Page 1

TM

Garage Door Opener

Owner's Manual

(Model Series 1200)

For Residential Use Only

The Chamberlain Group, Inc.

A DUCHOSSOIS ENTERPRISE

Complies with

UL 325

Regulations

effective

January 1, 1993.

845 Larch Avenue

Elmhurst, Illinois 60126

®

©

Model 1260 - 1/2HP

Model 1260-166 - 1/2HP

Model 1260-266 - 1/2HP

Model 1250 - 1/3HP

Model 1250-266 - 1/3HP

Model 1255 - 1/2HP

Model 1255-166 - 1/2HP

Model 1255-266 - 1/2HP

Model 1245 - 1/3HP

Model 1245-266 - 1/3HP

©

Model 1256 - 1/2HP

Model 1246 - 1/3HP

© ©

Model 1240 - 1/4HP

Owner's Manual

■ Please read this manual and the enclosed safety materials carefully!

■ Fasten the manual near the garage door after installation.

■ The door WILL NOT CLOSE unless the Protector System

properly aligned

■ Periodic checks and adjustment of the opener are required to ensure safe

operation.

■ The model number label is located on the front panel of your opener.

®

is connected and

Page 2

CONTENTS PAGE

A review of safety alert symbols.............................2

You'll need tools .....................................................3

Safety information regarding garage door locks

and ropes.............................................................3

Testing your garage door for sticking, binding

and balance.........................................................3

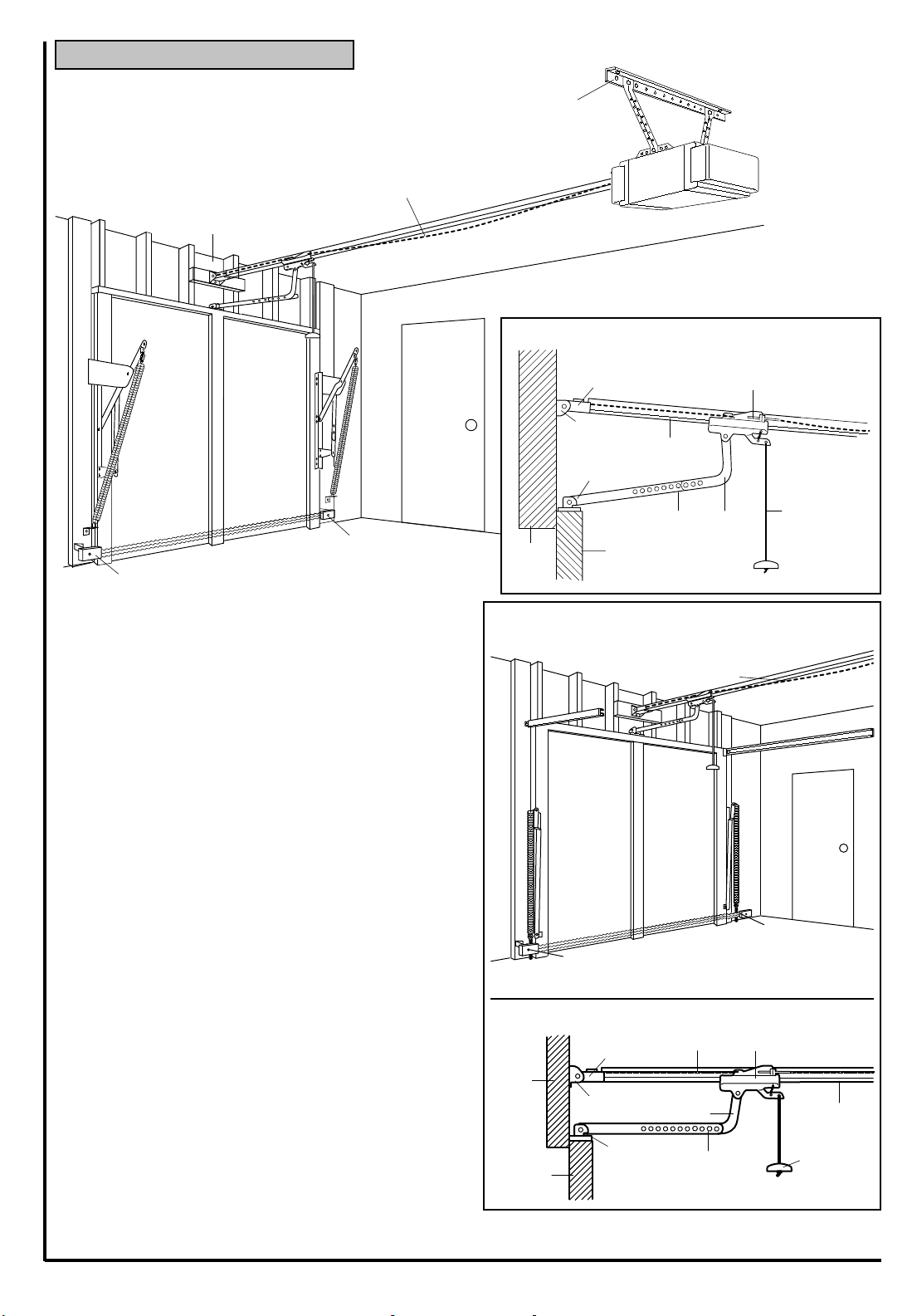

llustration of sectional door installation ..................4

Illustration of one-piece door installation................5

Carton inventory.....................................................6

Hardware inventory ................................................7

Assembly Section - Pages 8 – 11

Fasten T-rail to opener.....................................8, 9

Attach chain to sprocket, install sprocket cover....8

Attach chain spreader, re-install chain ...............10

Tighten the chain................................................11

Installation Section - Pages 11 – 27

Installation safety instructions.............................11

Determine header bracket location

Sectional door...................................................12

One-piece door.................................................13

Install header bracket.........................................14

Attach the T-rail to header bracket.....................15

Position the opener.............................................16

Hang the opener.................................................17

Install the door control........................................18

Install the light(s) and lens(es)............................19

CONTENTS PAGE

Attach manual release rope and handle.............19

Electrical requirements ........................................20

Safety reversing sensor information ....................21

Install the safety reversing sensor .................22, 23

Fasten door bracket (sectional door)...................24

Fasten door bracket (one-piece door)..................25

Connect door arm to trolley (sectional door)........26

Connect door arm to trolley (one-piece door) 27

Adjustment Section - Pages 28 – 30

Travel limit adjustments.......................................28

Force adjustments ...............................................29

Test the safety reversing sensor..........................30

Test the safety reverse system ...........................30

Operation safety instructions .................................31

Care of your opener...............................................31

Maintenance schedule...........................................31

Operation of your opener.......................................32

Receiver and remote control programming............33

Having a problem?...........................................34, 35

Repair parts, rail assembly ....................................36

Repair parts, installation ........................................36

Repair parts, opener assembly..............................37

Accessories............................................................38

Index......................................................................39

How to order repair parts.......................................40

Maintenance agreement........................................40

Warranty ................................................................40

Start by reviewing these important safety alert symbols

When you see these safety symbols on the following pages, they will alert you to the possibility of

serious injuries or death

come from something mechanical or from electric shock.

WARNING

if you do not comply with the corresponding instructions. The hazard may

Read the instructions carefully.

WARNING

Mechanical Electrical

When you see this safety symbol on the following pages, it will alert you to the possibility of damage

to your garage door and/or the garage door opener if you do not comply with the corresponding

instructions.

Read the instructions carefully.

CAUTION

This garage door opener is designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the safety instructions contained in this manual.

2

Page 3

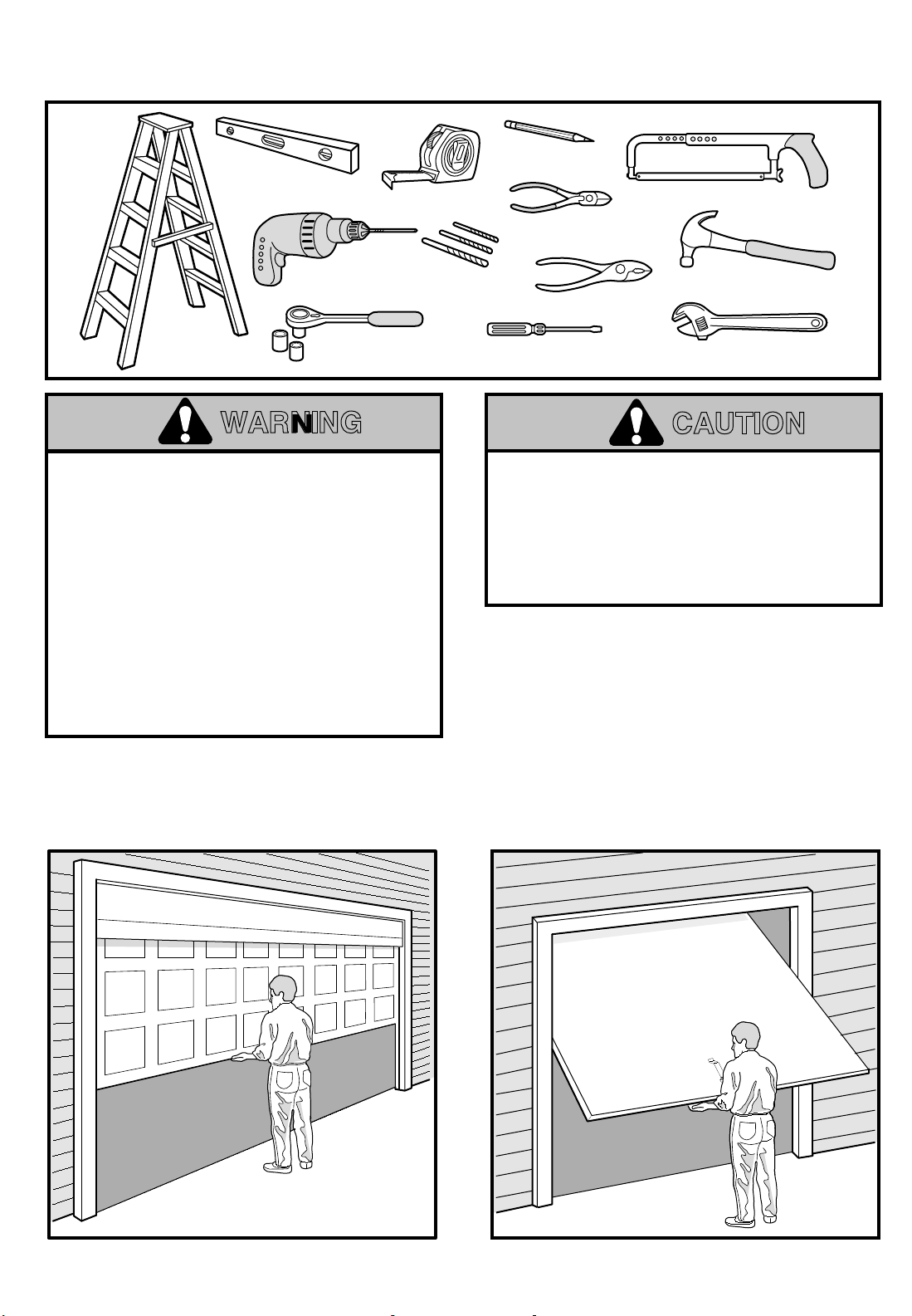

You'll Need Tools

During assembly , installation and ad justment of t he opener, instructions will call for hand tools shown below.

Pencil

Carpenter's

Level

2

1

Tape Measure

Hack Saw

Wire Cutters

Stepladder

Drill

1/2" and 7/16" Sockets

and Wrench

3/16", 5/16" and

5/32" Drill Bits

WARNING

An unbalanced garage door might not reverse

when required and someone under the door

could be seriously injured or killed.

If your garage door binds, sticks or is out of

balance, call for professional garage door

service.

pulleys, brackets and their hardware, are

under extreme tension and can cause serious

injury or death.

adjust them yourself!

Ropes left on a garage door could cause

someone to become entangled and killed.

Remove all ropes connected to the door before

installing and operating the opener.

Identify the type and height of your door and any

special conditions that exist and any additional

materials that may be required by referring to the lists

on page 4 or page 5.

Garage doors, door springs, cables,

Do not try to loosen, move or

Claw Hammer

Pliers

Screwdriver

Adjustable End Wrench

CAUTION

To avoid damage to the garage door and

opener, disable locks before installing and

operating the opener. Use a wood screw or nail

to hold locks in the "open" (unlocked)

position.

Operation at other than 120V 60 Hz will cause

opener malfunction and damage.

Before you begin, complete the following test to

make sure your door is balanced, and is not

sticking or binding:

• Lift the door about halfway as shown. Release the

door. It should stay in place, supported entirely by

its springs.

• Raise and lower the door to see if there is any

binding or sticking.

SECTIONAL DOOR

ONE-PIECE DOOR

3

Page 4

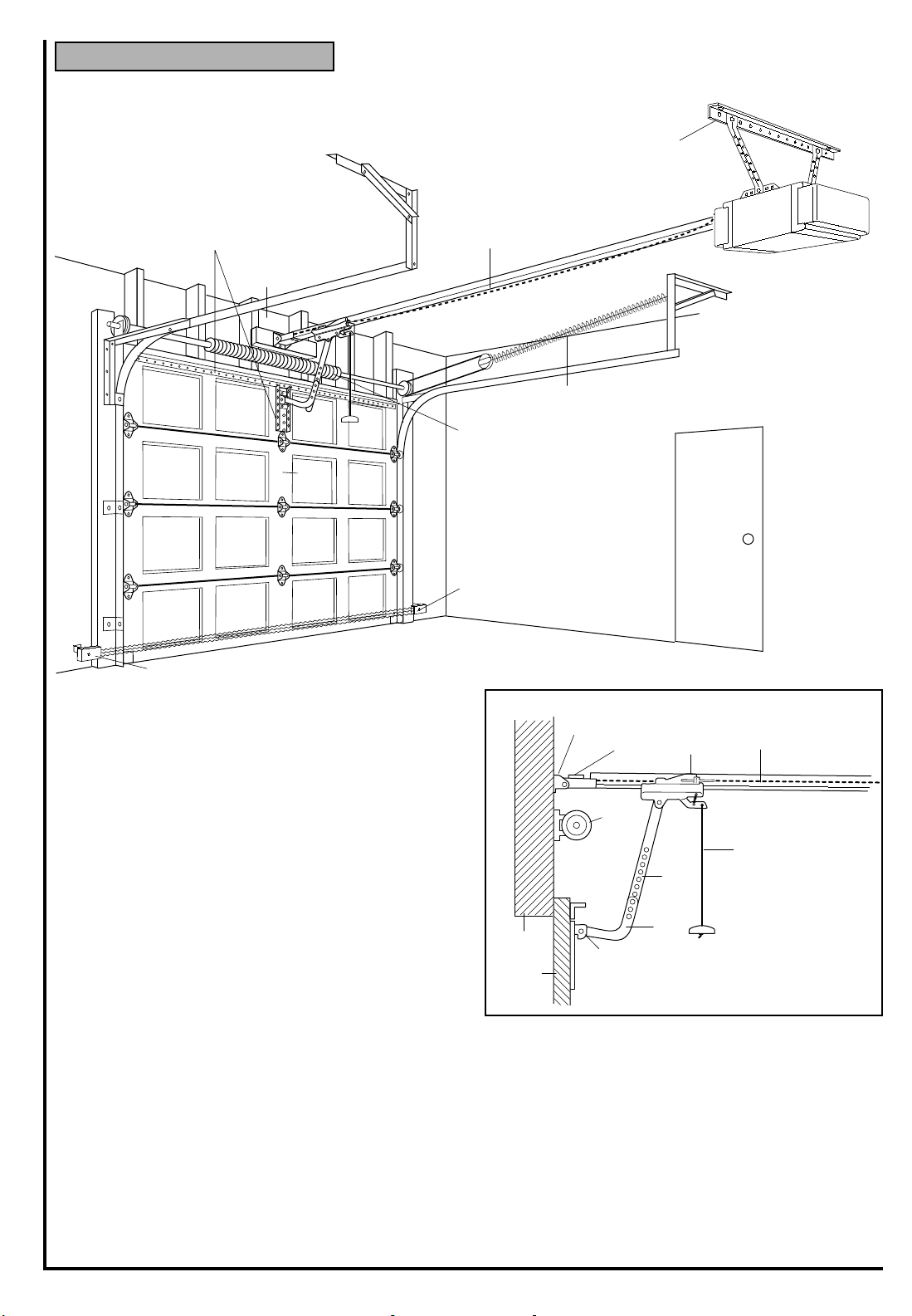

Sectional Door Installation

Before you begin, survey your garage area to see whether any of the conditions below apply to your installation.

FINISHED CEILING

Support bracket &

fastening hardware

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, steel, aluminum,

door with glass panels, etc.).

See page 20 for details.

Header Wall

— — — — — — — —

Door

Center

Slack in chain tension

is normal when

garage door is closed.

Extension Spring

OR

Torsion Spring

is required.

See page 13.

Access Door

Floor must be level

Safety

Reversing

Sensor

across width of door

Based on your particular requirements, there are

several installation steps which might call for

materials and/or hardware not included in the

carton.

• Step 1, page 12 - Look at the wall or ceiling above

the garage door. The header bracket

must

be

securely fastened to structural supports.

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket and

additional fastening hardware may be required.

• Safety reversing sensor, page 21 - Depending

upon garage construction, wood blocks may need

to be fastened to mounting locations before

sensors are installed.

• Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware not

provided.

• Step 11, page 24 - Do you have a steel, aluminum,

fiberglass or glass panel door? If so, horizontal

and vertical reinforcement is required.

• Look at the garage door where it meets the floor. It

must close on the floor all the way across. Otherwise, the safety reverse system may not work

properly. See page 30. Floor or door should be

repaired.

• If your door is more than 7 feet high, see longer

rails available on page 38.

Safety

Reversing

Sensor

Closed Position

Trolley

Straight

Door

Arm

Curved

Door

Arm

Rope & Handle

Chain

Manual

Release

Header

Wall

Garage

Door

Header

Bracket

Garage

Door Bracket

Chain

Pulley

Bracket

Door

Spring

• The opener can be installed within 2 feet to the left

or right of the door center if there is a torsion spring

or center bearing plate in the way of the header

bracket or door bracket area. If your door has

extension springs, the opener

must

be installed

in the center of the door. See pages 12 and 24.

• Do you have an access door in addition to the

garage door? If not, Model 1702 Outside Quick

Release is required. See page 38.

You may find it helpful to refer back to this page as

you proceed with the installation of your opener.

4

Page 5

One-Piece Door Installation

Before you begin, survey your garage area to

see whether any of the conditions below

apply to your installation.

Slack in chain tension

is normal when

garage door is closed.

Header

Wall

One-Piece Door without Track

FINISHED CEILING

Support bracket

& fastening

hardware is required.

See page 17.

Access Door

Safety Reversing Sensor

Gap between floor and bottom of

Safety

Reversing

Sensor

door must not exceed 1/4".

Based on your particular requirements, there are

several installation steps which might call for

materials and/or hardware not included in the carton.

• Step 1, page 12 - Look at the wall or ceiling above

the garage door. The header bracket

must

be

securely fastened to structural supports.

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket and additional

fastening hardware (not supplied) may be required

• Safety reversing sensor, page 21 - Depending on

garage construction, wood blocks may need to be

securely fastened to mounting locations before

sensors are installed.

• Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware that is

not provided.

• Step 11, page 25 - Generally, a one-piece door

does not require reinforcement. If your door is

lightweight, you can refer to the information relating

to sectional doors on page 24.

• Step 11, page 25 - Depending on your door's

construction, you might need additional mounting

hardware for the door bracket.

• Do you have an access door in addition to the

garage door? If not, Model 1702 Outside Quick

Release is required. See page 38.

• The gap between the bottom of the garage door and

the floor cannot exceed 1/4". Otherwise, the safety

reverse system may not work properly. See

page 30. The floor or the door should be repaired.

Closed Position

Chain

Header

Wall

Pulley Bracket

Header

Bracket

Door

Bracket

Garage

Door

T-rail

Straight

Door

Arm

Curved

Door

Arm

Trolley

Rope & Handle

Manual

Release

One-Piece Door with Track

Slack in Chain Tension

is Normal When

Garage Door is Closed

Access

Door

Safety

Safety

Reversing

Sensor

Floor must be level

across width of door

Closed Position

Header

Wall

Door

Chain

Pulley

Bracket

Header

Bracket

Door

Bracket

Chain

Curved

Door Arm

Straight

Door Arm

You may find it helpful to refer back to this page as

you proceed with the installation of your opener.

Reversing

Sensor

Trolley

T-rail

Manual Release

Rope & Handle

5

Page 6

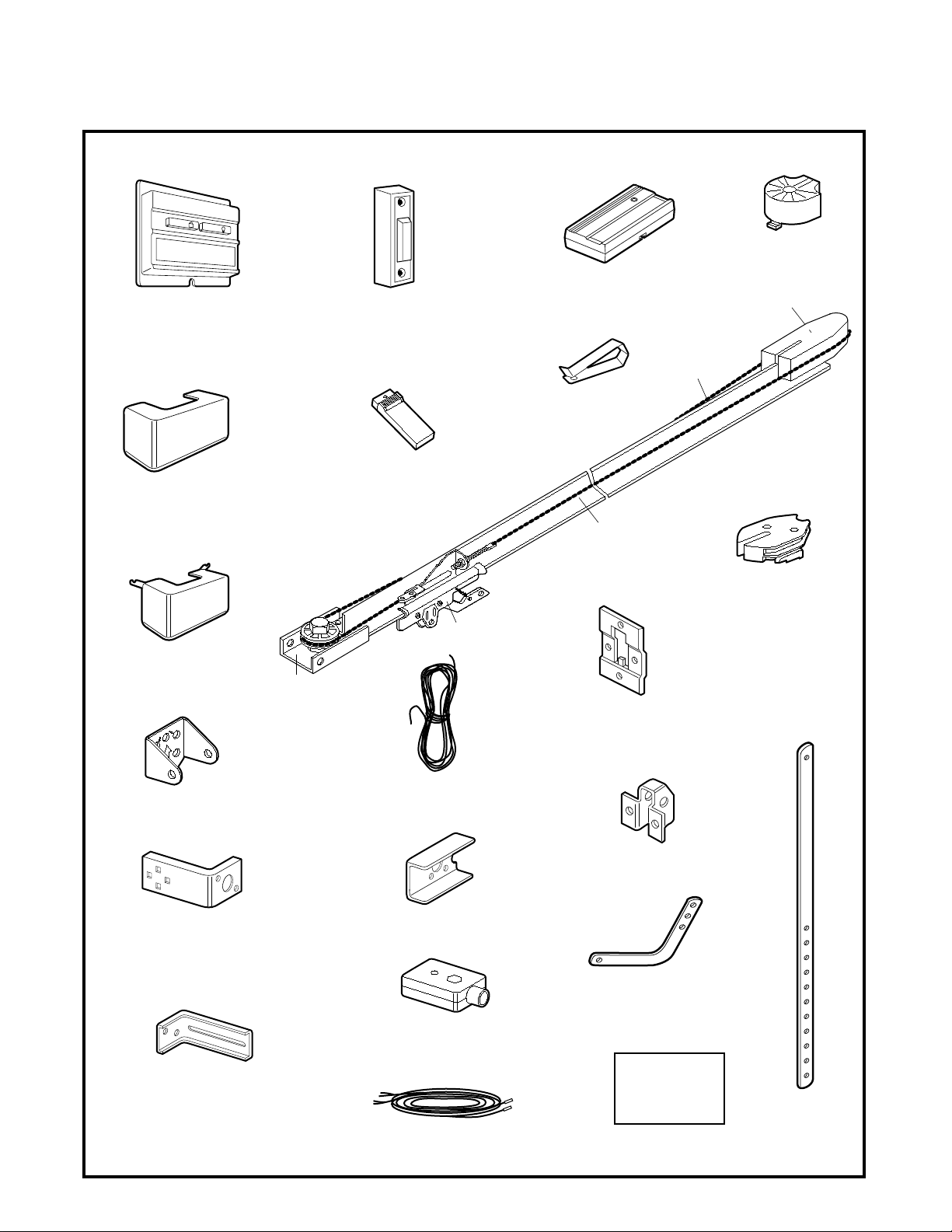

Opener Carton Inventory

Your garage door opener is packaged in two cartons which contain all parts illustrated below. If anything is

missing, carefully check the packing material. Parts may be "stuck" in the foam. Hardware for installation is

shown on page 7.

(Models 1260, 1260-266,

1260-166, 1250 &1250-266)

LOCK

LIGHT

Multi-Function Door

Control Panel

(Models 1260, 1260-266,

1260-166, 1250 & 1250-266)

Light Lens (2)

(Models 1256, 1255, 1255-266,

1255-166, 1246, 1245, & 1245-266)

Light Lens (1)

(Models 1256, 1255, 1255-266,

1255-166, 1246, 1245, 1245-266, & 1240)

Lighted Door Control Button

w/6ABx1-1/2" screws

(Models 1260-266, 1260-166, 1255-266,

1255-166, 1250-266 & 1245-266 only)

Keyless Entry

Trolley

(Models 1260-266 &

1255-266 (2)

All Other Models (1))

Remote Control

Transmitter

with 12V battery

Remote Control

Transmitter Visor Clip

One-Piece

T-rail

(All Models except

1256 & 1246)

Sprocket Cover

Styrofoam

Chain

(Models 1256 & 1246 only)

Chain Spreader with

Screws and Washers

CEILING MOUNT ONLY

UP

Header Bracket

Safety Reversing Sensor

Mounting Bracket

With Square Holes (2)

Safety Reversing Sensor

Mounting Bracket

With Slot (2)

Chain

Pulley Bracket

2-Conductor Bell Wire

White & White/Red

"C" Wrap (2)

Safety Reversing Sensor (2)

(1) Sending Eye

(1) Receiving Eye

2 Conductor Bell Wire with Connector

White & White/Black (2 rolls)

Door Bracket Plate

Door Bracket

Curved Door

Arm Section

Safety Labels

Literature

and

Straight Door

Arm Section

6

Page 7

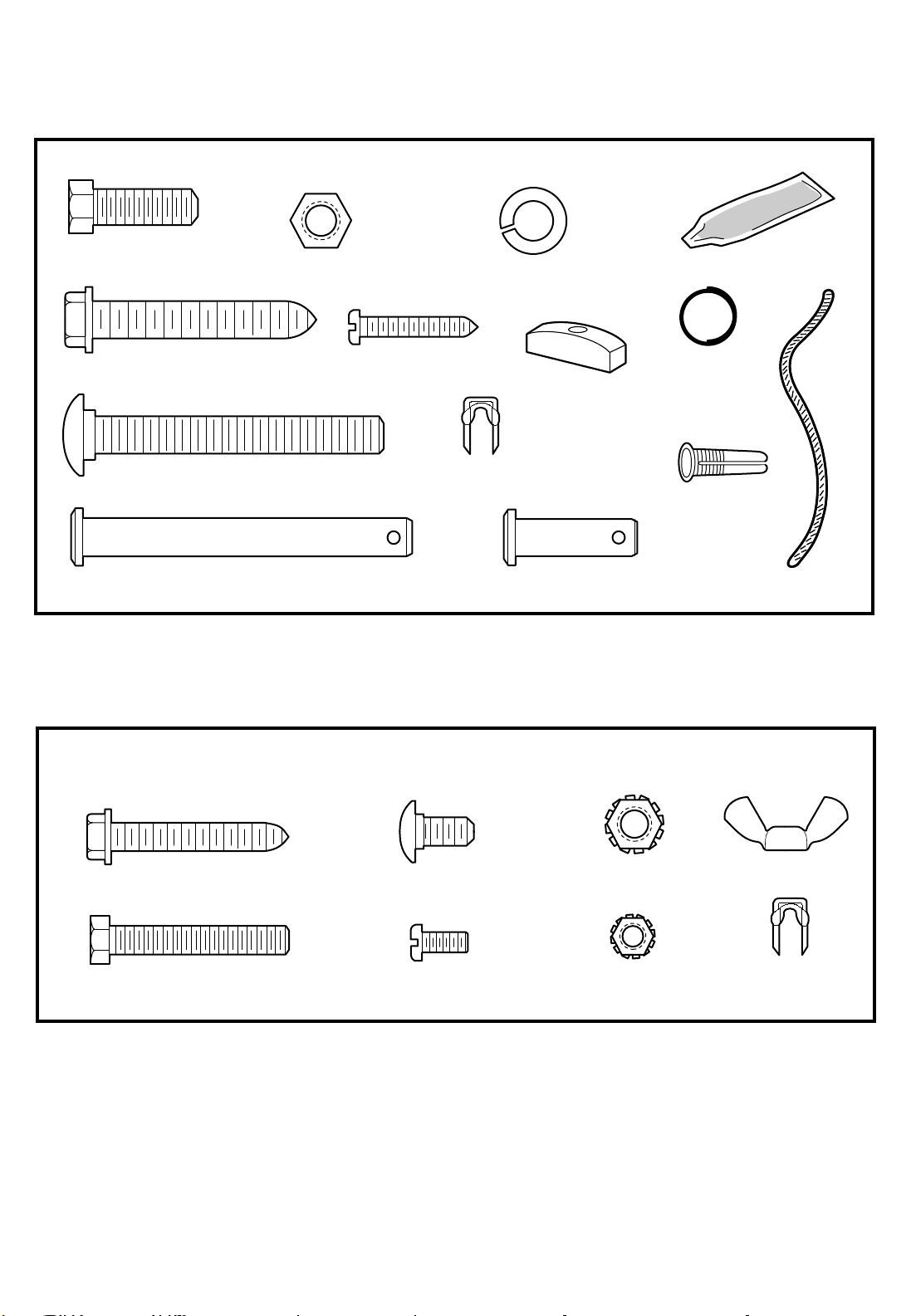

Group all hardware found in all packages contained in the opener carton into the two

kits illustrated below.

Installation Hardware Kit # 41A2770

RAIL GREASE

NO. 83A4

Hex Screw

5/16"-18x7/8" (4)

Nut 5/16"-18 (6)

Lock Washer 5/16" (6)

Rail Grease

Lag Screw

5/16"-18 x1-7/8" (4)

Carriage Bolt

5/16"-18x2-1/2" (2)

Clevis Pin

5/16"x2-3/4" (1)

Screw

6ABx1" (2)

Insulated Staples (10)

Handle

Clevis Pin

5/16"x1" (2)

Safety Reversing Sensor

Installation Hardware Kit #41A4116

NOTICE

Ring Fastener (3)

Dry Wall Anchors (2)

Rope

Lag Screw

1/4x1-1/2" (4)

Hex Screw

1/4-20x1-1/2" (2)

Carriage Bolts

1/4"-20x1/2" (4)

Screw

#10-32 x3/8" (4)

7

Lock Nut

1/4"-20 (4)

Lock Nut

#10x32 (4)

Wing Nut (2)

Insulated

Staples (20)

Page 8

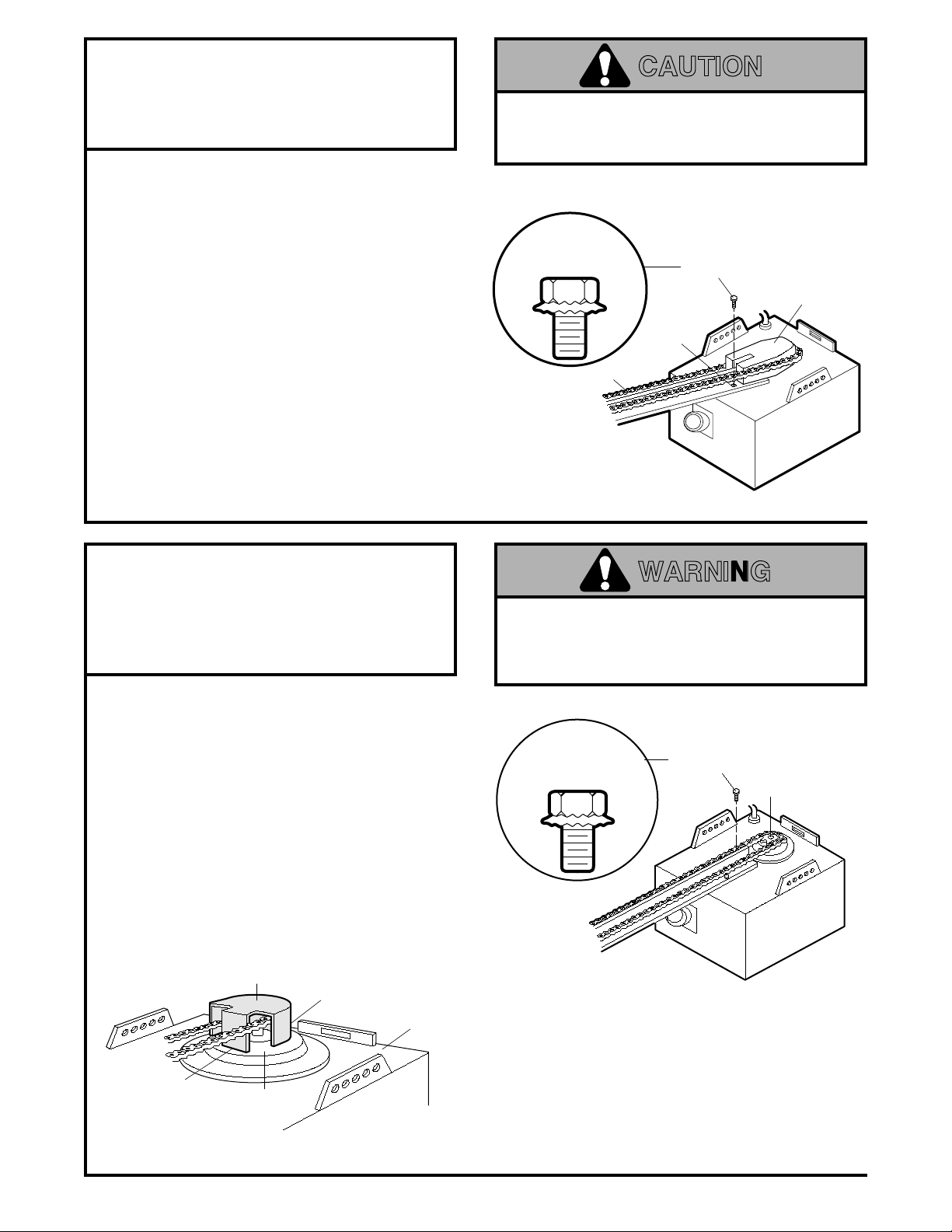

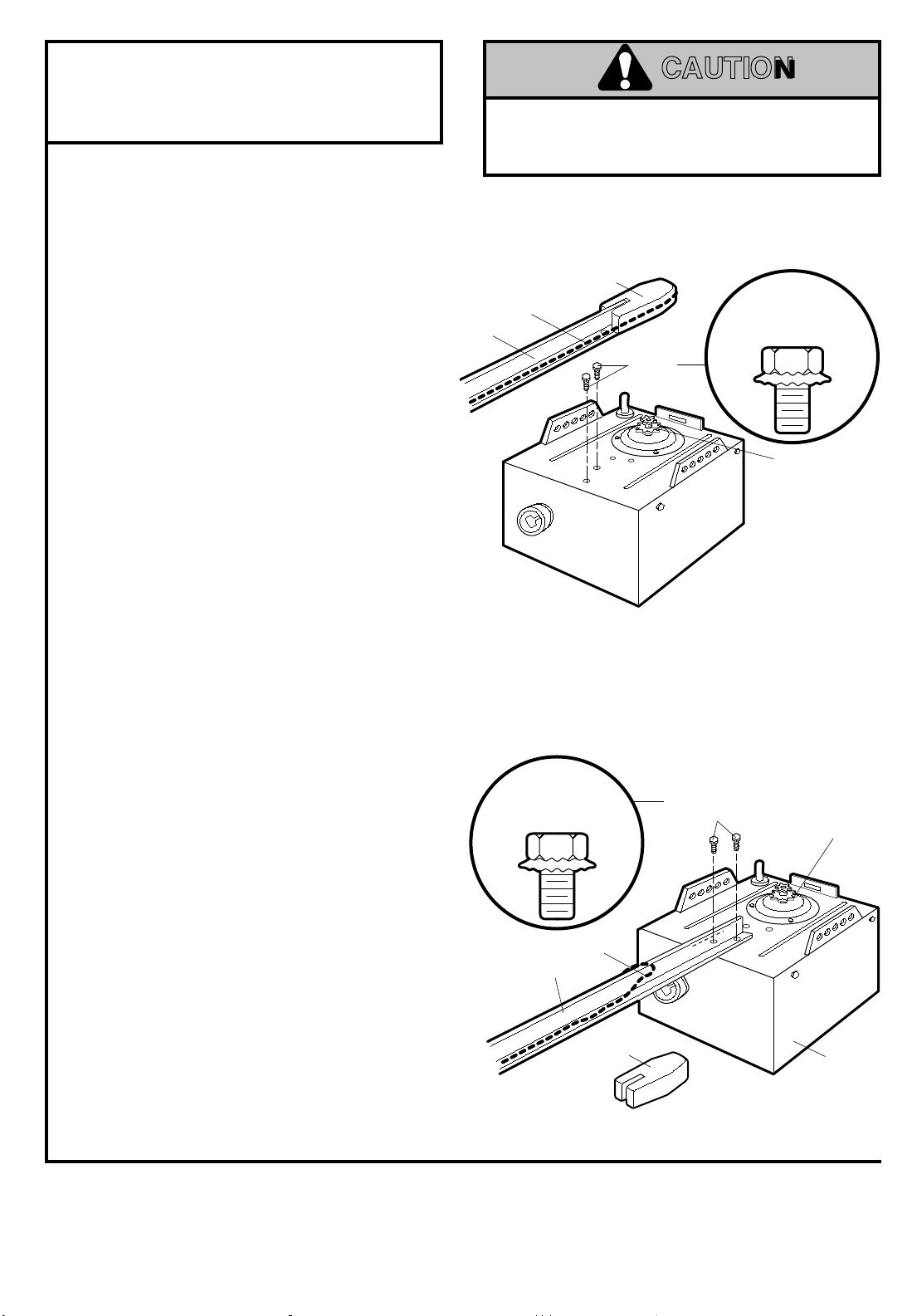

Assembly Step 1

Attach the T-rail to the Opener

For Models 1260, 1260-266, 1255,1255-266,

1250, 1250-266, 1245, 1245-266 and 1240

See page 9 for Models 1256 and 1246.

• Remove the two washered screws mounted in top

of opener

• Align T-rail at an angle with opener so one hole in

T-rail and opener line up.

• Thread one of the washered screws part way in.

Use only these screws!

will cause serious damage to door opener.

• Align T-rail and styrofoam over opener sprocket.

Cut tape from T-rail, chain and styrofoam.

• REMOVE STYROFOAM.

Use of any other screws

CAUTION

To fasten rail, use only those screws mounted

in top of the opener. Any other screws will

cause serious damage to the opener.

USE ONLY THIS

TYPE AND SIZE

SCREW

Chain

Washered Screw

5/16"-18x1/2"

Styrofoam

T-rail

Hole

Assembly Step 2

Attach Chain to Sprocket and Install Sprocket Cover

For Models 1260, 1260-266, 1255,1255-266,

1250, 1250-266, 1245, 1245-266 and 1240

• Position chain over the opener sprocket. If

necessary, loosen the outer nut on the trolley to

obtain more chain slack.

• Insert the second washered screw.

CAUTION: Use only the screw previously

removed from opener!

• Tighten both screws securely through the T-rail

into the opener as shown.

Install the sprocket cover:

• Insert the back tab in the opener slot. Squeeze the

cover slightly and insert the front tab in the slot on

the mounting plate.

Sprocket

Cover

Back Tab Slot

Top of Opener

WARNING

Serious injury can result if fingers become

entangled in moving opener sprocket. Attach

sprocket cover securely. Never operate opener

while your hand is near the opener sprocket.

USE ONLY THIS

TYPE AND SIZE

SCREW

Washered Screw

5/16"-18x1/2"

Opener

Sprocket

Front Tab Slot

Mounting

Plate

Proceed to Assembly Step 3, page 11.

8

Page 9

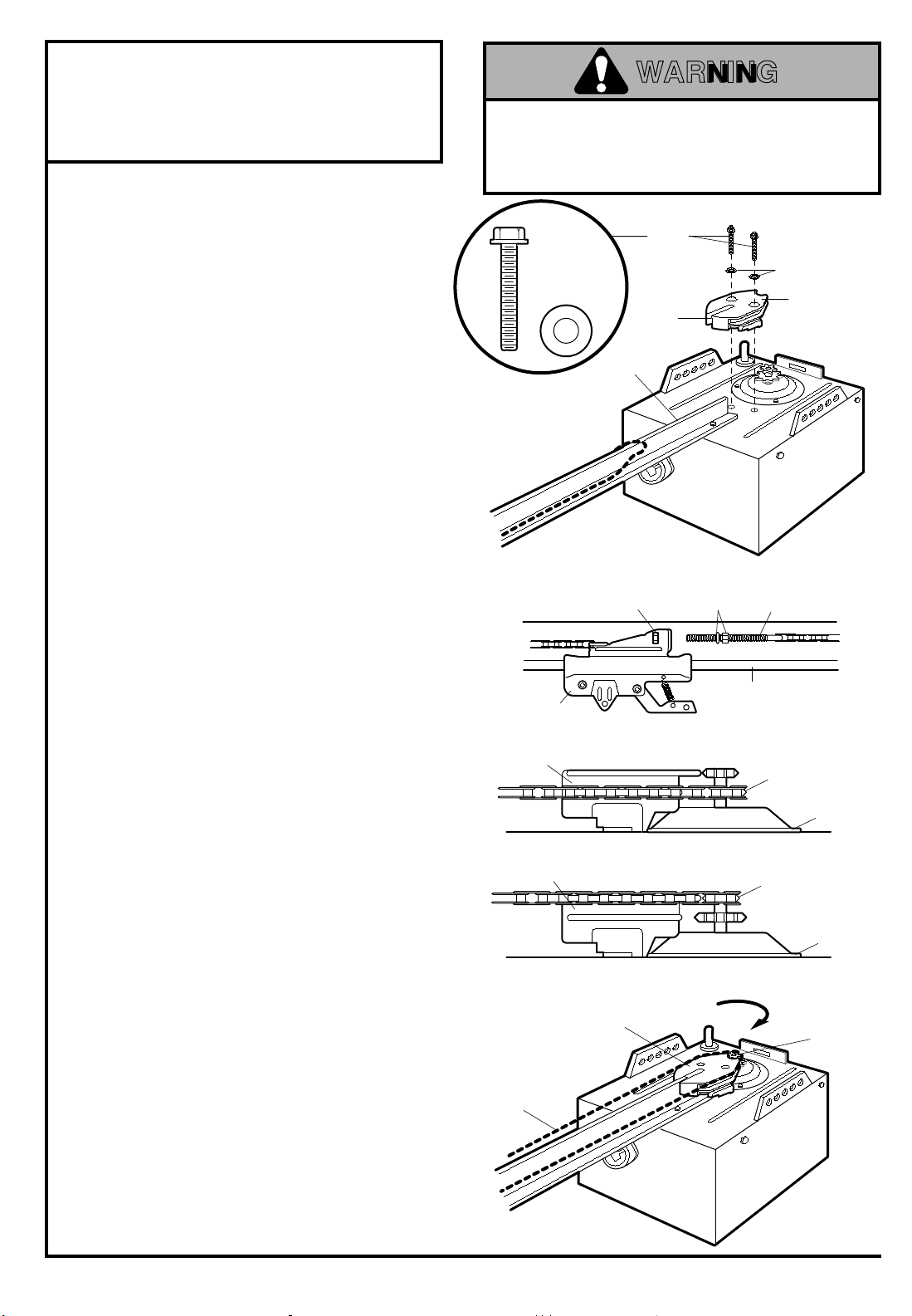

Assembly Step 1

Attach the T-rail to the Opener

For Models 1256 and 1246 only

CAUTION

To fasten rail, use only those screws mounted

in the top of the opener. Any other screws will

cause serious damage to the opener.

• Place the opener on packing material to protect

the cover.

• Remove the (2) 5/16"-18x1/2" washered screws

mounted in the top of the opener.

• Align T-rail and styrofoam over opener sprocket.

T-rail

Chain

Styrofoam

Packaging

USE ONLY THIS

TYPE AND SIZE

SCREW

Washered

Screws

5/16"-18x1/2"

Opener

Sprocket

• Cut tape from T-rail, chain and styrofoam.

Remove styrofoam and pull the chain back

(away from mounting plate)

• Fasten the rail with the (2) washered screws

previously removed. Tighten securely.

Remember to use only these screws!

Any other

screws will cause serious damage to the opener.

USE ONLY THIS

TYPE AND SIZE

SCREW

Chain

T-rail

Styrofoam

Packaging

Washered Screws

5/16"-18x1/2"

Mounting

Plate

Opener

Chassis

9

Page 10

Assembly Step 2

Attach the Chain Spreader

and Re-install the Chain

For Models 1256 and 1246 only

WARNING

Serious injury can result if fingers become

entangled in moving opener sprocket. Attach

sprocket cover securely. Never operate opener

while your hand is near the opener sprocket.

• Line up the holes in the chain spreader with the

holes in the opener as shown. The slot in the chain

spreader must fit over the T-rail flange.

• Securely fasten the chain spreader with the

hardware provided.

• Remove the trolley threaded shaft from the trolley

by loosening the inner nut and lock washer.

USE ONLY

THIS TYPE

AND SIZE

SCREW

Trolley

Hex Screw

T-rail

Flange

Outer

Nut

#8x1"

Slot

and Washer

Inner Nut

Washers

Chain

Spreader

Trolley

Threaded

Shaft

T-rail

• Guide the chain around the selected groove in the

chain spreader (to engage either the

8-tooth sprocket or the 6-tooth sprocket) as shown.

• Continue dispensing the chain forward to the

trolley. Reconnect the trolley to the trolley threaded

shaft. Proceed to page 11 for chain tightening

instructions.

Spreader

Chain

Chain

Chain

Spreader

Chain

Spreader

8-Tooth

Sprocket

Opener

Mounting Plate

6-Tooth

Sprocket

Opener

Mounting Plate

Install Chain

In This Direction

Opener

Sprocket

10

Page 11

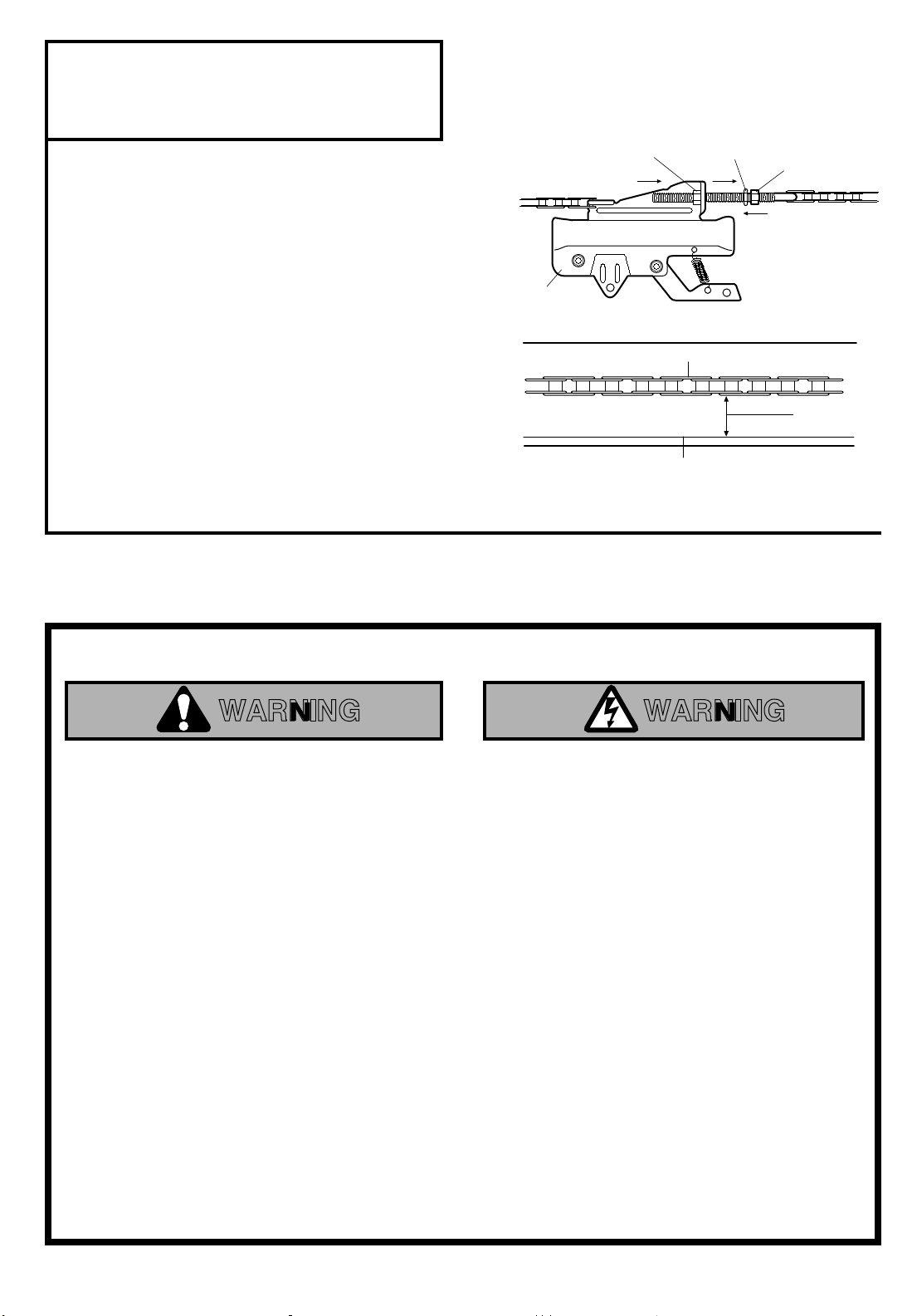

Assembly Step 3

Tighten the Chain

(All Models)

• Spin the inner nut and lock washer down the

threaded shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction

shown. As you turn the nut, keep the chain

from twisting.

• When the chain is approximately 1/2" above the

base of the T-rail at its midpoint, re-tighten the

inner nut to secure the adjustment.

Sprocket noise can result if chain is either too

loose or too tight.

When installation is complete, you may notice some

chain droop with the door closed. This is normal. If

the chain returns to the position shown when the

door is open,

NOTE: During future maintenance,

pull the manual release handle to disconnect

trolley before adjusting chain.

do not re-adjust the chain.

ALWAYS

Outer Nut

To Tighten Outer Nut

Trolley

Chain

Base of T-rail

Lock

Washer

Inner Nut

To Tighten

Inner Nut

1/2"

You have now finished assembling your garage door opener. Please read the following

warnings before proceeding to the installation section.

IMPORTANT INSTALLATION INSTRUCTIONS

WARNING

WARNING

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS

2. Install only on a properly balanced and lubricated garage door.

could result in severe injury or death.

must be made by a professional service person before installing opener.

3. Disable all locks and remove all ropes connected to the garage door before installing the opener.

Repairs to cables, spring assemblies and other hardware

Ropes connected to a garage door can cause entanglement and death.

4. If possible, install door opener 7 feet or more above floor with the manual release handle

mounted 6 feet above the floor.

5. Do not connect the opener to power source until instructed to do so.

6. Locate the Door Control within sight of the door at a minimum height of 5 feet where small

children cannot reach and away from all moving parts of the door.

An improperly balanced door

7. Install the User Safety Instruction Label on the wall adjacent to the control button and the

Maintenance Instruction Label in a prominent location on the inside of the garage door.

8. Upon completion of the installation, the door must reverse when it comes in contact with a

one-inch high object (or a 2x4 laid flat) on the floor.

9. Do not wear watches, rings or loose clothing while installing or servicing an opener. Jewelry or

loose clothing can be caught in the mechanism of the garage door or the opener.

11

Page 12

Vertical

Guideline

Finished

Ceiling

Vertical

Guideline

Header

Wall

2x4

Structural

Supports

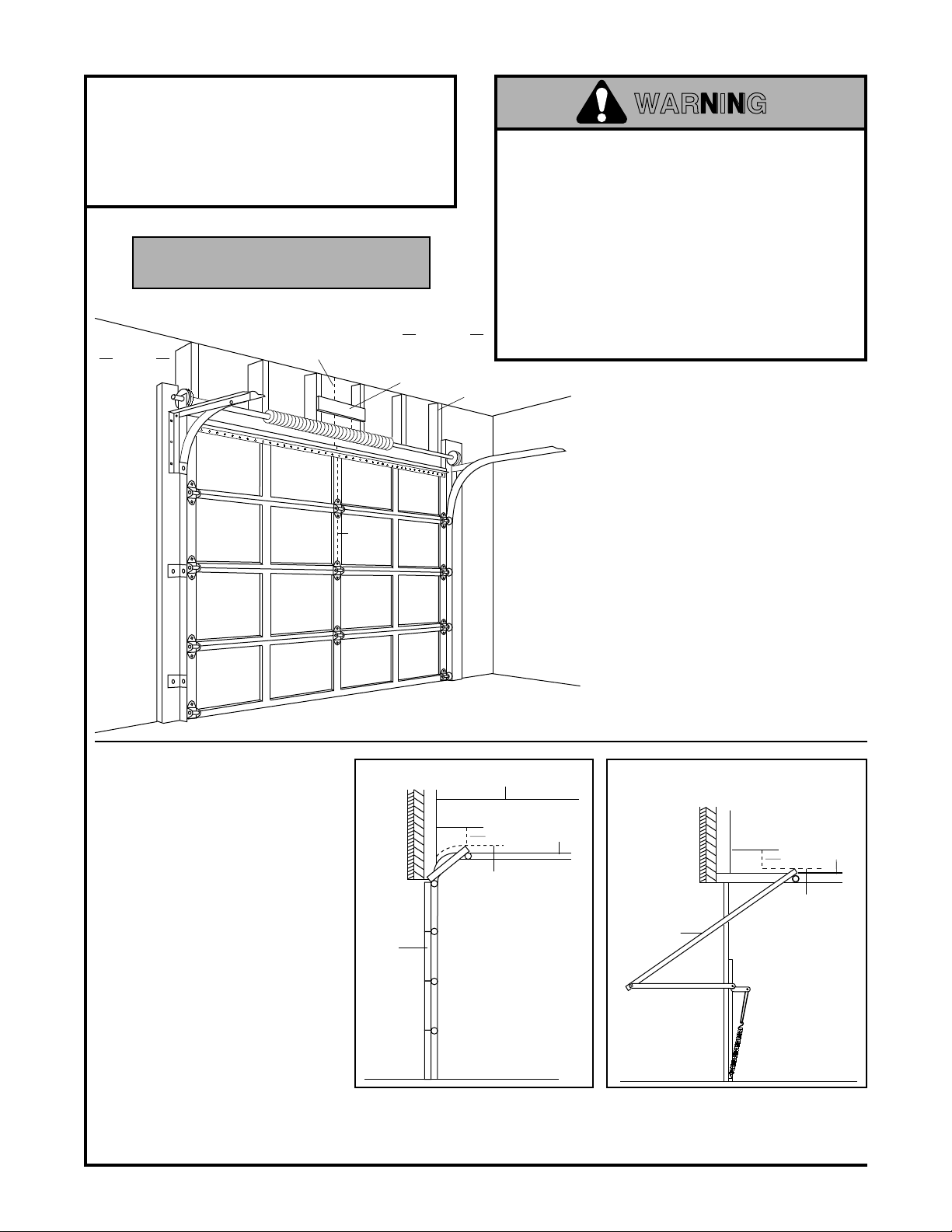

Installation Section: Pages 12 – 27

Installation Step 1

Determine Header Bracket Location

Installation procedures vary according to garage

door types. Follow the instructions which apply to

your door.

SECTIONAL Doors and

ONE-PIECE Door With Track

WARNING

If the header bracket is not rigidly fastened to

a structural support on the header wall or

ceiling, the safety reverse system may not

work properly (see page 30).

not reverse when required, and could cause

serious injury or death.

The garage door springs, cables, pulleys,

brackets and their hardware are under extreme

tension.

Do not attempt to loosen, move or

adjust them yourself. Serious personal injury

or death could result.

service.

• Close the door and mark the inside

vertical centerline of the garage door.

• Extend the line onto the header wall

above the door.

Remember, you can fasten the

header bracket within 2 feet to the

left or right of the door center

a torsion spring or center bearing

plate is in the way; or you can attach

it to the ceiling (refer to page 14)

when clearance is minimal.

If you need to install the header bracket

on a 2x4 (on wall or ceiling), use lag

screws (not supplied) to securely fasten

the 2x4 to structural supports as shown

here and on page 13.

The door might

Call for garage door

only

if

• Open your door to the highest

point of travel as shown. Draw

an intersecting horizontal line

on the header wall 2" above

the high point. This height will

provide travel clearance for the

top edge of the door.

Proceed to Step 2, page 14.

Door

Sectional door with

curved track

12

Ceiling

Header

Wall

2"

Highest Point

of Travel

Track

Header

Wall

Highest Point

Door

One-piece door with

horizontal track

2"

of Travel

Track

Page 13

ONE-PIECE Door Without Track

Read the Safety Instructions on page 12. They also apply to doors without tracks.

• Close the door and mark the

inside vertical centerline of

your garage door. Extend the

line onto the header wall

above door.

If headroom clearance is

minimal, you can install the

header bracket on the ceiling.

See page 14.

•

If you need to install the

header bracket on a 2x4 (on

wall or ceiling), use lag screws

(not supplied) to securely

fasten the 2x4 to structural

supports as shown.

Header Wall

Highest Point

of Travel

Header Wall

Vertical

Centerline

2x4

Vertical

Centerline of

Garage Door

Unfinished

Ceiling

2x4

OPTIONAL CEILING MOUNT

FOR HEADER BRACKET

Wall

Highest Point

of Travel

Header

Structural

Supports

Door

Jamb

Hardware

Distance

One-piece door without track

jamb hardware

• Open your door to the highest point of travel as

shown. Measure the distance from the top of the

door to the floor. Subtract the actual height of the

door. Add 8" to the remainder. (See Example).

• Close the door and draw an intersecting horizontal

line on the header wall at the determined height.

If the total number of inches exceeds the height

available in your garage, use the maximum

height possible, or refer to page 14 for ceiling

installation.

Door

Distance

Pivot

One-piece door without track

pivot hardware

EXAMPLE

Distance from top of door

(at highest point of travel) to floor...........................92"

Actual height of door ...........................................– 88"

Remainder................................................................4"

Add........................................................................+ 8"

Bracket height on header wall.............................= 12"

(Measure UP from top of CLOSED door.)

Proceed to Step 2, page 14.

13

Page 14

Installation Step 2

Install the Header Bracket

You can attach the header bracket either to the

wall above the garage door, or to the ceiling.

Follow the instructions which will work best for

your particular requirements.

Fasten the Header Bracket to the Wall

• Center the bracket on the vertical guideline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward

the ceiling).

Vertical

Header

2x4

Structural

Support

Highest

Point of Travel

(of Garage Door)

Wall

CEILING MOUNT ONLY

UP

Header

Bracket

2"

Center

Line

Garage

Vertical

Center

Line

Door

5/16"x18x1-7/8"

Door

Spring

• Mark either set of bracket holes (do not use the

holes designated for ceiling mount). Drill 3/16" pilot

holes and fasten the bracket securely to a structural

support with the hardware provided.

Wall

Mounting Holes

Lag Screws

CEILING MOUNT ONLY

UP

The nail hole is for positioning

only. You must use lag screws to

mount the header bracket.

Optional

Wall Mounting

Holes

Hardware Shown Actual Size

Lag Screw

5/16"-18x1-7/8"

Fasten the Header Bracket to the Ceiling

• Extend the vertical guideline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more

than 6" from the wall. Make sure the arrow is

pointing toward the wall. The bracket can be

mounted flush against the ceiling when clearance is

minimal.

• Mark holes designated for ceiling mount only. Drill

3/16" pilot holes and fasten bracket securely to a

structural support with the hardware provided.

Ceiling Mounting Holes

CEILING MOUNT ONLY

UP

The nail hole is for positioning only.

You must use lag screws to mount

the header bracket.

Door

Spring

6" Maximum

Garage

Door

Header

Bracket

Finished

Ceiling

Vertical

Center Line

UP

Lag Screws

5/16"x18x1-7/8"

Header

Wall

Vertical

Center Line

14

Page 15

Installation Step 3

Attach the T-rail to the Header Bracket

Header Wall

Header

Bracket

Chain

Pulley

Bracket

• Position the opener on the garage floor below the

header bracket. Use packing material as a

protective base.

If the door spring is in the way you'll need help.

Have someone hold the opener securely on a

temporary support to allow the T-rail to clear the

spring.

• Position the chain pulley bracket against the header

bracket.

• Align the bracket holes and join with a clevis pin as

shown.

• Insert a ring fastener to secure.

Garage

Door

T-rail

Clevis Pin

5/16"x2-3/4 "

INCREASE TRAVEL

DOWN

UP

Ring Fastener

Header Bracket

Chain

Pulley

Bracket

T-rail

Temporary

Support

Hardware Shown Actual Size

Clevis Pin

5/16"x2-3/4"

15

Ring Fastener

Page 16

Installation Step 4

Position the Opener

Follow instructions which apply to your door type

as illustrated.

SECTIONAL Door & ONE-PIECE Door with Track

A 2x4 laid flat is convenient for setting an ideal

door-to-T-rail distance.

• Raise the opener onto a stepladder.

You will need help at this point if the ladder is

not tall enough.

• Open the door all the way and place a 2x4 laid flat

on the top section beneath the T-rail.

•

If the top panel hits the trolley when you raise

the door, pull down on the trolley release arm

to disconnect inner and outer sections. The

trolley can remain disconnected until Step 12

is completed.

CAUTION

To prevent damage to steel, aluminum,

fiberglass or glass panel doors, do not rest the

opener on the door without using a 2x4.

T-rail

Door

2x4

Stepladder

Trolley

Release Arm

Trolley

ONE-PIECE Door without Track

• With the door fully open and parallel to the floor,

measure the distance from the floor to the top of

the door.

• Using a stepladder as a support, raise the opener

to the same distance as the door from the floor (it

will be at a slight angle as shown).

• The top of the door should be level with the top of

the opener. Do not position the opener more than

2" above this point.

Header

Bracket

Top of Opener

Top of Door

Stepladder

16

Page 17

Installation Step 5

Hang the Opener

Two representative installations are shown.

Yours may be different. Hanging brackets should

be angled, Figure 1, to provide rigid support. On

finished ceilings, Figure 2, attach a sturdy metal

bracket to structural supports before installing the

opener. The bracket and fastening hardware are not

supplied.

• Measure the distance from

to the structural support.

• Cut both pieces of the hanging bracket to required

lengths.

• Drill 3/16" pilot holes in the structural supports.

• Attach one end of each bracket to a support with

5/16"x1-7/8" lag screws.

• Fasten the opener to the hanging brackets with

5/16"-18x7/8" hex screws, lock washers and nuts.

• Check to make sure the T-rail is centered over the

door (or in line with the header bracket if the

bracket is not centered above the door).

• Remove the 2x4. Operate the door manually. If the

door hits the rail, raise the header bracket.

each

side of the opener

WARNING

The opener could fall and injure someone if it is

not properly secured.

securely to structural supports of the garage.

Figure 1

Measure

Distance

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

Fasten the opener

Structural

Supports

Lag Screws

5/16"x1-7/8"

RAIL GREASE

NO. 83A4

Grease the top and underside of the rail

surface where the trolley slides. A tube of

grease is supplied.

Rail Grease

Hardware Shown Actual Size

Lag Screw

5/16"-18x1-7/8"

Figure 2

Bracket

(Not Supplied)

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

Hidden

Support

— FINISHED CEILING —

Lag Screws

5/16"x1-7/8"

(Not Supplied)

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

Hex Screw

5/16"- 18x7/8"

Nut 5/16"-18

Lock Washer 5/16"

17

Page 18

Installation Step 6

2-Conductor

Bell Wire

Lighted

Door

Control

Terminal

Screws

2-Conductor

Bell Wire

WHT

2

RED

1

Door Control

Push Bar

LIGHT

LOCK

WHITE

Multi-Function

Door Control Panel

RED

Light Button

Lock Button

Multi-Function

Door Control Panel

Terminal Screws

2-Conductor

Bell Wire

Lighted

Door Control

Button

1

2

Opener

Terminal

Screws

Antenna

Back Panel

of Opener

KG

KG

1

3

9

7

5

1

3

9

7

5

2 3

1

Install the Door Control

• Strip 1/4" of insulation from one end of the bell

wire; connect the wire to the two screw terminals

on the back of the door control by color: white to 2

and white/red to 1.

• Locate the door control within sight of the door

at a minimum height of 5 feet where small

children cannot reach, and away from all

moving parts of the door and door hardware.

Fasten the Lighted Door Control Button securely

with 6ABx1-1/2" screws. The Multi-Function Door

Control Panel uses 6ABx1" screws. If installing

into drywall, drill 5/32" holes and use the anchors

provided.

• Run the bell wire up the wall and across the ceiling

to the opener. Use insulated staples to secure the

wire in several places. Be careful not to pierce the

wire with a staple, thereby resulting in a short.

• Receiver terminals screws and the antenna are

located on the back panel of the opener. Position

the antenna wire as shown.

• Then connect the bell wire to the opener terminal

screws: white to 2 and white/red to 1.

• Remember to affix the User Safety Instruction

label to the wall near the Door Control, and the

Maintenance Instruction label in a prominent

location on the inside of the garage door.

Page 32 explains how to operate the opener using

the Door Controls and the Lock and Light features

available on the Multi-Function Door Control Panel.

If the label adhesive will not adhere to your garage

wall surface (or becomes loose with time) use tacks

to secure the label alongside the control button.

Hardware Shown Actual Size

WARNING

Children operating or playing with a garage

door opener can injure themselves or others.

The garage door could close and cause

serious injury or death.

Install the Door Control (or any additional push

buttons) out of the reach of children and away

from all moving parts of the door and door

hardware,

Do not allow children to operate the push

button(s) or the remote control transmitter(s).

A moving garage door could injure someone

under it.

door is properly adjusted, you can see it clearly,

and there are no obstructions to door travel.

Do NOT connect the power and operate the

opener at this time.

full

open

close

connected and properly aligned.

See Safety Reversing Sensor instructions

beginning on page 21.

Outside Keylock Accessory Connections

To opener terminal screws: white to 2; white/red to 1

Models 1256, 1255,

1255-166, 1255-266,

1246, 1245, 1245-266

& 1240

but where the garage door is visible.

Activate the opener only when the

The trolley will travel to the

position but will not return to the

position until the sensor beam is

Models 1260, 1260-166,

1260-266, 1250 &

1250-266

6ABx1-1/2" Screw

Lighted Door Control Button

Multi-Function Door Control Panel

6ABx1" Screw

Insulated

Staples

Dry Wall Anchors

18

Page 19

Installation Step 7

Install the Light(s) and the Lens(es)

Install the light(s):

• Install a 75 watt maximum light bulb in each

socket. The light(s) will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the light(s) will turn OFF.

• If the bulbs burn out prematurely due to vibration,

replace with a standard-neck "Garage Door

Opener" bulb.

Install the lenses:

(Models 1260, 1260-266, 1260-166, 1250 and

1250-266 only)

• See Figure 1.

• Slide each lens into the guides. Snap bottom tabs

into lens slots.

• Reverse the procedure to remove the lenses

Figure 1

Figure 2

Lens

Guide

(Models 1250,

1250-266, 1260,

1260-266, &

1260-166 Only)

Lens

Tab

Lens

Slot

75 Watt Max.

Light Bulb

Install the lens:

(All other Models except 1240)

• See Figure 2.

• Locate and loosen (approximately 1/8") the two

screws near top of opener front panel. Position

lens against panel with slotted tabs directly below

screws. Slide lens up to seat tabs behind screws.

Snap bottom tabs of lens into panel slots.

Retighten top panel screws to secure lens.

Installation Step 8

Attach the Manual Release Rope and Handle

Overhand

Knot

Light

Lens

75 Watt Max.

Light Bulb

Lens Tab

Panel Screw

Lens Slot

WARNING

Do not use the red handle to pull the door

open or closed.

untied and you could fall.

release only to disengage the trolley and, if

possible, only when the door is closed.

Garage doors are heavy. If the door is open

when the handle is pulled, the door could

close inadvertently if it is not properly

balanced. Serious injury may result to persons

under the door. Make sure the doorway is clear

of persons and obstructions before pulling

handle when door is open.

The rope knot could become

Use the manual

Trolley

Rope

Overhand

Knot

NOTICE

Trolley

Release Arm

Manual

Release Handle

• Thread one end of the rope through the hole in the

top of the red handle so "NOTICE" reads right side

up as shown. Secure with an overhand knot.

The knot should be at least 1" from the end of the

rope to prevent slipping.

• Thread the other end of the rope through the hole in

the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet above the

floor. Secure with an overhand knot.

If it is necessary to cut the rope, heat seal the cut

end with a match or lighter to prevent unraveling.

19

Page 20

Installation Step 9

Electrical Requirements

To reduce the risk of electric shock, your garage

door opener has a grounding type plug with a third

grounding pin. This plug will

type outlet.

If the plug doesn't fit into the outlet you have,

contact a qualified electrician to install the

proper outlet.

only

fit into a grounding

WARNING

To prevent electrocution or fire,

and wiring must be in compliance with local

electrical and building codes.

installation

To avoid installation difficulties,

do not run the opener at this time.

Right Wrong

• Do not change the plug in any way.

• Do not use a 2-wire adapter.

• Do not use an extension cord.

If permanent wiring is required by your local code, refer to the following procedure:

WARNING

To prevent electrocution, remove power from

the garage door opener

you plan to use for the permanent

connection.

To make a permanent connection through the

7/8" diameter hole in the top of the opener

(according to local code):

• Remove the opener cover screws and set the

cover aside.

• Remove the attached 3-prong cord.

• Connect the black (line) wire to the screw on the

brass terminal; the white (neutral) wire to the

screw on the silver terminal; and the ground wire

to the green ground screw.

grounded.

• Reinstall the cover.

and

from the circuit

The opener must be

Ground Tab

Green

Ground

Screw

Ground Wire

Permanent wiring

connection

Black

Wire

To avoid installation difficulties,

do not run the opener at this time.

20

White Wire

Black

Wire

Page 21

Information you'll need before you begin the installation of the safety reversing sensor.

The safety reversing sensor

must

be connected

and aligned correctly before the garage door

opener will move in the down direction. This is a

required safety device and cannot be disabled.

Installation procedures are the same for sectional

and one-piece doors.

— Left Side of Garage —

WARNING

Without a properly working safety reversing

sensor, persons (particularly children) could

be injured or killed by a closing garage door.

Read and follow all instructions.

To protect small children, install the safety

reversing sensor so that the beam will be no

higher than 4"-6" above the garage floor.

Disconnect power to the garage door opener

before installing the safety reversing sensor.

— Right Side of Garage —

Sensor

Unit

Invisible Light Beam

Protection Area

Figure 1: Facing the door from inside the garage

Be sure power to the opener is disconnected.

The sending eye transmits an invisible light beam to

the receiving eye.The units can be installed on

either side of the garage door as long as the sun

never shines directly into the receiving eye lens.

Look at the label on the connector end of each case

to identify the sensors.

The brackets must be connected and fastened so

that the sending and receiving eyes face each other

as shown in Figure 1.

If an obstruction breaks the light beam while the

garage door is closing, the door will stop and

reverse to full open position; and the opener lights

will flash for 5 seconds.

Sensor

Unit

The brackets

must

be securely fastened to a solid

surface such as the studs on either side of the door,

or add a piece of wood at each location if installing in

masonry construction.

The invisible light beam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) can interrupt the

beam while the door is closing. If it does, use a piece

of wood to build out each sensor mounting location to

the minimum depth required for light beam clearance.

21

Page 22

Installation Step 10

Install the Safety Reversing Sensor (Receiving and Sending Eyes)

Figures 2 , 3 and 4 show recommended assembly

of bracket(s) and "C" wrap based on the

installation of the sensors on each side of the

garage door as shown on page 17, or on the

garage door tracks

For Garage Wall or Door Track

themselves.

Installation

• Fasten the "C" wraps to the mounting brackets

having square holes, using the hardware shown in

Figure 2.

For Door Track

Installation Only

• Discard slotted bracket. Drill 3/8" holes in each

track and fasten securely with hardware as shown

in Figure 3.

For Wall

Installation

• Connect each assembly to a slotted bracket, using

the hardware shown in Figure 4. Note alignment

of brackets for left and right sides of the door.

• Finger tighten the lock nuts.

• Use bracket mounting holes as a template to

locate and drill (2) 3/16" diameter pilot holes on

both sides of the garage door, 4"-6" above the

floor (but not exceeding 6"). (See warning on

page 21.)

• Attach bracket assemblies with 1/4"x1-1/2"

lag screws as shown in Figure 4.

• Adjust right and left side bracket assemblies to the

same distance out from mounting surface. Make

sure all door hardware obstructions are cleared.

Tighten the nuts securely.

wall

Figure 2

Garage WALL or DOOR TRACK Installation

#10-32

Lock Nuts

Figure 3

Garage

Door Track

Drill 3/8"

Holes

1/4"-20x1/2"

Carriage Bolts

Figure 4

Mounting Bracket

With Square Holes

"C" Wrap

Garage DOOR Track Installation

Inside

Garage

Wall

1/4"-20 Lock Nuts

Garage WALL Installation

1/4x1-1/2"

Lag Screws

Inside

Garage

Wall

Mounting Bracket

with Slot

1/4"-20

Lock Nuts

1/4-20x1/2" Carriage Bolts

Mounting Bracket

with Square Holes

#10-32x3/8"

Screws

Mounting Bracket

with Square Holes

"C" Wrap

(with square shoulder)

"C" Wrap

Figures 5 and 6 are variations which may fit your installation requirements better. Make sure the wraps and

brackets are aligned so the sensors will face each other across the garage door.

Figure 5

Alternate Wall Mount

Inside

Garage

Wall

Mounting Bracket

with Slot

Mounting Bracket

with Square Holes

"C" Wrap

Sensor

Indicator Light

Garage

Floor

Figure 6

Alternate Floor Mount

Inside

Garage

Wall

"C" Wrap

Indicator

Light

Sensor

Mounting Bracket

with Square Holes

Mounting Bracket

with Slot

Attach with

concrete anchors

(not provided)

Garage

Floor

Hardware Shown Actual Size

#10-32x3/8"

Screw

#10x32

Lock Nut

1/4x1-1/2"

Lag Screw

Staples

1/4"-20x1/2"

Carriage Bolts

1/4" - 20

Lock Nut

22

Page 23

• Insert the wire connector into each

sensor and push until you hear a

click, Figure 7. The white tab on the

sensor should be flush with the back

of the connector.

Safety Sensor

Figure 7

Tab should be

flush with back

of connector

Bell Wire

— Finished Ceiling —

Wire Connector

Bell Wire

White Tab

Push connector in

until you hear a click

Connect Wire to

Opener Terminals

Wall Control

Connections

(dotted line)

Sensor

Connections

1

OPENER TERMINAL SCREWS

2 3

• Center each sensor unit in a "C" wrap with lenses

pointing toward each other across the door.

• Secure sensors with the hardware shown. Finger

tighten the wing nut on the

for final adjustment. Securely tighten the

eye

wing nut.

receiving eye

to allow

sending

Sensor

Invisible Light Beam

Sensor

Protection Area

• Run paired wires from both sensors to the opener.

Use insulated staples to secure the wire to wall

and ceiling.

• Strip 1/4" of insulation from each set of wires.

Separate white and white/black wires sufficiently to

connect to the opener terminal screws:

white to 2 and white/black to 3.

• Plug in the opener. Make sure the Lock Feature is

off

. Green indicator lights in both the sending and

receiving eyes will

glow steadily

if wiring

connections and alignment are correct.

If the indicator light is

off

in the

receiving eye

(and the invisible light beam path is not obstructed),

alignment is required.

• Loosen the receiving eye wing nut to allow slight

rotation of unit. Adjust sensor vertically and/or

horizontally until the green indicator light

with a steady light

• When indicator lights are

.

glowing steadily

glows

in both

units, tighten the wing nut in the receiving eye unit.

Wing Nut

"C" Wrap

Sensor

Wire

Indicator Light

1/4-20x1-1/2"

Hex Bolt

Trouble Shooting

1. If the

sending eye

steadily

indicator light does not

after installation, check for:

• Electric power to the opener.

• A short in the white or white/black wires. These

can occur under staples or at screw terminal

connections.

• Incorrect wiring between sensors and opener.

• An open wire (wire break).

2. If the sending eye indicator light

glows steadily

the receiving eye indicator light doesn't:

• Check alignment.

• Check for an open wire to the receiving eye.

Hardware Shown Actual Size

1/4-20x1-1/2"

Hex Bolt

Wing Nut

glow

but

23

Page 24

Installation Step 11

Vertical

Guideline

Door

Bracket

Nut

5/16"-18

Carriage Bolt

5/16"-18x2-1/2"

Lock Washer

5/16"

Vertical

Guideline

Door

Bracket

Location

Header

Bracket

Door

Bracket

Door

Bracket

Plate

Inside Edge

of Door or

Reinforcement Board

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, aluminum, steel,

doors with glass panel, etc).

Vertical

Reinforcement

CAUTION

Fasten Door Bracket

Follow instructions which apply to your door type

as illustrated below or on page 25.

A horizontal brace should be long enough to be secured to 2 vertical supports. A vertical brace should

cover the height of the top panel.

The illustration shows one piece of angle iron as the horizontal brace. For the vertical brace, 2 pieces of

angle iron are used to create a "U"-shaped support. The best solution is to check with your garage door

manufacturer for an opener installation, door reinforcement kit.

To prevent damage to steel, aluminum,

fiberglass or glass panel doors, always

reinforce the inside of the door both vertically

and horizontally with angle iron.

SECTIONAL Door Installation Procedure

Figure 1

• Center the door bracket on the previously marked

vertical guideline used for the header bracket

installation.

• Position the bracket on the face of the door within

the following limits:

A) The top edge of the bracket 2"-4" below the top

edge of the door.

B) The top edge of the bracket directly below any

structural support across the top of the door.

• Mark and drill 5/16" left and right fastening holes.

Secure the bracket as shown in Figure 1 if there is

vertical reinforcement.

If your installation doesn't require vertical reinforcement but does need top and bottom fastening holes

for the door bracket, position the door plate over the

door bracket as shown in Figure 2. Fasten securely

with hardware shown in Figure 1.

Hardware Shown Actual Size

Nut 5/16"-18

Carriage Bolt

5/16"-18x2-1/2"

Figure 2

Lock Washer 5/16"

24

Page 25

Door

Bracket

Top of Door

(Inside Garage)

Carriage Bolt

5/16"-18x2-1/2"

Optional

Placement

Lock Washer

5/16"

Nut

5/16"-18

Horizontal and vertical

reinforcement is needed for

lightweight garage doors

(fiberglass, aluminum, steel,

door with glass panel, etc.).

Header Wall

Vertical

Centerline of

Garage Door

— Finished Ceiling —

Optional

Placement

of Door

Bracket

Header

Bracket

Top Edge

of Door

2x4 Support

Door

Bracket

For a door with no

exposed framing or for

the optional installation,

use 5/16"x1-1/2" lag

screw (not supplied) to

fasten door bracket.

All ONE-PIECE Door Installation Procedure

Please read and comply with the warnings and reinforcement instructions on page 24.

They apply to one-piece doors also.

• Center the bracket on the top of the door, in line

with the header bracket as shown. Mark holes.

• Drill 5/16" pilot holes and fasten the door bracket

with hardware supplied.

If the door has no exposed framing, drill 3/16" pilot

holes and fasten the bracket with 5/16"x1-1/2"

lag screws (not supplied) to the top of the door.

The door bracket may be installed on the top

edge of the door if required for your installation.

(Refer to the dotted line optional placement

drawing.) Drill 3/16" pilot holes and substitute

5/16"x1-1/2" lag screws (not supplied) to fasten

the bracket to the door.

Hardware Shown Actual Size

Nut 5/16"-18

Lock Washer 5/16"

Carriage Bolt

5/16"-18x2-1/2"

25

Page 26

Installation Step 12

Connect Door Arm to Trolley

Follow instructions which apply to your door type

as illustrated below and on page 27.

SECTIONAL Doors Only

Make sure garage door is fully closed. Pull the manual release handle to disconnect the outer trolley

from the inner trolley. Slide the outer trolley back (away from the door) about 2" as shown in

Figures 1, 2 and 3.

Figure 1:

• Fasten straight door arm section to outer trolley

with a clevis pin. Secure the connection with a

ring fastener.

• Fasten curved section to the door bracket in the

same way as shown.

Inner Trolley

Outer Trolley

Clevis

Ring

Fastener

Pin

Figure 2:

• Bring arm sections together. Find two pairs of holes

that line up and join sections. Select holes as far

apart as possible to increase door arm rigidity.

Lock

Washers

5/16"

Rope

Clevis Pin

Door

Bracket

Curved

Door Arm

Straight

Door Arm

Figure 1

Hole Alignment Alternative

Figure 3:

• If holes in curved arm are

arm, disconnect straight arm. Cut about 6" from

the solid end. Reconnect to trolley with

down

as shown.

• Bring arm sections together.

• Find two pairs of holes that line up and join with

screws, lock washers and nuts.

Hardware Shown Actual Size

Nut 5/16"-18

Lock Washer 5/16"

above

holes in straight

cut end

Ring Fastener

Nuts

5/16"-18

Door Bracket

Nuts

5/16"-18

Manual

Release

Handle

Screws

5/16"-18x7/8"

Figure 2

Lock

Washers

5/16"

Screws

5/16"-18x7/8"

Cut This End

Figure 3

Hex Screw

5/16"- 18x7/8"

Clevis Pin

5/16"x1"

Proceed to Adjustment Step 1, page 28. Trolley will re-engage automatically when the opener is operated.

26

Page 27

All ONE-PIECE Doors

Door

Assemble the Door Arm:

Bracket

• Fasten the straight and curved door arm sections

together to the longest possible length (with a 2 or

3 hole overlap).

• With the door closed, connect the straight door

Clevis Pin

Straight

Arm

arm section to the door bracket with a clevis pin.

• Secure with a ring fastener.

On one-piece doors, before connecting the door arm to the trolley the travel limits must be adjusted. Limit adjustment screws are located on the left side panel as shown on page 28. Follow adjustment procedures below.

Fully Closed

Trolley

Ring

Fastener

Screws

5/16"-18x7/8

Lock

Washers

5/16"

Fully Open

Trolley

Nuts

5/16"-18

Curved

Door Arm

Closed

Door

Door Arm

Open Door

Door Arm

Connector Hole

Adjustment Procedures for One-Piece Doors

Open Door Adjustment:

Decrease UP limit

• Turn the UP limit adjustment screw counterclockwise 5-1/2 turns.

• Press the Door Control button/push bar. The

trolley will travel to the fully open position.

• Manually raise the door to the open position

(parallel to the floor), and lift the door arm to the

trolley. The arm should touch the trolley just in

back of the door arm connector hole. Refer to the

fully open trolley/door arm positions in the

illustration. If the arm does not extend far enough,

adjust the limit further. One full turn equals 2" of

trolley travel.

Door with

Backward Slant

Door Arm

Connector Hole

Door Arm

Closed Door Adjustment:

Decrease DOWN limit

• Turn the DOWN limit adjustment screw clockwise

5 complete turns.

• Press the Door Control button/push bar. The trolley

will travel to the fully closed position.

• Manually close the door and lift the door arm to the

trolley. The arm should touch the trolley just ahead

of the door arm connector hole. Refer to the fully

closed trolley/door arm positions in the illustration. If

the arm is behind the connector hole, adjust the

limit further. One full turn equals 2" of trolley travel.

Connect the door arm to the trolley.

• Close the door and join the curved arm to the connector hole in the trolley with the remaining clevis pin. It may

be necessary to lift the door slightly to make the connection.

• Secure with a ring fastener.

• Run the opener through a complete travel cycle. If the door has a slight "backward" slant in full open position

as shown in the illustration, decrease the UP limit until the door is parallel to the floor.

27

Page 28

Adjustment Section: Pages 28 – 30

Adjustment Step 1

Adjust the UP and DOWN Limits

Limit adjustment settings regulate the points at

which the door will

The door will

interferes with door travel. The door will

the

down

direction if anything interferes with the

door travel (including binding or unbalanced doors).

To operate the opener, press the Door Control

button/push bar. Run the opener through a

complete travel cycle.

• Does the door open and close completely?

• Does the door stay closed and not reverse

unintentionally when fully closed?

If your door passes both of these tests, no limit

adjustments are necessary.

stop

stop

when moving up or down.

in the

up

direction if anything

reverse

in

WARNING

Improper adjustment of the travel limits will

interfere with the proper operation of the safety

reverse system.

when required and could seriously injure or kill

someone under it.

system following all adjustments to the travel

limits. See page 30.

The door might not reverse

Test the safety reverse

INCREASE TRAVEL

DOWN

Left Side

Panel

UP

Limit

Adjustment

Screws

INCREASE TRAVEL

DOWN

Adjustment Label

UP

Adjustment procedures are outlined below. Run the opener through a complete travel cycle after each

adjustment.

Repeated operation of the opener during adjustment procedures may cause the motor to overheat and

shut off. Simply wait 15 minutes and try again.

Read the procedures carefully before continuing on to Adjustment Step 2. Use a screwdriver to make limit

adjustments.

How and When to Adjust the Limits

If the door does not

but opens

Increase

at least

up

travel. Turn the UP limit adjustment

screw clockwise. One turn equals 2" of travel.

If door does not open at least 5 feet:

Adjust the UP (open) force as explained in

Adjustment Step 2.

If the door does not

Increase

down

adjustment screw counterclockwise. One turn

equals 2" of travel.

If door still won't close completely, try lengthening

the door arm. (See page 26.)

If you have adjusted the door arm to the maximum

length and the door still will not close completely,

lower the header bracket. See Installation Step 1,

pages 12 and 13.

open completely

five feet

close completely

travel. Turn the DOWN limit

If the opener

Decrease

reverses

down

travel. Turn the DOWN limit

in fully closed position

adjustment screw clockwise. One turn equals 2"

of travel.

If the door

reverses

when closing and

there is no visible interference to travel cycle

If the opener lights are flashing, the Safety Reversing

Sensor is obstructed. Remove the obstruction.

Test the door for binding: Pull the manual release

handle. Manually open and close the door. If the door

is binding, call for garage door service. If the door is

not binding or unbalanced, adjust the DOWN (close)

force. See Adjustment Step 2.

28

Page 29

Adjustment Step 2

Adjust the Force

Force adjustment controls are located on the back

panel of the opener. Force adjustment settings

regulate the amount of power required to open and

close the door.

The door will

interferes with its travel. The door will

down

direction if anything interferes with its travel

(including binding or unbalanced doors).

If the forces are set too light, door travel may be

interrupted by

direction and

conditions can affect the door movement, so

occasional adjustment may be needed.

The maximum force adjustment range is

260 degrees, about 3/4 of a complete turn. Do not

force controls beyond that point. Turn force

adjustment controls with a screwdriver.

stop

in the updirection if anything

nuisance reversals

stops

in the

up

in the

direction. Weather

reverse

down

in the

WARNING

Too much force on the door will interfere with

the proper operation of the safety reverse

system.

when required and could seriously injure or

kill someone under it.

force beyond the minimum amount required to

close the door. Do not use the force

adjustments to compensate for a binding or

sticking garage door. Test the safety reverse

system following all adjustments to force

levels. See page 30.

The door might not reverse properly

Do not increase the

Force

Adjustment

Controls

1

3

2

9

9

1

1

7

7

3

3

5

5

KG

KG

9

7

5

KG

Adjustment Label

9

1

3

7

1

3

5

KG

How and When to Adjust the Forces

Test the DOWN (close) force:

Grasp the door bottom when the door is about

halfway through DOWN (close) travel. The door

should reverse. (Reversal halfway through down

travel does not guarantee reversal on a two-inch

obstruction. See page 30.) If the door is hard to

hold or doesn't reverse, decrease the DOWN (close)

force by turning the control counterclockwise.

Make 10 degree turn adjustments until the door

reverses normally. After each adjustment, run the

opener through a complete cycle.

Back Panel

of Opener

Make 10 degree turn adjustments until the door stops

easily. After each adjustment, run the opener through

a complete travel cycle.

If the door doesn't open

at least

5 feet:

Increase UP (Open) force by turning the control

clockwise. Make 10 degree turn adjustments until

door opens completely. Re-adjust the UP limit if

necessary. After each adjustment, run the opener

through a complete travel cycle.

Test the UP (open) force:

Grasp the door bottom when the door is about

halfway through UP (open) travel. The door should

stop. If the door is hard to hold or doesn't stop,

decrease UP (open) force by turning the control

counterclockwise.

If the door

reverses

during the down (close) cycle

and the opener lights aren't flashing:

Increase DOWN (close) force by turning the control

clockwise. Make 10 degree turn adjustments until the

door completes a close cycle. After each adjustment,

run the opener through a complete travel cycle. Do

not increase the force beyond the minimum

amount required to close the door.

29

Page 30

Adjustment Step 3

Test The Safety Reversing Sensor

• Press the remote control push button to open

the door.

• Place the opener carton in the path of the door.

• Press the remote control push button to close the

door.

The door will not move more than an inch,

and the opener light(s) will flash.

The garage door opener will not close from a

remote if the indicator light in either sensor is

off,

alerting you to the fact that the sensor is

misaligned or obstructed.

The garage door can be closed by pressing and

holding the door control button/push bar until down

travel is completed.

Professional service is required if the opener

closes the door when the safety reversing

sensor is obstructed.

WARNING

Without a properly working safety reversing

sensor, persons (particularly children) could be

seriously injured or killed if trapped by a closing

garage door.

Safety Reversing Sensor

Repeat this test once a month.

Safety Reversing Sensor

Adjustment Step 4

Test the Safety Reverse System

Test:

• Place a one-inch board (or a 2x4 laid flat) on the

floor, centered under the garage door.

• Operate the door in the down direction.

must reverse on striking the obstruction.

Adjustment:

If the door

far enough in the down direction.

• Increase the DOWN limit by turning the DOWN

limit adjustment screw counterclockwise 1/4 turn.

• Repeat the test.

On a sectional door, make sure limit

adjustments do not force the door arm beyond a

straight up and down position. See the

illustration on page 26.

• When the door reverses on the one-inch object

(or 2x4 laid flat), remove the obstruction and run

the opener through 3 or 4 complete travel cycles to

test adjustment.

If the door will not reverse after repeated

adjustment attempts, call for professional

garage door service.

stops

on the obstruction, it is not traveling

The door

WARNING

Failure to test and adjust the safety reverse

system may result in serious injury or death

from a closing garage door.

once a month and adjust as needed.

GARAGE DOOR

One-inch Board

(2x4 laid flat)

Important safety check:

Repeat Adjustment Steps 1, 2 and 4 after:

• Each adjustment of door arm length, force controls

or limit controls.

• Any repair to or adjustment of the garage door

(including springs and hardware).

• Any repair to or buckling of the garage floor.

• Any repair to or adjustment of the opener.

Repeat this test

30

Page 31

IMPORTANT SAFETY INSTRUCTIONS

WARNING

WARNING

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Do not permit children either to operate or to play with the opener. Keep remote control in a

location inaccessible to children.

3. Operate opener only when the door is in full view and free from any obstruction. Keep the door in

sight until it is completely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

4. Check safety reversal system monthly. See page 30. The garage door

with a one-inch object (or a 2x4 board laid flat) placed on the floor. If an adjustment is made to

either the force or the limit of travel, both adjustments may be needed and the safety reversal

system must be checked.

Failure to properly adjust the opener may result in severe injury or death.

5. If possible, use the manual release only when the door is in a closed position. Caution should be

taken whenever the disconnect cord is actuated with the door open.

cause the door to fall rapidly, causing injury or death to persons.

6. KEEP GARAGE DOORS PROPERLY BALANCED. See page 3.

reverse when required and could result in severe injury or death

An improperly balanced door may not

. Repairs to cables, spring

assemblies and other hardware must be made by a professional garage door person.

7. Disconnect the electric power from the garage door opener before making any repairs or removing

the covers.

8. SAVE THESE INSTRUCTIONS.

MUST

reverse on contact

Weak or broken springs may

Care of Your Opener

Limit and force adjustment controls

Force ControlsLimit Controls

9

INCREASE TRAVEL

DOWN UP

Adjustment Label

(Located on the left side panel)

7

KG

Adjustment Label

(Located on the back panel)

Weather conditions may cause some minor

changes in door operation requiring some readjustments, particularly during the first year

of operation.

Pages 28 and 29 refer to the limit and force

adjustments. Only a screwdriver is required. Follow

the instructions carefully.

Repeat the safety reverse test (page 30) after any

adjustment of limits or force.

Once a Month

Manually operate door. If it is unbalanced or

binding, call for professional garage door service.

Check to be sure door opens & closes fully.

Adjust limits and/or force if necessary. (See pages

28 and 29.)

Repeat the safety reverse test. Make any

necessary adjustments (See page 30).

9

1

7

3

5

3

5

KG

Maintenance Schedule

The remote control transmitter

The opener must learn the code of any new remote

control. Page 33 explains how to program your

1

receiver and how to erase all codes if required. Self

service of your receiver and remote control is not

recommended. If service is needed, call the toll-free

number listed on the back page.

The remote control battery

The green battery test light will glow and the opener

will operate when the remote control is activated, as

long as there is adequate battery power.

If the test light is

dim or off

, replace the battery. Also

check the test light if transmission range decreases.

The 12 volt battery should produce power for at least

a year.

Dispose of your old battery properly.

Twice a Year

Check chain tension. Disconnect trolley first.

Adjust if necessary (See page 11).

Once a Year

Oil door rollers, bearings and hinges.

The opener does not require additional

lubrication.

Do not grease the door tracks.

31

Page 32

Operation of Your Opener

Activate the opener with any of the following

devices:

1. The Remote Control Transmitter. Hold push

button down until the door starts to move.

2. The Door Control. Hold button/push bar down

until the door starts to move.

3. The Outside Keylock or Keyless Entry.

(See Accessories)

When the Opener is Activated:

1. If open, the door will close. If closed, the door will

open.

2. If closing, the door will reverse.

3. If opening, the door will stop (allowing space for

entry and exit of pets and for fresh air).

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructed while closing, the door will reverse.

6. If obstructed while opening, the door will stop.

7. The garage door will reverse in the closing cycle

when the invisible beam is broken. If fully open, the

door will not close when the beam is broken. The

sensor has no effect in the opening cycle.

If the sensor is not installed, or is not aligned

correctly, the door won't close from any remote

control transmitter. You can close the door with the

Door Control, the Outside Keylock, or the Keyless

Entry, however, if you press and

bar until down travel is complete. If you release the

button/push bar too soon, the door will

The opener lights will

blink for 5 seconds

safety reversing sensor causes the door to reverse.

Opener Lights will turn on under the following

conditions: When the opener is initially plugged in;

when the power is interrupted; when the opener is

activated. They will turn off automatically after 4-1/2

minutes or provide constant light when the Light

feature is activated. Bulb size is 75 watts maximum.

hold

the button/push

reverse.

when the

WARNING

Weak or broken springs could allow an open

door to fall (either rapidly or unexpectedly),

resulting in serious injury, death or property

damage.

rope and handle

closed.

Trolley

Manual disconnect

The lockout feature

prevents the trolley from

reconnecting automatically. Pull the