Page 1

RECEIVING YOUR CYCLE

RECEIVING YOUR CYCLE

RECEIVING YOUR CYCLERECEIVING YOUR CYCLE

Your vehicle has been assembled and tuned. The front wheel, seat and handlebars may have been

disassembled for more compact shipment. There are a few items to reassemble, bolts to be tightened and

adjustments to be made. Your front wheel and other accessories may be in the cargo box or cargo pod on

your trike. Your control cables have been pre-stretched; however it is normal for the control cables to

stretch during use (a lot at first) and your shifters may need to be re-tuned after several miles of use.

If you use the Lightfoot Technical Manual to assemble and adjust your cycle, you will have learned in a few

hours the basics of what you need to know to keep it running efficiently and safely for a lifetime. This

chapter is designed to get you through reassembly so you can ride. The Lightfoot Tech manual is available

online at http://www.lightfootcycles.com/tech_man.php.

Lightfoot vehicles are all designed to be accessible to any qualified bicycle mechanic. As you put miles and

wear on the cycle, any bike shop should be able to troubleshoot and repair any mysterious behavior of

components or damage. Proper assembly, maintenance and adjustments will make your cycle safer and

more efficient to ride, and will avoid the potential frustration of trying to learn to ride on an improperly

assembled cycle. If in doubt as to your own ability to properly assemble this vehicle or some component of

it, please use a qualified bicycle mechanic.

it, please use a qualified bicycle mechanic.

it, please use a qualified bicycle mechanic. it, please use a qualified bicycle mechanic.

If damage has occurred during shipping, notify the shipping company imm

If damage has occurred during shipping, notify the shipping company immediately. Then, if anything appears

If damage has occurred during shipping, notify the shipping company immIf damage has occurred during shipping, notify the shipping company imm

to be missing or damaged on a factory

to be missing or damaged on a factory----direct shipment, please call or e

to be missing or damaged on a factoryto be missing or damaged on a factory

document the damage.

document the damage.

document the damage.document the damage.

For future reference: All Lightfoot cycles have a serial number stamped on the frame. On bicycles, the serial

number is stamped on the left rear dropout. On trikes, it is stamped near the top of the upper separation

plate between the front and rear frame. The serial number may be difficult to read under the

powdercoating, but it is there.

TO

TOOLS NEEDED

OLS NEEDED

TOTO

OLS NEEDEDOLS NEEDED

To adjust an assembled vehicle, you may need only a couple of tools. Bike shops will have all of these

tools. Also, you can buy these tools by the individual piece, or as part of a "home bicycle mechanic" set.

Certain vehicles or options may necessitate other tools. We recommend getting a portable bicyclist tool kit

(you will have most of the tools from the list above) for carrying with your vehicle as well as a homemechanic set for more extensive repairs.

1. Pliers to pull staples and cut wire ties.

2. Knife or scissors to cut tape.

3. Reversible hand held drill with a Phillips head driver bit for removing fork stabilizer.

4. Metric Allen wrench set. Specifically: an 8mm (crank arms), 6mm (shorty stem), 5mm (adjustable

stem and accessories), 4mm (seat and braces) and a 2.5 mm (Grip shifters). A 3mm wrench has

been supplied with your mirror. A Philips head screw driver is needed for some of the fender bolts.

5. 15mm pedal or open end box wrench for pedals on Bikes.

6. Grease for coating threads on pedals and freewheels, lubricating unsealed bearings, lubricating the

steerer tube. Phil Wood waterproof grease is one good choice. White Lightning is a good coating

for chains and cables.

7. Internal hub systems may require a wrench or small vise grip pliers, as well as a medium size flat

screwdriver.

8. A tire pump may be needed.

UNPACKING

UNPACKING A B

UNPACKING UNPACKING

If in doubt as to your own ability to properly assemble this vehicle or some component of

If in doubt as to your own ability to properly assemble this vehicle or some component of If in doubt as to your own ability to properly assemble this vehicle or some component of

ediately. Then, if anything appears

ediately. Then, if anything appears ediately. Then, if anything appears

A BIKE IN A CARTON

IKE IN A CARTON::::

A BA B

IKE IN A CARTONIKE IN A CARTON

direct shipment, please call or e----mail us.

direct shipment, please call or edirect shipment, please call or e

mail us. If at all possible photo

mail us. mail us.

If at all possible photo

If at all possible photo If at all possible photo

Technical Manual 1-1

Page 2

1. Lift the front end of the cycle and install the fork. The head set pieces are on the stem in the order

they go on the bike: bearings go round side into the cups on the head tube.

2. Install the stem and handlebars. Slide the stem on above the headset, place the steering stem cap

on and tighten down tight enough so there is no slop in the headset but not so much that the

steering is too tight or that when you turn the handlebars it feels ”crunchy”.

3. Remove frame from box and place it in a bike stand if you have one or on a carpet. Remove

dropout protectors and unwrap the frame.

4. Install the rear derailleur: position the derailleur over 10mm hole on rear dropout, Rotate it

clockwise so that the spring tension screw will clear the stop on the dropout as you tighten the

derailleur in place with a 5mm hex wrench. Allow tension screw to settle against stop before

tightening.

5. Install rear wheel: Insert the skewer into the wheel with the lever on the side opposite the brake

rotor (right side). Slide the wheel axle between the chains and allow the upper chain to rest on the

smallest sprocket. Position between dropouts and work into place as gently as possible so as not to

damage the rotor or brake pads. Make sure the wheel is pushed into the dropouts solidly and

tighten.

6. Install front wheel: install skewer into hub with tightening lever on the side opposite the brake rotor

(right side of wheel). Position between dropouts and work into place as gently as possible so as not

to damage the rotor or brake pads. Make sure the wheel is pushed into the dropouts solidly and

tighten.

7. Install pedals: There is either an L or an R on each pedal. The right pedal is reverse threaded.

8. Install the seat. Adjust to fit. Your leg should be just less than fully extended when the pedal is in the

most forward part of its stroke. Do not over tighten the clamp holding the seat to the frame, this

will deform the clamp.

9. Sit on the cycle and adjust the handlebars to fit you. Align the handlebars, stem and fork. Tighten all

bolts.

10. Unpack all optional components and be sure that there are none tucked away in packing materials.

11. Refer to the Lightfoot Technical Manual for further installation and maintenance instructions.

UNPACKING A

UNPACKING A TRIKE

UNPACKING A UNPACKING A

TRIKE IN

TRIKETRIKE

IN A

IN IN

A CARTON

CARTON::::

A A

CARTONCARTON

1. Remove staples, wire ties and strapping from the outside of the carton. Tip the carton and lay it

down on the side with the shipping label. This is the bottom of the trike. Remove the screws

holding the fork in place on the top of the carton.

2. Lift/pull the top of the box off the base.

3. Remove staples/screws holding the cycle in place.

4. Lift/pull and roll the cycle CAREFULLY out of box. There is some stretch wrap on the rear wheels

and the brakes may be on, so pull slowly and let the wheels slide

5. Remove packing being careful not to scratch the paint or cut cables and housing.

6. Follow #6 above.

UNCRATING A CYCLE IN

UNCRATING A CYCLE IN A WOODEN CRATE

UNCRATING A CYCLE INUNCRATING A CYCLE IN

A WOODEN CRATE (THIS IS RARE)

A WOODEN CRATEA WOODEN CRATE

(THIS IS RARE)

(THIS IS RARE)(THIS IS RARE)

1. Position the crate with the arrows up.

2. Remove the lid piece using a reversible drill with a Phillips screwdriver bit by removing the screws

around the sides near the top.

3. Your cycle may be held in place by its fork. Generally, the easiest way to free it is to unscrew the

screws holding the wood block to the crate, then remove the block from the cycle after it is out of

the crate.

4. The handlebars and front wheel(s) have been removed from your cycle in order to make it more

compact for shipping. In place of the handlebar stem we have placed a spacer to hold the fork stem

Technical Manual

1-2

Page 3

and bearings in position. Remove the black cap and spacer before installing the handlebar stem.

Tighten the cap as directed in the initial assembly pamphlet.

For trikes and four wheelers:

For trikes and four wheelers: You may lift the cycle out of the crate or remove all the screws around the

For trikes and four wheelers: For trikes and four wheelers:

sides of the crate at the rear and at the bottom of the rear panel. Remove the panel at the rear end of the

trike. This removes the corner braces of the crate so the cycle can be rolled out. Remove ties, internal

bracing and all packed components. Be careful in cutting cords or tape that you do not scratch the paint or

cut cables and housing.

Make sure the parking brake pin on the brake lever is released.

Cycle can now be lifted up in the front end and rolled out of the crate. Continue with #6 in section above.

For bikes:

For bikes: Begin to remove the ties that hold the components and bike in position. Lift the bike out of the

For bikes:For bikes:

crate.

Install the front fork, wheel(s), seat, handlebars and pedals.

Align handlebars and stem with the front wheel. Adjust to fit.

Refer to the Lightfoot Technical Manual for further installation and maintenance instructions.

FOR BOXED UNASSEMBLED TRIKES ONLY:

FOR BOXED UNASSEMBLED TRIKES ONLY:

FOR BOXED UNASSEMBLED TRIKES ONLY: FOR BOXED UNASSEMBLED TRIKES ONLY:

1. Bolt the frame together using 8mm frame bolts provided.

2. Lift the front end and install the fork; Follow #1 above

3. Install rear wheels: Insert the skewer into the wheel with the lever on the side opposite the brake

rotor. Slide the wheel axle between the chains and allow the upper chain to rest on the smallest

sprocket. Position between dropouts and work into place as gently as possible so as not to damage

the rotor or brake pads. Make sure the wheel is pushed into the dropouts solidly and tighten. Check

wheel alignment and reposition if needed.

4. Install front wheel: Follow #6 above.

5. Pedals: Follow directions from “Install pedals” above

Check your

Check your cycle

Check your Check your

Clean the frame regularly and check for cracks.

Clean the frame regularly and check for cracks. Keep bare metal lubricated.

Clean the frame regularly and check for cracks. Clean the frame regularly and check for cracks.

cycle every

every time you ride for brake function and secure wheels. Watch for loose fasteners.

cyclecycle

time you ride for brake function and secure wheels. Watch for loose fasteners.

everyevery

time you ride for brake function and secure wheels. Watch for loose fasteners. time you ride for brake function and secure wheels. Watch for loose fasteners.

Keep bare metal lubricated.

Keep bare metal lubricated.Keep bare metal lubricated.

Technical Manual

Enjoy your Lightfoot!

Enjoy your Lightfoot!

Enjoy your Lightfoot!Enjoy your Lightfoot!

RRRRemember

emember four

emember emember

1. Start with a power stroke

1. Start with a power stroke

1. Start with a power stroke1. Start with a power stroke

2. Lean back into the seat

2. Lean back into the seat

2. Lean back into the seat2. Lean back into the seat

3. Relax your arms when you ride!

3. Relax your arms when you ride!

3. Relax your arms when you ride!3. Relax your arms when you ride!

4. Look where you

4. Look where you WWWWANT to go!

4. Look where you 4. Look where you

four secrets of first riding a recumbent:

secrets of first riding a recumbent:

fourfour

secrets of first riding a recumbent:secrets of first riding a recumbent:

ANT to go!

ANT to go!ANT to go!

1-3

Page 4

Figure 2.1. Headset cup placement

INITIAL ASSEMBLY

Modular frames should be bolted together firmly, as

soon as possible. Do not fully tighten any bolts until

all bolts are inserted and the nuts are on finger

tight. Be careful not to put weight on the frame

until all bolts are in and fully tightened; a partially

bolted frame can be easily damaged. Our frames

are fabricated with the frame sections bolted

together and WILL go back together; however, the

frame may need to be gently "tweaked" a bit to line

up the holes.

In order to put the vehicle on its wheels, you may need to install the front forks. The sequence

of cups, bearings, races and seals is illustrated in Figure 2. 2. The headset cups will normally be

already installed (pressed in) on most vehicles, and the bottom-most race (the "crown race")

will be pressed on the fork (may not be on framesets).

Figure 2.2 Headset, stem, head tube and fork assembly. From Right to left: Cap bolt, headset cap, stem,

upper cover, shim washer seal, compression ring, upper cartridge bearing, (cups are in the space between

the 2 bearings) lower cartridge bearing, lower bearing race/dust seal, and fork.

From the right; steering stem cap with bolt, stem, upper cover, shim washer seal, compression

ring, upper cartridge bearing , upper cup, head tube, lower cup, lower bearing, bearing

race/dust seal, crown of fork. The bearings we now use are sealed and only need a light coat

of grease to keep them from rusting.

Figures 2.3 and 2.4 show the installation. Slide the stem on above the headset upper cover,

place the steering stem cap on and using a 5mm hex key, tighten down enough so there is no

slop in the headset but not so much that the steering is stiff or that when you turn the

handlebars it feels ”crunchy”or tight. Sit on your cycle and align the handlebars, stem and front

wheel. Use a 5 mm hex key to tighten the two bolts holding the stem on.

Technical Manual 2-1

Page 5

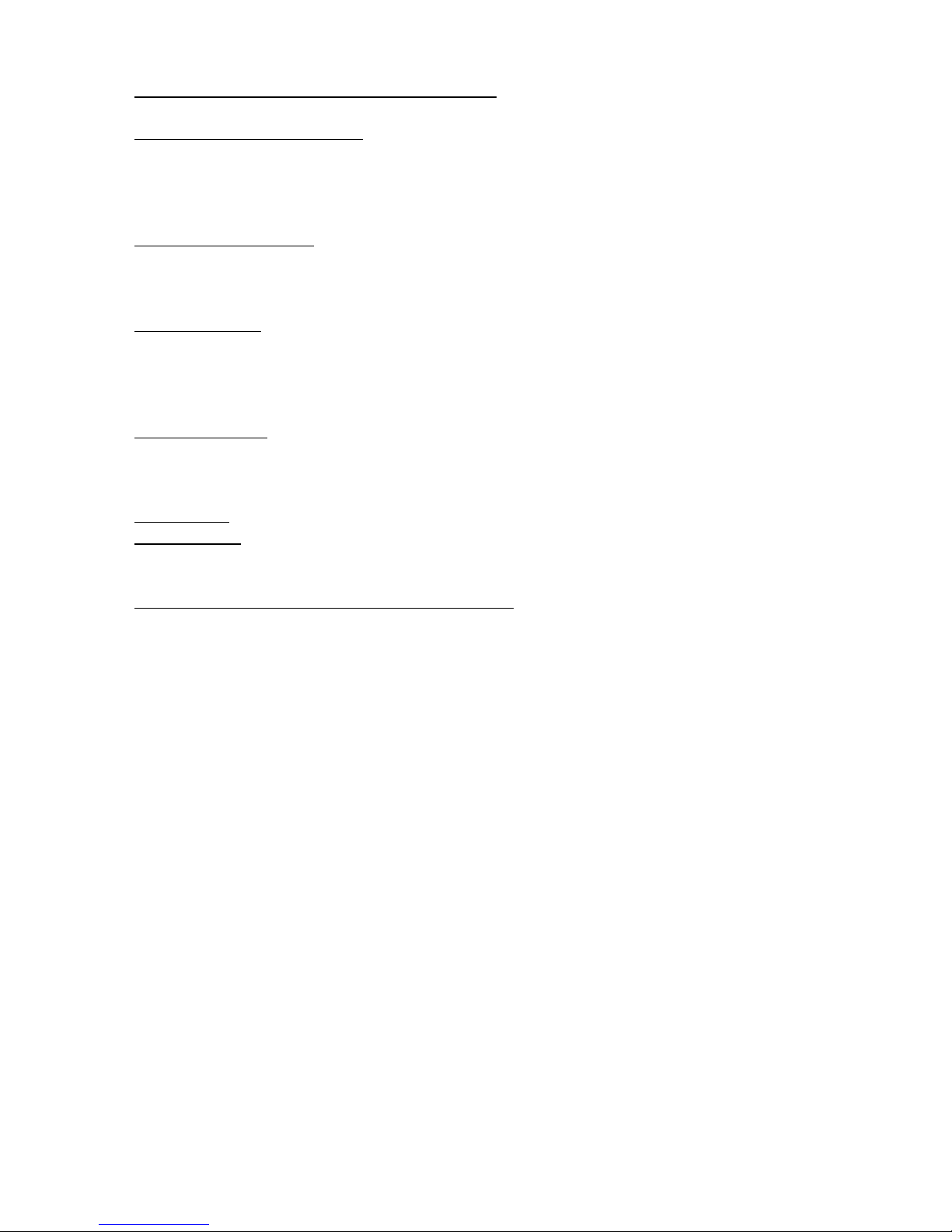

Figure 2.5. Tiller Steering setup

Figure 2.3 Above. Installation of fork into head set.

Figure 2.4 At right. Installing the stem.

INSTALLING HANDLEBARS AND STEM

Standard tiller steering includes a stem, either telescoping or

fixed-length. If telescoping, make sure that at least 2” are

inserted at maximum extension.

If your vehicle is a bike or trike with the 12” hi-rise bars", set

them in the stem so that the handle grip section just barely

reaches back and down. Trikes and four-wheelers with

"swept" bars actually may have a curve to the bar; set these

also so they reach back and down.

If a brace for the hi-rise bars is included with your model,

install it just below the curve of the handgrip area.

After the handlebar stem is put on the steerer tube (that

turns the fork), use a 5mm hex key to adjust the bolt

through the Star Fangled nut in the top of the head tube, to provide free movement of the fork

without sloppiness. The Star Fangled nut is set inside the steerer tube with a special tool. The

cap and bolt assembly thread into the Star Fangled nut and push down on the handlebar stem

and the headset bearings, thus creating the pressure that holds the headset together. Tighten

Technical Manual 2-2

Page 6

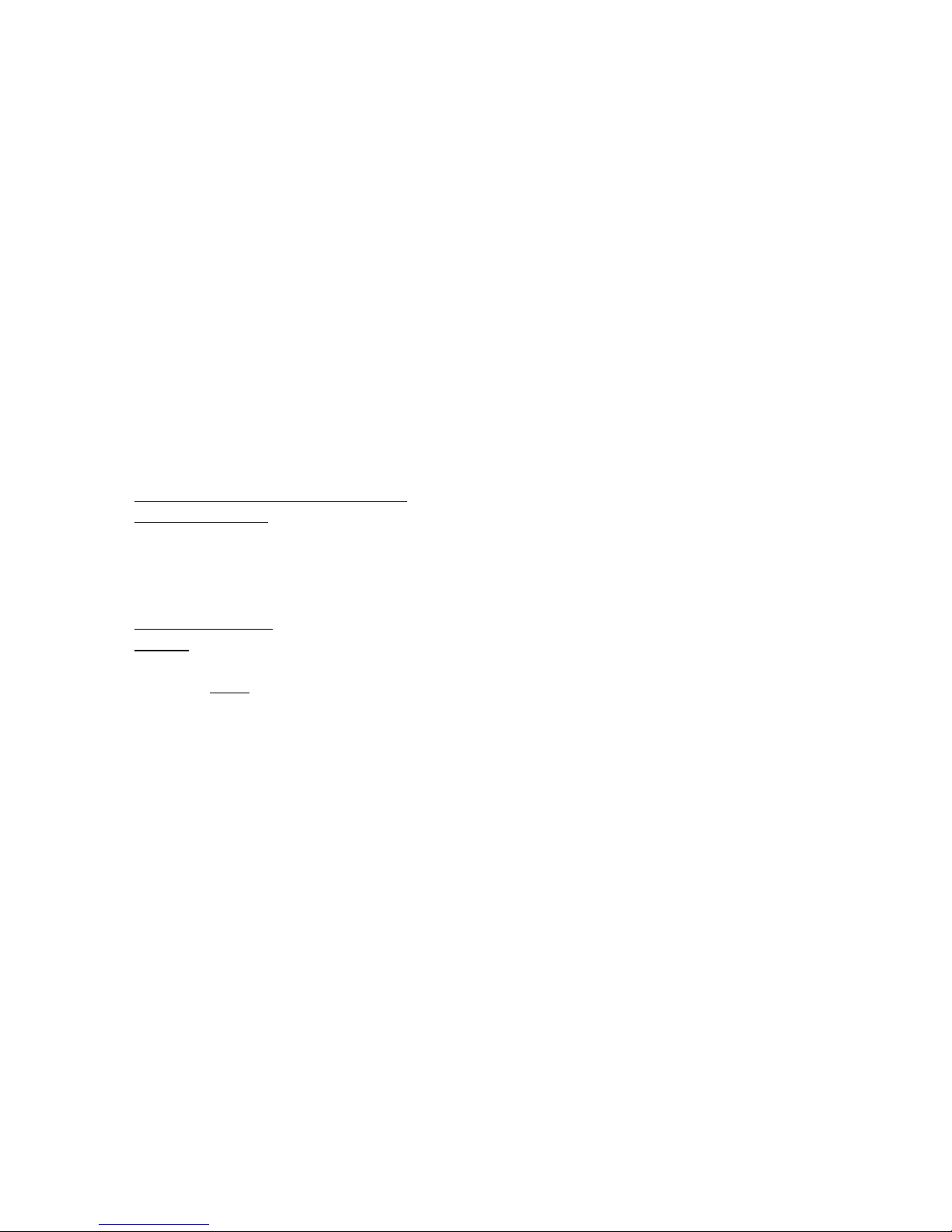

Figure 2.6. Installing the rear wheel

Figure 2.5a. Swept handlerbar and stem riser

the handlebar stem bolts that grip the steerer tube only after the headset is adjusted and

handlebars aligned.

Put three- or four-wheel vehicles on their

wheels as soon as feasible to avoid

damage to the components on the

underside of the vehicle. If you are

working on a two-wheeler, use a

mechanics stand or work on carpet to

avoid scraping the powdercoat finish.

We may have dropped your handlebars

on the stem riser so that we could pull

the stem riser out of the frame for

shipping. Please raise the handlebars back

up to the top of your stem riser when

you make your final fitting adjustments.

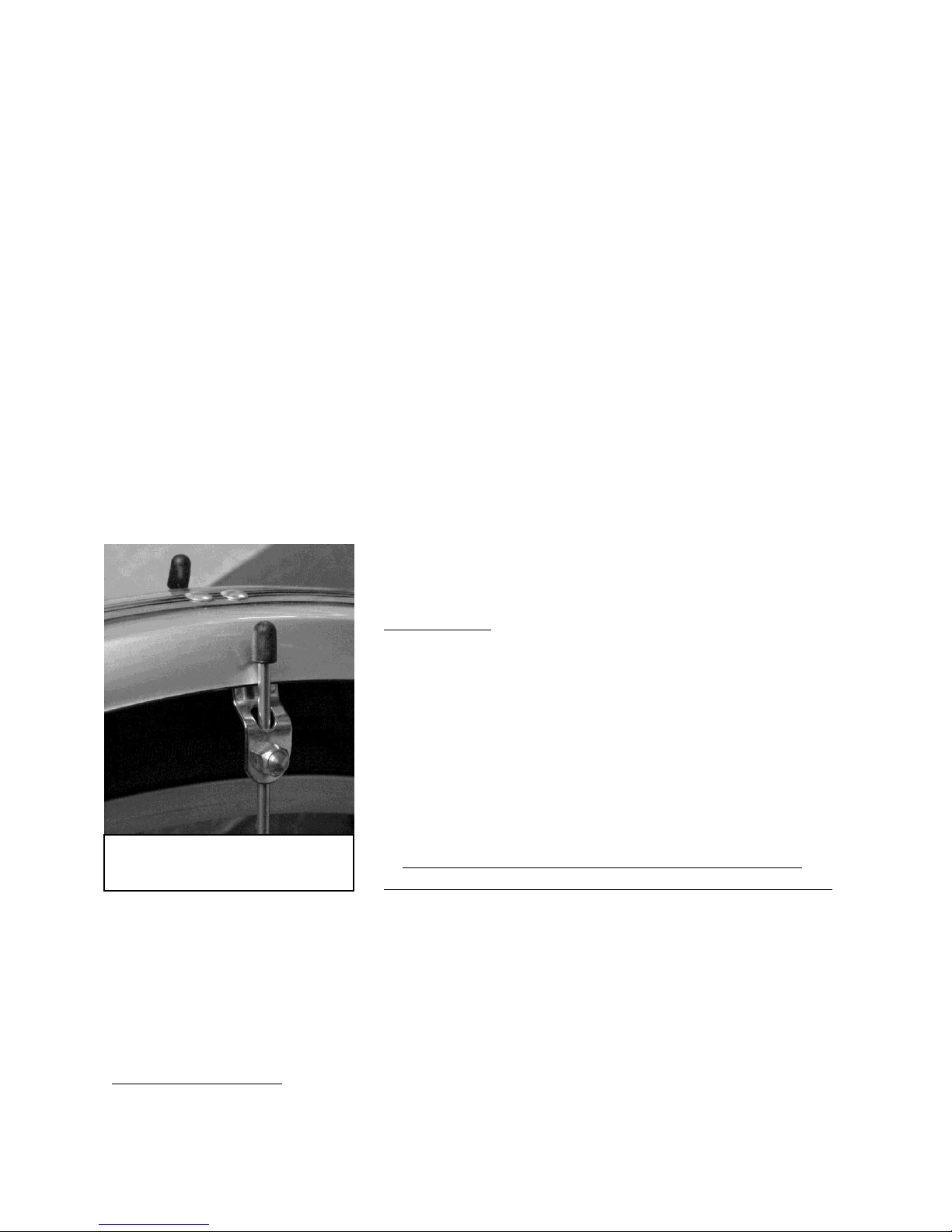

PARKING BRAKE

Most Lightfoot trikes have a dual pull

brake lever with a locking pin (see figure

2.5a). Some may also have an elastic band Parking Brake that holds the brake lever in the “on”

position. Activate it by squeezing either the front or rear brake lever and slipping the elastic

over the brake lever. The band stores on the grip when not in use. Use it when you are

loading your trike or parking it on uneven ground.

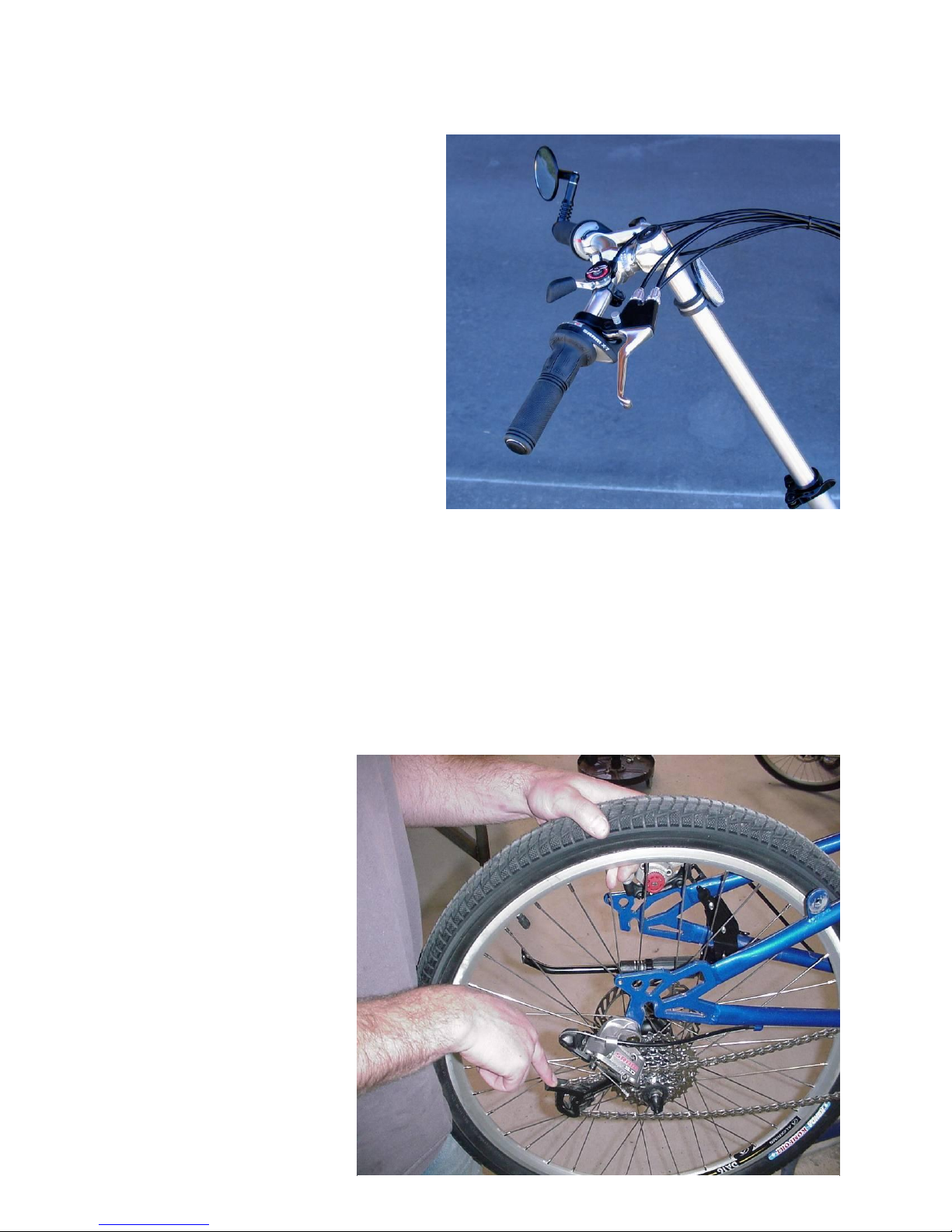

INSTALLING WHEELS

Some wheel axles may be quite tight in their fit into the "dropouts" (the slot that holds the

wheel axle) because of the very stiff nature of our frames, it may be difficult to get the axle

between the dropouts if the

fit is tight.

The disc brake rotor must be

aligned with the brake caliper

on the left side of the wheel.

There is a manual for

maintenance and operation of

your brakes in your owner’s

packet. Please familiarize

yourself with their operation.

While holding the derailleur

down and out of the way as

shown, position the wheel

into the base of the dropout,

then, as gently as possible,

work the axle up into the

Technical Manual 2-3

Page 7

dropout, and the rotor (“disc”) into the brake caliper, without damaging the rotor or brake

pads. DO NOT handle brake rotors with bare hands; they are very sharp!

Wheels need to be centered before the quick-release lever is tightened. Usually the weight of

the bike on the ground will center the wheels between the frame forks. If we have preassembled the bike, the brake rotor will be centered between the brake pads when the wheel

is correctly aligned.

Some axles (narrower than our standard 135 mm length) come with spacers (flat washers) on

them; these go to the inside of the dropout to fill gaps between the axle nut and the dropout.

Knurled washers (if any, often found on internal hubs) go to the outside, under the axle nut;

these help grip and hold the axle in the dropout.

Internally geared rear hubs that do not have derailleurs should have the chain installed over the

sprockets and then be slid up the dropouts until the chain is drawn tight. All wheels should be

"eye-balled" or measured to make sure they are straight before final tightening. It is possible to

bend the axle if the wheel is not relatively straight or if the cycle is ridden with only one side

tightened. Make sure axle nuts are tight.

Wheels with internal hubs will have

“alignment washers”. Make sure the rightangle flange of the alignment washer is

positioned in the dropout slot; tightening

the flange against the dropout could bend

the washer or even the axle.

Most Lightfoot models are equipped with

disc brakes. Use Gloves when handling

brake rotor discs. Slide the wheels into

place being careful to place the rotor

between the brake pads.

NEVER PUT HANDS NEAR

BRAKES OR ROTORS WHEN

WHEEL IS TURNING!

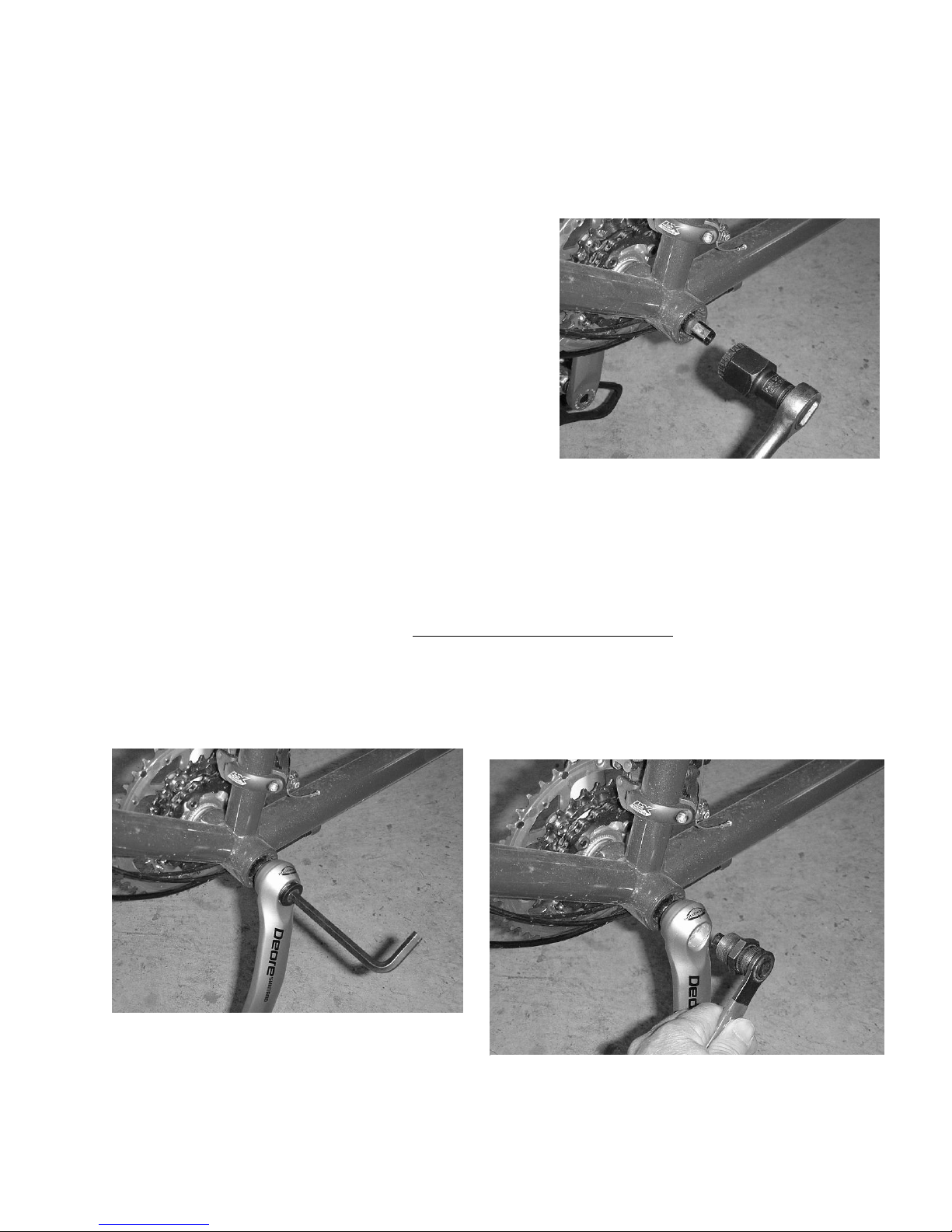

To remove or install a wheel with V-brakes ("linear-pull" brakes); squeeze the end of the Vbrake arms together, and release the curved aluminum tube which holds the brake cable from

its slot. This allows the brakes to spring open and make room for the tire.

Wheels with the Nexus internal hub and roller-cam brake are more complicated to install;

please follow the instruction under "Internal Hub" below for attaching cables. Once the

internally-geared hub’s shifter cable is attached and the axle is in the dropout, the roller-cam

brake’s arm will be bolted to a clip attached to the frame. The rear "brake cable-stop" slides

into a slot on the brake "actuator arm"--the one dangling from the hub. The barrel adjuster

slides into a slot on the brake arm once it is bolted to the frame. The barrel adjuster and the

actuator arm are held in position by the tension of the "brake actuator return spring".

Technical Manual 2-4

Page 8

Figure 2.9. Installing the crankset

Figure 2.8. Bottom bracket wrench

Figure 2.10. Crank arm puller

A word about maintenance: The hubs we use are not “sealed” but are “semi-sealed”. They

come well lubed. The bottom bracket does not come apart; it is maintenance free. IF the

threads start to "creak", back them out and grease them. They were well greased here. The

hubs will need some maintenance. We suggest twice a year lubing them.

THE BOTTOM BRACKET, CRANKSET AND

PEDALS

The bottom bracket bearing set may be already installed,

but may not be on framesets. If not, a special bike tool

is required to tighten it within the threaded "bottom

bracket shell".

The crankset is held on the bottom bracket spindle with

the included crankset bolts. Most cranksets are held on

with socket-head bolt, tightened with an 8mm Allen

wrench. Some types use a hex head bolt and a socket

wrench is needed. These bolts should be slightly

greased.

Wipe off any grease where the crank spindle slides into the crank arm--no more than a thin film

of grease is needed to keep the cranks from seizing onto the spindle. The crank with the

attached sprockets goes on the right side.

Pedals can be installed after the crank arms are on, so that the vehicle holds the arms--this

makes installing the pedals a bit easier. The left pedal is reverse-threaded. An open-end pedal

wrench is essential if you are going to remove and install the pedals frequently. Do not simply

hand tighten the pedals, as they may work loose and ruin the crank arm.

Maintenance: The bottom bracket does not come apart, it is maintenance free. If you begin to

feel a clunk or gritty spot, a bearing has gone out and it is time to replace the unit.

Technical Manual 2-5

Page 9

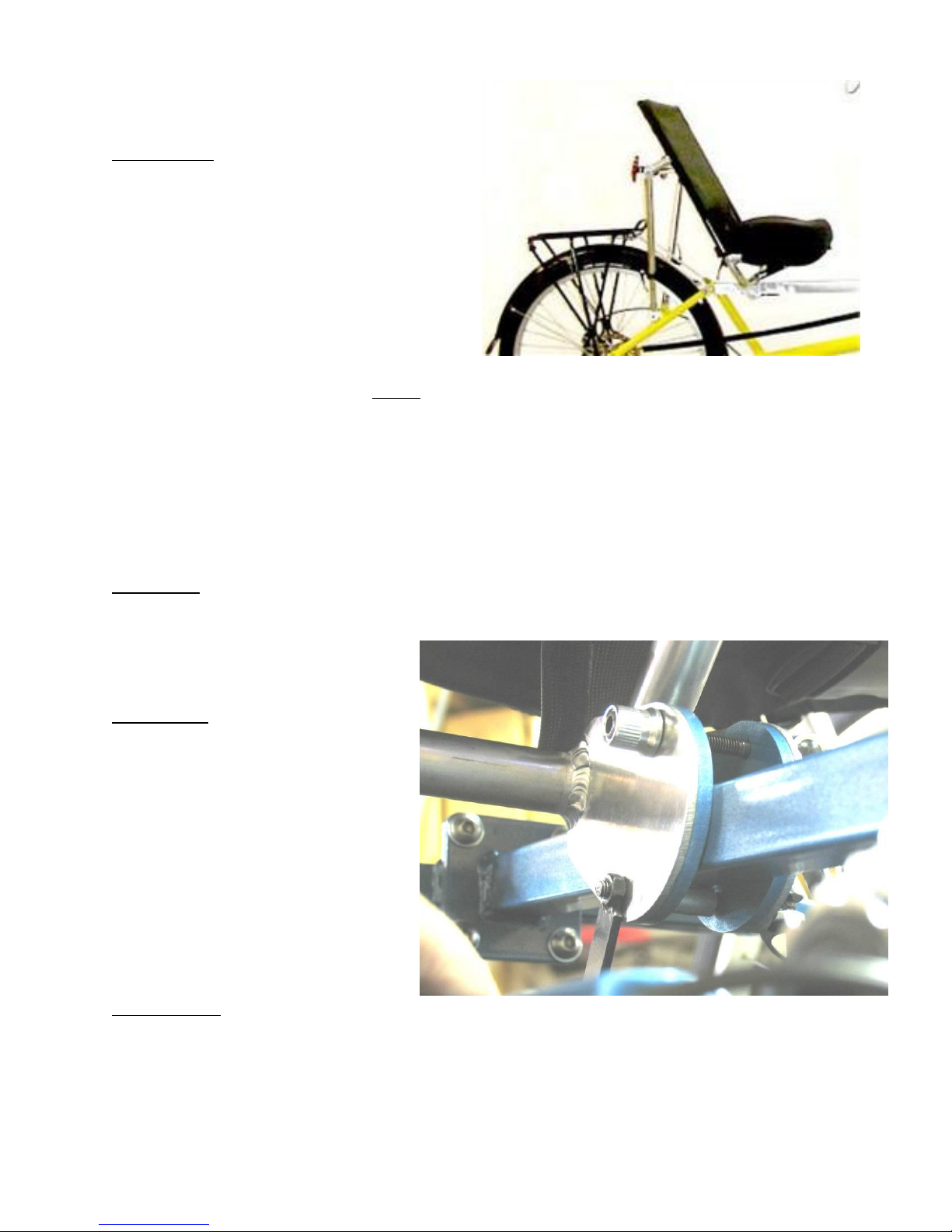

Figure 2.11. Mesh seat

INSTALLATION AND ADJUSTMENT

OF THE SEAT

Installation: Slide the two top pockets of the

seat cover over the top posts on the seat

frame. Slide the pocket of the seat bottom

over the seat horn. Buckle the large strap

around the seat supports and under the seat

fabric. Pull quite tight. You don’t want the

seat to bottom out on the frame.

Buckle the back straps starting at the top.

The top three straps should be tightened as

tight as they will go. The next two straps

should be tightened incrementally looser so

that the bottom strap follows the curve of the seat back. This allows for lumbar support and

can be adjusted to suit your needs. See more on this below.

Place the pad on the seat using the velcro to hold it in place.

Place the seat on the square rail and adjust it for the rider. Screw the quick release bolt into

the clamp while the lever is open until it snugs down when closed.

For Bikes: Attach the seat braces to the seat brace slotted tab on the rear frame of the bike.

Place the seat brace to the outside of the tab with the nylon washer between the slotted tab

and the seat brace. Tighten the nut

and bolt so that the seat brace does

not slip.

For Trikes: Attach the seat braces to

the seat brace slotted tab on the rear

frame of the bike. Place the seat

brace to the inside of the slotted tab

with the nylon washer between the

slotted tab and the seat brace.

Tighten the nut and bolt so that the

seat brace does not slip.

Figure 2.12. Seat clamp on Greenway

and RoadRunner trike

Adjustment: Adjust the seat braces so that the seat bottom supports are roughly parallel to

the ground. IF the seat is tipped too far forward, the horn will not be effective and the rider

will feel that she is falling out of the seat. Riding in a more recumbent position may require

shortening the horn.

When sliding the seat, push or pull as much as possible in the center so the tabs won’t bind.

Technical Manual 2-6

Page 10

Figure 6.7. Fender stay

adjustment

Release ALL 4 quick release bolts and/or pinch barrel bolts during adjustment, even if

adjusting only one part of the seat.

For Greenways and RoadRunners: The lower quick release bolt on the seat clamp should have

a small wing nut on the chain side ( as shown in figure 2.12) and spacers to “shorten” the bolt

on the left side of the trike. IF it doesn’t, in some positions, the nut will interfere with the

cassette.

To adjust the contours of the mesh Performance seat, adjust the tension of the straps on the

back of the seat and under the seat bottom. Most people will want the straps behind the small

of the back (the lumbar region) to be tighter for more support, while the straps at the very

bottom of the back will remain quite loose. The seat horn can be adjusted in two ways; reduce

the contour that the horn creates by tightening the large strap under the seat, and increase the

horn contour by substituting a longer piece of 5/8” dowel and/or loosening the large strap.

The rear edge of the seat pad cover has a Velcro closing that can be opened to allow the

removal, modification or replacement of the seat pad.

All the nylon straps as well as the mesh itself will stretch a little during break-in. Readjust the

straps as needed to keep the seat comfortable for you.

FENDERS (FROM CHAPTER 6 OF TECH MANUAL)

Front Fenders All of our front fenders require that

the left stay have a 30 degree bend 3” behind the

fork mount loop to clear the brake caliper. On 20”

front fenders, we trim the backside so it will not scrape

going over curbs and bumps. The front fenders have single

stays instead of double stays.

INSTALLATION

1. Bolt the fender top tab to the FRONT of the fork using

6mm x 2” bolt, lock washer and nut. Center the fender

over tire and tighten.

2. The left fender stay needs a 30 degree bend 3 inches

behind the attachment loop to clear the front brake caliper.

We usually do that for you. If you have to bend it, just make sure the bend is in line with the

flat plane of the loop.

3. Attach stays to the 5mm threaded mounts in fork using 5 mm bolt and washer.

4. Adjust stays to center fender over the wheel by loosening the stay nuts and sliding the stays

while centering the fender.

5. Tighten all nuts. Trim the ends of the stays with bolt cutters or hacksaw if you choose. File

off sharp edges and replace end cap. A dab of finger nail polish or glue will hold them on well.

Rear Fenders on Bikes Set up fender hardware as directed in instructions with this exception:

the front mount on the rear fender should be installed by bolting from the inside of the fender

Technical Manual 2-7

Page 11

Figure 6.8. Jackshaft, fender and brake setup

to the fender mount on the frame. Use two or more 1/4“ nuts as spacers between fender and

frame if needed.

Rear Fenders on Trikes 1.Place the fender on

the rear wheel. Open the Stays to approximate

width needed for mounting. 3. Bolt the stays to

the frame loosely. 4. Position the front of the

fender to the front of the outrigger above brake.

Use 5mm screws with flat and lock washers

from the inside of the fender to attach to fender

mount. 6. Adjust and tighten bolts and screws all

around when sure of fit. 6. After Stays are

adjusted, they may be cut off with bolt cutters,

filed and have caps placed on their ends—be

careful of the sharp cut ends.

Technical Manual 2-8

Page 12

WHEELS AND TRANSMISS

WHEELS AND TRANSMISSIONS

W

HEELS AND TRANSMISSWHEELS AND TRANSMISS

MOUNTING TIRES ON WH

MOUNTING TIRES ON WHEELS

MOUNTING TIRES ON WHMOUNTING TIRES ON WH

Install a rim strip or rim tape; this protects the tube from punctures caused by the tips of the

spokes and the spoke nipples. Align the hole in the rim strip for the valve stem with the hole in

the wheel rim.

Some tires have a certain rotating direction marked on their sidewall. Generally, any V in the tread

pattern should open toward the rear of the direction of tire travel. On our trikes, we often

mount the right rear wheel with the cassette mount on the inside, but it doesn’t really matter.

Mount one side of the tire on the rim, and then push the

inner tube into the partially mounted tire. Make sure

the tube is not folded or twisted. After the valve stem is

situated, use the tire levers to force the second side of

the tire onto the wheel rim. Take care not to pinch the

inner tube as you go. Some tires may prove to be very

tight and difficult to lever onto the rim; warming and thus

softening the tires--as well as lubricating with soapy

water--may help get them on.

Before inflating, rotate the tire and tube around the rim

as needed until the valve stem sticks straight out of its

hole. Inflate slightly and, before inflating further, check to

make sure that the tire is seated evenly on the rim.

Finally, inflate the tire to its highest recommended pressure.

Some of our vehicles utilize high pressure (80 to 110 psi) tires for lower rolling resistance on

pavement. Many tire models on the market are rated for a maximum of 45 to 60 psi. Sometimes

Figure 3-2. Tire Assembly

EELS

EELSEELS

Figure 3-1. Rim Strip

people choose to inflate these medium-pressure

tires over the rated pressure so that they roll

more easily. Be aware that over-inflation is not

recommended by the tire manufacturer.

If the tire still does not want to seat correctly,

then deflate to 15 or 20 PSI. Squirt some Windex

or dish soap on the trouble spot making sure to

work it in below the bead. Then re-inflate the tire

to desired PSI. The lubrication should help the

tire to seat itself.

For safety reasons, insert the quick release axle

into the wheel so that the quick release handle is

on the side opposite the disc brake if at all possible.

IONS

IONSIONS

Technical Manual 3-1

Page 13

gears on a trike.

T

RANSMISSIONS

TRANSMISSIONS

TRANSMISSIONSTRANSMISSIONS

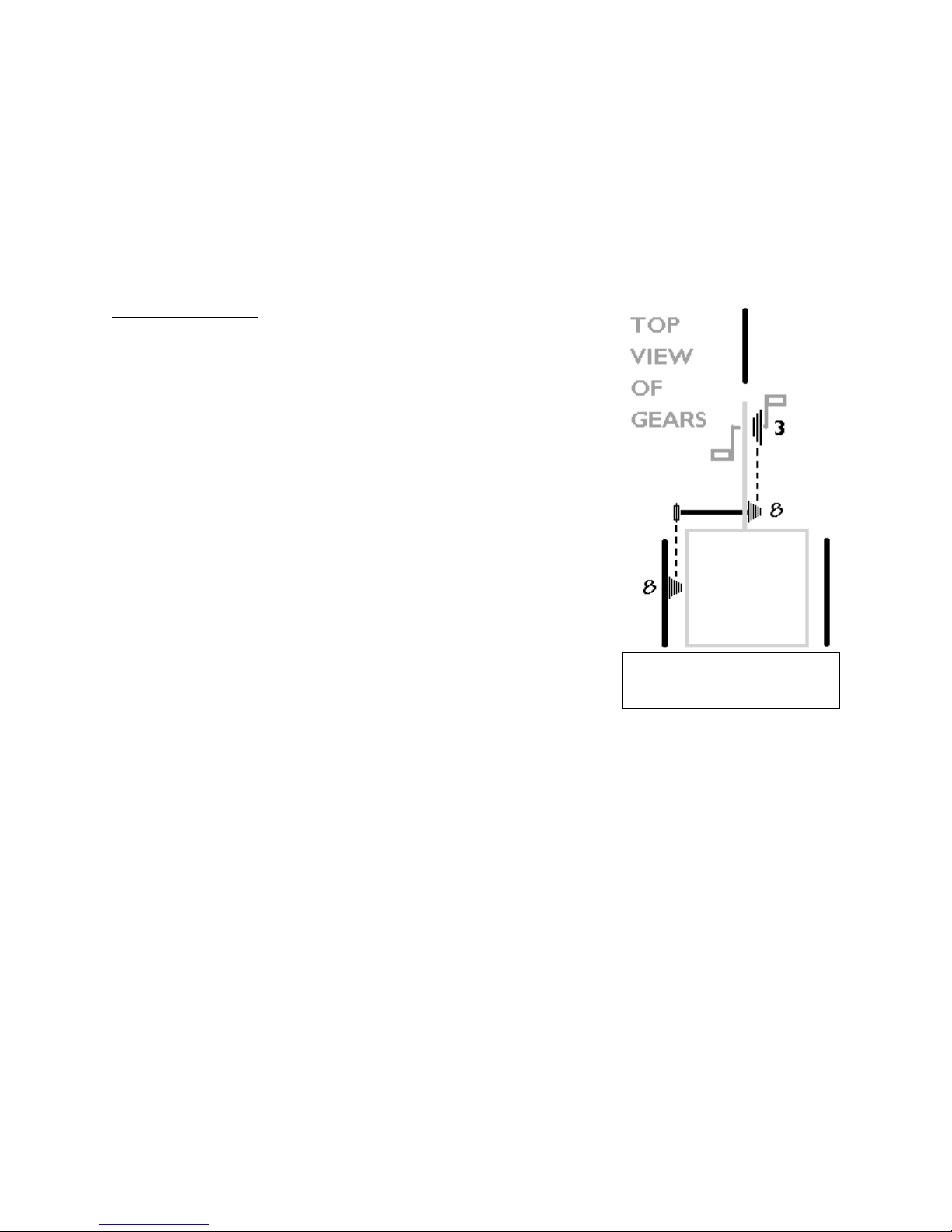

Our standard transmission for a single-seat three- or four-wheeler is illustrated

below. The pedals are attached to a triple-sprocket crankset, which creates rotation (by means of

a chain) of an 8-speed gear cluster on a jackshaft (thus turning the jackshaft). A single sprocket on

the outer end of the jackshaft then creates rotation (by chain) of the 8-speed gear on the left rear

wheel--the drive wheel.

Two-wheel drive is a custom option, wherein the jackshaft is extended to the right to drive the

right rear wheel as well.

Trike Compound Gears

Trike Compound Gears

rike Compound GearsTrike Compound Gears

T

When all three gear clusters are in low, the resulting gearing is very

"low", "slow" or "powerful". This means that one revolution of the

pedals will produce only a small forward motion of the vehicle.

The force required to turn the pedals in low gear is very little; thus

pedaling is easy.

When all three gear clusters are in high, the resulting gearing is very

"fast" or "high". One revolution of the pedals will produce a lot of

forward motion. Unless the vehicle is already moving fast, the

effort required to turn the cranks will be very great. The very

highest gears are used only at high speeds on downhills, with the

help of gravity.

The term "Gear Inches" is shorthand for describing the "size" of

gear you are in. Being in a "90 gear-inch" gear is like pedaling an

1890's high-wheeler with a 90" diameter wheel and fixed pedals; a

single turn of the cranks and you go a long way forward. This is

called a "tall" or "high" gear. Being in a "10-inch gear" is like

Figure 3-3 Top view of

pedaling a little kid's trike with 10" diameter wheel (a "low" gear);

you don't make much forward progress for each turn of the cranks, though pedaling is relatively

easy. Being in a 26 gear-inch gear on a mountain bike with 26" diameter wheels means that for

each turn of the pedals, the drive wheel goes around exactly once. In a 52" gear, the drive wheel

goes around exactly twice for each revolution of the cranks.

As normally set up; the left hand shifts the front triple sprocket by means of a twist-grip shifter.

The right hand shifts the middle 8-speed cluster, also using a twist-grip shifter. A third shifter (a

thumb lever) is used to shift the rear 8-speed cluster. The rear cluster is shifted only occasionally,

and is normally left in a position to give an appropriately low gear for the conditions in which you

are riding.

Contrary to some assumptions; single-wheel-drive on a trike (as Lightfoot Cycles uses it) with

appropriate tires almost always provides plenty of traction, even in snowy or gravelly conditions.

Single-wheel-drive also does not create any difficulties with tracking (traveling straight ahead) on a

properly laid-out long-wheelbase design, despite the fact that only one side of the vehicle has

power. Electric assist and two-wheel-drive options create two different forms of very positive

dual-wheel traction.

Technical Manual 3-2

Page 14

Page 15

recommend hairspray or any solvents that might damage the gel grip. You may have to trim the

g

rips; they may be a bit too long to fit on some handlebars with certain components.

Standard placement of the shifters connects the left grip shifter to the front triple chainring. The

right grip shift controls the rear derailleur on bikes, or the mid-frame derailleur on trikes and

quadracycles. On trikes and quadracycles, the thumb shifter controls the rear derailleur.

If an internal hub gearing system is used, then the right grip shift will control the internal hub in the

rear drive wheel, and the thumb shifter will control the mid-frame derailleur. This allows the most

commonly shifted gears (the internal gear hub) to be those most easily shifted, and leaves the

rarely-shifted “ranges” to be controlled by the more awkward thumb shifter.

The derailleur shifted by the thumb shifter is generally shifted only infrequently and is used to set a

"range" of operation such as low range, medium or high range.

ROUTING THE CABLES

ROUTING THE CABLES

ROUTING THE CABLESROUTING THE CABLES

Try to keep the length of the cable housing as short as possible, however; do not make tight bends

in the housing. Zip ties can be used to tie loose sections of cable to the frame.

The cable "saddle" is used to activate both rear brakes as shown in Figure 3.5. Place it about 3

inches in front of the mid-frame cable saddles. Before installing it, place a patch of frame protector

in the spot it will sit. This will protect the frame from scratching and noise.

Figure 3.6. Trike shift cable arrangement

Technical Manual 3-4

Page 16

Page 17

Page 18

F

ront derailleur adjustment is not an exact science. It requires a good eye and a bit of patience to

get it right. When you apply power to the pedals, the power is transmitted to the rear sprockets

by the upper run of the chain. The lower run of the chain is just the return path, and the only

tension on the lower run is that applied by the spring in the rear derailleur. Since the front

derailleur does its shifting with the upper, power-transmitting, section of chain, it has a harder task

to perform. In general, you should not expect a front derailleur to shift well while you are pedaling

hard, even if the rear derailleur does so.

The Three Front Derailleur

The Three Front

e Three Front The Three Front

Th

Clamp Position

The most critical adjustment of a front derailleur is its attachment to the bicycle frame. This must

be set correctly before you attempt to adjust the limit stops. There are two variables, angle and

height. The front derailleur comes with a small piece of plastic holding it into the extended (highgear) position. A small piece of clear plastic stuck to the side shows where the teeth of the

sprockets should meet the shifter when in high gear; this tells how high to mount the derailleur. As

you tighten the clamp, watch to make sure the derailleur cage remains parallel with the sprockets.

Remove the plastic spacer after the derailleur is firmly clamped to the frame.

of the front derailleur is judged by looking down on the cage from above. Modern front

Angle

derailleurs have very subtly shaped cages, so it is not always easy to tell when the ideal adjustment

has been made. In general, the centerline of the cage should be parallel to the centerline of the

frame. Rotating the derailleur so that the back of the cage is farther out will sometimes improve

shifting to the small ring of a triple by preventing overshifting, but may cause increased need for

trimming on the larger rings. It may also cause the crank to strike the cage.

Rotating the derailleur so that the front of the cage is farther out will help reduce the need for

trimming on the large chainwheel, and will provide crisper downshifting, but with a greater

tendency to overshift on the inside. This may be appropriate on bicycles equipped with an antiderailment device.

Height

recommend 2mm clearance between the bottom of the outer cage plate and the teeth of the

large chainwheel. This is a bit of an oversimplification. Best performance will result from the very

lowest position that still just barely keeps the cage from hitting the chainwheel teeth.

The lower you can get it, the better it will shift, and the less you will need to trim the front

derailleur.

Derailleur Chain wheel Mismatch

Derailleur Chain wheel Mismatch

Derailleur Chain wheel MismatchDerailleur Chain wheel Mismatch

To get the front derailleur as low as possible, the curvature of the outer cage plate has to match

the curvature of the largest chainwheel.

If you use a larger chainring than the derailleur was designed for, the rear of the cage will hit the

teeth of the big chainring before the front of the cage gets low enough to provide crisp shifting

without the need for trimming.

If you use a smaller chainring than the derailleur was designed for, it will shift OK, but you'll have to

do a fair amount of trimming, due to the rear of the cage being higher than it should be, so that

the chain crosses through it farther back.

Lately I've started modifying front derailleurs for improved shifting with larger rings. I have an RSX

on a bike with 50/38/28 Biopace (the sweep of a 50 Biopace is comparable to that of a 52 round.)

The RSX front derailleur works great on its intended 46/36/26 setup, but the cage doesn't match

the curve of the larger chainring. In a couple of minutes with a grinding wheel, I removed a good

bit of metal from the bottom rear of the outer cage plate, and a bit from the bridge section where

of the front derailleur is a principal factor in how well it will shift. Manufacturers commonly

Derailleur Adjustments

DerailleurDerailleur

Adjustments

AdjustmentsAdjustments

Technical Manual 3-7

Page 19

the inner and outer cage plates connect at the back. This made the derailleur match the curvature

o

f the larger chainwheel, and allowed me to set it low enough to provide good chain control. This

setup now works fine with an STI rig that doesn't permit "trimming" the front derailleur.

Low-gear limit stop.

The low-gear limit stop stops the derailleur from shifting past the smallest chainwheel and throwing

the chain onto the bottom bracket shell. If it is too loose, the chain will fall off when you try to

downshift to the small chainwheel. If it is too tight, you it will be difficult or impossible to shift

down to the low chainweel.

On older front derailleurs, the low-gear stop is the one closer to the frame. Many newer designs

reverse this position for reasons relating to the mechanism used.

The basic adjustment for the low-gear stop is to set it so that the chain just barely clears the inner

plate of the cage when the lowest gear (small front, large rear) is selected. This will usually be the

best position for double-chainwheel setups, and will permit the use of most or all of the rear

sprockets with a minimum of trimming.

For triple chainweels, it will sometimes be necessary to adjust the low-gear stop a bit looser, so

that the outer plate of the derailleur can travel far enough to knock the chain off of the middle ring.

Anti-derailment devices

In some instances, you may find that one adjustment of the low-gear stop causes the chain to

derail past the small chainring, but a tighter setting results in slow downshifting to the small ring.

In such cases, a good, if inelegant, solution is sometimes to install an anti-derailment device that

clamps to the seat tube. These products, such as the 3rd Eye Chain Watcher ® and the N-Gear

Jump Stop ® set up a barrier preventing the chain from overshooting the small ring, no matter

how loose the low-gear stop is set. This allows the low-gear stop to be set to allow the derailleur

to move farther inboard for faster, more precise shifting, even under some load. These devices can

often save the day when extra-wide range gearing is used on a mountain bike or tandem.

High-gear limit stop

The high-gear limit stop is pretty straightforward. It should be set so that the chain almost rubs on

the outside plate of the front derailer cage when the bicycle is in its highest gear (large front/small

rear). This will reduce the need for trimming as you shift the rear derailer.

If the shift to the large chainwheel is slow, make sure that you aren't pedaling too hard, front

upshifting requires being ready to have the cranks slow down when the shift takes place. If the shift

is unreliable even when you are pedaling lightly, you may be able to improve it by loosening the

high-gear stop a bit. If you do so, check to make sure that the derailer cage is not moving so far

out that it can be struck by the crank as it goes by.

Sometimes front upshifting may be improved by rebending the front edge of the inner cage plate

outward a bit. This may be done with an adjustable wrench. This is rarely necessary on modern

front derailers, but used to be a very common trick on older, cruder designs.

Front Derailleur Trimming

Front Derailleur Trimming

Front Derailleur TrimmingFront Derailleur Trimming

As you shift the rear derailleur one way or another, the direction from which the chain runs from

back to front changes a bit. As a result, sometimes it is necessary to "trim" the adjustment of the

front shifter after changing gears with the rear, even if you are staying on the same front chainring.

Technical Manual 3-8

Page 20

Trimming means using the shifter to move the front derailleur cage sideways just a little bit, enough

t

o stop the chain from rubbing, but not enough to make it shift to a different chainring.

Older front derailleurs designed for friction shifters used to require trimming as a matter of course,

but newer indexed systems can often be set up so that no trimming is necessary.

For a "trimless" front indexing, you will usually need to be using the particular chainwheel sizes for

which the front derailleur was designed, and the chainwheels must not be bent even a little bit.

The lower down the cage is mounted, the less trimming will be needed.

If your system requires trimming, it is essential that you do it. If you ride with the chain rubbing

against the front derailleur cage, you will wear a groove in the side of the cage and it will never shift

properly.

Adjusting

Adjusting derailleur systems

AdjustingAdjusting

turn freely. Make the initial "rough" adjustment without the chain installed. Fine-tune and test with

the chain in place.

Rough Adjustment:

position if it is the front derailleur). The shifter cable should be either disconnected or the shift

lever at the handlebars should be in the position in which it is taking up the least amount of cable.

(Note: the shift lever should be complementary to the derailleur in model or type.)

Then screw in or out the little "high/low limiting screw" that restricts the movement of the

derailleur in and out; this establishes how far the derailleur can move, so that it does not shift the

chain entirely off the sprocket cluster. There are two of these, usually marked with an H for high

(small sprocket) and an L for low (large sprocket). Move the screw until the derailleur jockey

wheels line up with the outermost cassette sprocket. Manually, push the derailleur to its other

extreme and adjust the other limiting screw until the derailleur lines up with that sprocket or chain

ring (front). The instructions that come with your front derailleur give metric settings for making

this adjustment. Return the derailleurs to their relaxed position. Above smallest chainring and

sprocket.

Now, Install the chain and connect the cables. Make sure that the housing (the tube in which the

cable is housed) is socketed into the mechanism or cable stops at each end by stretching the cable

under the midframe after everything is connected. Disconnect, take up the slack and reconnect.

When the shift lever is now rotated (while pedaling), the derailleur should shift the chain from one

sprocket to the next. When the derailleur reaches the farthest sprocket, re-adjust the “low” limiter

screw to permit the chain enough movement to shift onto the sprocket, but not so much that it

goes off the far side.

If the system is an index system (as most LFC vehicles are), fine-adjustment to exactly position the

rear derailleur for accurate shifts is generally made with a "barrel-adjuster" bolt, either where the

cable enters the derailleur or where the cable exits the shift lever. If your chain hesitates to shift

up (to the smaller sprocket), twist the barrel adjuster inward, thus taking some of the tension off of

the cable. If the chain does not shift down (to the larger sprocket), twist the barrel adjuster

outward, adding tension to the cable so that it pulls the derailleur further over toward the larger

sprocket.

derailleur systems is most easily done with the drive wheel elevated into the air so it can

derailleur systemsderailleur systems

with

withwith

Start by letting the spring-loaded derailleur relax to its highest position (lowest

Technical Manual 3-9

Page 21

I

ndicator marks for the front derailleur (even on index systems) do not accurately indicate what

gear the front triple sprocket is in. This is not a problem, but you can take the time to adjust it as

close as you wish.

The shifter for the rear-most derailleur on a trike or Tandem is a "friction shifter". The limits to

derailleur movement are adjusted in the same way as for the index shifter, but there is no need to

fine tune the operation of the shifter lever. Shifting is done by sound, sight, and feel. After a

learning period, this can be done fairly accurately without looking. The screw or "D-ring" on top of

the shifter can be tightened to adjust the tension of the thumb lever; it should not be so tight that

it is difficult to shift, but not so loose that the derailleur spring pulls the cable back out of gear.

You will be able to shift those "range" gears if you are climbing steep hills, starting heavy loads or

ying down a hill and need more gears. Generally, leave it in a center gear unless you are

fl

experiencing one of those conditions.

It's a tight squeeze on that shifter to get all 8 gears. Most of the time it can be set up to get all 8,

but occasionally only 7 are available. Don't get too excited if only 7 are available, You will still have

168 gear combinations. If it ever needs to be adjusted, you can have it set up for whichever end

you need the gears most, High or low.

JACK

JACK----SHAFT

SHAFT

JACKJACK

SHAFTSHAFT

The Jack-Shaft transfers power from the centerline to the outside drive wheel on trikes and some

quads. PROPER CARE AND MAINTENANCE IS CRITICAL FOR GOOD FUNCTION AND

REPLACEMENT EASE. Remove, clean and grease the parts every 1000 miles or each year.

Remove any burrs that develop around bolt holes with a round file or sandpaper. Check the bolts

holding the freewheel and cassette mounts frequently

frequently to make sure they are tight. Sloppy bolts

frequentlyfrequently

create burrs which will make removal of the jackshaft almost impossible.

Technical Manual 3-10

Page 22

Page 23

Page 24

Page 25

Page 26

Figure 4

-

2. Four wheeler front end

STEERING

STEERING

STEERINGSTEERING

LINKAGE STEERING

LINKAGE STEERING

LINKAGE STEERINGLINKAGE STEERING

Lightfoot’s Linkage Steering System consists of

these parts:

1. Handlebar and stem

2. Stem extension

3. Linkage Steerer Tube (inserts into bike

frame)

4. Linkage Rod

5. Fork Steerer Tube Clamp/Cap

6. Steering Assembly Standoff

7. 2)5/16” tie rod ball ends

8. 2) 5/16” Fine Thread Nuts

Adjust the steering columns so that they align

with the front wheel. The Steering Assembly

Standoff should be in line with the long axis of

the cycle. The tab on the Steering Assembly

Standoff and the Fork Steerer Tube Clamp

should be parallel to each other and

perpendicular to the long axis of the cycle. The

handlebars should be perpendicular to the long

axis of the cycle and especially the front wheel.

Tighten all bolts when everything is aligned.

DUAL WHEEL

DUAL WHEEL ALIGNMENT

DUAL WHEEL DUAL WHEEL

The steering linkages on the front of the four-wheel vehicles will in most cases come pre-adjusted

if the vehicle is assembled. Some may not be adjusted; you can tell this if there is excessive "toein", or if the front tires obviously "scrub" as you make a tight turn.

ALIGNMENT

ALIGNMENTALIGNMENT

Figure 4-1. Linkage Steering

Technical Manual 4-1

Page 27

You may also want to make adjustments to the "quickness" of the steering. You may need to read

the following paragraphs a couple times to make sense of these instructions. Adjustment is made in

one of three ways. Fine toe-in adjustment is made by unbolting one end of the tie-rods and

screwing the tie-rod-ends in or out. Ackerman adjustment can be made by rotating the head

stems on the steering tube of the front fork.

Akerman Steering

Akerman Steering

Akerman SteeringAkerman Steering

Ackerman steering is the design of the vehicle that allows the inside wheel to turn more sharply

than the outside wheel in a turn, thus avoiding "scrubbing" of the front tires and losing speed during

turns. It is adjusted by changing the angle of the stem that holds the outer tie rod bolt, in its

relationship to the front wheel. The amount of angle depends upon the wheelbase (length) and

track (width) of the vehicle. A short vehicle will have a wide Ackerman angle, with the outer stem

and tie-rod end angled 20 to 30 degrees from the long axis of the cycle. A very long wheelbase

vehicle may have only a 10 or 15 degree Ackerman angle. When correctly adjusted, sharply

turned front axles should aim at the same point just below level on an imaginary line drawn

through the rear axle(s) at right angles to the long axis of the cycle.

Toe

Toe----in

in

ToeToe

inin

Toe

Toe----in

in measures the amount that the wheels are out of parallel with each other. The front wheels

ToeToe

inin

should be 1/8" closer together at their front than at their rear (when pointing ahead). The rear

wheels should be parallel to each other. Make sure that the nuts that hold on the tie rods are

TIGHT.

Quickness of Steering

Quickness of Steering

Quickness of SteeringQuickness of Steering

Steering "quickness" can be adjusted if you find the vehicle handling to be TOO quick. By turning

the direction that the outer tie-rod bolts are facing so that they reach forward, you can reduce by

a small percent the "quickness" or amount that the wheels turn with a movement of the

handlebars. For a dramatic reduction in steering quickness, you can replace the center stem that

holds the center tie-rod bolt with a comparable, but shorter stem.

Technical Manual 4-2

Page 28

Figure 6.1. Canopy

with sides rolled up

OPTIONS AND ACCESSORIES

CANOPIES

You will need a drill with 3/16" bit, screw driver, 3/8” wrench and

(8+) 1 1/2" #10bolts and locknuts. Attach the Canopy pedestal to

the fender platform with 1 ½” x ¼ “bolts and lock nuts. Position it

on its center 17 1/2" forward from the back of the vehicle. They

should be on top of the fender panel, to the outside of the fender

panel frame.

The footman-loops of the canopy top may be fastened as close as

possible to the outside corners of the fender platform or the cargo

box with #10 bolts. They are secured the same way, with bolts or

rivets.

Assemble the bows as you put them into the canopy. The shortest bow belongs in the center.

The front and back bows are the same length. Attach the front and back bows to the swivel

plate using 1 ¼” x ¼” bolts and lock nuts. Attach the center bow to the swivel plate and the

pedestal with the 2” x ¼” bolt in this order: bow, plate, 4 washers, pedestal, lock nut. This will

take two people or a support for the other side. The bows have spring in them to give a curve

to the top of the canopy. Tying a piece of twine around the uprights of the center bow will

keep them from springing out as you work on them

Attach the straps to the canopy as follows: the shortest strap goes around the front and back

bows and through the footman loops. The other two straps go through the front and back

footman loops on the bows then down to the footman loop on the platform. Snug these down

so that the canopy top is level. Adjust the straps to get the proper attitude and tautness.

Attach the canopy sides to the velcro around the top of the cargo box.

On four wheeled cycles, you may have a front strap which attaches to the front frame cross

member. It should not interfere with steering at any point.

The fabric can be cleaned without being removed from the frame. Brush off any loose dirt,

hose down and clean with a mild soap in lukewarm water (no more than 100 degrees.

CARGO HAMMOCK

Align the cargo hammock in the opening. Fasten the nylon straps snugly around the framework

between the wheels. There are 4 or 5 straps per side. Near the brake rotors and derailleurs,

be sure to tuck the ends of the straps into the loop made around the frame to keep strap ends

out of the rotors and gears.

Cargo Hammocks can be hand washed or wiped with a cloth to keep clean. Do not wash in a

washing machine or dry in a dryer.

Technical Manual 6-1

Page 29

Figure 6.2. Chain Tubes

CHAIN TUBES

Chain Tubes function to keep the

chain cleaner, keep the rider

cleaner and support the chain on

large trikes, bikes and four

wheelers.

Chain Tube Mounting Mount

chain tubes as shown in Figure 6.2.

Keep bolts loose enough to allow

the tube and bracket mount to

swivel with different chain

positions, but not so loose that the

frame mount will twist out of

alignment.

Bikes: Mount clamp on mid frame brace using “p-clamp”(figure 6.2).

RoadRunner trike: Mount clamp on bottom tube 3-¾ inches in front of the mid-frame brace.

Align clamp with axis of cycle. Break chain below and behind the crank with chain tool and run

the chain through the tubes, threading correctly through the front derailleur. Reconnect chain

and be sure to work out any tight spot on the chain by flexing the chain back and forth from

side to side.

If necessary, loosen the tube clamps and reposition the tubes so that they are at least 1-½

inches from either sprocket. It is important not to pedal backwards when chain tubes

are on the cycle. If poorly adjusted, they may foul in the sprockets.

CHAINRING GUARD

The Lightfoot Chainring guard is

made to install on the Truvativ

Blaze Crankset. Slip the guard

over the crankarm and install the

bolts closest to the crank arm

first. Use #4x ½” or M3x 16mm

bolts, use an 5mm nylon locknut

between the guard and the outer

chainring as a spacer and tighten

using locktite or peen the tip of

the bolt to insure the nut stays

on.

Technical Manual 6-2

Page 30

Figure 6.3. Electric assist on trike

DECALS

Apply decals at 68 –75 degrees F. Clean the frame and your fingers with alcohol. Peel back off

the decal keeping fingers off the adhesive; use tweezers if you have no fingernails. Position

decal. Lay on frame. Use a credit card to “burnish” or set the decal working from center to

outside, pushing any air bubbles as you go.

Remove top cover by peeling back along the frame. Lifting may lift the decal especially if cold.

If you have trouble, allow the decal to sit for 24 hours with the cover on then remove cover.

Do not use citrus-based cleaners on decals; they will smear. Alcohol or ammonia based

window cleaners are OK.

ELECTRIC ASSIST

The electric assist system

battery pack rides in the

cargo hammock of our trikes,

and can ride on top of almost

any rear rack that is mounted

on our bikes. A red and a

black wire from the motor

pass through an opening in

the front of the cargo

hammock (or cargo box), and

attach to a similar pair coming

out of the front of the battery

pack; this connector clicks

together and apart easily. A grey cable from the motor attaches to the throttle. Unzip the

battery pack to see the pair of 12 volt sealed batteries wired in series inside. A silver metal

connector lies beside the batteries; this connects to the battery charger. The battery charger

can be carried in the cargo hammock (rough usage can be hard on the electronics of the

charger), or it can be left at the charging station. The battery pack rests on a platform that

serves to spread their weight across the fabric bottom of the hammock. If you wish to put a

piece of foam rubber under the platform, it will help reduce road shock to the batteries (and

charger if you carry it). Push the battery pack forward as far as possible to keep cargo room

available.

Technical Manual 6-3

Page 31

Figure 6.6 Upper fairing mount for linkage

steering

Figure 6.4. Lower fairing mount, 20 and 26" fork

Figure 6.5. Upper fairing mount for tiller

steering

Figure 6.65 – Fairing on suspension fork

When shifting, ease off of the throttle, so

that the shift is smooth. If you have the

assist in too high of a gear when starting up,

it will surge or stall.

FAIRING

The fairing mounts with T-Block clamps with

arms on the handlebars. The lower mounts

are P-clamps and twist tabs on the fork legs.

The fairing can be adjusted up in cold

weather so that the wind flow is directed

over your head. In hot weather, you may

want the air shed off the top of the fairing to

flow toward your face.

Place the lower mount clamp on the left

fork leg, just above the brake mount. Align

as shown in figure 6.4. Place the right clamp

on the rt fork leg even with the left. Insert foam

tape between mount and fairing.

Fairing Mount for Linkage steering

Linkage steering requires a customl “rhyno” steer

tube clamp mount that holds a 24” T-stem of 1-

1/4”x.058” AL tubing. Standard Zzipper 8” block

clamps attach to the .875 x .058 cross T-bar to

attach to the upper fairing mount holes.

Technical Manual 6-4

Page 32

FENDERS

Figure 6.8. Jackshaft, fender and brake setup

Figure 6.7. Fender stay

adjustment

Front Fenders All of our front fenders require that the left stay have a 30 degree

bend 3” behind the fork mount loop to clear the brake caliper. On 20” front fenders,

we trim the backside so it will not scrape going over curbs and bumps. The front fenders have

single stays instead of double stays.

INSTALLATION

1. Bolt the fender top tab to the FRONT of the fork using

6mm x 2” bolt. Center over tire and tighten.

2. The left fender stay needs a 30 degree bend 3 inches

behind the attachment loop to clear the front brake

caliper. We usually do that for you. If you have to bend it ,

just make sure the bend is in line with the flat plane of the

loop.

3. Attach stays to the 5mm threaded mounts in fork using

5 mm bolt and washer.

4. Adjust stays to center fender over the wheel by

loosening the stay nuts and sliding the stays while centering

the fender.

5. Tighten all nuts. Trim the ends of the stays with bolt

cutters or hacksaw if you choose. File off sharp edges and

replace end cap. A touch of finger nail polish or glue will

hold them on well.

Rear Fenders on Bikes Set up fender hardware as directed in instructions with this exception:

the front mount on the rear fender should be installed by bolting from the inside of the fender

to the fender mount on the frame. Use two or more 1/4“ nuts as spacers between fender and

frame if needed. Use a ¼” or 6mm washer and lock washer between the bolt head and the

fender slot to secure the mount.

Rear Fenders on Trikes 1.Place the fender on

the rear wheel. Open the Stays to approximate

width needed for mounting. 3. Bolt the stays to

the frame loosely. 4. Position the front of the

fender to the front of the outrigger above brake.

Use 5mm screws with flat and lock washers

from the inside of the fender to attach to fender

mount. 6. Adjust and tighten bolts and screws all

around when sure of fit. 6. After Stays are

adjusted, they may be cut off with bolt cutters,

filed and have caps placed on their ends—be

careful of the sharp cut ends.

Technical Manual 6-5

Page 33

KICKSTANDS

Lightfoot cycles accept standard kickstands with a slight modification. Protect the frame with

vinyl tape and install as shown in the photos below.

Figure 1 Seat brace tab forward

SAFETY FLAG

Place frame protection tape on frame where you want the flag (the left rear side of the frame is

a good visible spot).

Attach the flag mount using the #10 bolts and lock nuts provided. Sandwich the frame between

the flag mount and the flat tab,

straighten and tighten. Do not

over tighten or the mount may

bend making insertion of the

flagpole impossible.

Figure 6.9. Safety Flag mount

Technical Manual 6-6

Page 34

Figure 1. Timing position of the upper and

lower cranks

HANDCRANK ASSEMBLY

Tools needed: Metric hex set: 5mm, 7/16” open end

wrench, ½” open end wrench

Lift out of box TAKE CARE NOT TO CRIMP THE

CABLES OR CABLE HOUSING!

Unwrap lower portion, do not unwrap the crank yet.

Plug lower stem into derailleur tube of trike with chain

tubes on the right. Tighten the derailleur tube collar clamp.

Unwrap and slide fork stem clamp onto fork stem with tab

to left and bolts to the back of the trike. Tighten the

headset down using the headset top cap. Do not tighten

the clamp yet.

Connect the tie rod loosely to the linkage steering tab.

Now you can unwrap the top. MAKE SURE TO PUSH THE

CABLE HOUSING INTO THE BARREL ADJUSTERS ON THE BRAKES

AND SHIFTERS; DON’T CRIMP CABLES!

Here comes the 4-hand part:

Get some strong, mechanical help.

Holding the front wheel in alignment, align the linkage

steering system and tighten the bolts on the linkage

steering tab and fork stem clamp.

Insert the chain into the chain tubes. Loop around foot

crank and pin the chain back together. Check to make sure

the link moves freely.

Align the hand crank and pedals as shown in Figure 1.

Hand crank perpendicular to ground/foot crank

perpendicular to line between cranks. This is the timing

that allows the hand crank to not interfere with your

knees.

Loosen the bolt on the Linkage steering stem tube clamp.

This is tricky. Lift up hard on the hand crank, keeping it in

its vertical position, align with the front fork and have

someone else tighten the collar clamp to hold in place. The

bottom bracket in the center of the hand crank should be

at your shoulder height when everything is tightened in

place.

Attach the large cable tie to the spring, tighten enough to

hold in place but not too much to crimp tube and trim

flush. Figure 2.

When all that is done to your satisfaction, connect the new cables to your brakes and

derailleurs.

Run the housing between the frame and the linkage rod.

Technical Manual 6-7

Page 35

Figure 2. Detail of lower clamp

HEEL PLATES

Install Heel Plates by unbolting or popping rear pedal

reflector off with a flat screwdriver. Bolt heel plate

onto pedal using reflector holes, L opening down.

Place foot on pedal as normal. Slide heel cup up to

heel. Mark the underside with a marker and tighten

the bolts holding the plates together using the mark to

keep the proper length. Some pedals may have 5mm

holes. If so, use 5mm bolts supplied.

Technical Manual 6-8

Page 36

BRAKES

BRAKES

BRAKESBRAKES

Our standard brakes are cable-actuated disc

brakes. Disc brakes have a “burn-in” period

and the braking force gradually increases as

the “burn-in” period progresses. The

calipers and rotors heat up when used. Do

not touch them or try to adjust them when

hot. Be extremely careful with fingers

around rotating brake disks.

We use "linear-pull" or "vee-brakes" on

cycles with internal hubs. The brake arms

are held onto the brake bosses with a

button-cap hex bolt. The brake shoe

Figure 5.1 Cable actuated disc brake

rim when the lever is not being squeezed); these need to be set evenly, so that neither side drags.

These springs are generally adjusted with the small outside screws on most models of brake.

We have included the Avid Brake Manual with your cycle. Please read it and familiarize yourself

with the operating and adjustment instructions. Avid has instructions on adjusting and maintaining

the ball bearing disc brake BB-5 and BB-7 on this web site:

http://www.sram.com/_media/techdocs/2006_BB5and7_English.pdf

PARKING BRAKE

PARKING BRAKE

PARKING BRAKEPARKING BRAKE

Lightfoot trikes have 2 simple parking brake systems. The first is the brake loop; a very simple low

tech braking solution that comes with every cycle. Slip it over the grip, squeeze the brake lever.

Pull the shock cord loop over the brake lever.

The second is a factory add-on option. It is a locking brake lever. If your trike has a parking brake:

squeeze the left (front) brake lever to see a ¼” hole into which the parking brake pin fits snugly.

Use it when you are loading your trike or parking it on sloping ground.

BRAKE HOUSING

BRAKE HOUSING

BRAKE HOUSINGBRAKE HOUSING

On long cable runs, lubricate the cable where it goes through the housing by applying a few drops

of White Lightning or other lubricant. The very long runs create drag that the return springs on

brakes may not be able to easily overcome; lubrication helps brake levers and calipers return to

their fully open position.

ADJUSTING BRAKES

ADJUSTING BRAKES

ADJUSTING BRAKESADJUSTING BRAKES

Disc Brakes

Disc Brakes

Disc Brakes Disc Brakes

• Before each ride: 1) check cables for wear or fraying. 2) Squeeze the brake lever firmly and

check for proper brake function. Adjust for pad wear if necessary. 3) Check pads for wear

and replace if necessary. 4) Make sure the rotors are free of foreign substances and oils.

should be adjusted until the shoe lines up

with the wheel rim. Springs control the

"return" of the brakes (pulling back from the

Technical Manual 5-1

Page 37

• Spring tension adjustment: turn the spring tension adjustment screw with a 2.5 mm hex

wrench. Turning the screw clockwise increases spring tension, which equals a harder lever

pull.

• Cable slack adjustment: use the barrel adjuster on the brake lever to remove cable slack.

Turn the adjuster out until there is no free play in the lever, but not so far that the torque

arm on the caliper is advanced. The torque arm should return completely when the brake

lever is released.

• Pad wear adjustment: turn both inboard and outboard red adjusting knobs clockwise 1 or

2 clicks as needed to restore your brake to optimum settings.

adjuster to compensate f

adjuster to compensate for pad wear.

adjuster to compensate fadjuster to compensate f

or pad wear.

or pad wear.or pad wear.

DO NOT USE your barrel

DO NOT USE your barrel

DO NOT USE your barrel DO NOT USE your barrel

• Pad Wear: a pad should be replaced when its total thickness is less than 3 mm. To remove

the pads, back both red adjuster knobs all the way out (counter clockwise) then squeeze

the pad tabs together and pull both pads straight out of the caliper. Reverse the process

for installation of the new pads. Squeeze the brake pad/spring clip assembly together then

press firmly into the caliper until it clicks into place.

• Care and cleaning: Extreme care must be taken when cleaning both the cycle and the disc

brakes. Under normal use the pads and caliper rotor will not need to be cleaned. If

necessary, use only water and dish detergent. Be sure to thoroughly rinse all soap residues

from the rotor. Dry with a clean paper towel.

BALANCING BRAKE PAIR

BALANCING BRAKE PAIRSSSS

BALANCING BRAKE PAIRBALANCING BRAKE PAIR

All

All----wheel braking

wheel braking on three-wheelers or four-wheelers requires not only that each brake be

AllAll

wheel brakingwheel braking

symmetrically adjusted, but that each front or rear opposite pair is balanced. Both left and right

pairs that are controlled by a single brake lever should have approximately equal amount of spring

tension so that each pulls back from the rim in equal amount when that brake lever is released.

Figure 5.2. Trike brake cable arrangement

as hard as possible (under full braking) without the brake lever contacting the handlebar. As well,

the brake lever should move only a little (as your hand tightens upon it) before the brake begins to

activate.

Technical Manual 5-2

When brakes are adjusted properly, you

should be able to squeeze the brake lever

Page 38

RIDING YOUR CYCLE

RIDING YOUR CYCLE

RIDING YOUR CYCLERIDING YOUR CYCLE

Any of our cycles will feel odd to the first-time recumbent rider. Two-wheel models will seem

hard to balance at first, and clumsy to push or move around. Trikes and trucks will seem strange in

every respect. If you are a long-time upright bike rider, it may even be worse than if you haven't

ridden in 10 years. Have patience. With practice almost anyone will be able to ride straight and

efficiently and turn predictably. Pushing and maneuvering the bike will become second nature.

However, it may take some time.

When learning to ride a recumbent two-wheeler, begin in a level, paved parking lot, with lots of

room to maneuver and no traffic. Do not begin on a crowded street, or on gravel, or on a hill. Do

not use toe clips on your firs

not use toe clips on your first ride.

not use toe clips on your firsnot use toe clips on your firs

to ride slow. Start in a medium-low gear. Some people will have their balance in 20 seconds;

some will take 20 minutes.

TTTThree secrets to learning to ride a recumbent:

hree secrets to learning to ride a recumbent:

hree secrets to learning to ride a recumbent:hree secrets to learning to ride a recumbent:

1. Start with a power stroke (pedal straight up)

2. Lean back into the seat

3. Relax your arms when you ride.

Many of our vehicles use "tiller" steering. Practice swinging the handlebars back and forth to get a

feel for the motion of steering, and practice on level terrain before you steer down a hill and

around a corner.

SMOOTH SHIFTING

SMOOTH SHIFTING

SMOOTH SHIFTINGSMOOTH SHIFTING

Derailleur systems require that the rear wheel and pedals be turning when you shift. Also, you

must ease off on the pressure to the pedals as you shift. Index shifters must be adjusted

or they will not shift consistently and may not stay in gear.

or they will not shift consistently and may not stay in gear. If you cannot get your gears to shift

or they will not shift consistently and may not stay in gear.or they will not shift consistently and may not stay in gear.

consistently using the information printed in this owner's manual, have an experienced bike

mechanic help on this critical adjustment.

The wheel and pedals do NOT need to be turning when you shift an internal hub. The internal

hub systems can also shift under pressure; however, it will shift better and the internal components

will last longer if you ease off when shifting.

EFFECTIVE BRAKING

EFFECTIVE BRAKING

EFFECTIVE BRAKINGEFFECTIVE BRAKING

When braking a two-wheeler, keep in mind which lever controls the rear brake; it is almost always

the lever on the right. Use the rear brake for most of your braking. On gravel, snow, or slick

surfaces, use the rear brake and be cautious with using the front brake. If the front locks up, you

will loose your ability to steer. Experienced riders can skid the rear wheel in gravel without loosing

control.

On dry pavement, use the front brake strongly, in combination with the rear brake for fast stops.

USING

USING A MIRROR

USINGUSING

If your cycle did not come with a mirror, or if you do not have a good helmet mirror, get a mirror.

Immediately. You will be, and will feel, much safer.

A MIRROR

A MIRRORA MIRROR

Do not begin on a crowded street, or on gravel, or on a hill. Do

Do not begin on a crowded street, or on gravel, or on a hill. Do Do not begin on a crowded street, or on gravel, or on a hill. Do

t ride. A little bit of speed will help your balance on a bike; don’t try

t ride. t ride.

Index shifters must be adjusted correctly,

Index shifters must be adjusted Index shifters must be adjusted

correctly,

correctly, correctly,

Technical Manual 7-1

Page 39

Learn to use the mirror without turning your head. Make frequent checks of overtaking traffic by

glancing at the mirror, moving only your eyes. Don't stare at it, just check and go. This

continuously updated consciousness of what is behind you will make you much safer if you should

need to make an emergency maneuver.