™

Blood & Fluid Warming System

___________________________

USER MANUAL

™

Distributed by

35 Tedwall Ct. • Greer SC 29650 • USA

™

™

Blood & Fluid Warming System

CAUTION:

Federal (USA) law restricts this device to sale by or on the order of a physician.

It is important that users read and understand all information contained in this

manual concerning the intended use and proper operation of the Quantum

Blodd & Fluid Warming System. This manual is not intended as a substitute for

formal training in the use of intravenous administration systems, which may be

required by local, regional, or state protocol. Consult your local medical director

or governing agency for further information and requirements. For questions

concerning this manual or the device, contact Life Warmer, Inc.

Contact Us:

If you have questions regarding the use of the Quantum Blood and Fluid

Warming System or any component, please contact North American Rescue at

888-689-6277.

Life Warm er, Inc

Addiso n, TX 75001

972-908-9808

USA

lifeline@lifewarmer.com

ZZ-1098 • RE V050619

Distributed by

35 Tedwall Ct. • Greer SC 29650 • USA

-3-

LIFEWARMER

REF

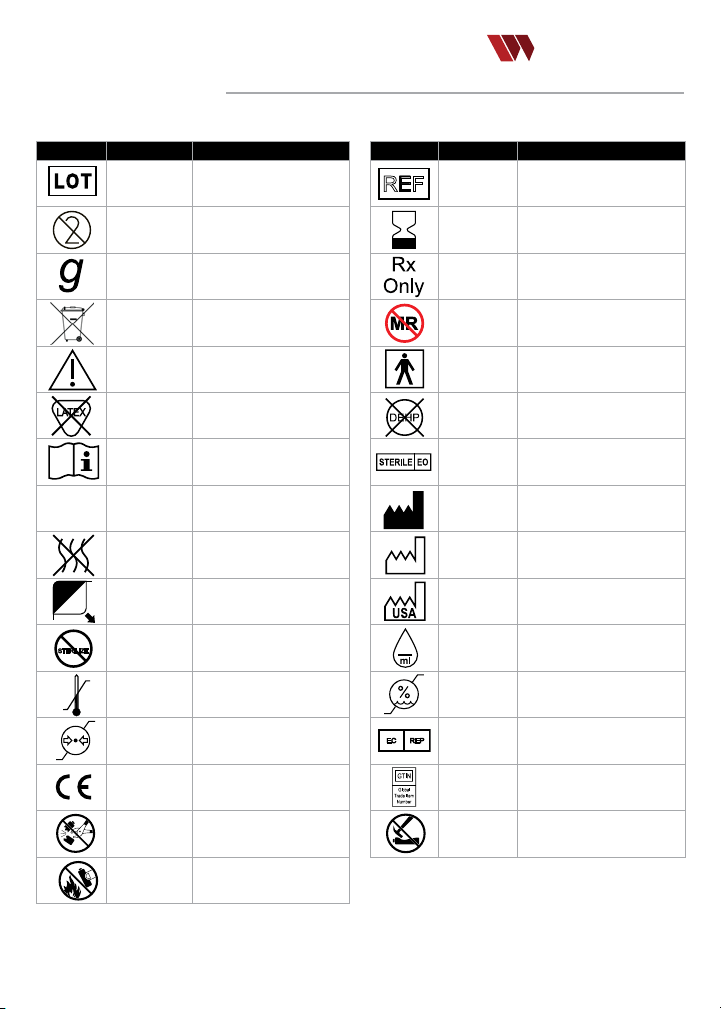

GLOSSARY OF SYMBOLS

The following symbols may appear on components or in information rel ated to the Quantum device.

™

Symbol Reference Title/Meaning

ISO -2492

SO 7000-1051 Do Not Reuse

I

ISO 7000-3832 Gravit y type

EN 50419

ISO 7000-043A Caution

ISO 15223 –

5.4.5

ISO 700 0-1641 Operating Instructions; eIFU

ISO 7010-M002 Follow Instructions for Use

ISO 7000-2724 Non-pyrogenic

ISO 7000-3079 Open he re

2

STERILIZE

ISO 7000-2608 Do n ot reste rilize

ISO 7000-0632

ISO 7000-2621

MDD

93/42/EEC

IEC 60086 -4

IEC 60086 -4

Batch Co de/

Manufacturer’s Lot

WEEE whee led bin

Recyle electronic equ ipmen t;

Do Not Throw in Trash

Not made w ith natu ral rub ber

Temperature limit s; Limi ts for

limit ation; R ange wh ich devi ce

latex

safe device exposure

Atmospheric pressure

can be safely exposed

CE Marks

Signies European technical

conformity

DO NOT disassem ble

(batte ry)

Do NOT inci nerate

(batte ry)

Symbol Reference Title/Meaning

20

EC REP

ISO 7000-

2493

ISO 7000-

2607

21 CFR Par t

801.109

ASTM F-2503

IEC 60417-

5333

BS EN 15986 -

4.2

ISO 7000-

2501

ISO 7000-

3082

ISO 7000-

2497

ISO 7000-

6049

ISO 7000-

2726

ISO 7000-

2620

BS/EN 1041

N/A

IEC 60086 -4

Catalogue Number

Use-by d ate;

Date afte r which the device is

not to be us ed

Caution: Fede ral (USA) law

restri cts this device to sale byor

on the ord er of a physi cian

MR Unsafe;

Device known to pose hazards in

all MR environme nts

Type BF Appli ed Par t

Non-DEHP

Does not contain the pht halate

plasticizer DEHP

Sterilized usin g ethylene oxide

Device Manufacturer

Date of manufacture

Country of manufacture

Numbe r of drops p er mlli litre

Humidity limitation;

Range wh ich me dical d evice can

be safely ex posed

Author ized repre sentative in the

European country

Global Trade Identicat ion

Numbe r; deno tes proximate UDI

barcode

Do NOT crus h

(batte ry)

-4-

TABLE OF CONTENTS

LIFEWARMER

Prescribing Information

Indications for Use .........................................................................................................................6

Warnings ..........................................................................................................................................6-7

Precautions ..........................................................................................................................................7

Intended Users & Use Environments ......................................................................................8

Quantum System Description

Device Description ........................................................................................................................9

Quantum System Components ..........................................................................................9

Quantum System Operation

Thermal Infusion Set (TIS) .................................................................................................... 10

Thermal Transfusion Set (TTS-B) ....................................................................................11

Charging/Connecting the Battery ................................................................................ 12

• Charging the Battery .................................................................................................... 12

• Checking Battery Charge Status ........................................................................ 12

• Connecting the Battery to the Controller ................................................... 12

• Important Battery Use Information .................................................................. 12

Connecting the Controller ....................................................................................................13

• Connecting the Controller to the TIS or TTS-B Tubing .....................13

• Disconnecting Components/Discontinuing Use ..................................13

Enabling/DIsabling Audible Alert System ...............................................................14

Instructions for Performing Manual Test of Audible Alert ...........................14

Sterility Status .........................................................................................................................................15

Sterile Components....................................................................................................................15

Single-Patient Use and Non-Sterile Reusable Components ...................15

Cleaning and Disinfecting ............................................................................................................15

Visual/Audio Indicators

User interface: Table of visual and audio indicators ................................ 16-17

Technical Specications ........................................................................................................18-19

Essential Performance .............................................................................................................18

System Information/Safety Classication ................................................................18

Performance .....................................................................................................................................18

Component Specications .................................................................................................. 19

Operating, Storage & Distribution Conditions ...........................................................20

EMC Compliance Statement .......................................................................................................21

APPENDIX ....................................................................................................................................................22

Troubleshooting Guide .................................................................................................. 22-23

Quantum Response by Temperature Table ...........................................................23

Glossary of Terms ....................................................................................................................... 24

Quantum Components List .........................................................................................24-25

Warranty .............................................................................................................................................26

™

-5-

PRESCRIBING INFORMATION

LIFEWARMER

INDICATIONS FOR USE:

The Qua ntum™ Bloo d & Fluid War ming System is ind icate d for warm ing blo od, blo od produ cts an d intrave nous

soluti ons pri or to administ ratio n in adult p atients. It i s intend ed for us e by healthcare professionals in hospital, c linical,

eld and t ransport environm ents to h elp preve nt hypothermia.

WARNINGS:

For the safe opera tion of the Quantum System,

•

all instructi ons, warnings and pre cautions

in this document must b e followed . Failure

to follow instructions fo r proper use may

result in d evice malfunction or injury.

Only the uid path and area s under protect ive

•

end cap s are STERILE. If end protectors

are not in place, DO NOT USE.

DO NOT pla ce tubin g sets or protect ive

•

end cap s in a sterile eld .

The TIS/ TTS -B is for S INGLE PATIENT USE ONLY.

•

DO NOT RES TERILIZE.

The Qua ntum Thermal Infusio n Set (T IS) IS NOT

•

for stan dalon e use with blood or blood product s.

A RED LED stro be and sustai ned audible ale rt on the

•

batter y indicates a ui d over-temperature condit ion

which can result i n hemolysis of blo od and e levatio n

of touch te mpera ture of the t hermal tubin g.

The over-temperatu re Audib le Alert System

•

may be man ually disable d. Ensu re that the

Audible Alert Sys tem is alway s enabled

unless a t actical haz ard is posed.

Repla ce Quan tum Transfu sion ( TTS-B) and I nfusi on

•

Sets ( TIS) in accordan ce with CURRENT A ABB/

CDC guidelin es and/or institutional p rotocol s.

All IV ui d bags mu st be vented of air p er IV ui d

•

manufa cturer s’ direct ions prior to co nnect ing to tub ing

set. Ca re must b e taken to e nsure th ere is not sucient

air in the uid bag and lin es to cau se an air e mbolism.

DO NOT ax, p lace or bind th e therm al (heated)

•

portion of the thermal tubin g directly to a patient.

It is recommend ed that t he Cont roller, Bat tery, and

•

Charger be surfaced cleaned and dis infecte d after

each pat ient us e following the instruc tions i n this

manual or accord ing to st andard insti tution al protocol.

DO NOT touch the Bat tery pins and

•

the pati ent at th e same time.

Warning: Use of thi s equipment ad jacen t to or

•

stacke d with other equ ipment shoul d be avoide d

ecaus e it could re sult in imprope r operation . If

b

such use i s necessar y, this equ ipmen t and the o ther

equipment should be observed to verif y that they are

operating normally.

-6-

The Qua ntum Syste m (including Therma l

•

Tubing TIS an d TTS-B) is MR UNSAFE .

The Qua ntum is in tende d for gravity admi nistration .

•

However, performan ce testi ng has b een

conduc ted in accordance with IS O 1135 -5 for

single u se tran sfusi on set s with pre ssure in fusio n

and foun d to be mec hanic ally st able. Th us,

the clinician may apply re asonable pres sure

to the infusate ba g if it is determin ed that

increa sed ui d ow is clinical ly indicated.

DO NOT attempt to use t he Quantum Syste m

•

components , inclu ding tubing sets (TI S,

TTS- B), Controller, Battery, or Charger wi th

uid war ming devices/component s from oth er

manufa cturer s. They a re not com patible.

DO NOT attempt to use chargin g device s, power

•

cables o r component s from oth er manu facturers

with the Quantu m System co mponents. They

are not com patib le and pose a safet y hazard.

DO NOT attempt to sterilize, au toclave

•

or submerge the C ontrol ler, Batte ry, or

Cha rger. Surface clean/disinfect only.

There are n o user-se rviceable parts i nclud ing the

•

Batter y. For all matters concernin g funct ionality

and ser vice, contact Life Warme r, Inc.

DO NOT attempt to ope n or access the

•

Controller, Batte ry, or Charger. Doin g so may

damage the components and /or result in

device ma lfunc tion, f ailure o r injur y.

DO NOT attempt to mod ify any c ompon ent

•

of the Quantum System. There may be NO

changes or mod icat ions to t he mech anics,

electronics , and/or sof tware of t he syste m.

DO NOT operate or store Quan tum comp onent s

•

outsi de of the speci ed environmen tal

limit s. A safety haza rd may occu r.

DO NOT use a mu ltiple s ocket ou tlet or ex tension

•

cord with a ny Quantum comp onent .

Degra datio n of sensors can re sult in inaccur ate

•

temperature rea dings a nd subs equent

outow temperatures. I f this oc curs, t he

Controller will indic ate a System Error.

™

PRESCRIBING INFORMATION (continued)

WARNINGS: (continued)

Use of acce ssori es, tr ansdu cers an d cables other than

•

those speci ed or provided by th e manuf acture r of this

equipment could result i n increased electrom agnet ic

emiss ions or d ecreased ele ctroma gneti c immun ity of

this eq uipme nt and res ult in improper o perat ion.

PRECAUTIONS:

Examine all sys tem com ponents for da mage, we ar,

•

and function ality p rior to u se. If any compon ent

appea rs fault y, damage d or defective, DO N OT USE.

Inspe ct all ca sings, component s and

•

enclos ures for da mage, cracks , breaks, or

loss of integrit y. If any of these are obs erved,

do not use a nd repl ace com ponent.

Exceeding rec ommended ow rates and /

•

or low ambi ent temperatu re may result

in lower out put temp eratu re.

Some dr ugs or dr ug preparatio ns may be sensitive

•

to warming. As with any ui d or bloo d warmi ng

system, carefu lly review th e drug manufac turers’

literature for info rmati on abou t therm al sensitivi ty.

Do not positio n the devi ce in a man ner tha t

•

makes it dicult to view or di sconn ect the

Controller and /or change the Batte ry.

When th e useful life of the lithium Batte ry

•

has bee n reached, it sh ould be dispos ed of

separ ately in accordance with na tiona l and

local co des. C ontac t your loc al enviro nment

control o r dispo sal agency for f urth er deta ils.

Used, single-use compone nts (TIS, T TS-B)

•

should b e disposed of in a ccorda nce with

local , national and /or international biohaz ard

protocols by the a ppropr iate personnel.

Porta ble RF communi catio ns equipment (including

•

peripheral s such as antenna c ables and external

antennas) shou ld be use d no closer than 30

cm (12 in ches) to any part of the Qua ntum Fluid

Warming Sys tem, in cluding cables spec ied by

the manufactu rer. Other wise, degradation of t he

performance of the equipme nt could re sult.

The Cont roller a nd Battery are not

•

intended for patient contact .

Although the Quantum has been tested to

•

insure it w ill sur vive a drop of 1 meter (3.28 ft),

care sho uld be ta ken that t he system is not

droppe d to reduce the pote ntial of damage.

It is recommend ed prop er Battery an d

•

Controller per formance be veri ed

before each use of th e Quantum.

Fully charg e new batteries u pon receipt and

•

prior to u se or sto rage to ex tend batter y life.

Check B atter y charge status p rior to e ach use to

•

ensure adequate charge fo r device o perat ion.

It is recommend ed that t he Battery be f ully

•

charge d before in itiating warming.

It is recommend ed that t he Battery

•

be charg ed afte r each us e.

The Battery Ch arger must be co nnected

•

to an ear thed mains socket outlet.

The Cont roller J acket should be replace d after every

•

10 uses (approximate) or six mo nths (whichever

occurs rst) o r at anytime the C ontrol ler Jacke t

appears damaged, loose-tting, or compromised.

LIFEWARMER

™

-7-

INTENDED USERS &

LIFEWARMER

USE ENVIRONMENTS

Intended Users:

Opera tors of th e Quantum should be knowledgeable in th e use of IV administration set s for infu sion of uids an d

transfusio n of blood /bloo d produc ts. The Quantum the rmal tub ing set s (TIS and TTS-B) deliver IV soluti ons and

blood/blood p roduct s in a similar man ner as co nventional IV in fusio n and tra nsfusion sets.The Qu antum is d esigned for

quick set up and de ployme nt usin g minim al steps. Inten ded users include mil itar y medi cs, EMS P aramedics , regis tered

nurses, physicians and mid- level practitioners . Patie nt-users of the Quantum i nclude any adult p atient presenting with

the nee d for IV solution s, bloo d or bloo d produc ts who m ay bene t from war med ui ds..

Intended Use Environments:

The Qua ntum Blo od & Flui d Warming System is transporta ble. The intended use env ironments in clude hospit als (e.g .,

in-pat ient /full service s facil ities), clinical environmen ts (e.g., satellite emergenc y center s, outp atien t center s, etc.),

and eld e nvironments (e .g., po int of inj ury in cludi ng civilian an d battle eld locations) and tr ansport environme nts

such as emergen cy vehicles en rou te (i.e., xed and rotary wing aircraft a nd ground and ai r ambul ance). The Quan tum

Controller, Batte ry, TIS/TTS- B are inte nded for u se in the Patien t Environment. N ote: The B atter y Charg er shou ld only

be used i n hospi tal and protecte d xed structure environ ment s.

QUANTUM SYSTEM DESCRIPTION:

Device Description:

The Qua ntum Blo od & Flui d Warming System is a lightwe ight, b atter y powered, high ly port able, u id warm ing sys tem

in which t he warm ing ele ment is i ntegra ted with s peci ally designed i ntravascula r admin istra tion tubing. Fluid war ming

is achieved in the tubing t hrough t he use of p roprie tary therm oplastic po lyureth ane and a s oftw are control .alg orithm.

The Qua ntum IV ad minis trati on

tubing i s double-ex trude d to yield a

congu ratio n that ha s both an i nner

tubing l ayer and a n outer tu bing

layer. A conductive heating e lemen t

is betwe en the t wo layers b ut does

not come i n conta ct with the uid

path [Fi gure 1]. T he outer tubing layer

acts as a n insul ator while the in ner

tubing l ayer tra nsfers t he heat f rom

the heating ele ment to the uid path.

The Qua ntum Syste m, fully c harge d,

is able to wa rm and maintain up to

2 units ( 9 00mL +/- 100mL) of cold

(4ºC) bloo d produc ts or IV solutio ns to a pre-set temperatu re of 38ºC ± 2 ºC (100.4ºF ± 2) at a ow rate of 100 mL/min

(depen ding on t he ambient tem perature). Or, approximately 1700 mL of 20ºC IV solution to a set p oint of 38ºC +/- 2ºC

at a ow rate of 20 0 mL/min . Eective w armin g ow rates range fro m 2 to 200 mL /minute de pending on input uid

temperature and ambient conditions.

Thermistors located in the tub ing con tinually meas ure temp erature a nd provide that in put to the Controller. The

Controller ass esses the temp eratu re input a nd regul ates the amount of e nergy a pplied to the heating e lemen t needed

to reach an d maint ain a con stant uid temperatu re. The monitor ing and i ndependent appli catio n of energy (heat ) along

the uid path allows the Qu antum to respond to varyi ng temp erature input s from the uid sou rce to nea r the point of

patient entr y to ensure uid tem perature is ≥ 36ºC to < 44ºC at deliver y.

The Qua ntum is powered by a rechargea ble lit hium- polymer batte ry. The co mplete Q uantum B lood & Fluid Warmi ng

System, includi ng the B atter y, weighs less than 1 ,5 lbs. a nd can t ravel wit h the pat ient ac ross multiple cl inical use

environments w hile maintaining opt imum u id temp erature.

Binding layer securing

the heating element

In n er tub in g (cond uc t s

-8-

Outer tubing

Heating element

sterile uid pat h and

absorbs heat)

Figure 1:

Quantum Tubing

C

ross Section

™

QUANTUM SYSTEM COMPONENTS:

The Qua ntum Blo od & Flui d Warming System con sist s of sterile ther mal

IV tubin g (TT S-B or TIS), a Controller (i ncluding Jacket), Bat tery, and B atter y Charger..

LIFEWARMER

TUBING SETS:

Thermal Transfusion Set -Blood (TTS-B) | Thermal Infusion Set (TIS)

Intrava scula r admin istration sets for infusio n (TIS) o f IV uid s and tra nsfus ion (TTS- B) of bloo d/blo od products an d IV

uids . The set s are ass emble d and con sist of L ife Warmer’s proprietary the rmopl asti c tubin g with integrate d coppe rnickel heating elements, tempera ture sensing th ermis tors, a nd sta ndard IV a dmini strat ion com ponents (se e Figure s 2

and 3). The TIS and T TS-B connec t to the Controlle r via the c ircuit c artr idge co nnector. The TIS and TTS -B are prov ided

sterile, for sing le-pa tient u se only.

00 micron ltered

2

drip chamber

Circuit cartridge

connector

RED Roller

Clamps

“Y” t ype

dual spikes

Figure 2:

TTS-B Thermal

Transfusion Set -

BLOOD

M

ale Luer

Connector

R

ED Downstream

Roller Clamp

Clamps

Injection

lide

S

Ports

chamber

2

M

ale Luer

Connector

ip

Dr

0 gtt/ml

Figure 3:

Thermal Infusion

et - IV FLUIDS

S

Controller:

The Cont roller i s the com mand ce nter of th e Quant um System . It cont ains th e microprocessor

and cont rol algorithm that continually a sses ses temperatu re input from tubing thermistors and

regula tes the energy prov ided to t he tubing heating elements i n the proximal and/or distal

segme nts to rea ch and ma intai n tempe rature between 3 8ºC ± 2ºC / 100.4ºF ± 2) at patient

delivery. The Co ntrolle r receives power wh en conn ected to the Bat tery. The Controller is

reusab le. Sur face clean/disinfe ct only. (Co ntrolle r does not suppo rt/req uire ste riliza tion)..

B

LUE Rolle r Clamp

TIS

& Slid e clamps

Controller

cartridge

connector

njection

I

Ports

in jacket

Circuit

Controller Jacket:

The Cont roller c omes t ted with a Jacket th at perm its th e mating (conne ction) of the TIS o r

TTS- B tubin g circuit conne ctor to th e conne ctor slot on the Co ntrolle r. The Jacket must rem ain

in place for device operation. T he Jacke t also p rotect s the Controlle r and sho uld be rep laced

after approxim ately 10 uses or 6 months.

Cleaning Kit:

Kit cont ains hydrophob ic coating pack, extr a Contro ller Jacket, an d cleani ng brush for Jacket conne ctor slot.

™

B

attery C harger

Battery:

Suppl ies power to the Controller. Batter y is lith ium-

polymer and rech argea ble. Sur face clean/disinfe ct only.

(Batte ry doe s not sup port /req uire ste riliza tion).

Charger:

For charging the Q uantum Battery. AC-powere d reusa ble

component. S urfa ce clean /disinfect o nly. (Charge r does

not supp ort /require sterilization ).

Batter y

-9-

QUANTUM OPERATION:

To begin usin g the Qu antum Blood & Fluid Warmin g System, s elect t he

approp riate tub ing set fo r infus ion of IV solutio ns (TI S) or tra nsfus ion of blo od/blood products o r IV solutions ( TTS -B).

F

ollow the d irections on p age 9 for ei ther the TIS or T TS-B tubing se lected .

THERMAL INFUSION SET (TIS) –

For Infusion of IV Solutions

Standard spike w ith vent

•

15 micron part icle lte r

•

•

•

WARNING:

TIS IS NOT for s tand alone use with blood products .

Only uid path and area und er protective end caps are S TERILE.

Luer act ivated i nject ion sites

Male Luer lock ada pter

•

•

LIFEWARMER

Tubing length: 80” (230 cm) long

Primin g volume: 16 mL

TIS USE: (Use Aseptic Technique):

1. Open po uch whe re indi cated . Remove tubing set

and clos e roller cl amp. DO NOT place tu bing, o r

protect ive end caps in ste rile eld.

2. Remove Sp ike protector end c ap. Insert spike into

the uid contai ner. Note: ke ep vent cap close d

unless i nfusing from a rigid solution co ntain er.

3. Fill the d rip chamber by sq ueezin g the dri p

chamber until a pproximately half full .

4. Remove pro tector e nd cap from male Lu er adapter.

5. Slowly op en rolle r clamp to prime tubing a nd purge

air. Invert a nd tap inject ion ports wh ile prim ing. O nce

prime d, close ro ller cl amp.

6. Attach ad apter to vascul ar access device. Twist to secu re

Luer lock conne ction .

7. Slowly open ro ller clamp and a djust fo r desired ow rate.

Luer Activated Injection Site:

Use only st anda rd Luer connect ion devi ces. D O NOT USE ne edles or blunt cannul as to acce ss the swabable valves.

sing a ste rile alcohol pa d, swab t he Luer activate d surf ace and let it air dr y. C arefully connect the syringe o r Luer

U

connector STR AIGHT into the valve in a clock wise t wisting moti on. To disco nnect, twis t counte r clock wise. Flush th e

Luer act ivated s ite afte r each us e per facilit y protoco l.

To Initiate Fluid Warming:

1. Completely prime the syste m followin g the ste ps above, p urging all air

from the l ine, and star t infusion at desired ow rate. (Note : 7 mL/minute

minimum ow rate is n eede d to initiate warm ing. O nce warming be gins

(Flashing Blue LED), User may titrate to lower ow rates if des ired.

2. Briey pres s the ‘Status’ button on the Batte ry to ch eck bat tery

charge. Three gre en LEDs i ndicate a full ch arge. One LED or

no LEDs in dicate insucient ch arge to op erate the device. If

the Bat tery has sucient cha rge, rem ove the prote ctive cove r

and connect th e Contro ller to th e Batte ry. A green blinking

Controller LED in dicates syste m is ready fo r use. (I mage 1 )

3. Connect t he Cont roller to t he circu it car tridge

of the TIS by re moving its red protecti ve cap

exposi ng the ci rcuit ca rtri dge. (I mage 2)

4. Co nnect the Controller to the tubing by rmly

pressi ng the tubing’s ci rcuit cartridge into the

connector slot o n the Controlle r (Imag e 3). A

Blue a shing L ED indicates th e uid is w armin g

but is <36º C. A sol id green LED indi cates u id is

≥36ºC and < 44ºC. At steady state, the System

strives to maint ain infusion at a s et poin t of

38ºC +/- 2ºC. (Image 4) Note: th e System will

attain set point only dur ing owing infus ion.

5. D epending on uid temp eratu re and ow rate, the

User may need to adjust th e infusion rate to s tay in th e set poi nt rang e.

6. Whe n infusion is complete, disconnect th e Contro ller

from the TIS and battery to conserve power.

Image 4

Image 1

Image 2

-10-

Status Button

Circuit cartridge

Image 3

™

THERMAL TRANFUSION SET (TTS-B) –

for Blood/Blood Products and IV Solutions

Dual spike/one vent

•

200 micro n lter

•

WARNING: Only uid path an d area under prote ctive en d caps are STERIL E.

Luer act ivated i nject ion sites (2)

•

Male Luer lock ada pter

•

•

•

LIFEWARMER

Tubing length: 80” (230 cm) long

Primin g volume: 22 mL

TTS-B USE: (Use Aseptic Technique)

1. Open po uch whe re indi cated . Remove th e

tubing s et and clo se all th ree rolle r clam ps.

IMPORTANT: Only uid path is sterile.

DO NOT pla ce tubin g, or protective end caps i n

sterile eld.

2. Remove Sp ike protector end c ap. Insert one

spike into the uid container, open roller cl amp

under uid cont ainer. Note: keep ve nt cap

closed u nless infusin g from a rig id cont ainer.

3. Invertlte rchamb er. Partia lly open roller

clamp d ownstre am of lte r chamb er. Allow

approxi mately ½ of ch ambe r to ll wit h uid.

Close downstrea m (regul ating ) roller clamp.

Luer Activated Injection Site:

Use only st anda rd Luer connect ion devi ces. D O NOT USE ne edles or blunt cannul as to acce ss the swabable valves.

U

sing a ste rile alcohol pa d, swab t he Luer activate d surf ace and let it air dr y. C arefully connect the syringe o r Luer

connector STR AIGHT into the valve in a clock wise t wisting moti on. To disco nnect, twis t counte r clock wise. Flush th e

Luer act ivated s ite afte r each us e per facilit y protoco l.

4. Part ially op en rolle r clamp o n unused lead, prime and

close this roller clamp .

5. Return lter cha mber to u prigh t posit ion and tap to

displ ace air t rappe d in lter. Slowly open d ownstream

roller cl amp to pr ime, purge air an d ll tub ing. Invert and

tap injectio n ports while uid is ow ing. En sure air i s

expelled, repeat prim e if nece ssar y.

6. Attach ad apter to vascul ar access device, twist to secure

Luer lock conne ction .

7. Slowly open ro ller clamp and a djust fo r desired ow rate.

To administer blood, atta ch blood contai ner to un used

lead. Close rolle r clamp under s olution conta iner. Open

roller cl amp under blood conta iner..

To Initiate Fluid Warming:

Status Button

Image 1

Circuit cartridge

Image 2

Image 3

1. Complete ly prime t he system followi ng the steps above, purgin g all air

from the l ine, and star t infusion at desired ow rate. (Note : 7 mL/minute

minimum ow rate is n eede d to initiate warm ing. O nce warming be gins

(Flashing Blue LED), use r may titr ate to lower ow rates if desired.

2. Briey pre ss the ‘Status’ b utton on t he Battery to check battery charge.

Three gre en LEDs indicate a full ch arge. One LED or no L EDs indicate

insucient ch arge to op erate the device. If the Batter y has su cient

charge, remove the p rotective cover and conne ct the Co ntrolle r to the

Batter y. A green bli nking c ontroller LED indicate s system i s ready for use.

(Image 1).

3. Connec t the Con troller to the circ uit car tridge of the

TTS- B by removing its re d protective cap ex posin g the

circuit c artridge. (Image 2).

4. C onnect the Co ntrolle r to the tub ing by rmly press ing

the tubi ng’s circuit car tridge into the connec tor slot on

the Controller ( Image 3). A Blue ashing LED i ndicates

the uid is warmi ng but is < 3 6ºC. A solid gre en LED

indic ates ui d is between ≥36º C and < 44º C. At ste ady

state, system st rives to ma intai n infus ion at a set p oint

of 38ºC +/- 2ºC. (Ima ge 4) Note: t he System w ill att ain

set point only during owin g infus ion.

5. Dependi ng on ui d tempe rature and ow rate, t he

User may need to adjust infusion rate to stay in the

temperature set point ra nge.

6. When infusi on is comple te, disconnect the Controller from TTS-B.

Image 4

-11-

™

CHARGING/CONNECTING THE BATTERY

STEP1: Charging the Battery

Plug the Charger i nto an AC wall outlet us ing the AC power cord provided .

•

The Charger is powe red from 100 to 264 Vac, 50/60 Hz

Conne ct the Batter y to the Charger as s hown.

•

A solid green LED on the Charger ind icates ready for u se. A ashing blue

•

LED on the Charger i ndicates battery ch arging failure a nd the b atter y

should b e removed /replace d.

Charge s tatus progress ion is di splaye d by green L EDs on the batter y. Th is

•

may be del ayed whe n batter y is warm and will initiate automatical ly once

the battery temp is safe to c harge. When fully charg ed, the batter y enters

sleep mode and the LEDs turn o.

Allow the B atter y to charg e for 90 min utes (if f ully discharge d).

•

STEP2:Checking Battery Charge Status

Verify th e charge status o f the Bat tery by b riey pre ssing the Status

button a nd obse rvin g the LED in dicators:

1 LED illum inated: Batte ry cha rge is “Low”. Batter y has insucie nt

•

charge to o perate the devi ce. Charge or repl ace the Batter y.

2 LEDs Illu minate d: Battery is approximately 50% c harge d.

•

All 3 LEDs il lumin ated: Batter y is fully charged . Allow th e Batte ry

•

to charge fo r 90 minu tes (if fully discharged ).

Note: Bat tery c harge status sh ould be checked prior to e ach use.

STEP3:Connecting the Battery to the Controller (if preparing to warm uids)

Remove the protect ive cover fro m the Bat tery.

•

Conne ct the Controller to the Batter y by inserting the barrel conn ector end.

•

Upon connect ion, al l three (3) B atter y RED LEDs w ill bli nk simu ltane ously with or wit hout an a udible tone

•

(depen ding on w hethe r the Audible Aler t Sys tem is en abled ) while th e Contro ller ini tiates i ts sta rt-up se quence

(i.e., LED ash sequen ce: blue, yellow, green).

A green, b linki ng LED indicate s the controller is ready for use

•

The Cont roller (w ith connecte d Battery) is now re ady for co nnect ion to th e TIS or T TS-B

•

Important Battery Use Information:

The Battery sh ould be FULLY charged o n receipt and pri or to eac h use.

•

Recharge the Ba tter y after e ach use – eve n if not fully discharged.

•

Repla ce the Battery if no gree n LEDs are illumin ated on status ch eck.

•

Conne ct to charger to troublesh oot.

•

A fully cha rged Battery should p rovide su cient power to wa rm two (2)

•

units of refrigerated b lood pro ducts or approx imately 1 .0 L of intrave nous

soluti on or at a ow rate of 100 mL/minute (ba sed on a uid input

temperature of 4º C (38ºF).

The waterproof vent on the bottom of the Batte ry is important to ma intai ning protecti on from mo isture a nd

•

particles. Before us e, ensure the vent is intact. If the ve nt is worn , frayed, o r not securely att ache d,

-12-

obtain a new Battery).

LIFEWARMER

Vent

™

CONNECTING THE CONTROLLER

Connecting the Controller to the TIS or TTS-B tubing

Circuit cartridge

LIFEWARMER

™

Step 1

STEP1:

the middle conn ector of t he tubi ng set to expose

t

STEP2: Firmly press th e circui t cart ridge o n

the tubi ng into th e conne ctor slot on the bl ack

Controller Jacket as shown in the ph oto..

Remove the red protective ca p from

he circuit cartridge. Disc ard the re d protec tive cap .

Step 2

STEP3:

Refer to Controlle r LED illuminati on for System status.

A

ashing Blue LED that increases in intensity and

speed i ndic ates the uid is wa rming b ut is <36ºC.

A solid green LED indica tes the u id is bet ween ≥36ºC

and < 44ºC.

One gree n LED ash every s econd (w hile connecte d

to tubing) indicates st and by mo de, no ow or uid

ow is too slow to warm.

A solid ye llow LED indicate s a low batte ry con dition.

A yellow strobe LED in dicates a dry l ine, po or

connection , disconnect ion or tu bing me chanical

failure.

Disconnecting Components /Discontinuing Use

When infusion is complete, disconne ct the Co ntroller from the tubing.

•

Disconnect t he Cont roller from the Ba tter y.

•

Dispo se of cont aminated bio hazard materials acc ording to CDC and i nstitutional Guid elines.

•

Surface clean/disinfect Controller, Batte ry, and Charger.

•

Conne ct Battery to Ch arger and allow to charge for 9 0 minute s for a fully d eplete d battery.

•

-13-

ENABLING/DISABLING AUDIBLE ALERT SYSTEM

The Qua ntum Blo od & Flui d Warming System is equipp ed with a v isual a nd Audible Aler t system in the event of an

over-tempe rature co nditi on. An ove r-temper ature con ditio n can res ult in hemolysis to blood and/or elevated touch

temperature of th e intrav ascul ar tubi ng. Quantum Systems are provided w ith thi s feature fu lly enab led.

However, the Aud ible Ale rt Syste m may pose a h azard to certa in mili tary and/or tact ical m edic al user s depen ding

on the use environ ment. For these users a nd use cases only, if the prese nce of th e audib le alert presents a

potential hazard, it may b e disabled by following th e instructions below.

LIFEWARMER

Disabling Audible Alert System

1. Press and hold the Status button on t he Battery

continuously for 15 seco nds unt il hear ing 3 beeps and

seein g three ashes of the Red L EDs.

2. The Audi ble Aler t System i s now deac tivate d.

The audible alert self c heck to ne on com ponent

connection a nd in the event of an over-te mpera ture

condit ion is now silenc ed unti l user re -ena bles. (Note:

the visu al over-temp erature alert ( Red LED st robe)

remains active.

Re-enabling/Self Check

of the Audible Alert System

1. Press and hold the Status button co ntinuo usly for 15 secon ds until h earing the audible alert be ep 1 time and the 3

LEDs bli nk once.

2. The Audi ble Aler t System i s now react ivated .

3. The audible self-check tone wil l now be active when the cont roller i s conne cted to th e batte ry.

It is stro ngly reco mmended that the (over-temperatu re) Audib le Alert System rem ain ena bled un less a ta ctical hazard

is pose d. Re- enable the Aud ible Alert System followin g the ste ps above as soon as p ossible afte r the tactica l hazard i s

no longe r prese nt.

™

-14-

STER ILIT Y STATUS

LIFEWARMER

Sterile Components

Only the uid path and area u nder th e protec tive end c aps of th e TIS and T TS-B tubing sets are STERILE. Sterilizatio n

is achieved by exposure to Ethylene Oxi de (EO). Note: the prote ctive en d caps on the tubing set s should ONLY be

removed im medi ately pri or to tubi ng use. D O NOT place tube sets or protective e nd caps in the ste rile eld.

Product m ust be s tored in t he orig inal un opened packaging where temperatu res are between -20ºC to 60ºC . Ver ify th e

‘Use By ’ date on th e packaging. I f it is pas t the ‘U se By’ date, DO NOT USE .

Single [Patient] Use Components

The Qua ntum TIS ( Thermal Infusion Set) and T TS-B (Therm al Transfu sion Se t – Blood ) are disposab le, for Single Patient

Use Only. Do not reprocess or res terilize.

Non-Sterile/Reusable Components

The Cont roller w ith Jacket, Bat tery and Charg er are reusable and are provi ded non-sterile. These components do

not supp ort sterilization, but ins tead sh ould be surfac e cleaned/disinfe cted af ter eac h patie nt use according to the

instructions contained i n this ma nual.

CLEANING AND DISINFECTING

Cleaning and Disinfecting Instructions

The Qua ntum Controlle r with Jacket, Battery, and Charge r are supplied n on-sterile and should be sur face cle aned/

disinfe cted af ter each patie nt use.

Before cle aning , disco nnect the Controller f rom the Batter y. Remove the B atter y from the Charger a nd/or unplu g the

Charger from AC power. (Failure to do so before init iatin g cleani ng may exp ose per sonnel to unsa fe condi tions a nd

result in d amage to the devi ce). Note: th e followi ng proce dures are not guarantee d to contro l the spread of pat hogens.

Consult the loc al hosp ital in fection contro l admin istrator rega rding cleanin g procedure pol icies at your ins tituti on..

Cleaning

After each use, clean all exteri or sur faces of t he Cont roller (w ith Jacket in pla ce), Batte ry, and Charger, with a s oft

cloth moistened with a mild detergent solution . Remove any residu al clean er from the component surfac es. Dr y all

component sur faces. As Nee ded: the Controller Ja cket Con necto r Slot may be cleane d using the bru sh provid ed in

the Clea ning Ki t.

™

Disinfecting

After each use, d isinfe ct all ex terior surfaces of th e reusa ble comp onent s, i.e., Controller wit h Jacket , Battery, and

Charger, with a low-level disinfe ctant (suci ent for normal us e condi tions) with one of the following: 70 -90% Ethyl or

Isopro pyl Alcohol, Sodium Hyp ochlo rite (5.25 -6.15% house hold ble ach diluted 1:500). or comm ercial medic al-gr ade

wipe (e.g ., Kim-Wipe). Dr y all com ponent surf aces.

Controller Cleaning/Jacket Replacement

After the Controller is u sed approximately 10 times (or six mo nths), rem ove the Jac ket and cle an the entire Controlle r,

includ ing the i nside o f the Circuit Car tridge, with 70-90% Ethyl or I sopropy l Alcoho l. Let dr y 2 minutes. Usin g Quant um

Cleaning Kit, reapply Hydropho bic Coating to the Circui t Cartridg e and ins tall a new Jacket . Note: On ce a Jacket h as

been removed, it s hould b e discarded an d repla ced wit h a new Jacke t.

When us ing in conditi ons of excessive mo isture (e .g., e ld use/rain, etc.), rea pply hydrophobi c coating and rep lace th e

Jacket af ter eac h use. (Note: do not re use Jac kets. If the Jac ket is removed, it mu st be rep laced with a new Jacket to

ensure proper t ).

Note: Do not use caustic o r abrasive clea ners or s trong solvents .

-15-

VISUAL/AUDIO INDICATORS

The Life Warmer Quantum Blood & Flui d Warming System is d esign ed for simple, rel iable operation.

Refer to the Visual/Audio Ind icators Legend prese nted be low.

LIFEWARMER

USER INTERFACE VISUAL/AUDIO LEGEND

Quantum Controller

LED INDICATOR MEANING(S) ACTION REQUIRED

Start-Up Sequence

Blue

Yel low

Flash

Flash

Green Fl ash - ever y 4 seconds

when NOT Connected to Tubing

Green Fl ash - ever y second

when Connected to Tubing

Blue Flashing RAMP UP

(Flashing LED with increasin g

ntensity/speed)

i

Yellow Solid Low battery condition Charge or replace Batte ry Pac k

Green

Flash

Green S olid

Clear

Flash

Controller initializing

Self-Check OK

Ready for U se

Controller connecte d to

tubing a nd ready for ow.

(Stand by Mode).

ow too slow to wa rm

Fluid is warming and/or

temperature (<36º C)

Fluid is warmed to

≥36ºC (in s teady s tate).

sequence

No ow or

NORMAL

Consi der redu cing ow r ate if clinical ly accept able.

Conditions

No action requi red.

Conne ct Cont roller to p rimed tubing s et

Increas e ow rate if warming is desired.

If no fur ther wa rming desired, disc onnect system

Flow rate may b e exceed ing heating ca pacit y.

Check tu bing for p ossible contact

with cold surfa ce outdo ors.

No action requi red

Refer to Qu antum Sys tem Resp onse

by Temperature Table in Appe ndix.

™

Quantum Controller

LED INDICATOR MEANING(S) ACTION REQUIRED

Poor connection

Intentional disconnection

Tube mechanical failure.

Remind er to reat tach to

*

tubing s et if fur ther

warmin g is desi red.

Poor con nection to Bat tery,

Batter y Dead or

Controller failure

Yellow – Flash ing

(3 ashes – 1 every h alf

econd)

s

NO LEDS

Dry li ne

ALERT

Conditions

Disconnect C ontrol ler from tu bing set, ensure tubin g

set is com pletely primed a nd no air i n line.

If prope rly primed, reat tach the Controller to the

tubing se t and the ye llow stro be should stop.

If yellow st robe pe rsist s, tubing set may have a

*

mecha nical f ailure . Disco nnect Controller and t ubing

from pati ent. O btain a n ew Quantum Tubing Set,

follow Quick Start to pri me and at tach to p atient.

Disconnect C ontrol ler from B atter y to conserve

batter y power if no furth er warm ing is de sired .

Check ch arge st atus of Batter y.

If conne ction is prope r and Battery is charg ed,

-16-

Check co nnection to Batter y.

replac e the Controller.

VISUAL/AUDIO INDICATORS

LIFEWARMER

USER INTERFACE VISUAL/AUDIO LEGEND (continued)

Quantum Battery Pack

LED INDICATOR MEANING(S) ACTION REQUIRED

Red –STROBE and/or

AUDIBLE ALERT

(Sustained)

3 Red LEDs ash

simultaneously during

Start-Up and Audible Ale rt

Military and Tactical Medicine users: If the pre sence of an audi ble aler t presents a hazard, it may b e deact ivated by

the use r. Press and hold the status bu tton con tinuo usly for 15 s econd s until h earin g three quick be eps and seein g

three ashes of the Red LEDs, the a udible alert i s now dis abled . To reactivate, press an d hold th e status button a gain

for 15 sec onds until one b eep occ urs and t he Red LEDs ash once.

FLUID OVE R

TEMPERATURE

Audible Alert

is enabled

ALERT

Conditions

Stop uid ow. Discon nect Controller

from Battery and from tub ing set ..

C

heck inf usion soluti on cont ainer a nd line.

If solution cont aine r does no t feel war m to the tou ch,

reapply (reconn ect) t he Quantum Syste m.

N

ote: If aud ible ale rt is di sable d,

then only RED LED will strobe.

The Red B atter y LEDs an d Audible Alert w ill activate bri ey

each tim e the Co ntrolle r is conn ected to the Bat tery in the

normal condit ion wit h a charged batte ry as a functi onal tes t.

If NO LEDs , the Bat tery m ay be out of charge or

malfunctioning.

™

Quantum Battery Pack

LED INDICATOR MEANING(S) ACTION REQUIRED

Green S olid

(Battery Status)

reen LED – Batter y

1 G

Low (insucient to

operate device)

2 Green LEDs – 50%

charged (approximate)

3 Green LEDs –

Fully charg ed

NORMAL

Conditions

Sucient to power device, b ut recom mend

Quantum Charger Conditions

LED INDICATOR MEANING(S) ACTION REQUIRED

Contin ue charg ing unt il Battery st atus indicate s fully

charge d (three LEDs illuminated). A fully de pleted B atter y

require s 90 minutes to fully c harge

Disconnect B atter y from Charger, wait 5 se conds

f condit ion pe rsist s, obt ain a new B atter y.

I

Green S olid Normal Charging

Blue - Flashing B atter y charging failure

Charge or replace Batte ry

charging until f ully cha rged

o action require d

N

and reco nnect to Charge r.

-17-

TECHNICAL SPECIFICATIONS

The Qua ntum Blo od & Flui d Warming System has been tested an d found to co mply wit h recognized

stand ards for electrical sa fety and e lectro magnetic com patib ility. Th ese limits are d esigned to provide

reason able protectio n again st harmful inte rferences in cl inical use env ironme nts. T he System gener ates

radio frequen cy energy and sh ould be instal led and u sed in ac cordan ce with these in struc tions .

LIFEWARMER

Essential Performance:

The Ess entia l Performance of the Qu antum Blood & Fluid Warmin g System is to indic ate out ow uid temperature

when at or o utsi de the pre -set temperatu re range (≥ 36 to < 44ºC a t steady state) to the Operatoan d to detect proper

operational status.

Essential pe rform ance is conrmed by verif ying start-up L ED sequences of t he Battery an d Contro ller up on conn ection.

This con rmation sho uld be pe rform ed before each use of the Syste m. Upo n conne ction, all three (3) Battery RED L EDs

will blink simultaneously with or wit hout an a udible tone (dependi ng on whe ther th e Audib le Alert System is e nable d)

while th e Contro ller ini tiates i ts start-up sequen ce (i.e. , LED as h seque nce: blue, yellow, green,clear ).

System Information/Safety Classications:

BF Appl ied Part – TIS/ TTS -B Flui d Path

ME System .........................................................................................................................................Battery, Cont roller, TIS/ TTS-B, Cha rger

ME Equipment.................................................................................................................................B atter y, Controller, TIS/T TS-B

Type of protection aga inst electri cal sho ck ..........................................................Class 1 / inte rnally p owered

Degree of protection ag ainst e lectr ic shoc k ........................................................Type BF

Mode of Operation ......................................................................................................................Continuous

Performance (Warming):

Fluid Temperature Set Point ...............................................................................................38ºC ± 2ºC (100.4º F ± 2)

Fluid Warm ing Volum e* ..........................................................................................................Up to 1000 mL of bloo d products at 4ºC

uid input at a ow rate of 100mL /min

Up to 1700 mL of IV soluti ons at 20º C input a

a ow rate of 200 m L/min

Eective S et Point Warming Flow Rate* ..................................................................2 to 100 mL/minute 4º C uid input

2 to 200 mL/min 20ºC uid input

™

*Base d on fully c harged batter y and depending upon s tarting am bient te mper ature.

-18-

TECHNICAL SPECIFICATIONS

Component Specications:

Controller

PARAMETER VAL UE

Opera ting In put

Volt age (Vd c)

Input Volt age

Absolute Max (Vdc)

Opera ting Current (A) 0.001 minim um / 8.0 Max

Power interrupti on

tolerance (ms)

Charge Volt age (Ma x) 4.20V +/- 0.03V /cell

Charge Current (M ax) 1.6A

Liquid/Solid Ingress Controller wit h Jacket: IP 53

Weig ht 2.5 oz

Service (Use) L ife 1000 insertions/removals

PARAMETER VALU E

Sterility – Flui d path/

area underneath

protect ive end caps

Biocompatibility ISO 10993

Infusi on Set

Compatibility

Liquid/Solid Ingress

With protective c ap on

card connector

Weig ht:

Service (Use) L ife (Per) Single Patient Use

33.0 (min); 4 4.4 Typical ; 55.0 Max

56.0

30

TIS/TTS-B

Ethylene O xide

ISO 8536 -4

IP 53

≤ 60g (TI S)

≤ 75g (T TS-B)

LIFEWARMER

Battery

PARAMETER VALUE

Conguration 12 S1P / Li-Pol pouch cells (3.7v)

Chemical System Lithium

Nominal Voltage 44.4 V

Capacity

Conguration 12S1P

Discharge Current

(Max)

Discharge Cuto

Voltage

Charge Volt age (Ma x) 4.2 0V +/- 0.03V /cell

Charge Cu rrent (Ma x) 1.6A

Energy Rat ing 40.4 Wh

Liquid/Solid Ingress IP 67

Weig ht 16 0z

Service (Use) Li fe 3 years/500 cycles

Shelf-Life

PARAMETER VALU E

AC Power 100 to 264 Vac, 5 0, 60 Hz

Equipment Class Class I

Type Part B

Charge Volt age (Ma x) 50.4Vdc +/- 1%

Liquid/Solid Ingress IP 22

ESD

Weig ht 20 oz

Service (Use) L ife

Rated: 910mAh

Minimum: 850mAh

6A continuous

9A peak, 200 Hz 50% dut y cycle

33.0V (2.75V per cell)

Stored bat terie s with 30%

charge wi ll last 3 months .

Charger

Level 3, 4KV direct

contact;

+/-8 KV air discharge

2500

insertions/removals

™

-19-

OPERATING, STORAGE and

LIFEWARMER

DISTRIBUTION CONDITIONS

TIS / TTS-B Tubing Sets

PARAMETER OPERATING CONDITIONS SHIPPING/STORAGE CONDITIONS

Temperature -15ºC to +60ºC -20ºC to +60ºC

Humidity 0% to 95% relative humidity, non-con densi ng 0% to 95% relative humidity, non-condensing

Atmosp heric P ressure 62 kPA to 106 kPA 62 kPA to 106 kPA

Warm-up/ Cool-Down

from Storage Ex tremes

Altitude 12,000 ft 12,000 ft

PARAMETER OPERATING CONDITIONS SHIPPING/STORAGE CONDITIONS

Temperature -15ºC to +50ºC -20ºC to +6 0ºC

Humidity 0% to 95% relative humidity, non-con densi ng 0% to 95% relative humidity, non-condensing

Atmosp heric P ressure 62 kPA to 106 kPA 62 kPA to 106 kPA

Warm-up/ Cool-Down

from Storage Ex tremes

Altitude 12,000 ft 12,000 ft

PARAMETER OPERATING CONDITIONS SHIPPING/STORAGE CONDITIONS

Temperature

Humidity 0% to 95% relative humidity, non-con densi ng 0% to 95% relative humidity, non-condensing

Atmosp heric P ressure 62 kPA to 106 kPA 62 kPA to 106 kPA

Warm-up/ Cool-Down

from Storage Ex tremes

Altitude 12,000 ft 12,000 ft

2 minutes 2 minutes

Controller

2 minutes 2 minutes

Battery

0ºC to +45ºC (chargin g)

-20 to +50ºC (d ischa rging)

2 minutes 2 minutes

-20ºC to +60ºC

™

Charger

PARAMETER OPERATING CONDITIONS SHIPPING/STORAGE CONDITIONS

Temperature -20ºC to +45ºC -20ºC to +60ºC

Humidity 0% to 95% relative humidity, non-con densi ng 0% to 95% relative humidity, non-condensing

Atmosp heric P ressure 62 kPA to 106 kPA 62 kPA to 106 kPA

Warm-up/ Cool-Down

from Storage Ex tremes

Altitude 12,000 ft 12,000 ft

2 minutes 2 minutes

-20-

EMC COMPLIANCE and

LIFEWARMER

WARN ING STATEM ENT

The Qua ntum Blo od & Flui d Warming System equipme nt has be en tested and fou nd to comply with the limits of the

stand ard for me dical devices, IEC 60601-1-2:2014. These l imits are desi gned to p rovide rea sonable protection agains t

harmfu l inter ference i n a typical medical i nstal lation. The Q uantu m Equipm ent is Cl ass B. C lass B e quipm ent is

equipment suitable for use in all esta blish ment s, incl uding d omest ic est ablishment s and those directly conn ected to

the public low-voltage power supply networ k that supplie s buildings used for dom estic purposes. However, there is n o

guarantee that interference w ill not occur in a pa rticular instal latio n. If the Quantum System should cause interfere nce

to other devices , the following actions m ay be take n to attempt to corre ct the interfere nce:

Ensure th e Quant um System i s at least 30 cm (12 inches) away from any po rtable RF communic ation s ystem .

•

Conrm proper f uncti oning of Contro ller by disconnectin g the Bat tery a nd rest arti ng the Sys tem.

•

Consult the man ufacturer for as sist ance.

•

The Qua ntum is in tende d for use in t he elec tromag netic e nvironm ent specie d below. The customer or the u ser of th e

Quantu m should assure t hat it is used in su ch an envi ronment.

™

EMISSIONS TEST COMPLIANCE

RF Emiss ions,

CISPR 11

IMMUNITY TEST COMPLIANCE

Radiate d RF EM Fields, IEC

61000-4-3

Rated Power Fre quency

Magnet ic Fields, IEC 6100 0-4- 8

Electrostati c Disch arge, IEC

61000-4-2

FAA Regul ation s: In accordance with the US Depa rtme nt of Transportat ion (DOT) and th e Federal Aviati on

Admini strat ion (FAA ), the ope ratio nal Qu antum co mpone nts (B atter y, Controller, TIS/T TS-B) meets t he appl icab le

safety re quirements fo r Medi cal Por table Electro nic Devices (M-PED) by not exceedi ng the ma ximum level of rad iated

radio frequen cy inter ference as descr ibed in t he RTCA/DO 160F, Sect ion 21, C ategory M.

The Qua ntum Cha rger should only b e used in hospital and p rotecte d xed st ructure environments, and ha s not been

tested fo r use on ai rcraft.

Group 1, Class B

80 MHz – 2.7 GHz, 10 V/m

Amplitude modulati on 80% 1 KHz

30 A/m, 60 Hz

± 8 kV conta ct,

±2, ±4, ±8, ±15 kV air discharge

ELECTROMAGNETIC ENVIRONMENT -

The Quantum uses RF e nergy on ly for its inte rnal

function. Therefore, it s RF emis sions a re very low

and are not likely to cause any inter ference in

ELECTROMAGNETIC ENVIRONMENT -

GUIDANCE

nearby el ectron ic equi pment .

GUIDANCE

-21-

APPENDIX

Troubleshooting Guide

•

Quantu m Respo nse by Temper ature Table

•

TROUBLESHOOTING GUIDE

Gloss ary of Terms

•

Components List

•

Warranty

•

LIFEWARMER

™

Quantum Controller

LED INDICATOR MEANING(S) ACTION REQUIRED

Green Fl ash - ever y second

when Connected

Blue Flashing RAMP UP

(Flashing wit h increasing

ntensity/speed)

i

Yellow Solid Low b atter y condition Ch arge or re place B atter y Pack

Controller is in Standby

Mode (connecte d to

Tubing/ready for ow).

No ow detected or ow

too slow to warm

Fluid is warming and/or

temperature (<36º C)

Quantum Controller

LED INDICATOR MEANING(S) ACTION REQUIRED

Poor connection

Intentional disconnection

Tube mechanical failure.

Reattach to tubi ng set if

*

furth er warm ing is desired .

Poor con nection to Bat tery,

Batter y Dead or

Controller failure

Yellow – Flash ing

(3 ashes – 1 every h alf

econd)

s

NO LEDS

Quantum Battery Pack

LED INDICATOR MEANING(S) ACTION REQUIRED

Red –STROBE and/or

AUDIBLE ALERT

(Sustained)

3 Red LEDs blink

simultaneously during

Start-Up and Audible Ale rt

FLUID OVE R

TEMPERATURE

Audible Alert

is enabled

Dry li ne

NORMAL

ALERT

Conditions

Increa se ow rate if warmin g is desi red.

If no fur ther wa rming desired, disc onnect system

Flow rate may b e exceed ing heating ca pacit y.

Consi der redu cing ow r ate if clinical ly accept able.

Check tu bing for p ossible contact

Conditions

Disconnect C ontrol ler from tu bing set, ensure tubin g

set is com pletely primed a nd no air i n line.

If prope rly primed, reat tach the Controller to the

tubing se t and the ye llow stro be should stop.

If yellow st robe pe rsist s, tubing set may have a

*

mecha nical f ailure . Disco nnect Controller and t ubing

from pati ent. O btain a n ew Quantum Tubing Set,

follow Quick Start to pri me and at tach to p atient.

Disconnect C ontrol ler from B atter y to conserve

batter y power if no furth er warm ing is de sired .

Check co nnection to Batter y.

Check ch arge st atus of Batter y.

If conne ction is prope r and Battery is charg ed,

ALERT

Conditions

Stop uid ow. Discon nect Controller

from Battery and from tub ing set ..

C

heck inf usion soluti on cont ainer a nd line.

If solution cont aine r does no t feel war m to the tou ch,

reapply (reconn ect) t he Quantum Syste m.

N

ote: If aud ible ale rt is di sable d,

then only RED LED will strobe.

The Red B atter y LEDs an d Audible Alert w ill activate bri ey

each tim e the Co ntrolle r is conn ected to the Bat tery in the

normal condit ion wit h a charged batte ry as a functi onal tes t.

If NO LEDs , the Bat tery m ay be out of charge or

-22-

with cold surfa ce outdo ors.

replac e the Controller.

malfunctioning.

APPENDIX

LIFEWARMER

™

TROUBLESHOOTING GUIDE

(continued)

Quantum Charger Conditions

LED INDICATOR MEANING(S) ACTION REQUIRED

NO LED No AC Power or Ch arger Failure

Blue Flashing B atter y charging failure

Check co nnections to P ower Source and Charger.

If power so urce and c onnec tions are conrmed an d

condit ion pe rsist s, then replace Charge r.

Disconnect B atter y from Charger, wait 5 se conds

and reco nnect to Charge r.

f condit ion pe rsist s, obt ain a new B atter y.

I

QUANTUM SYSTEM RESPONSE BY TEMPERATURE

FLUID

TEMP

≤ 30ºC Active Blu e -Flashing

31ºC Active Blue -Fla shing

32ºC Active Blue -Flashing

33ºC Active Blue -Flas hing

34ºC Active Blue -Fl ashing

35ºC Active Blue -Fl ashing

36ºC Active Green- Sol id

37ºC Active Green- So lid

38ºC Act ive Green- Sol id

39ºC O G reen- Solid

40ºC O Gree n- Solid

42ºC O Green- Solid

43ºC O G reen- S olid

≥ 44ºC O

> 47ºC O

> 48ºC O

> 49ºC O

> 50ºC O No LED Red Flashing & Audi ble Aler t Immediately

NOTE 1:

Controller and t riggers the Visual /Audible Alert System

(i.e., RED ashing LEDs w ith Audible Aler t on Battery).

HEATING

ELEMENT

41ºC O Green- So lid

The The rmal Cut- Out cut s power to th e

CONTROLLER B ATTE RY THERMAL CUT-OUT

Green So lid: ≤ 5 min su stai ned;

No LED: >5 min su stained Red Flashing & Audible Alert

Green So lid: ≤ 2 min su stai ned

No LED >2 min sustaine d Red Flashing & Aud ible Alert

Green So lid : ≤ 10 sec sus tained

No LED: >10 sec sust aine d Red Fl ashing & Audib le Alert

Green So lid: ≤4 se c sustained

No LED: >4 se c susta ined Red Flash ing & Aud ible Alert

LED INDICATIONS

NOTE 2:

If the Aud ible Alert Syste m has been manu ally

disab led, th e Batte ry will displ ay Red a shing L EDs Only.

No audible aler t.

E

D

After 5 minutes

After 2 minutes

After 10 seconds

After 4 se conds

-23-

APPENDIX

LIFEWARMER

GLOSSARY OF TERMS

TERM DESCRIPTION

Controller Comma nd cente r the Syste m. Contains t he micro proces sor that assesses an d regul ates temperatu re.

Controller Jacket

Set point tempe rature The man ufactu rer pre-set temperatu re of the System = 38ºC +/- 2ºC

mL/min Millil eters pe r minute

IP

IP 22

IP 53

IP 64

IP 67

Jacket pe rmit s the mating (connecti on) of the TIS or TTS-B tu bing ci rcuit connector to the co nnector

slot on the Controller. Protec ts the C ontroller and should be replac ed afte r approximately 10 us es or 6

months . The Jacket must remain in place for d evice op erati on.

Ingres s Protect ion. Ra ting system for for electronic eq uipme nt and/

or housings to ag ainst solid s (1st d igit) and liq uids (2nd digi t).

Solid s: Protec ted from solids >12.5mm

Liquids: Protected from dripping water.

Liquids: Protected from water spr ay less th an 60 deg rees fro m verti cal.

Liquids: Protected from immersion between 1 5 centim eters and 1 meter i n depth .

Solid s: Protec ted from l imited dust ingress.

Solid s: Protec ted from to tal dus t ingress

Liquids: Protected from water spr ay from any directi on

Solid s: Protec ted from to tal dus t ingress.

Quantum Blood & Fluid Warming System COMPONENTS LIST

PART NUMBER DESCRIPTION

35-0001 Quantu m Batte ry

35-0002 Quantu m Charge r

35-0003 Quantu m Contro ller

35-0004 Quantu m Therm al Infu sion Set (TIS)

35-0005 Quantu m Therm al Transfu sion Set (TT S-B)

35-0006 Qua ntum Syste m (Kit ): 1 x Controller, 1 x Battery, 1 x Charger, 2 x TTS -B

™

-24-

™

Blood & Fluid Warming System

COMPONENTS

Vent

Quantum

Charger

™

Status

Button

LED

Indicator

Lights

Quantum Battery

TTS-B Thermal Transfusion Set - Blood

(Blood, blood products & IV solutions)

2

00 micron ltered

drip chamber

Circuit cartridge

connector

RED Roller

Clamps

“

Y” typ e

dual spikes

LIFEWARMER

Quantum

Controller

RED Downstream

Roller Clamp

M

ale Luer

Connector

lide

S

Clamps

I

njection

Ports

™

TIS Thermal Infusi on Set (IV solutions)

Dr

chamber

2

0 gtt/ml

Male Luer

Connector

ip

BLUE Roller Clamp

C

cartridge

connector

I

njection

Ports

& Slid e clamps

ircuit

-25-

WARRANTY POLICY for

LIFEWARMER

PURCHASED EQUIPMENT

Life Warme r, Inc. warrants t hat all durable, or reusa ble, com ponents of th e Quantum Fluid a nd Bloo d Warming system

are patient-ready and are fre e from defe cts in b oth mate rial s and work mansh ip unde r normal use for a period of one

(1) year f rom the original purchase from L ife Warmer, Inc. or it s authorized dis tributor. Life Warmer, Inc. furthe r warrants

that all s terile d ispos able Quantum infusion sets a nd transfusion set s are pati ent-ready and are free from defects in

both mate rial s and workmanship under norm al use for a p eriod equivalent to th e packa ging sterility date.

Any state d warra nties a re in eect from the date of sale . Life Warme r, Inc. rese rves the right to repair, replace or re fund

(less cos t of ship ping) a ny item(s) requiring war ranty s ervi ce. The customer is resp onsib le for retur n shipp ing cos ts and

require d to contact Nor th Ame rican R escue at 888-689-627 7 prior to shipping the i tem(s) b ack.

This war ranty i s void if: (a) the equipm ent has b een damaged by n egli gence, accide nt or mis handl ing, or has not

been op erate d in accordance with the procedu res desc ribed i n the operating instructions; or (b) t he equipment has

been altered or re paired by any comp any or ent ity oth er than L ife Warmer, Inc. or adaptati ons or accesso ries have

been ma de or att ached to the equipme nt which, in the determination of Life Warmer, Inc. shall have aected the

performance, safety, or reliability of the equ ipmen t. NO OTHER WARR ANTY EXPRES SED OR IM PLIED, IN CLUDIN G

MERCHAN TABILITY, applies to the equi pment , nor is any perso n or comp any auth orized to a ssume a ny other warran ty.

This Limited Warr anty does not cove r normal wear an d tear of th e product. Thi s warranty doe s not apply to and Life

Warmer, Inc . will not be respo nsible for any defect in or damage to:

The product if it ha s been m isuse d, neg lected, impro perly in stalled, phys ically damaged or alte red, ei ther internal ly or

extern ally, or damaged fro m improp er use or use in an unsuit able environme nt or the u se of unauthori zed acces sories;

The product if it is used as a compon ent par t of a product expres sly warranted by an other m anufa cturer ; or

The product if it s origi nal ide ntic ation (labeling, t rade-mark , seria l numbe r) markings have b een def aced, a ltered , or

removed.

Disclaimer

THIS LIMITED WAR RANT Y IS TH E SOLE AND E XCLUSIVE WARR ANTY PROVIDED BY LIFE WARMER, INC . IN

CONNECTION WITH YOUR LIFE WARMER, INC. PRO DUCT AND IS , WHERE PERMITTED BY LAW, IN LIEU OF ALL

OTHER WARRANTIES, CONDITIONS, GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND LIABILITIES, EXPRESS

OR IMPLIED, STATUTORY OR OTHERWISE IN CONN ECTION WITH THE PRODUCT, HOWEVER ARI SING (W HETHER

BY CONTRACT, TORT, NEGLIGENCE, PRINCIPL ES OF MANU FACTURER’ S LIABI LITY, OPERATION OF LAW, CONDUCT,

STATEMENT OR OTHERWISE), INCLUDING WITHOUT RESTRICTION ANY IMPLIED WARRANTY OR CONDITION

OF QUALITY, MERCH ANTABILIT Y OR FITNE SS FOR A PARTICU LAR PURPOS E. ANY IMPLIED WARRANTY OF

MERCHAN TABILITY OR FITNESS FO R A PARTICULAR PURPO SE TO THE EXTENT REQUIRED U NDER AP PLICABLE L AW

TO APPLY TO THE PRO DUCT SHALL BE LIMITED IN DURATION TO THE PERIOD STIPULATED UNDER THIS LIMITED

WARRANT Y. IN N O EVENT WILL LI FE WARMER, INC. B E LIAB LE FOR ANY SPECIA L, DIR ECT, INDIR ECT, INCIDENTAL OR

CONSEQUENTIAL DAMAG ES, LOSSES , COSTS OR E XPENSES HOWEVER ARISING WHETHER IN CONTRACT OR TORT

INCLUDI NG WITHO UT RESTR ICTIO N ANY ECONOMIC LOSSES OF ANY KIND, ANY LOSS OR DAMAGE TO PROPERTY,

ANY PERSON AL INJURY, ANY DAMAGE OR INJURY AR ISING FR OM OR AS A R ESULT O F M ISUSE OR ABUSE, OR THE

INCORR ECT INSTALL ATION, INT EGRATION OR OPERATION O F THE PRODUCT

™

LifeWarm er,Inc.

Addiso n, TX 75 001

972-908-9808

lifeline@lifewarmer.com

-26-

™

Distributed by

35 Tedwall Ct. • Greer SC 29650 • USA

™

Blood & Fluid Warming System

™

Distributed by

35 Tedwall Ct. • Greer SC 29650 • USA

ZZ-1098 • RE V050619

Loading...

Loading...