Lifestand LSCT Service Manual

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 1 of 93

LSCT

Service manual:

ENGLISH

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 2 of 93

CONTACT LIFESTAND

The company Lifestand, which is part of the Permobil Group, is responsible for maintenance

and sales services undertaken by its local importers and distributors.

Do not hesitate to contact us to find the contact details of the point of sale and after sales

service closest to your domicile.

Registered office of the Permobil Group

Permobil AB

Box 120

861 23 Timrä

SWEDEN

Tel. +46 (0) 60 59 59 00

Fax: +46 (0) 60 57 52 50

E-mail: info@permobil.se

Lifestand Permobil Group

5 Rue Clément Ader

69740 Genas

FRANCE

Tel. +33 (0)4 37 26 27 28

Fax: +33 (0)4 37 26 27 29

E-mail: info@permobil.com

Please consult the user manual and/or the pre-sales information for any information not

mentioned in this manual, which can be downloaded from the Permobil & Lifestand websites or

contact the closest Permobil / Lifestand centre.

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 3 of 93

Contents

CONTACT LIFESTAND ............................................................................................................. 2

INFORMATION .......................................................................................................................... 4

REPAIRS .............................................................................................................................. 5-54

SETTINGS .......................................................................................................................... 55-72

WIRING ............................................................................................................................... 73-80

TROUBLESHOOTING ........................................................................................................ 81-93

GENERAL WARNINGS FOR ANY INTERVENTION CARRIED OUT ON THE CHAIR:

Before any repairs and/or modifications on the chair, analyse the intervention points so

that you can put the chair back together again.

When dismantling one or more components, always be careful of the weight and/or the

weight of the component(s) which it supports and/or holds.

Before any mechanical intervention on the chair, remove the fuse from the chair (see

section «Fuse»).

Put some medium threadlock on the screws which are not locked with a brake nut and/or

which are not adjustment screws.

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 4 of 93

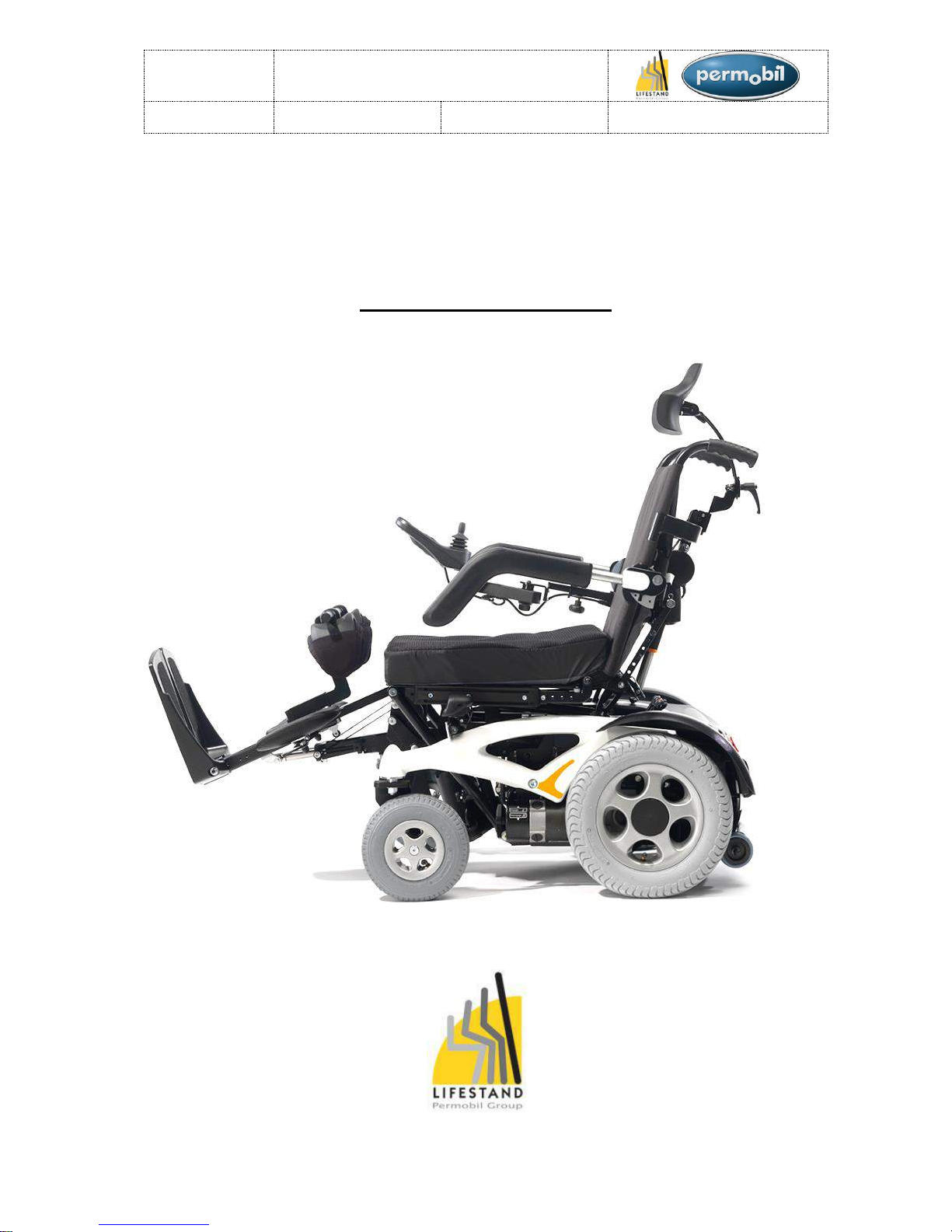

NAME PLATES:

FRAME:

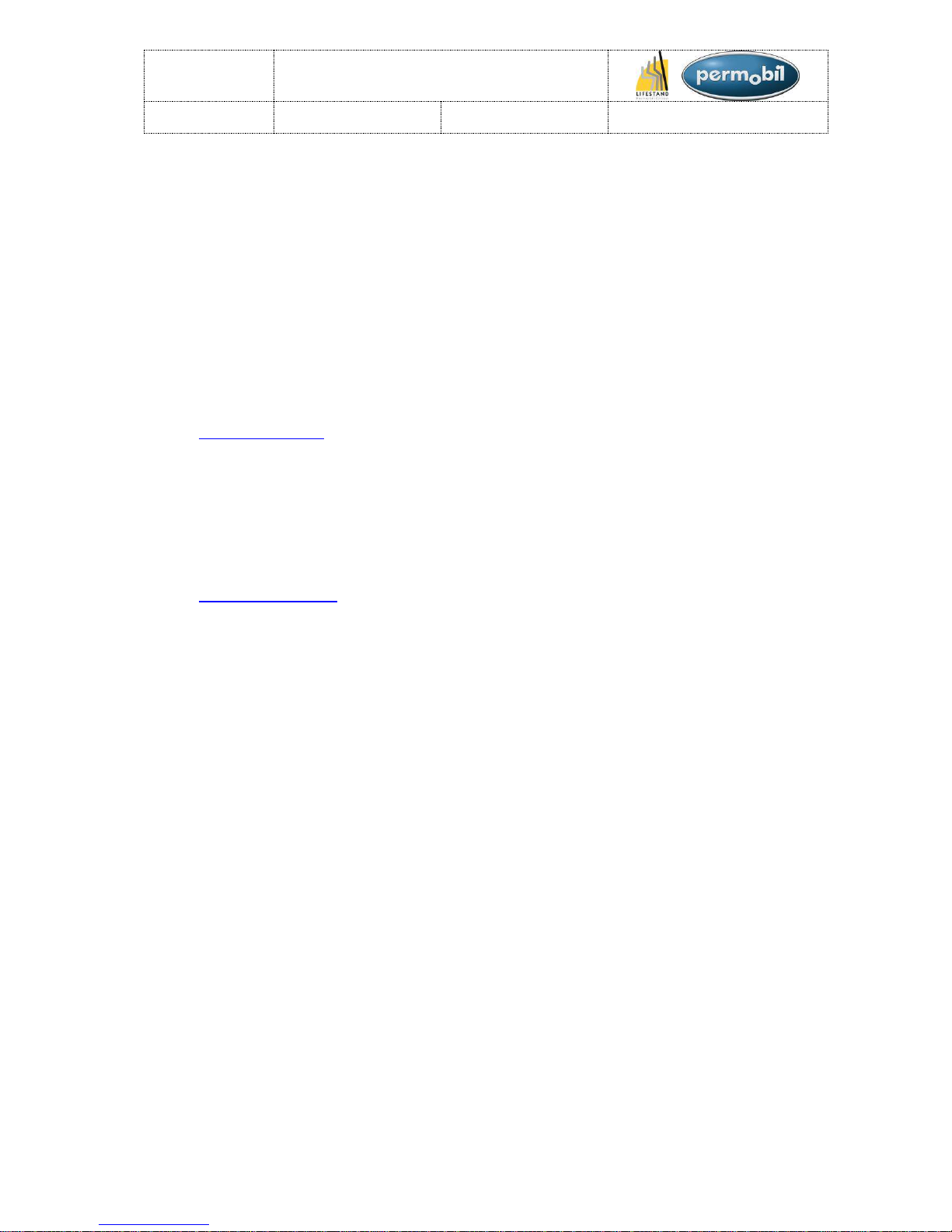

POWER MODULE R-NET:

(Dismantle the back cover to gain access to the

Power module R-NET; see section «Back cover».)

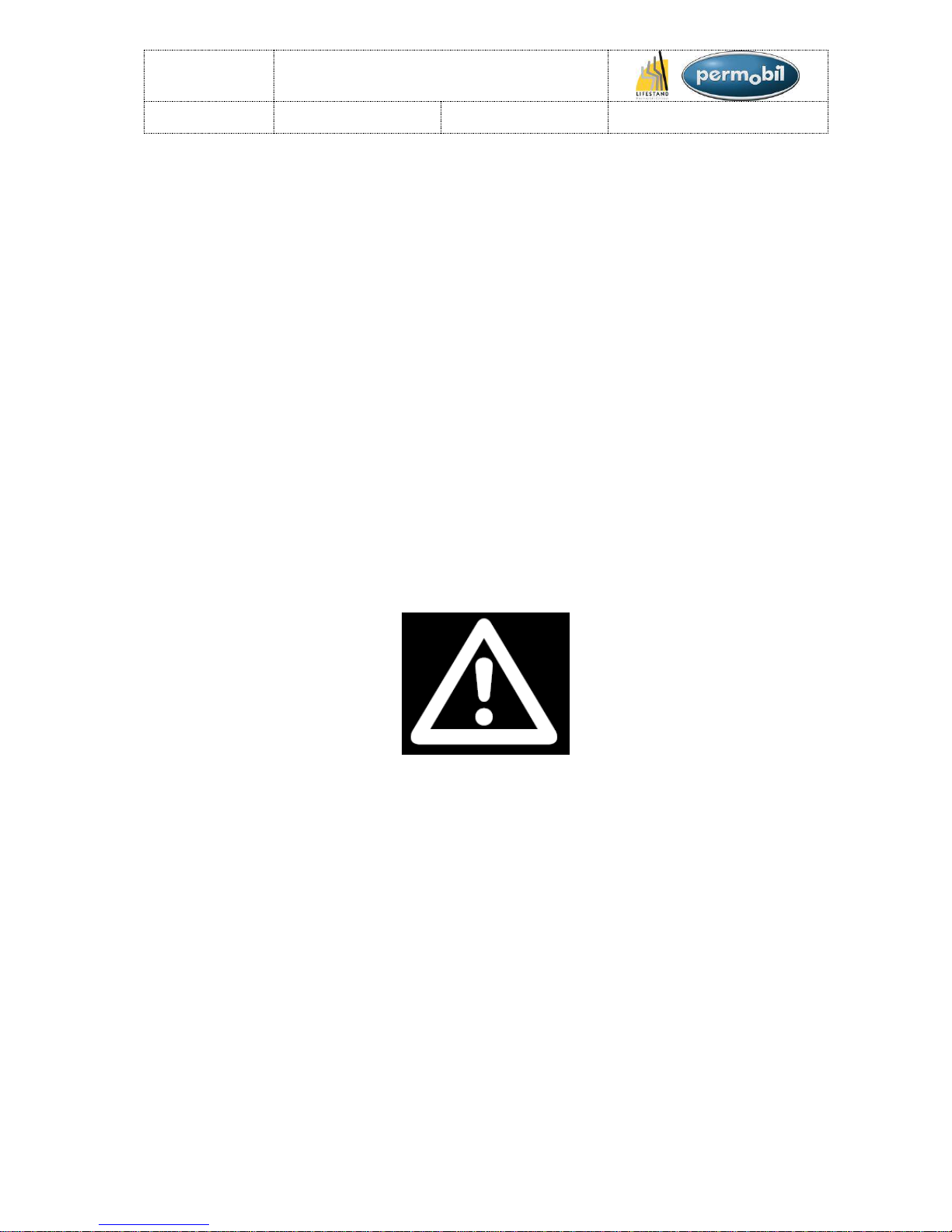

ISM R-NET:

(Dismantle the back cover to gain access to the

ISM R-NET; see section «Back cover».)

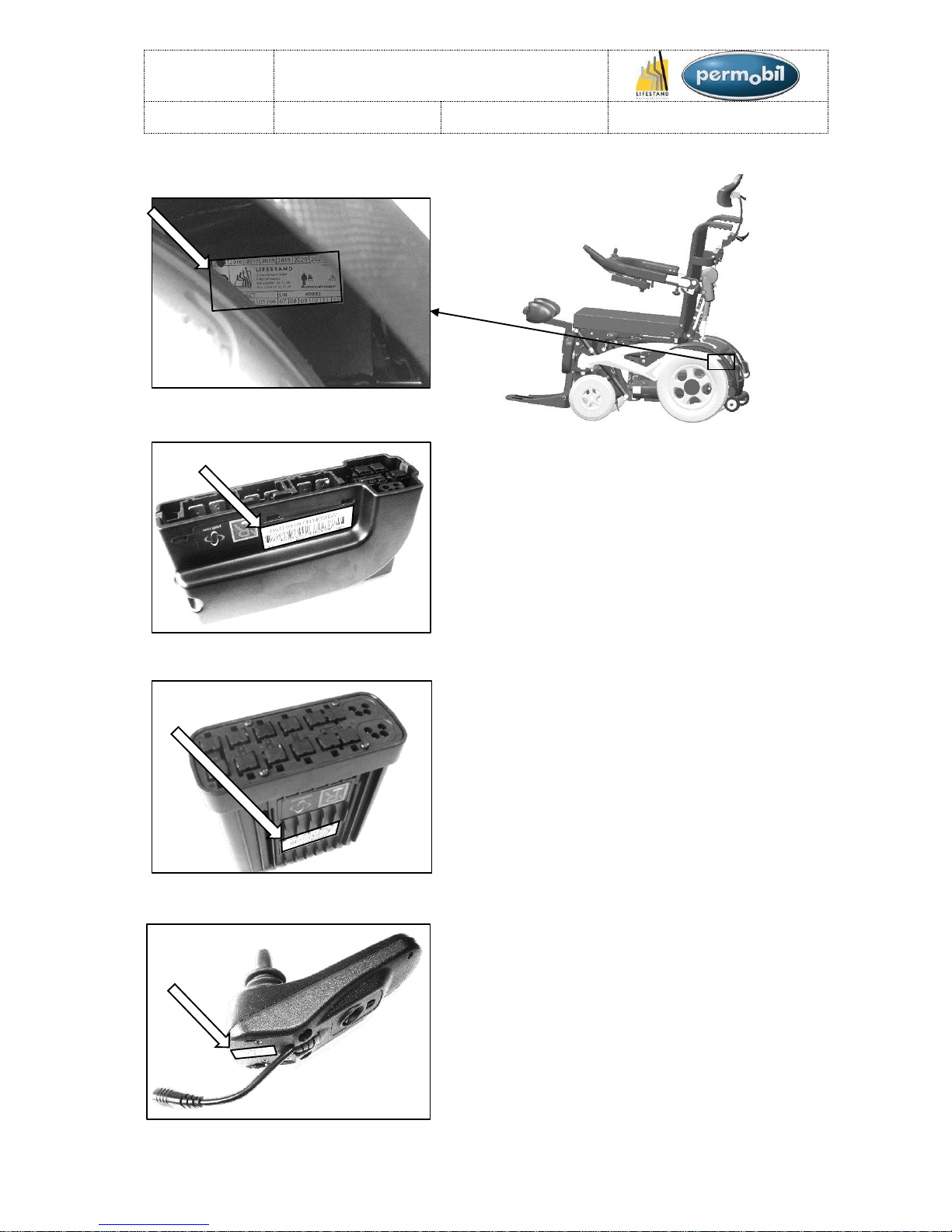

CONTROL BOX R-NET:

INFORMATION

Figure 1

Figure 2

Figure 3

Figure 4

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 5 of 93

REPAIRS

BACK COVER: ........................................................................................................................... 7

FUSE: ........................................................................................................................................ 8

UNDERRIDE GUARD AND ANTITIPPER WHEEL: ................................................................... 9

ISM AND/OR POWER MODULE: ........................................................................................... 10

BATTERIES (1/2): .................................................................................................................. 111

BATTERIES (2/2): .................................................................................................................... 12

REAR WHEELS (1/2) : ................................................................ ............................................ 13

REAR WHEELS (2/2) : ................................................................ ............................................ 14

FRONT WHEELS (1/2): ............................................................................................................ 15

FRONT WHEELS (2/2): ............................................................................................................ 16

FRONT WHEEL BEARINGS (1/2): ........................................................................................... 17

FRONT WHEEL BEARINGS (2/2): ........................................................................................... 18

FRAME (1/2): ........................................................................................................................... 19

FRAME (2/2): ........................................................................................................................... 20

SEAT TILT: .............................................................................................................................. 21

GUIDE RAILS ....................................................................................................................... 21

SEAT TILT ACTUATOR: ....................................................................................................... 22

FRONT TRANSLATION GUIDING: ....................................................................................... 23

SEAT STOP: ............................................................................................................................ 24

STANDING STOP: ................................................................................................................... 25

BACKREST ACTUATOR (1/2): ................................................................................................ 26

BACKREST ACTUATOR (2/2): ................................................................................................ 27

STANDING ACTUATOR (1/2): ................................................................................................ . 28

STANDING ACTUATOR (2/2): ................................................................................................ . 29

LEGREST: ............................................................................................................................... 30

LEGREST ACTUATOR (1/2): ................................................................................................... 31

LEGREST ACTUATOR (2/2): ................................................................................................... 32

LEGREST GUIDE RAIL (1/2): .................................................................................................. 33

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 6 of 93

LEGREST GUIDE RAIL (2/2): .................................................................................................. 34

LEGREST COMPENSATION STRAP: ..................................................................................... 35

LEGREST COMPENSATION STRAP ROLLERS: .................................................................... 36

LEGREST LOWER BEARING: ................................................................................................. 37

SHOCK ABSORBERS (1/2): .................................................................................................... 38

SHOCK ABSORBERS (2/2): .................................................................................................... 39

FRONT LIGHTS: ...................................................................................................................... 40

REAR LIGHTS: ........................................................................................................................ 41

MOTORS (1/2): ........................................................................................................................ 42

MOTORS (2/2): ........................................................................................................................ 43

UNITRACK RAILS: ................................................................................................................... 44

ARMRESTS (1/2): .................................................................................................................... 45

ARMRESTS (2/2): .................................................................................................................... 46

SEAT CUSHION : .................................................................................................................... 47

SEAT PLATES: ........................................................................................................................ 48

BACKREST COVERS: ............................................................................................................. 49

BACKREST STRAPS (1/2): ..................................................................................................... 50

BACKREST STRAPS (2/2): ..................................................................................................... 51

BACKREST (1/2): ..................................................................................................................... 52

BACKREST (2/2): ..................................................................................................................... 53

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 7 of 93

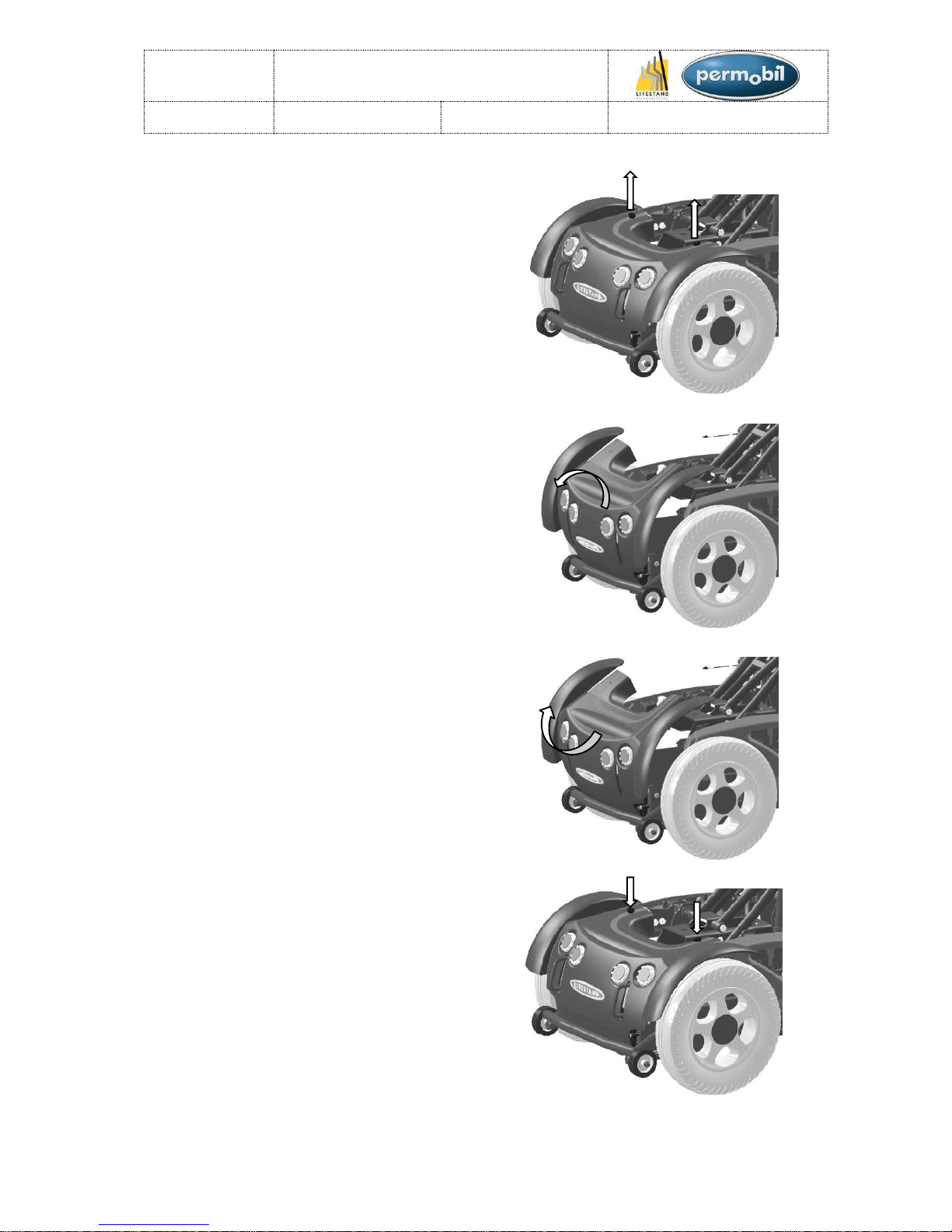

BACK COVER:

Dismantling:

1. Unscrew the two handles. (Place the

chair in standing position to facilitate

access to the handles). (See figure 5)

2. Carefully pull the back cover backwards

and disconnect the lights and indicators

before removing it completely. (Pay

attention to the way in which the back

cover is removed). (See figure 6)

Figure 5

Figure 6

Assembly:

Assemble in the reverse order.

1. Reconnect the lights and indicators (See

section «Electrical circuit diagram».

2. Replace the back cover by making the

opposite movement of removing it. (See

figure 7)

3. Replace and re-tighten the two handles.

(See figure 8)

Figure 7

Figure 8

REPAIRS:

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 8 of 93

FUSE:

1. Place the chair in standing position.

2. Take off the back cover (See section

«Back cover»).

3. Remove the protective housing of the

fuse holder. (See figure 9)

4. Remove the fuse. (See figure 9)

5. Insert the new fuse.

6. Replace the protective housing of the

fuse holder.

7. Put back the back cover (See section

«Back cover»).

Figure 9

REPAIRS:

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 9 of 93

UNDERRIDE GUARD AND ANTITIPPER WHEELS:

Dismantling:

1. Take off the back cover (See section

«Back cover»).

2. Take off the 4 nuts and washers then

remove the underride guard. (See figure

10)

Figure 10

3. Remove the nut cap and take off the nut

that is behind. (See figure 11)

4. Replace the antitipper wheel(s).

Figure 11

Assembly:

Assemble in the reverse order.

1. Re-tighten the nuts on the antitipper

wheels (adjust the tightening so that the

wheels can rotate freely). (See figure 12)

2. Replace the nut cap. (See figure 12)

Figure 12

3. Put back the underride guard with the 4

washers and the 4 nuts. (Tightening

torque: 27N.m). (See figure 13)

4. Put back the back cover (See section

«Back cover»).

Figure 13

REPAIRS:

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 10 of 93

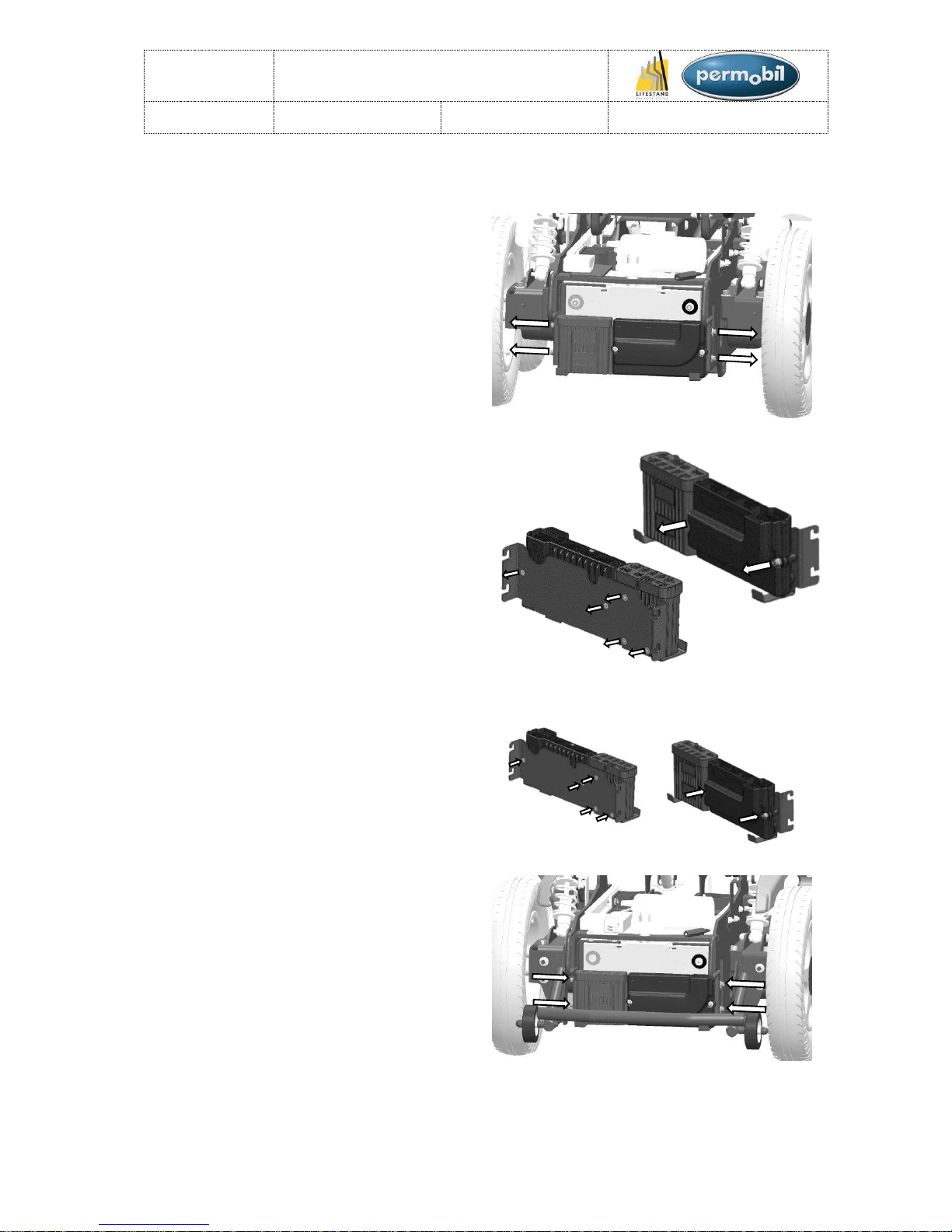

ISM AND/OR POWER MODULE:

Dismantling:

1. Remove the back cover (see section

«Back cover»).

2. Remove the underride guard (see section

«Underride guard and antitipper wheels).

3. Unscrew the 4 screws. (See figure 14)

4. Disconnect all the cables connected to

the ISM or the Power Module (noting their

position).

5. Remove the closing plate and unscrew

the ISM and/or the Power Module. (See

figure 15 & 16)

Figure 14

Assembly:

Assemble in the reverse order.

1. Reattach the Power Module and/or the

ISM. (See figure 17 & 18)

2. Reposition the closing plate.

3. Re-tighten the 4 screws (Tightening

torque: 11.1N.m). (See figure 19)

4. Put back the underride guard (Tightening

torque: 27N.m).

5. Reconnect the various connectors on the

power module and/or the ISM (See

section «Electrical circuit diagram» and

«Chair cabling»).

6. Put back the back cover (see section

«Back cover»).

Figure 19

REPAIRS:

Figure 15

Figure 16

Figure 18

Figure 17

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 11 of 93

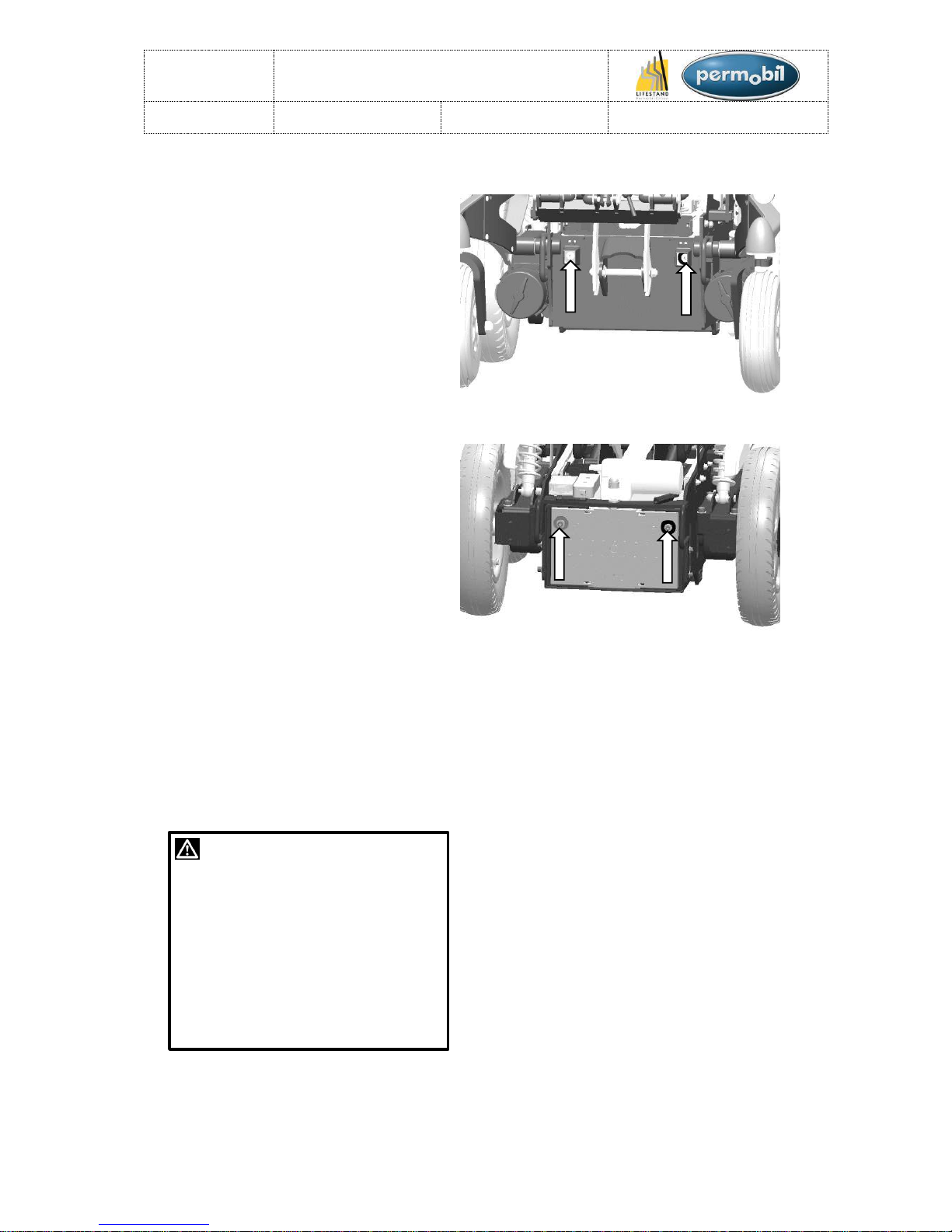

BATTERIES (1/2):

Dismantling:

1. Tilt completely the seat of the chair.

2. Remove the back cover (See section

«Back cover»).

3. Remove the fuse (See section

«fuse»)

4. Remove the underride guard (See

section «Underride guard and

antitipper wheels»).

5. Remove the closing plate (Step 3

section «ISM and/or Power Module»).

6. Unplug the motors and the power

cables from the power module (See

section «Electrical circuit diagram»).

7. Flip up the plate with the Ism and the

power module.

8. Unscrew the two screws on the front

battery and unscrew the two screws

on the rear battery. (See figure 20 &

21)

9. Remove the rear battery with the

assistance of its handles (WARNING:

do not place the battery connectors in

contact with anything else and be

careful to not damage the cables).

10. Then remove the second battery.

WARNING !

Be careful when using metal tools or

objects close to the batteries, a shortcircuit can easily cause an explosion.

Always use gloves and safety

glasses.

Remember that the batteries are

heavy and they must be handled

extremely carefully.

Figure 20

Figure 21

REPAIRS:

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 12 of 93

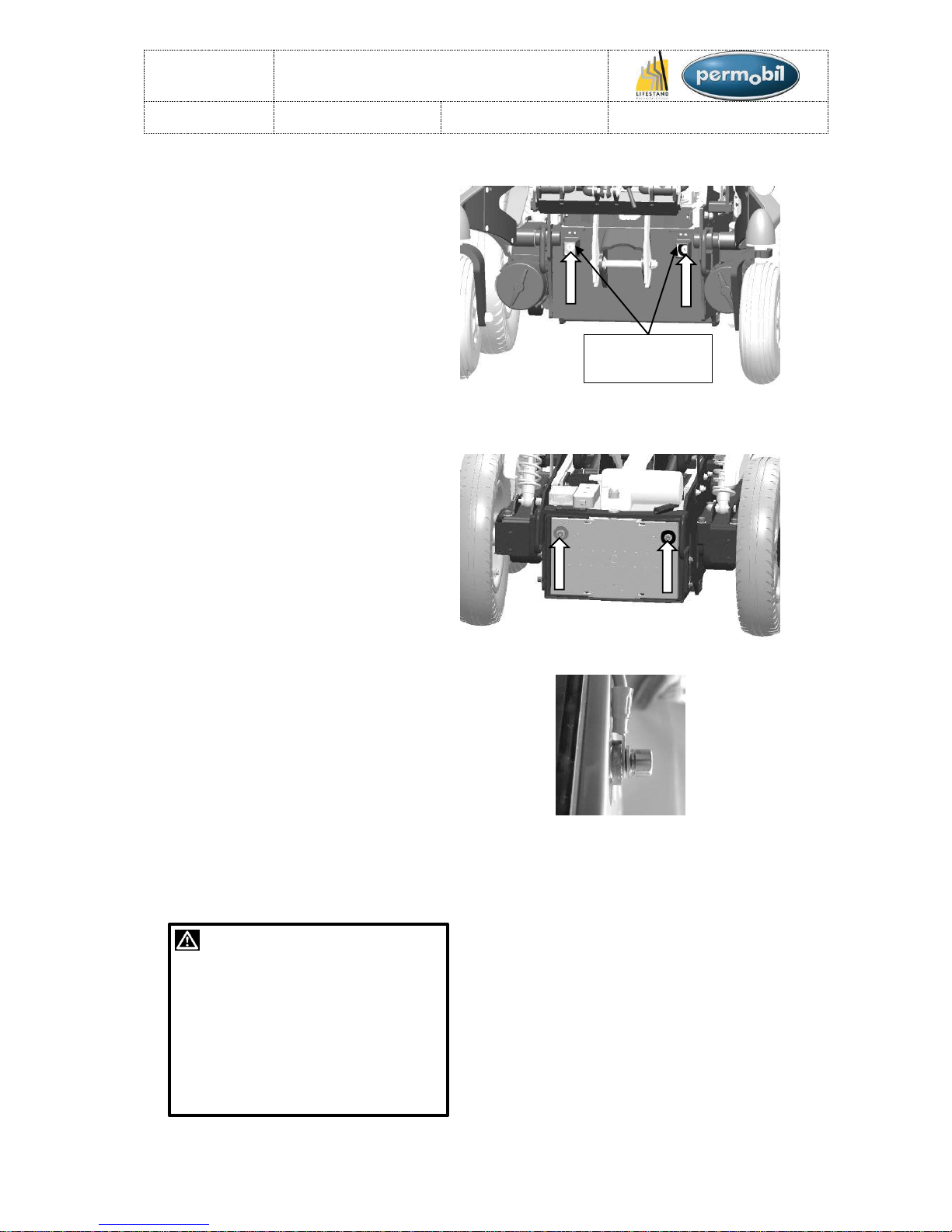

BATTERIES (2/2):

Assembly:

Assemble in the reverse order.

1. Insert the front battery ensuring that

the connector guards are in the right

position. (Warning, the battery

connectors must under no

circumstances come into contact with

any other components).

2. Reconnect the wire bundles to the

front battery and tightening the

screws (Be careful to the orientation

of the connector (see Figure 22 and

23-b)) (Tightening torque: 11.1N.m).

(See section «Electrical circuit

diagram»).

3. Insert the second battery and

reconnect the wire bundles to the

rear battery and tighten the screws

(Be careful to the orientation of the

connector (see Figure 23 and 23-b))

(Tightening torque: 11.1N.m). (See

section «Electrical circuit diagram»)

4. Put back the closing plate (See step

2 and 3 section «ISM and/or Power

Module»).

5. Put back the underride guard (See

section «Underride guard and

antitipper wheels»).

6. Plug back the motors and power

cables on the power module (See

section «Electrical circuit diagram»)

7. Put back the fuse (See section

«Fuse»)

8. Put back the back cover (See section

«Back cover»).

WARNING !

Be careful when using metal tools or

objects close to the batteries, a shortcircuit can easily cause an explosion.

Always use gloves and safety

glasses.Remember that the batteries

are heavy and they must be handled

extremely carefully.

Figure 22

Figure 23-a

Figure 23-b

Connector

guards

REPAIRS:

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 13 of 93

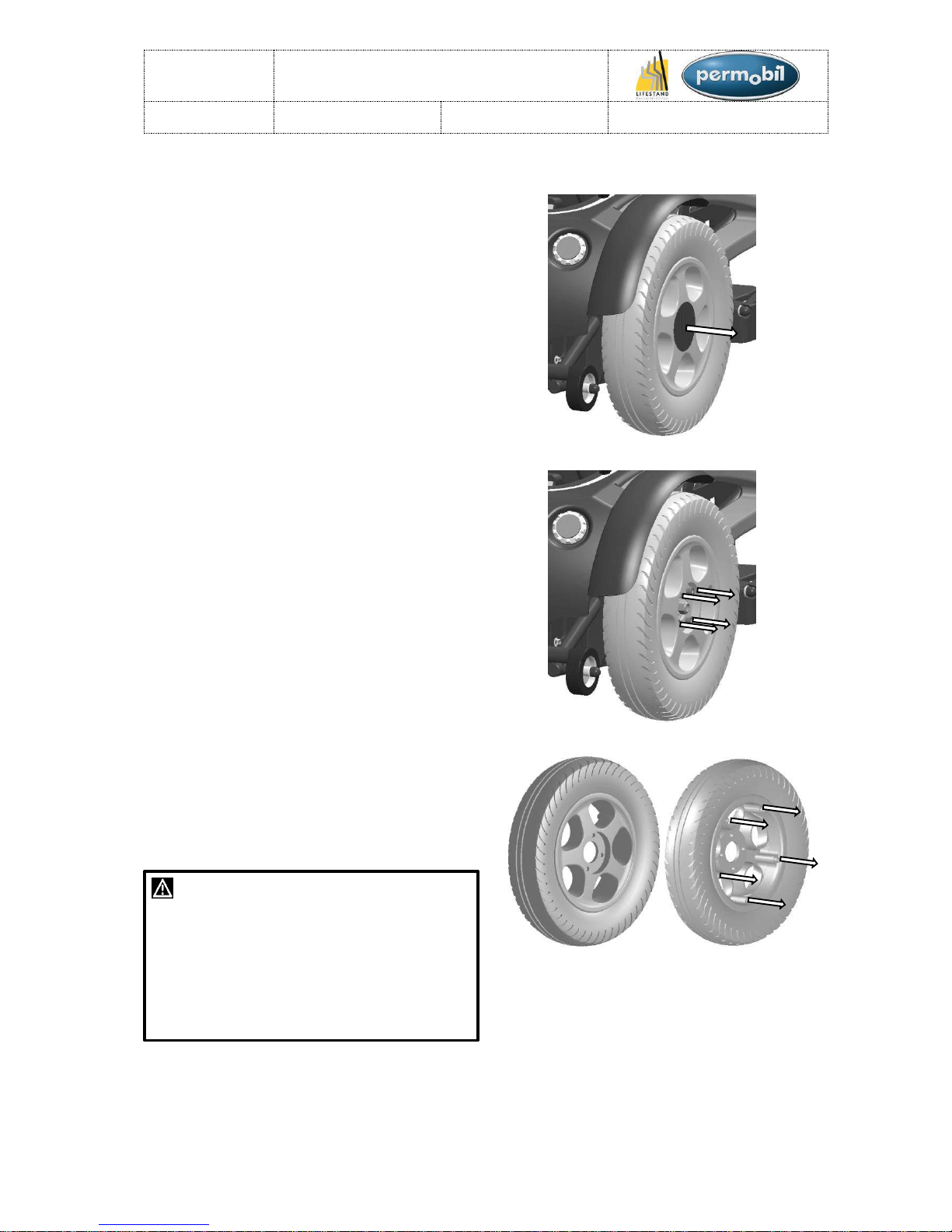

REAR WHEELS (1/2):

Dismantling:

1. Place the chair on wedges so that the

rear wheels are no longer in contact with

the ground. (Leave the motor in the

«ENGAGED» position).

2. Remove the plastic cover using a flathead screwdriver (be careful not to

damage the rim). (See figure 24).

Figure 24

3. Remove the 4 cylindrical head screws.

(See figure 25).

4. Remove the wheel.

Figure 25

5. To change the tyre, inner tube or the solid

tyre, remove the 5 screws (inside edge of

the wheel) and separate the interior

section from the outer section of the rim.

(See figure 27).

WARNING !

The tyre pressure recommended for the rear

tyres is between 2.5 and 3 bar. Over-inflation

can cause the tyre to explode. Underinflation will lead to stability and handling

problems, as well as premature wear and

tear. It is important to check the tyre pressure

regularly.

REPAIRS:

Figure 27

Figure 26

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 14 of 93

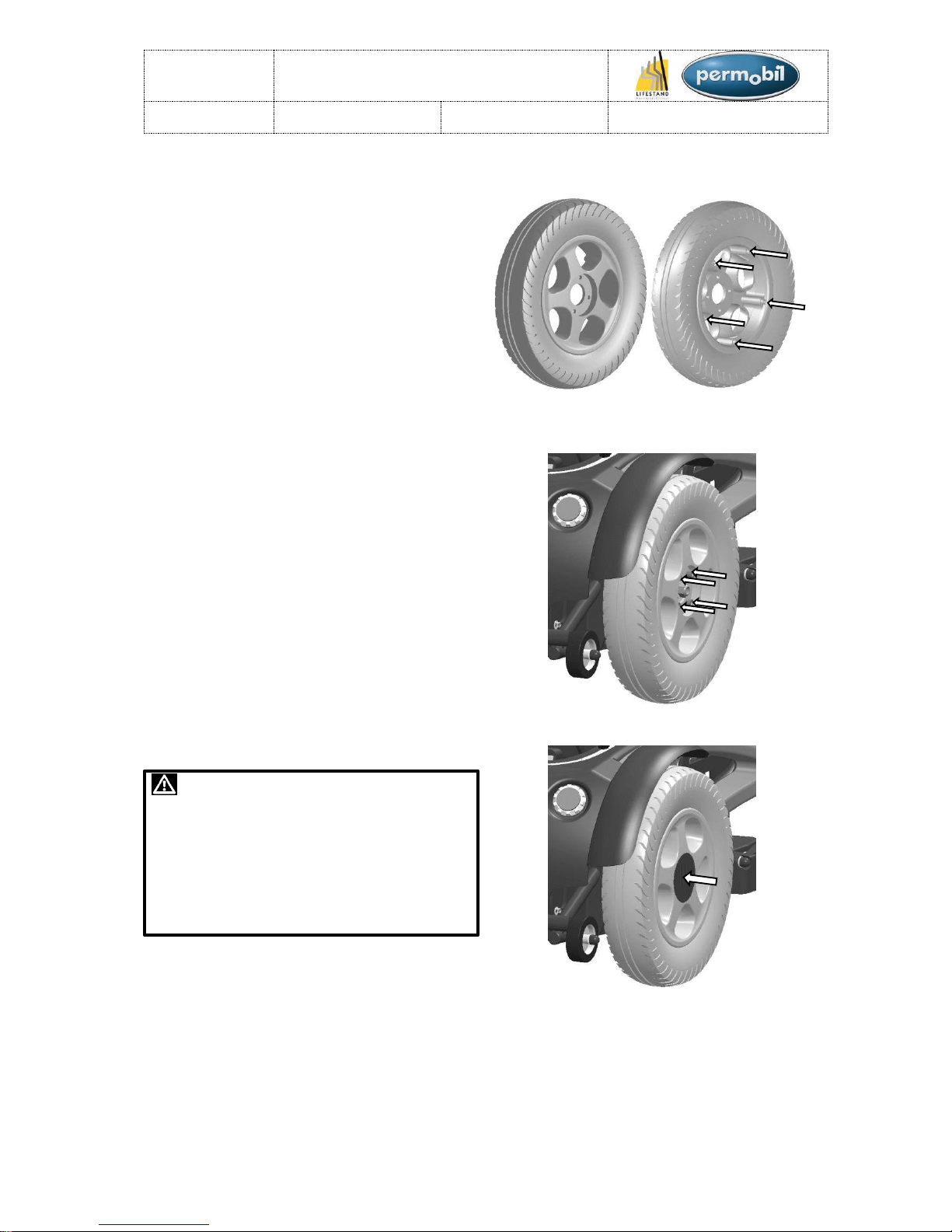

REAR WHEELS (2/2):

Assembly:

Assemble in the reverse order.

1. Reassemble the rear wheel and re-tighten

the 5 screws (Tightening torque: 27N.m)

(See figure 29).

2. Attach the wheel onto the hub with the 4

cylindrical head screws. (Tightening

torque: 27N.m) (See figure 30).

3. Replace the plastic cover. (See figure 31)

WARNING !

The tyre pressure recommended for the rear

tyres is between 2.5 and 3 bar. Over-inflation

can cause the tyre to explode. Underinflation will lead to stability and handling

problems, as well as premature wear and

tear. It is important to check the tyre pressure

regularly.

REPAIRS:

Figure 28

Figure 29

Figure 30

Figure 31

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 15 of 93

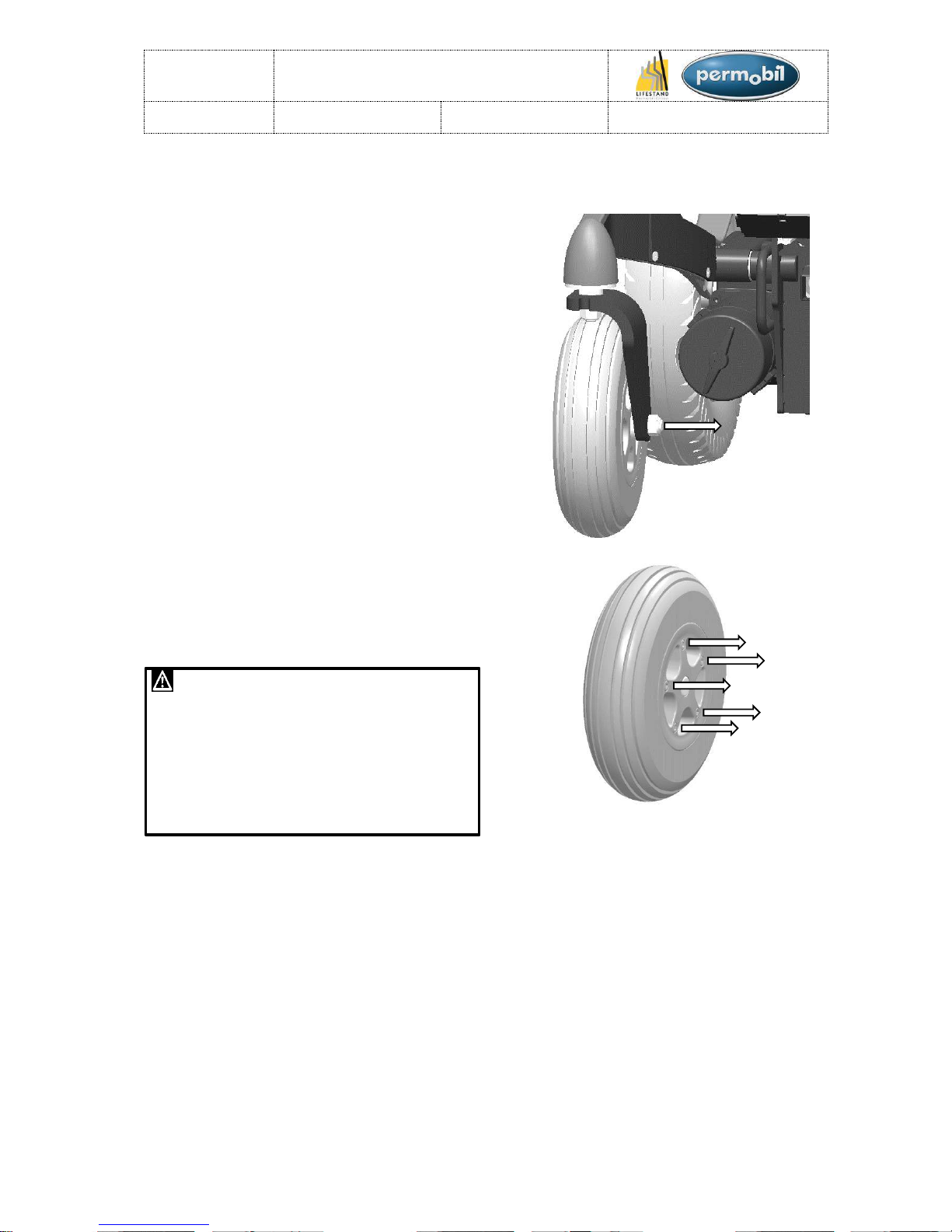

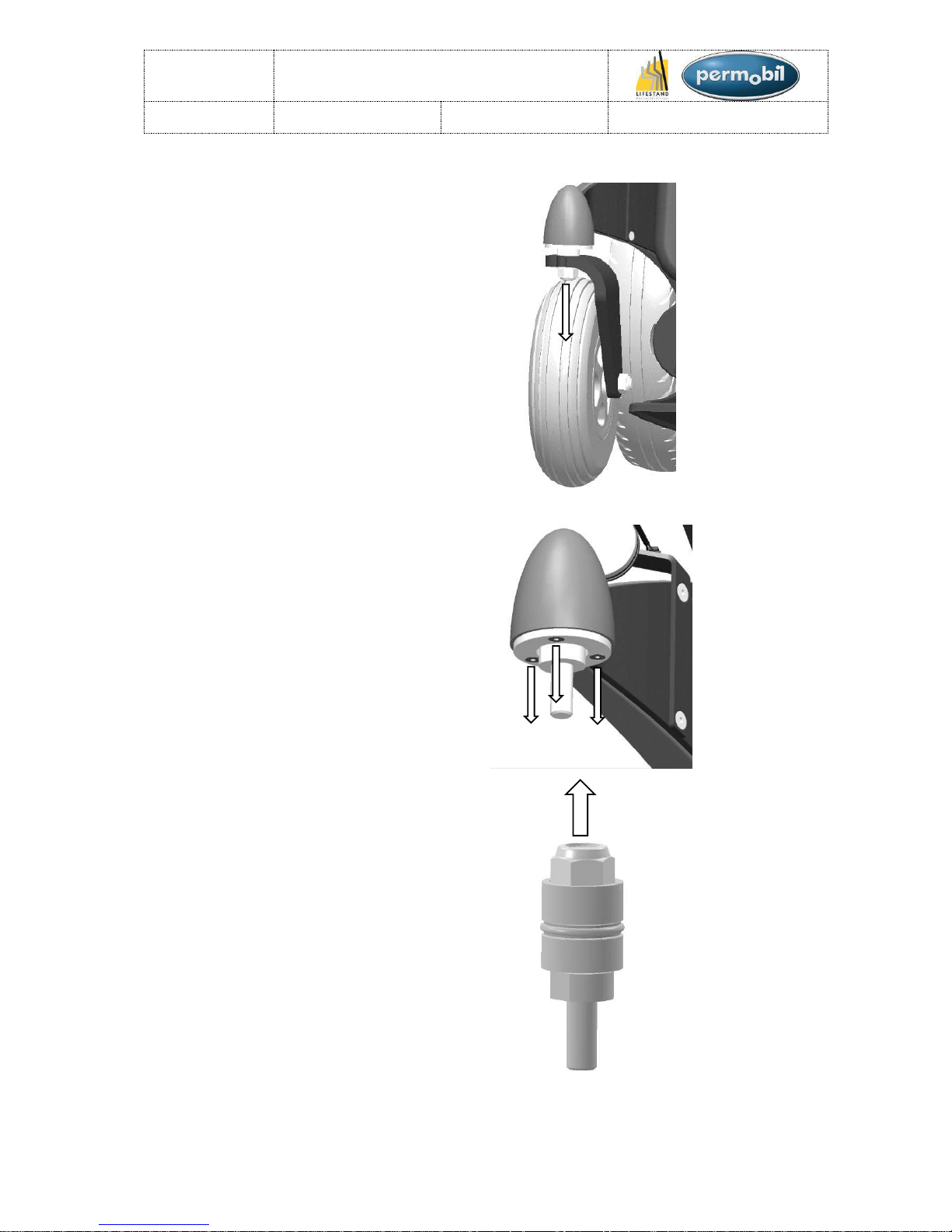

FRONT WHEELS (1/2):

Dismantling:

1. Place the chair on wedges so that the

front wheels do not touch the ground.

2. Remove the nut and take off the wheel.

(See figure 32)

3. To change the tyre or inner tube, remove

the 5 screws then separate the interior

section from the outer section of the rim.

(See figure 33)

WARNING !

The tyre pressure recommended for the front

tyres is between 2.5 and 3 bar. Over-inflation

can cause the tyre to explode and premature

wear and tear. Under-inflation will lead to

stability and handling problems, as well as

premature wear and tear. It is important to

check the tyre pressure regularly.

REPAIRS:

Figure 32

Figure 33

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 16 of 93

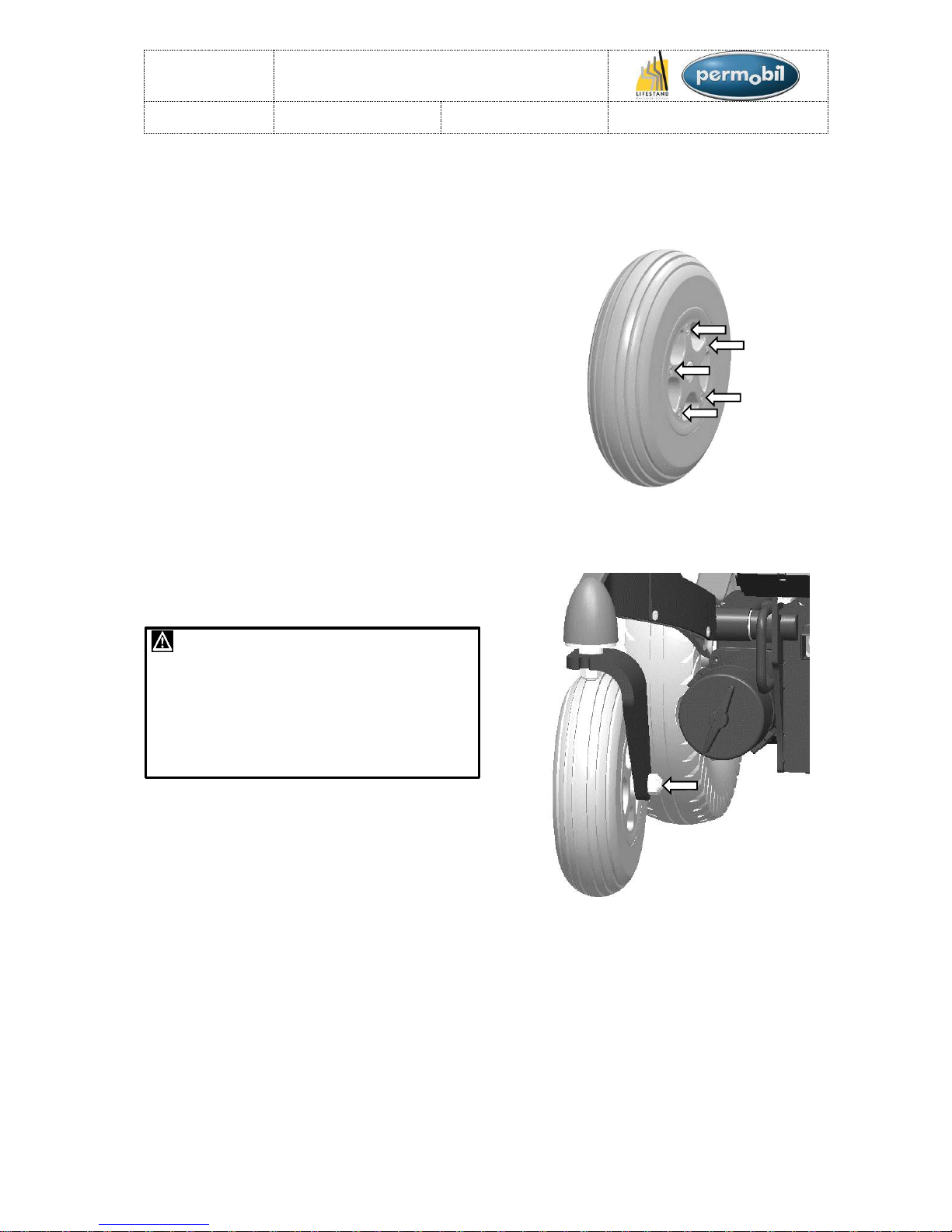

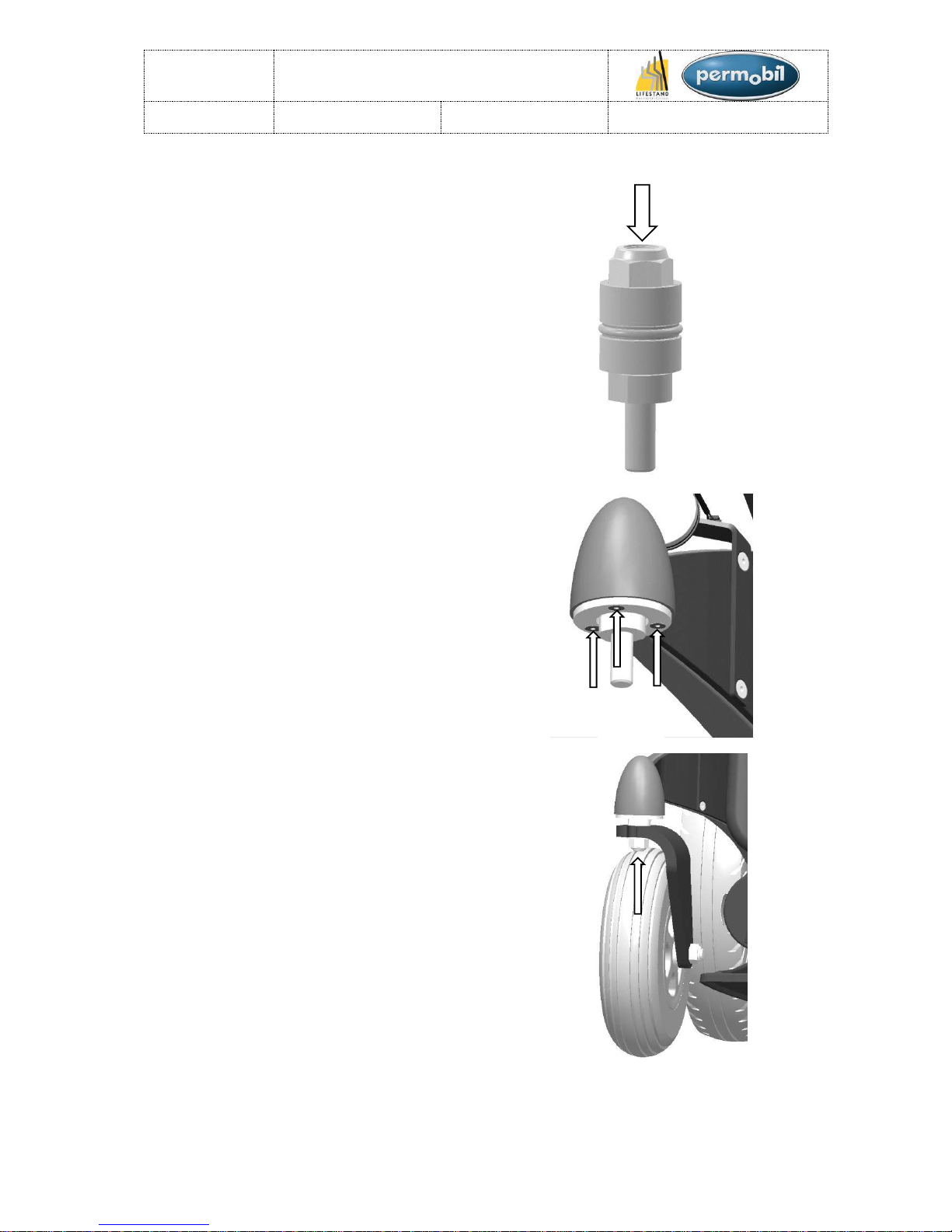

FRONT WHEELS (2/2):

Assembly:

Assemble in the reverse order.

1. Reassemble the front wheel and retighten the 5 screws (tightening torque:

27N.m) (See figure 34)

2. Put the front wheel back and tighten the

nut (Tightening torque: 92N.m). (See

figure 35)

WARNING !

The tyre pressure recommended for the front

tyres is between 2.5 and 3 bar. Over-inflation

can cause the tyre to explode. Underinflation will lead to stability and handling

problems. It is important to check the tyre

pressure regularly.

REPAIRS:

Figure 34

Figure 35

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 17 of 93

FRONT WHEEL BEARINGS (1/2):

Dismantling:

1. Place the chair on wedges so that the

front wheels do not touch the ground.

2. Remove the nut and take off the fork +

wheel set. (See figure 36)

3. Remove the 3 screws, take off the washer

then remove the axle + bearing set. (See

figure 37)

4. Remove the nut then replace the

bearings and/or the friction disc set. (See

figure 38)

REPAIRS:

Figure 36

Figure 37

Figure 38

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 18 of 93

FRONT WHEEL BEARINGS (2/2):

Assembly:

Assemble in the reverse order.

1. Re-tighten the nut (Tightening torque:

148N.m) (See figure 39)

2. Insert the axle + bearing set into the

frame housing (place a bit of grease onto

the bearings and the O-ring to make it

easier to insert into the frame).

3. Place the washer into position then

tighten the 3 countersunk head screws.

(Tightening torque: 3.22N.m). (See figure

40)

4. Reattach the fork + wheel set with the nut

and the washer (Tightening torque:

92N.m). (See figure 41)

REPAIRS:

Figure 39

Figure 40

Figure 41

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 19 of 93

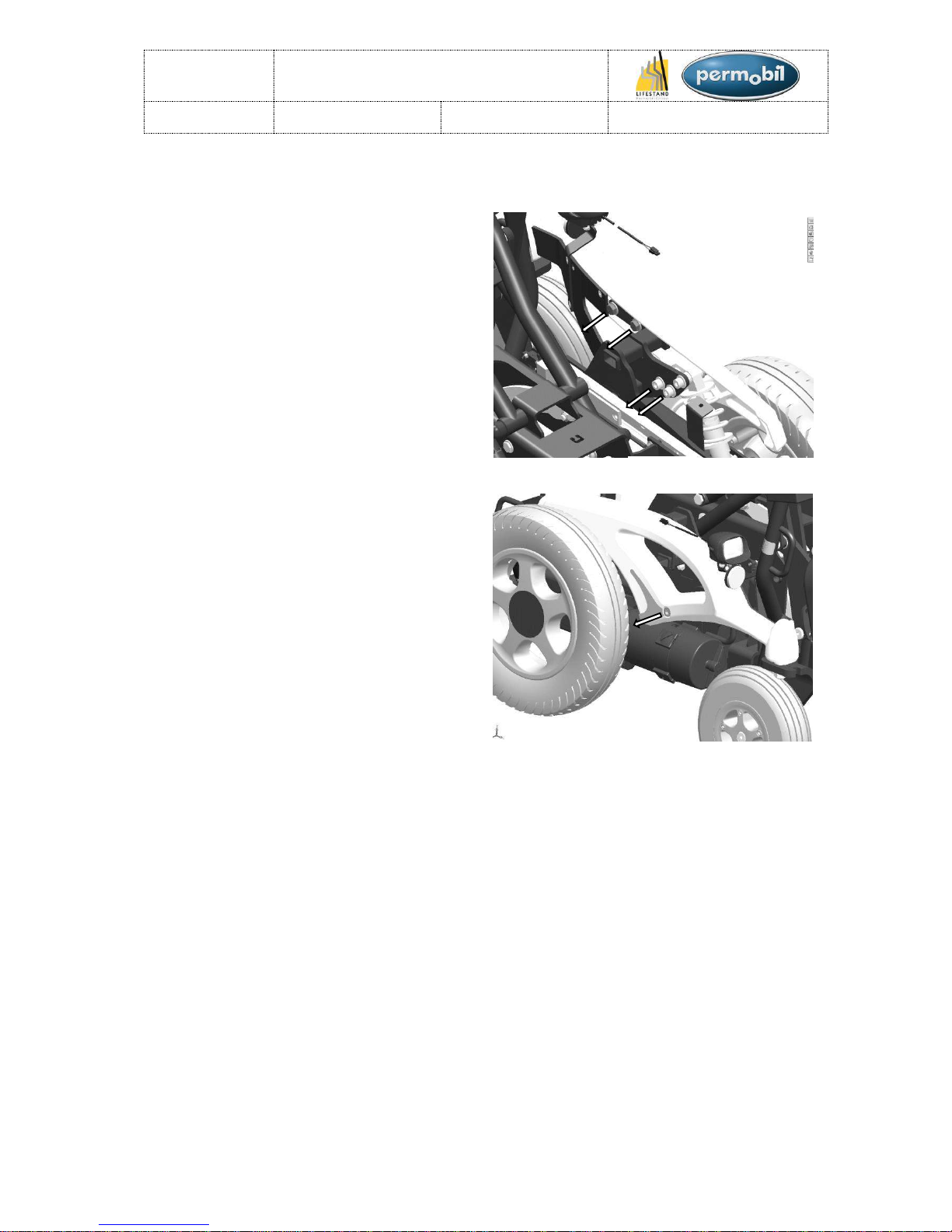

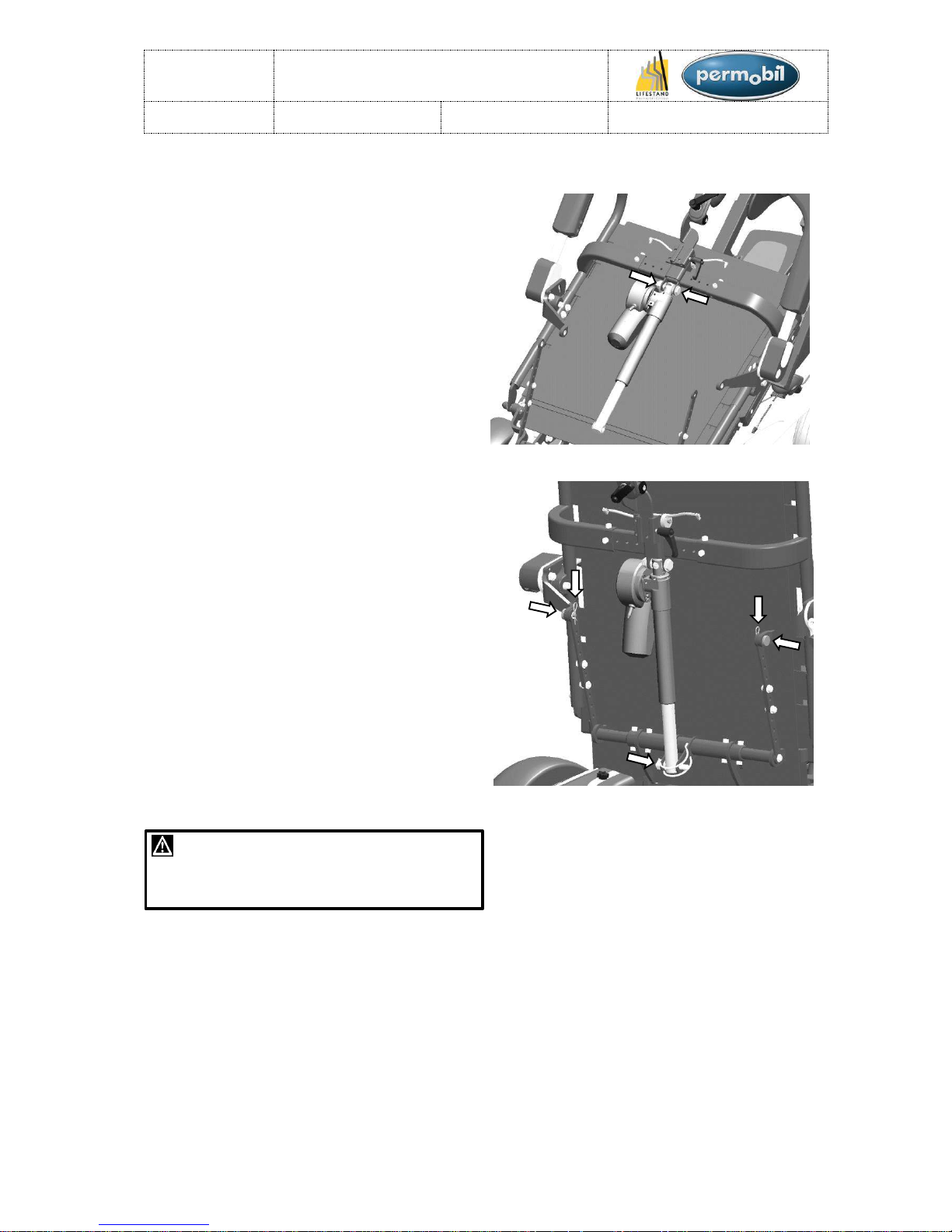

FRAME (1/2):

Dismantling:

1. Place the chair in standing position.

2. Take off the back cover (See section

«Back cover»).

3. Remove the front light (see section «Front

lights»).

4. Remove the 5 screws which hold the

frame. (See figure 42 & 43)

REPAIRS:

Figure 42

Figure 43

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 20 of 93

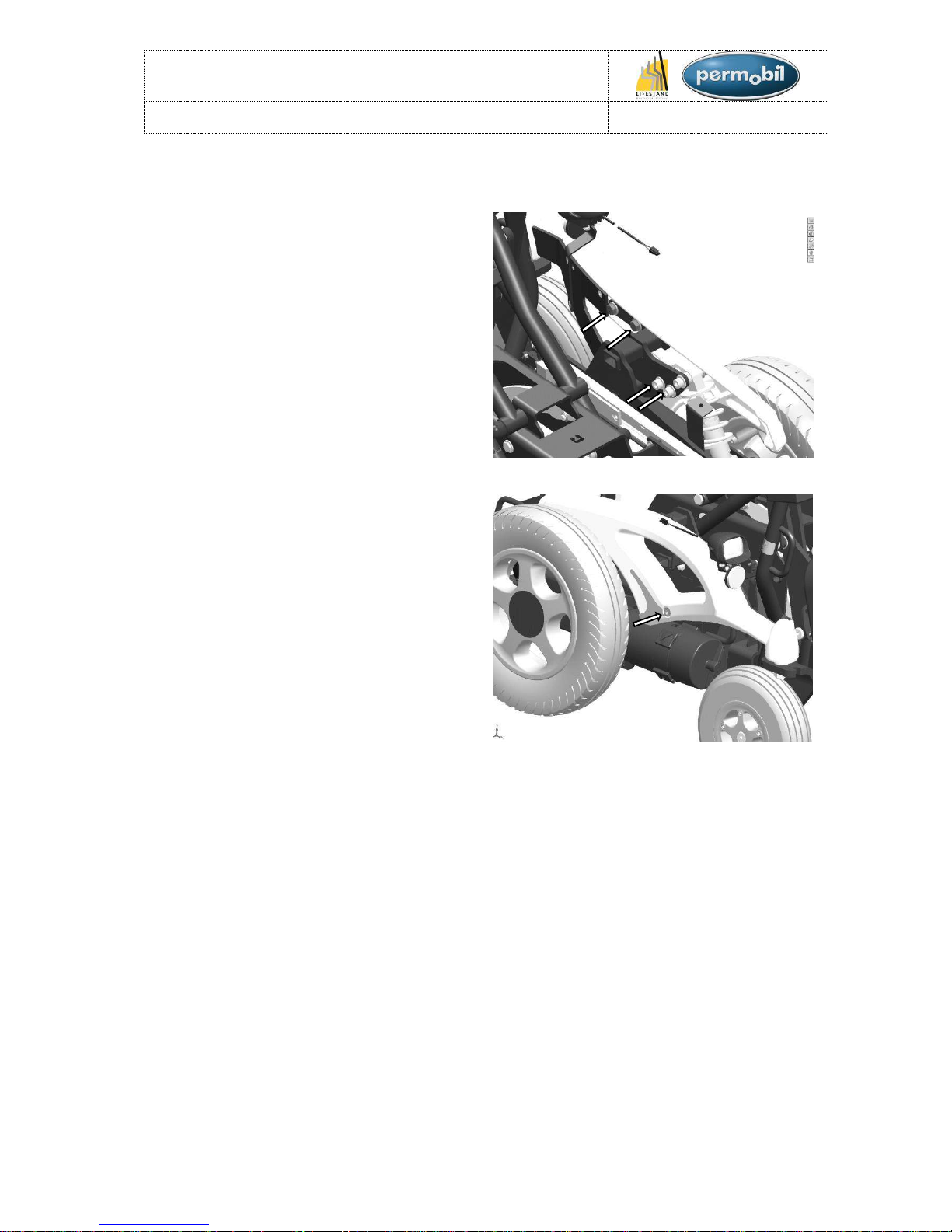

FRAME (2/2):

Assembly:

Assemble in the reverse order.

1. Position the frame in front of its attaching

holes.

2. Pre-tighten the 4 interior screws (only a

few turns of the thread) (See figure 44)

3. Pre-tighten the external screw. (See

figure 45)

4. Finish tightening the 4 interior screws

(Tightening torque: 27N.m). (See figure

44)

5. Finish tightening the external screw

(Tightening torque: 53N.m). (See figure

45)

6. Replace the front light (See section

«Front lights»).

7. Put back the back cover (See section

«Back cover»).

REPAIRS:

Figure 44

Figure 45

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 21 of 93

SEAT TILT:

GUIDE RAILS

Dismantling:

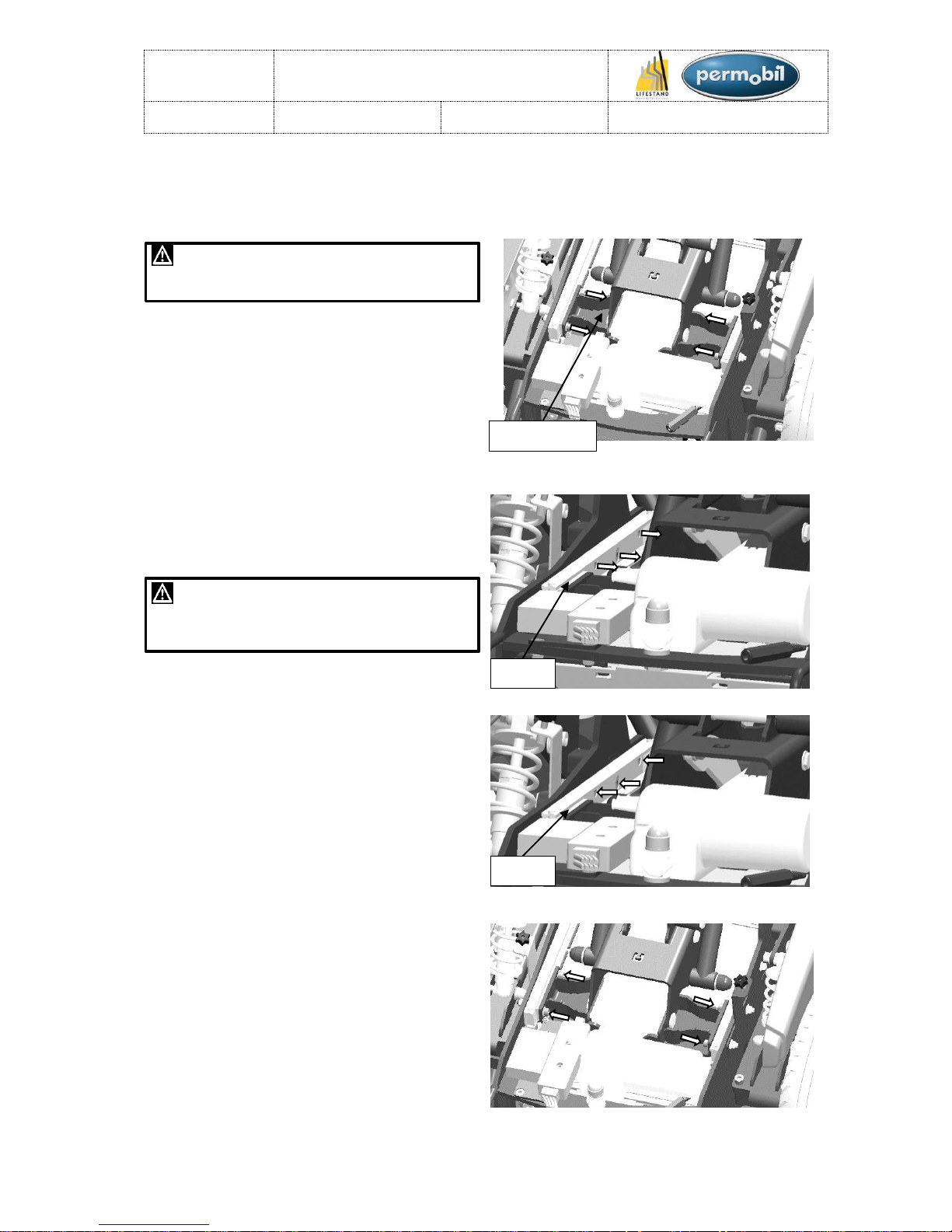

WARNING !

There must be no load on the wheelchair

1. Place the chair in standing position.

2. Take off the back cover (See section

«Back cover»).

3. Remove the 4 screws on the «trolley».

(See figure 46)

4. Place the trolley carefully on the batteries.

5. Remove the 5 screws fixed to the rail.

(move the rail pad to gain access to all

the screws). (See figure 47)

WARNING !

When removing the rails, hold the seat of the

chair to stop it tipping over.

6. Replace the rail.

Assembly:

Assemble in the reverse order.

1. Attach the rail by tightening the 5

countersunk head screws (Tightening

torque: 11.1N.m). (Move the pad to gain

access to all the screws). (See figure 48)

2. Reattach the trolley by tightening the 4

cylindrical head screws on the rail pads.

(Tightening torque: 9.8N.m). (See figure

49)

3. Replace the back cover (See section

«Back cover»).

REPAIRS:

«Trolley»

Pad

Pad

Figure 46

Figure 47

Figure 48

Figure 49

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 22 of 93

SEAT TILT:

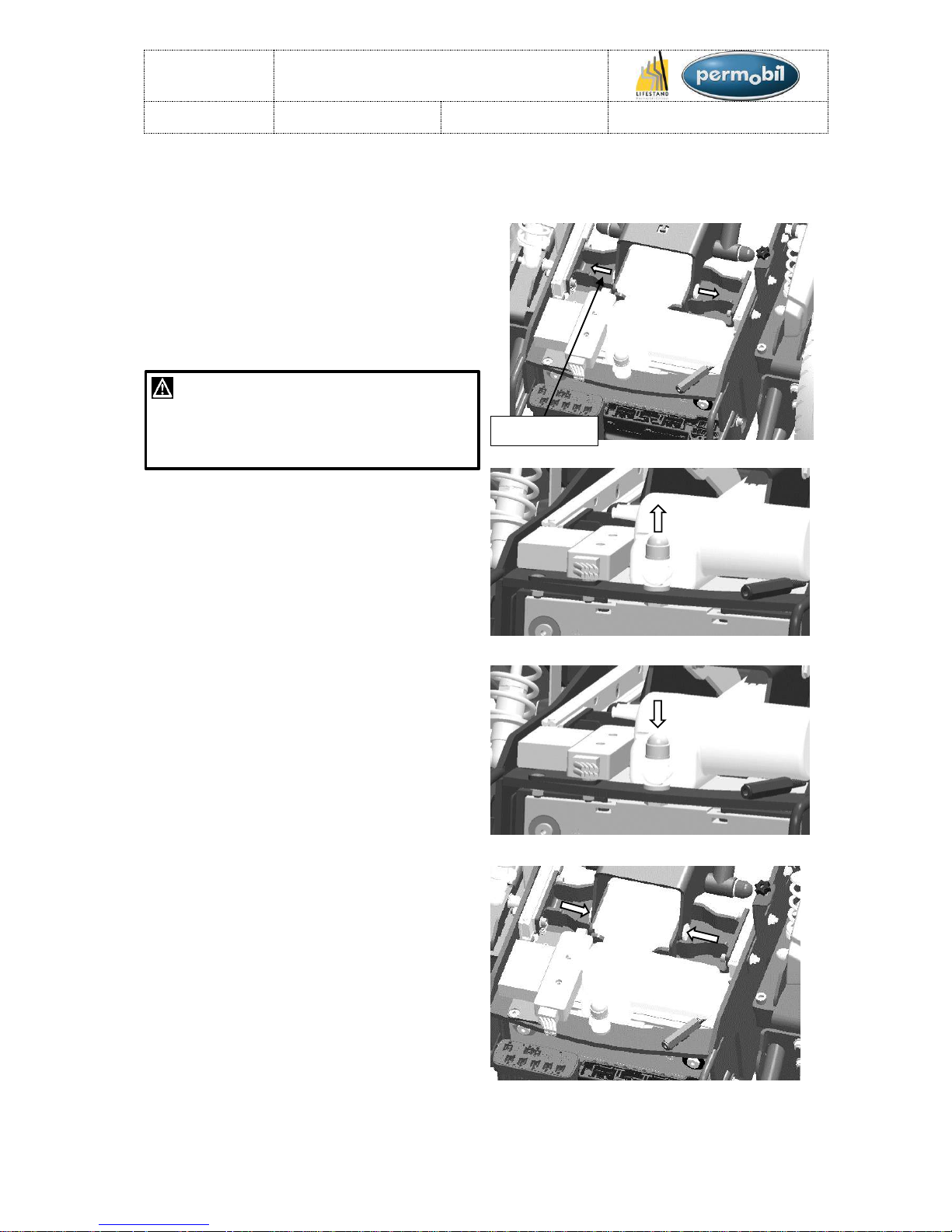

SEAT TILT ACTUATOR:

Dismantling:

1. Place the chair in standing position

2. Take off the back cover (See section

«Back cover»).

3. Remove the 2 axles from the «trolley».

(See figure 50)

WARNING !

When removing the two axles from the

trolley, hold the seat of the chair to stop it

tipping over.

4. Remove the nut cap and unscrew the nut.

(See figure 51)

5. Disconnect the actuator from the ISM.

6. Remove the actuator by lifting it up then

pulling it backwards.

Assembly:

Assemble in the reverse order.

1. Replace the actuator.

2. Insert the washer on the axle attaching

the actuator and pre-tighten the nut. (See

figure 52)

3. Reattach the 2 axles of the trolley

(Tightening torque: 17N.m). (See figure

53)

4. Finish tightening the rear fastening of the

actuator. (Tightening torque: 53N.m) (See

figure 52)

5. Reconnect the actuator to the ISM (See

section «Electrical circuit diagram»).

6. Put back the back cover (See section

«Back cover»).

REPAIRS:

«Trolley»

Figure 50

Figure 51

Figure 52

Figure 53

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 23 of 93

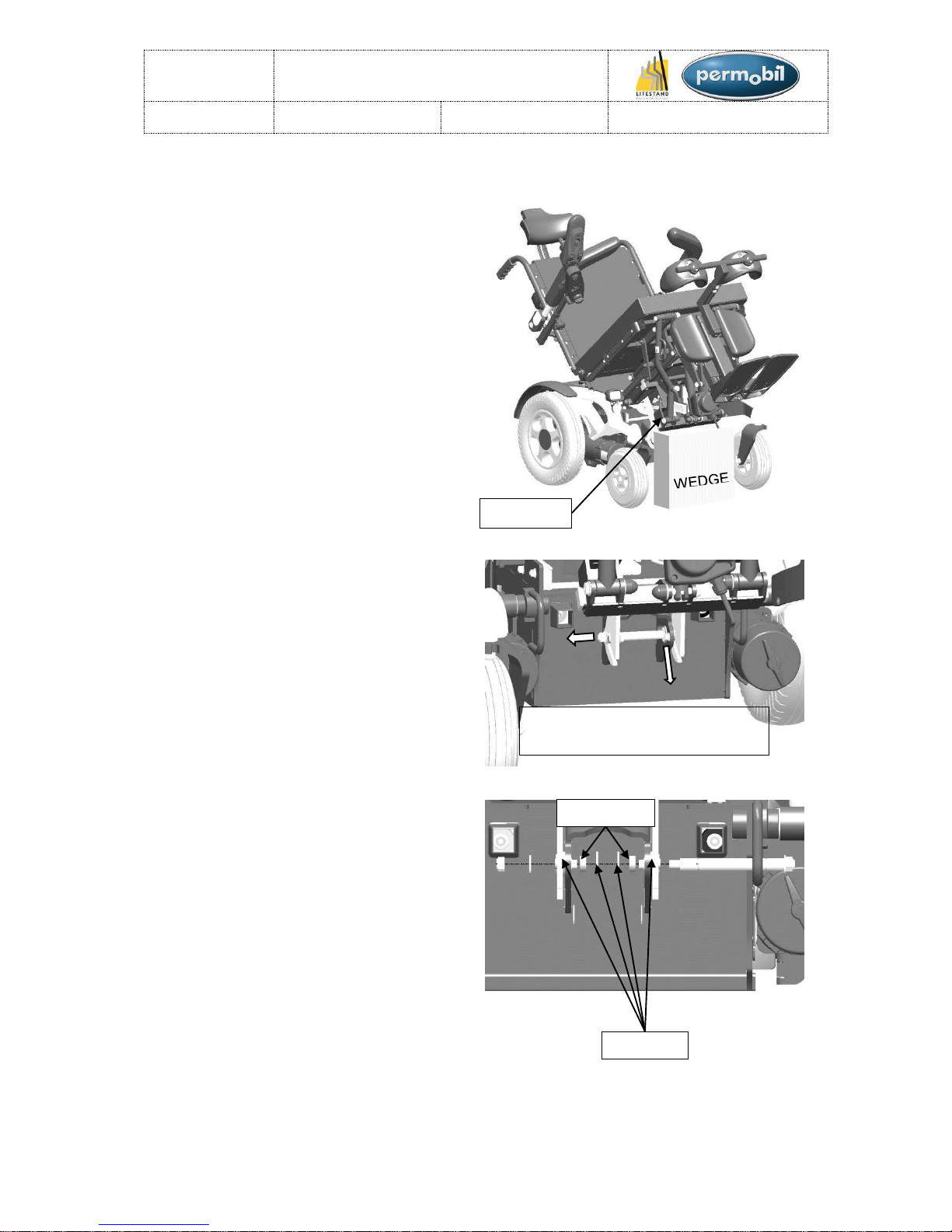

SEAT TILT:

FRONT TRANSLATION GUIDING:

Dismantling:

1. Tilt the seat backwards (to about 35°).

2. Place a wedge under the base. (See

figure 54)

3. Tilt the seat forwards until it is in contact

with the wedge (Do not continue the

movement once the wedge is in contact).

4. Unscrew the nuts. (only one of the two

nuts will unscrew). (See figure 55)

5. Pull out the two safety rings. (See figure

55)

6. Remove the axle (note the location of the

various components).

7. Replace the worn or damaged

components.

Assembly:

Assemble in the reverse order.

1. Insert the axle through the various

components as shown in the view

opposite. (See figure 56)

2. Replace the safety rings. (See figure 56)

3. Re-tighten the nut. (Tightening torque:

27N.m). (See figure 56)

4. Pull out the wedge.

REPAIRS:

For greater visibility, the wedge

has been hidden in this view

«Base»

Spacer

Washer

Figure 53

Figure 54

Figure 55

Figure 56

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 24 of 93

SEAT STOP:

Dismantling:

1. Tilt the seat backwards.

2. Unscrew the two fastening screws for the

seat stop by holding the seat stop. (See

figure 57)

3. Remove the seat stop from the side. (See

figure 58)

4. If required remove the retaining bracket of

the sensor on the right seat stop and

attach it to the new seat stop.

Assembly:

Assemble in the reverse order.

1. Replace the seat stop (remount the

retaining bracket of the sensor if it has

been removed).

2. Tighten the seat stop (Tightening torque:

11.1N.m).

REPAIRS:

View from below

Figure 57

Figure 58

Retaining

bracket of

the sensor

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 25 of 93

STANDING STOP:

Dismantling:

1. Place the chair in the sitting position.

2. Unscrew the standing stop. (See figure

59)

3. Recover the locknut screwed on the

standing stop and place it on the new

stop.

Assembly:

Assemble in the reverse order.

1. Replace and tighten the standing stop

using the locknut.

REPAIRS:

Figure 59

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 26 of 93

BACKREST ACTUATOR (1/2):

Dismantling:

1. Place the chair in standing position.

2. Remove the back cover (See section

«Back cover»).

3. Cut the clamping collars which hold the

cable from the actuator up to the ISM.

(Note the location of the clamping collars

so that the actuator can be rewired).

4. Place the chair in the sitting position. (Be

careful not to cut the cables which have

been detached when moving from the

standing position to the sitting position).

5. Remove the two pins «a» (See figure 60).

6. Remove the axles which held the pins.

(hold the armrests so that they do not

fall). (See figure 60)

7. Remove the half-moon pin «b». (See

figure 60)

8. Fold down the backrest.

9. Undo the top fastening of the backrest

actuator. (See figure 61)

10. Remove the backrest actuator.

WARNING !

When handling the hinged components

be careful not to pinch your fingers.

REPAIRS:

Figure 60

Figure 61

a

a

b

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 27 of 93

BACKREST ACTUATOR (2/2):

Assembly:

Assemble in the reverse order.

1. Insert the new backrest actuator.

2. Insert the higher fastening axle of the

backrest actuator and tighten the nut.

(See figure 62)

3. Straighten the backrest.

4. Insert the half-moon pin «b» through the

shaft of the actuator and the lower cross

beam of the backrest. (See figure 63)

5. Insert the axles or the armrest through the

armrest pads and the indexing ties. (See

figure 63)

6. Insert the pins «a». (See figure 63)

7. Place the chair in standing position.

8. Rewire the backrest actuator (See

sections «Electrical circuit diagram» and

«Chair wiring») and replace the clamping

collars.

9. Put back the back cover (See section

«Back cover»).

WARNING !

When handling the hinged components

be careful not to pinch your fingers.

REPAIRS:

Figure 62

Figure 63

b

a

a

LSCT

Maintenance manual

Item N° 326617

Revision A

Date 25/06/2015

Page 28 of 93

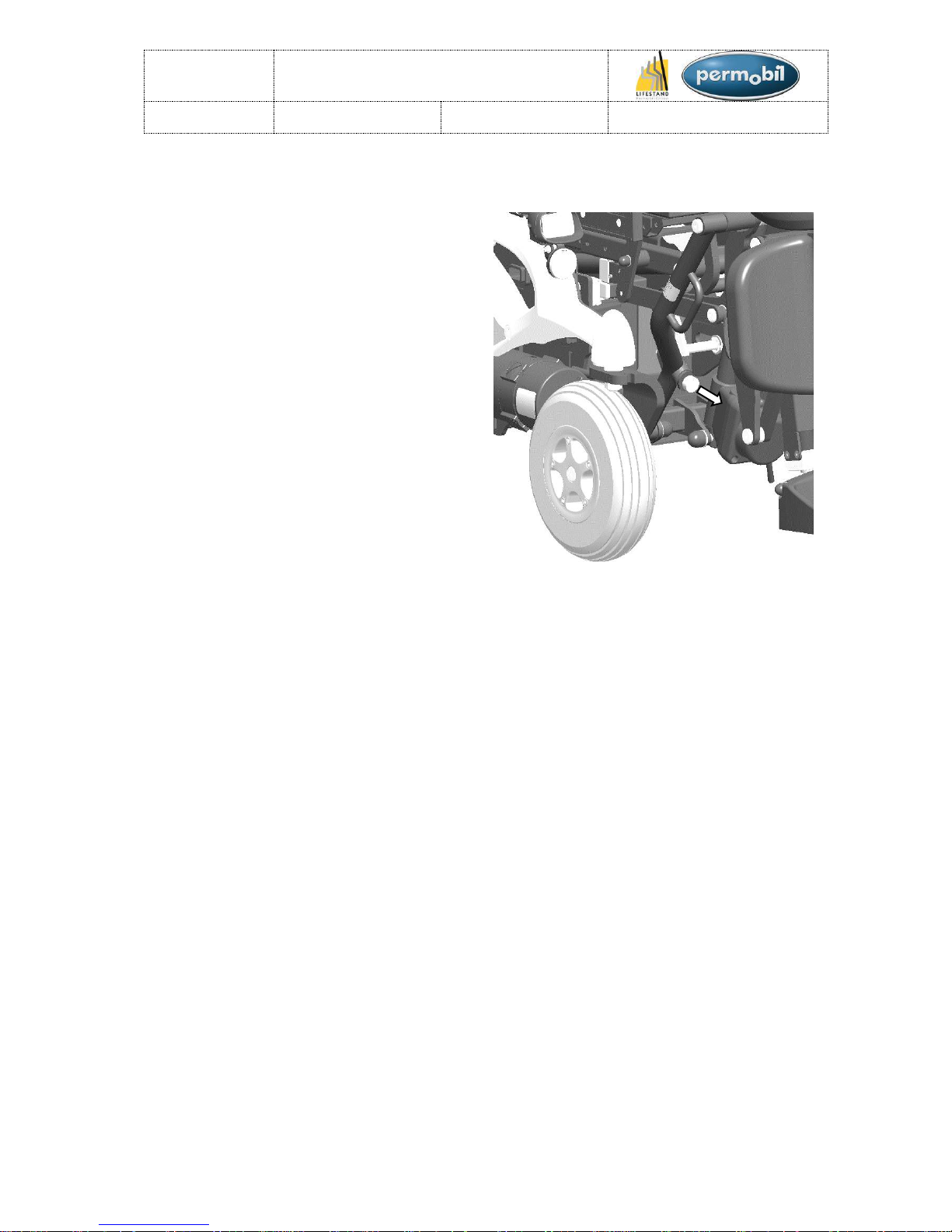

STANDING ACTUATOR (1/2):

Dismantling:

1. Place the chair in standing position.

2. Remove the back cover (See section

«Back cover»).

3. Cut the clamping collars which hold the

cable from the actuator up to the ISM. Do

not disconnect the actuator. (Note the

location of the clamping collars so that the

new actuator can be rewired.).

4. Place the chair in the sitting position.

5. Disconnect the jack plug of the standing

actuator.

6. Remove the seat cushion.

7. Undo the 4 screws holding the front seat

plate. (See figure 64)

8. Remove the front seat plate.

9. Undo the 2 screws above the standing

actuator (Only one of the two screws will

unscrew). (See figure 65)

10. Remove the axle. (Hold the actuator so

that it doesn't fall). (See figure 65)

11. Unscrew the lower actuator fastening.

(See figure 66)

12. Remove the standing actuator.

REPAIRS:

Figure 64

Figure 65

Figure 66

Loading...

Loading...