be recorded based on the set sample time and hold

time and can be viewed in the View Buffer and on the printouts.

There will be no indication on the record, however, that the data

was saved while the instrument was in BEEP mode.

Geiger Counter Mode

While in BEEP mode the instrument can be set to beep 1 to 4 beeps per

second depending on the number of particles the instrument has

counted per second.

To set up the instrument for Geiger Counter Mode:

1. Enable BEEP Mode.

2. Set the smallest particle channel to 1.

In Geiger Counter Mode the instrument will beep from 1 beep up to 4

beeps per second if it counts from 1 particle up to 4 particles per

second. The maximum beeps per second the instrument can emit are 4

per second even if the instrument counts 100 particles per second.

The value set in the smallest particle channel’s alarm is the trigger for a

single beep per second. If the smallest particle channel is set to 2, the

instrument will beep once every second for every 2 particles the

instrument counts per second.

4-22

248083400-1 Rev 7

Page 51

Operation

PARTICLE Display

Data on the instrument can be displayed in Differential (DIFF) or

Cumulative (CUML) counts.

For example, the cumulative count for the 1μm channel is the sum of

that channel’s count + 2.5μm count + the 5μm count.

The differential count for the 1μm channel is the number of particles

between 1μm and 2.5μm.

The data displays on the MAIN screen according to whichever is

selected (DIFF or CUML).

The data format is either Raw (RAW) or Normalized (NORM). Raw

data displays the actual number of particles counted. Normalized data

shows particle concentrations calculated from the raw data based on the

settings chosen (ft

3

or m3).

Volume of Air = Sample time (minutes) x FlowRate (CFM)

Normalized Data = Number of Particles/Volume of Air

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

ALARM

The user can enable alarming on specific channels as illustrated in

Figure 4-27.

Threshold Button

248083400-1 Rev 7

Figure 4-27 Particle Alarm Configuration, 2 Channels Enabled

4-23

Page 52

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Note: Alarming is only

applicable for AUTO and

MANUAL mode. It applies

only to Raw particle counts

even if the instrument is

displaying Normalized

data.

If the instrument is set to

Differential data, the alarm

threshold will apply to the

differential counts.

If the instrument is set to

display Cumulative data,

the alarm threshold will

apply to the cumulative

counts.

To enable the alarming for any channel, press the “X” next to that

channel. When a checkmark is displayed, that channel is enabled for

alarming. Press the checkmark to disable the alarming for that channel.

Alarm Threshold

Press the threshold button next to the enabled channel in order to set the

alarm threshold for that channel. See Figure 4-28.

Note: To receive alarms,

the Sample Time must be

greater than 1 second.

Figure 4-28 Configure Alarm Threshold

Enter the desired alarm threshold for the selected particle channel in

number of particles, then press ENTER. The threshold value will be

updated on the Particle Alarm screen as shown in Figure 4-29.

4-24

248083400-1 Rev 7

Page 53

Note:

triggered per sample

record. At the end of the

sample time, the alarms

reset.

Alarms are

Operation

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

Figure 4-29 2 channels Enabled for Alarming

Note:

enabled on two channels, if

the user presses the Alarm

Acknowledge button when

the first channel goes into

alarm, the alarm will not

sound if the second

channel’s threshold is

reached within the sample

period.

If alarms are

When a particle channel that is enabled for alarming goes into alarm,

the selection cursor (>) and the channel size are highlighted in red as

shown in Figure 4-30.

Figure 4-30 Channel in Alarm

When the instrument begins to beep in response to the Alarm settings,

silence the beep by pressing anywhere on the MAIN screen. After

acknowledging the alarm, the count will reset when the next sample

cycle begins.

248083400-1 Rev 7

4-25

Page 54

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Clear Buffer

Press the Clear Buffer button to clear the instrument’s data buffer. See

Figure 4-31.

DEVICE

SETUP

Figure 4-31 Clear Buffer Screen

Press OK to clear the data or press Cancel to exit screen without

clearing the data.

The Device Setup buttons allow the user to set and adjust how the

instrument operates when running samples. Specific functions can be

enabled and disabled for display options, data output and security. See

Figure 4-32.

Figure 4-32 Device Setup Options

4-26

248083400-1 Rev 7

Page 55

Operation

CLOCK

Use the Clock screen to set the instrument’s date and time. See Figure

4-33.

Figure 4-33 Date & Time Configuration Screen

Set the instrument’s Date by entering values for the desired month, day

and year and then press the ENTER button.

248083400-1 Rev 7

4-27

Page 56

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Note:

MONTH 1ST (M / D/

Y) is the default date format.

Change the Date’s format by pressing the M / D/ Y button to display the

date as month-first. Alternatively pressing the D / M/ Y button displays

the Date as day-first and the Y / M/ D button displays the date yearfirst. See Figure 4-34 and Figure 4-35.

Figure 4-34 Date Option: Day First

Figure 4-35 Date Option: Year First

4-28

248083400-1 Rev 7

Page 57

Set the instrument’s Time by pressing the TIME button. See

Figure 4-36.

Figure 4-36 Configuring TIME

Operation

Enter the desired Time in hours, minutes and seconds then press

ENTER to save the new time.

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

248083400-1 Rev 7

4-29

Page 58

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

OPTIONS

Several optional configuration settings are found on the OPTIONS

screen. See Figure 4-37.

Figure 4-37 Options Configuration Screen

CONTRAST ADJUST

The contrast/brightness of the LCD screen can be adjusted by pressing

the first set of UP and DOWN arrows.

AUDIBLE BEEP ADJUST

The audio level of the BEEP can be adjusted by pressing the second set

of UP and DOWN arrows.

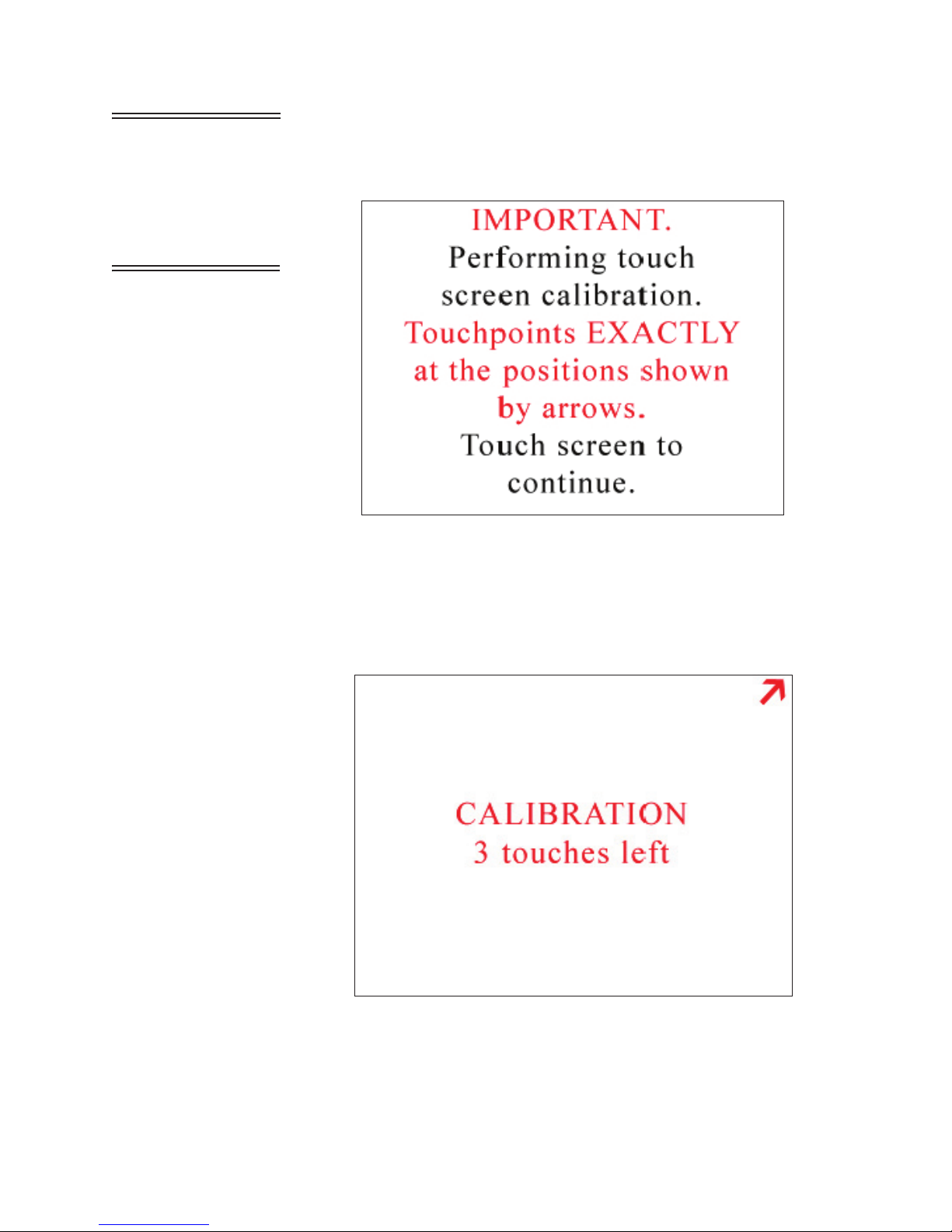

ALIGN TOUCH SCREEN

The ALIGN button allows you to re-align the touch screen so the

locations that you touch on the screen correspond to the expected

button or function.

• Press the ALIGN button.

4-30

248083400-1 Rev 7

Page 59

Operation

WARNING: Be

careful to touch the

screen at the specified

locations only. If

touching the screen

elsewhere during this

process, the screen will

be incorrectly aligned.

• The screen in Figure 4-38 appears. Touch anywhere on the screen

to continue calibration.

Figure 4-38 Alignment Screen 1

Note:

Using a PDA Stylus

provides higher accuracy to

the touch screen interface.

• At the next screen, touch the arrow displayed in the upper right

corner. This needs to be done a total of three times before

continuing to the next alignment. See Figure 4-39.

Figure 4-39 Alignment Screen 2

248083400-1 Rev 7

4-31

Page 60

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

• The third screen displays the arrow in the upper left corner. The

arrow will have to be touched three times to ensure calibration as

Figure 4-40 illustrates this.

Figure 4-40 Alignment Screen 3

• The fourth alignment screen shown in Figure 4-41, displays the

arrow in the at the bottom center of the screen. Touch the arrow

three times to finish the alignment process.

4-32

Figure 4-41 Final Alignment Screen

248083400-1 Rev 7

Page 61

Operation

Note: The screen

alignment function can

also be accessed by

touching the screen when

powering the instrument

on.

• Once the final alignment is complete, the following screen is

displayed. See Figure 4-42. Touch anywhere in the screen to return

to the OPTIONs screen.

Figure 4-42 Alignment Saved Screen

Autostart Mode

When Autostart mode is enabled, set the Delay time to at least 5

seconds.

If Autostart mode is enabled, when the instrument is powered on (or

regains power after a power outage), the instrument will immediately

begin sampling based its configured mode, delay, start, and hold times.

DiffCuml on Zoom

If DiffCuml on Zoom is enabled, the counter’s display will show two

columns of data simultaneously - Differential and Cumulative.

One Channel

If One Channel is enabled, only the first channel will be displayed on

the MAIN screen. Data will continue to be recorded, printed and

downloaded for all channels.

248083400-1 Rev 7

4-33

Page 62

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Note: If the first channel

is disabled and One

Channel mode is enabled,

the display and zoomed

data view will be blank.

One Channel mode only affects how data is displayed on the MAIN

screen. Refer to Figure 4-43.

Figure 4-43 Main Screen - One Channel Option Enabled

Note:

Output disables Alarming.

One Second

Note: Changing any

setting (mode, sample

time, hold time, etc)

disables the One Second

Output.

ONE SECOND OUTPUT

If One Second Output is enabled, the instrument’s settings reset to the

following.

• Mode: AUTO

• Cycles: Zero

• Sample Time: One second

• Hold Time: Zero seconds

• Cumulative/Differential: Cumulative (CUML)

• Raw/Normalized: Raw

When counting, the MAIN Screen will update continuously and data

will not be recorded to the data buffer.

4-34

248083400-1 Rev 7

Page 63

Operation

Pump Startup

This is ON by default and sets a three-second pump ramp up time at the

beginning of the first sample, or at the beginning of all samples if the

HOLD time is greater than one minute, to stabilize the laser and air

flow. This setting should be left in the default mode unless special

applications, such as “surface scans”, require it to be disabled.

LANGUAGE

Pressing the LANGUAGE button allows the user to change the

operating language displaying the screen shown in Figure 4-44.

248083400-1 Rev 7

Figure 4-44 Operating Language Selection Screen

Press the desired language button then BACK or MAIN. The default is

English.

4-35

Page 64

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

COMM ADDRESS

When the HANDHELD is connected to a data collection system or

daisy chained at the end of a chain of RS-485 instruments, the

instrument’s COMM address is used to identify it.

LMS XChange or LMS Express/RT will search for the instrument by

the COMM Address specified on the Communication screen shown

below. COMM addresses range from 1 to 63.

For RS-485 communications, each device on a multi-port chain must

have a unique address.

4-36

Figure 4-45 COMM Address Configuration screen

Set the COMM Address by using the numeric keypad to select the

address; press ERASE to erase a number, if needed. Press ENTER to

accept the value. See Figure 4-45.

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

248083400-1 Rev 7

Page 65

Operation

OUTPUT SETUP

The Print configuration has several options for printing the data that the

user sets on the Printer Setup screen shown in Figure 4-46.

Note:

both Differential and

Cumulative printing at the

same time. For normalized

values with more than 8

digits, only the whole

number will be printed.

You can select

Figure 4-46 Printer Setup Screen

• Output on Sample / Output on Alarm - When Output on

Sample is enabled, a single record will print at the end of every

sample.

When Output on Alarm is enabled, a single record printout will

print at the end of any sample that experiences an alarm condition.

• Model Name - When enabled, the Model name of the instrument

will print in the header of all printouts.

• Serial Number - When enabled, the Serial Number of the

instrument will print in the header of all printouts.

• Separator - When enabled, a line separator will print after the

Model Name and Serial Number in the header of all printouts.

• Differential / Cumulative Toggle - This toggle option specifies

how the data will appear on the printouts.

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

248083400-1 Rev 7

4-37

Page 66

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

SECURITY

To restrict access to the instrument and/or configuring the instrument,

the HANDHELD has two different password levels. See Figure 4-47.

Figure 4-47 Security Password Configuration Screen

To restrict who can operate the instrument, enable the POWER ON

password. When the POWER ON password is enabled, in order to use

the instrument the user will be required to enter the correct password

each time the instrument is turned on.

To restrict who can configure the instrument, enable the Configuration

(CFG) password. When the Configuration password is enabled, the

user will be required to enter the correct password before they can

access the Configuration screen.

• To set the password for the POWER ON, select the POWER ON

button, then type in a password using the numeric keypad. Press the

ERASE button to delete the last character, if needed.

• Press ENTER to save.

• To set the Configuration (CFG) password, select the CFG button,

then type in a password using the numeric keypad.

• Press the ERASE button to delete the last character, if needed.

• Press ENTER to save the changes.

• Press the “X” button to enable either or both passwords.

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

4-38

248083400-1 Rev 7

Page 67

POWER ON PASSWORD

Operation

WARNING:

record the unit’s passwords

in a safe place. If the

password is lost or

forgotten, contact

Lighthouse technical

support for assistance. The

unit may have to be

returned to the factory to

reset the password.

Be sure to

To require that a password must be entered before the instrument can be

used, enable the POWER ON password. See Figure 4-48.

Figure 4-48 POWER ON Password Access Screen

When the POWER ON password is enabled, you will see a password

access screen just after you turn the unit on. The instrument will remain

locked until the correct password is entered.

CONFIGURATION PASSWORD

The Configuration password prevents unauthorized access to the

Configuration screen. See Figure 4-49.

Figure 4-49 CONFIGURATION Password Access Screen

248083400-1 Rev 7

4-39

Page 68

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

SERVICE

This section of the Configuration screen is reserved for Lighthouse

Authorized Service Providers only. The correct service password must

be entered to access this area.

Three options on the lower CFG screen, STATUS, RECIPE and LOC

display the instrument’s current status, configure user recipes and

locations respectfully.

STATUS Touching the STATUS button displays the instrument programmed

version of the various firmware modules as shown in Figure 4-50. This

information is useful when contacting Lighthouse Technical Support

personnel.

4-40

Figure 4-50 HANDHELD 3016 STATUS Screen

248083400-1 Rev 7

Page 69

Operation

RECIPE Selecting the RECIPE button displays the Recipe setup screen. See

Figure 4-51.

Note:

selected is already

assigned to another recipe

or if there are no available

free locations, the user will

not be able to add a new

recipe. The “Add” button

will not be displayed.

If the location

Figure 4-51 Recipe Setup Screen

The Recipe feature allows the user to save instrument settings for

sampling and reports in a database that can store up to 50 recipes.

Selecting the ADD button displays the RECIPE text screen. See Figure

4-52. The recipe can be named using up to 12 characters.

248083400-1 Rev 7

Figure 4-52 Recipe Name Screen

4-41

Page 70

Lighthouse HANDHELD 2016, 3016, 5016 Gen F Operating Manual

Pressing the ENTER button will add the recipe to the database and

display the recipe CONFIG screen as shown in Figure 4-53. Each

option allows the user to configure the instrument to the current recipe.

Figure 4-53 Recipe Configuration

Press the BACK button to save the settings and return to the RECIPE

screen.

Pressing the EDIT button on the main RECIPE screen will allow the

user to change settings on the highlighted recipe.

The LOAD and UNLOAD buttons add or remove the highlighted

recipe as the instrument’s current operating configuration.

The DELETE button will delete any highlighted recipes from the

database.

4-42

248083400-1 Rev 7

Page 71

Operation

The VIEW button displays the current settings for the highlighted

recipe. See Figure 4-54.

Figure 4-54 Recipe - Channel Settings