ApexPortable

PARTICLE COUNTER

OPERATING MANUAL

ApexP3, ApexP5

00

Lighthouse Worldwide Solutions

ApexPortable Airborne Particle Counter

Operating Manual

Copyright © 2015-2019 by Lighthouse Worldwide Solutions. All rights reserved. No part of this

document may be reproduced by any means except as permitted in writing by Lighthouse

Worldwide Solutions.

The information contained herein constitutes valuable trade secrets of Lighthouse Worldwide

Solutions. You are not permitted to disclose or allow to be disclosed such information except as

permitted in writing by Lighthouse Worldwide Solutions.

The information contained herein is subject to change without notice. Lighthouse Worldwide

Solutions is not responsible for any damages arising out of your use of the LMS program.

LMS™, LMS Express™ and

ApexPortable™ are trademarks of Lighthouse Worldwide

Solutions.

Microsoft

®

, Microsoft Windows™, and Excel™ are trademarks of Microsoft Corporation.

Manufactured by:

Lighthouse Worldwide Solutions

1221 Disk Drive

Medford, Oregon 97501

LWS Part Number 248083440-1 Rev 5

EU DECLARATION OF CONFORMITY

Manufacturer’s Name: Lighthouse Worldwide Solutions, Inc.

Manufacturer’s Address: Lighthouse Worldwide Solutions, Inc.

1221 Disk Drive

Medford, OR 97501

Declares that the product:

Product Name: ApexP Airborne Particle Counters

Model Number(s): ApexP3/ApexP5

Conforms to the following Product Specifications:

SAFETY EN61010-1:2010 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use Part

I: General Requirements IEC 61010-1:2010

EMC EN61326-1:2013 Electrical Equipment for Measurement, Control

and Laboratory Use EN 61326-1:2013

Supplementary information

The product herewith complies with the requirements of the Low Voltage Directive 2014/35/EU and the EMC

Directive 2014/30/EC and carries the CE marking accordingly

_________________________________________

Fremont, CA, March 13, 2019 Jerry Szpak – VP Engineering

________

____

__

__

_____

J

y

S

zp

g

err

ak – VP Engineerin

00

Table of Contents

About this Manual

Text Conventions ................................................................................................................ i

Additional Help ................................................................................................................... i

Chapter 1 General Safety

Safety Considerations .................................................................................................... 1-1

LASER Safety Information ........................................................................................... 1-1

Sampling Safety ............................................................................................................. 1-2

Operating Safety ............................................................................................................ 1-2

Electrostatic Safety Information .................................................................................... 1-3

Chapter 2 Introduction

Overview ........................................................................................................................ 2-1

Description ..................................................................................................................... 2-1

Accessories .................................................................................................................... 2-2

ApexP3 Specifications ................................................................................................... 2-3

ApexP5 Specifications ................................................................................................... 2-4

Chapter 3 Get Started

Unpack and Initial Inspection ........................................................................................ 3-1

Configuration Kit ........................................................................................................... 3-1

Interchangeable Terms ....................................................................................... 3-1

Set Channels, Thresholds and Alarms ........................................................................... 3-2

Chapter 4 Communications

General ........................................................................................................................... 4-1

RS485 Communications .................................................................................... 4-2

Remote Run via LMS Software ..................................................................................... 4-3

Chapter 5 Operate the ApexPortable

Using the Instrument for the First Time ........................................................................ 5-1

Touch Screen Overview ................................................................................................. 5-2

248083440-1 Rev 5 t-i

Lighthouse ApexPortable Operating Manual

Menu Map .......................................................................................................... 5-2

MAIN Screen ................................................................................................................. 5-3

Select Location .................................................................................................. 5-6

Locations in AUTO Mode ..................................................................... 5-7

Zoomed Data View ............................................................................................ 5-7

Viewing Two Columns of Data ............................................................. 5-8

CONFIG (Configuration) Screen ................................................................................. 5-10

DATA SETUP ............................................................................................................. 5-11

PARTICLE ...................................................................................................... 5-11

SAMPLE .......................................................................................................... 5-12

SETTING ......................................................................................................... 5-14

Count MODEs ..................................................................................... 5-14

FORMAT ............................................................................................. 5-15

ALARM ........................................................................................................... 5-16

Alarm Threshold .................................................................................. 5-16

CLEAR ............................................................................................................ 5-17

DEVICE SETUP .......................................................................................................... 5-18

CLOCK ............................................................................................................ 5-18

OPTIONS ......................................................................................................... 5-19

Contrast Adjust .................................................................................... 5-20

Audible Beep Adjust ............................................................................ 5-20

ALIGN Touch Screen .......................................................................... 5-20

Autostart Mode .................................................................................... 5-22

Diff+Cuml Zoom ................................................................................. 5-22

One Channel ........................................................................................ 5-23

One Second Realtime Modbus Output ................................................ 5-23

Language .............................................................................................. 5-23

COMM ............................................................................................................. 5-24

COMM Serial Settings ......................................................................... 5-24

Set ETHERNET Settings ..................................................................... 5-25

OUTPUT .......................................................................................................... 5-27

Printer Output ...................................................................................... 5-27

USB Output ........................................................................................ 5-28

Security ........................................................................................................... 5-29

Service ............................................................................................................. 5-30

STATUS ...................................................................................................................... 5-30

RECIPE ........................................................................................................................ 5-31

LOCATION ................................................................................................................. 5-34

Remote Operation ........................................................................................................ 5-36

Data View Buffer Screen ............................................................................................. 5-36

Output Data .................................................................................................................. 5-39

Output Data to USB Printer ............................................................................. 5-39

Output a Range of Records to USB Flash Drive ........................................... 5-39

Report Requirements ....................................................................................... 5-42

Fed Std ft3 ............................................................................................ 5-42

ISO 14644-1 ......................................................................................... 5-42

t-ii 248083440-1 Rev 5

EU GMP 2009 ..................................................................................... 5-42

REPORT FEATURE ....................................................................................... 5-42

Set Up Report Room Parameters ..................................................................... 5-44

Set Up Counter to Run Reports ....................................................................... 5-49

Save Report ...................................................................................................... 5-51

Generate a Report From Data .......................................................................... 5-52

Printing a Previously Printed Report ............................................................... 5-54

Web Reports Interface ......................................................................... 5-55

Web Page Reports ................................................................................ 5-56

Sample Printouts of Standard Reports ................................................. 5-58

Power Shutdown Levels .............................................................................................. 5-61

Chapter 6 Maintenance Procedures

Introduction .................................................................................................................... 6-1

Safety ............................................................................................................................. 6-1

Maintenance ................................................................................................................... 6-1

Calibration ......................................................................................................... 6-1

Zero Count Test ............................................................................................................. 6-1

Fault Isolation ................................................................................................................ 6-2

Table of Contents

Chapter 7 Program with the MODBUS Protocol

General Info ................................................................................................................... 7-1

Protocol Settings ............................................................................................................ 7-1

Power On/Auto Start ...................................................................................................... 7-1

Running the Instrument Using MODBUS ..................................................................... 7-1

AUTOMATIC Counting Mode ......................................................................... 7-2

Configuring with the MODBUS Protocol ..................................................................... 7-3

Setting the Real Time Clock .............................................................................. 7-3

Changing the Default Instrument Parameters .................................................... 7-4

Using Sensor Setting Registers .............................................................. 7-4

Location (Register 40026) ..................................................................... 7-5

Hold Time (Registers 40031, 40032) .................................................... 7-5

Sample Time (Registers 40033, 40034) ................................................ 7-5

Alarm Enable Registers ..................................................................................... 7-6

Enable Alarming for a Channel ............................................................. 7-7

Threshold Setup Registers ................................................................................. 7-7

Setting the Alarm Threshold Value ....................................................... 7-8

Appendix A ApexPortable MODBUS Register Map v1.50

COMM Settings ............................................................................................................ A-1

Supported MODBUS Commands ................................................................................. A-1

Sensor Settings Registers .................................................................................. A-2

248083440-1 Rev 5 t-iii

Lighthouse ApexPortable Operating Manual

Device Status ........................................................................................ A-5

Alarm Enable Registers .................................................................................... A-8

Enable Alarming for a Channel ............................................................ A-9

Threshold Setup Registers .............................................................................. A-10

Setting the Alarm Threshold Value .................................................... A-10

Data Registers ............................................................................................................. A-11

Device Status Word ........................................................................................ A-14

Data Enable Registers ..................................................................................... A-15

Data Type Registers ........................................................................................ A-15

Data Units Registers ....................................................................................... A-17

Appendix B Limited Warranty

Limitation Of Warranties: .............................................................................................. B-1

Warranty Of Repairs After Initial Two (2) Year Warranty: .......................................... B-1

Index

t-iv 248083440-1 Rev 5

00

About this Manual

This manual describes the detailed operation and use of the Lighthouse

ApexPortable (ApexP3 and ApexP5) portable airborne particle

counters.

Text

Conventions

Note:

A note appears in

the sidebar to give extra

information regarding a

feature or suggestion.

WARNING:

appears in a paragraph

like this and indicates a

condition, which if not

met, could cause serious

personal injury or death,

and damage to the

instrument.

A warning

Additional

Help

The following typefaces have the following meanings:

italics Represents information not to be typed

or interpreted literally. For example, file

represents a file name. Manual titles are

also displayed in italics.

boldface Introduces or emphasizes a term.

Courier font Indicates command syntax or text

displayed by the diagnostic terminal.

Bold Courier Indicates commands and information that

the user types.

Helvetica Italics Indicates a comment on a command or

text output.

For more information about Lighthouse ApexPortable Airborne Particle

Counters, contact Lighthouse Worldwide Solutions.

Service and Support

Tel: 1-800-945-5905 (Toll Free USA)

Tel: 1-541-770-5905 (Outside of USA)

techsupport@golighthouse.com

248083440-1 Rev 5 i

Lighthouse ApexPortable Operating Manual

ii 248083440-1 Rev 5

00

1 General Safety

Safety

Considerations

WARNING:

no user-serviceable

components inside the

particle counter.

There are

LASER Safety

Information

Warnings and cautions are used throughout this manual and the reader

should become familiar with the meaning of a warning before

operating the particle counter. Most warnings will appear in the left

margin of the page next to the subject or step to which it applies. Take

care when performing any procedures preceded by or containing a

warning. The classifications of warnings are defined as follows:

• LASER - pertaining to exposure to visible or invisible LASER

radiation

• Electrostatic - pertaining to electrostatic discharge

• Network Connect - pertaining to communication ports and

instrument damage

This product is considered to be a Class 1 LASER product (as defined

by FDA 21 CFR, §1040.10 and IEC 60825-1:2014) when used under

normal operation and maintenance. Performing service on the internal

sensor can, however, result in exposure to invisible radiation.

WARNING:

of controls, adjustments

or procedures other than

those specified within

this manual may result in

personal injury and/or

damage to this

instrument.

248083440-1 Rev 5 1-1

The use

The particle counter has been evaluated and tested in accordance with

EN 61010-1:2012, “Safety Requirements For Electrical Equipment for

Measurement, Control and Laboratory Use” and IEC 60825-1:2014,

“Safety of LASER Products”.

For further technical assistance, contact our Technical Support Team at

1-800-945-5905 (USA Toll Free), 1-541-770-5905 (Outside of USA).

Lighthouse ApexPortable Operating Manual

Sampling

Safety

Operating

Safety

WARNING: While the flow path components will not be

adversely affected, sampling reactive gasses such as

hydrogen and oxygen can be dangerous. Appropriate

precautions should be taken.

Sampling of any pressurized gasses without the use of a

properly designed diffuser can cause damage to the

instrument and void the warranty.

Do NOT allow water, solvents, or other liquids to enter the

instrument as they can damage the instrument and void the

warranty.

WARNING: The use of controls, adjustments or procedures

other than those specified within this manual may result in

personal injury and/or damage to this instrument. Attempts

by untrained personnel to disassemble, alter, modify or

adjust the electronics or optics may result in personal injury

and damage to the instrument and will void its warranty.

There are no user-serviceable components inside the

particle counter. Only factory authorized service personnel

should repair or service this instrument and its optical

system.

If replacement of the power supply or its AC power cord is

required, replace it only with a power supply or cord having

as good as or better ratings than specifications provided by

Lighthouse Worldwide Solutions. Attempting to use an

under-rated power supply or cord can expose the

instrument, adjacent equipment or the user to dangerous

shock and fire hazards. Failure to meet this requirement will

void the CE certification, void the instrument warranty and

can result in serious personal injury.

1-2 248083440-1 Rev 5

General Safety

WARNING: The

ApexPortable uses a

5 Amp 24V DC power

supply. It connects to

the round connector

shown in Figure 1-1.

Remove AC power from

power supply, connect

DC cord to Apex then

connect power supply to

AC.

Electrostatic

Safety

Information

24VDC

Input

Connector

Figure 1-1 ApexPortable Power Input Connector

Electrostatic discharge (ESD) can damage or destroy electronic

components. Therefore, any service or maintenance work should be

done at a static-free work station. A static-free work station requires an

ESD consultant to evaluate the work environment and propose the

equipment and apparel needed for a work station to be successful.

248083440-1 Rev 5 1-3

Lighthouse ApexPortable Operating Manual

1-4 248083440-1 Rev 5

00

2 Introduction

Overview This operating manual introduces the Lighthouse ApexPortable

family of portable Airborne Particle Counters and includes instructions

for inspecting, installing, using and maintaining the instrument.

Description The ApexPortable instrument comes standard with four particle-size

channels of 0.3, 0.5, 1.0 and 5.0 microns (

and 10.0 microns (

the standard configuration. Figure 2-1 lists features and specifics about

the

ApexP3 and Table 2-2 lists the ApexP5.

ApexP5) with a flow of 1.0 CFM. Figure 2-1 shows

ApexP3) and 0.5, 1.0, 5.0

Figure 2-1 ApexPortable Airborne Particle Counter

The instrument uses a LASER diode light source and LASER beam

shaping optics to illuminate a cross section of the air flow path. As

particles move along this path, they cross the LASER beam and scatter

light. The light scattered is collected by an optical imaging system onto

a photodiode. The photodiode converts the image into a current which

is converted to a voltage and amplified by an electronic circuit.

The result is the electronic circuit outputs a voltage pulse each time a

particle crosses the LASER beam. The amplitude of the voltage pulse

is proportional to the light scattered which in turn is proportional to the

size of the particle.

248083440-1 Rev 5 2-1

Lighthouse ApexPortable Operating Manual

The voltage pulses created by the particles are then processed by

additional electronics that analyze the height of each pulse, therefore,

the size of each corresponding particle. The result is that the number of

particles of various sizes is determined.

The processed signals are sorted into bins, or channels, and displayed

on the screen as counts. The terms Particle Size and Particle Channel

are used synonymously to refer to the displayed information.

This instrument is effective in both ultra-clean areas (such as ISO Class

1 or Grade A) and in more traditional cleanzones rated as ISO Class 3

or higher. Refer to Specifications in this manual for additional

instrument information.

The

ApexPortable integrates seamlessly with large facility monitoring

and management systems and transfers particle count data using RS485

(using MODBUS RTU or ASCII protocols) or Ethernet via MODBUS

TCP.

Accessories Several items are shipped with each instrument but some optional

accessories can be ordered to tailor the instrument to specific needs.

Standard and optional accessories are listed below.

• Standard Accessories:

• 24VDC 5A Power Supply

• Operating Manual on included flash drive

• LMS Express Download Instructions

• Read Me First

•Parts List

• USB to RS-232 Serial cable

• 1.0 CFM Isokinetic Sampling Probe with Tubing

• 1.0 CFM Purge Filter Assembly with Tubing

• Optional Accessories:

• USB Thermal Printer and Operating Manual on CD

• Cable, per foot

• Sample Tubing, per foot

• ISO Probe Monopod

2-2 248083440-1 Rev 5

ApexP3

Specifications

Introduction

Size Range 0.3 - 5.0 μm

Channel Thresholds Standard 2-channel: 0.3, 0.5μm; 4-channel:

0.3, 0.5, 1.0, 5.0μm

Flow Rate 1.0 CFM (28.3 LPM)

Counting Efficiency Meets ISO 21501-4

Data Storage Rotating Buffer, 3000 records

Light Source LASER diode

External Connections RS485 RJ45 (RS485 and RS232 data); DIN

(factory); Ethernet RJ45 (Ethernet data);

calibration port

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Max ISO Probe tubing Maximum tubing length to ISO = 16 feet

Calibration NIST Traceable

Communication Modes MODBUS ASCII; MODBUS RTU;

Supporting Software LMS Pharma/Pro v7.3.1 or higher, LMS

Operating Altitude Sea Level to 2000 meters (6561.66 feet)

Power Input

Requirements

Power Supply

Specifications

Enclosure Stainless Steel, VHP compatible

Dimensions

Weight

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

Table 2-1 ApexP3 Specifications

MODBUS TCP

Express 7.5 or higher

24VDC ±5% @ 5.0A, 120W

100-240VAC, 47-63Hz 1.4A input, 24VDC

5.0A 120W max output

9.00” (w) x 8.46” (h) x 6.21” (d) [22.86 x 21.49 x

15.77 cm]

10.0 lbs (4.54 kg)

non-condensing at maximum 2000M altitude

non-condensing

248083440-1 Rev 5 2-3

Lighthouse ApexPortable Operating Manual

ApexP5

Specifications

Size Range 0.5 - 10.0 μm

Channel Thresholds Standard 2-channel: 0.5μm, 5.0μm; 4-channel

Flow Rate 1.0 CFM (28.3 LPM)

Counting Efficiency Meets ISO 21501-4

Data Storage Rotating Buffer, 3000 records

Light Source LASER diode

External Connections RS485 RJ45 (RS485 and RS232 data); DIN

Zero Count Level <1 count/5 minutes (per ISO 21501-4)

Max ISO Probe tubing Maximum tubing length to ISO = 16 feet

Calibration NIST Traceable

0.5, 1.0μm, 5.0μm, 10.0μm

(factory); Ethernet RJ45 (Ethernet data);

calibration port

Communication Modes MODBUS ASCII; MODBUS RTU;

MODBUS TCP

Supporting Software LMS Pharma/Pro v7.3.1 or higher, LMS

Express 7.5 or higher

Operating Altitude Sea Level to 2000 meters (6561.66 feet)

Power Input

24VDC ±5% @ 5.0A, 120W

Requirements

Power Supply

Specifications

100-240VAC, 47-63Hz 1.4A input, 24VDC

5.0A 120W max output

Enclosure Stainless Steel, VHP compatible

Dimensions

Weight

9.00” (w) x 8.46” (h) x 6.21” (d) [22.86 x 21.49 x

15.77 cm]

10.0 lbs (4.54 kg)

Operating Temp/RH 50° F to 104° F (10° C to 40° C) / 20% to 95%

non-condensing at maximum 2000M altitude

Storage Temp/RH 14° F to 122° F (-10° C to 50° C) / Up to 98%

non-condensing

Table 2-2 ApexP5 Specifications

The manufacturer recommends that the Lighthouse instrument be

calibrated annually by a Lighthouse Certified Service Provider in order

to ensure the unit continues to perform within specifications and to

protect its warranty. For information about returning instruments for

calibration or service, visit our website www.golighthouse.com/RMA.

2-4 248083440-1 Rev 5

3 Get Started

Get Started

Unpack and

Initial

Inspection

Configuration

Kit

The instrument is thoroughly inspected and tested at the factory and is

ready for use upon receipt.

When the instrument is received, inspect the shipping carton for

damage. If any is noted, ensure that the carrier is notified and the carton

is saved for carrier inspection. Remove the instrument and other

components from the packing materials and inspect them for broken

parts, scratches, dents, and other damage. Compare the contents with

the pack slip / invoice / parts list. Immediately report any damaged or

missing parts to Lighthouse.

Damaged cartons may be replaced by calling Lighthouse Sales. Keep

an undamaged carton for reshipment of the instrument for its annual

factory calibration.

Report all issues to Lighthouse Support at 1-800-945-5905 in the USA

or 1-541-770-5905 outside of USA.

Each order is shipped with a Ship Kit, which includes a 24VDC Power

Supply and a flash drive containing the Operating Manual.

Interchangeable Terms

The terms ApexPortable, instrument, counter and unit may be used

throughout this manual interchangeably; they mean the same thing

unless specified otherwise.

248083440-1 Rev 5 3-1

Lighthouse ApexPortable Operating Manual

Figure 3-1 ApexPortable Connectors

WARNING: Remove

AC power from Power

Supply, connect DC

cable then connect to

AC.

Set Channels,

Thresholds,

and Alarms

Always have the AC disconnected from the power supply before

attempting to connect the DC Output Connector to the ApexPortable.

This will prevent damaging the Power Input Connector.

It is suggested that the

ApexPortable be placed in the environment

where it will be used and attached to its power supply for several hours

to ensure its battery is fully charged before putting the instrument into

service.

Push the rear power button (see the image above) in to turn the

instument on - it should latch in the ON state. After about 5 seconds,

the unit will display its boot screen then display the Main Screen. The

following screens will display how to enable channels, set alarm levels

and enable the alarms. They are provided as examples and may vary on

individual instruments.

3-2 248083440-1 Rev 5

Quick Setup Guide:

Tou c h th e

CONFIG

button

Then

PARTICLE

Figure 3-2 MAIN Screen

Get Started

Figure 3-3 Config Screen Choose Particle

Enabled

Enable

Desired

Channels

Press the button

to

toggle state

Disabled

then press BACK

Figure 3-4 Particle Channel ON/OFF Setting

Press a to change its state to a to enable the channel.

Press a to change its state to a to disable the channel.

248083440-1 Rev 5 3-3

Lighthouse ApexPortable Operating Manual

When CONFIG

screen returns,

press ALARM

to enter the

Particle Alarm

screen

Figure 3-5 Config Screen - Choose Alarm

press a

button to

change

the alarm

threshold

Figure 3-6 Particle Alarm Enable/Disable

Use the

Numeric

Keypad

to enter

desired

values

followed by the ENTER

button

Disabled

Enabled

Press the button

to

toggle state

Acts

as a

backspace

Figure 3-7 Alarm Threshold Change Screen

3-4 248083440-1 Rev 5

Get Started

Return to

MAIN

screen

and note

that only

enabled

channels

are

displayed

Figure 3-8 Enabled Channels Displayed

Figure 3-8 shows enabled channels and the ’>’ indicates channels that

have alarms enabled, in this case both channels.

At this point, pressing the START button will start the

ApexPortable

counting cycle on the enabled channels. Please refer to Chapter 5,

Operating Counter, for detailed operating instructions for the

instrument.

248083440-1 Rev 5 3-5

Lighthouse ApexPortable Operating Manual

3-6 248083440-1 Rev 5

00

4 Communications

This chapter contains information regarding how to set up

communications to program and communicate with the

instrument.

General Table 4-1 lists the Communication Port (COMM Port) RJ45 pinouts.

Prevent accidental damage to Ethernet hardware: do NOT connect the

COMM port to Ethernet equipment, such as network switches, hubs

and the like.

Table 4-1 COMM Port RJ45 Pinouts

ApexPortable

RJ45 Pin Signal Name

1 RS232-TX (Output)

2 RS232 RX (Input)

3 RESERVED for future use

4 RS485B

5 RS485A

6 RESERVED for future use

7 RESERVED for future use

8 Ground

To connect the instrument to a computer using USB-to-RS232 cable:

1. Remove power from the instrument.

2. Connect the RJ45 end of a USB-to-RS232 or RS485 cable to the

RS485 RJ45 connect port on the instrument.

3. Connect the USB end of the cable to any computer USB Port.

248083440-1 Rev 5 4-1

Lighthouse ApexPortable Operating Manual

RS485 Communications

RS485 should be used if the instrument is more than 50 feet from the

computer or is installed in an industrial network. To do so, an optional

RS485 cable must be used. Refer to Table 4-2 for specifics about the

RS485 standard.

Table 4-2 shows the Electronics Industry Association (EIA) industry

standards specifications.

Table 4-2 EIA Industry Standards for RS485 Communications

SPECIFICATIONS RS485

Mode of Operation Differential

Total Number of Drivers and Receivers on

One Line (One driver active at a time for

32 Drivers

32 Receivers

RS485 networks)

Maximum Cable Length 4000 ft (1,219.2 m)

Maximum Data Rate (40 ft - 4000 ft for

100Kbs - 10Mbs

RS422/RS485)

Maximum Driver Output Voltage -7V to +12V

Driver Output Signal Level (Loaded

+/-1.5V

Min.): LOADED

Driver Output Signal Level (Loaded

+/-6V

Max.): UNLOADED

Driver Load Impedance (Ohms) 54

Max Driver Current in High Z State

+/-100μA

(POWER ON)

Max Driver Current in High Z State

+/-100μA

(POWER OFF)

Receiver Input Voltage Range -7V to +12V

Receiver Input Sensitivity +/-200mV

Receiver Input Resistance (Ohms), (1

>

12k

Standard Load for RS485)

4-2 248083440-1 Rev 5

Communications

Ethernet Port

SmartPort

COMM Port

Power Input

Connector

WARNING: The

ApexPortable uses a 5

Amp 24V DC power

supply. It connects to the

round connector shown

on the left in Figure 4-1.

The symbol shows the

voltage and polarity of

supplied power.

Figure 4-1 ApexPortable Rear Connectors

The ApexPortable uses Ethernet for large scale communication,

RS485 for industrial networks and RS232 for direct connection to

monitoring computers.

Remote Run

via LMS

Software

WARNING: Always have the AC disconnected from the power

supply before attempting to connect the DC Output Connector to

ApexPortable. This will prevent damage to the Power Input

Connector.

Only use the power cord provided with the instrument. If it

becomes necessary to replace the power cord or the power

supply, contact Lighthouse Service. Failure to heed this warning

may subject the user and equipment to a shock or fire hazard,

which may result in serious bodily injury and property damage.

The ApexPortable can be remotely accessed, started, stopped and run

by LMS Express Standard, LMS Express RT, LMS Net, Professional

and Pharma software products. The LMS software can retrieve the data

and present it in several user-set reports and report formats.

Facility monitoring products, such as the LMS Net, LMS Professional

or LMS Pharma, provide facility-wide and enterprise-wide monitoring,

alerting and reporting features that use the

ApexPortable environment

monitoring functions.

248083440-1 Rev 5 4-3

Lighthouse ApexPortable Operating Manual

4-4 248083440-1 Rev 5

00

5 Operate the

ApexPortable

Using the

Instrument for

the First Time

WARNING:

flow path componenets

will not be adversely

affected, sampling

reactive gases such as

hydrogen and oxygen

can be dangerous.

Appropriate precautions

should be taken.

Sampling of any

pressurized gasses

without the use of a

properly designed

diffuser can damage the

instrument and void its

warranty.

Please contact

Lighthouse at 1-800-9455905 (USA Toll Free) or 1541-770-5905 (Outside of

USA) for more

information.

While the

This chapter describes how to use the ApexPortable 1.0 CFM

Airborne Particle Counter. The ApexPortable battery is fulled charged

when it leaves the factory, but should be connected to external power

before initial power up.To start using the instrument, proceed as

follows:

WARNING: To prevent damage to the instrument, water, solvents or

other liquids of any kind must never be allowed to enter the

ApexPortable via the inlet tube. Failure to heed this warning can void

the warranty. Never operate the instrument with the inlet tube capped or

plugged. Failure to heed this warning may damage the internal pump

and void the

ApexPortable warranty.

1. Position the instrument in the environment to be measured.

2. Attach the external Power Supply and connect AC cord to AC.

3. Remove the protective cap from the inlet barb located on the top

of the unit. To use the isokinetic probe, attach the probe to the

instrument’s inlet barb using the tubing on the probe.

4. Press in on the rear power switch.

5. While booting, the unit displays a startup "splash" screen.

6. The MAIN screen displays.

7. On the touch screen, press the “START” button to start the

instrument.

8. "STARTING" will display when the pump starts running.

9. When the

ApexPortable starts counting, "COUNTING" appears

on the display. Particle counts are displayed according to which

size channel detected each particle.

248083440-1 Rev 5 5-1

Lighthouse ApexPortable Operating Manual

10. If the instrument has been programmed with a delay before

starting the pump, it displays, “DELAY”.

11. If the instrument is in AUTO mode with cycles and a hold time,

“HOLDING” will display after each cycle and “FINISHED” will

display when all the cycles are complete.

12. Press the "STOP" button to stop the instrument before the cycles

are complete. "STOPPED" will display on the screen.

Touch Screen

Overview

The ApexPortable incorporates a unique touch screen interface, which

allows the user to easily view and configure the instrument to specific

needs and applications. Figure 5-1 shows the menu tree.

Menu Map

Figure 5-1 Menu Map

5-2 248083440-1 Rev 5

Operate the ApexPortable

MAIN Screen The MAIN screen provides a snapshot view of the status of the

instrument. The instrument can be powered by AC power or the

internal battery. When the instrument is using battery power, the

battery indicator will show the approximate level and percentage of the

battery charge remaining as shown in Figure 5-2.

Note:

examples in this chapter

are for reference, only. The

values displayed may not

be indicative of actual

values.

The screen

Figure 5-2 MAIN Screen - Battery Operation

Figure 5-3 MAIN Screen - AC Operation

When an AC-powered power supply is attached, the battery changes to

one with a lightening bolt. Its approximate capacity is displayed as a

percentage above the icon. See Figure 5-3.

The MAIN screen displays the following options and information:

• LOC: Displays the location that is currently being measured. Up to

200 alphanumeric locations can be configured.

• Location Select button: At the MAIN screen, displays an

Abbreviated Location Screen that allows a user to change location

before sampling without requiring use of the CONFIG screen and

any associated password.

248083440-1 Rev 5 5-3

Lighthouse ApexPortable Operating Manual

Depleted Battery

Warning ICON

Full and

Depleted and

Charging

Charging

InsufficientSufficient

• RECIPE button: Allows the user to view, load and unload recipes

that have been configured and saved in the recipe data base via an

Abbreviated Receipe Screen. To edit the recipe or to add or delete

recipes, use CONFIG, which can be password-protected, from the

MAIN screen (see Figure 5-47). The CONFIG password is not

required here.

• Last-Sampled Record Print/USB Save: Indicates attached printer

or flash drive to be used to output the Last-Sampled Record

currently on the screen. Press the Print ICON to send to the

attached printer or USB ICON to send to flash drive. Restart will

clear the screen and nothing will be output.

• Date/Time: Displays the current date and time.

Note:

Users can continue to

run samples and take counts

while the unit is plugged in.

• Battery ICONs: Indicate that the instrument is being powered by

the rechargeable battery or its external power supply. The amount

of battery life left is depicted by the fill inside the battery icon and

the percentage above the icon. When the battery reaches 20%

charge, the ICON will start blinking and display a "BATTERY

LOW!" message. When it reaches 5% and the user tries to run a

sample, the large "Depleted" ICON shown on the left is displayed

and the unit will not run the pump until instrument is attached to the

external DC power supply for recharging.

WARNING:

Flow is insufficient, check

for and remove any

obstructions. If the issue

persists, turn the Apex off

and contact Lighthouse

Worldwide Solutions

technical support at 1945-5905 (USA Toll Free)

or 1-541-770-5905

(Outside of USA)

If the Air

800-

.

• While connected to the power supply, the battery icon changes to

indicate charging. See Figure 5-4.

Depleted Full

Figure 5-4 Battery Levels, On-Battery and Charging

On-Battery

Charging

• Flow Status: When the instrument is COUNTING, the Flow ICON

(left of battery) appears and displays sufficient or insufficient flow.

•USB: Indicates that a USB printer or flash drive is attached.

5-4 248083440-1 Rev 5

Operate the ApexPortable

• Service Indicator: Indicates that the instrument may be in need of

service. If wrench displays, please contact a Lighthouse authorized

Service Provider at 1-800-945-5905 (USA Toll Free) or 1-541-7705905 (Outside of USA) for assistance or send an email to

techsupport@golighthouse.com.

•

μ: The mu (m-yoo) symbol indicates the particle sizes, in

micrometers, configured for the instrument. These sizes are preconfigured at the factory. To order an instrument with non-standard

sizes, please contact a Sales at Lighthouse 510-438-0500 (Sales).

• DATA DISPLAY: This indicates whether the counts are being

displayed in Differential (Diff) mode or in Cumulative (Cuml)

mode and, if the counts are normalized to ft

3

or m3.

Differential

Normalized ft

3

Cumulative

Normalized m

3

•MODE: Displays the current mode selected; possible modes are

AUTO, MANUAL, CONC (Concentration) and BEEP. The

exception to this is when a recipe is being run in which case the

MODE area will display number of cycles run versus the total to be

run (x / 6).

•CYCLES: Indicates the number of times the count will be taken at

a given location in Auto mode. "1/ 3" indicates the count is the first

of three samples to be recorded at this location. The maximum

number of cycles is 999. When set to 0, the unit will run in Auto

mode continuously until the STOP button is pressed.

• SAMPLE: The Sample Time (hh:mm:ss) is the duration of one

counting cycle. The Sample Time will count down on the MAIN

screen when the instrument is in AUTO or Manual mode so the user

can see how much time is remaining in the sample period. In

Concentration mode, the Sample Time will count up to 6 seconds

per cycle.

Note:

greater than 1 minute, the

pump will stop during that

time. At the end of the hold

time, the pump will restart.

If Hold time is

•HOLD: Displays the hold time in between cycles. The maximum

hold time is 23 hours, 59 minutes, 59 seconds.

•RECS: This displays the current number of records stored in the

instrument and the total number of records that can be stored. The

data buffer is a circular buffer. The instrument can store up to 3000

records. An asterisk (*) will appear in front of counts when the

buffer wraps.

248083440-1 Rev 5 5-5

Lighthouse ApexPortable Operating Manual

• START/STOP: Press START button on the screen to start

counting. STARTING is displayed on the screen until the pump

and support electronics are stable and the

reliably count particles. COUNTING will display in the lower right

corner of the screen as shown in Figure 5-5 when the

ApexPortable is actually counting. When the STOP button is

pressed to stop counting, the word STOPPED will be displayed.

• The instrument may be stopped during sampling by an errorchecking process for insufficient battery power, pump over-current

or instrument over-temperature. Acknowledge the popup by

pressing the OK button to try to return to normal operation. If the

error condition persists, contact Lighthouse support.

ApexPortable can

Counting State

Figure 5-5 Three Counting States

Select Location

The location for the measured environment can be changed by pressing

the LOCATION button at the top of the MAIN screen. Figure 5-6

displays the abbreviated Select Location screen. To edit, add or delete

locations, the CONFIG button must be used, which can be passwordprotected. The password is not required here.

Figure 5-6 Location Select Screen

5-6 248083440-1 Rev 5

Operate the ApexPortable

Note: Also see Figure 5-

54 for more information on

Locations.

• The blue highlight indicates which location is currently selected.

• Use the UP and DOWN arrows to highlight a location. The arrows

will move pages up and down. Press on the location name desired

to select the location. A location that has been assigned to a recipe

will display an asterisk at the end of its name.

• When a highlighted location uses a specific recipe, it will be

prompted to load when the MAIN button is pressed.

• The AUTO INC button, when active, pauses the

ApexPortable to

allow the user to move the ApexPortable to the next location when

the current cycle is completed. It waits for the user to ackowledge

the change by pressing the Start button to continue counting at the

new location.

• Press the MAIN button to return to the MAIN screen. Whichever

location that was highlighted / selected will be the location

displayed on the MAIN screen.

Locations in AUTO Mode

When the instrument is in Automatic Mode and the START button is

pressed, the instrument will start counting particles automatically based

on the SAMPLE time, HOLD time and number of cycles that are

configured.

Zoomed Data View

There are two different Zoom views. The user can view a single

column of data (differential or cumulative) in a larger font or view both

differential and cumulative data on the same screen in a smaller font.

While the ApexPortable is stopped, tap anywhere in the Particle Data

area to display the Zoomed Data View. See Figure 5-7.

Figure 5-7 Zoomed Data View

248083440-1 Rev 5 5-7

Lighthouse ApexPortable Operating Manual

In the Zoomed Data View, functions can be enabled using the buttons

on the right side bar of Figure 5-7. Figure 5-8 shows examples and

explanations of the buttons.

START or STOP counting

Display Cumulative / Differential data

Display Raw / Normalized particle data

Display ft

3

/ m3 when configured

Figure 5-8 Zoomed Data View Buttons

When the instrument is STOPPED or HOLDING, the user may touch

anywhere in the white data area to return to the MAIN Screen view.

Viewing Two Columns of Data

The

ApexPortable can display both Differential and Cumulative data

at the same time on the Zoomed View screen. Press the CONFIG then

OPTIONS button to display the Options screen (Figure 5-9).

Figure 5-9 CONFIG: Options Screens

5-8 248083440-1 Rev 5

Operate the ApexPortable

START or STOP counting

Display Cumulative / Differential data

Display Raw / Normalized particle data

Display ft

3

/ m3 when configured

Press the “Diff+Cuml Zoom” button as shown in Figure 5-9, right

frame, to enable the feature. This will display both differential and

cumulative data on the Zoomed View screen as shown in Figure 5-10.

DIFF

Data

CUML

Data

Figure 5-10 Differential and Cumulative Data in Zoomed View

The buttons available after selecting Diff+Cuml Zoom are shown in

Figure 5-11. Their functions are the same as on single display screen.

Figure 5-11 Diff+Cuml Zoom Screen Button Actions

To return the instrument to the default single-column zoom view, return

to the MAIN Screen, press CONFIG, Options and deselect the

“Diff+Cuml Zoom” button. See Figure 5-9.

Press the MAIN button to return to the MAIN Screen or press BACK to

return to the previous level where the data type to be displayed on the

one-column Zoomed View screen is chosen.

248083440-1 Rev 5 5-9

Lighthouse ApexPortable Operating Manual

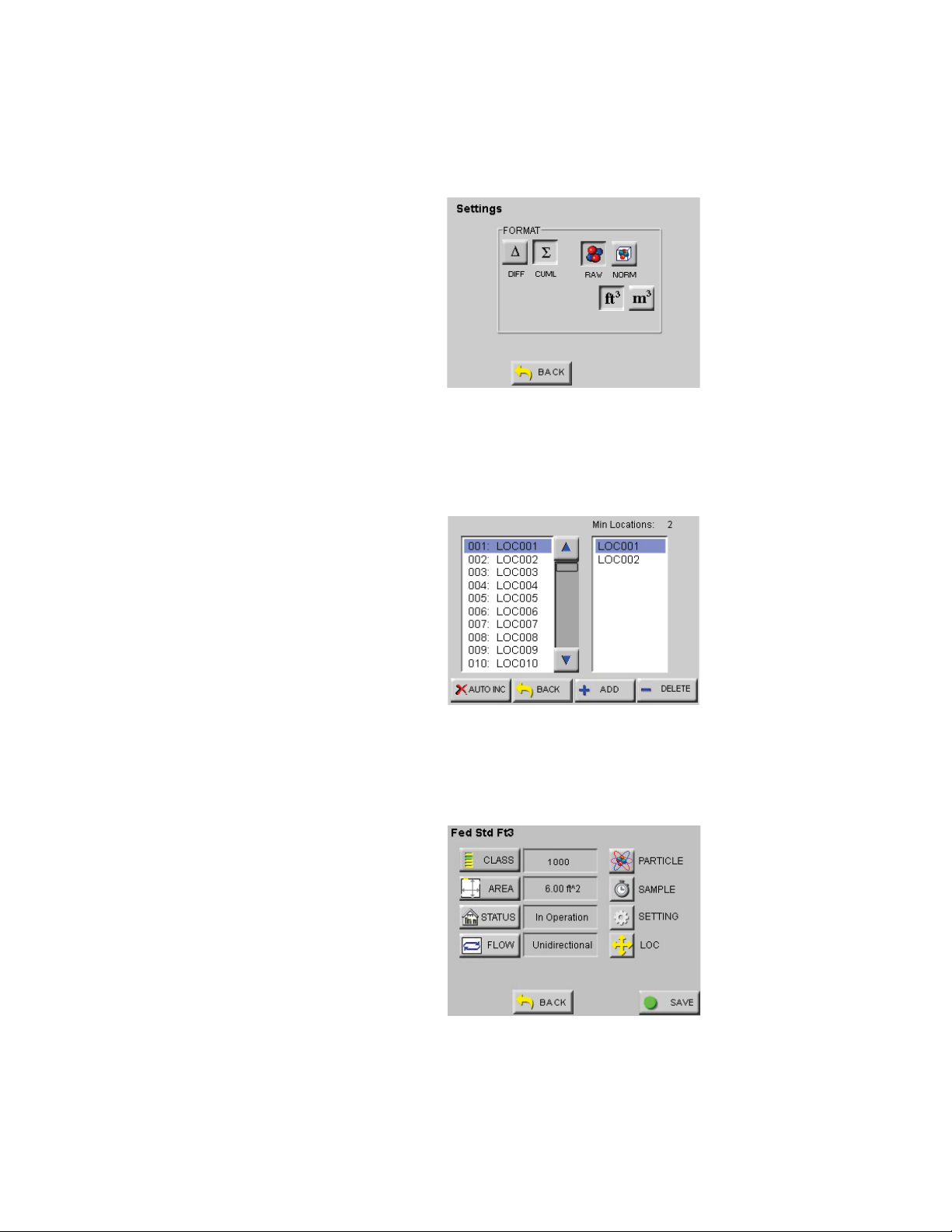

Go to the Settings screen and press Differential or Cumulative for the

data type. See Figure 5-12.

Figure 5-12 Settings Screen

CONFIG

(Configuration)

Screen

Press CONFIG on the MAIN screen to display the Configuration

screen as shown in Figure 5-13. This feature can be passwordprotected.

Figure 5-13 Configuration Screen

DATA SETUP provides buttons to enable/disable particle channels, set

sample record parameters, sample settings, thresholds, enable/disable

alarms and clear the data buffer.

DEVICE SETUP provides buttons to configure the instrument’s date

and time, set the LCD contrast, adjust the instrument’s beep volume,

enable the instrument to AutoStart, set it to display only one channel of

data, enable real-time MODBUS output, set the instrument’s

communication address, enabling output on sample, enable password

restrictions and/or (with proper authorization) adjust service settings.

5-10 248083440-1 Rev 5

Operate the ApexPortable

Disabled

Enabled

Press button to

Change State

then

Enable the

particle

sizes to

be measured

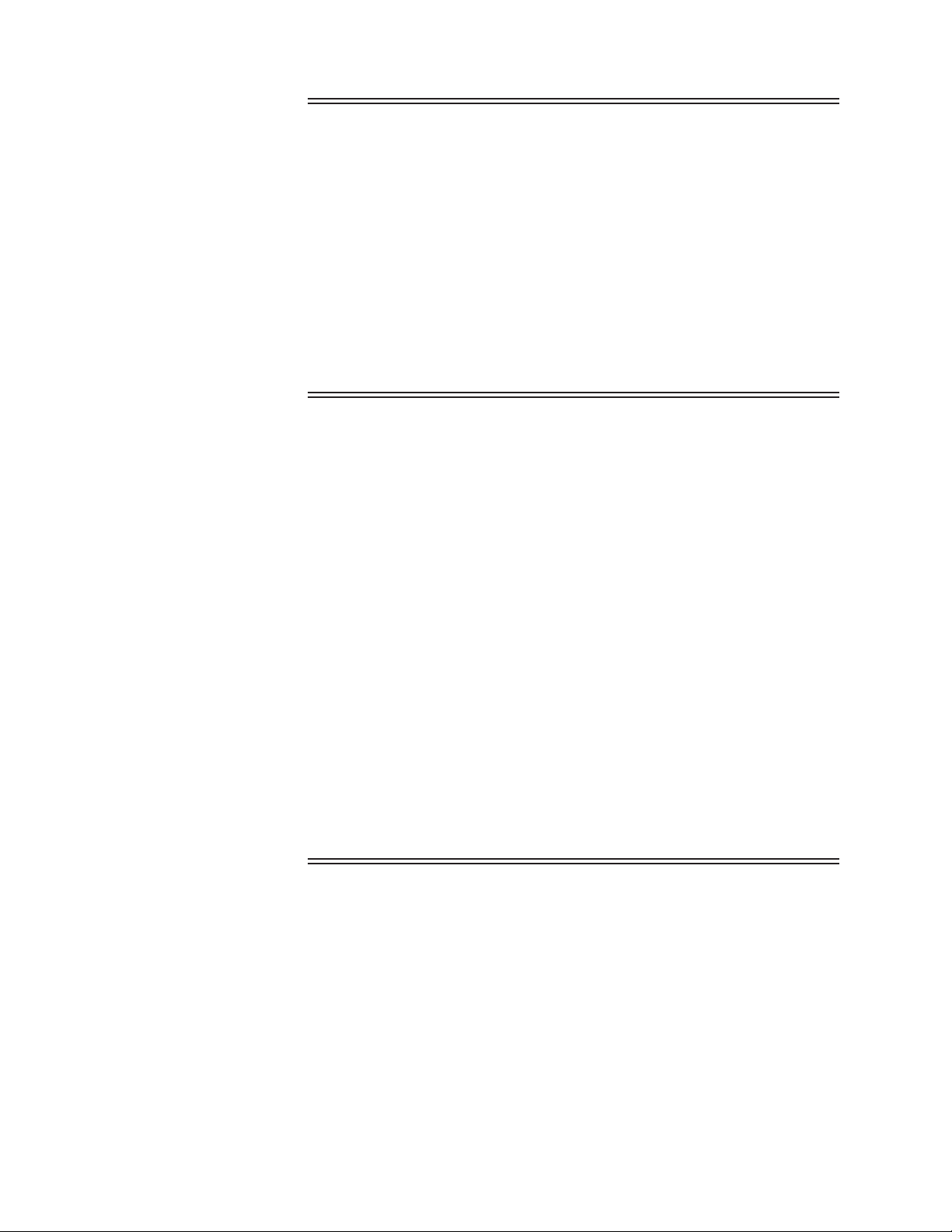

DATA SETUP Figure 5-14 shows the Data Setup option buttons. These options allow

the user to configure the parameters for data collection.

Figure 5-14 Data Setup Options

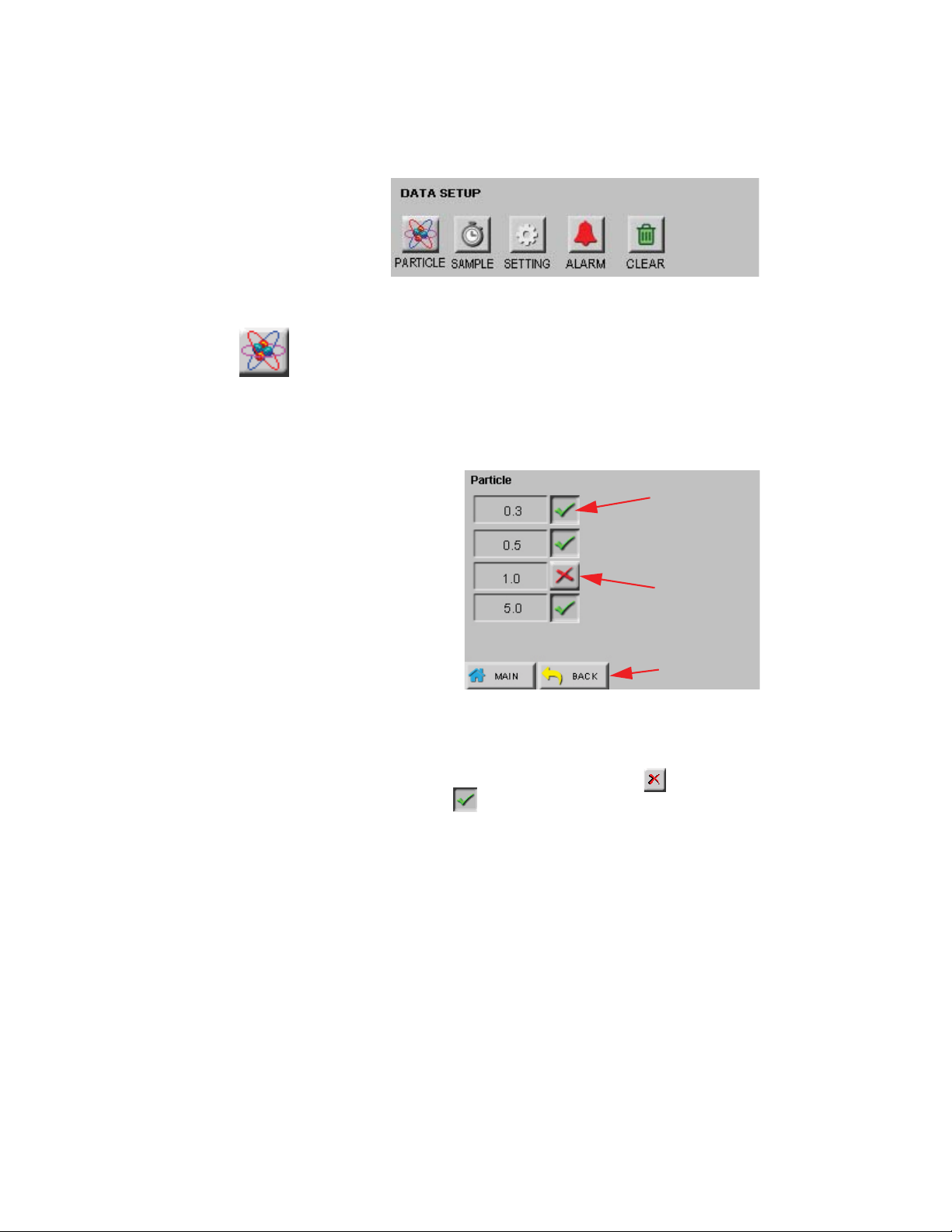

PARTIC LE

The instrument’s particle channels can be enabled or disabled on the

Particle screen. A checkmark is displayed next to each enabled

channel. See Figure 5-15.

Figure 5-15 Particle Channel Configuration

• The button on the right of each channel size is an ON/OFF toggle.

Press once to toggle a channel between a , disabling the channel

and the default , enabling the channel.

When channels are disabled, they are removed from the MAIN screen

display, from the reports and from the printouts.

248083440-1 Rev 5 5-11

Lighthouse ApexPortable Operating Manual

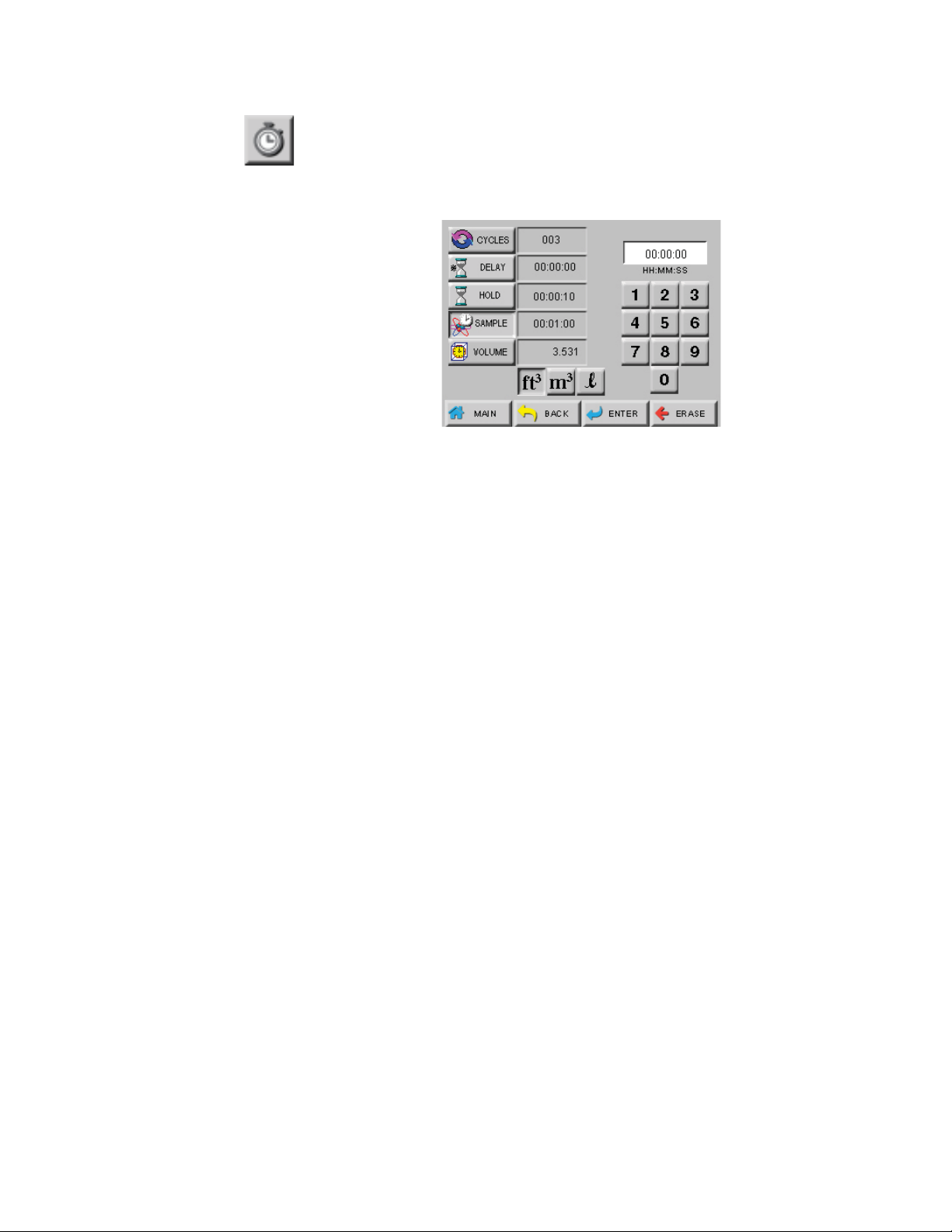

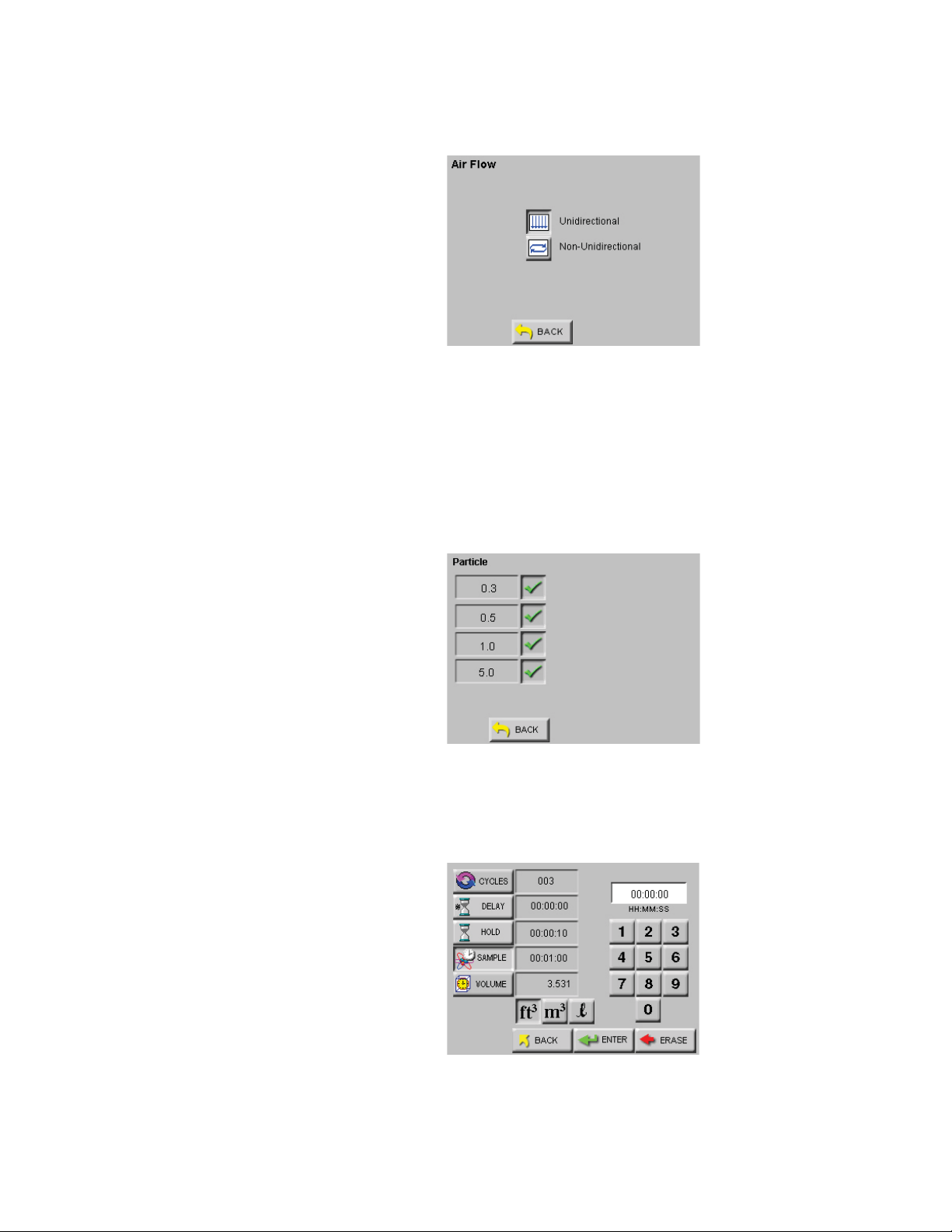

SAMPLE

The SAMPLE screen configures the number of cycles, count times and

volumes during a sample run. See Figure 5-16.

Figure 5-16 Sample Timing Configuration Screen

•CYCLES: The number of cycles is set to determine how many

times the instrument samples the air in a single location. This is

applicable only in AUTO mode. The range is 0 - 999. When

CYCLES is set to 0, the instrument will continue running samples

indefinitely until the STOP button is pressed.

Note:

set to 00:00:00 in Auto

Mode, the instrument will

run the samples according

to the sample time and the

# of cycles, but with no

hold time in between

cycles.

If the Hold time is

Press the CYCLES button; enter the number of desired cycles using

the numeric keypad on the right. Press ERASE to erase a number,

if needed. Press ENTER to set/save the Cycles.

• DELAY: The Initial Start Delay (hh:mm:ss) is the time between

when the START button is pressed and the unit actually starts

counting.

The Initial Start Delay gives the operator time to exit the area under

test so that the measurement is taken under a controlled condition.

The maximum delay time is 23 hours, 59 minutes and 59 seconds.

Press the DELAY button; enter the initial delay time in hours,

minutes and seconds using the numeric keypad. After the value is

entered, press ENTER.

• HOLD: The Hold Time (hh:mm:ss) is the time between count

cycles when the instrument is not counting particles. The maximum

hold time is 23 hours, 59 minutes and 59 seconds. This field on the

MAIN screen will count down to indicate how much time is left for

the Hold period.

Press the HOLD button, enter the time in hours, minutes and

seconds using the numeric keypad on the right. Press ERASE to

erase a number, if needed. Press ENTER to set the Hold Time.

5-12 248083440-1 Rev 5

Operate the ApexPortable

Note: The maximum

Sample Time is

23:59:59.

Note:

volume is ft

sample volume is 0.1 ft3. If

the particle volume is liters

or m

will be displayed in liters.

If the particle volume is

cubic feet (ft

volume is displayed in

cubic feet (ft

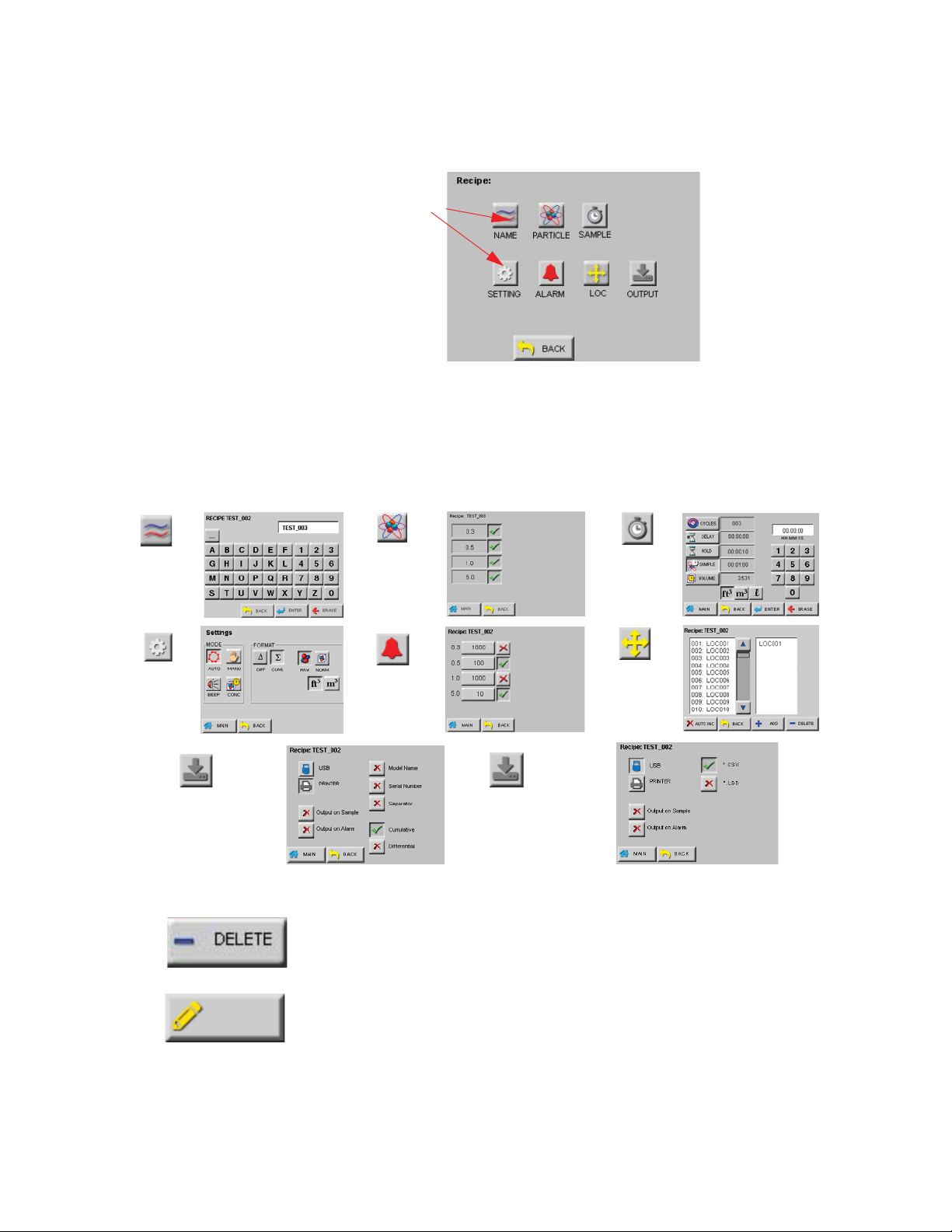

When the particle

3

, the minimum

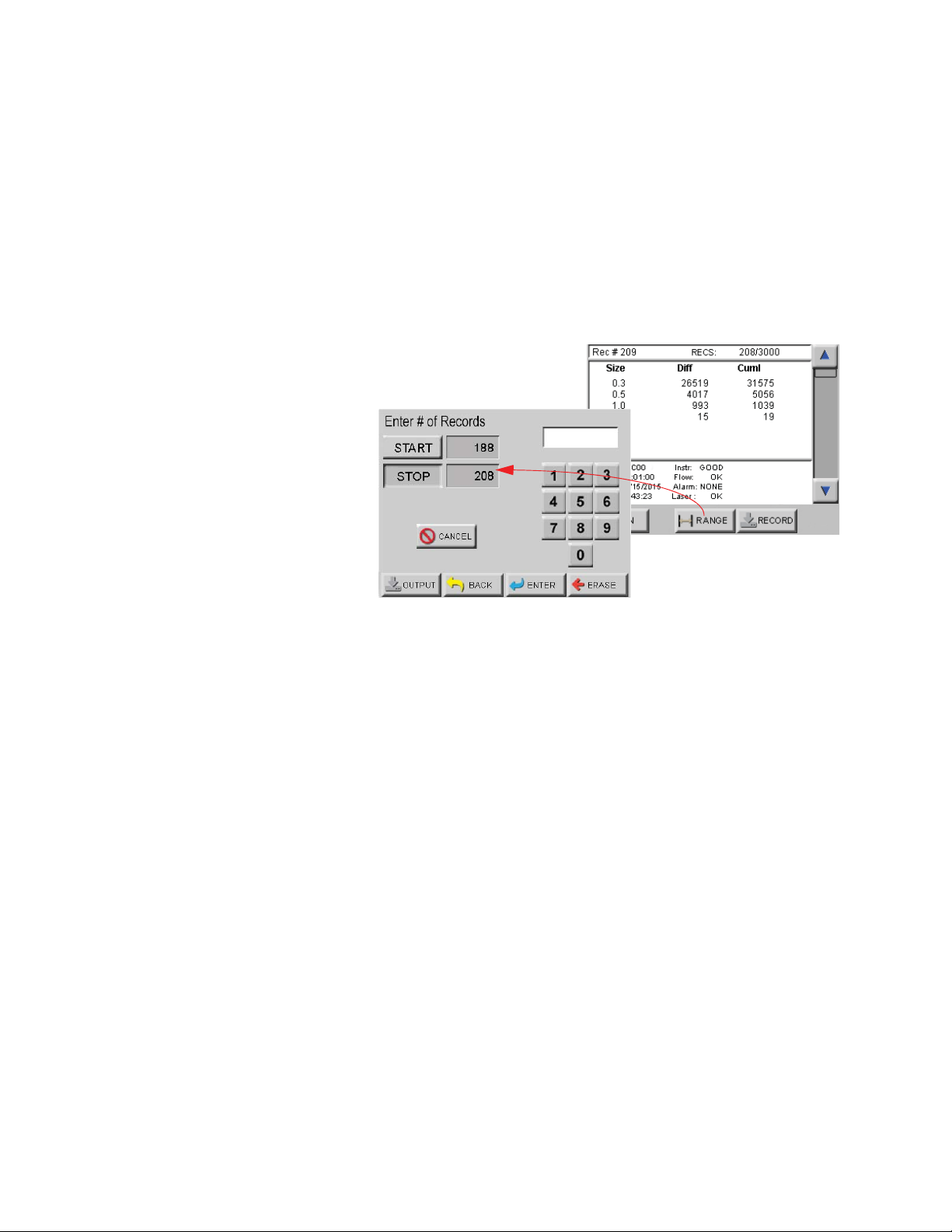

3

, the sample volume

3

), the sample

3

).

• SAMPLE: The Sample Time (hh:mm:ss) is the duration of one

counting cycle. The Sample Time will count down on the MAIN

screen when the instrument is in Auto or Manual mode to indicate

how much time is remaining in the Sample.

Press the SAMPLE button; enter the time in hours, minutes and

seconds using the numeric keypad on the right. Press ERASE to

erase a number, if needed. Press ENTER to set the Sample time.

•VOLUME: Instead of selecting a specific Sample Time, the

instrument can be set to measure a specific Sample Volume in cubic

feet (ft3), cubic meters (m3) or liters (l). When this is set, the

corresponding Sample Volume will automatically be set. See

Figure 5-17.

Figure 5-17 Changing Sample Volume Unit of Measure

Press BACK to return to the Configuration screen or press MAIN

to return to the MAIN screen.

248083440-1 Rev 5 5-13

Lighthouse ApexPortable Operating Manual

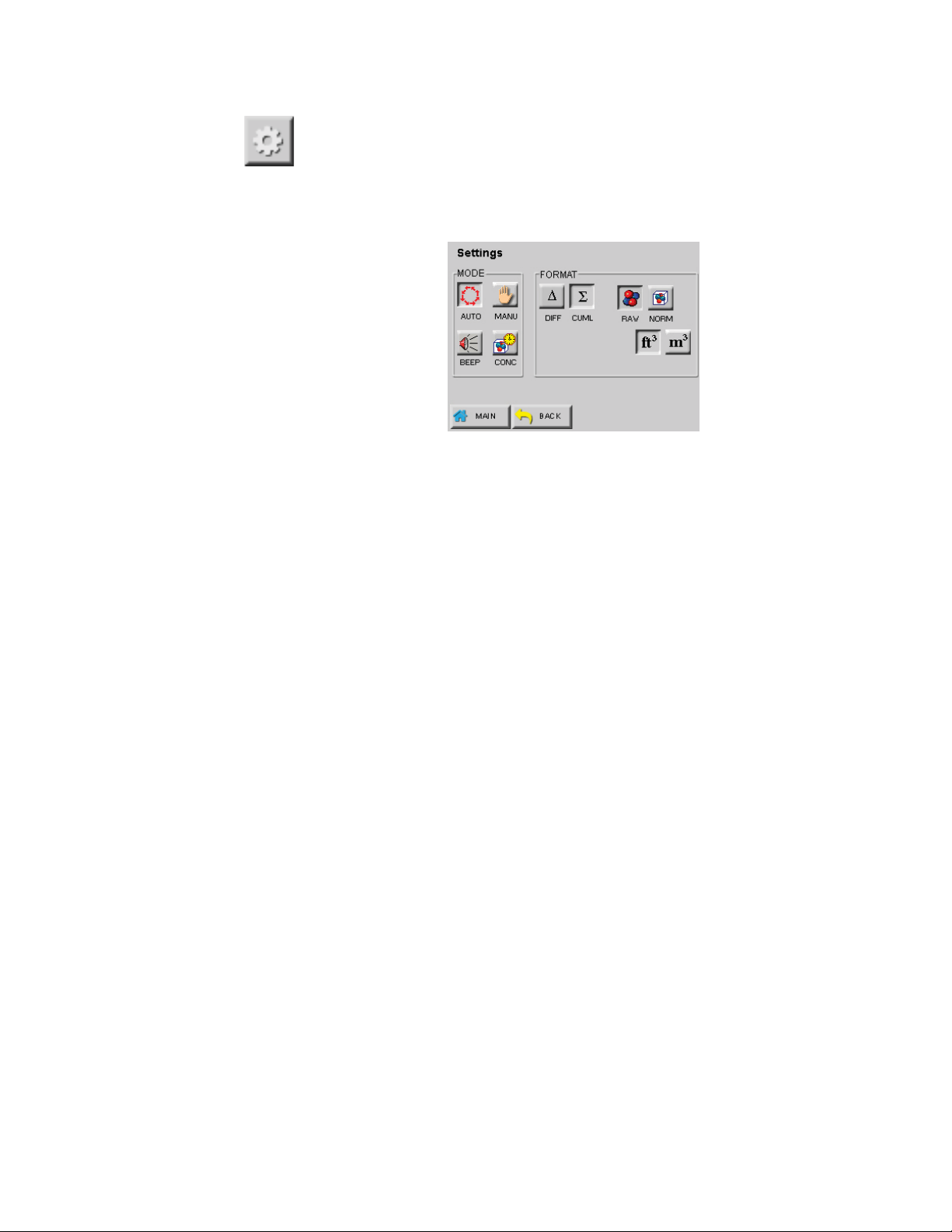

SETTING

The Settings screen allows the user to configure the instrument to count

in different modes and formats when running a sample. See Figure 5-

18.

Count MODEs

Figure 5-18 Sample Settings Screen

Note:

works with CUMULATIVE

data and for Sample Times

equal to or greater than 6

seconds.

BEEP mode only

Count modes available are Auto, Manual, Beep and Concentration.

Use of a recipe, however, overrides the display of these modes.

• AUTO - When the instrument is in Automatic Mode and the

START button is pressed, the instrument will start counting

particles automatically according to the Sample Time, Hold Time

and the number of Cycles that are configured.

If Cycles are set to 0, the instrument will continue indefinitely in

Auto Mode until the STOP button is pressed.

• MANU (Manual Mode) - When the instrument is in Manual

Mode, it will start counting when START is pressed and stop at the

end of one programmed Sample Time.

• BEEP - In this mode, the instrument is pre-configured to beep

according to the alarm threshold set in the Alarm configuration and

the instrument’s sample time when the instrument is set to collect

cumulative data. Counting starts after the START button is pressed

and the pump flow rate is stable. It will continue until the STOP

button is pressed or the number of configured cycles is reached.

If no channel is set for alarming when BEEP mode is selected, the

instrument will automatically use the smallest channel size and its

alarm threshold setting to alarm.

If alarming is enabled on more than one channel when the

instrument is in BEEP mode, it will beep if the alarm threshold is

exceeded on any of the channels enabled for alarming.

5-14 248083440-1 Rev 5

Operate the ApexPortable

Note: If BEEP mode is

set to one count, each

beep may not be for every

single count.

Note:

for Auto, Manual and Beep

modes count down and the

sample times for

Concentration mode count

up.

The sample time

• The data will be recorded based on the set sample and hold times

and can be viewed in the View Buffer and on the printouts. There

will be no indication on the record that the data was saved while the

instrument was in BEEP mode.

• CONC (Concentration Mode) - When the instrument is in

Concentration mode, it shows the calculated concentration of

particles in a volume of air measured and displayed on the MAIN

screen in either counts per cubic foot or per cubic meter.

Counting starts shortly after the START button is pressed and it will

continue until the STOP button is pressed or the sample time runs

out. The sample time for Concentration mode is six seconds. As the

sample time on the MAIN screen counts from one to six, the

particle counts are updated continuously.

Concentration data will be recorded and can be viewed in the Data

screen and on the printouts.

FORMAT

Instrument data is displayed as Differential (DIFF) or Cumulative

(CUML) counts. For clarity, cumulative mode shows all counts from

channel size of interest and above and displays on MAIN as .

Differential mode shows all counts from channel size of interest to next

channel size and displays on MAIN as the delta .

The data format is either Raw (RAW) or Normalized (NORM). Raw

data displays the actual number of particles counted. Normalized data

shows particle concentrations calculated from the raw data based on the

settings chosen (ft

3

or m3).

• Volume of Air = Sample time (minutes) x FlowRate (CFM)

• Normalized Data = Number of Particles/Volume of Air

Press BACK to return to the Configuration screen or press MAIN to

return to the MAIN screen.

248083440-1 Rev 5 5-15

Lighthouse ApexPortable Operating Manual

ALARM

Press ALARM button to open the Particle Alarm screen shown in

Figure 5-19 to enable alarming on specific channels.

Disable

Note: Alarming is only

applicable for Cumulative

Raw particle counts even if

the instrument is displaying

Normalized data.

If the instrument is set to

display Cumulative data,

the alarm threshold will

apply to the cumulative

counts.

press

button to

change

the alarm

threshold

Enable

Press button to

Change State

Figure 5-19 Particle Alarm Configuration Example

To enable or disable alarming for any channel, press the ICON to the

right of the channel. When the is displayed, the channel is enabled

for alarming. Press the ICON to change it to the and disable the

alarming for that channel.

Alarm Threshold

Press the enabled channel’s threshold button to set the alarm threshold

for that channel. The Alarm Threshold screen will open as shown in

Figure 5-20.

Figure 5-20 Configure Alarm Threshold

Note: To use alarms, the

Sample Time must be

greater than 1 second.

5-16 248083440-1 Rev 5

Enter the desired alarm threshold for the channel as a number of

particles then press ENTER. The threshold value will be updated on

the Particle Alarm screen.

Note:

triggered per sample

record. At the end of the

sample time, the alarm is

reset.

Note:

on two channels and the user

presses the screen to

acknowledge the alarm when

the first channel goes into

alarm, the alarm will not

sound if the second channel

threshold is reached within

the same sample period.

Alarms are

If alarms are enabled

Operate the ApexPortable

Press BACK to return to the CONFIG screen or press MAIN to return

to the MAIN screen. The alarm activated channels will display a

selection cursor (>) as shown in Figure 5-21.

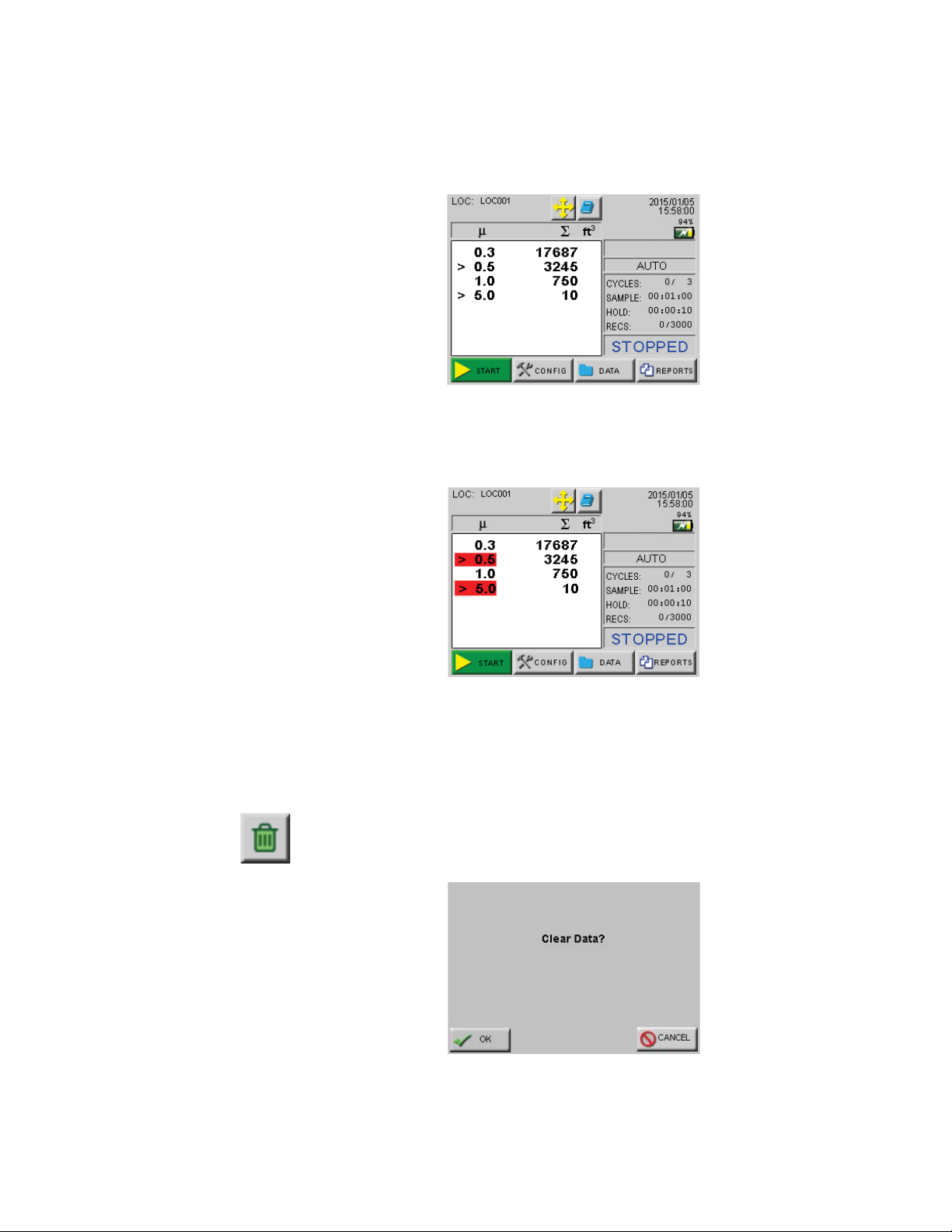

Figure 5-21 Channels Enabled for Alarming

When an alarm-enabled channel goes into alarm, the selection cursor

(>) and the channel size are highlighted in red. See Figure 5-22.

Figure 5-22 Channels in Alarm

When the instrument begins to beep in response to the Alarm settings,

touch anywhere on the MAIN screen to silence the beep. The count

will be reset when the next sample cycle begins after the alarm is

acknowledged.

CLEAR

Press Clear Buffer to clear the instrument data buffer. See Figure 5-23.

Figure 5-23 Clear Buffer Screen

Press OK to clear the data or Cancel to exit the screen without clearing

248083440-1 Rev 5 5-17

Lighthouse ApexPortable Operating Manual

data.

DEVICE

SETUP

The DEVICE SETUP buttons adjust how the instrument operates when

running samples. Specific functions for display options, data output

and security can be enabled or disabled . See Figure 5-24.

Figure 5-24 Device Setup Options

CLOCK

The Date & Time screen allows the user to change the instrument’s date

and time. See Figure 5-25.

Figure 5-25 Date & Time Configuration Screen

Use the Text Window and numeric buttons to enter the Date values for

desired month, day and year then press the ENTER button.

5-18 248083440-1 Rev 5

Note:

MONTH 1ST (M / D/

Y) is the default date format.

Operate the ApexPortable

Press the M / D/ Y button to display the date as month-first. Pressing

the D / M/ Y button displays the date as day-first and the Y / M/ D

button displays the date as year-first. See Figure 5-26 and 5-27.

Figure 5-26 Date Option: Day First

Figure 5-27 Date Option: Year First

Press the TIME button to set the instrument’s time. See Figure 5-28.

Figure 5-28 Configuring TIME

Enter the desired time in hours, minutes and seconds then press

ENTER to save the new time. Press BACK to return to the

Configuration screen or press MAIN to return to the MAIN screen.

248083440-1 Rev 5 5-19

Lighthouse ApexPortable Operating Manual

OPTIONS

The Options screen allows the user to make visual and sound

adjustments as well as selecting different language formats and start-up

functions. See Figure 5-29.

Figure 5-29 Options Configuration Screen

Contrast Adjust

Adjust the contrast/brightness of the LCD screen by pressing the upper

UP and DOWN arrows.

Audible Beep Adjust

Adjust the audio level of the BEEP by pressing the lower UP and

DOWN arrows.

ALIGN Touch Screen

Align the the touch screen by pressing the ALIGN button so the

locations touched on the screen correspond to the expected function.

Alignment can also be started from a power-off state by pressing on the

screen while turning the

ApexPortable on. The start screen shown in

5-30 will be displayed at that time. The screens shown on the next few

pages will be the same, regardless of how the process was started.

• Press the ALIGN button.

5-20 248083440-1 Rev 5

Operate the ApexPortable

WARNING: Be

careful to touch the

screen at the specified

locations, only. Touching

the screen elsewhere

during this process will

align the screen

incorrectly.

Note:

Using a PDA Stylus

provides higher accuracy to

the touch screen interface.

• The screen in Figure 5-30 appears. Touch anywhere on the screen

to continue calibration.

Performing touch

screen calibration.

Touch screen to

continue.

Figure 5-30 Display Calibration Start Screen

• At the next screen, touch in the center of the cicle displayed in the

upper left corner. Release the touch to move to the next alignment

circle. The tip of a stylus is suggested to successfully complete the

alignment by being on-target more accurately than by using a finger

tip. Exercise care to prevent puncturing the screen’s membrane,

which will void the instrument warranty. Figure 5-31 shows the

second and third Calibration screens.

Press & Release

on the filled

circle.

• The fourth and fifth alignment screens are shown in Figure 5-32;

Touch as close to the center as possible.

Press & Release

on the filled

circle.

Figure 5-31 Second and Third Calibration Screens

248083440-1 Rev 5 5-21

Lighthouse ApexPortable Operating Manual

touch the center circle to continue the alignment process.

Press & Release

on the filled

circle.

Figure 5-32 Fourth and Fifth Calibration Screens

• Figure 5-32 shows the final alignment screen. Touching the filled

circles properly completes the alignment process.

Press & Release

on the filled

circle.

To REPEAT calibration

reset the board while

pressing on the screen

until the calibration

prompt appears.

Touch screen to

continue.

Note: The screen

alignment function can

also be accessed by

touching the screen when

powering the instrument

on.

Figure 5-33 Display Calibration Completed

The final screen, shown Figure 5-33, instructs the operator to Touch

anywhere on the screen to complete the process. Touch anywhere

on the screen to return to the OPTIONS screen.

Autostart Mode

Autostart mode starts the instrument sampling immediately upon

power up. The instrument will sample based on its configured mode,

delay, start and hold times.

Diff+Cuml Zoom

If Diff+Cuml Zoom is enabled, the Zoomed display will show two

columns of data simultaneously - Differential and Cumulative.

5-22 248083440-1 Rev 5

Operate the ApexPortable

One Channel

If One Channel is enabled, only the first channel will be displayed on

the MAIN screen.

Note:

is disabled, the display and

zoomed data view will be

blank.

If the first channel

One Channel mode only affects how data is displayed on the MAIN

screen. When the instrument is in One Channel mode, data will

continue to be recorded, printed and downloaded for all channels. See

Figure 5-34.

Figure 5-34 One Channel Option Enabled

One Second Realtime Modbus Output

Set One Second Real-time MODBUS Output to change the

instrument’s settings to the following:

Note:

available when One

Second Real-time

MODBUS Output is

enabled.

Note:

sample time, hold time, etc.)

is changed, the One Second

Real-time MODBUS Output

mode will be automatically

disabled.

Alarming is not

If any setting (mode,

• Mode: AUTO

• Cycles: Zero

• Sample Time: One second

• Hold Time: Zero seconds

• Cumulative/Differential: Cumulative (CUML)

• Raw/Normalized: Raw

When counting, the MAIN Screen will update continuously and data

will not be recorded in the data buffer.

248083440-1 Rev 5 5-23

Lighthouse ApexPortable Operating Manual

Language

Press the LANGUAGE button to change the operating language as

shown in Figure 5-35.

Press the button next to the desired language to change it from the

to the to enable. Press BACK to return to OPTIONS or MAIN

button to return to MAIN screen. The default language is English.

Figure 5-35 Operating Language Screen

COMM

Press the COMM to set the ApexPortable communication mode.

Press the SERIAL’s toggle button to select SERIAL mode; press the

ETHERNET’s toggle button to select ETHERNET mode.

Press

Figure 5-36 COMM-mode Setup Screens

Press the SERIAL button (Figure 5-36) to configure serial settings at

the screen shown in Figure 5-37.

to select

COMM Serial Settings

When the

system or other RS485 network, the

5-24 248083440-1 Rev 5

ApexPortable is connected to a SCADA data collection

ApexPortable’s COMM address

Operate the ApexPortable

identifies it. The communication speed must be matched to the

requirements of the network to which it will be connected or the

connection will fail. Press the button describing the setting desired to

be changed, such as ADDRESS, BAUD, etc.

Figure 5-37 COMM Serial Settings Screen

Management programs like LMS Express/RT will search for the

instrument by the COMM Address specified on the screen shown in

Figure 5-37. COMM addresses can be 1 to 63 for the ApexPortable.

Each device on a multi-port chain must have a unique address.

Note: The Data-entry

screen text box will be

empty and won’t display

the previous values so it

may be wise to write down

the previous values from

the screen shown in Figure

5-37, first.

Press the ADDRESS button to open the Address input screen (Figure

5-38) and use the numeric keypad to type the address; press ERASE to

erase a digit, if needed and ENTER to accept the value and return to the

Comm SERIAL Settings screen.

Figure 5-38 Serial Address Input Screen

Check the other values and change them by pressing the parameter

button, such as BAUD, DATA BITS, PARITY. The data entry screen

will display a window for entering the value(s) desired. Make sure the

values entered are correct for the environment / network or the

ApexPortable communications will fail. The previously set values

will not be displayed.

248083440-1 Rev 5 5-25

Lighthouse ApexPortable Operating Manual

Set ETHERNET Settings

Press COMM at the Config screen to display Figure 5-39. Press the

ETHERNET’s toggle button to change it to the green check as shown.

Press the ETHERNET button to open the COMM Ethernet Settings

screen, Figure 5-40, which is displaying the original default values.

Figure 5-39 Comm ETHERNET Mode

Figure 5-40 COMM Ethernet Settings Screen

Press a number button to open the Data entry screen (Figure 5-41).

Enter the new value then ENTER to save and return to the Settings

screen. Press BACK to return to Settings screen and lose any changes.

Press ERASE to delete one digit at a time.

Figure 5-41 IP Data Entry Screen

5-26 248083440-1 Rev 5

Operate the ApexPortable

Make sure the values are correct. Incorrect values can cause the

ApexPortable to be lost on the network. It is suggested that site IT be

consulted for the IP and other values to ensure successful integration.

Typical Ethernet settings for most networks and the

ApexPortable are

a static IP, SUBNET empty/zeroes, and default Gateway is empty.

Lighthouse recommends using a static IP adress. .

OUTPUT

The Output Setup screens (Figure 5-42) provide formatting and other

options for printing to the optional USB printer or saving the data to a

USB flash drive. The port is shown in Figure 5-43.

Printer Output

Setup Screen

USB Output

Setup Screen

Figure 5-42 Output Setup Screens, Printer and USB Set Up

USB Port for

Printer or

Flash Drive

Useage

Figure 5-43 USB Port Location

248083440-1 Rev 5 5-27

Lighthouse ApexPortable Operating Manual

Printer Output

The default Printer Output or the last chosen screen will be shown

when entering the Output Setup screen. Cumulative (with nothing else

selected) is the default selection for Printer Output. Reports can be

printed using only Cumulative or Differential enabled or with both

enabled. At least one must be selected or the instrument will choose

Cumulative. Output trigger can be either Sample or Alarm or both.

From the MAIN screen, press CONFIG button then OUTPUT to go to

one of the screens shown in Figure 5-42. If USB output is active, go to

“USB Output”.

• Model Name - prints the product model name;

• Serial Number - prints the instrument serial number;

• Separator - prints a line of dashes to separate Serial Number

from data areas;

Note:

formatted devices; an

NTFS formatted device is

not compatible with the

ApexPortable. A

corrupted device will cause

data transfer failures.

Check the formatting and

functionality on a PC or

MAC before use.

Use only FAT32

• Output on Sample - when a sample is taken, the data for that

sample is printed;

• Output on Alarm - When an alarm threshold is exceeded, a

report of that data is printed;

• Cumulative - Data is reported in cumulative format;

• Differential - Data is printed in differential format.

USB Output

When a USB flash drive is attached to the USB port, the

ApexPortable

will acknowledge its presence by displaying the blue USB symbol on

the MAIN screen. From the MAIN screen, press CONFIG button then

OUTPUT to configure the USB settings - refer to Figure 5-44.

• Output on Sample - outputs data to the USB flash drive at the

completion of a sample;

• Output on Alarm - outputs data to the USB flash drive when

an alarm is triggered;

• *.CSV - data being stored on the USB flash drive is Comma-

Separated-Value, a spreadsheet compatible format - this is the

default setting displayed for the user;

• *.LSD - Lighthouse Secure Data format is used and can be

downloaded only by LMS Express, LMS Pro or LMS Pharma.

5-28 248083440-1 Rev 5

Operate the ApexPortable

Password

Enter the

desired

numeric

here

using this

keypad

Output on Sample and Output on Alarm can be chosen together or

separately, which is the preferred choice. Either *.CSV or *.LSD must

be chosen, but not both simultaneously. If neither *.CSV nor *.LSD is

chosen, *.CSV will be the default and will not leave screen until it is

set. A message will not be displayed when the save is completed.

Records are always stored on the

Figure 5-44 Example of USB Output Options

ApexPortable in LSD.

Security

Press the Security button to enter Figure 5-45 screen. User access to

the instrument can be restricted by configuring the

two different password levels.

Figure 5-45 Security Password Configuration Screen

ApexPortable’s

248083440-1 Rev 5 5-29

Lighthouse ApexPortable Operating Manual

WARNING:

record and store the unit’s

passwords in a safe place.

If the password is lost or

forgotten, contact

Lighthouse technical